Synthesis of Nano-Structured Conjugated Polymers with Multiple Micro-/Meso-Pores by the Post-Crosslinking of End-Functionalized Hyperbranched Conjugated Polymers

Abstract

1. Introduction

2. Experimental Section

2.1. Materials and Instruments

2.2. General Procedures of Syntheses

3. Results and Discussion

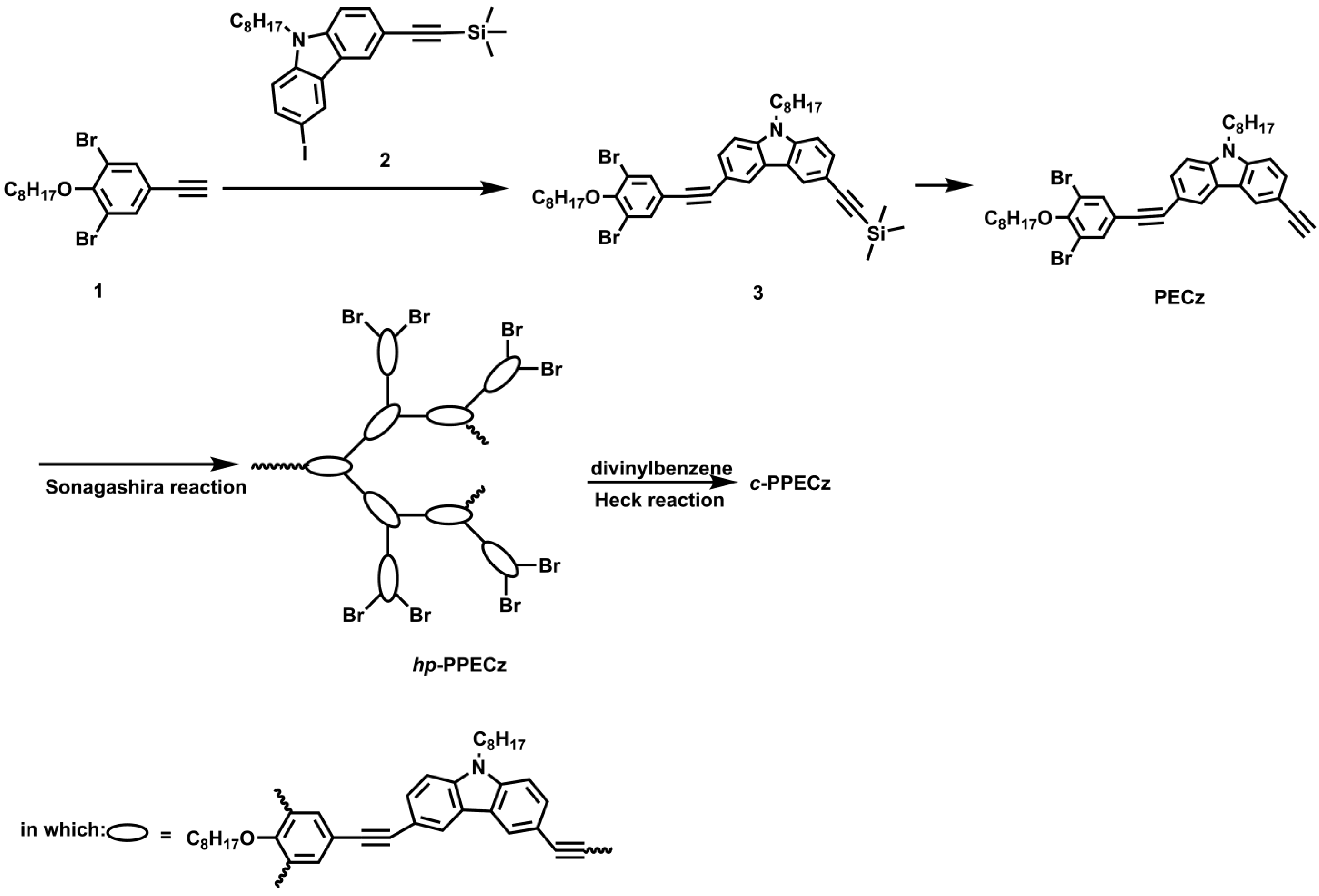

3.1. Synthesis of Hyperbranched Conjugated Prepolymer hb-PPECz

3.2. Photophysical and Electrochemical Properties of Hyperbranched Prepolymer hb-PPECz

