Exploring the Role of Advanced Composites and Biocomposites in Agricultural Machinery and Equipment: Insights into Design, Performance, and Sustainability

Abstract

1. Introduction

2. Background and Definitions

2.1. Definition of Composites

2.2. Definition of Biocomposites

2.2.1. Natural Fiber-Reinforced Conventional (Petroleum-Based) Matrices

2.2.2. Synthetic Fiber-Reinforced Bio-Based Matrices

2.2.3. Fully Bio-Based Composites (Green Composites)

3. Types of Materials Used in Composites and Biocomposites

3.1. Reinforcing Fibers

3.1.1. Synthetic Fibers

- Glass fibers: Among synthetic fibers, glass fibers—specifically E-glass (electrical grade)—are the most extensively used reinforcement due to their favorable combination of low cost, acceptable tensile strength, excellent electrical insulation, and corrosion resistance [59,60]. S-glass, which is more expensive, has superior mechanical performance (higher strength and stiffness) and can be utilized in niche agrarian uses when higher load-carrying capacity is required without resorting to carbon fiber [60]. Glass fibers are extremely versatile and are available in numerous forms to accommodate specific manufacturing processes and component requirements [33]. Chopped strands are applicable in mass production methods such as sheet molding compound (SMC) and bulk molding compound (BMC) for tractor body panels (hoods, fenders, roofs) or via injection molding with thermoplastic matrices for smaller, complex parts. Woven fabrics provide multi-directional reinforcement suitable for hand lay-up or resin transfer molding (RTM) processes to produce tough guards or semi-structural parts [20,53,61,62]. Continuous rovings are required for processes such as filament winding (for high-pressure tanks or pipes) and pultrusion, the latter being used extensively to produce the long, stiff, and light profile sections required for modern sprayer booms [63]. Generally, the cost-effectiveness and well-characterized performance of GFRP have made it the dominant composite reinforcement for a wide variety of agricultural applications where a significant advantage over traditional metals is desired without prohibitive cost increases.

- Carbon fibers: Offering excellent specific stiffness and specific strength—typically three to five times better than that of E-glass on a weight basis—carbon fibers represent the ultimate in lightweight structural reinforcement. Their high fatigue resistance and low density are highly attractive properties [64]. However, their significantly higher cost restricts their use in the typically cost-sensitive agricultural sector to high-value, performance-critical applications [65]. A prime example is in the production of ultra-wide sprayer booms [63]. For such applications, it is desirable to reduce the boom weight to lower soil compaction and increase stability, and to increase stiffness to prevent excessive boom whipping and yawing during operation on uneven terrain. This preserves the precise application height and pattern required for effective and efficient delivery of fertilizers or pesticides, minimizing waste and environmental impact. While GFRP suffices for smaller booms, the superior properties of CFRP become enabling at such wide extremes, justifying the cost premium through higher productivity and accuracy [63,66,67]. Beyond booms, CFRP can find future niche applications in high-speed rotating components where low inertia is most critical or in lightweight structural frames of specialized autonomous farming equipment or drones where minimization of mass is most critical to range or payload capacity.

- Aramid fibers: More commonly referred to by their trade names, e.g., Kevlar®, aramid fibers are prized for their toughness, impact resistance, and tensile strength [68]. They possess lower compressive strength compared to carbon or glass fibers and might be susceptible to moisture absorption if not effectively protected by the matrix, which could prove to be a weak point in humid agricultural environments. Due to these limitations, together with their relatively high cost, the use of aramid fibers in agricultural applications remains narrow [69,70,71]. Nevertheless, due to their unique mechanical properties, they represent potential candidates for high puncture or impact resistance parts [72,73]. Potential applications include protective shielding for underbody parts exposed to rock impact (e.g., on tractors or combines operating in rocky fields), durable guards for rotating power take-off (PTO) driveshafts, or reinforcement in specific impact-prone zones on harvesting headers or tillage tools, where localized toughness is more critical than overall structural stiffness [74].

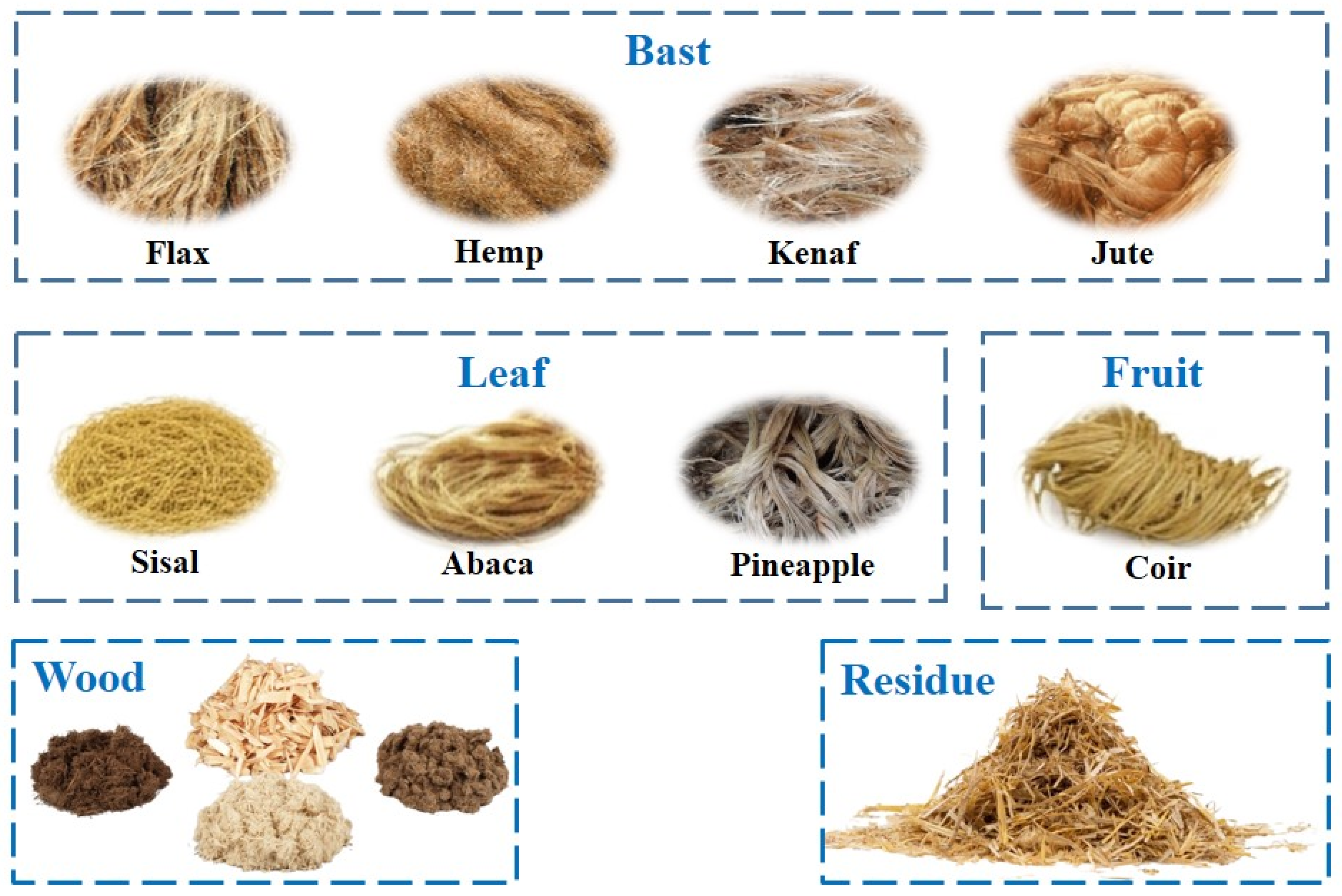

3.1.2. Natural Fibers

- Bast fibers: Extracted from the outer fibrous sheath of the plant stem, bast fibers such as flax, hemp, jute, and kenaf are among the most viable natural reinforcements for semi-structural applications [76]. Flax and hemp, however, possess sufficiently high tensile strength and rigidity, along with specific values of stiffness that are comparable to E-glass, and they are therefore favorable candidates to supplant GFRP in certain applications [77,78]. Their potential uses in agricultural machinery include interior cabin components (dashboards, door panels, headliners, trim pieces), where their look and vibration damping can be beneficial, and non-load-carrying exterior panels such as engine covers, access hatches, or toolboxes [53,79]. Their use in semi-structural elements—such as reinforcing ribs or brackets—is also conceivable, especially when combined with higher-performance thermoplastic or thermoset matrices. Jute is cheaper but typically produces low strength and durability, increased moisture sensitivity, and is likely to be confined to price-sensitive interior filling application or components that are not subjected to significant mechanical loading or exposure to weather [80]. Kenaf offers intermediate properties between jute and flax/hemp and continues to be actively researched [15].

- Leaf fibers: Leaf-derived fibers such as sisal (obtained from Agave species) and abaca (obtained from a banana family member) are documented to have good toughness, durability, and saltwater resistance—properties that have traditionally made them suitable for rope manufacturing [81,82]. While their stiffness is usually less than the best bast fibers, their toughness can be useful in agricultural components with abrasion or localized impact resistance requirements [82]. Prospective applications could include wear liners on material-handling chutes (such as grain or forage), cover plates in less structurally critical areas of tillage or harvest equipment, or elements where a degree of flexibility along with resiliency would be advantageous. However, their use in load-bearing structures is not currently considered as likely as some of the more robust bast fibers such as flax or hemp, but further studies may exhibit new applications.

- Seed/Fruit fibers: Cotton (used primarily in textiles due to its fineness and softness, thus of less interest for structural reinforcement) and coir (from coconut husks) belong to this group [83]. Coir fibers are extremely low in density, highly elongated, possess good resilience, and have relatively good resistance to rot and moisture. However, their mechanical stiffness and strength are comparatively much lower than bast or leaf fibers [84,85]. As such, their role in agricultural machinery composites is unlikely to be in structural reinforcement. They will potentially find other niche applications though as lightweight core material in sandwich panel structures (e.g., platforms or dividers), fillers to keep weight and expense low in components that are non-load-bearing, or possibly within components where damping and energy absorption would be a desirable attribute (e.g., seat padding or sound insulation within tractor cabs) [86,87].

