Discharge Energy Versus Exposure Time in Atmospheric-Pressure Air Plasma Surface Treatment of Polyimide and Polyamide 6 Films

Abstract

1. Introduction

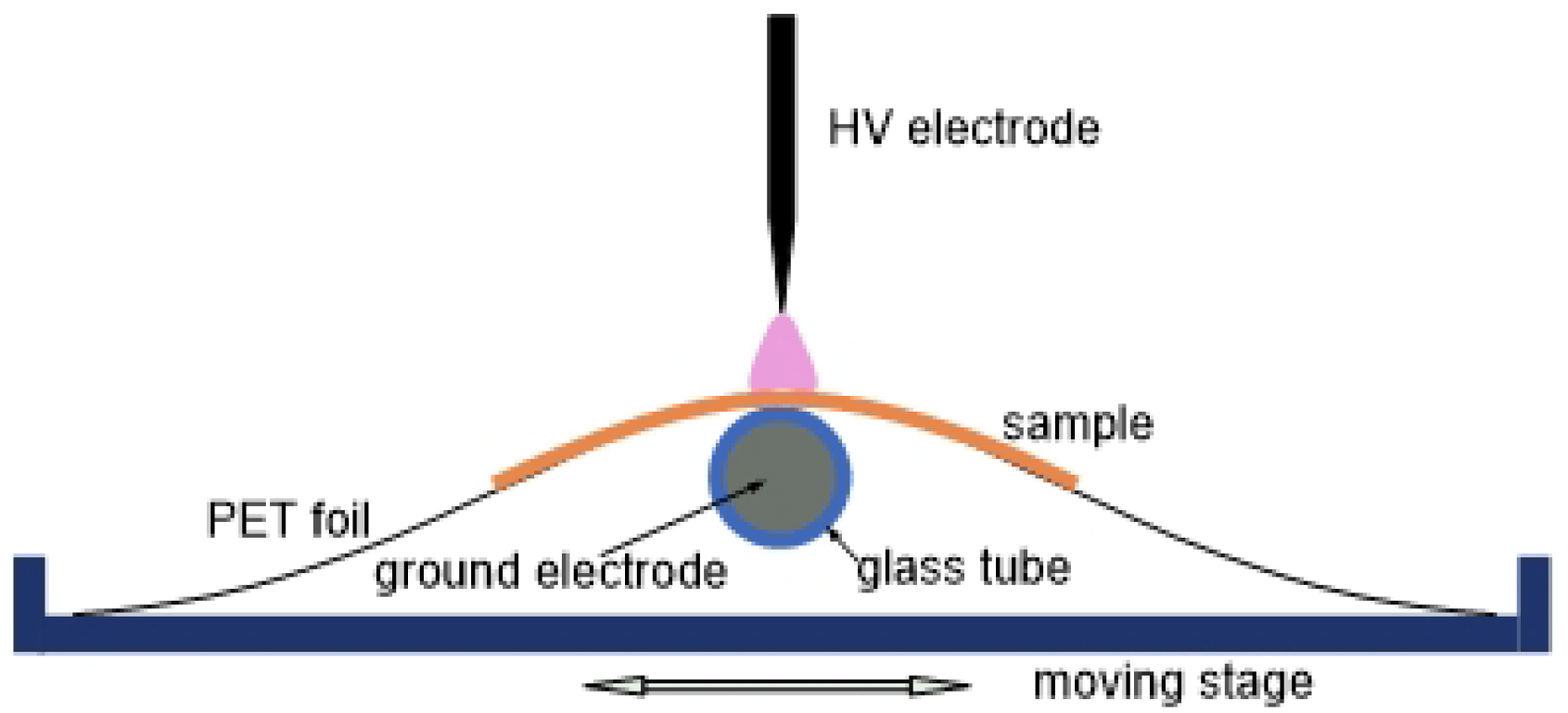

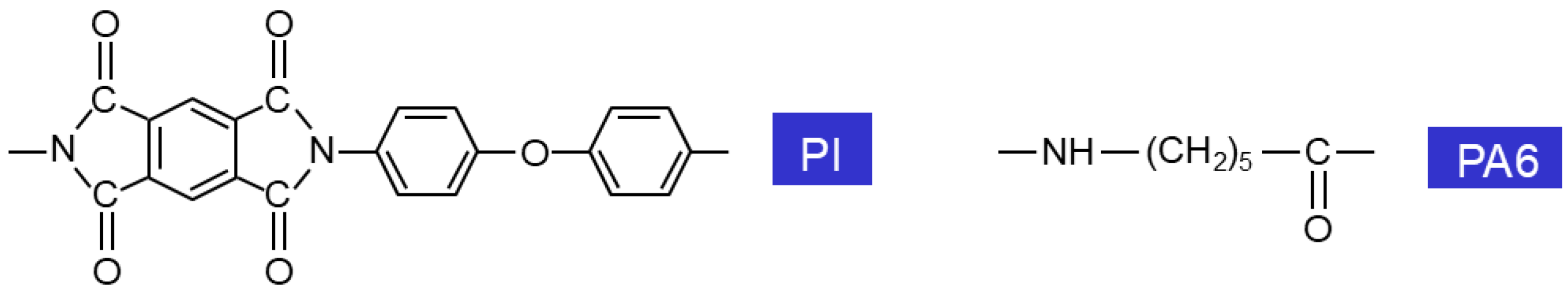

2. Materials and Methods

3. Results and Discussion

3.1. Amourphous–Crystalline Structure

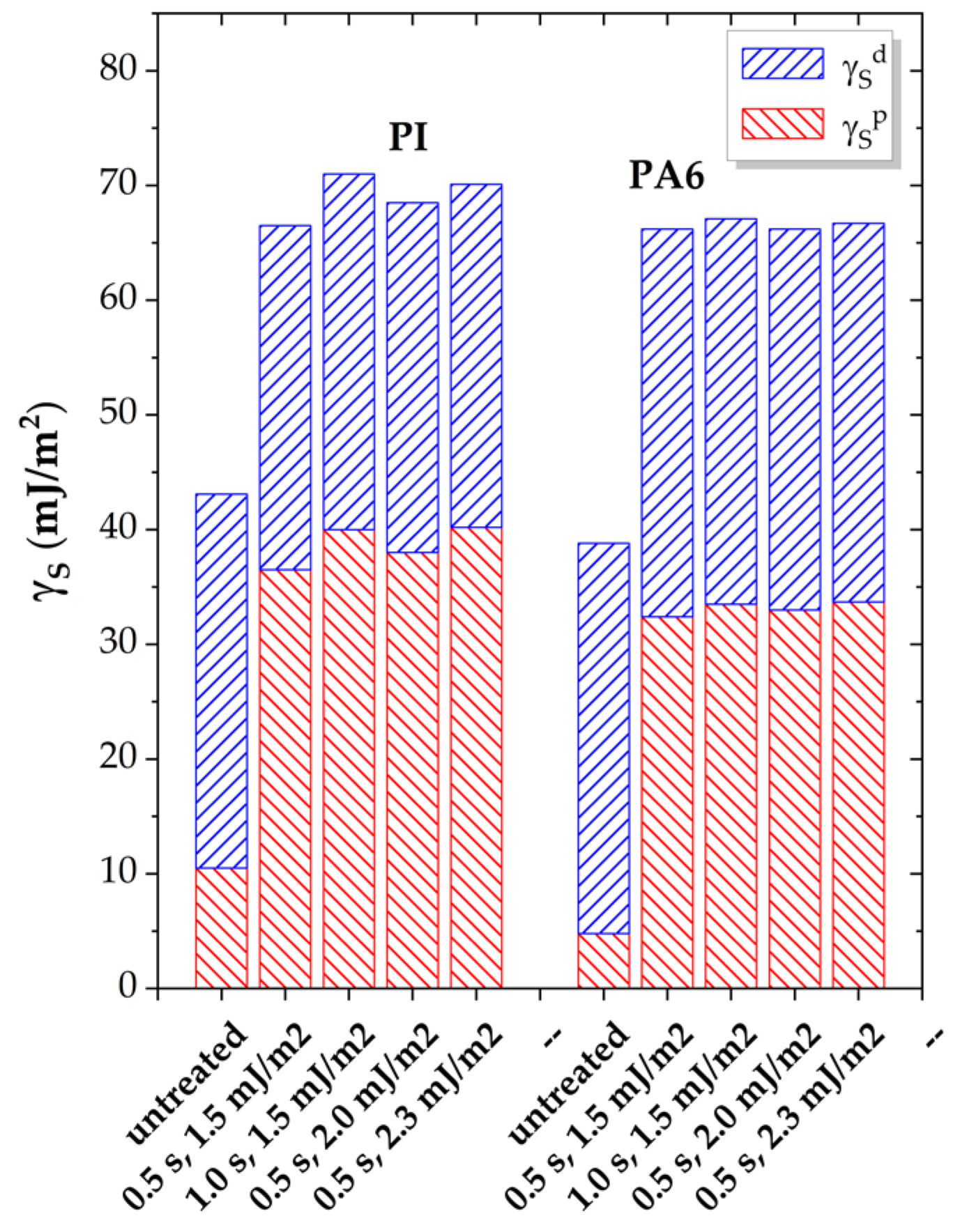

3.2. Surface Wettability, Adhesion, and Polarity

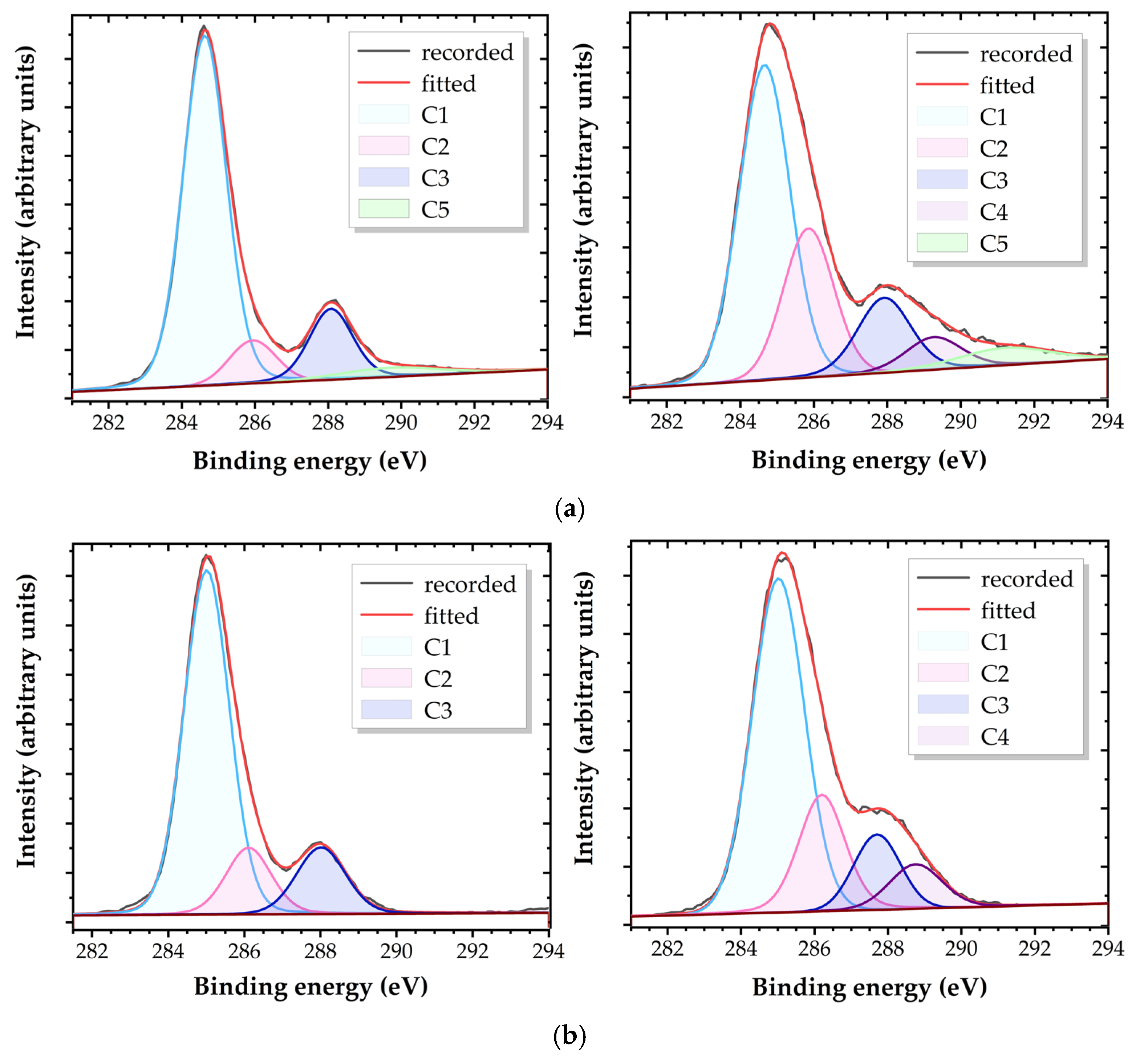

3.3. Surface Chemical Structure

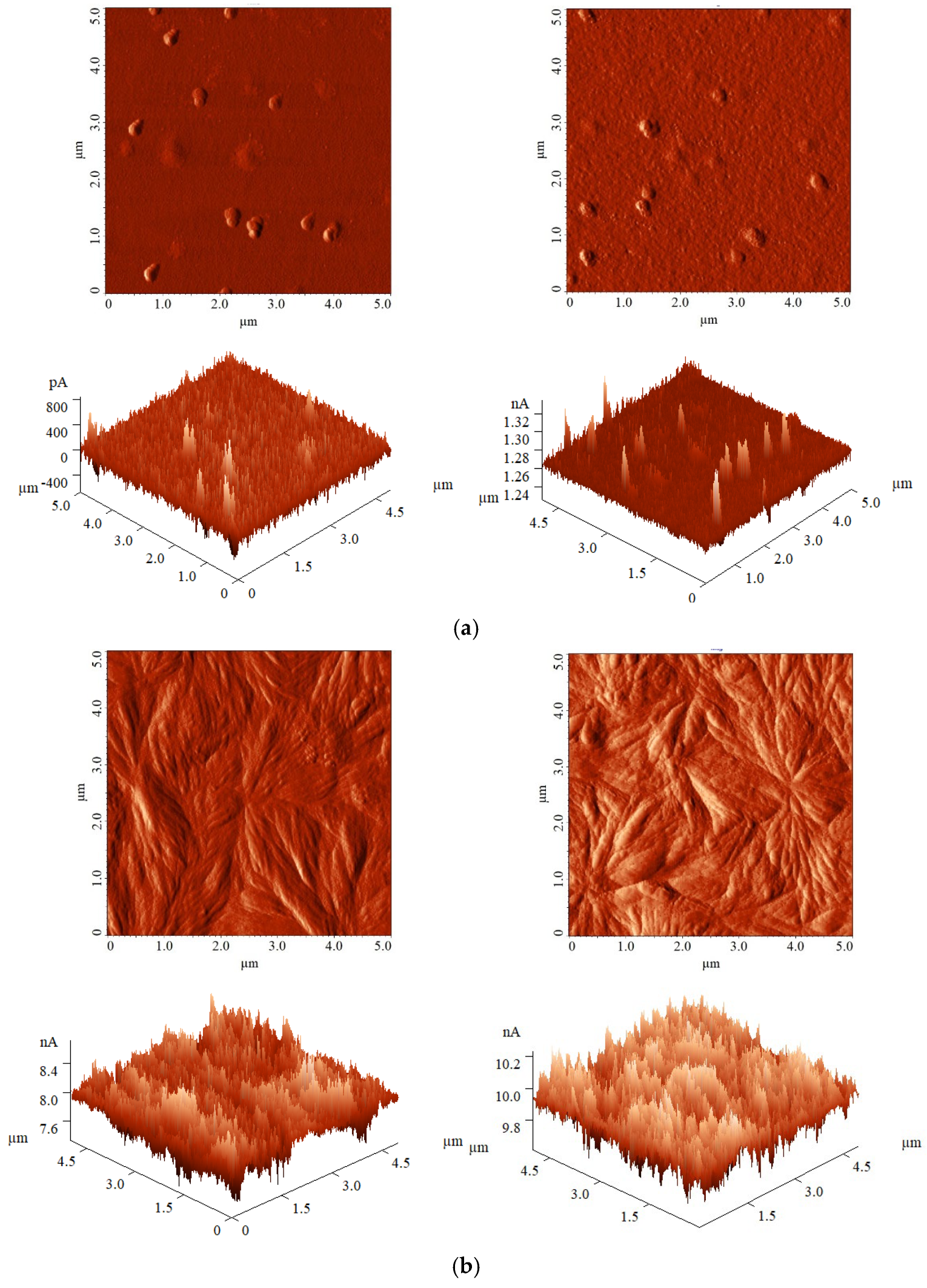

3.4. Surface Morphology

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bower, D.I. An Introduction to Polymer Physics; Cambridge University Press: New York, NY, USA, 2002. [Google Scholar]

- Primc, G.; Mozetič, M. Surface Modification of Polymers by Plasma Treatment for Appropriate Adhesion of Coatings. Materials 2024, 17, 1494. [Google Scholar] [CrossRef] [PubMed]

- Ghobeira, R.; Esbah Tabaei, P.S.; Morent, R.; De Geyter, N. Chemical characterization of plasma-activated polymeric surfaces via XPS analyses: A review. Surf. Interfaces 2022, 31, 102087. [Google Scholar] [CrossRef]

- Nimbekar, A.A.; Deshmukh, R.R. Plasma Surface Modification of Flexible Substrates to Improve Grafting for Various Gas Sensing Applications: A Review. IEEE Trans. Plasma Sci. 2022, 50, 1382–1394. [Google Scholar] [CrossRef]

- Homola, T.; Kelar, J.; Černák, M.; Kováčik, D. Large-area open air plasma sources for roll-to-roll manufacture. High-power density surface plasma generated by diffuse coplanar surface barrier discharge. Vak. Forsch. Prax. 2022, 34, 21–25. [Google Scholar] [CrossRef]