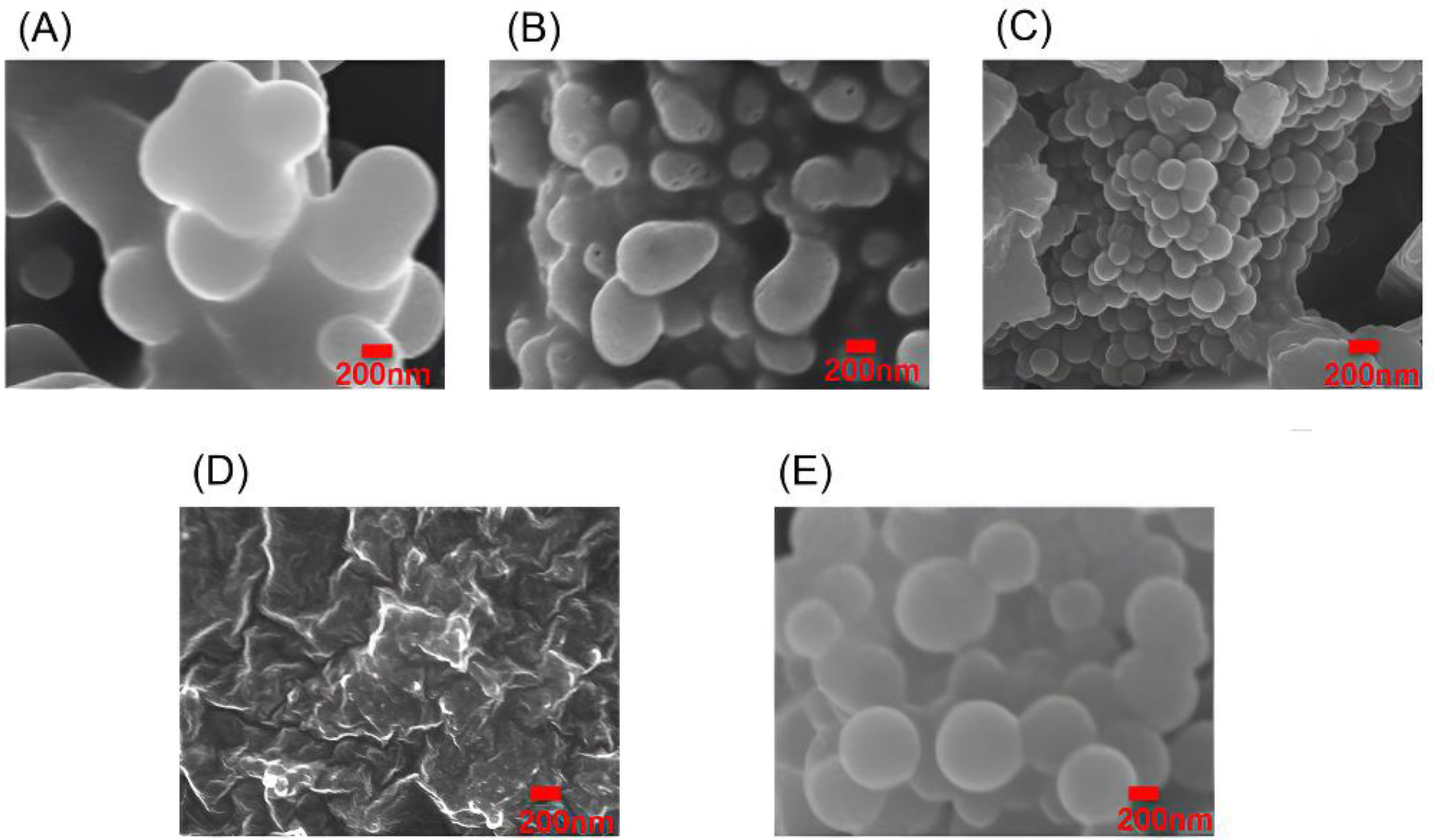

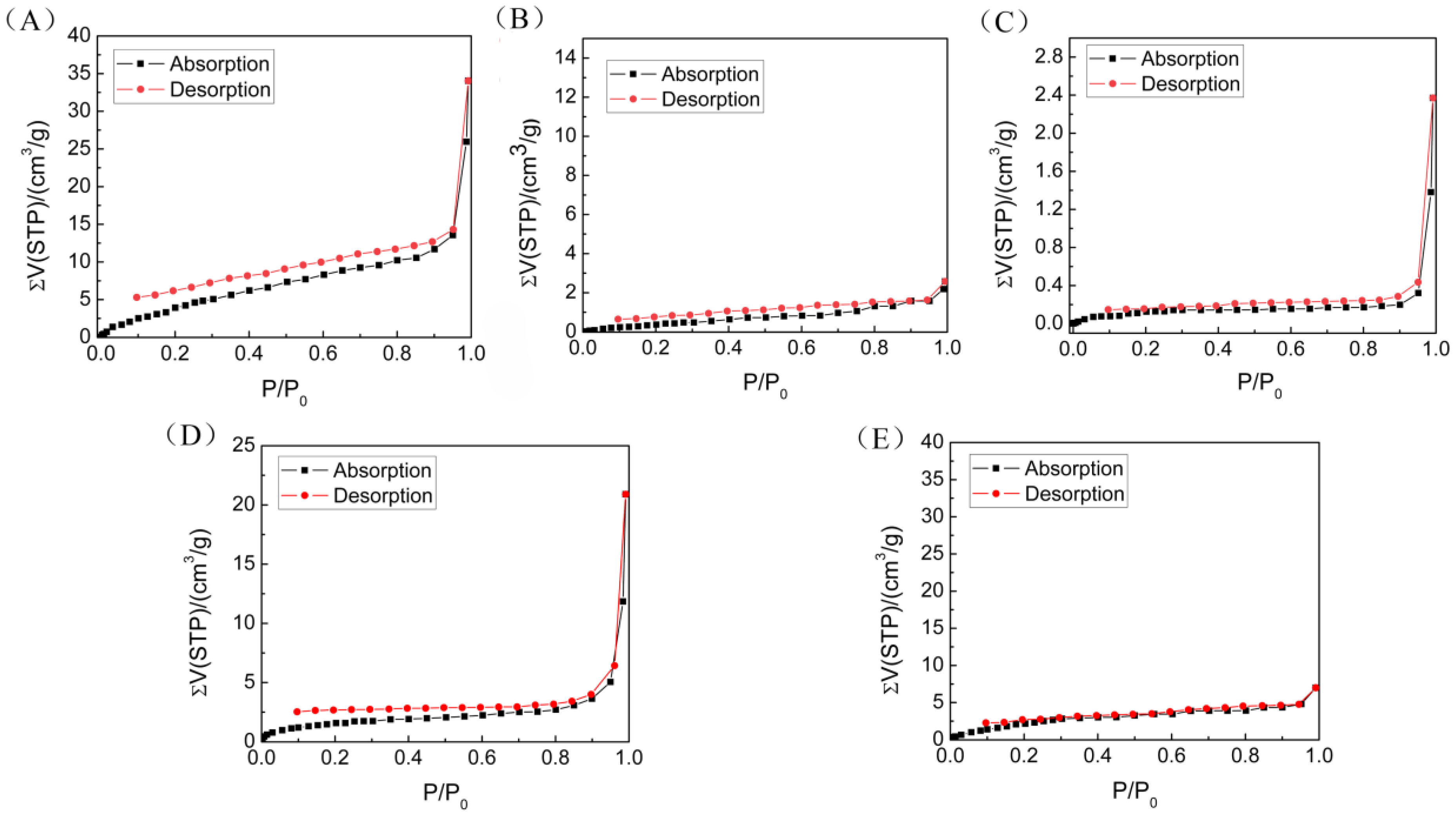

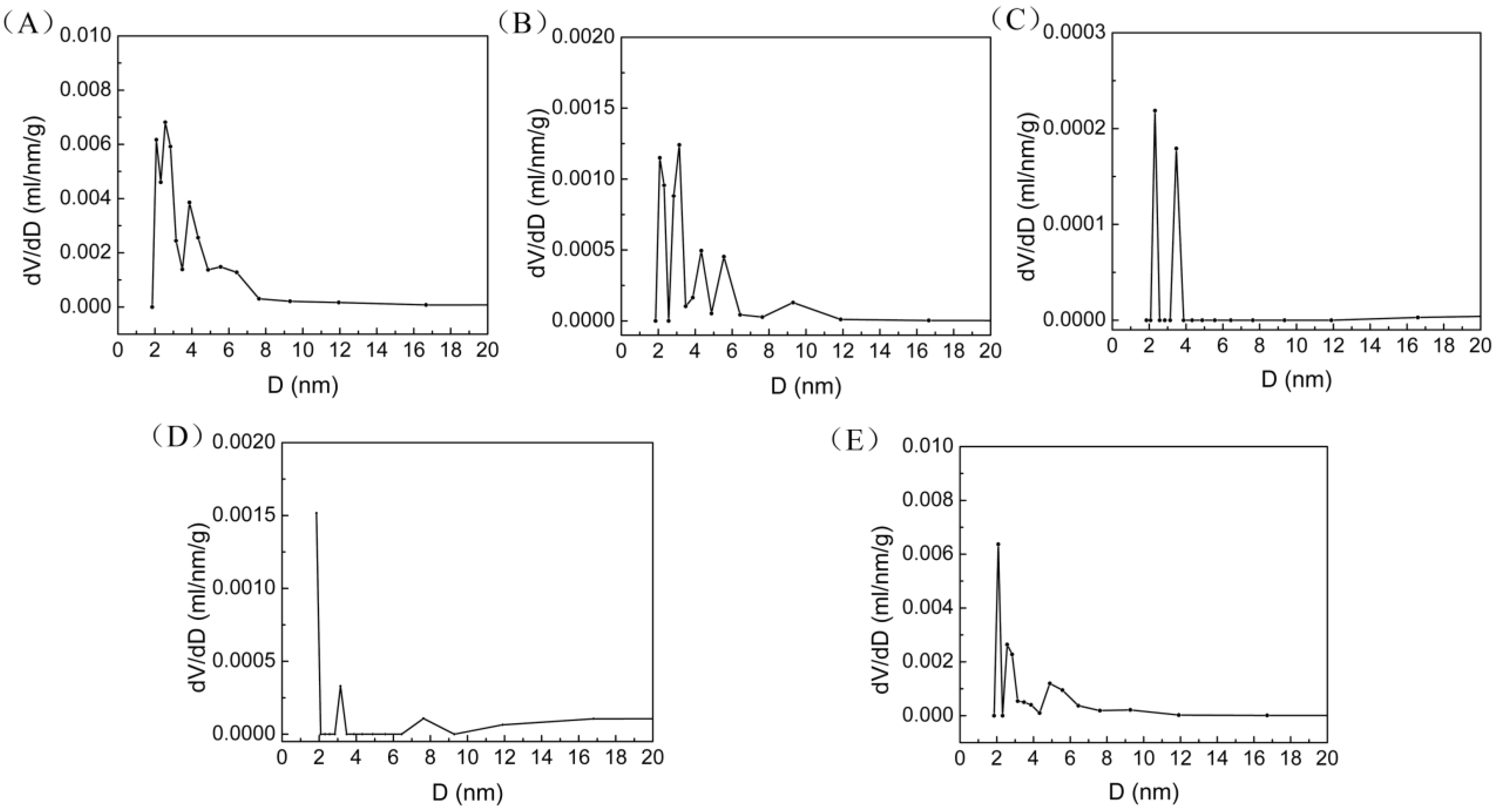

3.3. Synthesis and Pore Structure Characterization of Multiple Micro-/Meso-Porous Conjugated Polymer c-PPECz

3.4. Loading of Metal Ion in c-PPECz

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Amin, K.; Ashraf, N.; Mao, L.; Faul, C.F.; Wei, Z. Conjugated microporous polymers for energy storage: Recent progress and challenges. Nano Energy 2021, 85, 105958. [Google Scholar] [CrossRef]

