Discoloration and Surface Changes in Spruce Wood after Accelerated Aging

Abstract

1. Introduction

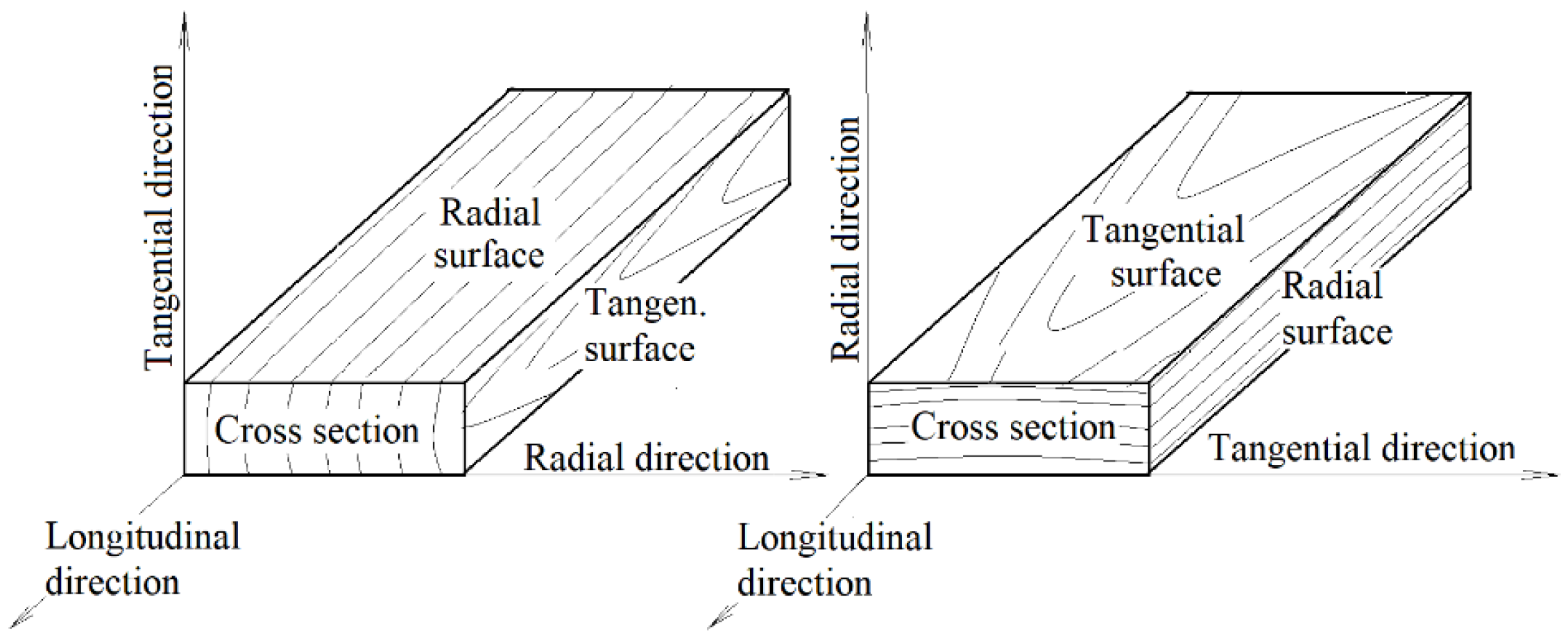

2. Materials and Methods

2.1. Experimental Material

2.2. Accelerated Aging

2.3. Fourier Transform Infrared (FTIR) Spectroscopy

2.4. Color Measurement

2.5. Evaluation of Wood Surface Morphology

2.6. Evaluation of the Results

3. Results and Discussion

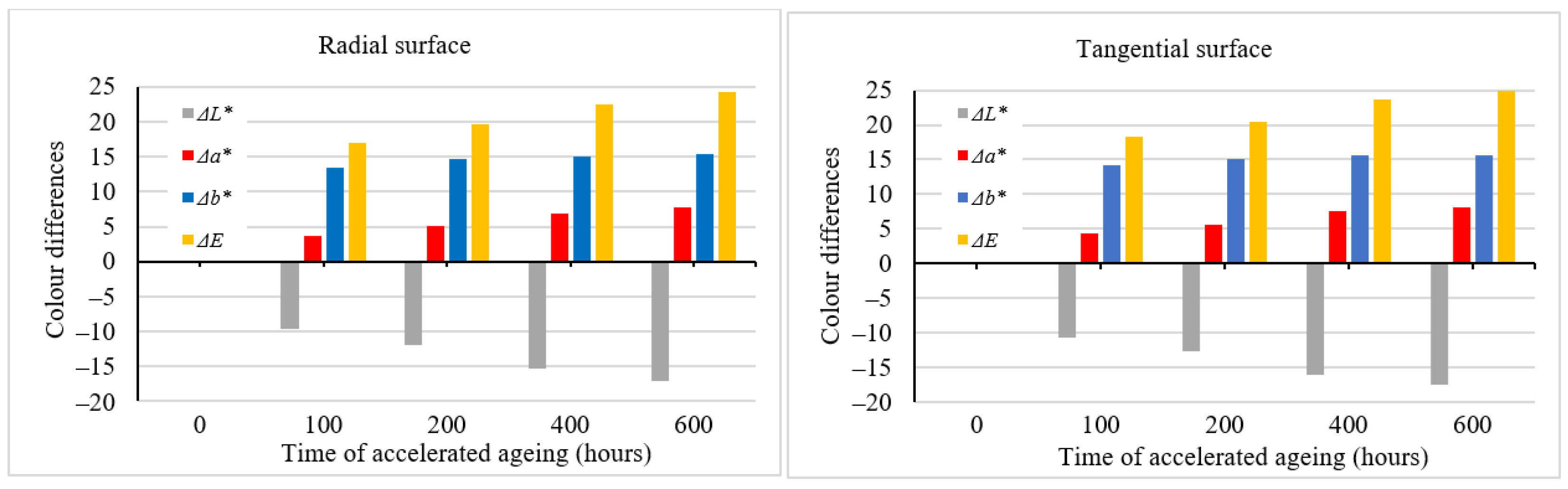

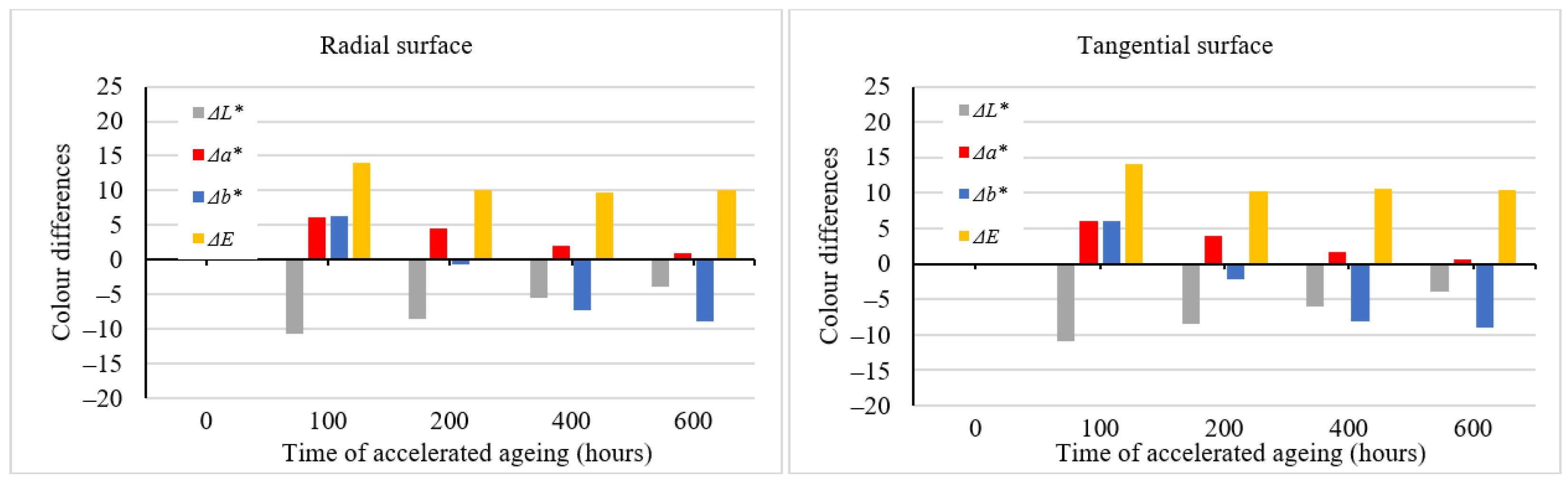

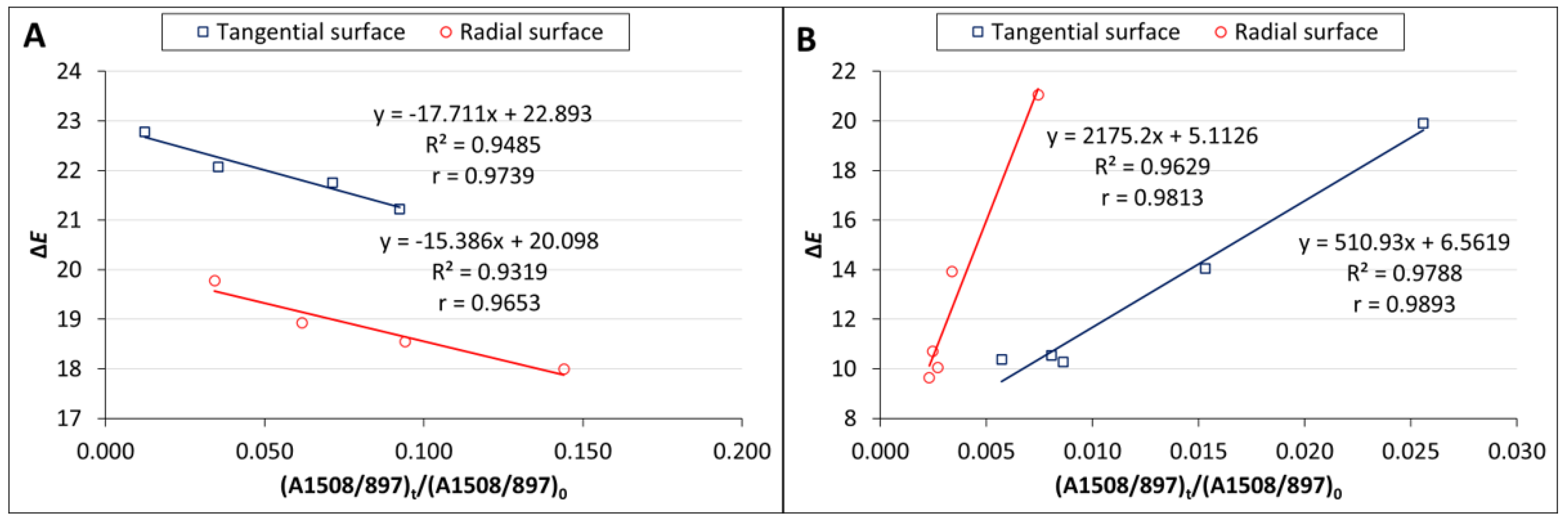

3.1. Wood Discoloration Induced by Accelerated Aging Process

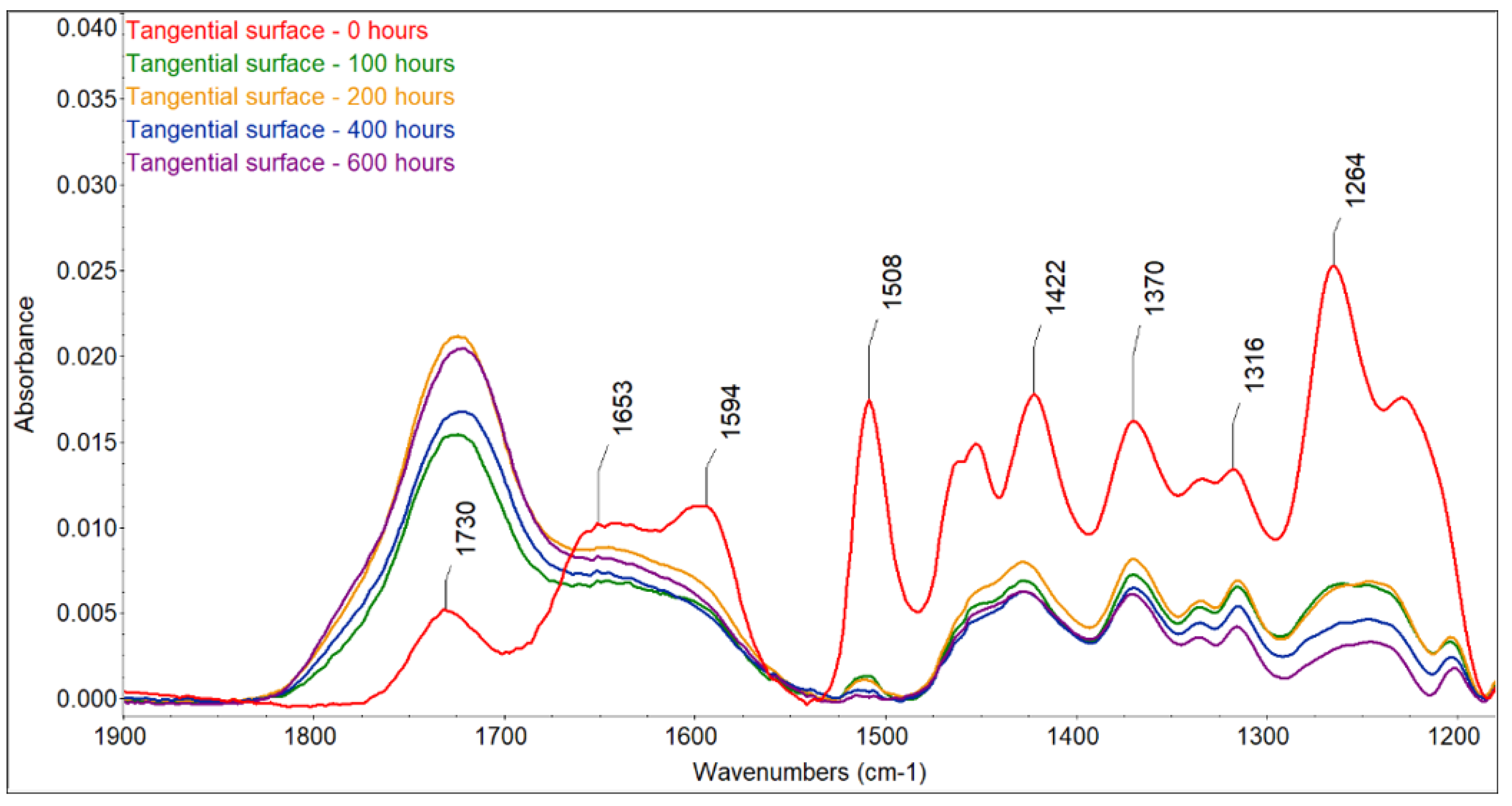

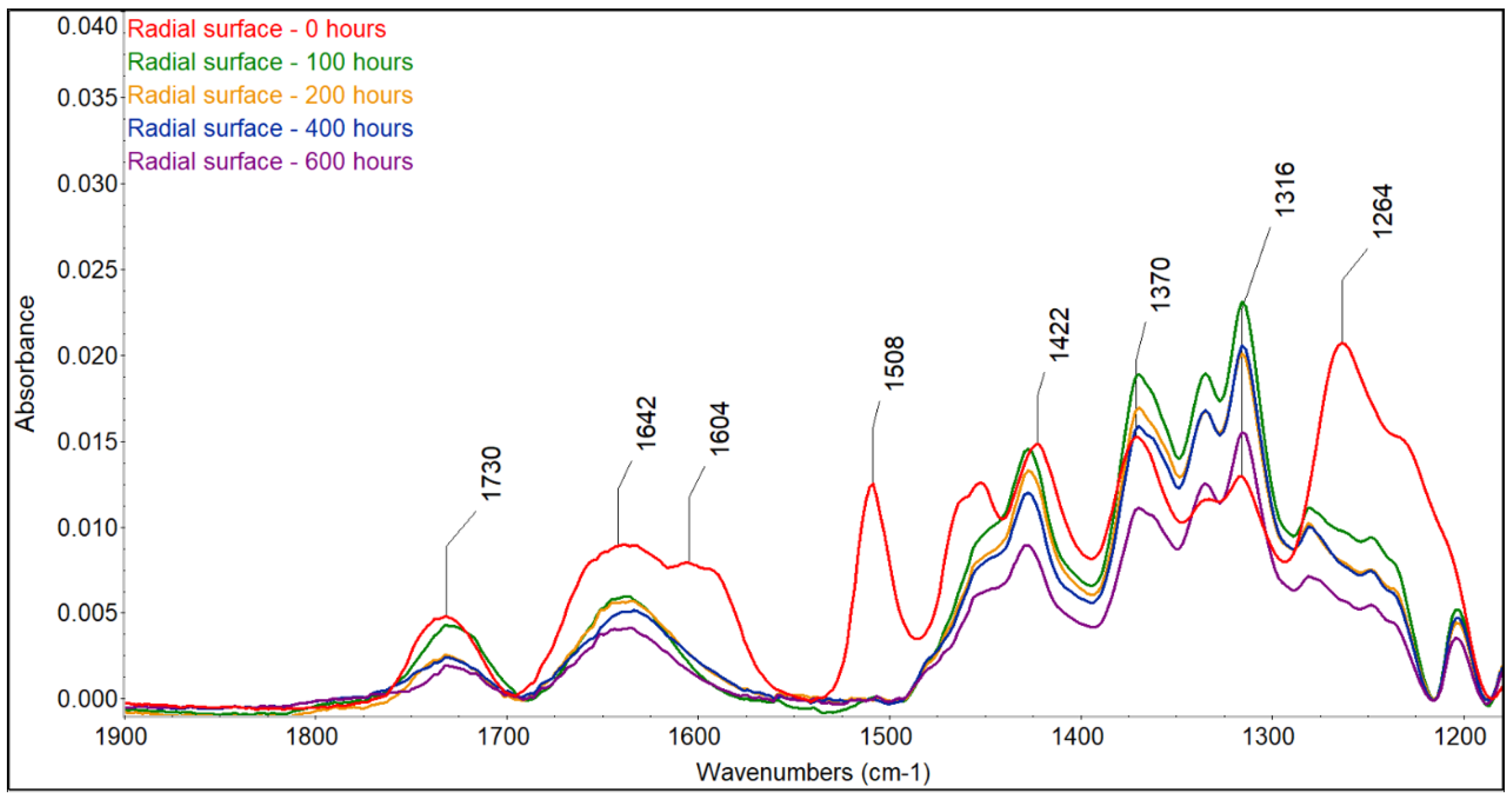

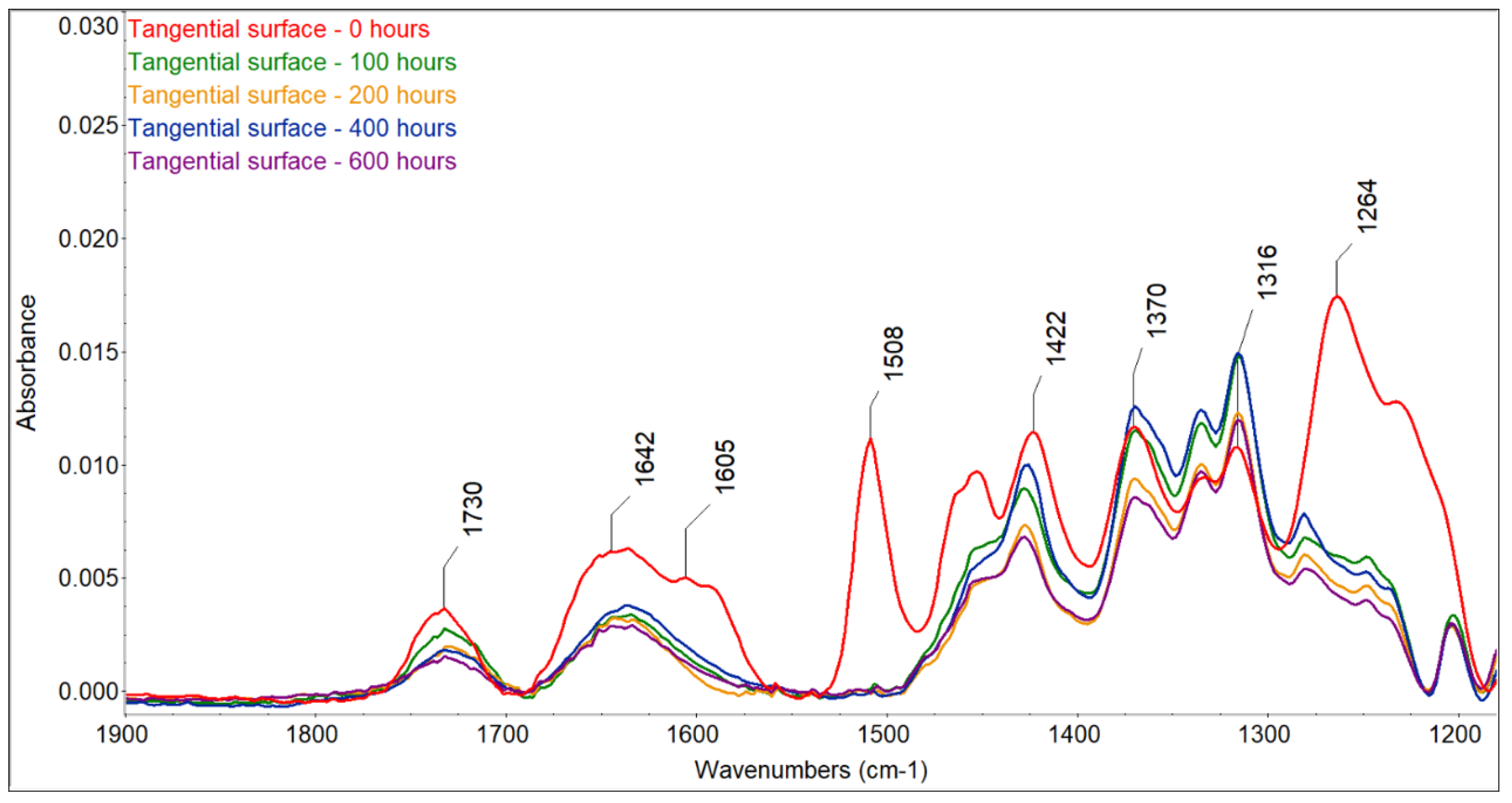

