Abstract

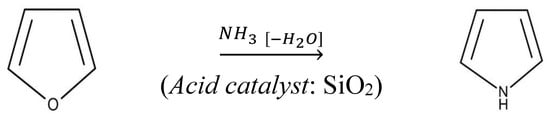

This work reports a study on the structural characterization, evaluation of thermal stability, and non-isothermal decomposition kinetics of urea–formaldehyde (UF) resin modified with hydrochar (obtained by the hydrothermal carbonization of spent mushroom substrate (SMS)) (UF-HC). The structural characterization of UF-HC, performed by scanning electron microscopy (SEM), Fourier transform infrared (FTIR), and X-ray diffraction analyses, showed that UF-HC consists of a large number of spheroidal particles, which are joined, thus forming clusters. It constitutes agglomerates, which are composed of crystals that have curved plate-like forms, including crystalline UF structure and graphite lattices with an oxidized face (graphene oxide, GO). The measurement of inherent thermal stability and non-isothermal decomposition kinetic analysis was carried out using simultaneous thermogravimetric–differential thermal analyses (TGA-DTA) at various heating rates. Parameters that are obtained from thermal stability assessment have indicated the significant thermal stability of UF-HC. Substantial variation in activation energy and the pre-exponential factor with the advancement of decomposition process verifies the multi-step reaction pathway. The decomposition process takes place through three independent single-step reactions and one consecutive reactions step. The consecutive stage represents a path to the industrial production of valuable heterocyclic organic compounds (furan) and N-heterocyclic compounds (pyrroles), building a green-protocol trail. It was found that a high heating rate stimulates a high production of furan from cellulose degradation via the ring opening step, while a low heating rate favors the production of urea compounds (methylolurea hemiformal (HFn)) by means of methylene ether bridges breaking.

1. Introduction

Amino resins include a group of products (e.g., urea–formaldehyde (UF) resins, melamine–formaldehyde (MF) resins, and benzo–guanine (BG) resins) that are used in the industry of coatings, adhesives, paper, textiles, etc. In the coating industry, amino resins are mainly used for thermoset topcoats. They produce rigid films by themselves, and when combined with the other resins (e.g., alkyd, polyester, and acrylic), they produce coatings characterized by high hardness, good chemical resistance, and good color retention [1]. The addition of amino resins to other resins can shorten the time required for coating drying, so amino resins are also classified as cross-linking agents (e.g., added to water-soluble coatings). Based on this, they are classified as slow, medium and fast cross-linking amino resins. Slow cross-linking amino resins are “butylated” and are more soluble than fast cross-linking resins, which are less “butylated”. A lower degree of alkylation increases the self-polymerization tendency of amino resins. In practice, two basic types of amino resins are mostly used: urea–formaldehyde (UF) and melamine–formaldehyde (MF) resins. The main difference between these resins is that urea–formaldehyde (UF) is made using the urea (U) and formaldehyde (F) monomers, whereas melamine–formaldehyde (MF) is made from the combination of melamine (M) and formaldehyde (F) monomers [2,3]. Both resins represent thermosetting polymers, which are obtained through irreversibly hardening (also known as the curing process) a soft solid or a viscous liquid pre-polymer.

When considering the chemical structure of UF, it contains the entity of the ‘formula’ [(O)CNHCH2NH]n as the repeating unit. Usually, this resin occurs as chain polymers, but it depends on the polymerization conditions. So, it can exist as a UF branched polymer or de-branched UF polymer. The conventional method of manufacturing UF resins comprises pre-condensing the urea with formaldehyde in aqueous solution under reflux at pH 7–9, and heating the mixture at pH 5–6, until the desired degree of water insolubility or viscosity is reached [4]. The UF resins are the most important type of adhesive resins for the production of wood-based panels [5]. Other than their excellent adhesive properties, they also are good electrical and thermal insulators, with good elasticity and inertness to the chemicals; so, they are used for producing sockets, different cases, and handles, and for coating electrical appliances [6]. Despite their wide use and a lot of benefits (they are colorless, have a good performance, and are fast curing and inexpensive), a serious problem related to the UF resins is the formaldehyde emission (FE). That is why it is very important to add fillers that bind free and liberated formaldehyde [7]. Practically, the low formaldehyde (F)/urea (U) mole ratio (at about F/U~1.50) represents a key parameter for lower FE [4]. The low F/U mole ratio of UF resins is necessitated by low functionality of U (≤2.30), which also limits the extent of cross-linking in the curing of UF polymers [4]. In addition, FE decreases as the mole ratio falls, but unfortunately, the other physical and mechanical properties were influenced negatively at the same time [8]. However, extensive work has reported that properties of UF resins are significantly influenced by the F/U mole ratio, and it is often done by the incorporation of excess urea, during the condensation reaction step [9]. The current procedure may remove the most of the free formaldehyde species and hemi-formals, when the hot pressing stage takes place [5].

Polymer composites are fabricated by incorporating fillers into a polymer matrix. The intent for the addition of fillers is to improve the physical, mechanical, chemical, and rheological properties of the composite [10]. Polymer composites have been used for various purposes, ranging from low-cost household products to high-performance industrial products. Despite their diverse properties, polymers have some drawbacks associated with their components, such as a low thermal stability, low conductivity, and low flame retardant properties. There are strong tendencies to resolve these issues, and one of the most effective solutions is the addition of filler in order to improve and modify the composite characteristics. Since there is a great interest in low-cost, sustainable, and environmentally friendly materials, biochar has received great interest for use as a filler, as an alternative to other non-environmentally and non-economically viable carbon fillers, such as carbon black, carbon nanotubes, and graphene [11]. Biochar is conventionally and widely used for soil amendment, or as an adsorbent for water treatment. Nevertheless, the need for transitioning to renewable materials has resulted in an expansion of biochar, for use as a filler for polymer composites [11,12]. Biochar, as a porous carbonaceous solid residue, can be obtained by the slow pyrolysis (carbonization) of biomass, at higher temperatures, ranging between T = 500 °C and T = 700 °C [13]. Similar to other carbon fillers, it is characterized by a greater thermal stability, there is a larger specific surface area, and it consists of several functional groups, such as hydroxyl, carboxyl, carbonyl, and others. The major aim of reinforcing biochar is to enhance the mechanical, thermal, and electrical conductivity properties of polymer composites [14]. Biochar can be used as a filler material in thermosets, thermoplastic, and ceramic polymer composites to improve their mechanical, thermal, and electrical properties [15]. Discussions related to properties and applications of biochar-based polymer composites were also provided by Bartoli et al. and Das et al. [16,17]. So, there are studies related to biochar as an effective filler on the properties of carbon fiber-reinforced bio-epoxy composites [18], biochar as a reinforcement filler for the styrene–butadiene rubber composites [19], the biochar reinforcing of PLA (polylactic acid) composite for fused deposition modelling [20], biochar as a sustainable and renewable additive for the production of poly(ε-caprolactone) composites [21], and many others. As for the usage of UF adhesives in composite materials, there are several important studies related to this topic, such as research described in the noted references [22,23,24]. These studies, performed by different authors, highlight the diverse approaches to improving the performance of UF adhesives in composite materials productions. The development of new materials based on renewable natural resources is a rapidly growing field of research due to the increasing demand for sustainable and eco-friendly products. This includes the use of bio-composites, based on UF resin and plant-derived (biomass) carbon materials, such as biochars. Therefore, the replacement of natural fiber with biochars to prepare bio-composites has attracted widespread attention recently. One of the breakthrough points represents the usage of hydrochar instead of bio-char. Namely, compared to slow pyrolysis, the hydrothermal carbonization (HTC) process is considered as a promising thermo-chemical conversion technology for the production of carbon-rich material (hydrochar), due to the elimination of the drying step. HTC is mostly considered economically viable for wet biomass feedstock [25]. Hydrothermal carbonization (HC) is usually carried out at temperatures ranging from T = 180 °C to T = 240 °C for t = 5–240 min, under sub-critical water pressures [26]. Hydrochar and biochar show different physicochemical properties, which significantly affect their potential applications. They reveal different chemical compositions and porous characteristics, as the biomass feedstock undergoes complex chemical reactions, such as degradation, dehydration, and re-polymerization in different reaction conditions (e.g., temperature, heating rate, time, and pressure). The process temperature has a significant impact on the physicochemical properties and the yield of biochar and hydrochar, as the reaction temperature influences which reaction mechanism dominates. Since hydrochar is produced via HTC in water media, the inorganic compositions of the biomass are demineralized, resulting in the reduction of ash content, and showing high affinity for both the polar and non-polar functional groups. Thus, compared to the biochar, which is produced through pyrolysis, hydrochar contains less ash content [27]. Hydrochar compared to biochar is slightly acidic, as the hydrochar contains more oxygenated functional groups. During HTC, some inorganics would be washed away in the water media, resulting in the acidic pH levels of hydrochar [28]. Generally, the literature [29] suggests that hydrochar is a valuable resource, and it is superior to biochar in certain ways, for example, it contains a reduced alkali and alkaline earth and heavy metal content, and possesses a higher heating value (HHV) compared to the biochar, produced at the same operating process temperature. Likewise, the hydrochar prepared by HTC represents an environment-friendly material, and thus, it does not generate any hazardous chemical or by-product, as other char’s products can. In the previous scientific literature, one can find papers related to the synthesis and characterization of UF eco-friendly composite material based on natural fibers [30], and the comparative study of bio-composites based on hydrochar and chitosan-modified urea–formaldehyde resins [6], but there are no detailed studies on the assessment of thermal stability properties, as well as an accurate pyrolysis (decomposition) reaction mechanism scheme of the synthesized urea–formaldehyde (UF)–hydrochar (HC) composite. Accordingly, UF bio-composite may have the potential to be a good adhesive material. Also, it should be emphasized that the use of the spent mushroom substrate (SMS) has proven to be a promising biomass precursor for hydrochar production as bio-filler, throughout hydrothermal carbonization (HTC), contributing to sustainable and economical waste management [31].