- Zabidi, N.Z.A.; Zaaba, S.K.; Sut, K.D.E.; Mohamad, C.W.S.R.; Masiman, R.I. A Brief Review on Atmospheric Air Plasma. J. Phys. Conf. Ser. 2021, 2071, 012004. [Google Scholar] [CrossRef]

- Weltmann, K.-D.; Kolb, J.; Holub, M.; Uhrland, D.; Simek, M.; Ostrikov, K.; Hamaguchi, S.; Cvelbar, U.; Černák, M.; Locke, B.R.; et al. The future for plasma science and technology. Plasma Process. Polym. 2019, 16, e1800118. [Google Scholar] [CrossRef]

- Vesel, A.; Mozetič, M. New developments in surface functionalization of polymers using controlled plasma treatments. J. Phys. D. Appl. Phys. 2017, 50, 293001. [Google Scholar] [CrossRef]

- Šimor, M.; Creyghton, Y. Treatment of Polymer Surfaces with Surface Dielectric Barrier Discharge Plasmas. In Atmospheric Pressure Plasma Treatment of Polymers: Relevance to Adhesion; Thomas, M., Mittal, K.L., Eds.; Scrinever Publishing, Wiley: Hoboken, NJ, USA, 2013; pp. 27–82. [Google Scholar]

- Fridman, A. Organic and Polymer Plasma Chemistry. In Plasma Chemistry; Cambridge University Press: Cambridge, UK, 2008; pp. 589–675. [Google Scholar]

- Booth, J.P.; Mozetič, M.; Nikiforov, A.; Oehr, C. Foundations of plasma surface functionalization of polymers for industrial and biological applications. Plasma Sources Sci. Technol. 2022, 31, 103001. [Google Scholar] [CrossRef]

- Förster, F. Atmospheric pressure plasma in industrial applications: Surface treatment of thermally sensitive polymers. Plasma Process. Polym. 2022, 19, 2100240. [Google Scholar] [CrossRef]

- Bertin, M.; Leitao, E.M.; Bickerton, S.; Johannes, C.; Verbeek, R.A. A review of polymer surface modification by cold plasmas toward bulk functionalization. Plasma Process Polym. 2024, 21, e2300208. [Google Scholar] [CrossRef]

- Bîrleanu, E.; Mihăilă, I.; Topală, I.; Borcia, C.; Borcia, G. Adhesion Properties and Stability of Non-Polar Polymers Treated by Air Atmospheric-Pressure Plasma. Polymers 2023, 15, 2443. [Google Scholar] [CrossRef]

- Ciobanu, R.; Mihăilă, I.; Borcia, C.; Borcia, G. Adhesion Properties and Stability of Polar Polymers Treated by Air Atmospheric-Pressure Plasma. Polymers 2024, 16, 1552. [Google Scholar] [CrossRef] [PubMed]

- Aktas, C.; Bhethanabotla, V.; Ayyala, R.S.; Sahiner, N. Modifying wetting properties of PI Film: The impact of surface texturing and CF4 and O2 plasma treatment. Appl. Surf. Sci. 2024, 656, 159729. [Google Scholar] [CrossRef]

- Gouzman, I.; Grossman, E.; Verker, R.; Atar, N.; Bolker, A.; Eliaz, N. Advances in polyimide-based materials for space applications. Adv. Mater. 2019, 31, 1807738. [Google Scholar] [CrossRef] [PubMed]

- Gao, H.; Lan, X.; Liu, L.; Xiao, X.; Liu, Y.; Leng, J. Study on performances of colorless and transparent shape memory polyimide film in space thermal cycling, atomic oxygen and ultraviolet irradiation environments. Smart Mater. Struct. 2017, 26, 095001. [Google Scholar] [CrossRef]

- Wang, J.; Yang, S.; Xiao, C.Y.; Yu, Z.Y.; Ren, R.; Xiong, X.H. Effects of atmospheric pressure plasma treatment and its aging behaviors on interfacial strength of PI/PEEK composite film. J. Appl. Polym. Sci. 2025, 142, e56369. [Google Scholar] [CrossRef]

- He, P.S.; Tran, D.P.; Kuo, T.Y.; Hsu, W.Y.; Lin, H.E.; Shie, K.C.; Chen, C. High-Bonding-Strength Polyimide Films Achieved via Thermal Management and Surface Activation. Nanomaterials 2023, 13, 1575. [Google Scholar] [CrossRef]

- Ji, B.; Wang, T.; Li, M.; Shi, L.; You, X.; Sun, F.; Luan, H. Localized Surface Hydrophilicity Tailoring of Polyimide Film for Flexible Electronics Manufacturing Using an Atmospheric Pressure Ar/H2O Microplasma Jet. Micromachines 2022, 13, 1853. [Google Scholar] [CrossRef]

- Li, Y.; Sun, G.; Zhou, Y.; Liu, G.; Wang, J.; Han, S. Progress in low dielectric polyimide film-A review. Prog. Org. Coat. 2022, 172, 107103. [Google Scholar] [CrossRef]

- Wang, P.; Hu, M.; Wang, H.; Chen, Z.; Feng, Y.; Wang, J.; Ling, W.; Huang, Y. The evolution of flexible electronics: From nature, beyond nature, and to nature. Adv. Sci. 2020, 7, 2001116. [Google Scholar] [CrossRef]

- Park, B.-G.; Lee, C.-J.; Jung, S.-B. Enhancing adhesion strength of photonic sintered screen-printed Ag circuit by atmospheric pressure plasma. Microelectron. Eng. 2018, 202, 37–41. [Google Scholar] [CrossRef]

- Tyuftin, A.A.; Kerry, J.P. Review of surface treatment methods for polyamide films for potential application as smart packaging materials: Surface structure, antimicrobial and spectral properties. Food Packag. Shelf Life. 2020, 24, 100475. [Google Scholar] [CrossRef]

- Primc, G. Surface Modification of Polyamides by Gaseous Plasma—Review and Scientific Challenges. Polymers 2020, 12, 3020. [Google Scholar] [CrossRef]