3.2. FTIR Spectroscopy

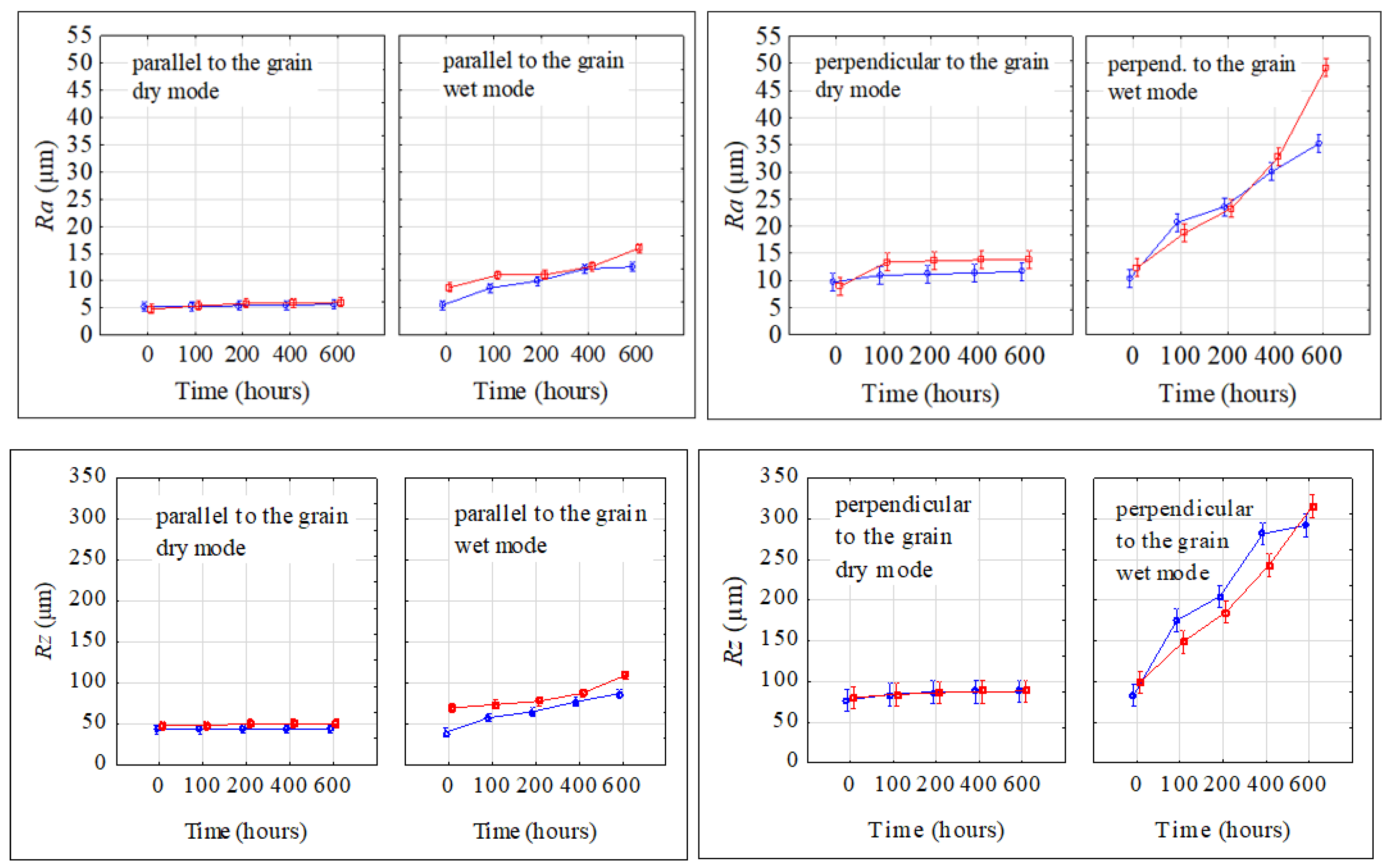

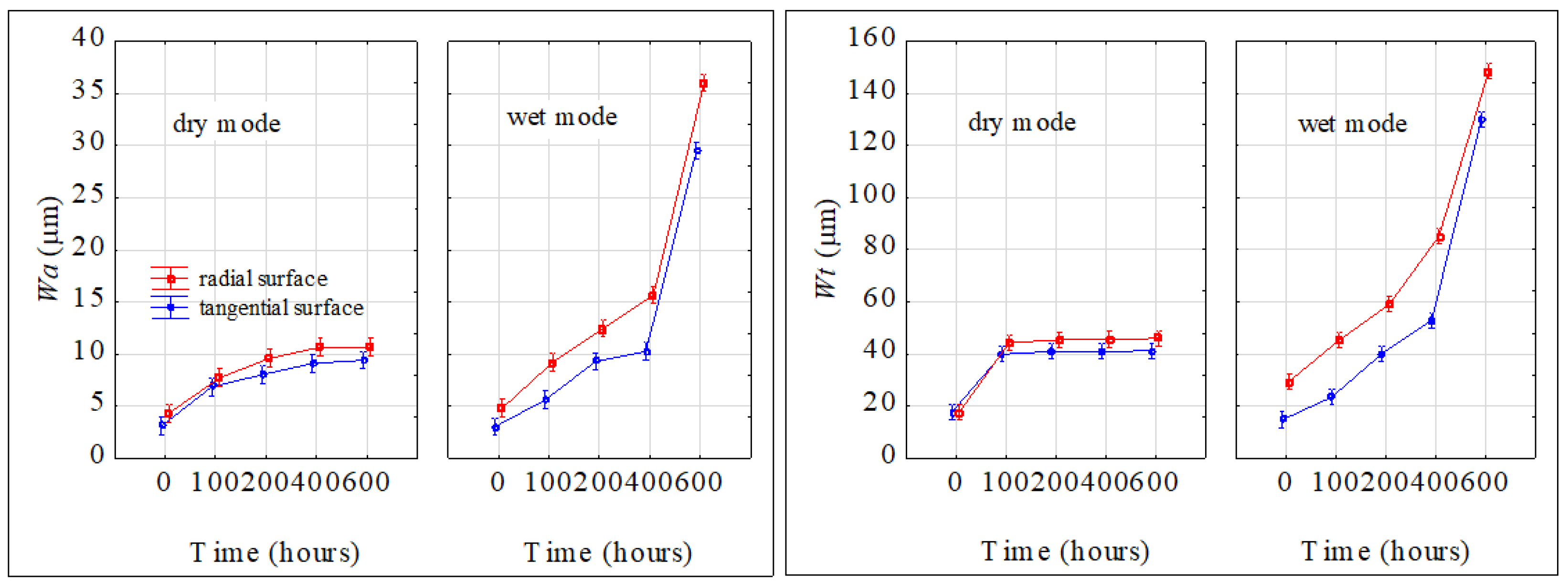

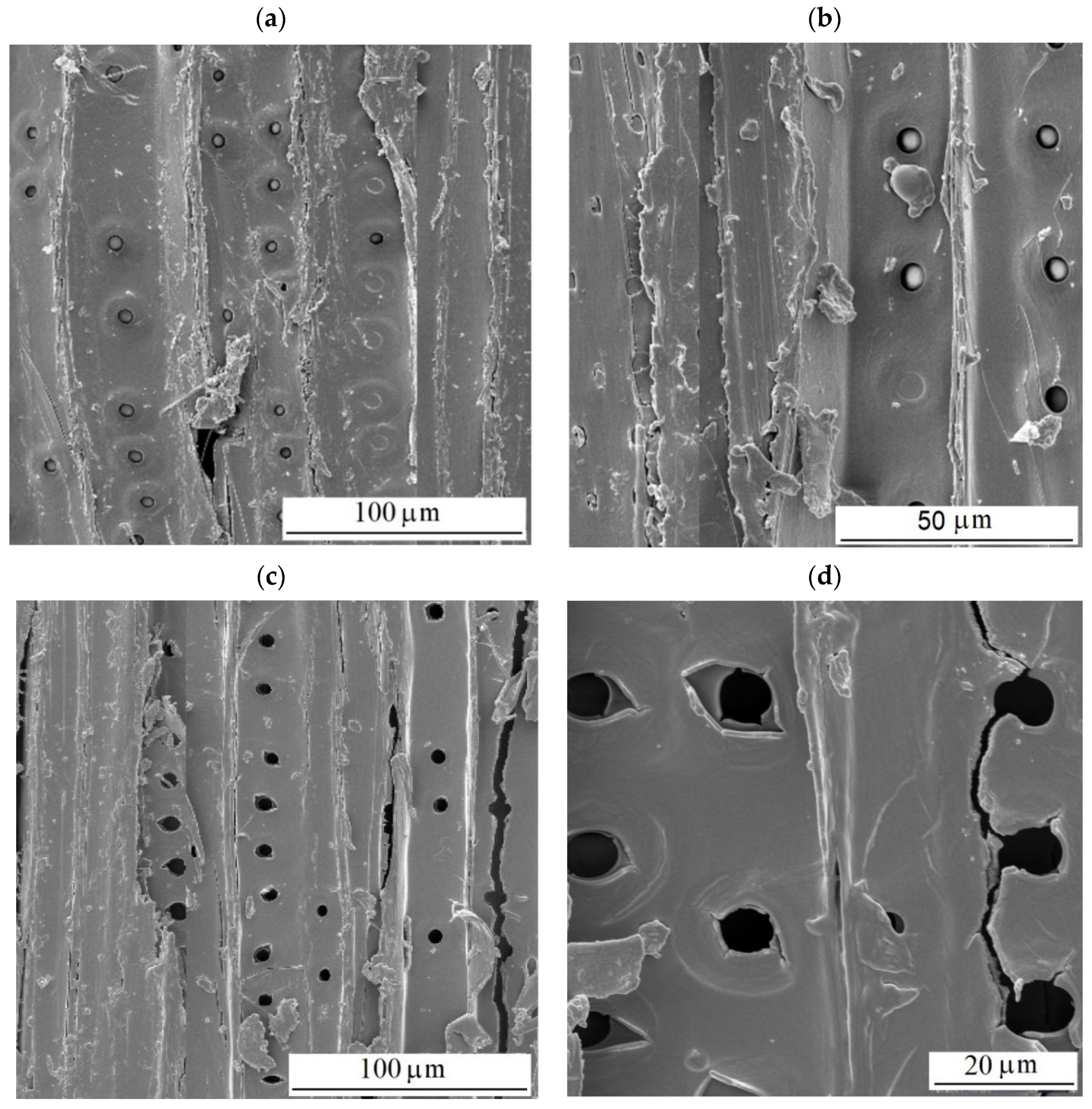

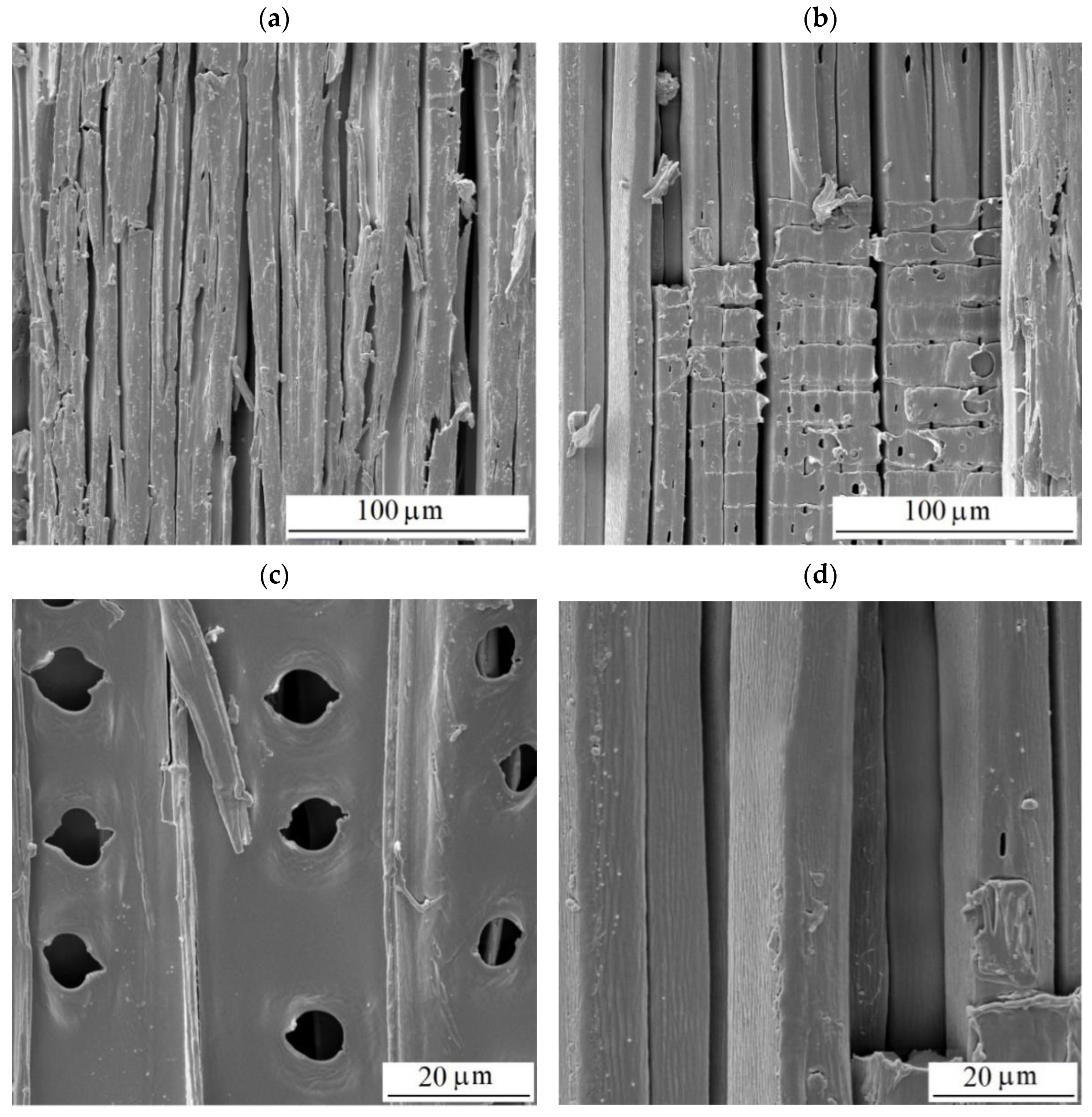

3.3. Spruce Wood Surface Geometry and Morphology

4. Conclusions

- Sunlight exposure was a major factor in spruce wood discoloration. As early as after 100 irradiation hours, the total color difference values were ∆E* > 12, thus representing a new wood color hue, different from the original one.

- The interaction of sunlight with water during aging resulted in qualitatively different discoloration compared with the dry mode, leading to the formation of a patina on the wood surface.