The main goal of this paper is to examine in detail the thermal stability properties of the synthesized UF resin bio-composite, where it was used as bio-filler, and the hydrochar (HC), produced from the hydrothermal carbonization (HTC) process of the spent mushroom substrate (SMS), as the starting biomass feedstock. The thermal stability characteristics were examined during the non-isothermal decomposition of the UF-HC composite at various heating rates, in an inert (Ar-argon) atmosphere. The inherent thermal properties were investigated under non-isothermal decomposition conditions for the studied bio-composite (based on the analysis of specific reaction temperatures, and characterization parameters such as the heat-resistance index (HRI), the comprehensive performance index (CPI), and integral procedure decomposition temperature (IPDT). For the kinetic analysis of the decomposition process, the model-free (isoconversional) methods and model-based method were used [32,33]. The first group of methods was used to identify and assess the degree of kinetic complexity of the investigated process. The second kinetic method was used to obtain the most reliable combination of different reaction models, which best describes the complex thermo-intensified process of bio-composites, but from a mechanistic point of view. The evaluation of the fit of the best model/method to the experimental data was carried out through rigorous statistical analysis (by using the adjusted R-squared (R2, a modified version of correlation coefficient, R) test, sum of squared deviations (S2), mean residual (MR), Student’s 95% confidence level test, and statistical F-test). The relationship between the kinetic parameters and reaction mechanisms of individual reaction components in polymer material, merged with general parameters of thermal stability, is also established. In addition to a detailed kinetic analysis of UF-HC decomposition (using the data from thermo-analytical measurements, such as simultaneous thermogravimetric analysis (TGA)–differential thermal analysis (DTA)), the physicochemical characterization of the synthesized bio-composite was carried out, using FTIR (Fourier transform infrared) spectroscopy (structural characterization) and SEM (scanning electron microscopy) (morphological characterization) techniques. Additionally, the XRD (X-ray Diffraction) analysis was used to investigate the structures of the tested sample, and for better understanding the synthesis from urea–formaldehyde (UF) resin and SMS-HTC hydrochar (sample label: UF-HC). To the best of the authors’ knowledge, this is the first study that evaluates inherent thermal stability properties during the UF-HC decomposition process, as well as the first investigation which gives a detailed insight into the reaction mechanism, that opens the channels for the production of important five-membered heterocyclic chemical compounds.

2. Materials and Methods

2.1. Materials

Urea supplied from Alkaloid (Skopje, North Macedonia) and 35% formaldehyde supplied from Unis (Goražde, Bosnia and Herzegovina) were used for the synthesis of UF resin. The chemicals used in this work, such as urea and formaldehyde, were of p.a. (pro analysis) purity, which means they meet high analytical standards and contain minimal impurities. This level of purity ensures consistent chemical reactivity, enhances the quality and performance of the final resin product, and reduces the likelihood of unwanted side reactions during synthesis procedure. Hydrochar was used as a natural bio-filler. The hydrochar was obtained from the biomass feedstock, i.e., the spent mushroom substrate (SMS) (received from the local mushroom production “Ekofungi”, located in Padinska Skela near Belgrade, the capital city) (the main ingredients of SMS are wheat straw, horse manure, and gypsum) by the hydrothermal carbonization process at temperature of T = 180 °C, under autogenous pressure, and with water medium in an autoclave reactor [31].

2.2. Synthesis of UF Bio-Composite

The synthesis of urea–formaldehyde resin with hydrochar (UF-HC) was performed according to the procedure described in previous work [34]. The molar ratio of formaldehyde (F) to urea (U) (F/U) in modified UF resin was 0.80. It has been confirmed [35] that the lower the ratio of F/U, the lower the Brinell hardness, pointing to the less rigid network structure in the low F/U mole ratio of UF resin. The average particle size of the UF-HC sample was 2.32 μm (the particle size measurements were conducted using SEM photographs analyzed with ImageJ software (Developer Michael Mateas and Andrew Stern) (version 1.54k adapted for Windows platforms and the last update has been done at November 11, 2024), and the average diameter was calculated by plotting a histogram in the Origin Pro 2017 software (Pro, 2017, version 9.4) (OriginLab Corporation, One Roundhouse Plaza, Suite 303 Northampton, MA 01060, USA) and Gaussian distribution function). The external appearance of the synthesized UF bio-composite (UF-HC) is shown in Figure 1.

Figure 1.

UF bio-composite (UF-HC) sample which was examined in this study.

2.3. Characterization Experimental Techniques for the Synthesized UF Bio-Composite

The FTIR (Fourier transform infrared) spectroscopy, XRD (X-ray diffraction) analysis, and SEM (scanning electron microscopy) technique were incorporated to characterize the UF bio-composite in this study. The knowledge of structural properties and surface morphology, are central for the proper use of the synthesized bio-composite material.

2.3.1. FTIR Analysis

The FTIR transmittance spectrum was obtained with a Thermo Nicolet 380 FT-IR (Fourier transform infra-red) spectrometer with Smart Orbit ATR (attenuated total reflectance) (Nicolet Instrument Corporation, Waltham, MA, USA). Imaging was performed in the wavenumber range from 4000 cm−1 to 400 cm−1, with the resolution of 4 cm−1 and 64 scans per spectrum.

2.3.2. XRD Analysis

The XRD measurement of the UF-HC powder sample was performed using a Rigaku MiniFlex600 (Rigaku Holdings Corporation, Tokyo, Japan) diffractometer with an X-ray lamp working on 40 kV/30 mA, and the radiation source Cu Kα with a wavelength of λ = 0.15418 nm. The diffraction data were recorded in a 2θ range from 2θ = 10° to 2θ = 80°, counting of 10° per minute, with 0.01° steps. The crystallinity index (CrI) was calculated based on the XRD peak height method, using the following equation [36]:

where I002 refers to the maximum intensity of the peak, corresponding to the plane having the Miller indices 002 (2θ ≈ 23°), while Iam represents the minimal intensity of the diffraction of the amorphous phase at 2θ ≈ 15°.

2.3.3. SEM Analysis

The morphology of the prepared UF-HC sample was examined by the Tescan FE-SEM Mira 3 XMU (TESCAN Orsay Holding, Brno, Czech Republic) scanning electron microscope at a 20 kV acceleration voltage. Prior to SEM recording, the sample was coated with a thin gold layer by using a sputter coater (Polaron SC503, Fisons Instruments, Ipswich, UK).

2.3.4. Simultaneous Thermogravimetric Analysis (TGA) and Differential Thermal Analysis (DTA) for Monitoring the Thermal Stability and Decomposition Process of UF Bio-Composite

Evaluations of the thermal stability and the non-isothermal decomposition process of the UF-HC sample were monitored by the simultaneous non-isothermal (dynamic) thermogravimetric analysis (TGA) and differential thermal analysis (DTA) techniques, using a Setaram Setsys Evolution 1750 Instrument (7 Rue de l’Oratoire, 69,300 Caluire-et-Cuire, France). The experimental specimens were heated from T = 30 °C to T = 950 °C, in a gas flow rate of φ = 30 cm3/min under the pure argon (Ar) gas, at the four different heating rates of β = 5.1, 10.2, 15.2, and 20.2 K/min. The average mass of the samples was about 5.0 ± 0.1 mg. Along with recorded thermogravimetry (TG) curves, the DTG (derivative thermogravimetry) curves at each heating rate used are also presented (DTG curve represents the first derivative of the TG curve, expressed in %/°C or %/min on the y-axis). Each measurement was repeated twice to check the reproducibility of a given measurement. It has been established that the deviation between replicates was below 0.1%.

2.4. Assessment of Thermal Stability of UF Bio-Composite

For the estimation of the thermo-chemical performances of the UF-HC sample in an inert (Ar) atmosphere, two characterization parameters were used. The first one represents the heat-resistance index (HRI) [37], and the second one represents a comprehensive performance index (CPI) [38]. The appropriate mathematical expressions for these indices are presented by Equations (2) and (3) [39], as follows:

where T5 and T30 represent the temperatures at the mass loss equaling to 5% and 30%, respectively. These values are determined from TG-curves. In the following, DTGp and DTGmean are the maximum mass loss rate (the maximum on the mass change rate curve, expressed in %/min) and the average mass loss rate (the average of the mass change rate curve, expressed in %/min), respectively (these values are determined from the differential thermo-analytical curves). Ti and Tp are the initial devolatilization temperature, and the temperature at the DTGp. Finally, ΔT1/2 represents the temperature range corresponding to DTG/DTGp = 0.5, i.e., the half-peak width range. A higher CPI value indicates a better thermo-chemical performance of the investigated polymer material (CPI is expressed in %2·min−2·°C−3). It should be emphasized that the initial temperature of devolatilization differs from the onset temperature (Tonset) in the actual process of interest. Namely, the onset temperature, Tonset, is the registered temperature on the thermo-analytical curve showing the first (origin) changes in the material under testing, in the pre-pyrolytic zone. The temperature Ti is connected only to the primary (main) pyrolytic (decomposition) zone, where the abundance of gaseous products comes to the fore. At the last place, the final (ending) temperature, Tf, is the temperature at which visible changes in the mass of the studied sample cease, after the completion of an entire decomposition process. Consequently, the thermal stability of UF bio-composite in respect to the heating rate applied, can be evaluated by various parameters including Tonset, Ti, Tp, and Tf temperatures, as well as the HRI value. Although, an efficacious and physically more meaningful parameter called the integral procedure decomposition temperature (IPDT) is employed to estimate the exact inherent thermal stability of the investigated material. The IPDT correlates the volatile parts of the polymer composites, and is expressed by following equation [40]:

where

In Equation (4), Ti and Tf have the meanings described above, while A* and K* represent the constants which can be calculated by Equations (5) and (6). In Equations (5) and (6), Aa and Ab are the areas above and below the TG-curve, respectively, while Ac is the complementary area of oblong rectangle, which was previously established [40].

