Influence of Manufacturing Process on the Conductivity of Material Extrusion Components: A Comparison between Filament- and Granule-Based Processes

Abstract

1. Introduction

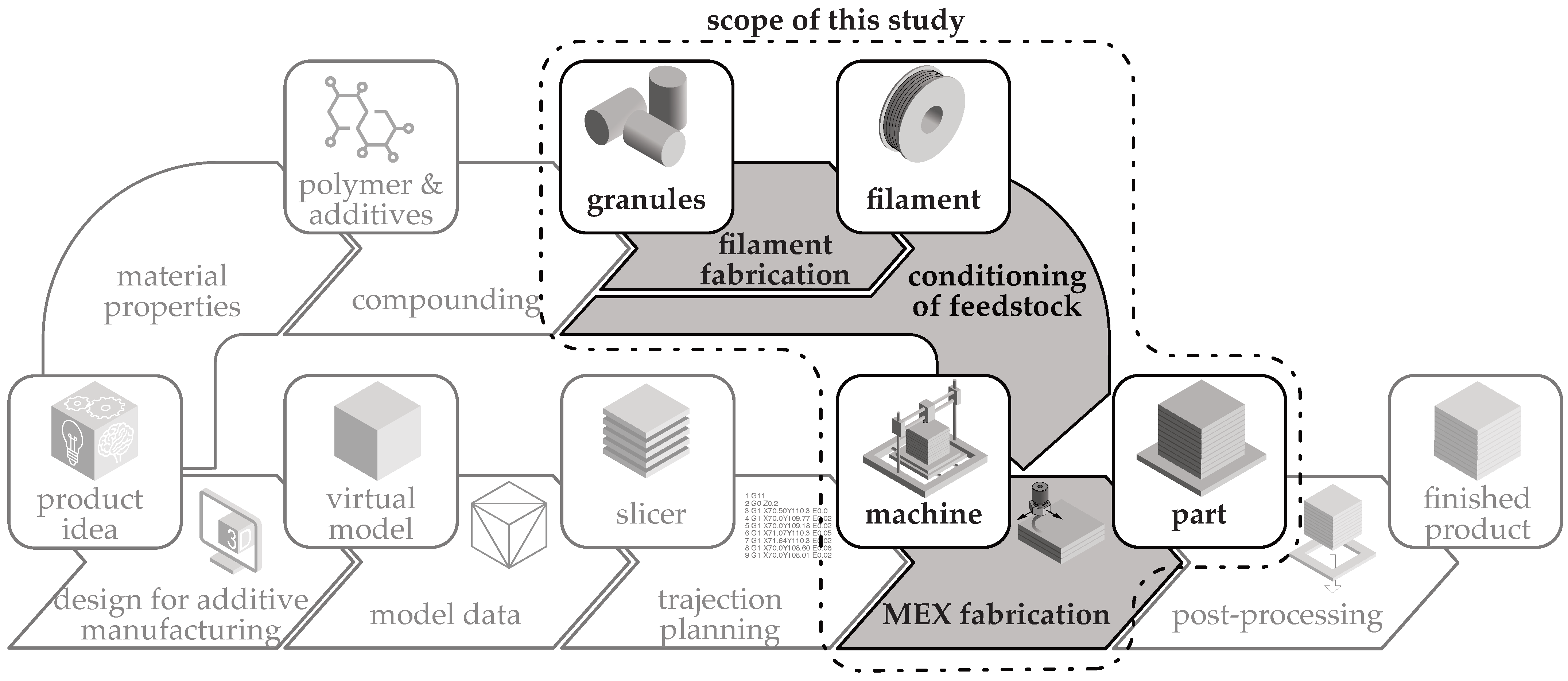

1.1. Material Extrusion

1.2. MEX Process Chain Overview

1.2.1. Process Chain: Granule MEX

1.2.2. Process Chain: Filament MEX

1.3. Current Literature

2. Materials and Methods

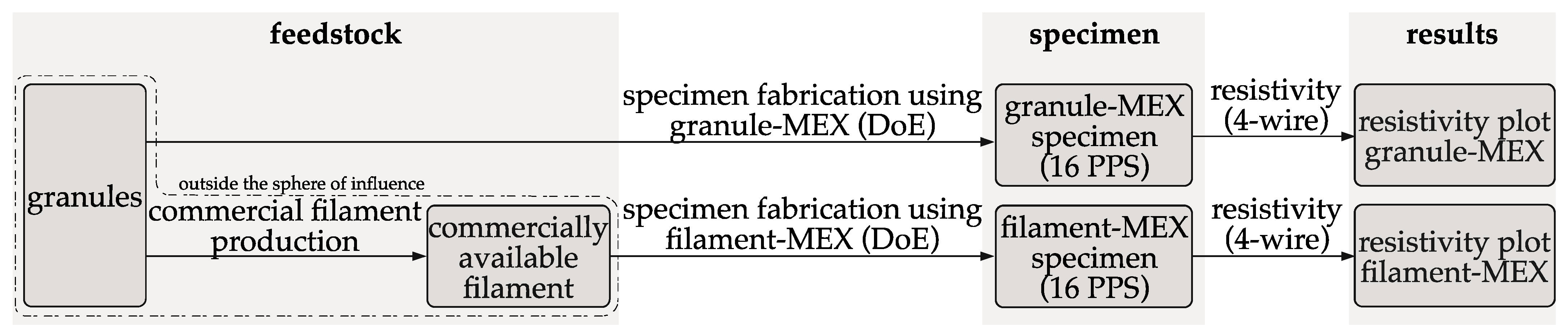

- MEX specimens were manufactured from filaments and granules using two feedstock-specific AM machines (filament MEX and granule MEX).

- MEX specimens were produced for each process using 16 different process parameter sets (PPSs).

- The specimens’ resistivity was determined using a four-wire measurement method in accordance with DIN EN ISO 3915:2022-5 [5].