- Water leaching during UV photodegradation increased the hydrophilicity of spruce wood by leaching out carbonyl groups. The accelerated aging of wood causes faster degradation of lignin compared with cellulose, and greater changes occurred in the wet mode compared with the dry mode.

- Spruce tracheids showed increased fragility with aging. Wet mode aging led to irreversible hydrogen bonding (hornification), impacting microstructural damage differently compared with dry mode aging.

- The compound middle lamella was eroded at many spots, which resulted in a significant decline in the coherence of the tracheids.

- The direction of wood fibers influenced the extent to which the surface roughness was affected by aging, with moisture exposure (wet mode) potentially amplifying this effect.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Cogulet, A.; Blanchet, P.; Landry, V. The Multifactorial Aspect of Wood Weathering: A Review Based on a Holistic Approach of Wood Degradation Protected by Clear Coating. BioResources 2017, 13, 2116–2138. [Google Scholar] [CrossRef]

- Kropat, M.; Hubbe, M.A.; Laleicke, F. Natural, Accelerated, and Simulated Weathering of Wood: A Review. BioResources 2020, 15, 9998–10062. [Google Scholar] [CrossRef]

- Yona, A.M.C.; Žigon, J.; Matjaž, P.; Petrič, M. Potentials of Silicate-Based Formulations for Wood Protection and Improvement of Mechanical Properties: A Review. Wood Sci. Technol. 2021, 55, 887–918. [Google Scholar] [CrossRef]

- Gaff, M.; Kačík, F.; Gašparík, M. Impact of Thermal Modification on the Chemical Changes and Impact Bending Strength of European Oak and Norway Spruce Wood. Compos. Struct. 2019, 216, 80–88. [Google Scholar] [CrossRef]

- Sandberg, D.; Kutnar, A.; Karlsson, O.; Jones, D. Wood Modification Technologies: Principles, Sustainability, and the Need for Innovation, 1st ed.; CRC Press: Boca Raton, FL, USA, 2021; ISBN 978-1-351-02822-6. [Google Scholar]

- Wagenführ, R. Holzatlas; 6., Neu Bearbeitete und Erweiterte Auflage; Carl Hanser Verlag GmbH & Co. KG: Leipzig, Germany, 2007; ISBN 978-3-446-40649-0. [Google Scholar]