It should be pointed out that one of the subjects of debate related to composite materials represents the process control, attached for efficiency optimization and accordingly eventual commercialization. The answer to this task should include the investigation of polymer composites, not only their structures, but also, and especially, deeper consideration of the temperature-dependent reaction mechanisms. The kinetic analysis of thermally stimulated heterogeneous processes (such as pyrolysis/decomposition) is capable of determining the kinetic parameters (the activation energy (Ea) and pre-exponential factor (A)) of such processes, in order to analyze the transition states, and finally, the process reaction mechanisms. Kinetic parameters are physically meaningful in controlling the process under the current consideration, as well as to predict the thermal stability of the materials, outside of the experimental range. However, the majority of the thermally activated heterogeneous processes are kinetically complex, i.e., they can consist of several elementary reaction steps. In the next section, some of the important advanced kinetic approaches are presented, for the kinetically complex decomposition process, which includes multi-step mechanisms, as for the studied UF resin hydrochar (HC)-reinforced material.

2.5. Methods for Determining the Kinetic Triplet of a Process and Its Optimization

The rate of the process in the condensed state is mainly a function of temperature and degree of conversion, and can be represented by Equation (7) as follows:

where dα/dt is the conversion rate of thermal decomposition, A is the pre-exponential factor (1/s), Ea is the apparent (effective) activation energy (J/mol), f(α) represents the reaction (kinetic) model or reaction mechanism function, R is the universal gas constant (8.314 J·(1/K)·(1/mol)), and T is the absolute temperature (in K). The degree of conversion (or the conversion) (α) can be obtained from the mass ratios at a given temperature or time, expressed as α = (mo − mT)/(mo − mf) (the dimensionless quantity), where mo is the initial mass, mT is the mass obtained at the estimated temperature (or time), and mf is the final mass at analyzed instant. Equation (7) represents the origin background of the first assumption of model-free (isoconversional) kinetic analysis [41], which was based on the dependence of Ea and A on the reaction progress (conversion, α). The second assumption is related to the fact that the reaction rate at a constant conversion value can be described as a function, which is only dependent on the temperature, T. Isoconversional kinetic methods are employed to examine the variation in the apparent activation energy with the degree of conversion, and therefore, the nature and complexity of the process. A condensed phase process is fairly approximated as the single-step, if the variation in its apparent activation energy with α is insubstantial; otherwise, the reaction is deemed as the following a complex reaction pathway. This kinetic approach represents a “model-free” approach, because Ea is calculated independently from the reaction model (f(α)), so for the calculation of Ea, no assumptions are made. Isoconversional kinetic methods can be isothermal/non-isothermal, differential/integral, and linear/non-linear (advanced) methods [42].

Taking the logarithm of Equation (7) gives the following linear differential isoconversional (model-free) method, known as the Friedman’s (FR) method [43]:

where Ea,α values can be determined by plotting ln(dα/dt)α,β against 1/Tα,β, at the constant values of α at considered heating rate β, which demands numerical differentiation. Furthermore, the reaction type (f(α)) is usually not required to calculate the Ea. However, it is not possible to determine the number of reaction steps, their contribution to the total effect, or the order in which they occur. In addition, when using derivative conversion data, this makes the differential isoconversional method prone to noise sensitivity and numerical instability, but modern software contain very effective filters for removing noise and background difficulties, thus obtaining reliable data and facilitating their interpretation.

Vyazovkin’s (VY) advanced model-free method [44] is a widely recommended integral isoconversional approach, for accurate determination of the apparent activation energies, Ea’s. In this method, the apparent activation energy is then obtained for each value of α at different temperatures, Ti(t), by minimizing the function, Φ(Ea), as follows:

where the current method uses the non-linear regression proposed by Senum and Yang, which makes it more accurate over a wider range of thermo-analytical data, and circumvents the inaccuracies related to the analytical approximation of the temperature integral [45]. However, its application remains limited as the mass transfer becomes limiting, at very high conversions (above α = 0.75/0.80 (=75%/80%)). In the above equations, Ea,α and Tα are the apparent activation energy and the temperature at conversion, α, respectively, obtained from the independent experimental runs i and j, and performed at the different heating rates, β’s. The integral is numerically evaluated by using the trapezoidal rule and the uniform grid spacing, which is continually decreased until a difference in the integral values is smaller than 10−6 between the consecutive interactions was obtained. This minimization can be carried out at the different values of α, to obtain the related apparent activation energy (Ea) [46].

The numerical optimization (NM) method represents the model-free approach, using non-linear least square optimization. The numerical method searches the optimal functions such as Ea(α) and logA(α) in order to obtain the best fit for the conversion (T, t). The numerical method is based on the results of the analytical differential Friedman’s method (it is often called the modified Friedman’s method (MFM)). Results of the Friedman’s isoconversional method (the curves Ea(α) and A(α)) are optimized numerically, in order to achieve a better fit between the experimental and simulated thermo-analytical curves. The function for optimization is the sum of the squares of deviations between the measured value, Conversion-experimental_(T), and the calculated value, Conversion-simulated_(T). This sum is calculated over all the curves and over all the points in each observed curve, as follows:

where α(T)icalc and α(T)iexp represent the calculated and experimental conversion values, for the considered i-th heating rate used. The numerical method searches the numerical values of Ea(α) and logA(α), which minimize the function, Ω. Internally, each point of curves Ea(α) and A(α) is the subject of the small changes, and for each change, the sum of squares of residuals is checked: is it better or worse than before? If better, then the new point in Ea(α) or A(α) is saved. The iterations are repeated until no numerical improvements happen. The advantage of the numerical optimization method is reflected in the fact that it can be applied to the multiple-step reactions with the evaluation of each reaction point at various heating rates.

For all the presented conversion-dependent methods, Kinetics Neo (The NETZSCH Group Holding, Selb, Germany) computational kinetics software (Version 2.7.0.11; Build date: 21 January 2024) was used. This software, for the application of the Friedman (FR) isoconversional method, instead of the “ln” scale, uses “log” scale data, where software normally operates. Considering all the model-free methods, the kinetic parameters are determined using the points at the same conversion, between α = 0.01 (α = 1%) and α = 0.99 (α = 99%), with the conversion step increment of Δα = 0.01, from the measurements at four different heating rates (5.1, 10.2, 15.2, and 20.2 K/min). It should be noted that for the calculation of the pre-exponential factor, this software uses one of two possible approaches to find a logarithm of the pre-exponential factor (logA): (a) logA can be estimated from the intercept of the Equation (8) (FR method) and the following mathematical relations for other two isoconversional methods, on the similar principle as for the determination of Ea, for known or assumed f(α) (usually first-order kinetics), and (b) logA can be found from the application of the kinetic compensation effect (KCE) [47]. Software uses the first approach, assuming the first-order reactions, in the form of the f(α) function, as follows: f(α) = (1 − α).

Model-based kinetic analysis represents the procedure for complex chemical processes, consisting of individual reaction steps, where each step can be individually connected to another reaction step (consecutive, competitive, independent, etc.), in order to build a kinetic model of the complex process under study. The model-based kinetic approach describes the reaction rate of multi-step chemical reactions by the system (or the set) of kinetic equations, where each reaction step has its own kinetic equation and own kinetic triplet, containing the activation energy (E), the pre-exponential factor (A), as well as the reaction type function (f(α)), as shown in Table 1. Kinetics Neo uses the multivariate non-linear regression method (MVarNLRM) to resolve concentration equations in a multi-step process.

Table 1.

Kinetic model functions (in differential form of analytical kinetic functions, f(α)) used in this work, for computational procedure in the model-based analysis [48].

Namely, the model-based approach allows the determination of the reaction mechanism by the minimization of differences between experimental and calculated values. Accordingly, the function f(α) is used to describe the rate limiting the mechanistic reaction, which is chosen from a row of tabulated functions (Table 1), based on the data obtained from a preliminary best-selected model-free estimation. Therefore, the result of the model-based kinetic analysis provides information about the reaction mechanism, the form of equations for the elementary reaction steps, and the values of kinetic triplets [i.e., E, A, and f(α)].

In this paper, a complete model-based kinetic analysis was carried out using Kinetics Neo software (The NETZSCH Group Holding, Selb, Germany) (Version 2.7.0.11; Build date: 21 January 2024), and it was based on models that include several process steps, in which the individual steps can be linked as independent, parallel, competing, etc. For each of the models selected, the reaction type for each step has some unknown kinetic parameters, such as the activation energy (E), the pre-exponential factor (A), and the reaction order, as well as the contribution of each step to the entire process. All the unknown parameters can be found from the fit of measured data, with simulated thermo-analytical curves. The statistical comparison of the fit for different models allows one to select an appropriate model, with a corresponding set of kinetic parameters [49].

Related to the kinetic parameters estimation, the kinetic compensation shows a strong positive correlation between the effective activation energy (Ea) and the pre-exponential factor (A), for a reaction between the same reactants under similar experimental conditions, or similar reactants under the same conditions, even though these parameters are supposed to be independent [50]. According to the insightful papers [51,52], the kinetic compensation effect (KCE) was based on the mathematical source of the linear relationship, as follows:

where a and b are the constant coefficients, for a series of related rate processes. Namely, the KCE means that the alteration in Ea values will prompt a complementary compensating response in A, which can also be used to test the experimental results. The coefficients a and b represent the intercept and the slope of the regression line, equal to logkiso = a (kiso = 10a) and 1/RTiso = b, where Tiso = 1/R·b. The kiso and Tiso are the iso-kinetic rate constant and iso-kinetic temperature, respectively, where at the temperature Tiso, all the chemical compounds studied are characterized by the same rate constant, equal to the kiso. The difference in decomposition mode for solid-state reactions is the most common cause for the appearance of KCE. KCE in fact provides a possible means to predict the effects of experimental factors on kinetic parameters. According to this relationship, for any change in the experimental Ea, arising from variation in experimental conditions, a corresponding change in the pre-exponential factor also occurs; thus, we could correlate different parameters under different experimental conditions. The true KCE can prove to be useful in chemical research, for identifying the governing reaction mechanism in the process under investigation.