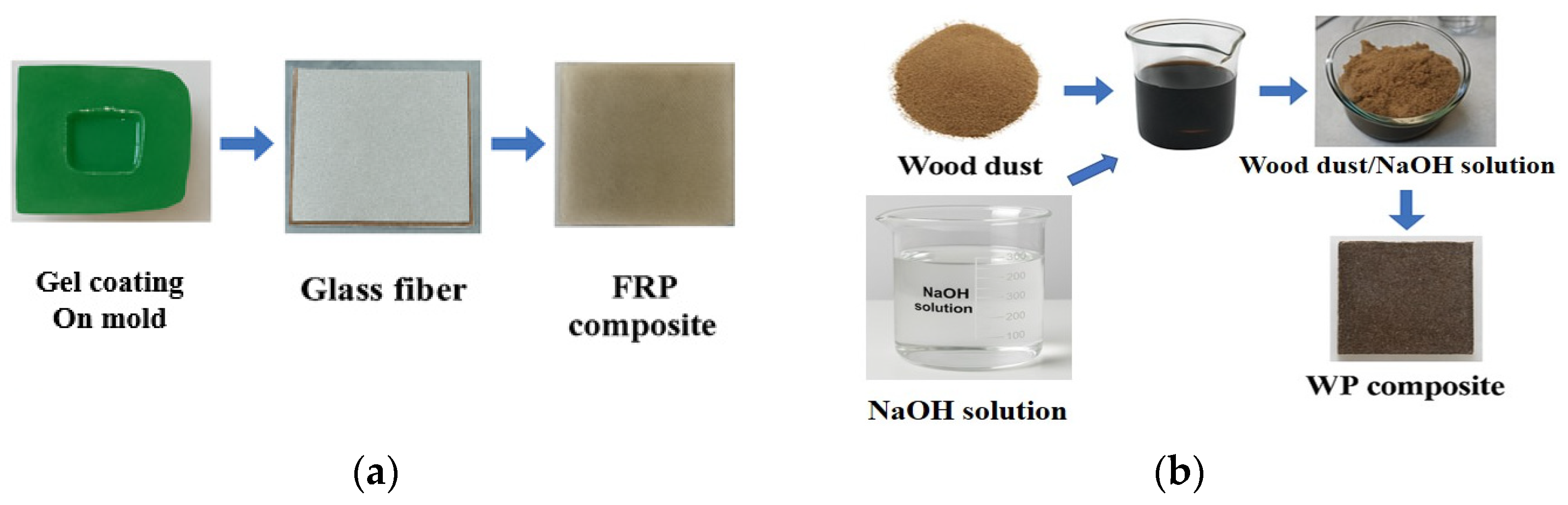

- Wood fibers: Inexpensive, readily available wood industry by-products known as wood fibers are commonly used, particularly in wood–plastic composites (WPCs) [88]. Wood particles are typically blended with thermoplastic matrices such as PE, PP, or PVC, often by extrusion or injection molding [89,90,91]. While WPCs are extremely prevalent in their application for such purposes as outdoor decking, fencing, and window profiles, they are not widely utilized in farm equipment but could provide some opportunities [92,93]. For instance, WPCs can be applied on components such as utility trailer flooring panels or shipping box components, non-load carrying auxiliary equipment coverings, operators’ platforms, or possibly as replaceable wear surfaces where high structural integrity is not a primary requirement and where cost-effectiveness and moderate durability/moisture resistance (relative to untreated wood) are sufficient. However, their mechanical properties are generally inferior to those of continuous fiber-reinforced composites.

- Agricultural residues: Utilization of residues such as wheat straw, rice straw, corn stover (stalks and leaves), or sugarcane bagasse as reinforcement directly falls into circular economy principles in the agricultural sector with the possibility of adding value to huge quantities of low-cost biomass [94]. These are sustainable and abundant materials. Today, a vast quantity of agricultural residues is mostly utilized for energy generation—either as feedstock for biofuels, greenhouse heating, or powering farm operations—rather than being extensively utilized in the production of biocomposites for machinery components [95,96]. Despite such a prevalent trend for energy applications, research continues to seek their utilization as part of composite materials. However, from a mechanical point of view, these residues offer lower strength and stiffness and higher variability compared to dedicated fiber crops such as flax or hemp. Moreover, their harvesting, cleaning, and processing effectively are logistically demanding [97]. Therefore, their current use in agromachinery composites can be primarily as low-cost fillers to reduce material consumption and weight in non-critical components, or as reinforcement in parts subjected to low mechanical loads. Some possibilities include internal panels, sound insulation, or biodegradable components such as temporary plant supports or mulch film holders, where high mechanical strength is not required.

3.2. Polymer Matrices

3.2.1. Conventional Thermosets

- Unsaturated polyesters (UPs): These are considered the workhorse thermoset resins in many industries, including agriculture, primarily due to their low cost and ease of processing using relatively simple techniques such as hand lay-up, spray-up, and increasingly, compression molding using SMC or BMC [102]. This makes them economically viable for manufacturing large, relatively low-volume components common in agricultural machinery, such as tractor hoods, fenders, roofs, and equipment enclosures. Their good balance of mechanical properties (adequate strength and stiffness for non-primary structural parts), inherent corrosion resistance compared to steel, and ability to be molded into complex shapes are key benefits [102,103]. However, standard UP resins exhibit only moderate chemical resistance, limiting their use in direct contact with aggressive agrochemicals, and their mechanical properties are generally lower than those of vinyl esters or epoxies [104]. Furthermore, processing often involves the emission of volatile organic compounds, such as styrene, raising environmental and workplace safety concerns—issues that are being addressed by newer low-styrene or styrene-free formulations [103,104]. SMC/BMC formulations allow for higher production volumes with better dimensional control and surface finish, making them suitable for series production of panels [102].

- Vinyl esters (VEs): Chemically related to both polyesters and epoxies, VE resins offer significant advantages in enhanced chemical resistance, particularly against hydrolysis, acids, and various solvents commonly found in fertilizers and pesticides [105]. This superior chemical inertness stems from the placement of the reactive ester groups primarily at the ends of the molecular chains, reducing their vulnerability to chemical attack compared to the numerous ester linkages along the backbone of UP resins. Consequently, VE resins are the preferred matrix material for manufacturing durable chemical storage tanks and sprayer tanks in agricultural equipment, ensuring containment integrity, preventing the contamination of tank contents, and prolonging service life in chemically aggressive environments [106,107]. While more expensive than UP, their enhanced performance justifies the cost for these critical applications. VE resins also generally exhibit better mechanical properties (e.g., strength, toughness) than UP and can be processed using similar methods including hand lay-up, resin transfer molding, and filament winding for tanks [106].

- Epoxies (EPs): Epoxy resins are renowned for their superior mechanical properties (high strength, stiffness, and fatigue resistance), excellent adhesion to a wide range of fibers, good dimensional stability, and broad chemical resistance [106,107]. This performance profile makes them the matrix of choice for high-performance composite applications in agriculture. Their excellent adhesion is critical for maximizing the performance of expensive reinforcing fibers such as carbon, hence their prevalent use in CFRP components including ultra-wide sprayer booms, where efficient stress transfer ensures the required stiffness and strength are obtained at minimum weight [63,108]. Epoxies may also be used with glass fibers for components subjected to higher structural loads, significant fatigue cycles, or demanding durability requirements—beyond what is achievable with UP or VE—such as load-bearing brackets or reinforcement structures [63,109]. However, epoxies are typically more expensive than polyesters or vinyl esters and often require longer, more carefully controlled curing cycles, sometimes at elevated temperatures, increasing manufacturing complexity and cost. Their superior performance comes at a premium, limiting their widespread use to applications where the performance benefits outweigh the additional expense [106,107].

3.2.2. Conventional Thermoplastics

- Polypropylene (PP): As one of the most common thermoplastics utilized, PP offers an advantageous combination of low cost, inertness to bases and acids (especially), and low density (~0.9 g/cm3) with good processability, particularly through injection molding [110]. In agriculture applications, PP is employed similarly to its use in the automotive sector—for components such as interior parts of tractor cabs (e.g., dashboards, trim panels, and consoles), enclosures for auxiliary equipment, protective covers, and small tanks or containers for non-aggressive liquids [53,111]. When reinforced with short or long glass fibers, its mechanical properties—strength, stiffness, and creep resistance—are significantly enhanced, making it suitable for semi-structural components [66,67]. PP is also widely used as a matrix for natural fiber composites (e.g., flax/PP, hemp/PP) and wood–plastic composites, offering a viable pathway for integrating renewable materials into cost-sensitive applications [112]. However, limitations include its relatively low service temperature (compared to engineering thermoplastics such as PA) and moderate UV resistance, which necessitate stabilization for prolonged outdoor exposure [110].

- Polyamides (PAs, Nylons): Thermoplastics such as PA6 and PA66 possess higher strength, stiffness, wear resistance, and thermal properties than PP [113]. These materials can be used in combination with glass fibers (GF/PP) to produce more demanding agricultural components, including moderately loaded gears (when lubricated), wear pads, robust enclosures located near heat sources, fan blades, and structural brackets that require a higher load-bearing capacity than those made with GF/PP [114,115,116]. However, polyamides are more costly than PP and exhibit a notable drawback in agricultural applications—moisture absorption [113]. In the typically damp environments of farming, absorbed moisture acts as a plasticizer, reducing the stiffness and strength of the material and leading to dimensional changes that must be considered during component design.

- Polyethylene (PE): Available in various densities (e.g., LDPE, HDPE), PE is valued for its excellent chemical resistance, impact toughness (especially in HDPE at low temperatures), low cost, and ease of processing [34]. High-density polyethylene (HDPE) is widely used in rotational molding to produce large, seamless tanks for storing water, liquid feed, diesel fuel, diesel, or non-aggressive chemicals, offering a cost-effective and durable alternative to GFRPs [117,118]. Due to its chemical inertness, PE is highly suitable for such containment applications. It is also commonly used as a matrix in extruded WPC profiles for non-structural parts [88]. However, PE’s lower strength, stiffness, and thermal resistance, compared to PP or PA, limit its suitability for load-bearing or high-temperature machinery components.

3.2.3. Bio-Based Matrices

- Polylactic acid (PLA): Derived from fermented plant starch (e.g., corn, sugarcane), PLA is among the most commercially available bio-based compostable polymers. It exhibits good stiffness (comparable to polystyrene) and transparency, making it suitable for certain non-load-bearing applications [51,76]. However, its use in durable agricultural machinery is limited by its inherent brittleness, low heat distortion temperature (typically around 50–60 °C), and susceptibility to hydrolysis—factors that impair its performance in hot or humid agricultural environments [119]. As a result, PLA is more appropriate for short-term items (e.g., biodegradable clips, tags, or planting aids), protected interior components, or packaging. Ongoing research focuses on enhancing PLA’s toughness and thermal resistance through blending, copolymerization, or fiber reinforcement [120].

- Polyhydroxyalkanoates (PHAs): These are polyesters biosynthesized by various microorganisms [121]. A key advantage of PHAs is their biodegradability in a wide range of environments, including soil and aquatic systems—unlike PLA, which requires industrial composting. The properties of PHAs can be tuned from rubbery to stiff by modifying the fermentation process and bacterial strains [122]. Nevertheless, PHAs are currently limited by high production costs and thermal instability during processing. Consequently, their use in agricultural machinery is confined to niche applications where biodegradability in soil is a critical requirement (e.g., coatings for slow-release fertilizers, or biodegradable sensor housings) [123,124].

- Bio-based Polyethylene (Bio-PE): Produced from ethanol derived from sugarcane fermentation, Bio-PE is chemically identical to fossil-based PE [125]. Such “drop-in” compatibility allows it to be directly substituted for traditional PE in existing applications—such as rotationally molded tanks or WPC production—without sacrificing performance or the need for equipment redesign. Its main benefit is the use of renewable feedstocks, thereby reducing the carbon footprint.

- Other promising bio-based options: High-performance bio-based matrices are gaining attention. Bio-based polyamides (e.g., PA11 derived from castor oil) have the same characteristics as conventional PAs, including chemical and heat resistance, and might therefore find application in components such as fuel lines and hydraulic systems [126]. Likewise, bio-based polyesters such as polybutylene succinate (PBS) and polytrimethylene terephthalate (PTT) offer varying mechanical properties and degrees of biodegradability [127]. Vegetable oil-, lignin-, or other biomass-based bio-derived epoxies and polyurethanes are also being created as sustainable alternatives to thermosets in structural composites [128,129]. Despite their potential, the broader application of these new bio-matrices in agriculture will depend on overcoming challenges related to cost competitiveness, large-scale manufacturability, long-term durability, and effective end-of-life strategies.