- Golovin, Y.I.; Gusev, A.A.; Golovin, D.Y.; Matveev, S.M.; Vasyukova, I.A. Multiscale Mechanical Performance of Wood: From Nano- to Macro-Scale across Structure Hierarchy and Size Effects. Nanomaterials 2022, 12, 1139. [Google Scholar] [CrossRef] [PubMed]

- Rowell, R.M. Understanding Wood Surface Chemistry and Approaches to Modification: A Review. Polymers 2021, 13, 2558. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.; Timar, M.C.; Varodi, A.M.; Nedelcu, R.; Torcătoru, M.-J. Colour and Surface Chemistry Changes of Wood Surfaces Coated with Two Types of Waxes after Seven Years Exposure to Natural Light in Indoor Conditions. Coatings 2022, 12, 1689. [Google Scholar] [CrossRef]

- Vidholdová, Z.; Reinprecht, L.; Pánek, M. The Effect of Outdoor Weathering of Thermally Modified Spruce and Pine Woods on Their Surface Properties. Acta Fac. Xylologiae Zvolen 2023, 65, 23–34. [Google Scholar] [CrossRef]

- Huang, X.; Kocaefe, D.; Kocaefe, Y.; Boluk, Y.; Pichette, A. A Spectrocolorimetric and Chemical Study on Color Modification of Heat-Treated Wood during Artificial Weathering. Appl. Surf. Sci. 2012, 258, 5360–5369. [Google Scholar] [CrossRef]

- Gurău, L.; Timar, M.C.; Coșereanu, C.; Cosnita, M.; Stanciu, M.D. Aging of Wood for Musical Instruments: Analysis of Changes in Color, Surface Morphology, Chemical, and Physical-Acoustical Properties during UV and Thermal Exposure. Polymers 2023, 15, 1794. [Google Scholar] [CrossRef]

- Wang, Y.; Huang, Y.; Xue, J.; Peng, Y.; Cao, J. Effects of heat treatment temperatures on the photostability of Moso bamboo during accelerated UV weathering. Wood Mater. Sci. Eng. 2022, 17, 823–833. [Google Scholar] [CrossRef]

- Preklet, E.; Tolvaj, L.; Tsuchikawa, S.; Varga, D. Photodegradation Properties of Earlywood and Latewood Spruce Timber Surfaces. Acta Silv. Lignaria Hung 2021, 17, 9–20. [Google Scholar] [CrossRef]

- Rubino, G.; Lo Monaco, A.; Lanteri, L.; Pelosi, C. Improving the Technical Characteristics of Untreated and Heat-Treated Ayous Wood against Accelerating Ageing by Testing Two Application Modalities of an Innovative Polyurethane Coating for Outdoor Uses. Coatings 2023, 13, 1312. [Google Scholar] [CrossRef]

- Peters, F.B.; Rapp, A.O. Wavelength-dependent photodegradation of wood and its effects on fluorescence. Holzforschung 2021, 76, 60–67. [Google Scholar] [CrossRef]

- Colom, X.; Carrillo, F.; Nogués, F.; Garriga, P. Structural Analysis of Photodegraded Wood by Means of FTIR Spectroscopy. Polym. Degrad. Stab. 2003, 80, 543–549. [Google Scholar] [CrossRef]

- Mi, X.; Li, Y.; Qin, X.; Li, J. Effects of Natural Weathering on Aged Wood from Historic Wooden Building: Diagnosis of the Oxidative Degradation. Herit. Sci. 2023, 11, 109. [Google Scholar] [CrossRef]

- Kanbayashi, T.; Kataoka, Y.; Ishikawa, A.; Matsunaga, M.; Kobayashi, M.; Kiguchi, M. Confocal Raman Microscopy Reveals Changes in Chemical Composition of Wood Surfaces Exposed to Artificial Weathering. J. Photochem. Photobiol. B 2018, 187, 136–140. [Google Scholar] [CrossRef]

- Kránitz, K.; Sonderegger, W.; Bues, C.-T.; Niemz, P. Effects of Aging on Wood: A Literature Review. Wood Sci. Technol. 2016, 50, 7–22. [Google Scholar] [CrossRef]

- Ghavidel, A.; Scheglov, A.; Karius, V.; Mai, C.; Tarmian, A.; Vioel, W.; Vasilache, V.; Sandu, I. In-Depth Studies on the Modifying Effects of Natural Ageing on the Chemical Structure of European Spruce (Picea abies) and Silver Fir (Abies alba) Woods. J. Wood Sci. 2020, 66, 77. [Google Scholar] [CrossRef]

- Kúdela, J.; Javorek, L.; Mrenica, L. Influence of Milling and Sanding on Beech Wood Surface Properties. Part I. Surface Morfology. Ann. Wars. Univ. Life Sci.-SGGW Land Reclam. 2016, 2016, 148–153. [Google Scholar]

- Hrčka, R. Identification of Discoloration of Beech Wood In CIELAB Space. Wood Res. 2008, 53, 119–124. [Google Scholar]

- Olsson, S.K.; Johansson, M.; Westin, M.; Östmark, E. Reactive UV-Absorber and Epoxy Functionalized Soybean Oil for Enhanced UV-Protection of Clear Coated Wood. Polym. Degrad. Stab. 2014, 110, 405–414. [Google Scholar] [CrossRef]

- Reinprecht, L. Wood Deterioration, Protection and Maintenance, 1st ed.; Wiley: New York, NY, USA, 2016; ISBN 978-1-119-10653-1. [Google Scholar]

- Kúdela, J.; Mrenica, L.; Čunderlík, I.; Šmíra, P. Morphological Changes on Spruce Wood Surface, Induced by Treatment with Dry Ice. Mater. Sci. Forum 2015, 818, 177–180. [Google Scholar] [CrossRef]

- Song, J.; Zhao, J.; Deng, J.; Lu, S.; Hang, G.; Zhang, Y.; Shu, C.-M. Effect Mechanism of Dry and Wet Alternate Ageing on Wood during Exothermic Behaviour. J. Therm. Anal. Calorim. 2023. [Google Scholar] [CrossRef]

- Tolvaj, L.; Persze, L.; Albert, L. Thermal Degradation of Wood during Photodegradation. J. Photochem. Photobiol. B 2011, 105, 90–93. [Google Scholar] [CrossRef] [PubMed]

- Froidevaux, J.; Navi, P. Aging Law of Spruce Wood. Wood Mater. Sci. Eng. 2013, 8, 46–52. [Google Scholar] [CrossRef]

- ASTM-G155-05; Practice for Operating Xenon Arc Light Apparatus for Exposure of Non-Metallic Materials. ASTM International: West Conshohocken, PA, USA, 2005.

- Sikora, A.; Kačík, F.; Gaff, M.; Vondrová, V.; Bubeníková, T.; Kubovský, I. Impact of Thermal Modification on Color and Chemical Changes of Spruce and Oak Wood. J. Wood Sci. 2018, 64, 406–416. [Google Scholar] [CrossRef]

- Kúdela, J.; Andrejko, M.; Kubovský, I. The Effect of CO2 Laser Engraving on the Surface Structure and Properties of Spruce Wood. Coatings 2023, 13, 2006. [Google Scholar] [CrossRef]

- Allegretti, O.; Travan, L.; Cividini, R. Drying Techniques to Obtain White Beech. In Proceedings of the Wood EDG Conference, Bled, Slovenia, 23 April 2009; Volume 53. [Google Scholar]

- Ouadou, Y.; Aliouche, D.; Thevenon, M.-F.; Djillali, M. Characterization and Photodegradation Mechanism of Three Algerian Wood Species. J. Wood Sci. 2017, 63, 288–294. [Google Scholar] [CrossRef]

- Sandak, A.; Sandak, J.; Noël, M.; Dimitriou, A. A Method for Accelerated Natural Weathering of Wood Subsurface and Its Multilevel Characterization. Coatings 2021, 11, 126. [Google Scholar] [CrossRef]