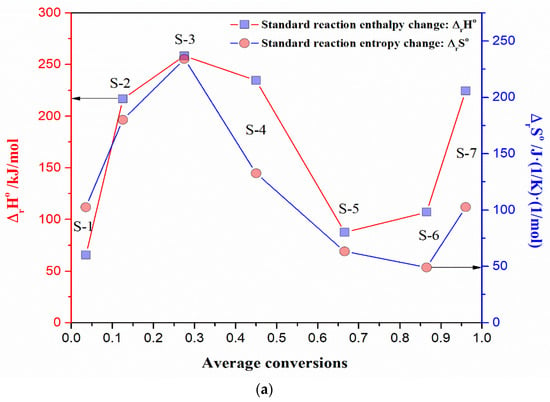

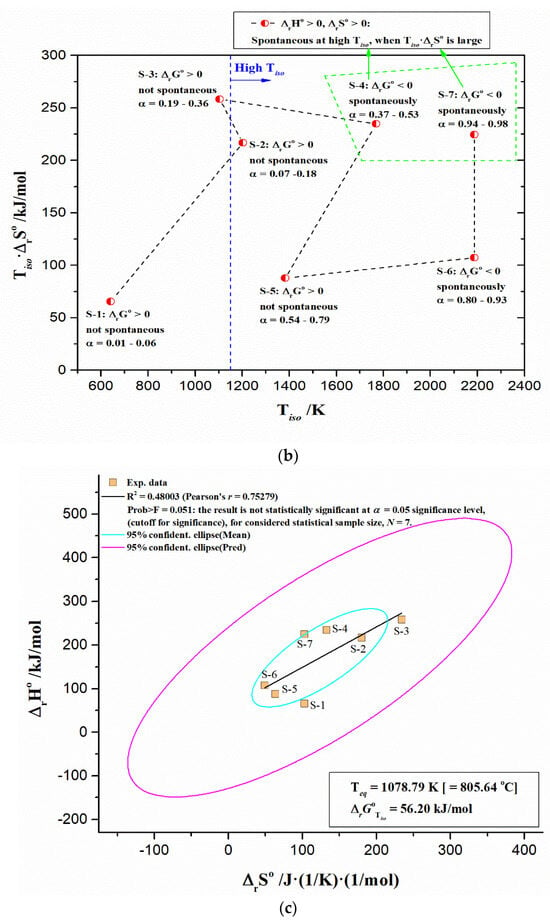

The linear correlation between logA and Ea can be expressed through Equation (13), including rigorous physicochemical meaning related to intrinsic kinetic parameters (Aint, Ea,int) and thermodynamic parameters (ΔrH°—the change of the standard reaction enthalpy (J/mol), and ΔrS°—the change of the standard reaction entropy (J(K·mol)−1)), as follows:

The KCE is often correlated with the concept of the isokinetic point (IKP). The IKP refers to a common point of intersection of the Arrhenius lines. Comparing with Equation (12), it can be observed that for all rate processes, whose kinetic parameters are in the parameter set which satisfies Equation (12), the corresponding Arrhenius plots have a common point of intersection [logkiso, Tiso−1], so the Equation (12) can be re-written as follows:

In the case of the isoconversional methods, the IKP that appeared at different conversion (α) values varied as the reaction progresses. So, according to Equation (13), the quantity Tiso can be expressed as follows:

The following equation shows the linear relationship for thermodynamic equilibrium, as follows:

where the quantity B has the dimension of temperature (in Kelvins, K), and it is often defined as iso-equilibrium temperature (Teq) and the corresponding behavior is called the iso-kinetic or iso-equilibrium effect, because it seems that at the temperature Teq, all the reactions in the series should have the same rate (or equilibrium) constant [53]. The intercept in the linear correlation between ΔrH° and ΔrS°, expressed through Equation (16), represents the standard Gibbs free energy reaction change, at a specific iso-equilibrium temperature. When T = Teq, ΔrG° becomes the same for all reactants, Teq represents the temperature at which ΔrH° and ΔrS° are completely compensated. It is an axiom of extra-thermodynamic relationships, that all sets of reactions which exhibit enthalpy-entropy compensation are governed by a single mechanism, and all related reactions, which have the same compensation temperature, take place via the same reaction mechanism [54]. As for kinetic compensation, when thermodynamic compensation occurs, the mechanism is the same for the entire range of the experimental variables, which are covered substantially.

3. Results and Discussion

3.1. FTIR Results

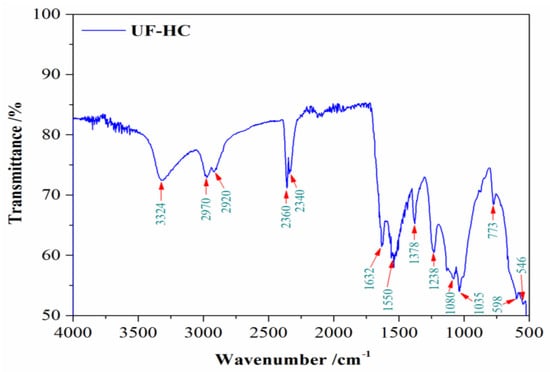

FTIR spectroscopy in the attenuated total reflectance (ATR) mode represents a non-destructive and essential characterization technique to elucidate the structure of tested specimen at molecular scale. Thus, this technique permits the determination of components or groups of atoms that absorb in infrared at specific frequencies, permitting the identification of the molecular structure. The FTIR-ATR spectrum of UF-HC is shown in Figure 2.

Figure 2.

FTIR-ATR spectrum of powdered UF bio-composite (UF-HC), with the marked specific vibrational bands (expressed in cm−1).

The resulting FTIR-ATR spectrum is characteristic for the synthesized bio-composite sample with clearly separated regions related to each of the phases, counting the polymer matrix and the biological filler from derived hydrochar (HC). Namely, the broad band situated at 3324 cm−1 can be assigned to the strong N–H stretching of secondary amides [55,56]. Urea contains primary amines, which indicates that the urea might be fully reacted during the resin preparation and curing process, so this band reflects the characteristic functional group of the UF resin. The vibrational peaks at 1632 cm−1 and 1550 cm−1 can be attributed to the stretching of carbonyl group (C=O), and C–N stretching of secondary amines, respectively [55,56]. The vibrational band, which appears at the wavenumber position of 1378 cm−1, is a characteristic band attached to –CH2OH, illustrating a typical reaction between urea (U) and formaldehyde (F) [55]. The intense peak at 1238 cm−1 can be attributed to the stretching of C–N and N–H of tertiary amines [55,57]. The emphasized peak at 1035 cm−1 is assigned to the methylene bridge (–NCH2N–) [55,58].

The peak positioned at 1080 cm−1 belongs to the aliphatic ethers (C–O deformations) [59,60]. The vibrational band at 2920 cm−1 is attributed to the asymmetric stretching vibrations ν(C–H) in the methylene (–CH2) group. The specific vibrational band located at 1035 cm−1 belongs to the C–O–C band, which represents O-containing functional groups of hydrochar (HC) [61]. The weak peak at 773 cm−1 belonged to the aromatic C–H out-of-plane deformation, probably due to the presence of lignin residue in HC [61,62]. The absorbance peak located at 2970 cm−1 represents CHn stretching vibrations, pointing to aliphatic (al.) and aromatics (ar.) [62,63]. The two vibrational peaks at positions of wavenumbers of 2340 cm−1 and 2360 cm−1 can be attributed to –OH stretch from the strong H-bonded-COOH [64]. These peaks in the indicated wavenumbers range (2340–2360 cm−1) could also be assigned to the CO2 that was absorbed during the recording of the FTIR spectrum [65]. The remaining two identified vibrational bands originate from impurities present in the UF-HC sample. The peak located at 546 cm−1 is attributed to coupling between the O–Si–O bending vibration and the K–O stretching vibration [66], while the peak located at 598 cm−1 (Figure 2) can be assigned to Si–O–Si bending vibration in depolymerized structural units of quartz [67]. All the obtained vibrational bands on the measured FTIR spectrum are autonomous and reflect an excellent agreement with the effective transfer of UF polymer matrix, and the organic filler, into the newly synthesized product—UF-HC. The FTIR results are also in very good agreement with studies reported earlier [68,69,70,71]. It should be emphasized that identified impurity in the form of quartz originates from biomass source in SMS, and it is closely related to its constituents, primarily wheat straw and gypsum [72,73].

3.2. XRD Results

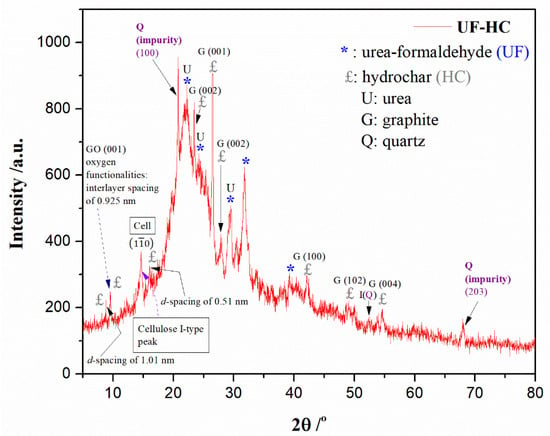

X-ray diffraction (XRD) is an important and widely used material characterization instrumental technique. Consequently, this technique enables obtaining information about the degree of crystallinity for semi-crystalline, amorphous polymeric, and composite materials. In that context, XRD is a very useful technique for the identification and confirmation of the preparation of the urea–formaldehyde (UF) resin/hydrochar (HC) composite material (UF-HC). Figure 3 shows the XRD pattern for the synthesized UF bio-composite (UF-HC sample).