3.3. Fillers

3.3.1. Mineral Fillers

- Calcium carbonate (CaCO3): A very ubiquitous and inexpensive mineral filler, precipitated or ground CaCO3 is usually added to thermoset (e.g., SMC/BMC) and thermoplastic composites to reduce costs. It is accountable for raising the stiffness and hardness of the composite [131]. Its relatively high density (approximately 2.7 g/cm3) makes it so that it can contribute to the composite density, potentially negating weight-saving objectives gained from fiber reinforcement [132]. This compromise can be acceptable in applications where lightness is less critical, such as immovable housing or ballast components. However, overloading reduces impact resistance due to agglomeration or poor interfacial adhesion, which creates stress concentration points [131,133]. Therefore, its use in impact-sensitive parts such as bumpers needs to be carefully formulated.

- Talc: A hydrated magnesium silicate with a platy (lamellar) structure, talc provides notable stiffness and flexural modulus improvements, often outperforming particulate fillers at similar loadings [134]. Talc also enhances dimensional stability and warpage minimization, beneficial for producing precise parts such as dashboards or ventilation components. Furthermore, talc increases the heat deflection temperature (HDT), making it a good choice for employment in the vicinity of engines or hydraulic systems [135].

- Silica (SiO2): Silica, available in various forms such as ground quartz, fumed silica, and precipitated silica, primarily enhances the composite’s hardness, scratch resistance, and compressive strength [136]. Due to its abrasive nature, it significantly enhances wear resistance—a very important property for agricultural machinery exposed to friction or contact with soil, crops, or granular materials. It is also used as a filler in expert wear-resistant coatings applied to tillage machines or harvester parts [137]. Although these coatings are metallic or ceramic, polymer composites filled with silica can serve as an economical replacement for moderate wear applications. Moreover, fumed or precipitated silicas, due to their extremely small particle size and high surface area, find applications in dilute concentrations as rheology modifiers (thixotropes) in liquid thermoset resins such as polyesters and epoxies [138,139]. These additives are utilized for regulating resin flow during processing, inhibiting drainage on vertical surfaces when the lay-up of large tractor body panels is manual, and imparting a uniform thickness throughout the composite.

- Other mineral fillers: Nanoclays (e.g., montmorillonite) enhance barrier properties, stiffness, and flame retardancy at low loadings [140]. Mica improves the stiffness and insulation properties [141]. Glass microspheres reduce the density while maintaining stiffness, making them suitable for lightweight parts such as core materials or molded housings [142].

3.3.2. Bio-Fillers

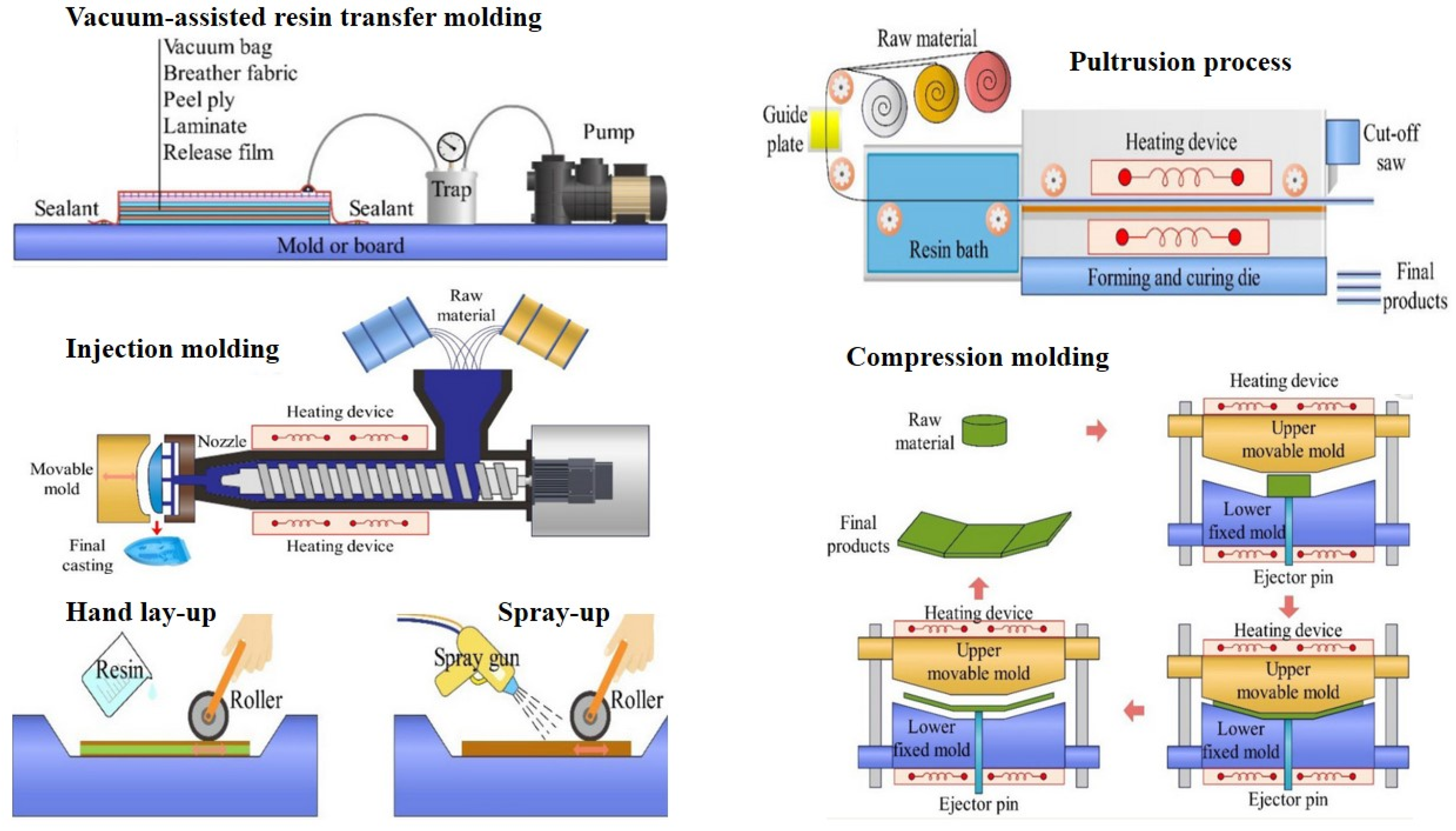

4. Fabrication Processes of Composites and Biocomposites

5. Applications of Composites and Biocomposites in Agricultural Machinery and Equipment

5.1. Tractor Components

- Exterior panels (hoods, fenders, roofs): GFRP is suitable for use in exterior panels, offering 25–40% weight savings compared to steel. These parts resist corrosion and impacts and allow for modern aerodynamic designs [62,66]. Biocomposites such as hemp/PP and flax/PP can also be used for these non-structural components, especially where sustainability is prioritized [3,112]. Findings from the automotive sector regarding non-structural biocomposite panels are often directly transferable, although long-term UV stability and impact resistance in the harsher AME environment require specific validation.

- Interior cab parts (dashboards, trim panels): Thermoplastic composites reinforced with glass or natural fibers (e.g., flax/PP, WPCs) are used for their weight reduction, integrated design features, and acoustic insulation, enhancing operator comfort.

5.2. Sprayer Components

- Tanks: Holding potentially corrosive liquid fertilizers, pesticides, and herbicides requires materials with excellent chemical resistance. GFRP, particularly when fabricated using specialized chemical-resistant VE or isophthalic polyester resins, is considered the industry standard for sprayer tanks [106,107]. These materials eliminate the risk of rust contamination associated with steel tanks, ensuring chemical purity and preventing nozzle blockages. Their lightweight nature allows manufacturers to either increase tank capacities—thereby improving field efficiency by reducing refill stops—or reduce the overall vehicle weight, which contributes to lower soil compaction and enhanced maneuverability, especially on softer terrain. For smaller-sized tanks or sprayers used to contain less-aggressive chemicals, rotationally molded PE tanks also offer an economic, seamless, and chemically resistant option.

- Booms: The large truss booms carrying spray nozzles are one of the most conspicuous and impactful applications of high-performance composites in AME. As boom widths increase (often exceeding 30 m) to enhance productivity, the weight and inertia of traditional steel or aluminum booms become significant limitations, leading to instability, increased soil compaction under the wheels, and potential structural fatigue [146]. GFRP booms, typically manufactured using pultrusion for the main profiles or resin transfer molding for sections and joints, offer substantial weight savings—often a 30–50% reduction compared to steel [63]. This weight reduction improves boom stability, allowing for a more consistent spray height and application patterns, which is critical to spray efficacy and reducing drift. For extremely wide booms (over 36–40 m), the greater specific stiffness of CFRP becomes the decisive factor [63]. CFRP allows these ultra-wide structures to maintain sufficient rigidity, preventing excessive deflection and vibration, thereby ensuring precise spray application, which is vital for precision agriculture practices. Although CFRP is much more expensive than GFRP, cost justification is provided by the performance enhancement—including the higher work rate, reduced chemical usage through more precise targeting, and lower field passes that minimize compaction—where the expenditure on CFRP is justified on premium class large-scale spraying operations.

5.3. Combine Harvester Components

- External panels and covers: Similar to tractors, heavy external panels (e.g., side shields, engine covers), protective guards, and access doors are typically capable of being manufactured from GFRP through techniques such as sheet molding compound or lay-up processes. Not only does this make the machine lighter in general but also provides high resistance to corrosion from plant juices and moisture. Additionally, GFRP offers enhanced durability against impacts from crop stalks or field debris, ensuring longer service life and improved performance in harsh agricultural environments. In addition to GFRP, biocomposites (e.g., bamboo/flax) are also applicable to the design and manufacture of exterior and protective components. As seen in recent years, these materials have been successfully employed in the automotive industry, providing an eco-friendly alternative with similar benefits, such as weight reduction and improved performance [147].

- Internal components: While metals continue to dominate most internal components due to their high abrasion resistance to grain and crop materials, there is growing interest in the use of composites for some internal components. Some potential applications are grain handling parts, such as auger troughs and elevator housings, where the lighter weight would decrease drive power requirements. Abrasion resistance, however, remains a key issue and may require special wear-resistant coatings or composite structures. Components used in the separation of grain from chaff, such as shaker pans or sieve frames, could benefit from the reduced inertial loads of lightweight composites. This could allow for increased operating frequencies or reduced transmission of vibration, leading to improved efficiency. However, the widespread adoption of composites in these applications is hindered by concerns about their durability under continuous vibration and impact from grain, as well as cost considerations. Biocomposites will find limited use in non-load bearing, non-abrasive internal covers or ducting, where their environmental benefits align with performance requirements.

5.4. Planting and Seeding Equipment

- Hoppers: Fertilizer and seed hoppers may be made from composites such as GFRP or specially formulated biocomposites. The most significant advantage of using such a material is the excellent resistance to corrosion from hygroscopic and potentially acidic fertilizers. The composites also enable the production of smooth, molded shapes that facilitate consistent material flow towards the metering system, thereby preventing bridging or clogging and ensuring accurate application rates. Their lightweight characteristics contribute to easier handling and lower draft force requirements during operation. It is also feasible for certain GFRP hoppers to be designed to be transparent, so the material level can be seen by operators without the necessity of additional sensors.