- Károly, Z.; Kalácska, G.; Zsidai, L.; Mohai, M.; Klébert, S. Improvement of Adhesion Properties of Polyamide 6 and Polyoxymethylene-Copolymer by Atmospheric Cold Plasma Treatment. Polymers 2018, 10, 1380. [Google Scholar] [CrossRef]

- Abdel–Fattah, E.; Alshaer, M. Polyimide Surface Modification Using He-H2O Atmospheric Pressure Plasma Jet-Discharge Power Effect. Coatings 2020, 10, 662. [Google Scholar] [CrossRef]

- Akram, M.; Jansen, K.M.B.; Ernst, L.J.; Bhowmik, S. Atmospheric plasma modification of polyimide sheet for joining to titanium with high temperature adhesive. Int. J. Adhes. Adhes. 2016, 65, 63–69. [Google Scholar] [CrossRef]

- Vo, T.S.; Vo, T.T.B.C. Surface characterization of polyimide and polyethylene terephthalate membranes toward plasma and UV treatments. Prog. Nat. Sci. Mater. 2022, 32, 314–327. [Google Scholar] [CrossRef]

- Gerullis, S.; Gerschütz, A.; Beier, O.; Kretzschmar, B.S.M.; Pfuch, A.; Schmidt, J.; Grünler, B. Modification of Dry Lubricant Powders by Atmospheric Pressure Plasma and Embedding into Nickel Dispersion Coatings. Surf. Innov. 2020, 8, 304–314. [Google Scholar] [CrossRef]

- Suzuki, H.; Ogasawara, T.; Iwata, Y.; Bae, H.; Toyoda, H. High-speed hydrophilic and ashing treatments of polyimide using Ar/O2 atmospheric-pressure microwave line plasma. Jpn. J. Appl. Phys. 2022, 61, SI1008. [Google Scholar] [CrossRef]

- Zhao, C.X.; Li, X.X.; Agrawal, D.K.; Yan, Z.L.; Qi, S.Y.; Liu, Y.; Ma, T.B.; Chen, Q.; Zhang, Y.; Wang, C.; et al. Microwave atmospheric pressure plasma jet generated from substrate integrated waveguide resonator. Plasma Process. Polym. 2023, 20, e2200230. [Google Scholar] [CrossRef]

- Khomiakova, N.; Hanuš, J.; Kuzminova, A.; Kylián, O. Investigation of Wettability, Drying and Water Condensation on Polyimide (Kapton) Films Treated by Atmospheric Pressure Air Dielectric Barrier Discharge. Coatings 2020, 10, 619. [Google Scholar] [CrossRef]

- Xiao, C.; Jing Wang, J.; Yang, S.; Wang, L.; Xiong, X. Mechanism analysis of PI/PEEK interface bonding properties enhanced by atmospheric plasma treatment: Experiment and DFT calculation. Appl. Surf. Sci. 2024, 643, 158614. [Google Scholar] [CrossRef]

- Choi, H.Y.; Kang, S.C.; Park, S.J.; Yoo, H.I.; Jeon, S.-W.; Kim, T.-H.; Moon, S.Y. Multifunctional surface treatment of boron nitride nanotube-coated polyimide films with atmospheric-pressure cold plasma. Plasma Process. Polym. 2024, 21, e2400031. [Google Scholar] [CrossRef]

- Chen, H.-W.; Huang, S.-H.; Chiou, C.-S.; Lai, Y.-H.; Hong, G.-B.; Chen, W.-T. Enhancing filter efficiency of polyimide/polyethersulfone nanofiber membranes via novel treatments of high pressure processing, thermocompression, atmospheric plasma, and corona discharge. Chem. Eng. Sci. 2024, 293, 120060. [Google Scholar] [CrossRef]

- Liu, W.-W.; Wu, L.-H.; Weng, B.; Lai, L.-M.; Chen, K.-H. Plasma Treatment for Robust Interface Adhesion of Wafer Level Packaging. In Proceedings of the 16th International Microsystems, Packaging, Assembly and Circuits Technology Conference (IMPACT), Taipei, Taiwan, 21–23 December 2021; IEEE: Piscataway, NJ, USA, 2021; pp. 64–67. [Google Scholar] [CrossRef]

- Riyanto, E. Surface treatment of polyimide using atmospheric pressure dielectric barrier discharge plasma. Scienceasia 2020, 46, 444–449. [Google Scholar] [CrossRef]

- Kondo, T.; Watanabe, R.; Shimoyama, Y.; Shinohe, K.; Kulinich, A.A.; Iwamori, S. Effect of reactive oxygen species generated with ultraviolet lamp and plasma on polyimide surface modification. Surf. Interface Anal. 2017, 49, 1–9. [Google Scholar] [CrossRef]

- Peng, S.; Li, L.; Li, W.; Wang, C.; Guo, Y.; Shi, J.; Zhang, J. Surface Modification of Polyimide Film by Dielectric Barrier Discharge at Atmospheric Pressure. Plasma Sci. Technol. 2016, 18, 337–341. [Google Scholar] [CrossRef]

- Zheng, P.; Liu, K.; Wang, J.; Dai, Y.; Yu, B.; Zhou, X.; Hao, H.; Luo, Y. Surface modification of polyimide (PI) film using water cathode atmospheric pressure glow discharge plasma. Appl. Surf. Sci. 2012, 259, 494–500. [Google Scholar] [CrossRef]

- Park, S.-J.; Lee, H.-Y. Effect of atmospheric-pressure plasma on adhesion characteristics of polyimide film. J. Colloid Interface Sci. 2005, 285, 267–272. [Google Scholar] [CrossRef]

- Hnilica, J.; Potočňáková, L.; Stupavská, M.; Kudrle, V. Rapid surface treatment of polyamide 12 by microwave plasma jet. Appl. Surf. Sci. 2014, 288, 251–257. [Google Scholar] [CrossRef]

- Štěpánová, V.; Šrámková, P.; Sihelník, S.; Stupavská, M.; Jurmanová, J.; Kováčik, D. The effect of ambient air plasma generated by coplanar and volume dielectric barrier discharge on the surface characteristics of polyamide foils. Vacuum 2021, 183, 109887. [Google Scholar] [CrossRef]