Figure 3.

The XRD diffractogram (XRD pattern) for UF-HC sample (Abbreviation: Cell ≡ cellulose).

The obtained XRD profile clearly suggests the existence of crystalline phases and amorphous regions in the UF-HC composite material. So, the sharp peaks at 2θ = 22.2°, and 24.3° and wide peak at 2θ = 31.8° are typical X-ray diffraction peaks of urea–formaldehyde (UF) [74]. The broader peak located at 2θ~22° is the proof of the presence of an amorphous area in the material, but the shape of the XRD peak of UF indicates increased crystallinity (it prevented the formation of the cross-linked network after curing; decreased F/U molar ratio (~0.80)).

One additional XRD peak of UF with a lower intensity appears around 2θ~40° (Figure 3), but no new peaks at higher Bragg’s angles at 2θ ≈ 47° and 57°, which would then be attributed to interactions between UF and SiO2, resulting in the formation of hydrogen bonds between UF and silanol groups of SiO2 [57]. However, as designated with I(Q) in Figure 3, one smaller, sharper peak at a position around 2θ = 52° is identified, which may indicate a possible interpenetration of SiO2 into the UF resin [57]. In the XRD diffractogram, one sharper diffraction peak is also observable, located at 2θ = 29.8°, belonging to the (003) crystal plane of urea [75].

It should be noted that UF resin with a low F/U molar ratio is less branched and more linear in structure, compared to the UF resin with a high F/U molar ratio, and this could be due to hydrogen bonds between the linear molecules thereby keeping the ordered arrangements (see discussion above). It was found [76] that UF resin with a lower F/U molar ratio exhibits two sharper peaks with greater intensities at positions of 2θ = 22.2° and 2θ = 24.3°, respectively (Figure 3). The two additional peaks that appeared at about 2θ~31° and 2θ~40° indicate supplementary crystalline regions, for the used UF resin. Therefore, in our considered case, UF resin with a lower F/U molar ratio (~0.80) shows a more crystalline structure (Figure 3) [76,77]. Within Bragg’s angles region of 2θ = 20–25°, a very sharp quartz peak appears at 2θ = 20.8° with crystal plane (100) (Figure 3) [78,79], which represents a typical impurity content present in the UF-HC sample. Also, one additional quartz peak (Q (203) plane) [79,80] appears at the position of 2θ = 68° (Figure 3).

From the obtained XRD pattern of the UF-HC sample, a graphite sharp peak can be observed at 2θ = 26.5° (Figure 3), which can be attributed to hexagonal interlayer spacing (001) [81]. In the 2θ region, between 2θ = 41° and 2θ = 47°, reflection (100) was identified at around 2θ = 43° (Figure 3), suggesting the existence of randomly stacked graphene sheets [81]. This also indicates that in the current amorphous domain, “non-graphitic” carbon may appear [82]. In addition, graphite reflection (102) with a weaker intensity at around 2θ = 50° [83] is also observed (d-spacing is 0.18 nm) (Figure 3). In addition, the reference peak for the graphite (004) at 2θ = 54.6° [84] was also identified. From the presented XRD profile, the diffraction peaks at 2θ = 23.5° and at around 2θ = 43° can be attached to the disordered graphitic (002) and (100) planes, respectively [85]. It should be noted that the above-indicated peak at 26.5° (interlayer distance of 0.339 nm) is the referent point that probably originates from graphene layers (preliminary already hinted—see above discussion), which makes up the carbon structure of HC in the synthesized UF-HC composite. The proposed structure is indeed supported by the appearance of the diffraction peak at 2θ = 27.8° (Figure 3).

However, at the shorter 2θ angles, there is one sharp narrow peak at about 2θ = 17°, corresponding to the d-spacing of 0.51 nm, and one even sharper, but very narrow peak at 2θ~8.8°, corresponding to the d-spacing of 1.01 nm [86] (Figure 3). This indicates that the most important spacings are not randomly determined, but may be due to the “linker” between lattices. So, the occurrence of these peaks suggest a polycrystalline sample, and also a lot of minor variation, potentially resulting in similar, but distinct structures. This is supported by the appearance of a very narrow and sharp single peak at 2θ = 9.5° (Figure 3), which corresponds to “oxidized” graphite, i.e., graphene oxide (GO) (graphene oxide (GO) basal plane (001)—Figure 3), and refers to the interlayer spacing of 0.925 nm [87,88]. Therefore, the synthesized UF-HC composite material contains lattices with an oxidized face, which increases the lattice spacing to account for oxygen-containing groups. Considering these results with ones obtained from FTIR measurement (Figure 2), there is excellent agreement among the results so far.

In the continuation of this discussion, it is necessary to pay special attention to the appearance of a pronounced diffraction peak at 2θ = 14.9° (Figure 3), which represents a characteristic peak for residual cellulosic material, i.e., cellulose I-type peak, and this can be referred to cellulose I crystallographic plane () [36]. This diffraction peak is evidence of the presence of a cellulose I crystalline structure produced from hydrochar (HC). Namely, this is proof that speaks of the retention of cellulose’s own properties, and the incomplete carbonization of biomass feedstock (SMS), under mild hydrothermal conditions. Under the actual hydrothermal conditions for the thermo-chemical treatment of SMS to produce hydrochar, hemicelluloses component degrades much faster than cellulose, while lignin behavior is more inert, but its decomposition kinetics are strongly dependent on the set of conditions, during the hydrothermal processing of SMS (lignin component is fragmented and dissolves with an increase in reaction time). Obviously, for the hydrothermal carbonization process implemented here, the mentioned components in the biomass used in this study have less tight bonds than the cellulose (Cell) (Figure 3).

From XRD data, the crystallinity index (CrI) was calculated using the Segal equation, as previously established. The obtained value of crystallinity index was CrI = 54.95%. One of the reasons for the rather high CrI lies in a more progressive removal of amorphous non-cellulosic materials (hemicelluloses and lignin), reducing the amorphous contribution, and increasing the crystallinity of investigated sample. This is a good reason for the required feature, for using SMS-HC as bio-filler, in the development of such bio-composites. On the other hand, the crystalline region has a higher chemical stability than that of the non-crystalline region in the UF bio-composite. The increase in crystalline regions enhances the water resistance of the synthesized material. Correlated with this fact, it was also reported [89] that the crystallinity of UF resin may increase with the treatment of hydrolysis [34], considering the greater decomposition of amorphous regions. Obviously, for the manufactured UF bio-composite, the elevating of CrI implies that the percentage of amorphous regions in the UF-HC sample decreased (Figure 3). At the same time, it must be borne in mind that UF resin with a lower F/U molar ratio contains more linear molecules forming crystal regions by hydrogen bonds, and thus augmentative crystallinity (see also the discussion above, as well as the general appearance of the XRD spectrum).

3.3. SEM Results

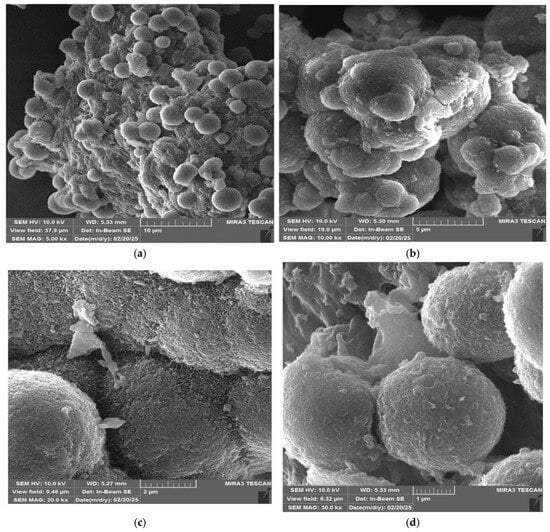

Figure 4 shows the morphological structure of the UF-HC sample, represented in a form of SEM images at different magnification scales: (a) 5.00 kx, (b) 10.00 kx, (c) 20.0 kx, and (d) 30.0 kx, respectively. The synthesized UF-HC specimen is characterized by a bio-polymer–UF resin microspheres structure, which retains its original morphology and uniform particle size (Figure 4a). The SEM image at a low magnification (Figure 4a) shows that UF-HC had a more spherical and rounded shape, with a small difference in the particle size.

Figure 4.

Scanning electron microscopy (SEM) images of UF-HC composite, at different magnifications: (a) 5.00 kx, (b) 10.00 kx, (c) 20.0 kx, and (d) 30.0 kx, respectively.

The SEM image under the higher resolution (Figure 4b) shows that the synthesized sample still has a spherical, plump, and relatively uniform particle size distribution, but they aggregated more severely. However, the SEM images under high magnifications, such as Figure 4c,d, clearly show that the particle size is relatively small (the average diameter ranges between 2.0 µm and 2.5 µm), whereby the degree of agglomeration of microcapsules and their strength largely depends on the used F/U ratio. Scanning electron microscopy (SEM) (Figure 4d) showed that the microcapsule walls possessed a rough surface. Namely, the capsule roughness (Figure 4c,d) has been attributed to the precipitation of polymerized urea–formaldehyde from the water phase and its deposition onto the capsule wall during in situ polymerization [34]. This shell roughness is desirable as it promotes the ‘capsule’ adhesion to the polymer matrix, and provides a greater possibility for microcapsule rupture in the event of the propagation of cracks [90]. It should be noted that the particle sizes and structure of the microspheres can be changed with temperature. Namely, with the increase in the temperature [34], the particle size of produced microsphere can be significantly reduced, while the surface can change from a porous surface structure to a dense surface structure (Figure 4c). It was found that the standard deviation of microsphere size decreases continuously with an increase in the temperature, indicating that the distribution of microspheres tends to be more uniform, and this is attributed to the decomposition of urea at higher temperatures [91]. The increase in the temperature results in more decomposition of urea, leading to the decrease in the urea-to-formaldehyde ratio. So, such a decrease produces smaller-sized UF-HC microspheres.