- Luo, S.; Zeng, Z.; Wang, H.; Xiong, W.; Song, B.; Zhou, C.; Duan, A.; Tan, X.; He, Q.; Zeng, G.; et al. Recent progress in conjugated microporous polymers for clean energy: Synthesis, modification, computer simulations, and applications. Prog. Polym. Sci. 2021, 115, 101374. [Google Scholar] [CrossRef]

- Luo, S.; Zeng, Z.; Zeng, G.; Liu, Z.; Xiao, R.; Xu, P.; Wang, H.; Huang, D.; Liu, Y.; Shao, B.; et al. Recent advances in conjugated microporous polymers for photocatalysis: Designs, applications, and prospects. J. Mater. Chem. A 2020, 8, 6434–6470. [Google Scholar] [CrossRef]

- Yang, L.; Ma, Y.; Xu, Y.; Chang, G. Cation–π induced lithium-doped conjugated microporous polymer with remarkable hydrogen storage performance. Chem. Commun. 2019, 55, 11227–11230. [Google Scholar] [CrossRef] [PubMed]

- Yuan, S.; Dorney, B.; White, D.; Kirklin, S.; Zapol, P.; Yu, L.; Liu, D.-J. Microporous polyphenylenes with tunable pore size for hydrogen storage. Chem. Commun. 2010, 46, 4547–4549. [Google Scholar] [CrossRef]

- Zeng, W.; Zhang, Y.; Zhao, X.; Qin, M.; Li, X.; Jin, W.; Zhang, D. One-pot synthesis of conjugated microporous polymers based on extended molecular graphenes for hydrogen storage. Polymer 2019, 174, 96–100. [Google Scholar] [CrossRef]

- Sun, C.-J.; Wang, P.-F.; Wang, H.; Han, B.-H. All-thiophene-based conjugated porous organic polymers. Polym. Chem. 2016, 7, 5031–5038. [Google Scholar] [CrossRef]

- Qiao, S.; Wei, H.; Wang, T.; Huang, W.; Gu, C.; Yang, R.; Li, X. A ribbon-like ultramicroporous conjugated polycarbazole network for gas storage and separation. New J. Chem. 2016, 40, 3172–3176. [Google Scholar] [CrossRef]

- Qiao, S.; Huang, W.; Du, Z.; Chen, X.; Shieh, F.-K.; Yang, R. Phosphine oxide-based conjugated microporous polymers with excellent CO2 capture properties. New J. Chem. 2015, 39, 136–141. [Google Scholar] [CrossRef]

- Broicher, C.; Foit, S.R.; Rose, M.; Hausoul, P.J.; Palkovits, R. A bipyridine-based conjugated microporous polymer for the Ir-catalyzed dehydrogenation of formic acid. ACS Catal. 2017, 7, 8413–8419. [Google Scholar] [CrossRef]

- Okubo, M.; Hosono, E.; Kim, J.; Enomoto, M.; Kojima, N.; Kudo, T.; Zhou, H.; Honma, I. Nanosize effect on high-rate Li-ion intercalation in LiCoO2 electrode. J. Am. Chem. Soc. 2007, 129, 7444–7452. [Google Scholar] [CrossRef]

- Zhang, Q.; Dai, Q.; Li, M.; Wang, X.; Li, A. Incorporation of MnO nanoparticles inside porous carbon nanotubes originated from conjugated microporous polymers for lithium storage. J. Mater. Chem. A 2016, 4, 19132–19139. [Google Scholar] [CrossRef]

- Chen, Y.; Li, H.; Tang, M.; Zhuo, S.; Wu, Y.; Wang, E.; Wang, S.; Wang, C.; Hu, W. Capacitive conjugated ladder polymers for fast-charge and-discharge sodium-ion batteries and hybrid supercapacitors. J. Mater. Chem. A 2019, 7, 20891–20898. [Google Scholar] [CrossRef]

- Liao, Y.; Wang, H.; Zhu, M.; Thomas, A. Efficient supercapacitor energy storage using conjugated microporous polymer networks synthesized from Buchwald–Hartwig coupling. Adv. Mater. 2018, 30, 1705710. [Google Scholar] [CrossRef] [PubMed]

