High-Temperature Performance Enhancement of Asphalt Binders Modified with Single-Use Masks: A Rheological Analysis with Predictive Modeling

Abstract

1. Introduction

- Investigating the impact of SUM incorporation into asphalt binders on their viscoelastic behavior and G*/sin (δ) through assessments involving temperature variations and FS analyses;

- Utilizing the RSM to explore the combined influences of SUM concentration, temperature, and loading frequency on binder performance indicators, specifically G*/sin (δ) and G*, and subsequently formulating predictive models for these characteristics;

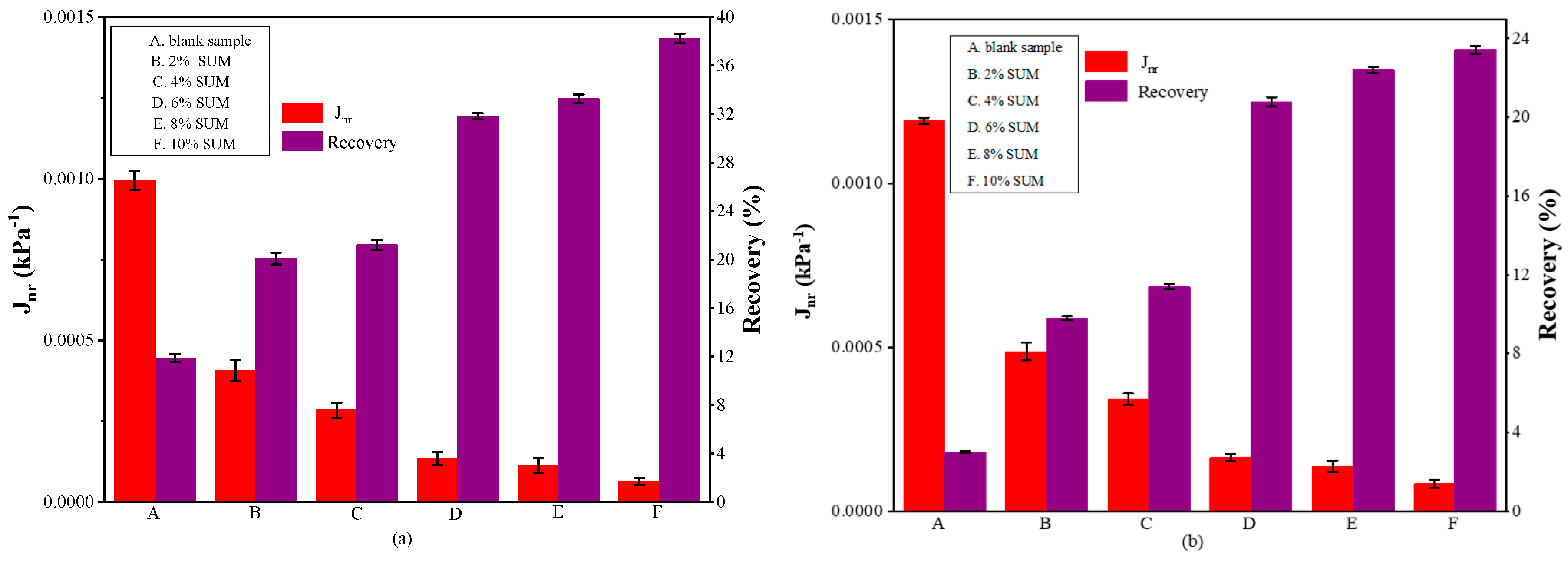

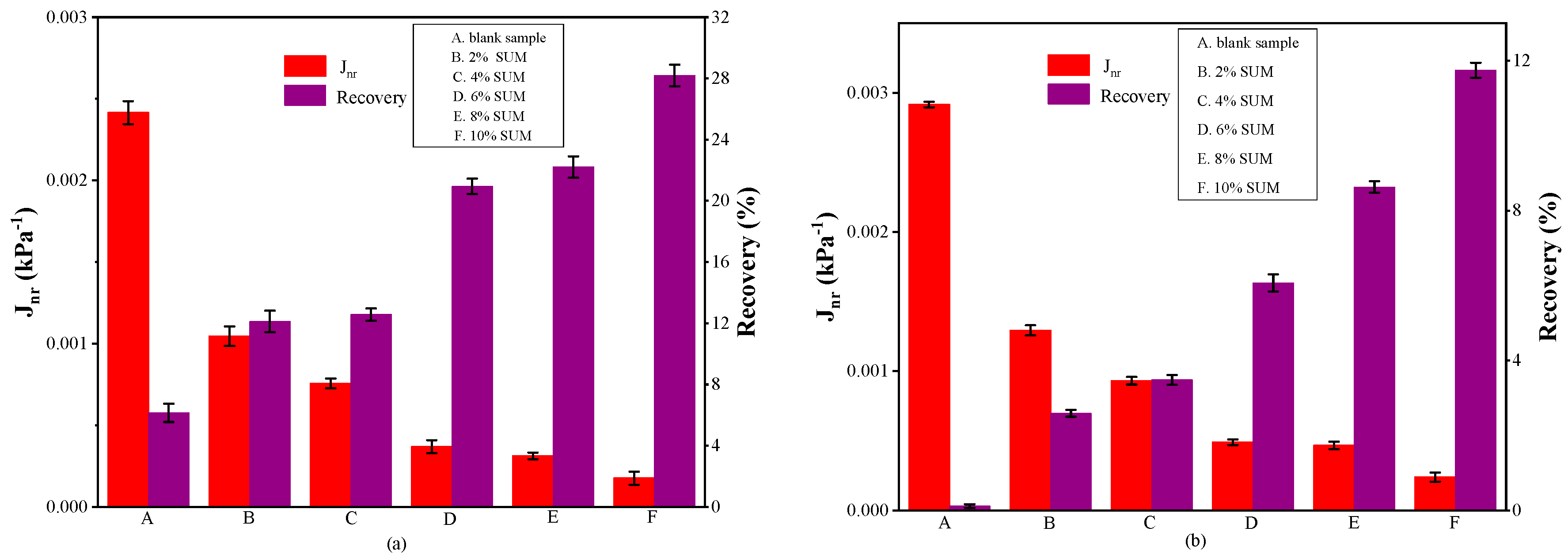

- Evaluating the performance of SUM-modified asphalt binders (SUMMs) at elevated temperatures by determining percent recovery (R) and Jnr, using MSCR testing;