- Kuzminova, A.; Shelemin, A.; Kylián, O.; Choukourov, A.; Valentová, H.; Krakovský, I.; Nedbal, J.; Slavínská, D.; Biederman, H. Study of the effect of atmospheric pressure air dielectric barrier discharge on nylon 6,6 foils. Polym. Degrad. Stab. 2014, 110, 378–388. [Google Scholar] [CrossRef]

- Che, C.; Dashtbozorg, B.; Qi, S.J.; North, M.J.; Li, X.Y.; Dong, H.S.; Jenkins, M.J. The Ageing of μPlasma-Modified Polymers: The Role of Hydrophilicity. Materials 2024, 17, 1402. [Google Scholar] [CrossRef]

- Bahrami, M.; Lavayen-Farfan, D.; Martínez, M.A.; Abenojar, J. Experimental and numerical studies of polyamide 11 and 12 surfaces modified by atmospheric pressure plasma treatment. Surf. Interfaces 2022, 32, 102154. [Google Scholar] [CrossRef]

- Károly, Z.; Kalácska, G.; Sukuraman, J.; Fauconnier, D.; Kalácska, A.; Mohai, M.; Klébert, S. Effect of Atmospheric Cold Plasma Treatment on the Adhesion and Tribological Properties of Polyamide 66 and Poly(Tetrafluoroethylene). Materials 2019, 12, 658. [Google Scholar] [CrossRef] [PubMed]

- Weidinger, A.; Hermans, P.H. On the determination of the crystalline fraction of isotactic polypropylene from X-ray diffraction. Macromol. Chem. Phys. 1961, 50, 98–115. [Google Scholar] [CrossRef]

- Good, R.J.; Girifalco, L.A. A theory for estimation of surface and interfacial energies, III: Estimation of surface energies of solids from contact angle data. J. Phys. Chem. 1960, 64, 561–565. [Google Scholar] [CrossRef]

- Good, R.J.; Srivatsa, N.R.; Islam, M.; Huang, H.T.L.; Van Oss, C.J. Theory of the acid-base hydrogen bonding interactions, contact angles, and the hysteresis of wetting: Application to coal and graphite surfaces. J. Adhes. Sci. Technol. 1990, 4, 1–617. [Google Scholar] [CrossRef]

- Chen, L.; Luo, W.; He, Y.; Huang, L.; Xu, J.; Li, K.; Min, Y. High-Performance Polyimide Films Derived from Biomass-Based Furfural: Fabrication and Properties. Coatings 2023, 13, 1726. [Google Scholar] [CrossRef]

- Cagiao, M.E.; Connor, M.; Balta Calleja, F.J.; Seferis, J.C. Structure Development in a Thermoplastic Polyimide. Cold Crystallization as Revealed by Microhardness. Polym. J. 1999, 31, 739–746. [Google Scholar] [CrossRef]

- Koning, C.E.; Teuwen, L.; De Plaen, A.; Mercier, J.P. Enhancement of the crystallinity of a thermoplastic polyimide. Polymer 1996, 37, 5619–5625. [Google Scholar] [CrossRef]

- Nagata, Y.; Ohnishi, Y.; Kajiyama, T. Highly Crystalline Polyimide Particles. Polymer 1996, 28, 980–985. [Google Scholar] [CrossRef][Green Version]

- Borcia, C.; Punga, I.L.; Borcia, G. Surface properties and hydrophobic recovery of polymers treated by atmospheric-pressure plasma. Appl. Surf. Sci. 2014, 317, 103–110. [Google Scholar] [CrossRef]

- Sun, X.Y.; Bu, J.F.; Liu, W.W.; Niu, H.Q.; Qi, S.L.; Tian, G.F.; Wu, D.H. Surface modification of polyimide fibers by oxygen plasma treatment and interfacial adhesion behavior of a polyimide fiber/epoxy composite. Sci. Eng. Compos. Mater. 2017, 24, 477–484. [Google Scholar] [CrossRef]

- Bouhamed, A.; Kia, A.M.; Naifar, S.; Dzhagan, V.; Müller, C.; Zahn, D.R.T.; Chour, S.; Kanoun, O. Tuning the adhesion between polyimide substrate and MWCNTs/epoxy nanocomposite by surface treatment. Appl. Surf. Sci. 2017, 422, 420–429. [Google Scholar] [CrossRef]

- Borcia, G. Chapter 3 X-ray photoelectron spectroscopy of polymers. In Surface Properties of Polymers; Vasile, C., Pascu, M.C., Eds.; Research Signpost: Kerala, India, 2007; pp. 91–129. [Google Scholar]

- Borcia, G.; Cazan, R.; Borcia, C. DBD surface modification of polymers in relation to the spatial distribution of reactive oxygen species. Plasma Chem. Plasma Process. 2011, 31, 729–740. [Google Scholar] [CrossRef]

- Borcia, C.; Borcia, G.; Dumitrascu, N. Relating plasma surface modification to polymer characteristics. Appl. Phys. A-Mater. Sci. Process. 2008, 90, 507–515. [Google Scholar] [CrossRef]

| Material, Reference | Treatment Conditions | WCA | Recovery | Chemical Modification | Morphology, Mechanical Properties, Other |

|---|---|---|---|---|---|

| PI film [19] | APP torch, 400–1000 W, unspecified duration | 61° → min. 28° | ~50°, decrease in O/C values and peeling force over 30 days | O/C: 0.2 → max. 0.39; N/C: 0.09 → max. 0.17 (XPS) | strong etching effect; non-monotonous evolution of the peel force vs. power |

| PI film [21] | microAPP jet, Ar/H2O, 6–15 W, 60 s | 70° → 25° | 62° within 9 days | O/C: ~0.35 →~0.5: N/C: ~constant (XPS) | 2.3 nm → 4.1 nm (AFM) |

| PI film [24] | DBD, Ar/O2, 100 W, 1 min | 65° → 25° | - | increased oxygen content (XPS) | increased peel strength |

| PI (Kapton tape) [28] | He-0.15% H2O plasma jet, 5.2 W, 30 s | 60° → 15° | - | O/C: 0.3 → 0.6; N/C: 0.06 → 0.1 (XPS) | non-uniform node-like structure Ra: 11 nm → 41 nm |