5.5. Other Equipment and Components

5.6. Review of Existing Research and Technological Trends

6. Advantages and Challenges

6.1. Advantages

6.1.1. Lightweighting

6.1.2. High Specific Strength and Stiffness

6.1.3. Corrosion and Chemical Resistance

6.1.4. Design Flexibility

6.1.5. Sustainability Potential

6.1.6. Other Advantages

6.2. Challenges

6.2.1. Costs

6.2.2. Durability in Agricultural Environments

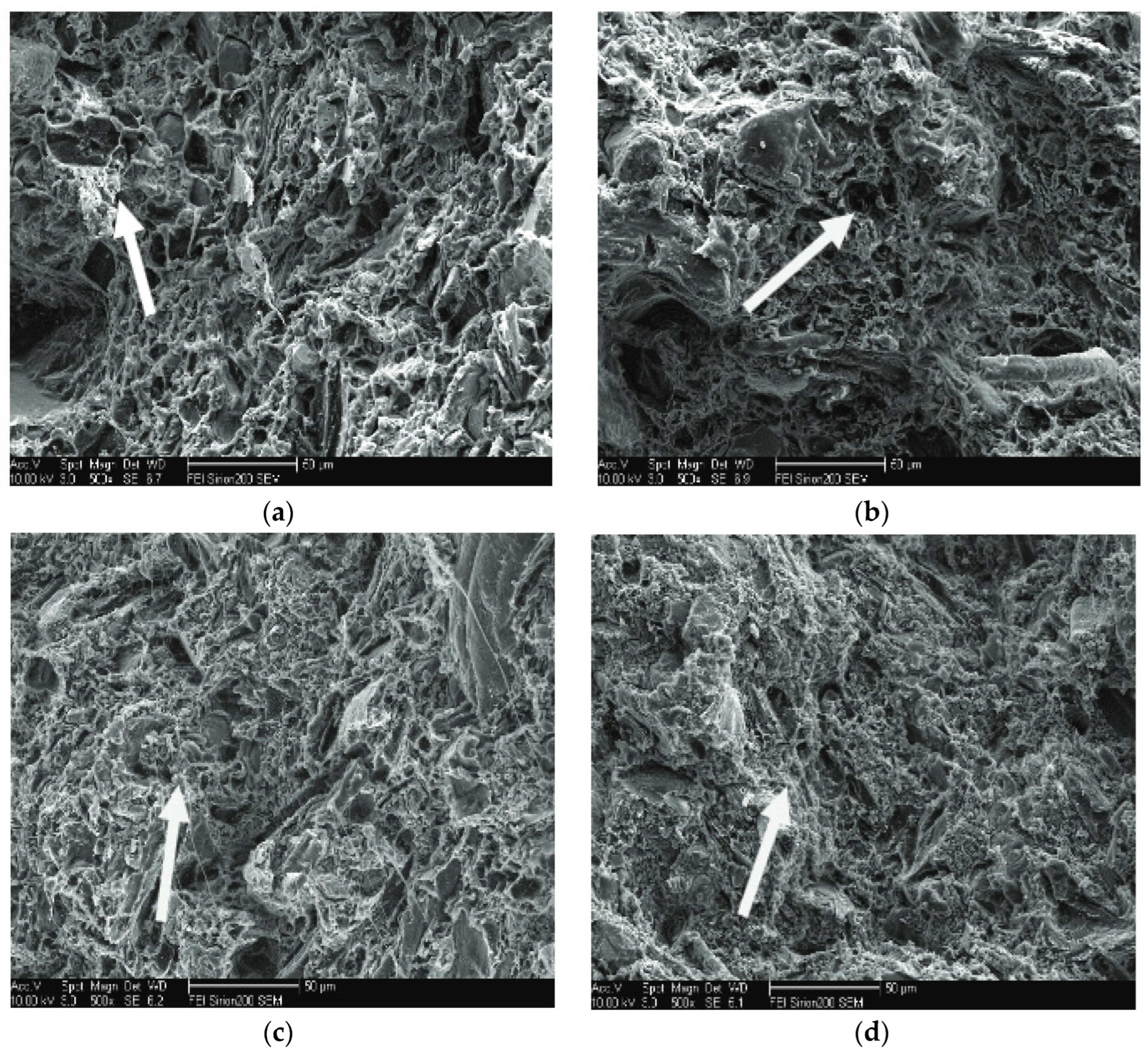

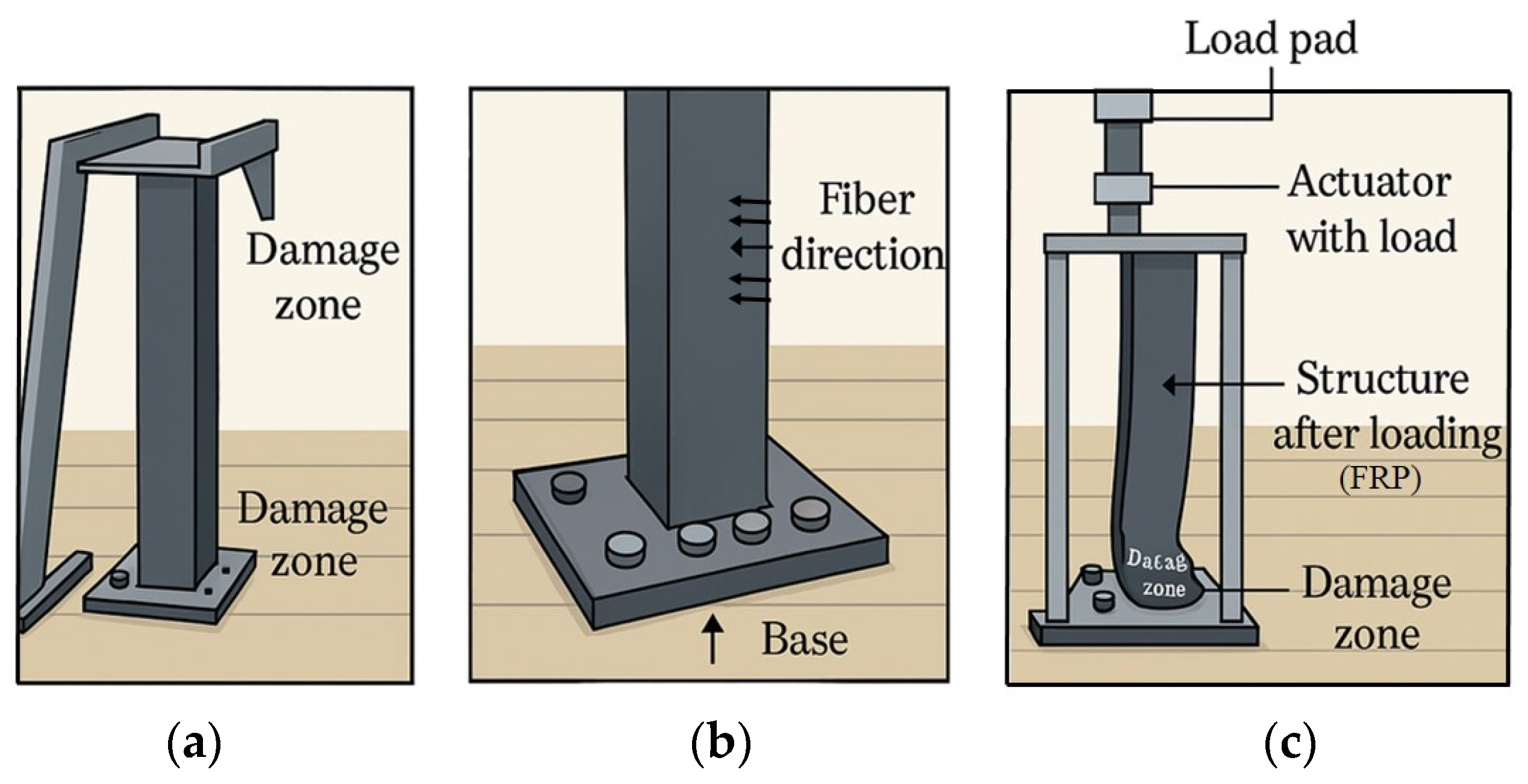

6.2.3. Damage Tolerance, Inspection, and Repair

6.2.4. Manufacturing and Consistency

6.2.5. Standardization and Long-Term Data

6.2.6. Fiber–Matrix Adhesion

7. Future Directions and Research Recommendations

- Development of advanced material systems.

- Long-term durability assessment in realistic agricultural environments.

- Sustainable and efficient manufacturing processes.

- Circular economy strategies in agricultural applications.

- Hybridization and smart structures.

8. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Zheng, C.; Peng, X.; Wang, Z.; Ma, T.; Lu, J.; Chen, L.; Shen, Z. A review on blockchain applications in operational technology for food and agriculture critical infrastructure. Foods 2025, 14, 251. [Google Scholar] [CrossRef] [PubMed]

- Danda, R.R. Innovations in agricultural machinery: Assessing the impact of advanced technologies on farm efficiency. J. Artif. Intell. Big Data 2023, 3, 1156. [Google Scholar] [CrossRef]

- Getahun, S.; Kefale, H.; Gelaye, Y. Application of precision agriculture technologies for sustainable crop production and environmental sustainability: A systematic review. Sci. World J. 2024, 2024, 2126734. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Li, D.; Nie, C.; Gong, P.; Yang, J.; Hu, Z.; Ma, M. Research progress on the wear resistance of key components in agricultural machinery. Materials 2023, 16, 7646. [Google Scholar] [CrossRef]

- Hamza, M.A.; Anderson, W.K. Soil compaction in cropping systems: A review of the nature, causes and possible solutions. Soil Tillage Res. 2005, 82, 121–145. [Google Scholar] [CrossRef]

- Zhang, B.; Jia, Y.; Fan, H.; Guo, C.; Fu, J.; Li, S.; Ma, R. Soil compaction due to agricultural machinery impact: A systematic review. Land Degrad. Dev. 2024, 35, 3256–3273. [Google Scholar] [CrossRef]

- Mikkola, H.J.; Ahokas, J. Indirect energy input of agricultural machinery in bioenergy production. Renew. Energy 2010, 35, 23–28. [Google Scholar] [CrossRef]

- Nasr, G.E.; Hamid, Z.A.; Refai, M. Agricultural machinery corrosion. In Introduction to Corrosion-Basics and Advances; Singh, A., Ed.; IntechOpen: London, UK, 2023. [Google Scholar] [CrossRef]

- Diniță, A.; Ripeanu, R.G.; Ilincă, C.N.; Cursaru, D.; Matei, D.; Naim, R.I.; Portoacă, A.I. Advancements in fiber-reinforced polymer composites: A comprehensive analysis. Polymers 2023, 16, 2. [Google Scholar] [CrossRef]

- Alshammari, B.A.; Alsuhybani, M.S.; Almushaikeh, A.M.; Alotaibi, B.M.; Alenad, A.M.; Alqahtani, N.B.; Alharbi, A.G. Comprehensive review of the properties and modifications of carbon fiber-reinforced thermoplastic composites. Polymers 2021, 13, 2474. [Google Scholar] [CrossRef]

- Ramesh, M.; Selvan, M.T.; Saravanakumar, A. 4—Evolution and recent advancements of composite materials in structural applications. In Woodhead Series in Materials, Applications of Composite Materials in Engineering; Elsevier Science Ltd.: Amsterdam, The Netherlands, 2025; pp. 97–117. [Google Scholar] [CrossRef]

- Gente, V.; Pattanaro, G. The place of eco-innovation in the current sustainability debate. Waste Manag. 2019, 88, 96–101. [Google Scholar] [CrossRef]

- Mohanty, A.K.; Misra, M.A.; Hinrichsen, G.I. Biofibres, biodegradable polymers and biocomposites: An overview. Macromol. Mater. Eng. 2000, 276, 1–24. [Google Scholar] [CrossRef]

- Bahrami, M.; Abenojar, J.; Martínez, M.Á. Recent progress in hybrid biocomposites: Mechanical properties, water absorption, and flame retardancy. Materials 2020, 13, 5145. [Google Scholar] [CrossRef] [PubMed]

- Kuram, E. Natural fiber-based polymer composites for biomedical applications. J. Biomater. Sci. Polym. Ed. 2025, 36, 1027–1084. [Google Scholar] [CrossRef] [PubMed]