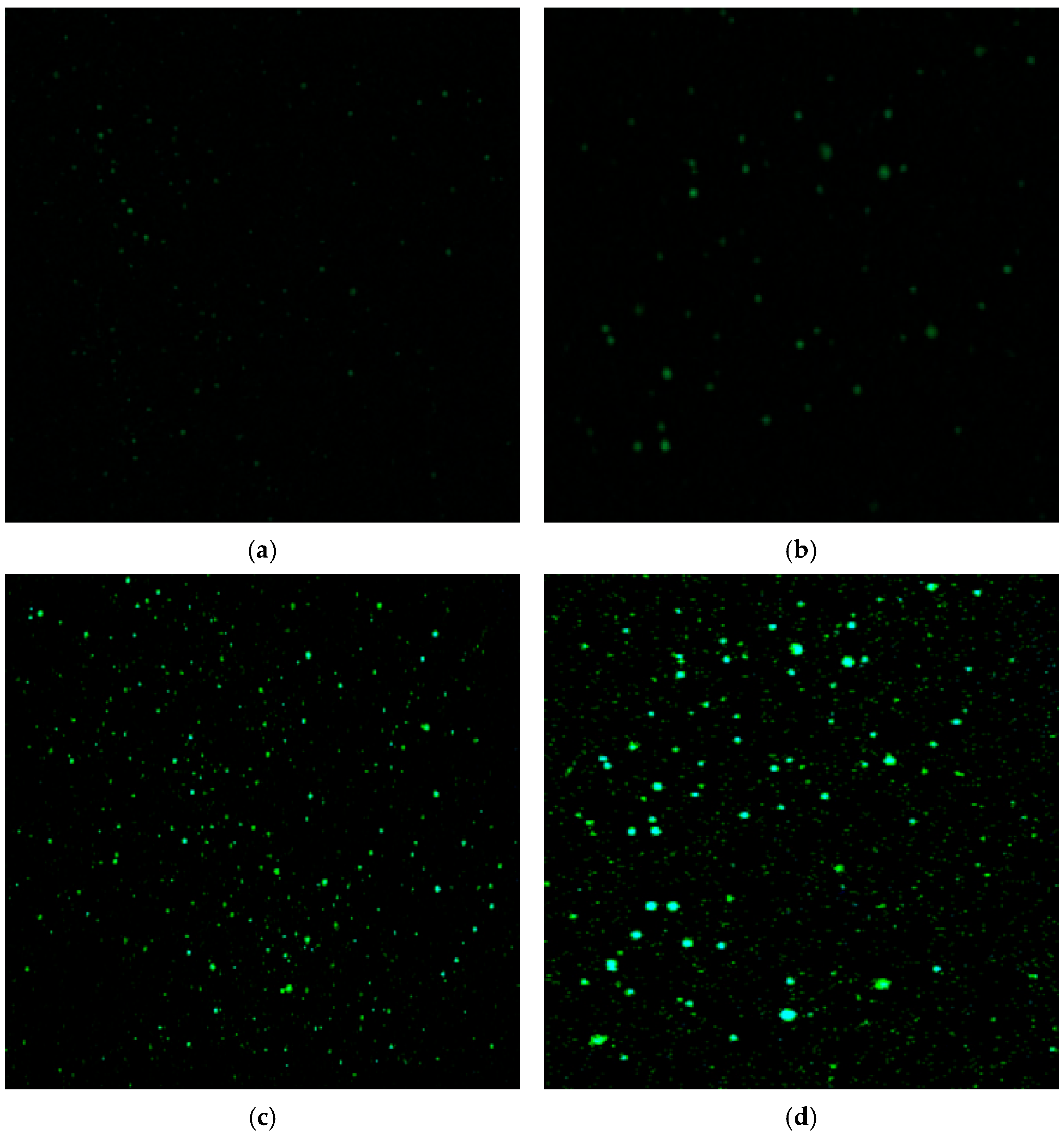

- Employing fluorescence microscopy (FM) to examine the surface morphology of the asphalt binders.