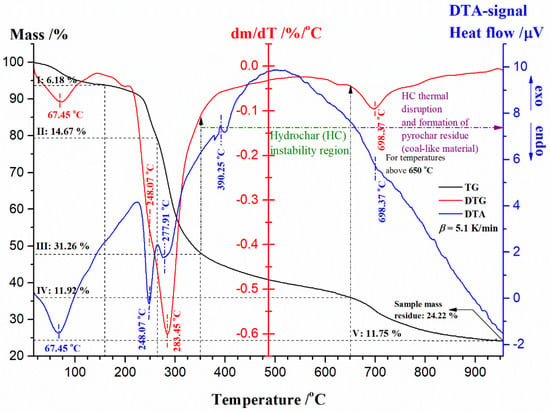

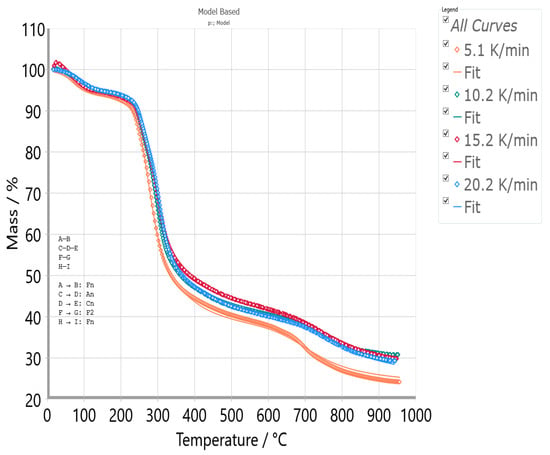

3.4. TG-DTG-DTA Measurements of UF-HC Composite Decomposition

Figure 5 shows a simultaneous display of thermogravimetric (TG—expressed as % vs. °C), derivative thermogravimetry (DTG—expressed as %/°C vs. °C), and the differential thermal analysis (DTA—expressed as heat flow/μV vs. °C) curves, at the heating rate of β = 5.1 K/min, for the non-isothermal decomposition of UF-HC, in an inert (Ar) atmosphere. From the results presented in Figure 5, the first (I) sample mass loss (~6.18% with max. T at 67.45 °C, and ranges between ambient temperature and 160 °C) corresponds to the evaporation of water, formaldehyde releases, then scission weak linkages like hydrogen bonding, and particularly to the transformation of methyl ether bridges into methylene bridges [92,93], leading to formaldehyde emission. The removal of water results from a polycondensation reaction between hydroxymethyl and amine groups in a resin structure [93]. This stage is characterized by an endothermic effect. After this, the second (II) (~14.67%) and the third stages (III) (~31.26%) occur, together making the largest loss in the mass of the sample (the total ~45.93%) (Figure 5), and represent the rapid decomposition region of UF-HC. Namely, the second (II) stage is characterized by the appearance of a “shoulder” on the DTG curve, and a peak appears on the correspondent DTA curve, at the same temperature value of 248.07 °C (Figure 5). Next, the third (III) stage is reflected in the main peak on the DTG curve and DTA peak, with temperature differences at a maximum of 5.54 °C (Figure 5). Both of these stages are characterized by endothermic events, and actually determine two temperature points of UF resin decomposition in UF-HC sample, and they are 248.07 °C and 283.45 °C (considering DTG-curve) (both decomposition stages cover a temperature range from approx. 200 °C up to 350 °C). Based on the external appearance of the DTG-curve, with the “shoulder” peak manifestation, it is likely that these decomposition process steps of UF-HC have overlapping temperature behavior (it can be assumed that the temperature region, where the “shoulder” peak and the main DTG peak appears, can be directed towards the rupture of the methylene ether link related to UF resin structure—this is the main reaction area in which resin destruction takes place, where initial devolatilization temperature is transferred to the higher temperatures; therefore, it may follow that the lower quality loss causes good thermal stability (the latter largely depends on the UF synthesis procedure)).

Figure 5.

Simultaneous TG-DTG-DTA curves of the non-isothermal thermal decomposition process of UF-HC composite at β = 5.1 K/min. The corresponding stages in the mass loss of the sample are also marked, as well as the positions of the specific temperature values, which characterize the entire process. In the same figure, the sample mass residue was also indicated.

It can be observed that the main DTG peak takes place at higher temperatures, closer to the T ~ 300 °C, which may suggest that the dominant reaction here could be the conversion of methyl ether functional groups into methylene functional groups, where a temperature shift occurs at higher temperatures. So, it appears to be a possible consequence of interactions between the cellulose residue and UF [92]. This effect was transferred into another decomposition stage of UF-HC (stage IV, with sample mass loss of ~11.92%, and which occurs in temperature range from 380 °C to 650 °C), where a smaller and sharper exothermic peak takes place at 390.25 °C (Figure 5), which enters into the HC instability reaction region. This may encompass the cross-linking reactions, which are responsible for char-residue formation (the formation of cross-linking structures); so, the percentage of carbon (C) increases (carbon-rich residue) [94]. Within stage IV, the decomposition of lignin and cellulosic-derived compounds can also be performed. It should be noted that in the current stage, a “secondary” char product may be produced, which arises from sugar-derived compounds dissolution in the liquid phase (such as HMF (5-hydroxymethylfurfural)) by the condensation and re-polymerization reactions [95]. In the considered temperature zone (between 380 °C to 650 °C), we can also expect decomposition reactions of oxygen-containing functional groups, such as carboxyl (–COOH) and carbonyl (C=O) groups on the surface of the HC constituent in the UF-HC sample, with CO2 emissions. A further increase in temperature leads to the final process stage (stage V, with sample mass loss of ~11.75%, that takes place for temperatures above T = 650 °C), which is characterized by a broader DTG peak and the endothermic effect at ~698.37 °C (Figure 5). This stage can be attributed to the decomposition of oxidized sp2 structures in the graphitic core of the UF-HC sample (with an additional formation of the pyrochar residue). Figure 6 shows DTG curves (expressed as the mass change rate curves in the %/min units) of the thermal decomposition process of the UF-HC sample, at different heating rates (β = 5.1, 10.2, 15.2, and 20.2 K/min) in an inert (Ar) reaction atmosphere.

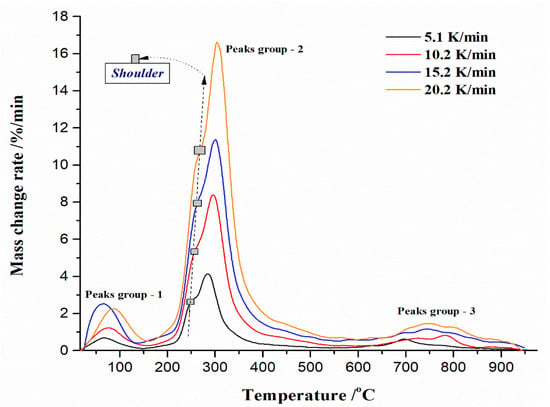

Figure 6.

DTG curves (mass change rate (%/min) vs. temperature (°C)) of the non-isothermal thermal decomposition process of the UF-HC sample, at the different heating rates (β = 5.1, 10.2, 15.2, and 20.2 K/min). Corresponding groups of reaction peaks, as well as “shoulder” peaks, are also marked in the same figure (position of “shoulder” peak at different heating rates is marked by gray square).

The first group of peaks (“Peaks group-1” (Figure 6)) extends over the temperature range of ΔT1 = RM (the room temperature)—approx. 200 °C, and these peaks can be attached to methylene ether bridges transformation into methylene bridges, and branching and cross-linking reactions. Above 200 °C (the second group of peaks—“Peaks group-2”—(Figure 6)), the decomposition process probably involves C–N bond scission (corresponds to position of “shoulder” at about T ≈ 250 °C). However, with a further increase in the process temperature, competition between chain scission and cyclization may take place, forming stable chemical structure products, at about T ≈ 300 °C (the main DTG peak, within “Peaks group-2”) [96]. These products may suffer further temperature-intensified fragmentation above 300 °C, which would correspond to the descending part of the DTG curve (on the right wing of DTG curves at various heating rates) in the temperature range between 350 °C and 425 °C. Fragmentation products can be accumulated in the next stage of decomposition, where oxygen functionalities degrade (with temperature range between approx. 430 °C and 600 °C) (see the above discussion). With a further rise in the temperature, above 600 °C, the third group of peaks (“Peaks group-3”—(Figure 6)) takes place, and they are attributed to the decomposition of sp2 carbon and other organic-like structures, in the core of UF-HC. Considering actual reaction zones, the abundance of volatile products, such as H2O, CO2, CO, HCNO, HCN, and NH3 gases takes place [97].

3.5. Inherent Thermal Stability Analysis Estimated from Thermo-Analytical Measurements

Dynamic TG-DTG measurements were applied in this study for the assessment of thermal stability, for the UF-HC composite, regarding the applied heating rates (β = 5.1, 10.2, 15.2, and 20.2 K/min). For this purpose, the following values of characteristic parameters important for this analysis were derived: Tonset temperature as the basic thermal stability parameter, the “shoulder” peak temperature, Tsh, the peak (maximum) temperature, Tp, the initial devolatilization temperature (Ti), the final decomposition temperature (Tf), T5, T10, T30, and T50 which correspond to temperatures of 5%, 10%, 30%, and 50% of the mass losses on TG-curves, at different heating rates (see Figure S1, Supplementary Material), respectively. The values of the maximum mass change rate (Rmax) at the Tp’s were also determined. Likewise, the values of the comprehensive performance index (CPI), the heat-resistance index (HRI), and the integral procedure decomposition temperature (IPDT) were also established. The values of the obtained parameters for the UF-HC composite are listed in Table 2.

Table 2.