- Akter, M.; Uddin, M.H.; Tania, I.S. Biocomposites based on natural fibers and polymers: A review on properties and potential applications. J. Reinf. Plast. Comp. 2022, 41, 705–742. [Google Scholar] [CrossRef]

- Rajeshkumar, L.; Kumar, P.S.; Ramesh, M.; Sanjay, M.R.; Siengchin, S. Assessment of biodegradation of lignocellulosic fiber-based composites—A systematic review. Int. J. Biol. Macromol. 2023, 253, 127237. [Google Scholar] [CrossRef]

- Paglicawan, M.A.; Emolaga, C.S.; Sudayon, J.M.B.; Tria, K.B. Mechanical properties of abaca–glass fiber composites fabricated by vacuum-assisted resin transfer method. Polymers 2021, 13, 2719. [Google Scholar] [CrossRef]

- Olorunnisola, A.O. Potentials of wood, bamboo and natural fibre-reinforced composite products as substitute materials for fabricating affordable agricultural equipment and processing machines in Africa. In Technology in Agriculture; IntechOpen: London, UK, 2021. [Google Scholar]

- Alves, C.; Freitas, M.; Silva, A.J.; Luz, S.M.; Alves, D.E. Sustainable design procedure: The role of composite materials to combine mechanical and environmental features for agricultural machines. Mater. Des. 2009, 30, 4060–4068. [Google Scholar] [CrossRef]

- Mourdikoudis, S.; Kostopoulou, A.; LaGrow, A.P. Magnetic nanoparticle composites: Synergistic effects and applications. Adv. Sci. 2021, 8, 2004951. [Google Scholar] [CrossRef]

- Yu, Z.; Yu, L.; Zhu, W.; Liu, J.; Wei, X. An analytical model for customizing reinforcement plasticity to address the strength-ductility trade-off in staggered composites. J. Mech. Behav. Biomed. Mater. 2025, 166, 106959. [Google Scholar] [CrossRef]

- Zhang, J.; Qian, M.; Yang, R.; Yu, F.; Zhang, X.; Jia, Z.; Geng, L. Corrosion behavior of nacre-inspired (TiBw-TiB2)/Al composites fabricated by freeze casting. Materials 2024, 17, 2534. [Google Scholar] [CrossRef]

- Patel, S.; Badjena, S.K.; Padhi, P.C. Comparative study of wood polymer composites and frp in farm machinery for sustainable agriculture. Plant Arch. 2025, 25, 527–531. [Google Scholar]

- Adam, T.J.; Wierach, P.; Mertiny, P. Multifunctional hybrid fiber composites for energy transfer in future electric vehicles. Materials 2022, 15, 6257. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Liu, X.; Liu, J.; Wu, M.; Huang, Y. Tailoring interfacial adhesion between PBAT matrix and PTFE-modified microcrystalline cellulose additive for advanced composites. Polymers 2022, 14, 1973. [Google Scholar] [CrossRef] [PubMed]

- Zvonek, M.; Sirjovova, V.; Branecky, M.; Plichta, T.; Skacel, J.; Cech, V. Plasma nanocoatings developed to control the shear strength of polymer composites. Polymers 2019, 11, 1188. [Google Scholar] [CrossRef]

- Muna, I.I.; Mieloszyk, M.; Rimasauskiene, R.; Maqsood, N.; Rimasauskas, M. Thermal effects on mechanical strength of additive manufactured CFRP composites at stable and cyclic temperature. Polymers 2022, 14, 4680. [Google Scholar] [CrossRef]

- Abotbina, W.; Sapuan, S.M.; Ilyas, R.A.; Sultan, M.T.H.; Alkbir, M.F.M.; Sulaiman, S.; Bayraktar, E. Recent developments in cassava (Manihot esculenta) based biocomposites and their potential industrial applications: A comprehensive review. Materials 2022, 15, 6992. [Google Scholar] [CrossRef]

- Madyaratri, E.W.; Ridho, M.R.; Aristri, M.A.; Lubis, M.A.R.; Iswanto, A.H.; Nawawi, D.S.; Fatriasari, W. Recent advances in the development of fire-resistant biocomposites—A review. Polymers 2022, 14, 362. [Google Scholar] [CrossRef]

- Islam, M.H.; Afroj, S.; Karim, N. Toward sustainable composites: Graphene-modified jute fiber composites with bio-based epoxy resin. Glob. Chall. 2023, 7, 2300111. [Google Scholar] [CrossRef]

- Khan, M.Z.; Srivastava, S.K.; Gupta, M.K. Tensile and flexural properties of natural fiber reinforced polymer composites: A review. J. Reinf. Plast. Compos. 2018, 37, 1435–1455. [Google Scholar] [CrossRef]

- Wang, G.; Zhang, D.; Wan, G.; Li, B.; Zhao, G. Glass fiber reinforced PLA composite with enhanced mechanical properties, thermal behavior, and foaming ability. Polymer 2019, 181, 121803. [Google Scholar] [CrossRef]

- Soo, X.Y.D.; Muiruri, J.K.; Wu, W.Y.; Yeo, J.C.C.; Wang, S.; Tomczak, N.; Zhu, Q. Bio-polyethylene and polyethylene biocomposites: An alternative toward a sustainable future. Macromol. Rapid Commun. 2024, 45, 2400064. [Google Scholar] [CrossRef] [PubMed]

- Schuhladen, K.; Lukasiewicz, B.; Basnett, P.; Roy, I.; Boccaccini, A.R. Comparison of the influence of 45S5 and Cu-containing 45S5 bioactive glass (BG) on the biological properties of novel polyhydroxyalkanoate (PHA)/BG composites. Materials 2020, 13, 2607. [Google Scholar] [CrossRef] [PubMed]

- Atmakuri, A.; Palevicius, A.; Vilkauskas, A.; Janusas, G. Review of hybrid fiber based composites with nano particles—Material properties and applications. Polymers 2020, 12, 2088. [Google Scholar] [CrossRef] [PubMed]

- Momeni, S.; Safder, M.; Khondoker, M.A.H.; Elias, A.L. Valorization of hemp hurds as bio-sourced additives in PLA-based biocomposites. Polymers 2021, 13, 3786. [Google Scholar] [CrossRef]

- Fartash Naeimi, E.; Selvi, K.Ç.; İnanç, İ.; Ungureanu, N. Mechanical and thermal behavior of hemp-reinforced starch/agar biocomposites: Insights from Finite Element Simulation and Machine Learning Models. Polymers 2025, 17, 855. [Google Scholar] [CrossRef]

- Simões, S. High-performance advanced composites in multifunctional material design: State of the art, challenges, and future directions. Materials 2024, 17, 5997. [Google Scholar] [CrossRef]

- Skosana, S.J.; Khoathane, C.; Malwela, T. Driving towards sustainability: A review of natural fiber reinforced polymer composites for eco-friendly automotive light-weighting. J. Thermoplast. Compos. Mater. 2025, 38, 754–780. [Google Scholar] [CrossRef]

- Quintana-Gallardo, A.; Alba, J.; Del Rey, R.; Crespo-Amorós, J.E.; Guillén-Guillamón, I. Life-cycle assessment and acoustic simulation of drywall building partitions with bio-based materials. Polymers 2020, 12, 1965. [Google Scholar] [CrossRef]

- Zwawi, M. A review on natural fiber bio-composites, surface modifications and applications. Molecules 2021, 26, 404. [Google Scholar] [CrossRef]

- Mohammed, M.; Jawad, A.J.A.M.; Mohammed, A.M.; Oleiwi, J.K.; Adam, T.; Osman, A.F.; Jaafar, M. Challenges and advancement in water absorption of natural fiber-reinforced polymer composites. Polym. Test. 2023, 124, 108083. [Google Scholar] [CrossRef]

- Mohammed, M.; Oleiwi, J.K.; Mohammed, A.M.; Jawad, A.J.A.M.; Osman, A.F.; Adam, T.; Jaafar, M. Comprehensive insights on mechanical attributes of natural-synthetic fibres in polymer composites. J. Mater. Res. Technol. 2023, 25, 4960–4988. [Google Scholar] [CrossRef]

- Huang, Y.; Sultan, M.T.H.; Shahar, F.S.; Łukaszewicz, A.; Oksiuta, Z.; Grzejda, R. Kenaf fiber-reinforced biocomposites for marine applications: A review. Materials 2025, 18, 999. [Google Scholar] [CrossRef] [PubMed]

- Ramachandran, A.; Mavinkere Rangappa, S.; Kushvaha, V.; Khan, A.; Seingchin, S.; Dhakal, H.N. Modification of fibers and matrices in natural fiber reinforced polymer composites: A comprehensive review. Macromol. Rapid Commun. 2022, 43, 2100862. [Google Scholar] [CrossRef] [PubMed]

- Sharma, D.; Kumar, M.; Jain, V.P.; Chaudhary, S.; Jaiswar, G. Bio-based polyamide nanocomposites of nanoclay, carbon nanotubes and graphene: A review. Iran. Polym. J. 2023, 32, 773–790. [Google Scholar] [CrossRef]

- Coltelli, M.B.; Cinelli, P.; Anguillesi, I.; Salvadori, S.; Lazzeri, A. Structure and properties of extruded composites based on bio-polyesters and nano-chitin. In Proceedings of the E-MRS 2014 Fall Meeting, Warsaw, Poland, 15–19 September 2014; p. 192. [Google Scholar]

- Li, T.; Zhang, Y.; Jin, Y.; Bao, L.; Dong, L.; Zheng, Y.; Wang, J. Thermoplastic and biodegradable sugarcane lignin-based biocomposites prepared via a wholly solvent-free method. J. Clean. Prod. 2023, 386, 135834. [Google Scholar] [CrossRef]

- Ramakrishnan, K.R.; Le Moigne, N.; De Almeida, O.; Regazzi, A.; Corn, S. Optimized manufacturing of thermoplastic biocomposites by fast induction-heated compression moulding: Influence of processing parameters on microstructure development and mechanical behaviour. Compos.—A Appl. Sci. Manuf. 2019, 124, 105493. [Google Scholar] [CrossRef]

- Almeida, V.H.M.; Jesus, R.M.; Santana, G.M.; Pereira, T.B. Polylactic acid polymer matrix (Pla) biocomposites with plant fibers for manufacturing 3D printing filaments: A review. J. Compos. Sci. 2024, 8, 67. [Google Scholar] [CrossRef]

- Yapıcı, S.; Baltacı, Ö.A.; Güzel, S.; Mihaliç, F. Application of polymer matrix composite materials for the tractor safety frames. Tarmak 2014, 10, 317–322. [Google Scholar]

- Holbery, J.; Houston, D. Natural-fiber-reinforced polymer composites in automotive applications. JOM 2006, 58, 80–86. [Google Scholar] [CrossRef]

- Becenen, N.; Eker, B.; Sahin, M. Mechanical properties of plastic matrix composite materials used in tractor bonnets. J. Reinf. Plast. Compos. 2010, 29, 3637–3644. [Google Scholar] [CrossRef]

- Chegdani, F.; El Mansori, M. Friction scale effect in drilling natural fiber composites. Tribol. Int. 2018, 119, 622–630. [Google Scholar] [CrossRef]

- Boccarusso, L.; Pinto, F.; Myronidis, K.; De Fazio, D.; Durante, M. Thin hybrid hemp/carbon fiber composites: Manufacturing, flexural, and impact behavior. J. Mater. Eng. Perform. 2023, 32, 3914–3922. [Google Scholar] [CrossRef]