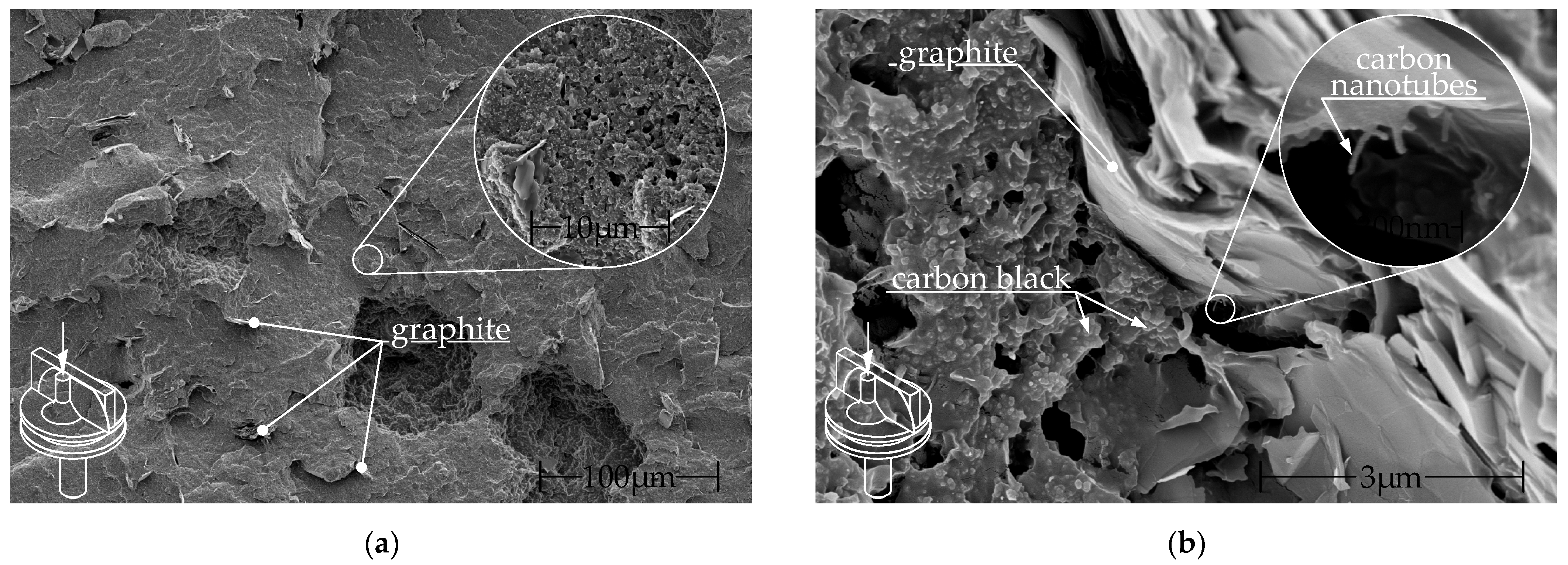

2.1. Materials

2.2. Additive Manufacturing Machines

2.3. Resistivity Measurement

2.4. Design of Experiments

3. Results and Discussion

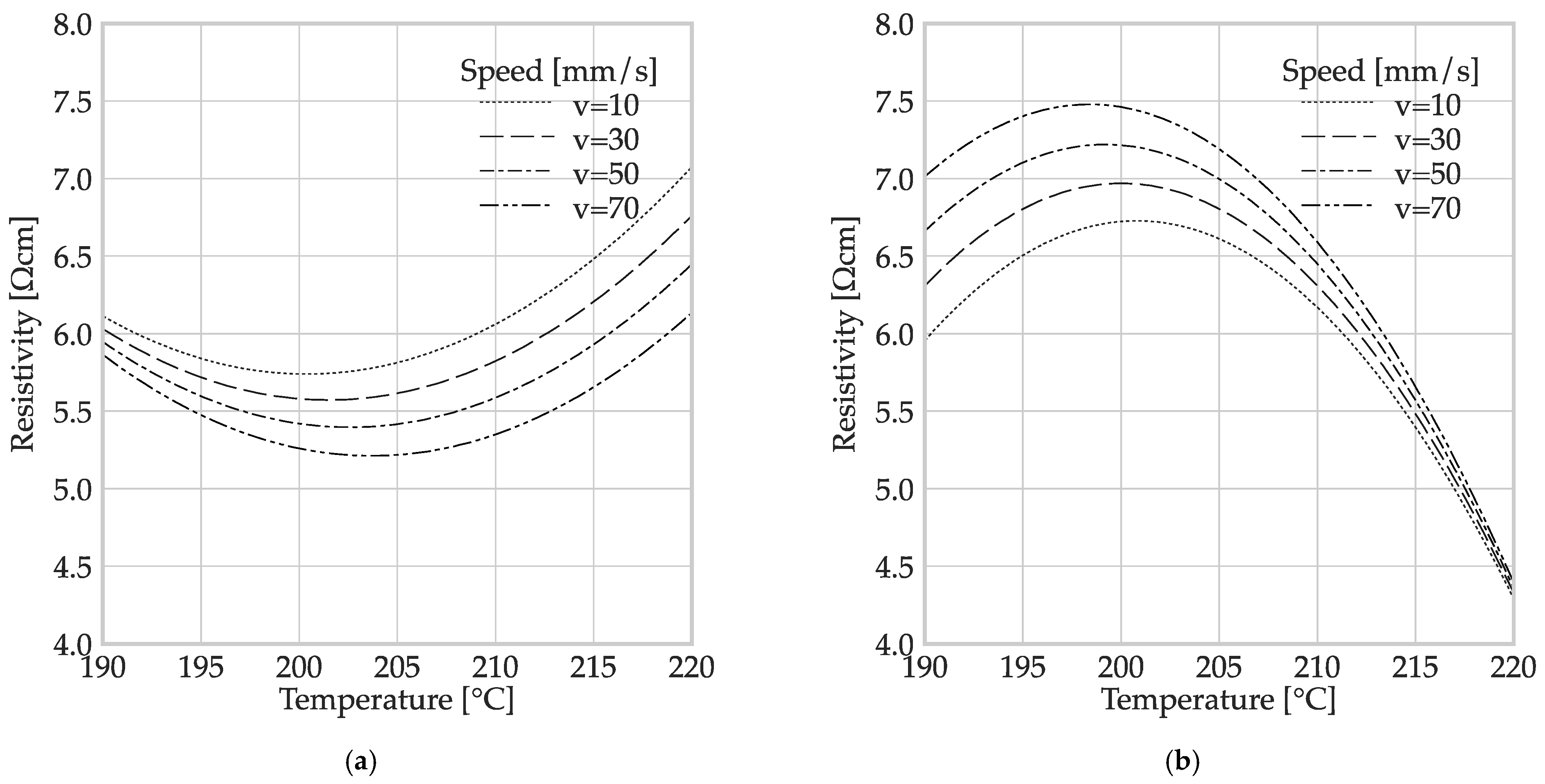

3.1. Resistivity as a Function of Process Variant and Process Parameters

3.2. Influence of the Nozzle Diameter on Resistivity in Filament MEX

4. Summary and Conclusions

- The resistivity of electrically conductive MEX structures was not significantly affected by the processes investigated.

- Better absolute lowest resistivity could be achieved with the granule MEX process using the optimal process parameter set.