Thermal stability characteristic parameters for UF-HC composite, determined at different heating rates (β = 5.1, 10.2, 15.2, and 20.2 K/min).

From the results presented in Table 2, it can be observed that all the specific reaction temperatures increase with an increasing heating rate, moving towards higher values.

As the heating rate increases, the maximum (peak) decomposition temperature (Tp) is shifted from 279.49 °C at 5.1 K/min to 303.91 °C at 20.2 K/min (the T difference amounts to ~24.42 °C), while the maximum decomposition rate (Rmax) also increased from 3.420%/min at 5.1 K/min to 16.616%/min at 20.2 K/min. The thermo-analytical curves are shifted to higher temperatures, due to the heat transfer enlarging with increasing the heating rate. Also, both Tonset and Ti increase with an increasing heating rate, so, transformations related to these temperatures are dependent on the heating rate used, whereby a symmetric shift in their values with β’s takes place. The situation is similar in the case of temperatures T5, T10, T30, and T50. The heating rates do not affect the change in the shape of both the TG (Figure S1) and DTG curves (Figure 6), but the increase in β-value leads to their movement into higher temperature regions. The reason for this shift is probably related to differences in the heat transfer and kinetic rates, indicating that the decomposition rate of reaction products may slow down as the heating rate increases. When the heating rate increases, the heat transfer resistance may cause a larger temperature difference between the heater and the sample, thus delaying UF-HC decomposition. Furthermore, at higher heating rates, the time required to reach the decomposition temperature becomes shorter, and then the temperature difference between the tested sample inside and outside may turn to be larger as well, subsequently causing thermal lagging that may cause a delay in the thermal decomposition. This can be observed from Figure 6, since the main DTG peak becomes stronger and wider with an increasing heating rate from 5.1 K/min to 20.2 K/min, and these facts are confirmed by both promoted Tsh and Tp temperatures, which are shown in Table 2. The Tf temperatures at all heating rates are positioned at high values, pushing the process towards the high-temperature zone (Tf rises with elevating the heating rate, β), where HC significantly affects the thermal stability of the sample, in which a larger amount of heat energy is required to break down the sp2 hybridized carbon atoms. Considering Tonset values, they tend to go up when the heating rate increases. These results may suggest that when the working temperature approaches Tonset, a significant mass loss of the sample may occur.

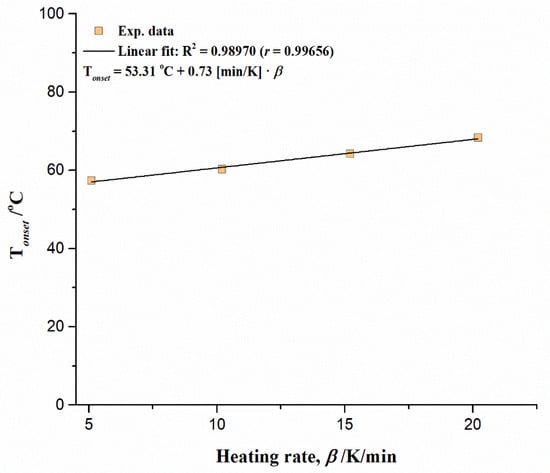

The influence of heating rate (β) on Tonset, in the case of the non-isothermal decomposition of UF-HC, is graphically presented in Figure 7. It is clear that temperature Tonset has an increase trend in a linear fashion, as the heating rate increases. Other characteristic temperatures (Tp, T5, T10, T30, and T50) are also subject to the same law, regarding the influence of the heating rate on their behavior (Figure S2, Supplementary Material). The obtained intercept values (Figure 7 and Figure S2) correspond to the limiting case (through extrapolation procedure), when β → 0 K/min. So, the dependence of these specific temperatures on the heating rate (β) is quantitatively expressed through established series of linear equations (Figure 7 and Figure S2), where diversity in linear regression coefficients can be observed. Since the value of Tsh also shifts towards higher temperatures along with Tp, it is obvious that a strong influence exists of the heating rate on the thermal decomposition process of UF-HC, where the parallel reactions may take place. The predominance of one of these reactions can be determined by the value of the selected heating rate.

Figure 7.

The influence of heating rate (β) on onset temperature (Tonset), for the non-isothermal thermal decomposition process of UF-HC composite.

As for the parameter CPI (the comprehensive performance index), directly abstracted from TG and DTG results (which primarily refers to the stage III; Figure 5), it shows an increase in the value, with an increase in heating rates (Table 2), where CPI is significantly improved with an increasing heating rate. Consequently, a better thermo-chemical performance of UF-HC is achieved at higher heating rates (larger CPI means a better suitability of the process).

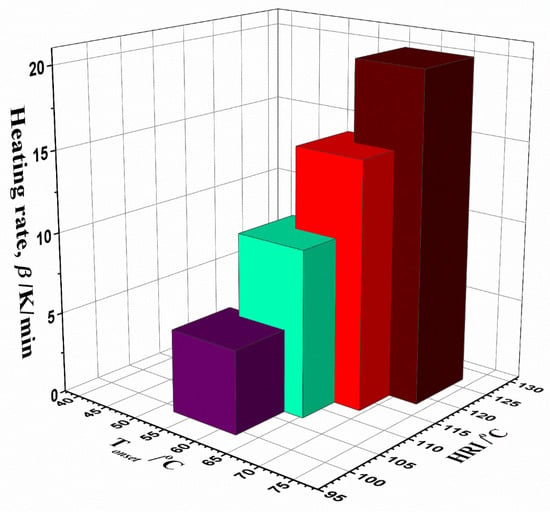

Namely, the rise in both values, Rmax and CPI, at high heating rates (Table 2), improves the decomposition performance of UF-HC. Considering HRI, the presented HRI values are almost twice as high as those for Tonset, and the largest jump in the HRI value is observed, when moving from 5.1 K/min to 10.2 K/min (for Δ(HRI) = 7.88 °C), while the ultimate change amounts to Δu(HRI) = 18.88 °C (from 5.1 K/min to 20.2 K/min) (Table 2). So, there is a large impact of heating rate on the thermal resistance of UF-HC. The composite material already shows a higher thermal resistance at lower heating rates, and this resistance increases more and more as the heating rate increases (enhancement of HRI) (Table 2). These results are consistent with the temperature hysteresis observed in the thermo-analytical results. The influence of heating rate on both parameters, observing simultaneous changes in the Tonset–HRI plane, can be seen in the 3D Tonset–HRI–β body feature dependency shown in Figure 8. The obtained results show that the thermal characteristics of the UF-HC composite are incomparably better than in the case of pure UF conventional resin (polymer matrix) [98]. In addition, as the heating rate increases, the IPDT increases more and more, reaching the highest value at β = 20.2 K/min (Table 2).

Figure 8.

3D Tonset–HRI–β body feature dependency, for the non-isothermal decomposition process of UF-HF composite.

The values of integral procedure decomposition temperature (IPDT) regarding the heating rate are located within the high-temperature regions. Taking these facts into account, it was shown that the synthesized composite exhibits a greater thermal stability (under similar experimental conditions) than the epoxy resin [40], urea–formaldehyde cellulose (UFC) composite [92], and pristine polyurethane (PU) retardant, as well as the polyurethane (PU)/hyper-branched nitrogen–phosphorous–silicon (PU/HBNPSi) hybrid composites [99].

3.6. Isoconversional Kinetic Analysis and Mechanistic Predictions of UF-HC Thermal Decomposition

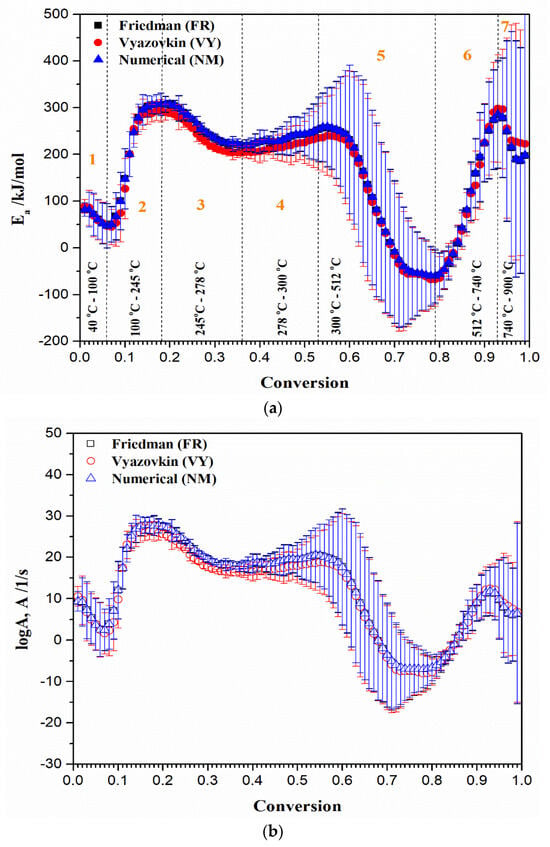

Figure 9a,b show the conversion-dependent effective activation energy (Ea) and logarithm of the pre-exponential factor (logA), for the non-isothermal thermal decomposition process of the UF-HC composite. From the obtained results, it can be seen that both kinetic parameters exhibit significant variation with conversion (α), indicating a strong kinetic complexity of the process. It can be observed from Figure 9a that seven different regions of reactivity exist, and they occupy different temperature zones, marked from “1” to “7”. These reaction zones are characterized by specific variations of both kinetic parameters, with progress of the process. It is worth noting that all the applied isoconversional (model-free) methods show an identical variation of effective activation energies and pre-exponential factors with conversion, and give very similar values of kinetic parameters. Likewise, in the area of higher conversions, for temperatures above 370 °C, the appearance of negative values of kinetic parameters was observed, especially for Ea, which even reaches the value of −67.8 kJ/mol, observing the VY method. This phenomenon will be considered later, during the discussion of the presented results. However, in order to gain a deeper insight into the mechanistic profile of a given process, based on the data obtained from Ea = Ea(conversion) and logA = logA(conversion) plots, it is necessary to interpret each reaction region (Figure 9a), which would have physical meaning, and real consequences, arising from previously obtained results. Therefore, the general mechanistic picture (reactivity landscape) of the studied process would consist of the following items:

Figure 9.