2. Materials and Test Program

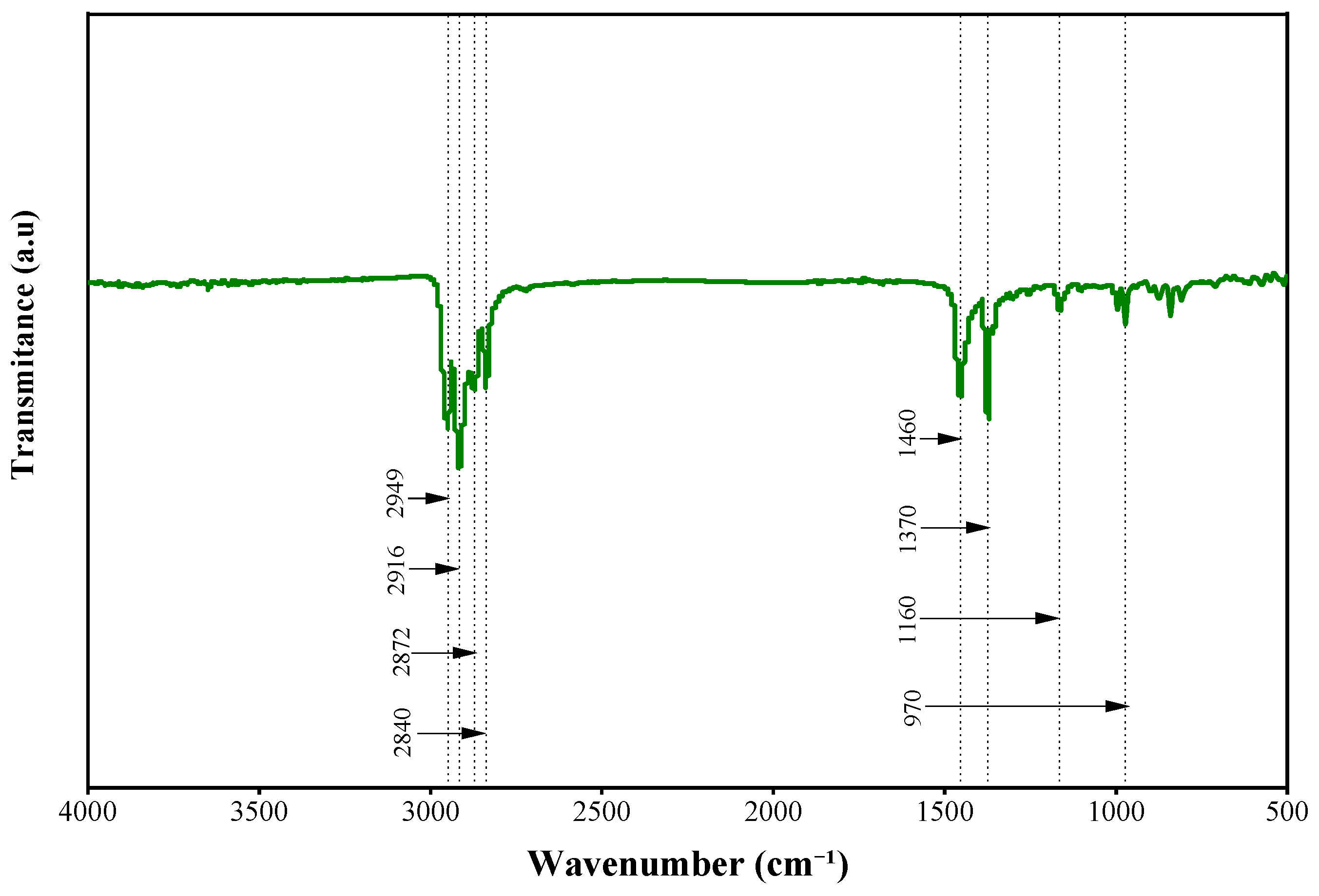

2.1. Raw Materials

2.2. Preparation of SUMM Samples

2.3. Temperature Sweep Test

2.4. FS Test

2.5. MSCR Test

2.6. RSM

2.7. Fluorescence Microscopy (FM)

3. Results and Discussion

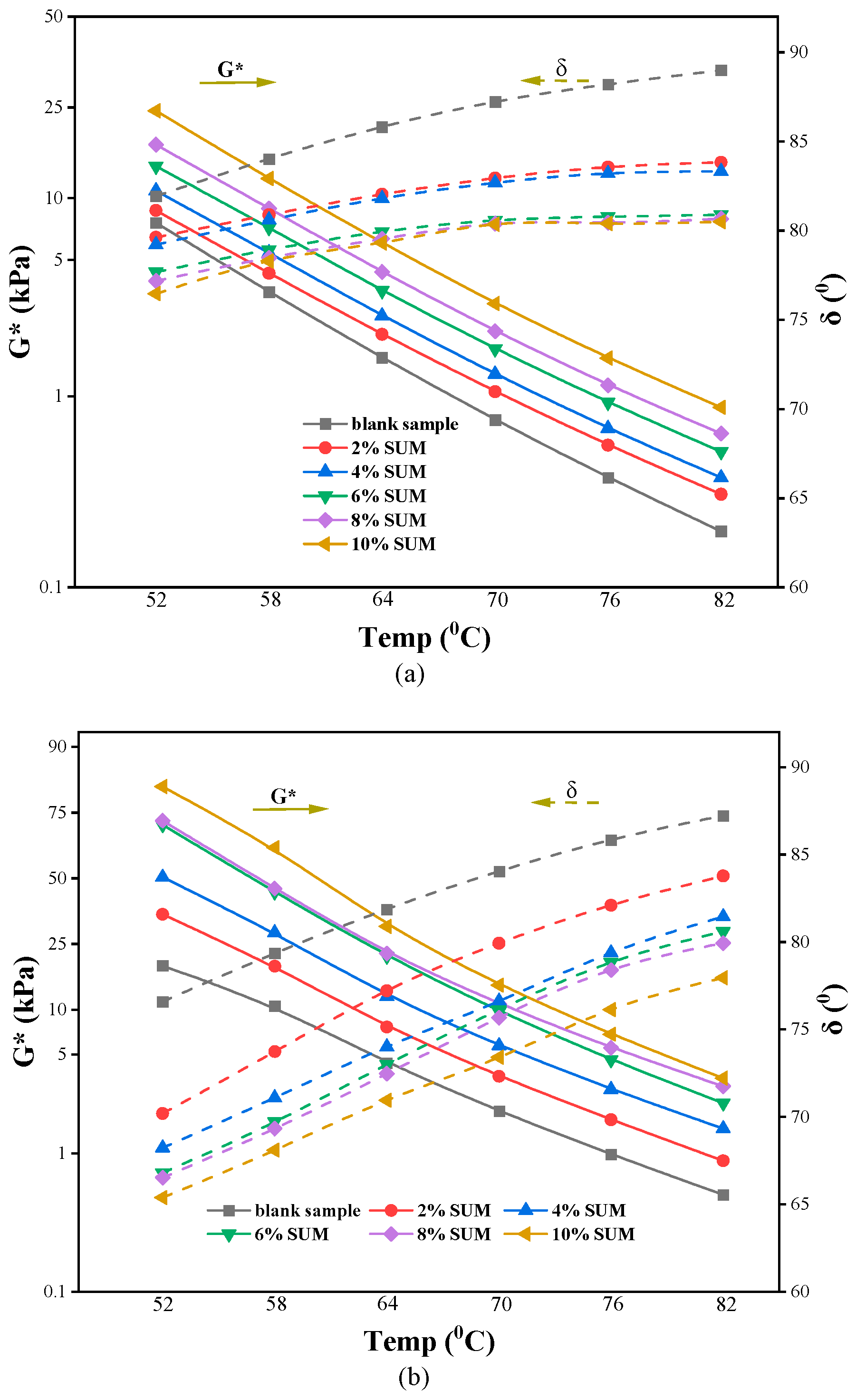

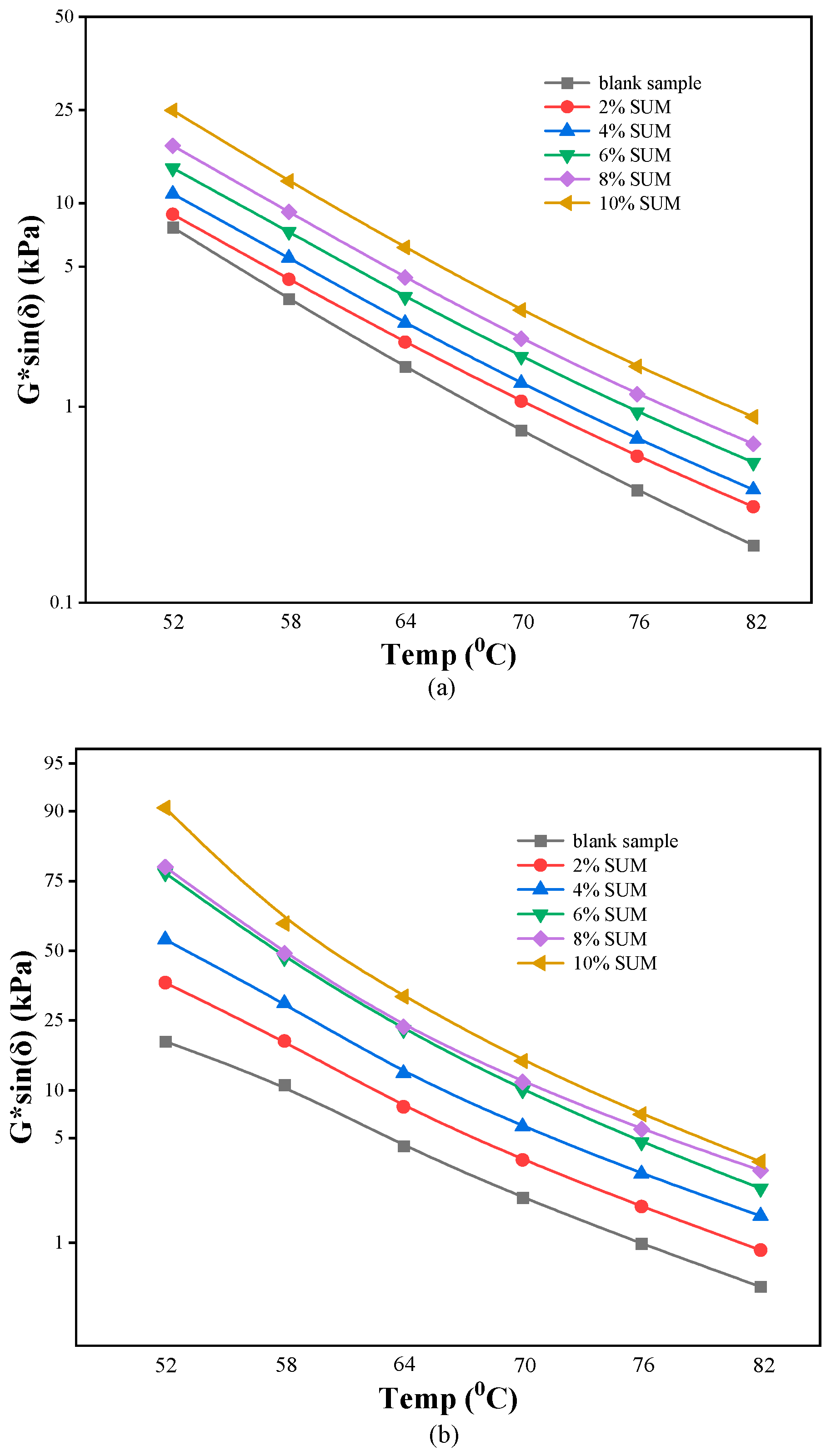

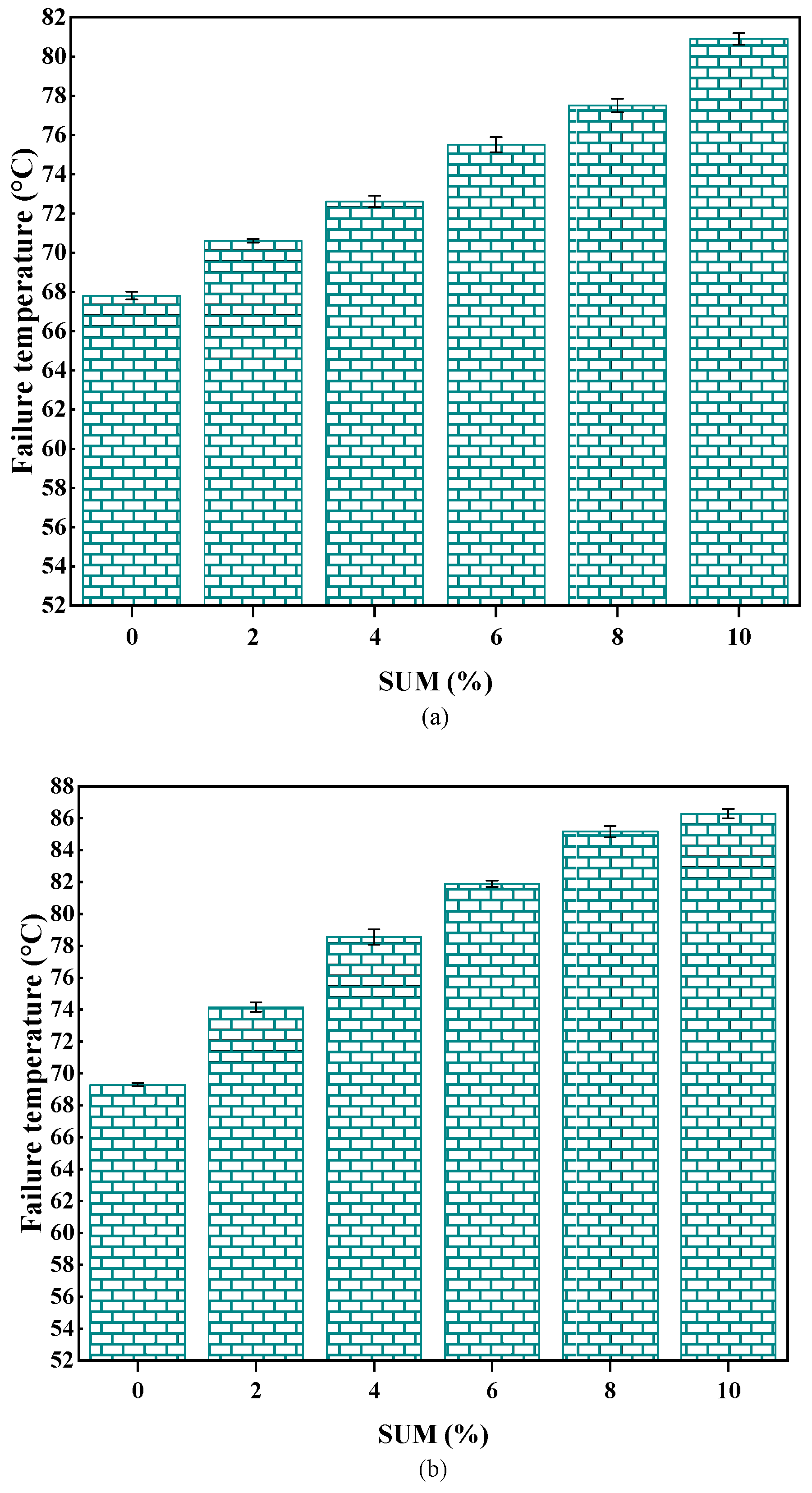

3.1. Temperature Sweep Test

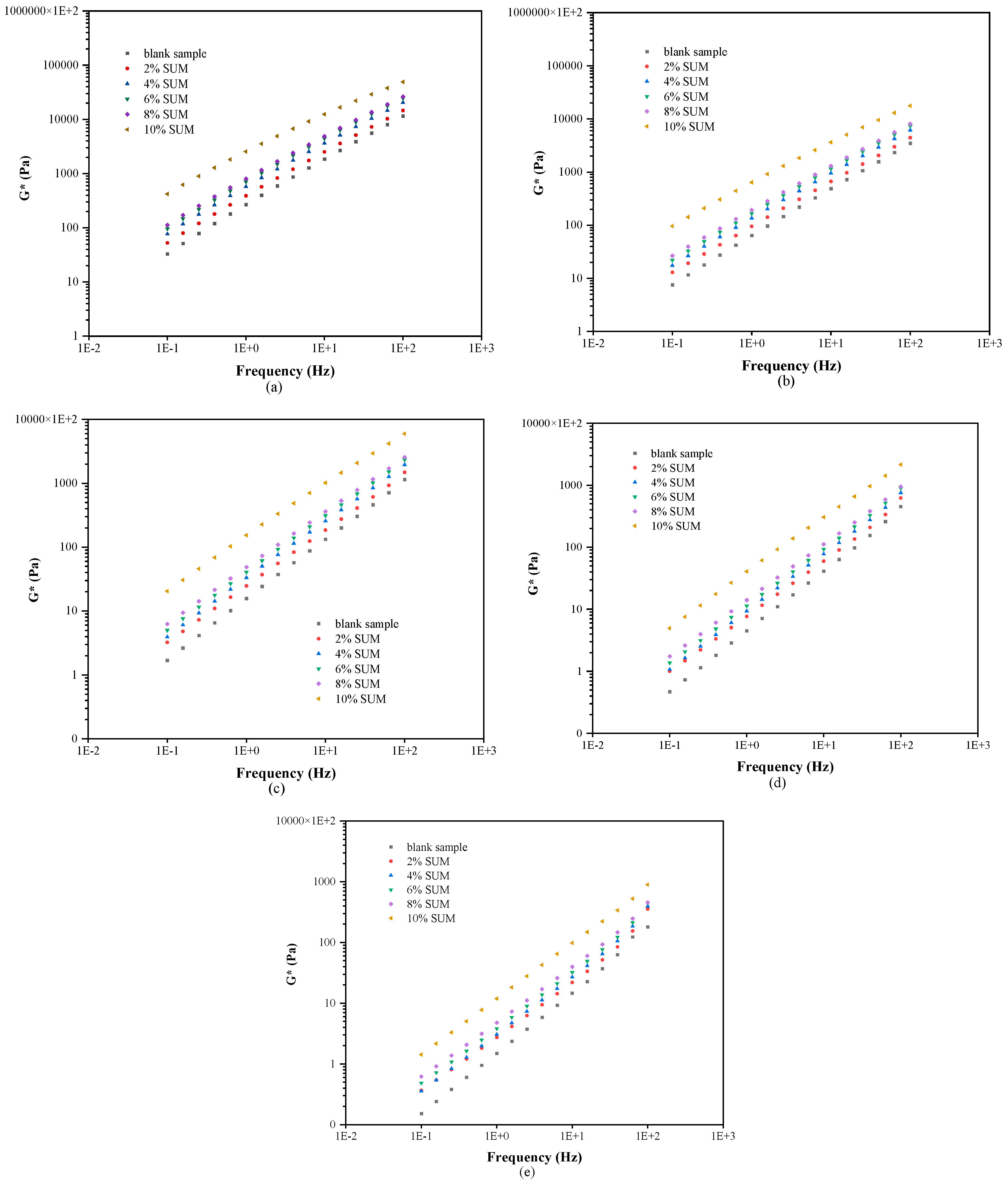

3.2. FS Results

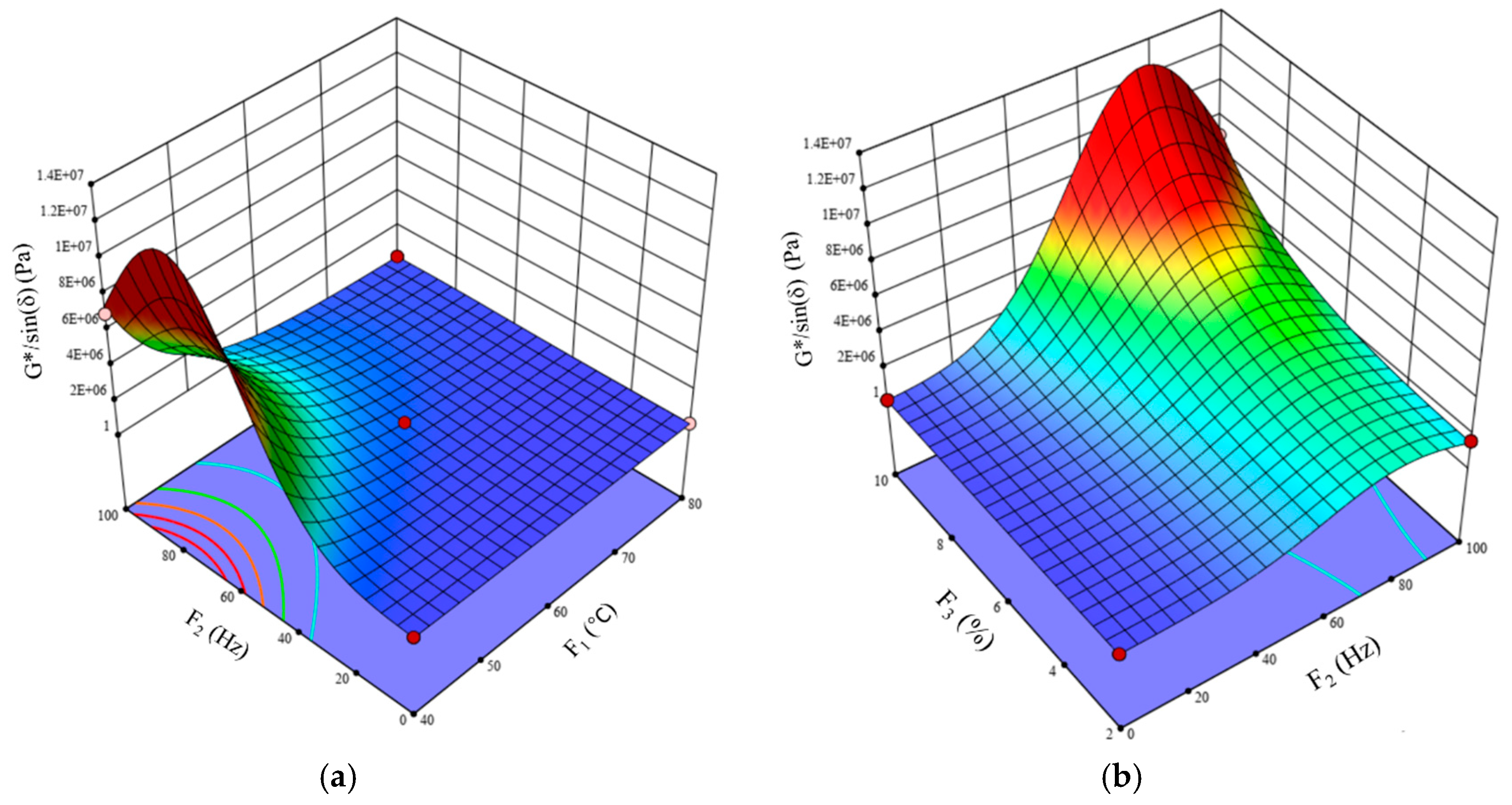

3.3. Analytical Assessment and Establishment of Models Describing Characteristics of Rut Deformation

3.4. MSCR Evaluation

3.5. FM Analysis

- Improved Elastic Recovery: The inherent elasticity of the PP network enhances the binder’s ability to recover its shape after loading. This is directly confirmed by the higher R values observed in the MSCR tests (Figure 13).

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bornand, E.; Letourneux, F.; Deschanvres, C.; Boutoille, D.; Lucet, J.-C.; Lepelletier, D.; Leclere, B.; Mayol, S.; Peiffer-Smadja, N.; Birgand, G. Social representations of mask wearing in the general population during the COVID-19 pandemic. Front. Public Health 2023, 11, 1136980. [Google Scholar] [CrossRef] [PubMed]