- Roy, S.; Bandyopadhyay, A.; Das, M.; Ray, P.P.; Pati, S.K.; Maji, T.K. Redox-active and semi-conducting donor–acceptor conjugated microporous polymers as metal-free ORR catalysts. J. Mater. Chem. A 2018, 6, 5587–5591. [Google Scholar] [CrossRef]

- Liu, W.; Wang, K.; Wang, C.; Liu, W.; Pan, H.; Xiang, Y.; Qi, D.; Jiang, J. Mixed phthalocyanine-porphyrin-based conjugated microporous polymers towards unveiling the activity origin of Fe–N 4 catalysts for the oxygen reduction reaction. J. Mater. Chem. A 2018, 6, 22851–22857. [Google Scholar] [CrossRef]

- Rao, K.V.; Haldar, R.; Maji, T.K.; George, S.J. Dynamic, conjugated microporous polymers: Visible light harvesting via guest-responsive reversible swelling. Phys. Chem. Chem. Phys. 2016, 18, 156–163. [Google Scholar] [PubMed]

- Yu, Y.-Y.; Tsai, T.-W.; Chen, C.-P. Efficient ternary organic photovoltaics using two conjugated polymers and a nonfullerene acceptor with complementary absorption and cascade energy-level alignment. J. Phys. Chem. C 2018, 122, 24585–24591. [Google Scholar] [CrossRef]

- Xu, Y.; Chen, L.; Guo, Z.; Nagai, A.; Jiang, D. Light-emitting conjugated polymers with microporous network architecture: Interweaving scaffold promotes electronic conjugation, facilitates exciton migration, and improves luminescence. J. Am. Chem. Soc. 2011, 133, 17622–17625. [Google Scholar] [CrossRef]

- Jiang, J.-X.; Trewin, A.; Adams, D.J.; Cooper, A.I. Band gap engineering in fluorescent conjugated microporous polymers. Chem. Sci. 2011, 2, 1777–1781. [Google Scholar] [CrossRef]

- Gu, C.; Huang, N.; Chen, Y.; Qin, L.; Xu, H.; Zhang, S.; Li, F.; Ma, Y.; Jiang, D. π-conjugated microporous polymer films: Designed synthesis, conducting properties, and photoenergy conversions. Angew. Chem. 2015, 127, 13798–13802. [Google Scholar] [CrossRef]

- Gu, C.; Huang, N.; Chen, Y.; Zhang, H.; Zhang, S.; Li, F.; Ma, Y.; Jiang, D. Porous organic polymer films with tunable work functions and selective hole and electron flows for energy conversions. Angew. Chem. Int. Ed. 2016, 55, 3049–3053. [Google Scholar] [CrossRef]

- Downey, J.S.; Frank, R.S.; Li, W.-H.; Stöver, H.D. Growth mechanism of poly (divinylbenzene) microspheres in precipitation polymerization. Macromolecules 1999, 32, 2838–2844. [Google Scholar] [CrossRef]

- Almog, Y.; Reich, S.; Levy, M. Monodisperse polymeric spheres in the micron size range by a single step process. Br. Polym. J. 1982, 14, 131–136. [Google Scholar] [CrossRef]

- Wang, B.; Tan, Q.; Lu, J.; Liang, H. Facile synthesis of hyperbranched poly (p-phenyleneethynylene-alt-m-phenyleneethynylene) with narrow dispersity and high branching degree by sonogashira polymerization of an AB2 monomer. J. Polym. Sci. Part A Polym. Chem. 2018, 56, 96–104. [Google Scholar] [CrossRef]

- Vives, G.; Guerrero, J.M.; Godoy, J.; Khatua, S.; Wang, Y.-P.; Kiappes, J.; Link, S.; Tour, J.M. Synthesis of fluorescent dye-tagged nanomachines for single-molecule fluorescence spectroscopy. J. Org. Chem. 2010, 75, 6631–6643. [Google Scholar] [CrossRef]

- Hayat, A.; Sohail, M.; El Jery, A.; Al-Zaydi, K.M.; Raza, S.; Ali, H.; AI-Hadeethi, Y.; Taha, T.A.; Din, I.U.; Khan, M.A.; et al. Recent advances in ground-breaking conjugated microporous polymers-based materials, their synthesis, modification and potential applications. Materials Today 2023, 64, 180–208. [Google Scholar] [CrossRef]

