Utilizing Excess Resin in Prepregs to Achieve Good Performance in Joining Hybrid Materials

Abstract

1. Introduction

2. Materials and Sample Manufacturing

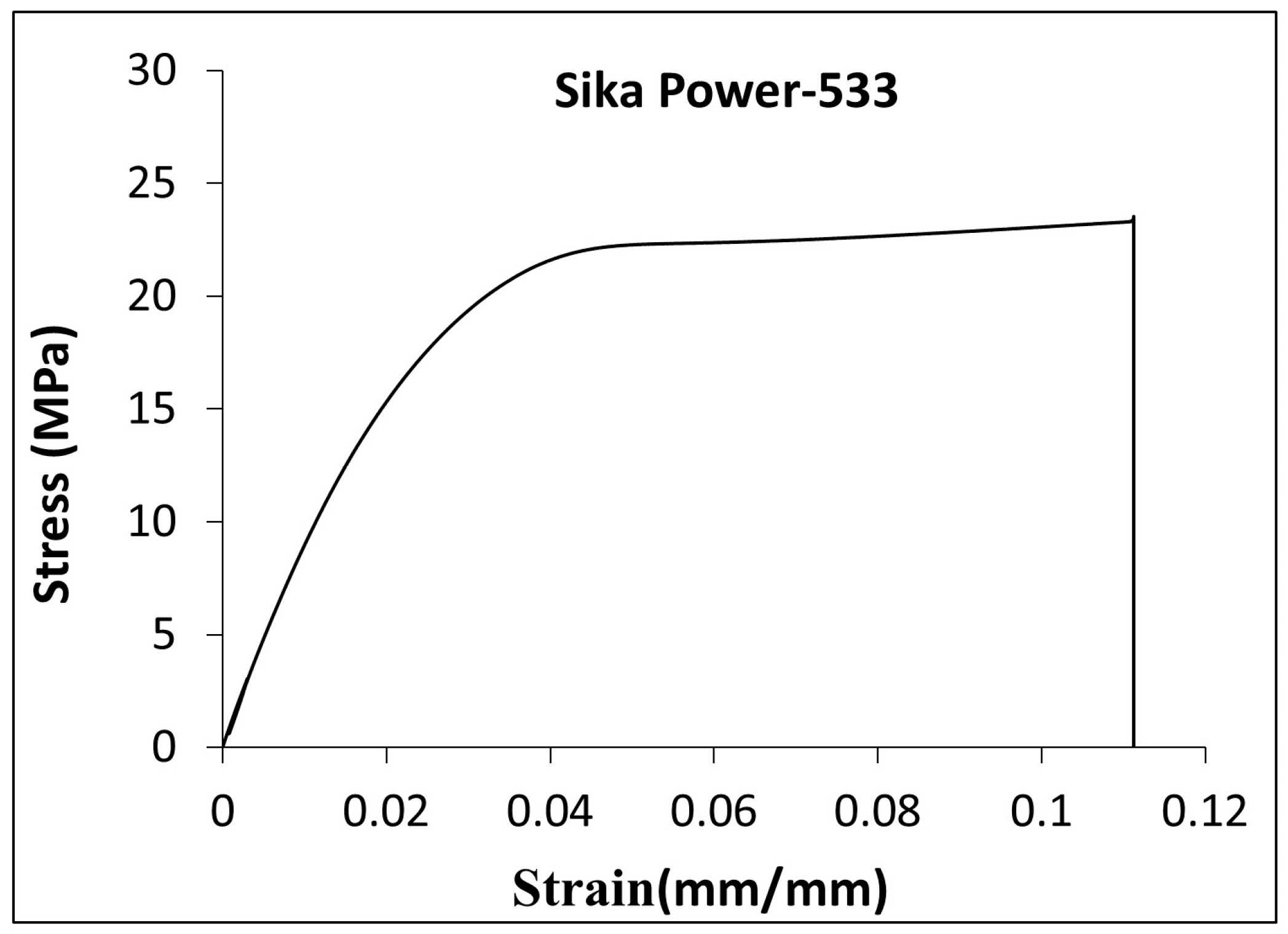

2.1. Materials

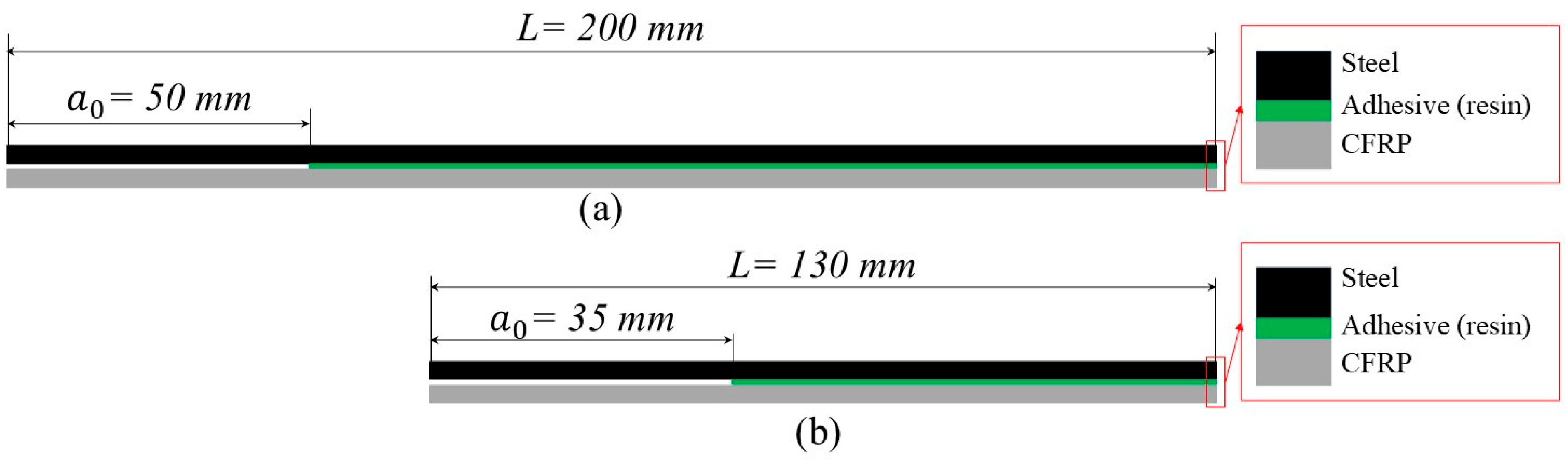

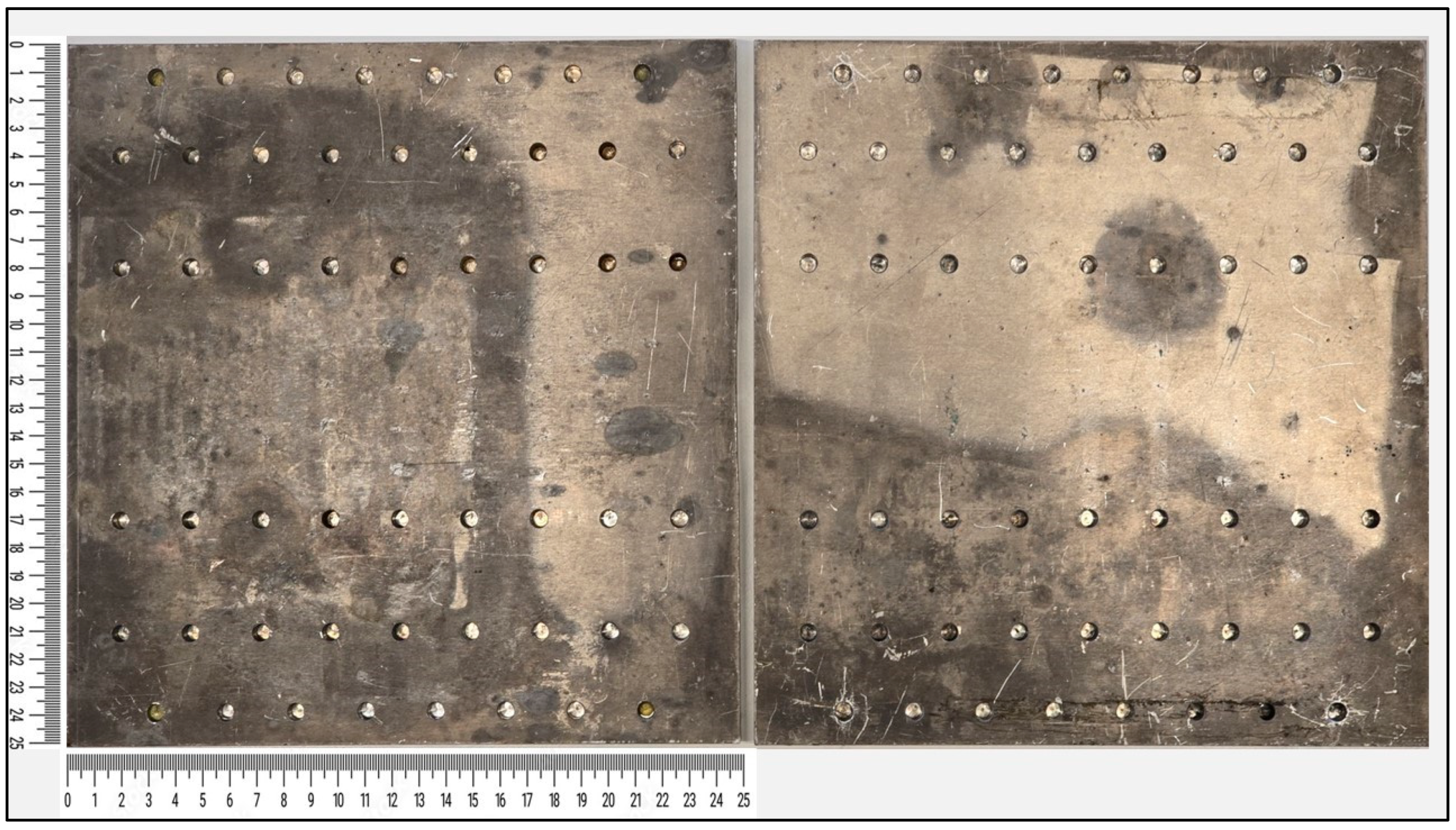

2.2. Sample Manufacturing

2.2.1. Joining Methods

2.2.2. Manufacturing of Specimens

3. Experimental Procedure

4. Results and Discussion

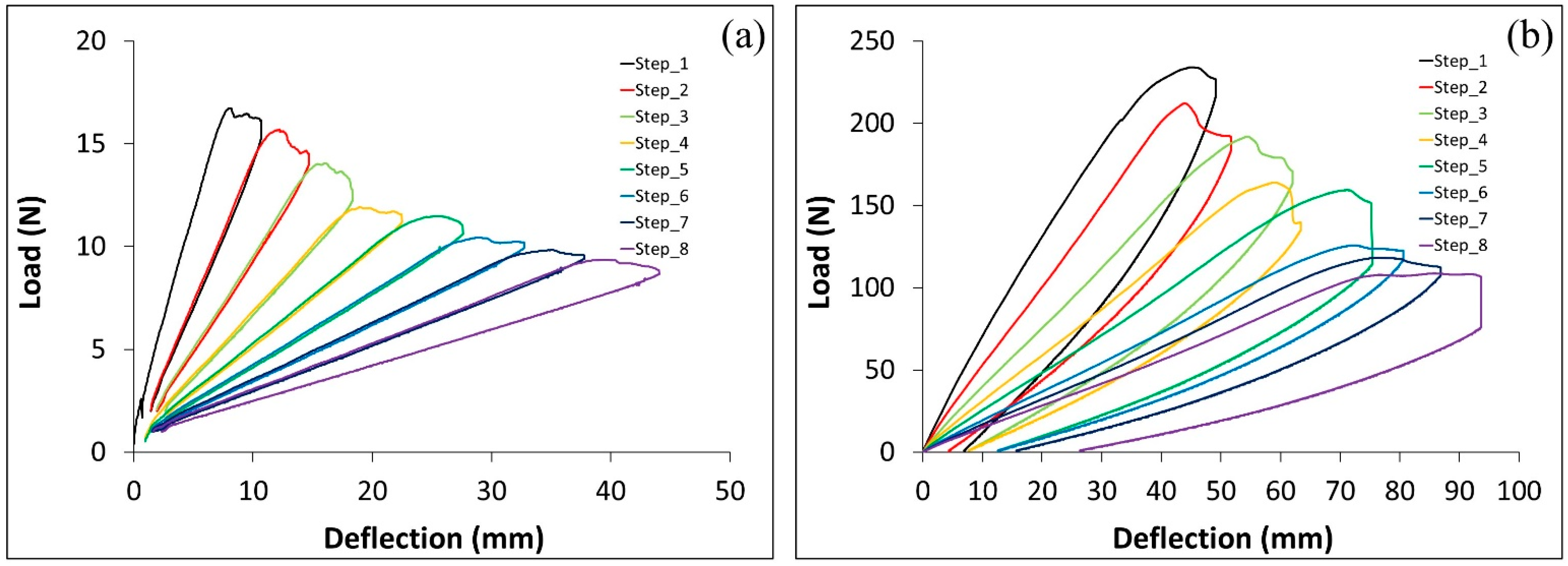

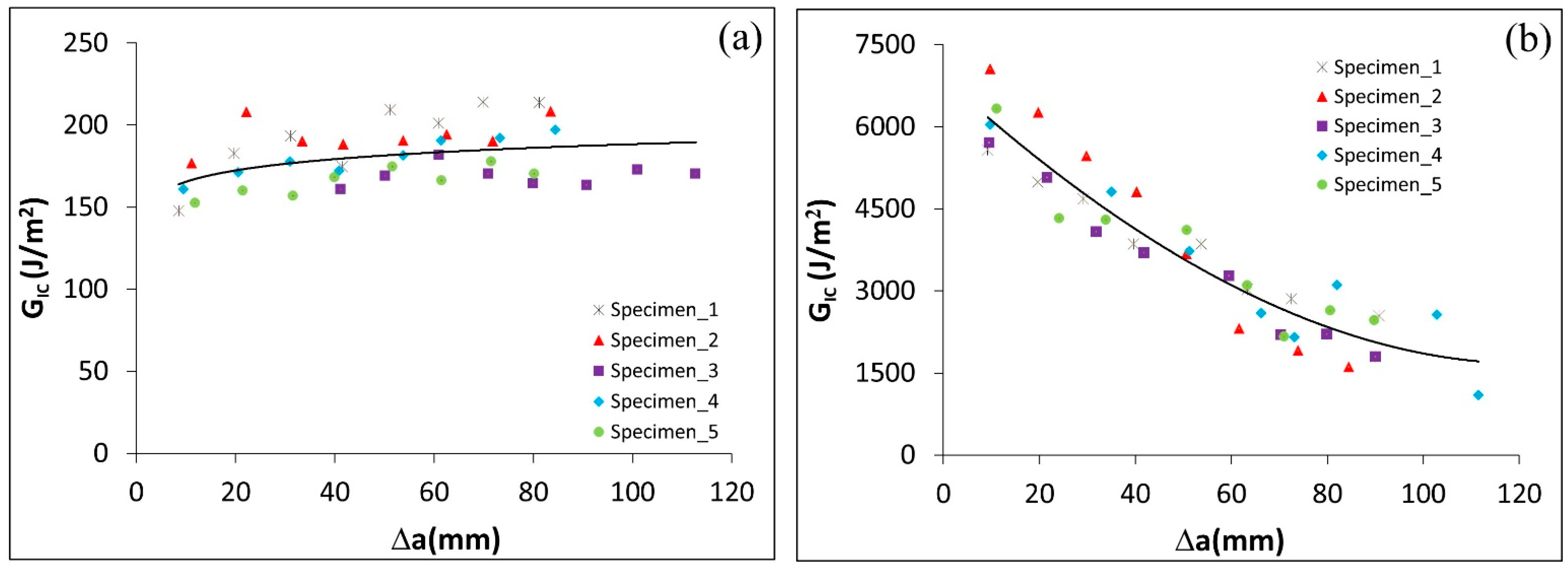

4.1. The Effect of Adhesive Type and Thickness on GIC