Conversion-dependent kinetic parameters estimated for non-isothermal thermal decomposition of UH-HC composite, by different isoconversional (model-free) methods: (a) Ea = Ea(conversion), and (b) logA = logA(conversion) plots, respectively. Corresponding values of standard deviations for the obtained kinetic parameters are presented in the form of vertical error bars.

- For the first (1) region (for α = 0.01–0.06 and T = 40–100 °C) (Figure 9a) considering estimated values from the numerical optimization (NM) method): There is decrease in the Ea value, from 81.61 kJ/mol to 46.56 kJ/mol. This reaction zone corresponds predominantly to the initial mass loss of the sample, and can be attributed to the dehydration of resin and/or some weaker interactions present in the current macromolecular structure [57]. The mean effective activation energy value for the actual zone (Ea(mean1)) amounts 65.56 kJ/mol. This is a reasonable value, since dehydration energy covers values between 60 kJ/mol and 100 kJ/mol;

- For the second (2) region (for α = 0.07–0.18 and T = 100 °C–245 °C) (Figure 9a): The reaction zone is characterized by a jump in the value of effective activation energy, from 49.77 kJ/mol to 307.48 kJ/mol. In this part of the decomposition process, the mean effective activation energy value (Ea(mean2)) of 217.28 kJ/mol was obtained. This event can be attributed to the conversion of methyl ether functional groups into methylene functional groups, with the release of free formaldehyde. The Ea value estimated for the current conversion path may be also dependent on the F/U molar ratio, where it was reported that Ea increases with an increasing F/U molar ratio (for F/U molar ratio of 1.25, the Ea value of 287.2 kJ/mol was reported) [100]. Therefore, the obtained values of effective activation energy for the observed conversion path are quite realistic, considering the F/U molar ratio used here;

- For the third (3) and fourth (4) regions (for α = 0.19–0.36 and T = 245–278 °C, and for α = 0.37–0.53 and T = 278–300 °C, respectively) (Figure 9a): The two “joined” regions are characterized firstly by decreasing the value of Ea from 307.78 kJ/mol (α~0.19) to 218.94 kJ/mol (α~0.36/0.37), and then by the gradual increase in the value of Ea, from 220.60 kJ/mol (α~0.37/0.38) to 258.55 kJ/mol (α~0.53/0.54). These regions may include parallel temperature overlapping competitive reactions, in the multi-step complex reaction mechanism of UF-HC thermal decomposition. Namely, considering these reaction zones, the balance between bond breaking and cross-linking events coexists with each other. Within the third (3) region, the cleavage of C–N linkages to produce volatiles containing nitrogen should be expected [101], so that, probably, there are losses of chemical entities related to the reduction in N, O, and H; Further, a gradual increase in the Ea value in the fourth (4) region may include the decomposition of residual lignin (arises from HC bio-filler), which could produce H2, that acts as an oxidizer and hydrogen donor for resin further decomposition. The current reaction zone involves the decomposition of UF resin-releasing products (mostly volatile products emitted during the non-isothermal decomposition of the resin). Considering the actual process reactivity zones, the UF-HC sample has lost the highest percent of its initial mass, including the largest share of volatiles in its further decomposition. The mean effective activation energy value for these zones (Ea(mean3+4)) amounts to 246.92 kJ/mol. This value is in good agreement with the range of Ea values, obtained for UF resin decomposition (150 kJ/mol–300 kJ/mol) [102];

- For the fifth (5) region (for α = 0.54–0.79 and T = 300–512 °C) (Figure 9a): This part of the process is characterized by a drastic drop in the effective activation energy (Ea), which goes from approx. ~256.60 kJ/mol up to the lower values of Ea until ~–60.53 kJ/mol. This Ea area represents the transition from stage III to stage IV (the HC instability region) (Figure 5), in which decomposition of cellulose residues from HC mostly occurs, and also to the continued decomposition of biomass lignin. Namely, this part of the UF-HC thermo-chemical conversion is characterized by a primary charring process, where a fair amount of aromatic compounds is produced. Considering the thermo-analytical profiles of UF-HC decomposition shown in Figure 5, the main reinforcements arise from, firstly, stage IV, and then, and finally, stage V, where they slowly pace. Namely, the contribution of UF is minor, because, as can be seen from the TG curve of the UF-HC sample (Figure 5), the UF resin has lost the majority of its mass at an earlier stage, and here, only the release of volatiles from its further decomposition takes place, in a very slow rate manner. Therefore, chemical reactions which probably occur between UF resin and biomass residual components (primary cellulose-Cell) during the heating of the composite in earlier stages create an a more stable material thermally, at the end of this reaction region (at α ~ 0.79, Figure 9a). In other words, it can be said that the UF resin increases the thermal stability of lignocelluloses components left behind in HC, as it renders a decrease in their mass loss rate at the higher temperatures. However, the appearance of some negative Ea values was observed, as we approach at the end of this part of the process. This phenomenon has both a mathematical and a physical explanation, because the negative value means that by increasing the temperature of the process, the rate constant then decreases (the negative dependence on the temperature), and this behavior represents a non-Arrhenius addiction (it is possible that a reversible reaction exists, which should be justified by two reaction paths, each of which has a positive activation energy, E). Namely, it is possible that a reaction mechanism exists, which is a ‘composite’ of the several elementary reaction steps, which have a negative activation energy. It can be assumed that a rapid pre-equilibrium occurs, which is exothermic in the first reaction step, followed by a second reaction step, which has a low positive activation energy value. In this mechanism, the net temperature dependence of the rate will be negative, i.e., the rate decreases with a decreasing temperature, and that is because the equilibrium constant (Keq) for the first reaction step decreases with an increasing temperature. This can be expected, considering the existence of exothermicity, related to stage IV, shown in Figure 5. However, this also should be linked with thermodynamic feasibility, through the possible occurrence of intermediate species. Namely, the overall decrease in the rate of the process may implicate that a negative Ea exists in the current case, when reduction is caused by the decrease in the intermediate specie, as the process temperature is increased;

- For the sixth (6) region (for α = 0.80–0.93 and T = 512–740 °C) (Figure 9a): The region is characterized by rapid increase in the Ea value, from approx. ~–56.29 kJ/mol up to ~286.23 kJ/mol (at α ~ 0.93). The current reactivity region is strictly connected with the pyrolysis of the carbon framework. The removal of oxygen functional groups probably occurred previously, within the (5) region. The “oxidized” graphite (Figure 3) has a high level of oxygen groups, which requires a lower level of energy for its decomposition, compared to the graphene and graphite. So, higher Ea values are transferred to a high temperature zone (Figure 9a), since graphene demands a greater amount of thermal energy for the breaking of sp2 hybridized carbon atoms, ordered by covalent bonds in the hexagonal carbon framework. On the other hand, graphite, as the most thermodynamically stable carbon material, demands even more thermal energy, due to its strong 3D carbon network, consisting of a large number of graphene stacked layers, held by additional van der Waals forces [103];

- For the seventh (7) region (for α = 0.94–0.98/0.99 and T = 740–900 °C) (Figure 9a): Finally, the last region is characterized by decrease in the Ea value, from approx. ~279.07 kJ/mol, up to ~187.06 kJ/mol. This reactivity region of UF-HC can be attributed to the thermal conversion process, where the majority of carbon atoms are converted from graphitic sp2 to non-graphitic sp3 carbon material. In this ultimate stage, there is a high probability that most of the oxygen functional groups from graphene oxide (GO) have been removed, during the reduction from GO.

Emergence of Kinetic Compensation Effect (KCE) During UF-HC Decomposition Process and Its Analysis

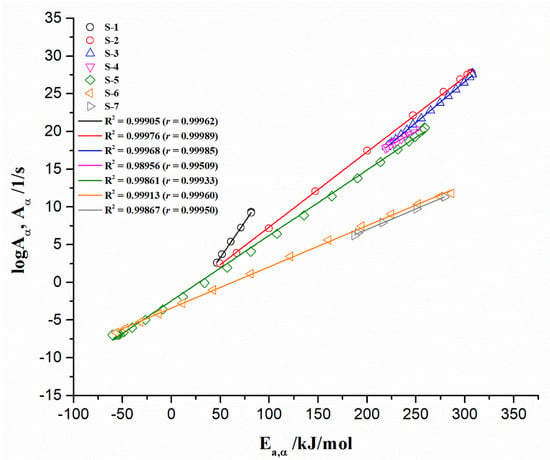

The data logAα and Ea,α were plotted to gain further insights into UF-HC thermal decomposition reactions, under different pyrolysis temperature regions. Figure 10 shows the linear relationships between kinetic parameters (logAα and Ea,α), estimated from the numerical optimization method (NM) (similar plots were obtained by other two isoconversional methods), and associated with stages “1–7” in Figure 9 (designated as S-1–S-7). This phenomenon is attributed to the kinetic compensation effect (KCE), where S-1–S-7 represents the KCE “branches” (Figure 10).

Figure 10.

The KCE “branches” plots (S-1–S-7) derived for non-isothermal decomposition process of UF-HC composite.

All the plots exhibit high values of Adjusted R-squared (R2) (also the values of Pearson’s correlation coefficient (r)) improving the existence of KCE, from the isoconversional (model-free) method/model. Table 3 lists the values of KCE coefficients (a and b), iso-kinetic rate constants, and iso-kinetic temperatures, related to each individual stage (S-1–S-7), and considering different conversion areas (Δα) (Figure 9).

Table 3.

KCE parameters (a, b, kiso, and Tiso) obtained for non-isothermal decomposition process of UF-HC composite.