- Barrett, K.E. Dispersion polymerisation in organic media. Br. Polym. J. 1973, 5, 259–271. [Google Scholar] [CrossRef]

- Parlett, C.M.; Wilson, K.; Lee, A.F. Hierarchical porous materials: Catalytic applications. Chem. Soc. Rev. 2013, 42, 3876–3893. [Google Scholar] [CrossRef]

- Zhang, Q.; Ge, S.; Wang, X.; Sun, H.; Zhu, Z.; Liang, W.; Li, A. Novel MnO/conjugated microporous polymer derived-porous hard carbon nanocomposite for superior lithium storage. RSC Adv. 2014, 4, 41649–41653. [Google Scholar] [CrossRef]

- Mu, P.; Sun, H.; Zhu, Z.; Liang, W.; Liu, J.; Li, A. Synthesis and Properties of Nitrogen-Containing Conjugated Microporous Polymers. Macromol. Mater. Eng. 2016, 301, 451–456. [Google Scholar] [CrossRef]

- Zhang, Q.; Meng, Y.; Li, M.; Wang, X. Thiophene containing conjugated microporous polymers derived sulfur-enriched porous carbon supported Fe3O4 nanoparticles with superior lithium storage properties. J. Mater. Sci. Mater. Electron. 2019, 30, 1425–1433. [Google Scholar] [CrossRef]

- Zhang, B.; Wang, W.; Liang, L.; Xu, Z.; Li, X.; Qiao, S. Prevailing conjugated porous polymers for electrochemical energy storage and conversion: Lithium-ion batteries, supercapacitors and water-splitting. Coord. Chem. Rev. 2021, 436, 213782. [Google Scholar] [CrossRef]

| c-PPECz-1 | c-PPECz-2 | c-PPECz-3 | c-PPECz-4 | c-PPECz-5 * | |

|---|---|---|---|---|---|

| [hb-PPECz] (wt/v%) | 2 | 0.6 | 1 | 4 | 1 |

| product appearance | dispersion | dispersion | dispersion | bulky gel | dispersion |

| BET Specific Surface Area/(m2·g−1) | Pore Volume/(cm3·g−1) | Average Pore Size/nm | Percentage of Pore Size below 10 nm | |

|---|---|---|---|---|

| c-PPECz-1 | 15.7014 | 0.0476 | 12.1263 | 83.24% |

| c-PPECz-2 | 1.4085 | 0.0034 | 9.6557 | 93.72% |

| c-PPECz-3 | 0.3207 | 0.0032 | 39.9100 | 54.39% |

| c-PPECz-4 | 5.9429 | 0.0306 | 20.5960 | 58.73% |

| c-PPECz-5 | 10.7781 | 0.0108 | 4.0081 | 94.47% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liang, Z.; Liang, H. Synthesis of Nano-Structured Conjugated Polymers with Multiple Micro-/Meso-Pores by the Post-Crosslinking of End-Functionalized Hyperbranched Conjugated Polymers. Polymers 2024, 16, 1192. https://doi.org/10.3390/polym16091192

Liang Z, Liang H. Synthesis of Nano-Structured Conjugated Polymers with Multiple Micro-/Meso-Pores by the Post-Crosslinking of End-Functionalized Hyperbranched Conjugated Polymers. Polymers. 2024; 16(9):1192. https://doi.org/10.3390/polym16091192

Chicago/Turabian StyleLiang, Zhenfeng, and Hui Liang. 2024. "Synthesis of Nano-Structured Conjugated Polymers with Multiple Micro-/Meso-Pores by the Post-Crosslinking of End-Functionalized Hyperbranched Conjugated Polymers" Polymers 16, no. 9: 1192. https://doi.org/10.3390/polym16091192

APA StyleLiang, Z., & Liang, H. (2024). Synthesis of Nano-Structured Conjugated Polymers with Multiple Micro-/Meso-Pores by the Post-Crosslinking of End-Functionalized Hyperbranched Conjugated Polymers. Polymers, 16(9), 1192. https://doi.org/10.3390/polym16091192