- Zborowska, M.; Stachowiak-Wencek, A.; Nowaczyk-Organista, M.; Waliszewska, B.; Prądzyński, W. Analysis of Photodegradation Process of Pinus Sylvestris L. Wood after Treatment with Acid and Alkaline Buffers and Light Irradiation. BioResources 2015, 10, 2057–2066. [Google Scholar] [CrossRef]

- Hofmann, T.; Tolvaj, L.; Visi-Rajczi, E.; Varga, D. Chemical Changes of Steamed Timber during Short-Term Photodegradation Monitored by FTIR Spectroscopy. Eur. J. Wood Wood Prod. 2022, 80, 841–849. [Google Scholar] [CrossRef]

- Müller, U.; Rätzsch, M.; Schwanninger, M.; Steiner, M.; Zöbl, H. Yellowing and IR-Changes of Spruce Wood as Result of UV-Irradiation. J. Photochem. Photobiol. B 2003, 69, 97–105. [Google Scholar] [CrossRef] [PubMed]

- Mastouri, A.; Azadfallah, M.; Kamboj, G.; Rezaei, F.; Tarmian, A.; Efhamisisi, D.; Mahmoudkia, M.; Corcione, C.E. Kinetic Studies on Photo-Degradation of Thermally-Treated Spruce Wood during Natural Weathering: Surface Performance, Lignin and Cellulose Crystallinity. Constr. Build. Mater. 2023, 392, 131923. [Google Scholar] [CrossRef]

- Bhagia, S.; Ďurkovič, J.; Lagaňa, R.; Kardošová, M.; Kačík, F.; Cernescu, A.; Schäfer, P.; Yoo, C.G.; Ragauskas, A.J. Nanoscale FTIR and Mechanical Mapping of Plant Cell Walls for Understanding Biomass Deconstruction. ACS Sustain. Chem. Eng. 2022, 10, 3016–3026. [Google Scholar] [CrossRef]

- Preklet, E.; Tolvaj, L.; Visi-Rajczi, E.; Hofmann, T. Effect of Water Leaching on Photodegraded Scots Pine and Spruce Timbers Monitored by FTIR Spectroscopy. Forests 2021, 12, 833. [Google Scholar] [CrossRef]

- Pandey, K.K. A Note on the Influence of Extractives on the Photo-Discoloration and Photo-Degradation of Wood. Polym. Degrad. Stab. 2005, 87, 375–379. [Google Scholar] [CrossRef]

- Bergamasco, S.; Zikeli, F.; Vinciguerra, V.; Sobolev, A.P.; Scarnati, L.; Tofani, G.; Scarascia Mugnozza, G.; Romagnoli, M. Extraction and Characterization of Acidolysis Lignin from Turkey Oak (Quercus cerris L.) and Eucalypt (Eucalyptus camaldulensis Dehnh.) Wood from Population Stands in Italy. Polymers 2023, 15, 3591. [Google Scholar] [CrossRef] [PubMed]

- Bejo, L.; Tolvaj, L.; Kannar, A.; Preklet, E. Effect of Water Leaching on Photodegraded Spruce Wood Monitored by IR Spectroscopy. J. Photochem. Photobiol. Chem. 2019, 382, 111948. [Google Scholar] [CrossRef]

- Doczekalska, B.; Stachowiak-Wencek, A.; Roszyk, E.; Sydor, M. Thermochemical modification of beech wood with ammonium hydroxide. Eur. J. Wood Prod. 2024, 82, 299–308. [Google Scholar] [CrossRef]

- Tolvaj, L.; Molnar, Z.; Nemeth, R. Photodegradation of Wood at Elevated Temperature: Infrared Spectroscopic Study. J. Photochem. Photobiol. B 2013, 121, 32–36. [Google Scholar] [CrossRef] [PubMed]

- Kačík, F.; Kubovský, I.; Bouček, J.; Hrčka, R.; Gaff, M.; Kačíková, D. Colour and Chemical Changes of Black Locust Wood during Heat Treatment. Forests 2023, 14, 73. [Google Scholar] [CrossRef]

- Lionetto, F.; Del Sole, R.; Cannoletta, D.; Vasapollo, G.; Maffezzoli, A. Monitoring Wood Degradation during Weathering by Cellulose Crystallinity. Materials 2012, 5, 1910–1922. [Google Scholar] [CrossRef]

- Oh, S.Y.; Yoo, D.I.; Shin, Y.; Kim, H.C.; Kim, H.Y.; Chung, Y.S.; Park, W.H.; Youk, J.H. Crystalline Structure Analysis of Cellulose Treated with Sodium Hydroxide and Carbon Dioxide by Means of X-ray Diffraction and FTIR Spectroscopy. Carbohydr. Res. 2005, 340, 2376–2391. [Google Scholar] [CrossRef] [PubMed]

- Oh, S.Y.; Yoo, D.I.; Shin, Y.; Seo, G. FTIR Analysis of Cellulose Treated with Sodium Hydroxide and Carbon Dioxide. Carbohydr. Res. 2005, 340, 417–428. [Google Scholar] [CrossRef] [PubMed]

- Poletto, M.; Zattera, A.J.; Santana, R.M.C. Structural Differences between Wood Species: Evidence from Chemical Composition, FTIR Spectroscopy, and Thermogravimetric Analysis. J. Appl. Polym. Sci. 2012, 126, E337–E344. [Google Scholar] [CrossRef]

- Prasetia, D.; Purusatama, B.D.; Kim, J.-H.; Jang, J.-H.; Park, S.-Y.; Lee, S.-H.; Kim, N.H. X-ray Diffraction, Fourier Transform Infrared Spectroscopy, and Thermal Decomposition Analyses of Virgin Cork Elements in Quercus Variabilis Grown in Korea. Wood Sci. Technol. 2024, 58, 313–332. [Google Scholar] [CrossRef]

- Nelson, M.L.; O’Connor, R.T. Relation of Certain Infrared Bands to Cellulose Crystallinity and Crystal Latticed Type. Part I. Spectra of Lattice Types I, II, III and of Amorphous Cellulose. J. Appl. Polym. Sci. 1964, 8, 1311–1324. [Google Scholar] [CrossRef]

- Åkerholm, M.; Hinterstoisser, B.; Salmén, L. Characterization of the Crystalline Structure of Cellulose Using Static and Dynamic FT-IR Spectroscopy. Carbohydr. Res. 2004, 339, 569–578. [Google Scholar] [CrossRef]

- Schwanninger, M.; Rodrigues, J.C.; Pereira, H.; Hinterstoisser, B. Effects of Short-Time Vibratory Ball Milling on the Shape of FT-IR Spectra of Wood and Cellulose. Vib. Spectrosc. 2004, 36, 23–40. [Google Scholar] [CrossRef]

- Tribulová, T.; Kačík, F.; Evtuguin, D.V.; Čabalová, I.; Ďurkovič, J. The Effects of Transition Metal Sulfates on Cellulose Crystallinity During Accelerated Ageing of Silver Fir Wood. Cellulose 2019, 26, 2625–2638. [Google Scholar] [CrossRef]

- Huang, X.; Kocaefe, D.; Kocaefe, Y.; Boluk, Y.; Krause, C. Structural Analysis of Heat-Treated Birch (Betule Papyrifera) Surface during Artificial Weathering. Appl. Surf. Sci. 2013, 264, 117–127. [Google Scholar] [CrossRef]

- Liptáková, E.; Kúdela, J.; Bastl, Z.; Spirovová, I. Influence of Mechanical Surface Treatment of Wood on the Wetting Process. Holzforschung 1995, 49, 369–375. [Google Scholar] [CrossRef]

- Kúdela, J.; Mrenica, L.; Javorek, L. The Influence of Milling and Sanding on Wood Surface Morphology. Acta Fac. Xylologiae 2018, 60, 71–83. [Google Scholar] [CrossRef]

- Gurau, L. Quantitative Evaluation of the Sanding Quality in Furniture Manufacturing; Transilvania University: Brașov, Romania, 2007; ISBN 978-973-598-126-6. [Google Scholar]