- The nozzle diameter had a significant influence on the resistivity, with smaller diameters leading to significantly higher resistivity.

- Larger nozzle diameters enable both a higher material deposition rate and, depending on the chosen process parameter set, a better overall conductivity. Therefore, if the geometric constraints, such as the thinnest wall of the structure, allow, larger nozzle diameters are preferable.

- The granule MEX process can directly process granules and is more economical due to the elimination of filament production. Therefore, it is preferable to filament extrusion. However, precise process control is required.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Gibson, I.; Rosen, D.W.; Stucker, B.; Khorasani, M. Additive Manufacturing Technologies; Springer: Berlin/Heidelberg, Germany, 2021. [Google Scholar]

- Diegel, O.; Nordin, A.; Motte, D. A Practical Guide to Design for Additive Manufacturing; Springer: Berlin/Heidelberg, Germany, 2020. [Google Scholar]

- Godec, D.; Gonzalez-Gutierrez, J.; Nordin, A.; Pei, E.; Alcázar, J.U. A Guide to Additive Manufacturing; Springer International Publishing AG: Berlin/Heidelberg, Germany, 2022. [Google Scholar]

- Nowka, M.; Hilbig, K.; Schulze, L.; Jung, E.; Vietor, T. Influence of process parameters in material extrusion on product properties using the example of the electrical resistivity of conductive polymer composites. Polymers 2023, 15, 4452. [Google Scholar] [CrossRef] [PubMed]

- DIN Deutsches Institut für Normung e. V. Additive Fertigung—Grundlagen—Terminologie; Beuth Verlag GmbH: Berlin, Germany, 2022. [Google Scholar]

- DIN Deutsches Institut für Normung e. V. Fertigungsverfahren—Begriffe, Einteilung; Beuth Verlag GmbH: Berlin, Germany, 2022. [Google Scholar]

- Lachmayer, R.; Ehlers, T.; Lippert, R.B. Entwicklungsmethodik für die Additive Fertigung; Springer Vieweg: Berlin/Heidelberg, Germany, 2022. [Google Scholar]

- Gebhardt, A. Generative Fertigungsverfahren Additive Manufacturing und 3D-Drucken für Prototyping—Tooling—Produktion; Hanser: München, Germany, 2016. [Google Scholar]

- Johannaber, F.; Ast, W. Kunststoffmaschinenführer; Hanser: München, Germany, 1992. [Google Scholar]

- Watschke, H.; Hilbig, K.; Vietor, T. Design and characterization of electrically conductive structures additively manufactured by material extrusion. Appl. Sci. 2019, 9, 779. [Google Scholar] [CrossRef]

- Stankevich, S.; Sevcenko, J.; Bulderberga, O.; Dutovs, A.; Erts, D.; Piskunovs, M.; Ivanovs, V.; Ivanov, V.; Aniskevich, A. Electrical resistivity of 3D-printed polymer elements. Polymers 2023, 15, 2988. [Google Scholar] [CrossRef] [PubMed]

- Kumar, N.; Jain, P.K.; Tandon, P.; Pandey, P.M. Additive manufacturing of flexible electrically conductive polymer composites via CNC-assisted fused layer modeling process. J. Braz. Soc. Mech. Sci. Eng. 2018, 40, 175. [Google Scholar] [CrossRef]

- Georgopoulou, A.; Clemens, F. Pellet-based fused deposition modeling for the development of Soft Compliant Robotic grippers with integrated sensing elements. Flex. Print. Electron. 2022, 7, 25010. [Google Scholar] [CrossRef]

- Bajpai, A.; Jain, P.K. Investigation on 3D printing of graphene and multi-walled carbon nanotube mixed flexible electrically conductive parts using fused filament fabrication. J. Mater. Eng. Perform. 2022, 32, 6319–6328. [Google Scholar] [CrossRef]

- Bajpai, A.; Jain, P.K. Investigation on using graphite filler for 3d printing of flexible electrically conductive polymer by extrusion-based additive manufacturing. Polym. Eng. Sci. 2023, 64, 328–338. [Google Scholar] [CrossRef]

- Georgopoulou, A.; Egloff, L.; Vanderborght, B.; Clemens, F. A sensorized soft pneumatic actuator fabricated with extru-sion-based additive manufacturing. Actuators 2021, 10, 102. [Google Scholar] [CrossRef]

- Urra Sanchez, O.; Besharatloo, H.; Yus, J.; Sanchez-Herencia, A.J.; Ferrari, B. Material thermal extrusion of conductive 3D electrodes using highly loaded graphene and graphite colloidal feedstock. Addit. Manuf. 2023, 72, 103643. [Google Scholar] [CrossRef]