- Palcu, J.; Schreier, M.; Janiszewski, C. Facial mask personalization encourages facial mask wearing in times of COVID-19. Sci. Rep. 2022, 12, 891. [Google Scholar] [CrossRef]

- Rab, S.; Javaid, M.; Haleem, A.; Vaishya, R. Face masks are new normal after COVID-19 pandemic. Diabetes Metab. Syndr. Clin. Res. Rev. 2020, 14, 1617–1619. [Google Scholar] [CrossRef]

- Abaluck, J.; Kwong, L.H.; Styczynski, A.; Haque, A.; Kabir, M.A.; Bates-Jefferys, E.; Crawford, E.; Benjamin-Chung, J.; Raihan, S.; Rahman, S.; et al. Impact of community masking on COVID-19: A cluster-randomized trial in Bangladesh. Science 2022, 375, eabi9069. [Google Scholar] [CrossRef]

- Limon, M.R.; Vallente, J.P.C.; Cajigal, A.R.V.; Aquino, M.U.; Aragon, J.A.; Acosta, R.L. Unmasking emerging issues in solid waste management: Knowledge and self-reported practices on the discarded disposable masks during the COVID-19 pandemic in the Philippines. Environ. Chall. 2022, 6, 100435. [Google Scholar] [CrossRef] [PubMed]

- Petrescu, D.C.; Rastegari, H.; Petrescu-Mag, I.V.; Petrescu-Mag, R.M. Determinants of proper disposal of single-use masks: Knowledge, perception, behavior, and intervention measures. PeerJ 2023, 11, e15104. [Google Scholar] [CrossRef] [PubMed]

- Singh, N.; Tang, Y.; Ogunseitan, O.A. Environmentally Sustainable Management of Used Personal Protective Equipment. Environ. Sci. Technol. 2020, 54, 8500–8502. [Google Scholar] [CrossRef]