- Prabhu, R.; Mendonca, S.; D’Souza, R.; Bhat, T. Effect of water absorption on the mechanical properties of alkaline treated bamboo and flax fiber reinforced epoxy composites. Trends Sci. 2022, 19, 5779. [Google Scholar] [CrossRef]

- del Borrello, M.; Mele, M.; Campana, G.; Secchi, M. Manufacturing and characterization of hemp-reinforced epoxy composites. Polym. Compos. 2020, 41, 2316–2329. [Google Scholar] [CrossRef]

- Sayyar, M.; Soroushian, P.; Sadiq, M.M.; Balachandra, A.; Lu, J. Low-cost glass fiber composites with enhanced alkali resistance tailored towards concrete reinforcement. Constr. Build. Mater. 2013, 44, 458–463. [Google Scholar] [CrossRef]

- Kumara, N.S.; Kumarb, G.; Kumarc, C.; Prabhud, M. Experimental investigation on mechanical behavior of E-glass and S-glass fiber reinforced with polyester resin. SSRG Int. J. Mech. Eng. 2018, 5, 19–26. [Google Scholar] [CrossRef]

- Arpitha, G.R.; Jain, N.; Verma, A. Banana biofiber and glass fiber reinforced hybrid composite for lightweight structural applications: Mechanical, thermal, and microstructural characterization. Biomass Convers. Biorefin. 2024, 14, 12589–12598. [Google Scholar] [CrossRef]

- Mlýnek, J.; Petrů, M.; Martinec, T.; Herák, D. Design of composite frames used in agricultural machinery. In Proceedings of the 7th International Conference on Trends in Agricultural Engineering, Prague, Czech Republic, 17–20 September 2019. [Google Scholar]

- Albernaz, D.F.; Ferraz-Almeida, R. Performance and efficiency of glass and carbon fiber bars for self-propelled sprayers. Energ. Agric. 2020, 35, 330–338. [Google Scholar] [CrossRef]

- Giancaspro, J.W.; Papakonstantinou, C.G.; Balaguru, P.N. Flexural response of inorganic hybrid composites with E-glass and carbon fibers. J. Eng. Mater. Technol. 2010, 132, 021005. [Google Scholar] [CrossRef]

- Bello, S.A. Carbon-fiber composites: Development, structure, properties, and applications. In Handbook of Nanomaterials and Nanocomposites for Energy and Environmental Applications; Springer International Publishing: Cham, Switzerland, 2021; pp. 63–84. [Google Scholar]

- Rajak, D.K.; Wagh, P.H.; Linul, E. Manufacturing technologies of carbon/glass fiber-reinforced polymer composites and their properties: A review. Polymers 2021, 13, 3721. [Google Scholar] [CrossRef]

- Karataş, M.A.; Gökkaya, H. A review on machinability of carbon fiber reinforced polymer (CFRP) and glass fiber reinforced polymer (GFRP) composite materials. Def. Technol. 2018, 14, 318–326. [Google Scholar] [CrossRef]

- Wang, B.; Tian, W.; Wang, C.; Wang, Q. Research on interlayer toughening and damage detection of laser-induced graphene and short kevlar fibers aramid fiber/epoxy resin composites. Polymers 2024, 16, 3380. [Google Scholar] [CrossRef] [PubMed]

- Takayama, T.; Kobayashi, S.; Yuasa, Y.; Jiang, Q. Effect of carbon nanofiber distribution on mechanical properties of injection-molded aramid-fiber-reinforced polypropylene. Polymers 2024, 16, 1110. [Google Scholar] [CrossRef] [PubMed]

- Talikoti, R.S.; Kandekar, S.B. Strength and durability study of concrete structures using aramid-fiber-reinforced polymer. Fibers 2019, 7, 11. [Google Scholar] [CrossRef]

- Rajasekaran, T.; Varun, V. An review on aramid fiber reinforced composites. J. Manuf. Eng. 2015, 10, 200–206. [Google Scholar]

- Sun, H.; Kong, H.; Ding, H.; Xu, Q.; Zeng, J.; Jiang, F.; Zhang, Y. Improving UV resistance of aramid fibers by simultaneously synthesizing TiO2 on their surfaces and in the interfaces between fibrils/microfibrils using supercritical carbon dioxide. Polymers 2020, 12, 147. [Google Scholar] [CrossRef]

- Chuang, Y.C.; Bao, L.; Lou, C.W.; Lin, J.H. Hybrid-fiber-reinforced composite boards made of recycled aramid fibers: Preparation and puncture properties. Fibers Polym. 2019, 20, 398–405. [Google Scholar] [CrossRef]

- Gore, P.M.; Kandasubramanian, B. Functionalized aramid fibers and composites for protective applications: A review. Ind. Eng. Chem. Res. 2018, 57, 16537–16563. [Google Scholar] [CrossRef]

- Mohanty, A.K.; Misra, M.; Drzal, L.T. Sustainable bio-composites from renewable resources: Opportunities and challenges in the green materials world. J. Environ. Polym. Degrad. 2002, 10, 19–26. [Google Scholar] [CrossRef]

- Kian, L.K.; Saba, N.; Jawaid, M.; Sultan, M.T.H. A review on processing techniques of bast fibers nanocellulose and its polylactic acid (PLA) nanocomposites. Int. J. Biol. Macromol. 2019, 121, 1314–1328. [Google Scholar] [CrossRef]

- Chaudhary, V.; Bajpai, P.K.; Maheshwari, S. Studies on mechanical and morphological characterization of developed jute/hemp/flax reinforced hybrid composites for structural applications. J. Nat. Fibers 2018, 15, 80–97. [Google Scholar] [CrossRef]

- Stochioiu, C.; Ciolcă, M.; Deca, A.L. Mechanical characterization of flax and hemp fibers cultivated in Romania. Materials 2024, 17, 4871. [Google Scholar] [CrossRef] [PubMed]

- Nawawithan, N.; Kittisakpairach, P.; Nithiboonyapun, S.; Ruangjirakit, K.; Jongpradist, P. Design and performance simulation of hybrid hemp/glass fiber composites for automotive front bumper beams. Compos. Struct. 2024, 335, 118003. [Google Scholar] [CrossRef]

- Singh, H.; Singh, J.I.P.; Singh, S.; Dhawan, V.; Tiwari, S.K. A brief review of jute fibre and its composites. Mater. Today 2018, 5, 28427–28437. [Google Scholar] [CrossRef]

- Eyupoglu, S. Sustainable plant-based natural fibers. In Sustainability in the Textile and Apparel Industries: Sourcing Natural Raw Materials; Muthu, S., Gardetti, M., Eds.; Springer: Cham, Switzerland, 2020; pp. 27–48. [Google Scholar] [CrossRef]

- Ramesh, M.; Rajeshkumar, L.; Bhuvaneswari, V. Leaf fibres as reinforcements in green composites: A review on processing, properties and applications. Emerg. Mater. 2022, 5, 833–857. [Google Scholar] [CrossRef]

- Darda, M.A.; Bhuiyan, M.R.; Bari, M.A.; Islam, S.; Hossen, M.J. Mechanically robust and thermally insulating natural cotton fiber-reinforced biocomposite panels for structural applications. RSC Adv. 2025, 15, 9534–9545. [Google Scholar] [CrossRef]

- Maia Pederneiras, C.; Veiga, R.; de Brito, J. Physical and mechanical performance of coir fiber-reinforced rendering mortars. Materials 2021, 14, 823. [Google Scholar] [CrossRef]

- Hasan, K.F.; Horváth, P.G.; Bak, M.; Alpár, T. A state-of-the-art review on coir fiber-reinforced biocomposites. RSC Adv. 2021, 11, 10548–10571. [Google Scholar] [CrossRef]

- Kamarian, S.; Song, J.I. Review of literature on eco-friendly sandwich structures made of non-wood cellulose fibers. J. Sandw. Struct. Mater. 2022, 24, 1653–1705. [Google Scholar] [CrossRef]

- Azmi, M.A.; Abdullah, H.Z.; Idris, M.I. Properties of polyurethane foam/coconut coir fiber as a core material and as a sandwich composites component. IOP Conf. Ser. Mater. Sci. Eng. 2013, 50, 012067. [Google Scholar] [CrossRef]

- Chen, F.; Han, G.; Li, Q.; Gao, X.; Cheng, W. High-temperature hot air/silane coupling modification of wood fiber and its effect on properties of wood fiber/HDPE composites. Materials 2017, 10, 286. [Google Scholar] [CrossRef] [PubMed]

- Smith, P.M.; Wolcott, M.P. Opportunities for wood/natural fiber-plastic composites in residential and industrial applications. For. Prod. J. 2006, 56, 4–11. [Google Scholar]

- Matuana, L.M.; Kamdem, D.P.; Zhang, J. Photoaging and stabilization of rigid PVC/wood-fiber composites. J. Appl. Polym. Sci. 2001, 80, 1943–1950. [Google Scholar] [CrossRef]

- Arthur, D.; Danlami, D.A.; Uwaiya, E.; Aroh, A. Studies on some mechanical properties of PVC-wood fiber composite. Chem. Rev. Lett. 2021, 4, 85–91. [Google Scholar]

- Brischke, C.; Meyer-Veltrup, L.; Bornemann, T. Moisture performance and durability of wooden façades and decking during six years of outdoor exposure. J. Build. Eng. 2017, 13, 207–215. [Google Scholar] [CrossRef]

- Šubic, B.; Ugovšek, A.; Starman, N.; Tatić, U.; Kovačič, A.; Fajdiga, G. Influence of glued-in reinforcement profiles on the thermal characteristics of wooden window profiles. Procedia Struct. Integr. 2018, 13, 503–510. [Google Scholar] [CrossRef]

- Sharma, C.; Pathak, P.; Gautam, S. Transforming agri-crop residue biomass for value addition: An innovative strategy toward resilient circular economy. In Handbook of Biomass; Thomas, S., Hosur, M., Pasquini, D., Jose Chirayil, C., Eds.; Springer Nature: Singapore, 2024; pp. 1517–1542. [Google Scholar]

- Licata, M.; Farruggia, D.; Sgroi, F.; Salamone, F.; Leto, C.; Di Miceli, G. A comparative study to assess the production of two oilseed crops (Brassica carinata A. Braun and Carthamus tinctorius L.) and the energy potential of their agricultural biomass residues. Heliyon 2024, 10, e38654. [Google Scholar] [CrossRef]

- Naeimi, E.F.; Gürdil, G.A.K.; Demirel, B. Integrating GIS mapping and Artificial Neural Networks for assessing biomass energy potential from agricultural residues in Iran. Food Energy Secur. 2025, 14, e70045. [Google Scholar] [CrossRef]

- Ābele, A.; Merijs-Meri, R.; Žiganova, M.; Iesalniece, Z.; Bochkov, I. Effect of agricultural biomass residues on the properties of recycled polypropylene/polyethylene composites. Polymers 2023, 15, 2672. [Google Scholar] [CrossRef]

- Wang, Q.; Chen, T.; Wang, X.; Zheng, Y.; Zheng, J.; Song, G.; Liu, S. Recent progress on moisture absorption aging of plant fiber reinforced polymer composites. Polymers 2023, 15, 4121. [Google Scholar] [CrossRef]

- Lee, C.H.; Khalina, A.; Lee, S.H. Importance of interfacial adhesion condition on characterization of plant-fiber-reinforced polymer composites: A review. Polymers 2021, 13, 438. [Google Scholar] [CrossRef] [PubMed]

- Abdul Razak, N.I.; Ibrahim, N.A.; Zainuddin, N.; Rayung, M.; Saad, W.Z. The influence of chemical surface modification of kenaf fiber using hydrogen peroxide on the mechanical properties of biodegradable kenaf fiber/poly (lactic acid) composites. Molecules 2014, 19, 2957–2968. [Google Scholar] [CrossRef] [PubMed]