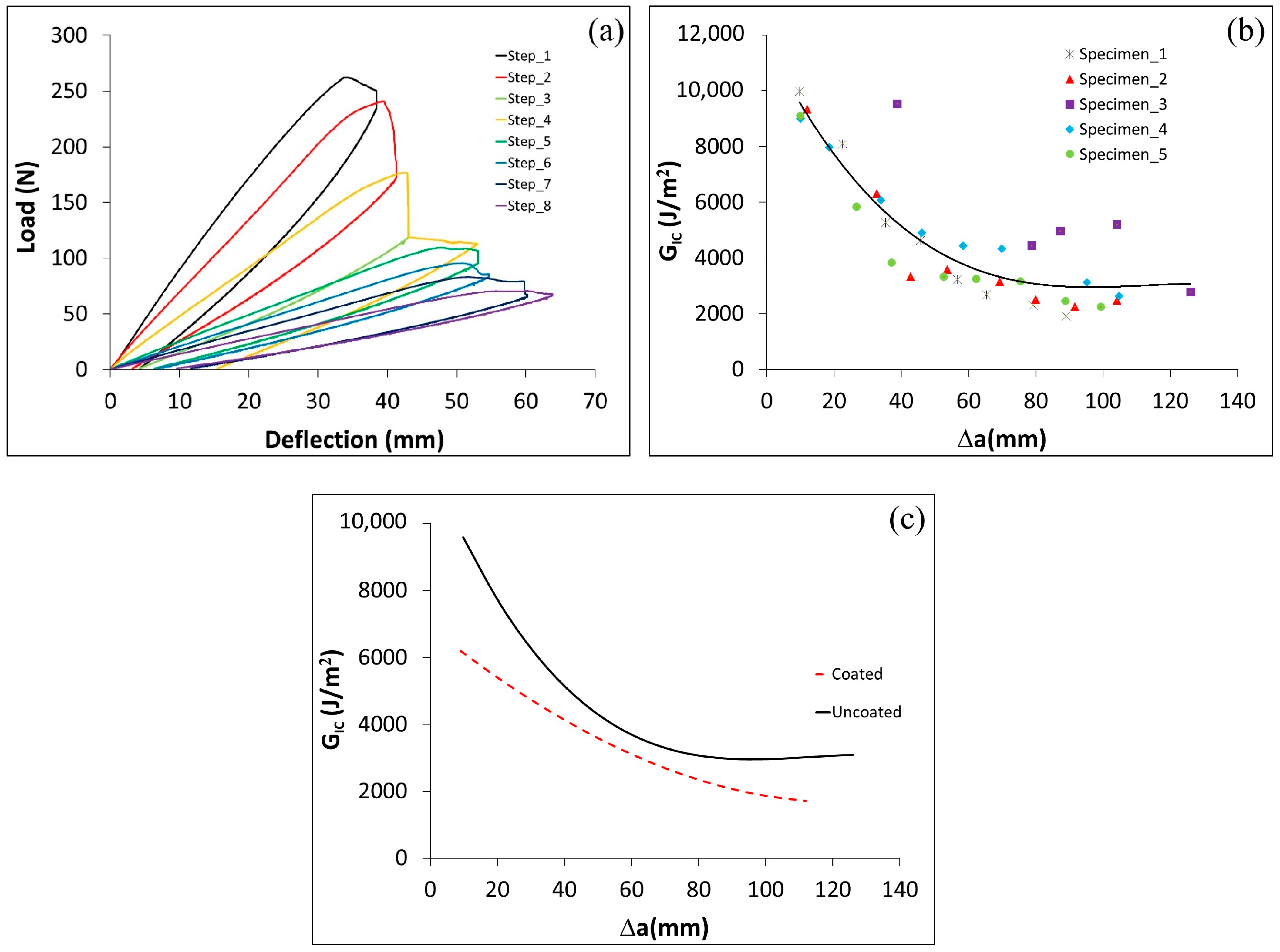

4.2. Effect of Coating on GIC of DCB Specimens with Sika Adhesive

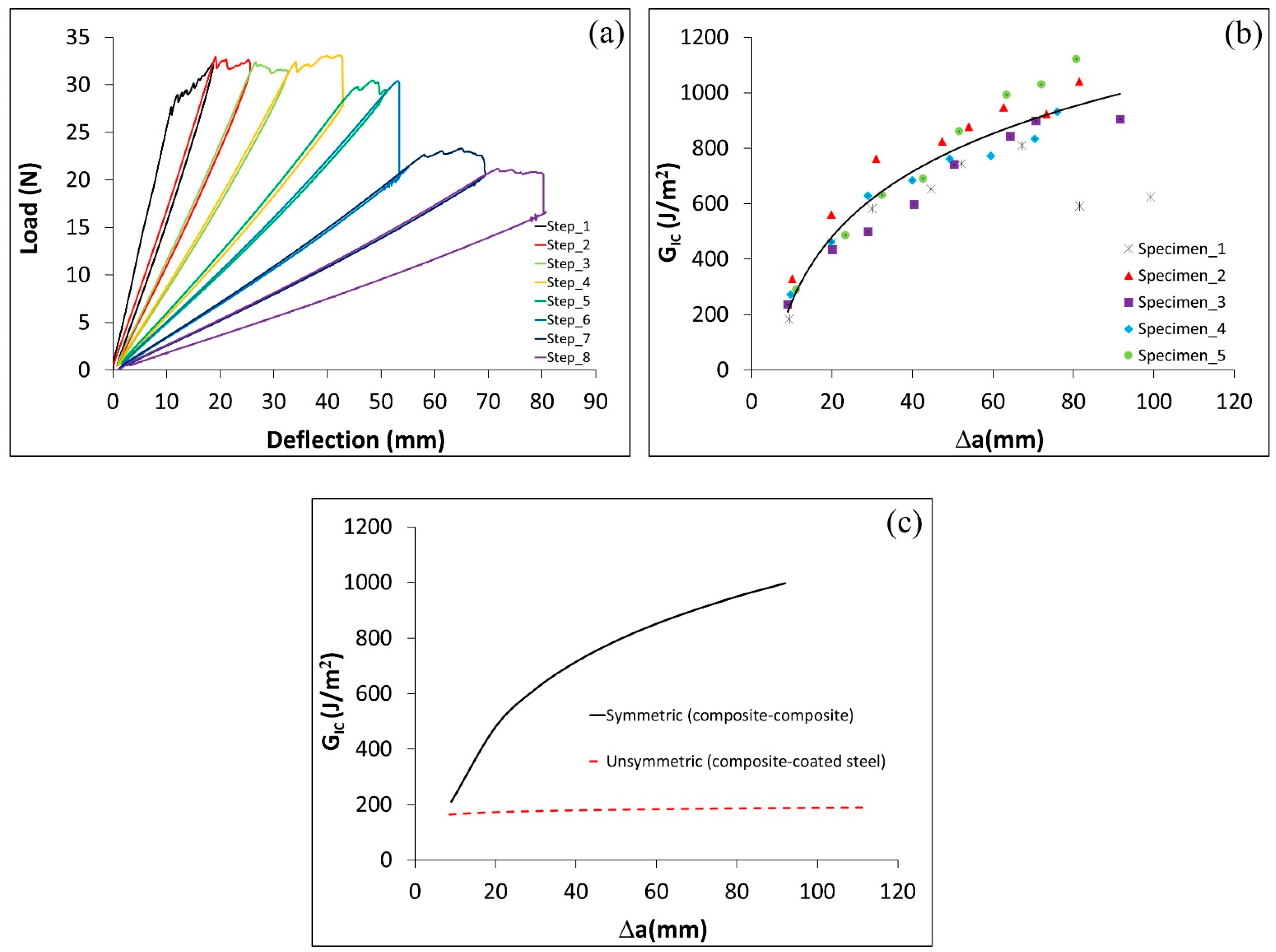

4.3. GIC of Joints with C-C and C-cS Adherends with an ET Adhesive Layer

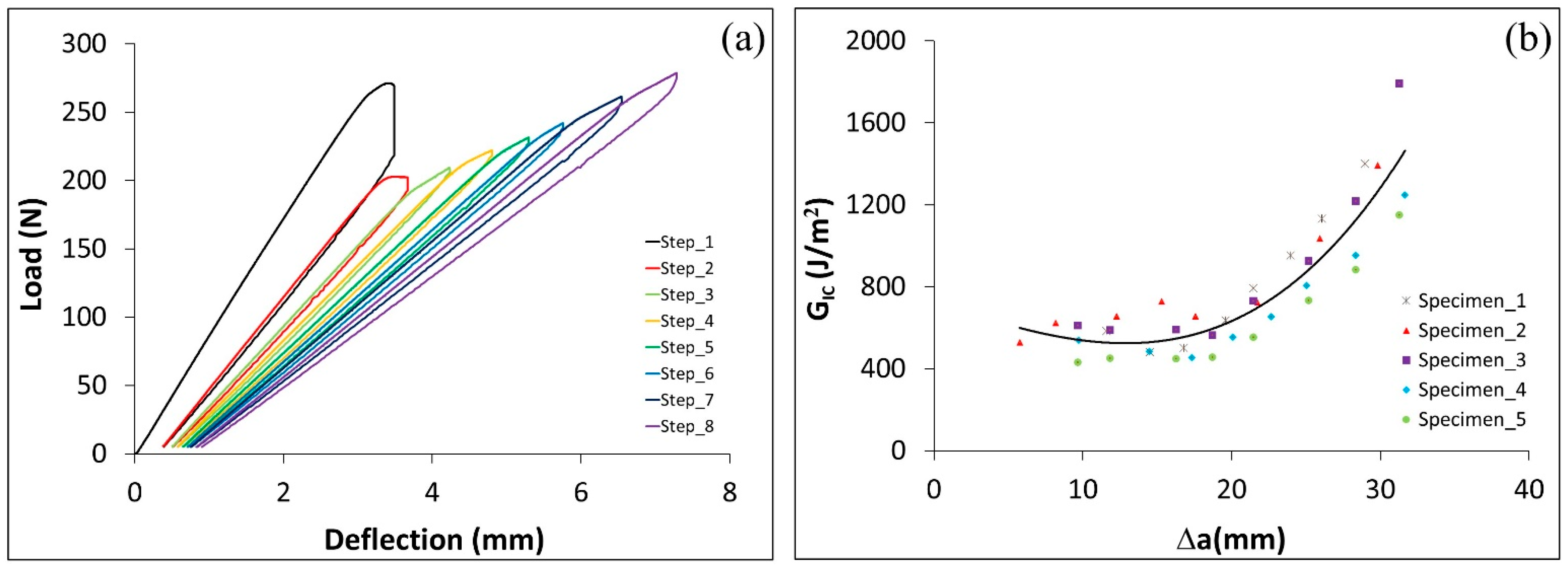

4.4. GIIc of ENF Specimens with C–C and C–cS Adherends and ET Adhesive

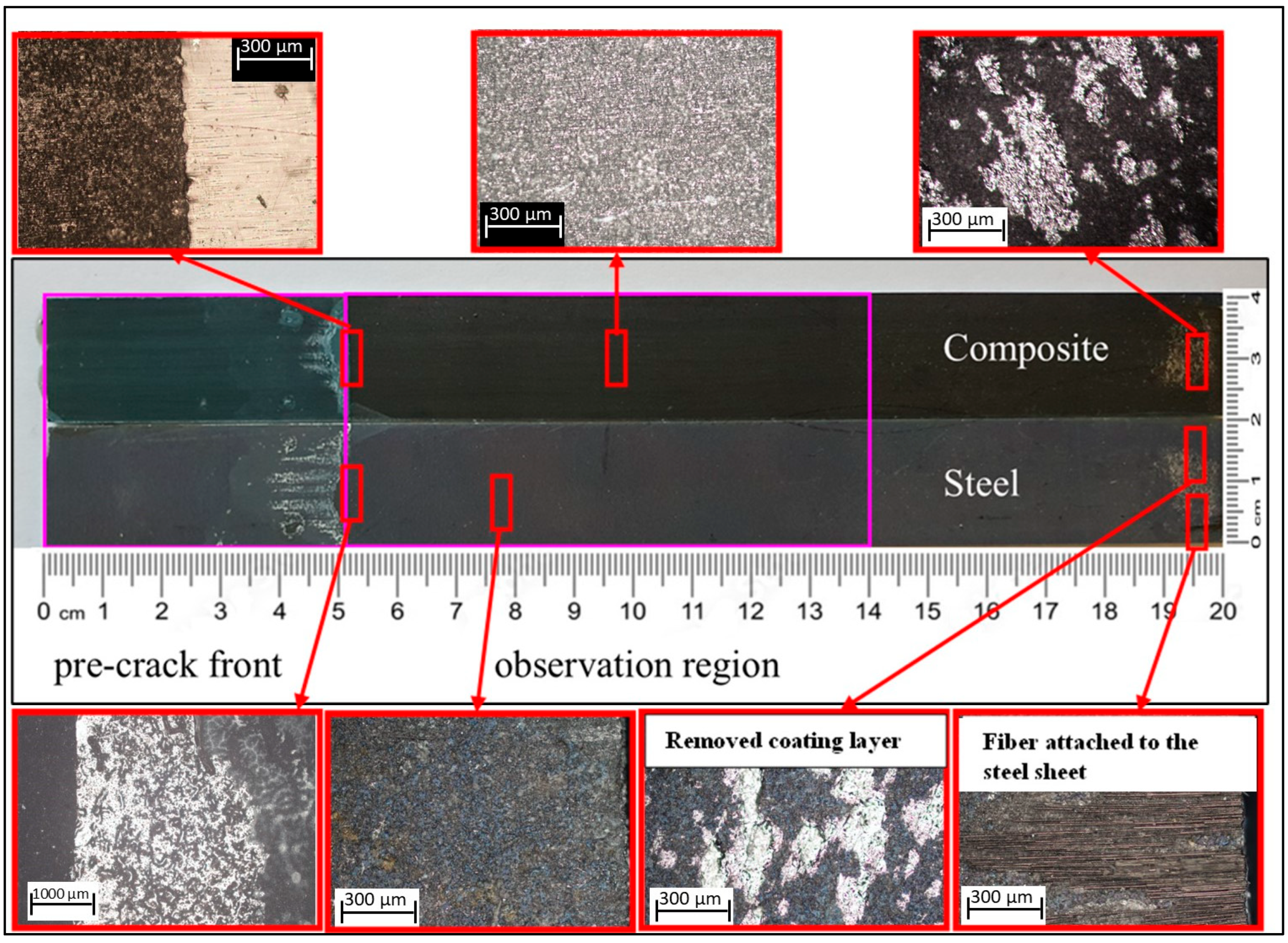

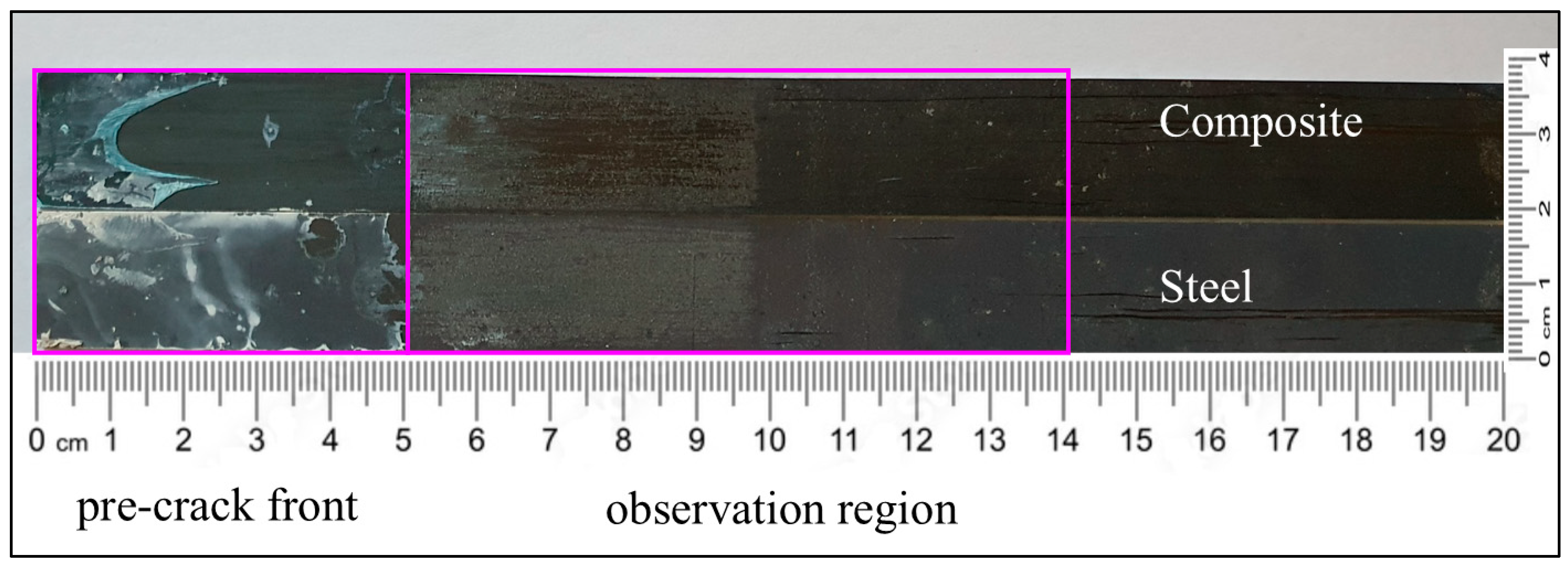

4.5. Fracture Surface and Failure Mode in the Joint (Fractography)

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Li, X.; Guan, Z.; Li, Z.; Liu, L. A new stress-based multi-scale