- Kilmartin-Lynch, S.; Roychand, R.; Saberian, M.; Li, J.; Zhang, G. Application of COVID-19 single-use shredded nitrile gloves in structural concrete: Case study from Australia. Sci. Total Environ. 2022, 812, 151423. [Google Scholar] [CrossRef]

- Chowdhury, H.; Chowdhury, T.; Sait, S.M. Estimating marine plastic pollution from COVID-19 face masks in coastal regions. Mar. Pollut. Bull. 2021, 168, 112419. [Google Scholar] [CrossRef]

- Xu, G.; Jiang, H.; Stapelberg, M.; Zhou, J.; Liu, M.; Li, Q.-J.; Cao, Y.; Gao, R.; Cai, M.; Qiao, J.; et al. Self-Perpetuating Carbon Foam Microwave Plasma Conversion of Hydrocarbon Wastes into Useful Fuels and Chemicals. Environ. Sci. Technol. 2021, 55, 6239–6247. [Google Scholar] [CrossRef]

- Ali, M.; Opulencia, M.J.C.; Chandra, T.; Chandra, S.; Muda, I.; Dias, R.; Chetthamrongchai, P.; Jalil, A.T. An Environmentally Friendly Solution for Waste Facial Masks Recycled in Construction Materials. Sustainability 2022, 14, 8739. [Google Scholar] [CrossRef]

- Webb, H.K.; Arnott, J.; Crawford, R.J.; Ivanova, E.P. Plastic Degradation and Its Environmental Implications with Special Reference to Poly(ethylene terephthalate). Polymers 2013, 5, 1–18. [Google Scholar] [CrossRef]