| PI sheet [29] | APP, air, 30–120 s | polar surface energy doubles | - | - | 150 nm → 250 nm (AFM), ablation (SEM), increased adhesive bond strength |

| PI membranes [30] | APP air, 150 W, 2–10 min | 56° → 14° → superhydrophilic | ~14° over unspecified interval | C=O and -OH groups (FTIR) | streaks on SEM images; slight surface damage; minor changes in peel force |

| PI powder particles [31] | DCSBD, air, 400 W, 5 min | - | - | O/C: 0.19 → ~0.29; N/C: constant (XPS) | improved dispersability in water, embedding in metal layers, wear behaviour |

| PI film [32] | microwave line APP, Ar/O2, 3.5 kW, 0–100 ms | 70° → min. 18° | - | - | rapid ashing |

| PI film [33] | microwave APP jet, Ar, 40 W, 1–5 min | 66° → 24° → 8° | - | - | etching, nanoscale particles |

| PI (Kapton films) [34] | DBD, air, 30 W, 1–20 s (40 times higher to swipe the samples) | 80° → 24° | ~60° over extended interval (>1 month) | O/C: 0.2 → ~0.3; N/C: constant (XPS) | randomly distributed nanostructures, Sq: 1 nm → 25 nm due to fast etching (4 nm/s) |

| PI film [35] | APP jet, air, 300–600 W, unspecified duration | 85° → ~30° | - | small increase in C=O and C-O groups (XPS) | decrease in tensile strength, increase in peel strength attributed to etching |

| PI film [36] | APP, Ar, 100 W, unspecified duration | 68° → 25° | - | reduced chemical modification (XPS) | improved coating uniformity |

| PI/PES membranes [37] | APP jet (60 W) and corona (25 kV), unspecified duration | - | - | - | altered fibre morphology, improved filter efficiency by corona |

| PI film [38] | APP, O2, N2, unspecified parameters | - | - | O/C: 0.13 → 0.32 (XPS) | high-temp PI: 4 nm → 6 nm, 12 nm; low-temp PI: 0.1 nm → ~1 nm (SEM); increased shear force |

| PI [39] | DBD, He, He-O2, 200–300 W RF, 20–60 s | 82° → 7° | complete hydrophobic recovery within 7 days | increase in -C=O and -OH groups (FTIR) | cluster formation, 0.9 nm → 6.8 nm (AFM) |

| PI film [40] | RF plasma, O2, 2 kPa, 10 min | 75° → 26° | - | O/C: 0.2 → 0.3; N/C: ~constant (XPS) | unchanged roughness (AFM) |

| PI film [41] | DBD, Ar, 5.4 W, 0–300 s | 78° → 10–20° | - | some indication on oxidation (FTIR) | strong morphology modification at micrometre scale (SEM) |

| PI film [42] | APGD, water cathode, air, 5–90 s | 68° → 46° | 62° within 11 days | - | 6 nm → 13 nm (AFM) |

| PI film [43] | APP, RF, Ar-O2, 0–300 W, 1 min | increased polar surface energy | ageing within 7 days | O/C: 0.23 → max. 0.39 (XPS) | increased peel strength |

| PA6 [27] | DCSBD, air, 320 W, 30 s | 70° → 28° | continued recovery for >2 months | O/C: 0.17 → 0.3 N/C: constant (XPS) | smoother surface at micrometric level; sample heating |

| PA12 [44] | microwave surface wave jet, Ar (+O2, N2), ~1 cm2 exposed area, 25 ms−1 s | 79° → min. 19° | ~50° within 30 days | O/C: 0.3 → 0.6 N/C: 0.05 → 0.09 (XPS) | 26 nm → 90 nm (AFM) |

| PA6 foils [45] | VDBD and DCSBD, hundreds of W, 0.25–2 s | DCSBD: 65° → 41° → 28° VDBD: 65° → 47° → 45° | DCSBD: >40°; VDBD: >55° within 14 days | O/C: 0.2 → max. 0.4; N/C: ~constant (XPS) | peel resistance increases beyond error bars for at least 1 s exposure |

| PA66 [46] | DBD, air, 0.5–32 s | 64° → 30° (0.5 s) → 25° | 30–35° within 4 days | O/C: 0.2 → 0.6; N content constant (XPS) | 14 nm → 35 nm (AFM) |

| PA6, PA12 moulded sheets [47] | microdischarge, 24-needle electrode system, unspecified duration | PA6: 76° → 26°; PA12: 82° → 40° | PA6: >50° PA12: >60° within 2–3 h | -OH, C=O and C-O bands, decreasing over ageing (FTIR) | Sq: PA6: 21→24 nm PA12: 10→12 nm |

| PA11, PA12 sheets [48] | APP torch, air, unspecified duration | PA11: 93° → 26°; PA12: 83° → 22° | complete recovery within 21 days | PA11: O/C: 0.4 → 0.9; N/C: 0.2 → 0.4 (XPS) | decrease in roughness parameters |

| PA66 [49] | DCSBD, air, 320 W, 30 s | 63° → 33° | ~55° within 8 days and continued >2 months | O/C: 0.16 → 0.47; N/C: 0.15 → 0.23 (XPS) | smoother surface at micrometric level; sample heating |

| Test Liquid | γL (mJ/m2) | γLd (mJ/m2) | γLp (mJ/m2) |

|---|---|---|---|

| Water (W) | 72.8 | 21.8 | 51.0 |

| Formamide (F) | 58.2 | 35.1 | 23.1 |

| Time (s) | Untreated | 0.5 | 1.0 | 0.5 | 0.5 |

|---|---|---|---|---|---|

| EDBD (mJ/Pulse) | 1.5 | 1.5 | 2.0 | 2.3 | |

| PI | 78.7 ± 1.1 | 42.6 ± 0.8 | 35.9 ± 0.7 | 38.0 ± 0.8 | 35.6 ± 0.8 |

| PA6 | 75.9 ± 1.0 | 45.7 ± 0.9 | 39.6 ± 0.8 | 41.5 ± 0.9 | 39.5 ± 0.8 |

| PI | PA6 | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Time (s) | Untreated | 0.5 | 1.0 | 0.5 | 0.5 | Untreated | 0.5 | 1.0 | 0.5 | 0.5 |