- Andrew, J.J.; Srinivasan, S.M.; Arockiarajan, A.; Dhakal, H.N. Parameters influencing the impact response of fiber-reinforced polymer matrix composite materials: A critical review. Compos. Struct. 2019, 224, 111007. [Google Scholar] [CrossRef]

- Chirayil, C.J.; Peter, B.; George, L.; Jorly, A.; Jipson, S.; Varghese, A.; Thomas, S. 6-Processing methods of unsaturated polyester. In Applications of Unsaturated Polyester Resins; Sabu, T., Cintil, J.C., Eds.; Elsevier: Amsterdam, The Netherlands, 2023; pp. 71–89. [Google Scholar]

- Ezeh, E.M. Advances in the development of polyester resin composites: A review. World J. Eng. 2024. ahead of print. [Google Scholar] [CrossRef]

- Penczek, P.; Czub, P.; Pielichowski, J. Unsaturated polyester resins: Chemistry and technology. In Crosslinking in Materials Science; Advances in Polymer Science; Springer: Berlin/Heidelberg, Germany, 2005; Volume 184, pp. 1–95. [Google Scholar] [CrossRef]

- Møller, V.B.; Dam-Johansen, K.; Frankær, S.M.; Kiil, S. Acid-resistant organic coatings for the chemical industry: A review. J. Coat. Technol. Res. 2017, 14, 279–306. [Google Scholar] [CrossRef]

- Nodehi, M. Epoxy, polyester and vinyl ester based polymer concrete: A review. Innov. Infrastruct. Solut. 2022, 7, 64. [Google Scholar] [CrossRef]

- Kelly, P. Epoxy vinyl ester and other resins in chemical process equipment. In Reinforced Plastics Durability; Elsevier: Amsterdam, The Netherlands, 1998; pp. 282–293. [Google Scholar]

- Kaynak, C.; Orgun, O.; Tincer, T. Matrix and interface modification of short carbon fiber-reinforced epoxy. Polym. Test. 2005, 24, 455–462. [Google Scholar] [CrossRef]

- Venkatesan, D.B.; Vellayaraj, A.; Chelliah, S.K. The influence of thickness and recycled milled glass fiber fillers on the delamination resistance of polymer composite angle brackets. Polym. Compos. 2024, 45, 3067–3080. [Google Scholar] [CrossRef]

- Hossain, M.T.; Shahid, M.A.; Mahmud, N.; Habib, A.; Rana, M.M.; Khan, S.A.; Hossain, M.D. Research and application of polypropylene: A review. Discov. Nano 2024, 19, 2. [Google Scholar] [CrossRef]

- Elseify, L.A.; Midani, M.; El-Badawy, A.; Jawaid, M. Manufacturing Automotive Components from Sustainable Natural Fiber Composites; Springer Nature: Cham, Switzerland, 2021; pp. 1–83. [Google Scholar] [CrossRef]

- Yan, Z.L.; Wang, H.; Lau, K.T.; Pather, S.; Zhang, J.C.; Lin, G.; Ding, Y. Reinforcement of polypropylene with hemp fibres. Compos. B Eng. 2013, 46, 221–226. [Google Scholar] [CrossRef]

- Suresha, B.; Kumar, B.R.; Venkataramareddy, M.; Jayaraju, T. Role of micro/nano fillers on mechanical and tribological properties of polyamide66/polypropylene composites. Mater. Des. 2010, 31, 1993–2000. [Google Scholar] [CrossRef]

- Singh, A.K.; Siddhartha. Thermal and wear behavior of glass fiber-filled functionally graded material-based polyamide 66 spur gears manufactured by a novel technique. J. Tribol. 2018, 140, 021601. [Google Scholar] [CrossRef]

- Selmy, A.I.; Abd El-baky, M.A.; Hegazy, D.A. Wear behavior of glass–polyamide reinforced epoxy hybrid composites. J. Thermoplast. Compos. Mater. 2020, 33, 214–235. [Google Scholar] [CrossRef]

- Hazra, S.; Khan, A. Modelling and simulation approach for fiber-reinforced polymer components in passenger car engine mounting brackets. SAE Int. 2024, 28, 1–11. [Google Scholar] [CrossRef]

- Tyukanko, V.; Demyanenko, A.; Semenyuk, V.; Dyuryagina, A.; Alyoshin, D.; Tarunin, R.; Voropaeva, V. Development of an ultrasonic method for the quality control of polyethylene tanks manufactured using rotational molding technology. Polymers 2023, 15, 2368. [Google Scholar] [CrossRef]

- Thompson, M.R.; Mu, B.; Ewaschuk, C.M.; Cai, Y.; Oxby, K.J.; Vlachopoulos, J. Long term storage of biodiesel/petrol diesel blends in polyethylene fuel tanks. Fuel 2013, 108, 771–779. [Google Scholar] [CrossRef]

- Coote, J.P.; Larson, M.C.; Bates, F.S.; Ellison, C.J. Persistent toughness and heat triggered plasticization in polylactide modified with poly (ethylene oxide)-block-poly (butylene oxide). ACS Macro Lett. 2025, 14, 80–86. [Google Scholar] [CrossRef]

- Zhu, J.; Sun, H.; Yang, B.; Weng, Y. Modified biomass-reinforced polylactic acid composites. Materials 2024, 17, 336. [Google Scholar] [CrossRef]

- Choi, S.Y.; Cho, I.J.; Lee, Y.; Kim, Y.J.; Kim, K.J.; Lee, S.Y. Microbial polyhydroxyalkanoates and nonnatural polyesters. Adv. Mater. 2020, 32, 1907138. [Google Scholar] [CrossRef]

- Naser, A.Z.; Deiab, I.; Defersha, F.; Yang, S. Expanding poly (lactic acid)(PLA) and polyhydroxyalkanoates (PHAs) applications: A review on modifications and effects. Polymers 2021, 13, 4271. [Google Scholar] [CrossRef]

- Kontárová, S.; Přikryl, R.; Škarpa, P.; Kriška, T.; Antošovský, J.; Gregušková, Z.; Mikolajová, M. Slow-release nitrogen fertilizers with biodegradable poly (3-hydroxybutyrate) coating: Their effect on the growth of maize and the dynamics of N release in soil. Polymers 2022, 14, 4323. [Google Scholar] [CrossRef]

- Koh, L.M.; Khor, S.M. Current state and future prospects of sensors for evaluating polymer biodegradability and sensors made from biodegradable polymers: A review. Anal. Chim. Acta 2022, 1217, 339989. [Google Scholar] [CrossRef] [PubMed]

- Morcillo, M.D.C.; Tejada, R.; Lascano, D.; Garcia-Garcia, D.; Garcia-Sanoguera, D. Manufacturing and characterization of environmentally friendly wood plastic composites using pinecone as a filler into a bio-based high-density polyethylene matrix. Polymers 2021, 13, 4462. [Google Scholar] [CrossRef] [PubMed]

- Khedr, M.S.F. Bio-based polyamide. Phys. Sci. Rev. 2023, 8, 827–847. [Google Scholar] [CrossRef]

- Huang, S.; Dong, Q.; Che, S.; Li, R.; Tang, K.H.D. Bioplastics and biodegradable plastics: A review of recent advances, feasibility and cleaner production. Sci. Total Environ. 2025, 969, 178911. [Google Scholar] [CrossRef]

- Gonçalves, F.A.; Santos, M.; Cernadas, T.; Ferreira, P.; Alves, P. Advances in the development of biobased epoxy resins: Insight into more sustainable materials and future applications. Int. Mater. Rev. 2022, 67, 119–149. [Google Scholar] [CrossRef]

- Mo, Y.; Huang, X.; Hu, C. Recent advances in the preparation and application of bio-based polyurethanes. Polymers 2024, 16, 2155. [Google Scholar] [CrossRef]

- Ouyang, X.; Pan, Z.; Qian, Z.; Ma, Y.; Ye, G.; Van Breugel, K. Numerical modelling of the effect of filler/matrix interfacial strength on the fracture of cementitious composites. Materials 2018, 11, 1362. [Google Scholar] [CrossRef]

- Thenepalli, T.; Jun, A.Y.; Han, C.; Ramakrishna, C.; Ahn, J.W. A strategy of precipitated calcium carbonate (CaCO3) fillers for enhancing the mechanical properties of polypropylene polymers. J. Chem. Eng. 2015, 32, 1009–1022. [Google Scholar] [CrossRef]

- Wang, C.; Cai, L.; Shi, S.Q.; Wang, G.; Cheng, H.; Zhang, S. Thermal and flammable properties of bamboo pulp fiber/high-density polyethylene composites: Influence of preparation technology, nano calcium carbonate and fiber content. Renew. Energy 2019, 134, 436–445. [Google Scholar] [CrossRef]

- Hongzhen, C.; Keyan, Y.; Weiming, Y. Effects of calcium carbonate on preparation and mechanical properties of wood/plastic composite. Int. J. Agric. Biol. Eng. 2017, 10, 184–190. [Google Scholar]

- Huang, R.; Mei, C.; Xu, X.; Kärki, T.; Lee, S.; Wu, Q. Effect of hybrid talc-basalt fillers in the shell layer on thermal and mechanical performance of co-extruded wood plastic composites. Materials 2015, 8, 8510–8523. [Google Scholar] [CrossRef] [PubMed]

- Austermann, J.; Kuscera, R.; Wipperfürth, J.; Hopmann, C.; Dahlmann, R. Influence of material modification and fillers on the dimensional stability and warpage of polypropylene in screw-extrusion-based large area additive manufacturing. Polym. Eng. Sci. 2023, 63, 1598–1612. [Google Scholar] [CrossRef]

- Alameri, I.; Oltulu, M. Mechanical properties of polymer composites reinforced by silica-based materials of various sizes. Appl. Nanosci. 2020, 10, 4087–4102. [Google Scholar] [CrossRef]

- Malvajerdi, A.S. Wear and coating of tillage tools: A review. Heliyon 2023, 9, e16669. [Google Scholar] [CrossRef]

- Hao, T.; Wang, Y.; Liu, Z.; Li, J.; Shan, L.; Wang, W.; Tang, J. Emerging applications of silica nanoparticles as multifunctional modifiers for high performance polyester composites. Nanomaterials 2021, 11, 2810. [Google Scholar] [CrossRef]

- Tarrio-Saavedra, J.; López-Beceiro, J.; Naya, S.; Artiaga, R. Effect of silica content on thermal stability of fumed silica/epoxy composites. Polym. Degrad. Stab. 2008, 93, 2133–2137. [Google Scholar] [CrossRef]

- Ma, X.; Chen, X.; Wang, X.; Yang, X.; Yao, Z.; Yu, H.; Zhang, Y. Enhancing flame retardancy and heat insulation performances of polyamide 66 composite film by adding CNC/Al2O3 nanohybrids. Int. J. Biol. Macromol. 2024, 278, 134702. [Google Scholar] [CrossRef]

- Xia, L.; Wu, H.; Guo, S.; Sun, X.; Liang, W. Enhanced sound insulation and mechanical properties of LDPE/mica composites through multilayered distribution and orientation of the mica. Compos.—A Appl. Sci 2016, 81, 225–233. [Google Scholar] [CrossRef]

- Zhang, J.; Zhou, Y.; Li, C.; Wang, Z. Advancements in solid-state hydrogen storage: A review on the glass microspheres. Langmuir 2024, 40, 10433–10448. [Google Scholar] [CrossRef]

- Pokhrel, G.; Han, Y.; Gardner, D.J. Comparative study of the properties of wood flour and wood pellets manufactured from secondary processing mill residues. Polymers 2021, 13, 2487. [Google Scholar] [CrossRef]

- Ismail, H.; Mohamad, H. Bioactivity and biocompatibility properties of sustainable wollastonite bioceramics from rice husk ash/rice straw ash: A review. Materials 2021, 14, 5193. [Google Scholar] [CrossRef] [PubMed]

- Dobrosielska, M.; Dobrucka, R.; Brząkalski, D.; Frydrych, M.; Kozera, P.; Wieczorek, M.; Przekop, R.E. Influence of diatomaceous earth particle size on mechanical properties of PLA/diatomaceous earth composites. Materials 2022, 15, 3607. [Google Scholar] [CrossRef] [PubMed]

- İtmeç, M.; Bayat, A. Comparison of boom design parameters of three different tractor mounted domestically manufactured field crop sprayer booms. Tarmak 2017, 13, 99–105. [Google Scholar]

- Elmasry, A.; Azoti, W.; Ghoniem, E.; Elmarakbi, A. Modelling of hybrid biocomposites for automotive structural applications. Compos. Sci. Technol. 2024, 251, 110562. [Google Scholar] [CrossRef]

- Etherton, J.R.; Ronaghi, M.; Current, R.S. Development of a pultruded FRP composite material ROPS for farm tractors. Compos. Struct. 2007, 78, 162–169. [Google Scholar] [CrossRef]

- SAE J2194; Performance Criteria for Rollover Protective Structures (ROPS) for Wheeled Agricultural Tractors. SAE International: Warrendale, PA, USA, 2016.