- Patrício Silva, A.L.; Prata, J.C.; Walker, T.R.; Duarte, A.C.; Ouyang, W.; Barcelò, D.; Rocha-Santos, T. Increased plastic pollution due to COVID-19 pandemic: Challenges and recommendations. Chem. Eng. J. 2021, 405, 126683. [Google Scholar] [CrossRef]

- Du, H.; Huang, S.; Wang, J. Environmental risks of polymer materials from disposable face masks linked to the COVID-19 pandemic. Sci. Total Environ. 2022, 815, 152980. [Google Scholar] [CrossRef] [PubMed]

- Kwak, J.I.; An, Y.-J. Post COVID-19 pandemic: Biofragmentation and soil ecotoxicological effects of microplastics derived from face masks. J. Hazard. Mater. 2021, 416, 126169. [Google Scholar] [CrossRef]

- Ahmedzade, P.; Demirelli, K.; Günay, T.; Biryan, F.; Alqudah, O. Effects of Waste Polypropylene Additive on the Properties of Bituminous Binder. Procedia Manuf. 2015, 2, 165–170. [Google Scholar] [CrossRef]

- Ayash, A.A.; Raouf, R.M.; Eweed, K.M. Mechanical Characteristics of Asphalt Mixture Modified by Polypropylene Waste. In Defect and Diffusion Forum; Trans Tech Publications Ltd.: Stafa-Zurich, Switzerland, 2020; pp. 90–97. [Google Scholar]

- Al-Hadidy, A.-R.I. Evaluation of pyrolisis polypropylene modified asphalt paving materials. Al-Rafidain Eng. J. 2006, 14, 36–50. [Google Scholar] [CrossRef]

- Al-Hadidy, A.I.; Yi-qiu, T. Mechanistic approach for polypropylene-modified flexible pavements. Mater. Des. 2009, 30, 1133–1140. [Google Scholar] [CrossRef]

- Cheng, Y.; Fu, Q.; Fang, C.; Zhang, Q.; Lu, C. Preparation, Structure, and Properties of Modified Asphalt with Waste Packaging Polypropylene and Organic Rectorite. Adv. Mater. Sci. Eng. 2019, 2019, 5362795. [Google Scholar] [CrossRef]

- Qadir, A. Rutting performance of polypropylene modified asphalt concrete. Int. J. Civ. Eng. 2014, 12, 304–312. [Google Scholar]

- Tapkın, S. Optimal polypropylene fiber amount determination by using gyratory compaction, static creep and Marshall stability and flow analyses. Constr. Build. Mater. 2013, 44, 399–410. [Google Scholar] [CrossRef]

- Wang, S.; Mallick, R.B.; Rahbar, N. Toughening mechanisms in polypropylene fiber-reinforced asphalt mastic at low temperature. Constr. Build. Mater. 2020, 248, 118690. [Google Scholar] [CrossRef]

- Vamegh, M.; Ameri, M.; Chavoshian Naeni, S.F. Experimental investigation of effect of PP/SBR polymer blends on the moisture resistance and rutting performance of asphalt mixtures. Constr. Build. Mater. 2020, 253, 119197. [Google Scholar] [CrossRef]

- Al-Hadidy, A.I. Engineering behavior of aged polypropylene-modified asphalt pavements. Constr. Build. Mater. 2018, 191, 187–192. [Google Scholar] [CrossRef]

- Shi, X.; Younho, R.; Enrique, I.; Chang-Seon, S.; Stenger, E.M.; Park, P. Effects of thermally modified asphalt concrete on pavement temperature. Int. J. Pavement Eng. 2019, 20, 669–681. [Google Scholar] [CrossRef]

- Chen, Z.; Leng, Z.; Jiao, Y.; Xu, F.; Lin, J.; Wang, H.; Cai, J.; Zhu, L.; Zhang, Y.; Feng, N.; et al. Innovative use of industrially produced steel slag powders in asphalt mixture to replace mineral fillers. J. Clean. Prod. 2022, 344, 131124. [Google Scholar] [CrossRef]

- Ma, Y.; Wang, S.; Zhou, H.; Hu, W.; Polaczyk, P.; Huang, B. Recycled polyethylene and crumb rubber composites modified asphalt with improved aging resistance and thermal stability. J. Clean. Prod. 2022, 334, 130102. [Google Scholar] [CrossRef]

- Amin, I.; El-Badawy, S.M.; Breakah, T.; Ibrahim, M.H.Z. Laboratory evaluation of asphalt binder modified with carbon nanotubes for Egyptian climate. Constr. Build. Mater. 2016, 121, 361–372. [Google Scholar] [CrossRef]

- Azarhoosh, A.; Koohmishi, M. Investigation of the rutting potential of asphalt binder and mixture modified by styrene-ethylene/propylene-styrene nanocomposite. Constr. Build. Mater. 2020, 255, 119363. [Google Scholar] [CrossRef]

- Cosme, R.L.; Teixeira, J.E.S.L.; Calmon, J.L. Use of frequency sweep and MSCR tests to characterize asphalt mastics containing ornamental stone residues and LD steel slag. Constr. Build. Mater. 2016, 122, 556–566. [Google Scholar] [CrossRef]

- Lu, C.; Lu, Z.; Li, Z.; Leung, C.K.Y. Effect of graphene oxide on the mechanical behavior of strain hardening cementitious composites. Constr. Build. Mater. 2016, 120, 457–464. [Google Scholar] [CrossRef]

- Saboo, N.; Kumar, P. Analysis of Different Test Methods for Quantifying Rutting Susceptibility of Asphalt Binders. J. Mater. Civ. Eng. 2016, 28, 04016024. [Google Scholar] [CrossRef]

- Shafabakhsh, G.; Mana, M.; Mahdi, F.; Isazadeh, M. Experimental investigation of the effect of asphalt binder modified with nanosilica on the rutting, fatigue and performance grade. Pet. Sci. Technol. 2019, 37, 1495–1500. [Google Scholar] [CrossRef]

- Zhong, Y.L.; Tian, Z.; Simon, G.P.; Li, D. Scalable production of graphene via wet chemistry: Progress and challenges. Mater. Today 2015, 18, 73–78. [Google Scholar] [CrossRef]

- Ziari, H.; Amini, A.; Goli, A.; Mirzaiyan, D. Predicting rutting performance of carbon nano tube (CNT) asphalt binders using regression models and neural networks. Constr. Build. Mater. 2018, 160, 415–426. [Google Scholar] [CrossRef]

- Skronka, G.; Jasso, M.; Vacin, O. Determination of rutting distresses on hot mix asphalts by advanced techniques. MATEC Web Conf. 2019, 276, 03004. [Google Scholar] [CrossRef]

- Ameri, M.; Mirzaiyan, D.; Amini, A. Rutting Resistance and Fatigue Behavior of Gilsonite-Modified Asphalt Binders. J. Mater. Civ. Eng. 2018, 30, 04018292. [Google Scholar] [CrossRef]

- Habibnejad Korayem, A.; Ziari, H.; Hajiloo, M.; Moniri, A. Rutting and fatigue performance of asphalt mixtures containing amorphous carbon as filler and binder modifier. Constr. Build. Mater. 2018, 188, 905–914. [Google Scholar] [CrossRef]

- Yang, X.; You, Z. High temperature performance evaluation of bio-oil modified asphalt binders using the DSR and MSCR tests. Constr. Build. Mater. 2015, 76, 380–387. [Google Scholar] [CrossRef]