| EDBD (mJ/Pulse) | 1.5 | 1.5 | 2.0 | 2.3 | 1.5 | 1.5 | 2.0 | 2.3 | ||

| Wa (mJ/m2) | 87.1 | 126.4 | 129.5 | 130.2 | 132.0 | 90.5 | 123.6 | 128.9 | 127.3 | 129.0 |

| ΔWa/Wa (%) | — | 45% | 49% | 49% | 51% | — | 37% | 42% | 41% | 42% |

| ΔWa/Wa (%) (aged) | — | 40% | 43% | 37% | 37% | — | 30% | 32% | 30% | 28% |

| PEs, PP | PS | PET | PEEK | PMMA | PI | PA6 | |

|---|---|---|---|---|---|---|---|

| [14] | [14] | [15] | [15] | [15] | |||

| Wa (mJ/m2) | 103 | 113 | 117 | 120 | 112 | 124 | 119 |

| ΔWa/Wa (%) | 80% | 65% | 27% | 27% | 22% | 43% | 32% |

| WCA (°) | 62 | 56 | 53 | 49 | 57 | 45 | 50 |

| γSp/γS | Time (s) | Untreated | 0.5 | 1.0 | 0.5 | 0.5 |

|---|---|---|---|---|---|---|

| EDBD (mJ/Pulse) | 1.5 | 1.5 | 2.0 | 2.3 | ||

| PI | 0.243 | 0.548 | 0.563 | 0.554 | 0.573 | |

| PA6 | 0.123 | 0.489 | 0.499 | 0.498 | 0.505 |

| PI | PA6 | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Time (s) | Untreated | 0.5 | 1.0 | 0.5 | 0.5 | Untreated | 0.5 | 1.0 | 0.5 | 0.5 |

| EDBD (mJ/Pulse) | 1.5 | 1.5 | 2.0 | 2.3 | 1.5 | 1.5 | 2.0 | 2.3 | ||

| C1s | 80 | 77 | 75 | 74 | 72 | 81 | 75 | 73 | 73 | 72 |

| O1s | 13 | 16 | 18 | 20 | 22 | 10 | 15 | 16 | 17 | 18 |

| N1s | 7 | 7 | 7 | 6 | 6 | 9 | 10 | 11 | 10 | 10 |

| O1s/C1s | 0.16 | 0.21 | 0.24 | 0.27 | 0.30 | 0.12 | 0.20 | 0.22 | 0.23 | 0.25 |

| N1s/C1s | 0.09 | 0.09 | 0.09 | 0.08 | 0.08 | 0.11 | 0.13 | 0.15 | 0.14 | 0.14 |

| Functional Groups | Assignment | BE (eV) |

|---|---|---|

| carbon/hydrogen -C-C-, -C-H | C1 | 284.6, 285.0 |

| carbon/nitrogen or oxygen -C-N-, -C-O- | C2 | 286.0, 286.5 |

| amide –N–C=O | C3 | 288.0 |

| carboxyl –O–C=O | C4 | 289.0 |

| π–π* shake-up | C5 | ~291.8 |

| PI | PA6 | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Time (s) | Untreated | 0.5 | 1.0 | 0.5 | 0.5 | Untreated | 0.5 | 1.0 | 0.5 | 0.5 |

| EDBD (mJ/Pulse) | 1.5 | 1.5 | 2.0 | 2.3 | 1.5 | 1.5 | 2.0 | 2.3 | ||

| C1 | 73 | 59 | 55 | 54 | 51 | 70 | 63 | 61 | 59 | 56 |

| C2 | 11 | 16 | 17 | 19 | 21 | 14 | 17 | 18 | 20 | 22 |

| C3 | 12 | 13 | 13 | 11 | 12 | 15 | 14 | 14 | 13 | 14 |

| C4 | - | 8 | 10 | 12 | 11 | - | 6 | 7 | 8 | 8 |

| C5 | 4 | 4 | 5 | 4 | 5 | - | - | - | - | - |

| ΔO | — | 14 | 18 | 19 | 22 | — | 7 | 9 | 11 | 14 |

| PI | PA6 | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Time (s) | Untreated | 0.5 | 1.0 | 0.5 | 0.5 | Untreated | 0.5 | 1.0 | 0.5 | 0.5 |

| EDBD (mJ/Pulse) | 1.5 | 1.5 | 2.0 | 2.3 | 1.5 | 1.5 | 2.0 | 2.3 | ||

| Sa | 2.2 | 3.5 | 4.7 | 4.9 | 5.1 | 9.3 | 10.2 | 10.8 | 11.1 | 11.4 |

| Sq | 3.1 | 4.8 | 5.9 | 6.2 | 6.5 | 11.9 | 13.2 | 13.5 | 14.0 | 14.5 |

| Sy | 33 | 45 | 64 | 69 | 73 | 95 | 129 | 138 | 143 | 147 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hatescu, I.; Borcia, C.; Ciobanu, R.; Borcia, G. Discharge Energy Versus Exposure Time in Atmospheric-Pressure Air Plasma Surface Treatment of Polyimide and Polyamide 6 Films. Polymers 2025, 17, 1394. https://doi.org/10.3390/polym17101394

Hatescu I, Borcia C, Ciobanu R, Borcia G. Discharge Energy Versus Exposure Time in Atmospheric-Pressure Air Plasma Surface Treatment of Polyimide and Polyamide 6 Films. Polymers. 2025; 17(10):1394. https://doi.org/10.3390/polym17101394

Chicago/Turabian StyleHatescu, Iustina, Cătălin Borcia, Roxana Ciobanu, and Gabriela Borcia. 2025. "Discharge Energy Versus Exposure Time in Atmospheric-Pressure Air Plasma Surface Treatment of Polyimide and Polyamide 6 Films" Polymers 17, no. 10: 1394. https://doi.org/10.3390/polym17101394

APA StyleHatescu, I., Borcia, C., Ciobanu, R., & Borcia, G. (2025). Discharge Energy Versus Exposure Time in Atmospheric-Pressure Air Plasma Surface Treatment of Polyimide and Polyamide 6 Films. Polymers, 17(10), 1394. https://doi.org/10.3390/polym17101394