- Csanády, E.; Magoss, E.; Tolvaj, L. Quality of Machined Wood Surfaces; Springer International Publishing: Cham, Switzerland; Heidelberg, Germany; New York, NY, USA; Dordrecht, The Netherlands; London, UK, 2015; ISBN 978-3-319-22418-3. [Google Scholar]

- Temiz, A.; Yildiz, U.C.; Aydin, I.; Eikenes, M.; Alfredsen, G.; Çolakoglu, G. Surface Roughness and Color Characteristics of Wood Treated with Preservatives after Accelerated Weathering Test. Appl. Surf. Sci. 2005, 250, 35–42. [Google Scholar] [CrossRef]

- Feist, W.C. Outdoor Wood Weathering and Protection. In Archaeological Wood; Advances in Chemistry; American Chemical Society: Washington, DC, USA, 1989; Volume 225, pp. 263–298. ISBN 978-0-8412-1623-5. [Google Scholar]

- Moliński, W.; Cunderlik, I.; Krauss, A.; Fabisiak, E.; Jurek, P. Gradient of Density and Tensile Strength along the Grains of Spruce Wood (Picea abies) within Individual Annual Rings. Ann. Wars. Univ. Life Sci.-SGGW For. Wood Technol. 2009, 69, 87–92. [Google Scholar]

- Rowell, R.M. (Ed.) Handbook of Wood Chemistry and Wood Composites, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2021; ISBN 978-1-03-209916-3. [Google Scholar]

- Ko, J.K.; Kim, Y.; Ximenes, E.; Ladisch, M.R. Effect of Liquid Hot Water Pretreatment Severity on Properties of Hardwood Lignin and Enzymatic Hydrolysis of Cellulose. Biotechnol. Bioeng. 2015, 112, 252–262. [Google Scholar] [CrossRef]

- Mamoňová, M.; Reinprecht, L. The Impact of Natural and Artificial Weathering on the Anatomy of Selected Tropical Hardwoods. IAWA J. 2020, 41, 333–355. [Google Scholar] [CrossRef]

radial surface,

radial surface,  tangential surface.

tangential surface.

radial surface,

radial surface,  tangential surface.

tangential surface.

| Step | Mode | Radiation Intensity (W/m2) | Black Panel Temperature (°C) | Air Temperature (°C) | Relative Air Humidity (%) | Time (min.) |

|---|---|---|---|---|---|---|

| 1 | Radiation | 0.35 | 63 | 48 | 30 | 102 |

| 2 | Radiation-free | - | - | 38 | – | 18 |

| Step | Mode | Radiation Intensity (W/m2) | Black Panel Temperature (°C) | Air Temperature (°C) | Relative Air Humidity (%) | Time (min.) |

|---|---|---|---|---|---|---|

| 1 | Radiation | 0.35 | 63 | 48 | 30 | 102 |

| 2 | Radiation + water spraying | 0.35 | 63 | 48 | 90 | 18 |

| Surface | Color Coordinates | Basic Statistical Characteristics | Aging Time (Hours) | ||||

|---|---|---|---|---|---|---|---|

| 0 | 100 | 200 | 400 | 600 | |||

| Dry Mode | |||||||

| Radial | L* | 83.82 | 74.10 | 71.88 | 68.57 | 66.71 | |

| s | 1.67 | 1.26 | 1.22 | 1.20 | 1.18 | ||

| a* | 3.82 | 7.46 | 8.92 | 10.74 | 11.55 | ||

| s | 0.70 | 0.35 | 0.36 | 0.34 | 0.31 | ||

| b* | 20.57 | 33.94 | 35.29 | 35.66 | 36.00 | ||

| s | 0.71 | 0.60 | 0.68 | 0.87 | 0.89 | ||

| Tangential | L* | 84.46 | 73.70 | 71.80 | 68.42 | 66.82 | |

| s | 1.65 | 1.57 | 1.24 | 1.36 | 1.40 | ||

| a* | 3.34 | 7.73 | 8.96 | 10.91 | 11.46 | ||

| s | 0.72 | 0.62 | 0.57 | 0.58 | 0.60 | ||

| b* | 20.01 | 34.11 | 35.14 | 35.71 | 35.60 | ||

| s | 1.76 | 0.90 | 0.69 | 1.07 | 0.95 | ||

| Wet mode | |||||||

| Radial | L* | 87.19 | 76.44 | 78.52 | 81.72 | 83.30 | |

| s | 0.61 | 1.28 | 1.40 | 1.52 | 1.63 | ||

| a* | 2.84 | 8.97 | 7.34 | 4.79 | 3.67 | ||

| s | 0.29 | 0.57 | 0.70 | 0.55 | 0.53 | ||

| b* | 18.04 | 24.31 | 17.32 | 10.77 | 9.10 | ||

| s | 0.69 | 1.69 | 1.96 | 2.04 | 1.95 | ||

| Tangential | L* | 87.71 | 76.81 | 79.19 | 81.63 | 83.76 | |

| s | 1.16 | 2.01 | 2.46 | 3.19 | 3.06 | ||

| a* | 2.42 | 8.63 | 6.35 | 4.09 | 3.09 | ||

| s | 0.45 | 0.86 | 1.04 | 0.81 | 0.66 | ||

| b* | 17.56 | 23.58 | 15.32 | 9.54 | 8.63 | ||

| s | 2.05 | 2.59 | 2.80 | 2.01 | 1.85 | ||

| Time (h) | Radial Surface | Tangential Surface | ||||||

|---|---|---|---|---|---|---|---|---|

| TCI | LOI | HBI | CI | TCI | LOI | HBI | CI | |

| 0 | 2.52 | 1.02 | 1.63 | 1.10 | 2.40 | 1.32 | 1.85 | 0.93 |

| 100 | 2.49 | 0.72 | 1.99 | 5.55 | 2.25 | 0.68 | 1.66 | 6.00 |

| 200 | 2.46 | 0.74 | 1.77 | 8.73 | 2.19 | 0.73 | 1.85 | 8.10 |

| 400 | 2.39 | 0.74 | 2.30 | 13.46 | 2.14 | 0.70 | 1.92 | 15.61 |

| 600 | 2.11 | 0.79 | 1.92 | 26.22 | 1.94 | 0.83 | 2.44 | 50.00 |

| Time (h) | Radial Surface | Tangential Surface | ||||||

|---|---|---|---|---|---|---|---|---|

| TCI | LOI | HBI | CI | TCI | LOI | HBI | CI | |

| 0 | 2.24 | 1.24 | 1.95 | 1.22 | 2.64 | 1.73 | 1.79 | 1.05 |

| 100 | 2.00 | 0.86 | 1.78 | 313.33 | 2.02 | 0.88 | 1.46 | 44.23 |

| 200 | 2.11 | 0.85 | 1.75 | 384.09 | 2.02 | 1.06 | 1.46 | 93.00 |

| 400 | 2.11 | 0.90 | 1.69 | 493.75 | 2.08 | 1.12 | 1.60 | 120.88 |

| 600 | 2.18 | 1.16 | 1.54 | 555.00 | 2.13 | 1.31 | 1.27 | 170.00 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kúdela, J.; Ihracký, P.; Kačík, F. Discoloration and Surface Changes in Spruce Wood after Accelerated Aging. Polymers 2024, 16, 1191. https://doi.org/10.3390/polym16091191

Kúdela J, Ihracký P, Kačík F. Discoloration and Surface Changes in Spruce Wood after Accelerated Aging. Polymers. 2024; 16(9):1191. https://doi.org/10.3390/polym16091191

Chicago/Turabian StyleKúdela, Jozef, Pavel Ihracký, and František Kačík. 2024. "Discoloration and Surface Changes in Spruce Wood after Accelerated Aging" Polymers 16, no. 9: 1191. https://doi.org/10.3390/polym16091191

APA StyleKúdela, J., Ihracký, P., & Kačík, F. (2024). Discoloration and Surface Changes in Spruce Wood after Accelerated Aging. Polymers, 16(9), 1191. https://doi.org/10.3390/polym16091191