- Ziari, H.; Babagoli, R.; Razi, S.E.T. The Evaluation of Rheofalt as a Warm Mix Asphalt Additive on the Properties of Asphalt Binder. Pet. Sci. Technol. 2015, 33, 1781–1786. [Google Scholar] [CrossRef]

- Adamu, M.; Mohammed, B.S.; Shahir Liew, M. Mechanical properties and performance of high volume fly ash roller compacted concrete containing crumb rubber and nano silica. Constr. Build. Mater. 2018, 171, 521–538. [Google Scholar] [CrossRef]

- Hamzah, M.O.; Lillian, G.; Golchin, B. Estimation of optimum binder content of recycled asphalt incorporating a wax warm additive using response surface method. Int. J. Pavement Eng. 2017, 18, 682–692. [Google Scholar] [CrossRef]

- He, Z.; Zhu, P.-F.; Park, S.-H. A robust desirability function method for multi-response surface optimization considering model uncertainty. Eur. J. Oper. Res. 2012, 221, 241–247. [Google Scholar] [CrossRef]

- Ali, M.; Kumar, A.; Yvaz, A.; Salah, B. Central composite design application in the optimization of the effect of pumice stone on lightweight concrete properties using RSM. Case Stud. Constr. Mater. 2023, 18, e01958. [Google Scholar] [CrossRef]

- Putra, O.N.; Musfiroh, I.; Paramitasari, D.; Pudjianto, K.; Ikram, E.H.K.; Chaidir, C.; Muchtaridi, M. Sago-Starch-Derived Sodium Starch Glycolate: An Effective Superdisintegrant to Enhance Formulation Performance. Polymers 2025, 17, 1208. [Google Scholar] [CrossRef]

- Usman, A.; Sutanto, M.H.; Napiah, M.; Zoorob, S.E.; Abdulrahman, S.; Saeed, S.M. Irradiated polyethylene terephthalate fiber and binder contents optimization for fiber-reinforced asphalt mix using response surface methodology. Ain Shams Eng. J. 2021, 12, 271–282. [Google Scholar] [CrossRef]

- Rafiq, W.; Napiah, M.; Habib, N.Z.; Sutanto, M.H.; Alaloul, W.S.; Khan, M.I.; Musarat, M.A.; Memon, A.M. Modeling and design optimization of reclaimed asphalt pavement containing crude palm oil using response surface methodology. Constr. Build. Mater. 2021, 291, 123288. [Google Scholar] [CrossRef]

- Omranian, S.R.; Othman, H.M.; Sek, Y.T.; Mohd Hasan, M.R. Effects of short-term ageing scenarios on asphalt mixtures’ fracture properties using imaging technique and response surface method. Int. J. Pavement Eng. 2020, 21, 1374–1392. [Google Scholar] [CrossRef]

- Luo, Y.; Guo, P.; Gao, J.; Meng, J.; Dai, Y. Application of Design-Expert response surface methodology for the prediction of rejuvenated asphalt fatigue life. J. Clean. Prod. 2022, 379, 134427. [Google Scholar] [CrossRef]

- Baghaee Moghaddam, T.; Soltani, M.; Karim, M.R.; Baaj, H. Optimization of asphalt and modifier contents for polyethylene terephthalate modified asphalt mixtures using response surface methodology. Measurement 2015, 74, 159–169. [Google Scholar] [CrossRef]

- Haghshenas, H.F.; Khodaii, A.; Mehrara, A.; Dehnad, M.H.; Ahari, A.S. Frequency and Temperature Interactive Effects on Hot Mix Permanent Deformation Using Response Surface Methodology. J. Mater. Civ. Eng. 2014, 26, 06014003. [Google Scholar] [CrossRef]

- JTG F40-2004; Technical Specifications for Construction of Highway Asphalt Pavements. Ministry of Communications of the People’s Republic of China: Beijing, China, 2004.

- ASTM D638-14; Standard Test Method for Tensile Properties of Plastics. ASTM International: West Conshohocken, PA, USA, 2014.

- ASTM D570-98; Standard Test Method for Water Absorption of Plastics. ASTM International: West Conshohocken, PA, USA, 1998.

- ASTM D7138-16; Standard Test Method to Determine Melting Temperature of Synthetic Fibers. ASTM International: West Conshohocken, PA, USA, 2016.

- ASTM D792-20; Standard Test Methods for Density and Specific Gravity (Relative Density) of Plastics by Displacement. ASTM International: West Conshohocken, PA, USA, 2020.

- Liu, C.; Dai, Z.; Zhou, R.; Ke, Q.; Huang, C. Fabrication of Polypropylene-g-(Diallylamino Triazine) Bifunctional Nonwovens with Antibacterial and Air Filtration Activities by Reactive Extrusion and Melt-Blown Technology. J. Chem. 2019, 2019, 3435095. [Google Scholar] [CrossRef]

- ASTM D2872; Standard Test Method for Effect of Heat and Air on a Moving Film of Asphalt (Rolling Thin-Film Oven Test). ASTM International: West Conshohocken, PA, USA, 2022.

- ASTM D7405-15; Standard Test Method for Multiple Stress Creep and Recovery (MSCR) of Asphalt Binder Using a Dynamic Shear Rheometer. ASTM International: West Conshohocken, PA, USA, 2015.

- Ferdosian, I.; Camões, A. Eco-efficient ultra-high performance concrete development by means of response surface methodology. Cem. Concr. Compos. 2017, 84, 146–156. [Google Scholar] [CrossRef]

- Segura-Méndez, K.L.; Puente-Córdova, J.G.; Rentería-Baltiérrez, F.Y.; Luna-Martínez, J.F.; Mohamed-Noriega, N. Modeling of Stress Relaxation Behavior in HDPE and PP Using Fractional Derivatives. Polymers 2025, 17, 453. [Google Scholar] [CrossRef]

- Khodaii, A.; Haghshenas, H.F.; Kazemi Tehrani, H. Effect of grading and lime content on HMA stripping using statistical methodology. Constr. Build. Mater. 2012, 34, 131–135. [Google Scholar] [CrossRef]

- Abdulkadir, I.; Mohammed, B.S.; Liew, M.S.; Wahab, M.M.A. Modelling and multi-objective optimization of the fresh and mechanical properties of self-compacting high volume fly ash ECC (HVFA-ECC) using response surface methodology (RSM). Case Stud. Constr. Mater. 2021, 14, e00525. [Google Scholar] [CrossRef]

- Montgomery, D.C. Design and Analysis of Experiments; John Wiley & Sons: Hoboken, NJ, USA, 2017. [Google Scholar]

- Oyelere, A.; Wu, S.; Rodriguez, E. Evaluation of High-Temperature Rheological and Aging Characteristics in Asphalt Binders Modified with Recycled High-Density Polyethylene and Recycled Polypropylene. Adv. Civ. Eng. Mater. 2024, 13, 134–150. [Google Scholar] [CrossRef]

- Zhou, S.; Wang, W.; Zhao, S.; Xin, Z.; Shi, Y. Shear-induced β-form polypropylene in long chain branching isotactic polypropylene. Polym. Eng. Sci. 2016, 56, 240–247. [Google Scholar] [CrossRef]

- Attoh-Okine, N.; Cook, P.; Martey, E.; Boyce, T.; Alshali, A. Asphalt Rheology and Strengthening Through Polymer Binders; Center for Advanced Infrastructure and Transportation, Rutgers University: Rutgers, NJ, USA, 2016. [Google Scholar]

- Yang, Q.; Lin, J.; Wang, X.; Wang, D.; Xie, N.; Shi, X. A review of polymer-modified asphalt binder: Modification mechanisms and mechanical properties. Clean. Mater. 2024, 12, 100255. [Google Scholar] [CrossRef]

- Hamdane, H.; Tamraoui, Y.; Mansouri, S.; Oumam, M.; Bouih, A.; El Ghailassi, T.; Boulif, R.; Manoun, B.; Hannache, H. Statistical modeling of geopolymers from dual-alkali activation of un-calcined phosphate sludge and their potential applications as sustainable coating materials. J. Clean. Prod. 2021, 283, 125421. [Google Scholar] [CrossRef]

- AASHTO M 332-2021; Performance-Graded Asphalt Binder Using Multiple Stress Creep Recovery (MSCR) Test. American Association of State Highway and Transportation Officials: Washington, DC, USA, 2012.