- Misirli, C.; Becenen, N.; Şahin, M. An investigation on plastic matrix composite materials. Appl. Mech. Mater. 2014, 555, 406–412. [Google Scholar] [CrossRef]

- Mlýnek, J.; Petrů, M.; Knobloch, R. Modelling of composite reinforcements in agricultural equipment. In Proceedings of the 8th International Conference on Trends in Agricultural Engineering, Prague, Czech Republic, 20–23 September 2022. [Google Scholar]

- Vodyakov, V.N.; Radaykina, E.A.; Kotin, A.V.; Kuznetsov, V.V.; Murneva, M.I. New polyamide composites for friction power cylinders of agricultural machinery. Key Eng. Mater. 2019, 816, 157–161. [Google Scholar] [CrossRef]

- Zhbanov, N.; Byshow, N.; Kostenko, N.; Rembalovich, G.; Kostenko, M. Improvement of the working bodies of the harvesting machines by means of the use of composite materials. BIO Web Conf. 2020, 17, 00191. [Google Scholar] [CrossRef]

- Zagurskiy, A. Technical overview of the main types, designs, and materials of brake pads for mobile agricultural machinery. Sci. Rep. NULES Ukr. 2024, 4, 119–130. [Google Scholar] [CrossRef]

- Irawan, A.P.; Fitriyana, D.F.; Tezara, C.; Siregar, J.P.; Laksmidewi, D.; Baskara, G.D.; Najid, N. Overview of the important factors influencing the performance of eco-friendly brake pads. Polymers 2022, 14, 1180. [Google Scholar] [CrossRef]

- Abbood, I.S.; aldeen Odaa, S.; Hasan, K.F.; Jasim, M.A. Properties evaluation of fiber reinforced polymers and their constituent materials used in structures—A review. Mater. Today 2021, 43, 1003–1008. [Google Scholar] [CrossRef]

- Singh, M.M.; Kumar, H.; Kumar, G.H.; Sivaiah, P.; Nagesha, K.V.; Ajay, K.M.; Vijaya, G. Determination of strength parameters of glass fibers reinforced composites for engineering applications. Silicon 2020, 12, 1–11. [Google Scholar] [CrossRef]

- Aliotta, L.; Gigante, V.; Coltelli, M.B.; Cinelli, P.; Lazzeri, A.; Seggiani, M. Thermo-mechanical properties of PLA/short flax fiber biocomposites. Appl. Sci. 2019, 9, 3797. [Google Scholar] [CrossRef]

- Rajulwar, V.V.; Shyrokykh, T.; Stirling, R.; Jarnerud, T.; Korobeinikov, Y.; Bose, S.; Sridhar, S. Steel, aluminum, and FRP-composites: The race to zero carbon emissions. Energies 2023, 16, 6904. [Google Scholar] [CrossRef]

- Pornwannachai, W.; Horrocks, A.R.; Kandola, B.K. Surface modification of commingled flax/PP and flax/PLA Fibres by Silane or atmospheric argon plasma exposure to improve fibre–matrix adhesion in composites. Fibers 2021, 10, 2. [Google Scholar] [CrossRef]

- Melo, J.D.D.; Villena, J.E.N. Effect of fiber volume fraction on the energy absorption capacity of composite materials. J. Reinf. Plast. Compos. 2012, 31, 153–161. [Google Scholar] [CrossRef]

- Parodo, G.; Sorrentino, L.; Turchetta, S.; Moffa, G. Manufacturing of sustainable composite materials: The challenge of flax fiber and polypropylene. Materials 2024, 17, 4768. [Google Scholar] [CrossRef]

- Wang, L.; Abenojar, J.; Martínez, M.A.; Santiuste, C. Degradation of mechanical properties of flax/PLA composites in hygrothermal aging conditions. Polymers 2024, 16, 528. [Google Scholar] [CrossRef]

- Sharma, H.; Kumar, A.; Rana, S.; Guadagno, L. An overview on carbon fiber-reinforced epoxy composites: Effect of graphene oxide incorporation on composites performance. Polymers 2022, 14, 1548. [Google Scholar] [CrossRef]

- Kukharets, S.; Zabrodskyi, A.; Sheludchenko, B.; Jasinskas, A.; Domeika, R.; Šarauskis, E. Assessment of changes in soil contact stress depending on tractor tire parameters. Sci. Rep. 2025, 15, 172. [Google Scholar] [CrossRef]

- Yang, Q.; Zhou, Y.; Li, Z.; Mao, D. Effect of hot deformation process parameters on microstructure and corrosion behavior of 35CrMoV steel. Materials 2019, 12, 1455. [Google Scholar] [CrossRef] [PubMed]

- Quan, Z.; Wu, A.; Keefe, M.; Qin, X.; Yu, J.; Suhr, J.; Chou, T.W. Additive manufacturing of multi-directional preforms for composites: Opportunities and challenges. Mater. Today 2015, 18, 503–512. [Google Scholar] [CrossRef]

- Alameda, B.M.; Kumler, M.S.; Murphy, J.S.; Aguinaga, J.S.; Patton, D.L. Cyclic ketal bridged bisepoxides: Enabling the design of degradable epoxy-amine thermosets for carbon fiber composite applications. RSC Appl. Polym. 2023, 1, 254–265. [Google Scholar] [CrossRef]

- Ascione, F.; Maselli, G.; Nesticò, A. Sustainable materials selection in industrial construction: A life-cycle based approach to compare the economic and structural performances of glass fibre reinforced polymer (GFRP) and steel. J. Clean. Prod. 2024, 475, 143641. [Google Scholar] [CrossRef]

- Wu, Y.; Xia, C.; Cai, L.; Garcia, A.C.; Shi, S.Q. Development of natural fiber-reinforced composite with comparable mechanical properties and reduced energy consumption and environmental impacts for replacing automotive glass-fiber sheet molding compound. J. Clean. Prod. 2018, 184, 92–100. [Google Scholar] [CrossRef]

- Bashir, A.; Niu, H.; Maqbool, M.; Usman, A.; Lv, R.; Ashraf, Z.; Bai, S. A novel thermal interface material composed of vertically aligned boron nitride and graphite films for ultrahigh through-plane thermal conductivity. Small Methods 2024, 8, 2301788. [Google Scholar] [CrossRef]

- Brebu, M. Environmental degradation of plastic composites with natural fillers—A review. Polymers 2020, 12, 166. [Google Scholar] [CrossRef]

- Balakrishnan, V.S.; Seidlitz, H. Potential repair techniques for automotive composites: A review. Compos. B Eng. 2018, 145, 28–38. [Google Scholar] [CrossRef]

- Hadjab, A.; Fatmi, L.; Ouelaa, N. Effect of foam density and load levels on fatigue characteristics of pvc foam core sandwich composites. U.P.B. Sci. Bull. Ser. D 2024, 86, 121–134. [Google Scholar]

- Patil, N.A.; Hole, J.; Wankhede, S.; Marjiwe, S.; Raundal, D.; Kumbhar, P.; Andhare, S. Microstructure and mechanical properties of vacuum infused RHA reinforced polymer composites. U.P.B. Sci. Bull. Ser. D 2024, 86, 226–238. [Google Scholar]

- Iosif, A.; Maican, E.; Biriș, S.Ș.; Vlăduț, N.V. Application of machine learning models for predictive maintenance of biotechnical systems. INMATEH—Agric. Eng. 2025, 75, 930–949. [Google Scholar] [CrossRef]

| Property | Steel | Aluminum | GFRP (Glass/Epoxy-VE) | CFRP (Carbon/Epoxy) | NFRP (e.g., Flax/PP) * | Biocomposite (e.g., Flax/PLA) * |

|---|---|---|---|---|---|---|

| Density (g/cm3) | ~7.8 | ~2.7 | ~1.8–2.1 | ~1.5–1.6 | ~1.1–1.4 | ~1.2–1.4 |

| Specific strength | Low | Medium | High | Very High | Medium | Low-Medium |

| Specific stiffness | Low | Medium | High | Very High | Medium | Low-Medium |

| Corrosion resistance | Poor | Good | Excellent | Excellent | Fair-Good | Fair-Good |

| Chemical resistance | Fair-Good | Fair-Good | Good-Excellent | Excellent | Fair-Good | Fair |

| Moisture absorption | None | Low | Very Low | Very Low | High | High |

| UV resistance | Excellent | Excellent | Good | Good | Poor-Fair | Fair-Poor |

| Max service temp (°C) | >500 | ~200–300 | ~100–200 | ~150–250 | ~80–120 | ~50–60 |

| Recyclability | Excellent | Excellent | Difficult | Difficult | Fair–Good | Good |

| Environmental impact | High | High | Medium–High | Medium–High | Low-Medium | Low-Medium |

| Cost | Low | Medium | Medium | High | Low-Medium | Low-Medium |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fartash Naeimi, E.; Selvi, K.Ç.; Ungureanu, N. Exploring the Role of Advanced Composites and Biocomposites in Agricultural Machinery and Equipment: Insights into Design, Performance, and Sustainability. Polymers 2025, 17, 1691. https://doi.org/10.3390/polym17121691

Fartash Naeimi E, Selvi KÇ, Ungureanu N. Exploring the Role of Advanced Composites and Biocomposites in Agricultural Machinery and Equipment: Insights into Design, Performance, and Sustainability. Polymers. 2025; 17(12):1691. https://doi.org/10.3390/polym17121691

Chicago/Turabian StyleFartash Naeimi, Ehsan, Kemal Çağatay Selvi, and Nicoleta Ungureanu. 2025. "Exploring the Role of Advanced Composites and Biocomposites in Agricultural Machinery and Equipment: Insights into Design, Performance, and Sustainability" Polymers 17, no. 12: 1691. https://doi.org/10.3390/polym17121691

APA StyleFartash Naeimi, E., Selvi, K. Ç., & Ungureanu, N. (2025). Exploring the Role of Advanced Composites and Biocomposites in Agricultural Machinery and Equipment: Insights into Design, Performance, and Sustainability. Polymers, 17(12), 1691. https://doi.org/10.3390/polym17121691