failure criterion of composites and its validation in open hole tension tests. Chin. J. Aeronaut. 2014, 27, 1430–1441. [Google Scholar] [CrossRef]

- Banea, M.D.; da Silva, L.F.M. Adhesively bonded joints in composite materials: An overview. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2009, 223, 1–18. [Google Scholar] [CrossRef]

- Kim, K.-S.; Yi, Y.-M.; Cho, G.-R.; Kim, C.-G. Failure prediction and strength improvement of uni-directional composite single lap bonded joints. Compos. Struct. 2008, 82, 513–520. [Google Scholar] [CrossRef]

- Baker, A.A.; Jones, R. Bonded Repair of Aircraft Structures; Martinus Nijhoff Publishers: Dordrecht, The Netherlands, 1988. [Google Scholar]

- Floros, I.S.; Tserpes, K.I.; Löbel, T. Mode-I, mode-II and mixed-mode I+II fracture behavior of composite bonded joints: Experimental characterization and numerical simulation. Compos. B Eng. 2015, 78, 459–468. [Google Scholar] [CrossRef]

- Krueger, R. Virtual crack closure technique: History, approach, and applications. Appl. Mech. Rev. 2004, 57, 109–143. [Google Scholar] [CrossRef]

- Agarwal, B.D.; Broutman, L.J.; Chandrashekhara, K. Analysis and Performance of Fiber Composites; John Wiley & Sons: Hoboken, NJ, USA, 2006. [Google Scholar]