- Liu, H.; Zeiada, W.; Al-Khateeb, G.G.; Shanableh, A.; Samarai, M. Use of the multiple stress creep recovery (MSCR) test to characterize the rutting potential of asphalt binders: A literature review. Constr. Build. Mater. 2021, 269, 121320. [Google Scholar] [CrossRef]

| Test | Result | Requirement |

|---|---|---|

| Penetration depth (100 g, 5 s, 25 °C), 0.1 mm | 71 | 60–80 |

| Penetration index PI | −0.87 | −1.5–+1.0 |

| Softening point (°C) | 48 | ≥46 |

| Ductility (15 °C), cm | >100 | ≥100 |

| Flash point (°C) | >300 | ≥260 |

| Dynamic viscosity at 60 °C (Pa s) | 223 | ≥180 |

| Property | Standard | Value |

|---|---|---|

| Rupture force (N) | ASTM-D638-14 [54] | 19.38 |

| Tensile strength (MPa) | ASTM-D638-14 [54] | 3.45 |

| Water absorption 24 h (%) | ASTM-D570-98 [55] | 8.2 |

| Melting point (°C) | ASTM-D7138-16 [56] | 155 |

| Specific gravity | ASTM-D792-20 [57] | 0.91 |

| Run | Factors | Responses | |||

|---|---|---|---|---|---|

| F1: Temperature (°C) | F2: Frequency (Hz) | F3: SUM (%) | G*/sin (δ) (KPa) | G* (KPa) | |

| 1 | 60 | 50.05 | 6 | 126 | 124 |

| 2 | 60 | 100 | 6 | 240 | 234 |

| 3 | 60 | 50.05 | 6 | 129 | 126 |

| 4 | 80 | 0.1 | 2 | 0.038 | 0.037 |

| 5 | 40 | 0.1 | 2 | 5.40 | 5.28 |

| 6 | 60 | 50.05 | 6 | 122 | 118 |

| 7 | 80 | 100 | 2 | 35.4 | 35.4 |

| 8 | 60 | 50.05 | 2 | 77.4 | 75.0 |

| 9 | 80 | 0.1 | 10 | 0.147 | 0.146 |

| 10 | 60 | 50.05 | 10 | 399 | 364 |

| 11 | 40 | 100 | 10 | 7050 | 5180 |

| 12 | 40 | 50.05 | 6 | 1670 | 1500 |

| 13 | 40 | 0.1 | 10 | 46.9 | 44.6 |

| 14 | 80 | 100 | 10 | 93.0 | 90.8 |

| 15 | 60 | 50.05 | 6 | 133 | 130 |

| 16 | 80 | 50.05 | 6 | 16.2 | 16.2 |

| 17 | 60 | 0.1 | 6 | 0.507 | 0.503 |

| 18 | 60 | 50.05 | 6 | 128 | 126 |

| 19 | 40 | 100 | 2 | 1630 | 1470 |

| Responses | Source | SS | df | MS | F-Value | p-Value |

|---|---|---|---|---|---|---|

| G*/sin (δ) | Model | 32.8 | 9 | 3.64 | 3990 | <0.001 |

| F1 | 10.4 | 1 | 10.4 | 11,400 | <0.001 | |

| F2 | 17.2 | 1 | 17.2 | 18,800 | <0.001 | |

| F3 | 1.09 | 1 | 1.09 | 1190 | <0.001 | |

| F1F2 | 0.155 | 1 | 0.155 | 170 | <0.001 | |

| F1F3 | 0.0403 | 1 | 0.0403 | 44.2 | <0.001 | |

| F2F3 | 0.0277 | 1 | 0.0277 | 30.4 | 0.0004 | |

| F12 | 0.0452 | 1 | 0.0452 | 49.6 | <0.001 | |

| F22 | 2.98 | 1 | 2.98 | 3270 | <0.001 | |

| F32 | 0.0676 | 1 | 0.0676 | 74.2 | <0.001 | |

| G* | Model | 31.9 | 9 | 3.54 | 2490 | <0.001 |

| F1 | 9.96 | 1 | 9.96 | 6990 | <0.001 | |

| F2 | 16.8 | 1 | 16.8 | 11,800 | <0.001 | |

| F3 | 1.00 | 1 | 1.00 | 705 | <0.001 | |

| F1F2 | 0.201 | 1 | 0.201 | 141 | <0.001 | |

| F1F3 | 0.0278 | 1 | 0.0278 | 19.5 | 0.0017 | |

| F2F3 | 0.0397 | 1 | 0.0397 | 27.9 | 0.0005 | |

| F12 | 0.0380 | 1 | 0.0380 | 26.7 | 0.0006 | |

| F22 | 2.95 | 1 | 2.95 | 2070 | <0.001 | |

| F32 | 0.0561 | 1 | 0.0561 | 39.4 | 0.0001 |

| Response | R2 | R2_pre | R2_adj |

|---|---|---|---|

| G*/sin (δ) | 0.9997 | 0.9972 | 0.9995 |

| G* | 0.9996 | 0.9950 | 0.9992 |

| SUMM (%) | Jnr,diff Values (%) | |

|---|---|---|

| 58 °C | 64 °C | |

| 0 | 19.26 | 21.90 |

| 2 | 19.50 | 23.78 |

| 4 | 20.0 | 23.06 |

| 6 | 20.74 | 26.22 |

| 8 | 20.20 | 28.17 |

| 10 | 30.29 | 35.66 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abdelmagid, A.A.A.; Jin, G.; Chen, G.; Huang, B.; Li, Y.; Idriss, A.I.B. High-Temperature Performance Enhancement of Asphalt Binders Modified with Single-Use Masks: A Rheological Analysis with Predictive Modeling. Polymers 2025, 17, 1746. https://doi.org/10.3390/polym17131746

Abdelmagid AAA, Jin G, Chen G, Huang B, Li Y, Idriss AIB. High-Temperature Performance Enhancement of Asphalt Binders Modified with Single-Use Masks: A Rheological Analysis with Predictive Modeling. Polymers. 2025; 17(13):1746. https://doi.org/10.3390/polym17131746

Chicago/Turabian StyleAbdelmagid, Alaaeldin A. A., Guanghui Jin, Guocan Chen, Baotao Huang, Yiming Li, and Aboubaker I. B. Idriss. 2025. "High-Temperature Performance Enhancement of Asphalt Binders Modified with Single-Use Masks: A Rheological Analysis with Predictive Modeling" Polymers 17, no. 13: 1746. https://doi.org/10.3390/polym17131746

APA StyleAbdelmagid, A. A. A., Jin, G., Chen, G., Huang, B., Li, Y., & Idriss, A. I. B. (2025). High-Temperature Performance Enhancement of Asphalt Binders Modified with Single-Use Masks: A Rheological Analysis with Predictive Modeling. Polymers, 17(13), 1746. https://doi.org/10.3390/polym17131746