- Irwin, G.R. Analysis of stresses and strains near the end of a crack transversing a plate. J. Appl. Mech. 1957, 24, 361–364. [Google Scholar] [CrossRef]

- Erdogan, F.; Sih, G.C. On the crack extension in plates under plane loading and transverse shear. J. Fluids Eng. Trans. ASME 1963, 85, 519–525. [Google Scholar] [CrossRef]

- Chousal, J.A.G.; De Moura, M.F.S.F. Mixed-mode I+II continuum damage model applied to fracture characterization of bonded joints. Int. J. Adhes. Adhes. 2013, 41, 92–97. [Google Scholar] [CrossRef]

- Mikulik, Z. Application of Fracture Mechanics to Predict the Growth of Single and Multi-Level Delaminations and Disbonds in Composite Structures; UNSW: Sydney, Australia, 2008. [Google Scholar] [CrossRef]

- Balzani, C.; Wagner, W.; Wilckens, D.; Degenhardt, R.; Büsing, S.; Reimerdes, H.G. Adhesive joints in composite laminates–A combined numerical/experimental estimate of critical energy release rates. Int. J. Adhes. Adhes. 2012, 32, 23–38. [Google Scholar] [CrossRef]

- Fernlund, G.; Spelt, J.K. Mixed-mode fracture characterization of adhesive joints. Compos. Sci. Technol. 1994, 50, 441–449. [Google Scholar] [CrossRef]

- Dimitri, R.; Cornetti, P.; Mantič, V.; Trullo, M.; De Lorenzis, L. Mode-I debonding of a double cantilever beam: A comparison between cohesive crack modeling and Finite Fracture Mechanics. Int. J. Solids. Struct. 2017, 124, 57–72. [Google Scholar] [CrossRef]

- Olsson, R. A simplified improved beam analysis of the DCB specimen. Compos. Sci. Technol. 1992, 43, 329–338. [Google Scholar] [CrossRef]

- Asgari Mehrabadi, F. Experimental and numerical failure analysis of adhesive composite joints. Int. J. Aerosp. Eng. 2012. [Google Scholar] [CrossRef]

- Goutianos, S.; Sørensen, B.F. Fracture resistance enhancement of layered structures by multiple cracks. Eng. Fract. Mech. 2016, 151, 92–108. [Google Scholar] [CrossRef]

- Wang, W.; Lopes Fernandes, R.; Teixeira De Freitas, S.; Zarouchas, D.; Benedictus, R. How pure mode I can be obtained in bi-material bonded DCB joints: A longitudinal strain-based criterion. Compos. B Eng. 2018, 153, 137–148. [Google Scholar] [CrossRef]

- Shirasu, K.; Tsuyuki, J.; Higuchi, R.; Onodera, S.; Okabe, T. Experimental and numerical study on open-hole tension/compression properties of carbon-fiber-reinforced thermoplastic laminates. J. Compos. Mater. 2022, 56, 2211–2225. [Google Scholar] [CrossRef]

- Yenigun, B.; Chaudhry, M.S.; Gkouti, E.; Czekanski, A. Characterization of Mode I and Mode II Interlaminar Fracture Toughness in CNT-Enhanced CFRP under Various Temperature and Loading Rates. Nanomaterials 2023, 13, 1729. [Google Scholar] [CrossRef] [PubMed]

- Sekiguchi, Y.; Sato, C. Experimental investigation of the effects of adhesive thickness on the fracture behavior of structural acrylic adhesive joints under various loading rates. Int. J. Adhes. Adhes. 2021, 105, 102782. [Google Scholar] [CrossRef]

- Sika Power-533 MBX. Product Data Sheet, version 2 (5/2016).

- Wahab, M.A. DEStech Publications I. Joining Composites with Adhesives: Theory and Applications; Destech Publications, Incorporated: Lancaster, PA, USA, 2016. [Google Scholar]

- ASTM D5528-13; Standard Test Method for Mode I Interlaminar Fracture Toughness of Unidirectional Fiber Reinforced Polymer Matrix Composites. ASTM International: West Conshohocken, PA, USA, 2013.

- Zhu, Y. Characterization of Interlaminar Fracture Toughness of a Carbon/Epoxy Composite Material. Master’s Thesis, Pennsylvania State University, University Park, PA, USA, 2008. [Google Scholar]

- ASTM D7905/D7905M-14; Standard Test Method for Determination of the Mode II Interlaminar Fracture Toughness of Unidirectional Fiber-Reinforced Polymer Matrix Composites 1st. ASTM International: West Conshohocken, PA, USA, 2019. [CrossRef]

- Carlsson, L.A.; Gillespie, J.W.; Pipes, R.B. On the Analysis and Design of the End Notched Flexure (ENF) Specimen for Mode II Testing. J. Compos. Mater. 1986, 20, 594–604. [Google Scholar] [CrossRef]

- Al-Ramahi, N.J.; Joffe, R.; Varna, J. Investigation of end and edge effects on results of numerical simulation of single lap adhesive joint with non-linear materials. Int. J. Adhes. Adhes. 2018, 87, 191–204. [Google Scholar] [CrossRef]

- Anderson, T.L. Fracture Mechanics: Fundamentals and Applications, 4th ed.; CRC Press: Boca Raton, FL, USA, 2017. [Google Scholar] [CrossRef]

| Material Type | Mechanical Properties | Value |

|---|---|---|

| steel | Young’s modulus | 206 GPa |

| Poissons’s ratio | 0.3 | |

| UD T700/E445 CFRP | Longitudinal tensile Young’s modulus | 113.6 GPa |

| Longitudinal tensile strength | 1901 MPa | |

| Transverse tensile Young’s modulus | 7.7 GPa | |

| Transverse tensile strength | 27.6 MPa | |

| Longitudinal compression Young’s modulus | 111.7 GPa | |

| Longitudinal compression strength | 923.2 MPa | |

| Transverse compression Young’s modulus | 8.7 GPa | |

| Transverse compression strength | 140.5 MPa | |

| Curing conditions | 7 min at 160 °C & 3 bar | |

| Sika Power-533 MBX | Young’s modulus | ∼850 MPa |

| Tensile strength | 20 MPa approx. | |

| Elongation at break | ~20% | |

| Glass transition temperature | ~95 °C | |

| Curing conditions | 20 min at 175 °C |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Al-Ramahi, N.J.; Hassoni, S.M.; Varna, J.; Joffe, R. Utilizing Excess Resin in Prepregs to Achieve Good Performance in Joining Hybrid Materials. Polymers 2025, 17, 1689. https://doi.org/10.3390/polym17121689

Al-Ramahi NJ, Hassoni SM, Varna J, Joffe R. Utilizing Excess Resin in Prepregs to Achieve Good Performance in Joining Hybrid Materials. Polymers. 2025; 17(12):1689. https://doi.org/10.3390/polym17121689

Chicago/Turabian StyleAl-Ramahi, Nawres J., Safaa M. Hassoni, Janis Varna, and Roberts Joffe. 2025. "Utilizing Excess Resin in Prepregs to Achieve Good Performance in Joining Hybrid Materials" Polymers 17, no. 12: 1689. https://doi.org/10.3390/polym17121689

APA StyleAl-Ramahi, N. J., Hassoni, S. M., Varna, J., & Joffe, R. (2025). Utilizing Excess Resin in Prepregs to Achieve Good Performance in Joining Hybrid Materials. Polymers, 17(12), 1689. https://doi.org/10.3390/polym17121689