- Gao, H.; Meisel, A. Exploring the Manufacturability and Resistivity of Conductive Filament Used in Material Extrusion Additive Manufacturing; University of Texas at Austin: Austin, TX, USA, 2020. [Google Scholar]

- Zhang, J.; Yang, B.; Fu, F.; You, F.; Dong, X.; Dai, M. Resistivity and its anisotropy characterization of 3D-printed acrylonitrile butadiene styrene copolymer (abs)/carbon black (CB) composites. Appl. Sci. 2017, 7, 20. [Google Scholar] [CrossRef]

- Dembek, K.; Podsiadły, B.; Słoma, M. Influence of process parameters on the resistivity of 3D printed electrically conductive structures. Micromachines 2022, 13, 1203. [Google Scholar] [CrossRef] [PubMed]

- Yang, L.; Chen, Y.; Wang, M.; Shi, S.; Jing, J. Fused deposition modeling 3D printing of Novel Poly(vinyl alcohol)/graphene nanocomposite with enhanced mechanical and electromagnetic interference shielding properties. Ind. Eng. Chem. Res. 2020, 59, 8066–8077. [Google Scholar] [CrossRef]

- Paz, R.; Moriche, R.; Monzón, M.; García, J. Influence of manufacturing parameters and post processing on the electrical conductivity of extrusion-based 3D printed nanocomposite parts. Polymers 2020, 12, 733. [Google Scholar] [CrossRef] [PubMed]

- Ciceri de Mondel S.r.l. a Socio Unico. Technical Data Sheet ALFAOHM.; FVia Galvani 13, 20080 Ozzero (MI), Spanien. 2019. Available online: https://www.filoalfa3d.com/img/cms/MSDS%20&%20TDS/TDS%20ALFAOHM%20Sept,%202019.pdf (accessed on 28 January 2023).

- Contreras-Naranjo, J.E.; Perez-Gonzalez, V.H.; Mata-Gómez, M.A.; Aguilar, O. 3D-printed hybrid-carbon-based electrodes for electroanalytical sensing applications. Electrochem. Commun. 2021, 130, 107098. [Google Scholar] [CrossRef]

- ASTM D257-14(2021)e1; D09 Committee. Test Methods for DC Resistance or Conductance of Insulating Materials. ASTM International: West Conshohocken, PA, USA, 2021. [CrossRef]

- Spahr, M.E.; Gilardi, R.; Bonacchi, D. Carbon Black for Electrically Conductive Polymer Applications. In Fillers for Polmer Applications; Rothon, R., Ed.; Springer International Publishing: Cham, Switzerland, 2017; pp. 375–400. ISBN 978-3-319-28117-9. [Google Scholar]

- Baur, E.; Brinkmann, S.; Osswald, T.A.; Rudolph, N.; Schmachtenberg, E. Saechtling Kunststoff Taschenbuch, 31st ed.; Carl Hanser Verlag: München, Germany, 2012; ISBN 978-3-446-43442-4. [Google Scholar]

- Gilardi, R.; Bonacchi, D.; Spahr, M.E. Graphitic Carbon Powders for Polymer Applications. In Fillers for Polymer Applications; Rothon, R., Ed.; Springer International Publishing: Cham, Switzerland, 2017; pp. 401–424. ISBN 978-3-319-28116-2. [Google Scholar]

- INDART3D S. COOP. PEQUEÑA—RUBÉN GARCÍA. DATASHEET: NX PRO PELLETS; C/Gorostiaga 67, 20305, Irun, Spain. 2019. Available online: https://it3d.com/wp-content/uploads/download-files/ficha-tecnica/en/data-sheet-NX-PRO-Pellets-(ENG).pdf (accessed on 16 April 2024).

- DIN EN ISO 10350-1:2018-03; Kunststoffe_Ermittlung und Darstellung vergleichbarer Einpunktkennwerte_Teil_1: Formmassen (ISO_10350-1:2017); Deutsche Fassung EN_ISO_10350-1:2017. Beuth Verlag GmbH: Berlin, Germany, 2022.

- DIN EN ISO 3915:2022-05; Kunststoffe—Messung des Spezifischen Elektrischen Widerstands von Leitfähigen Kunststoffen (ISO_3915:2022); Deutsche Fassung EN_ISO_3915:2022. Beuth Verlag GmbH: Berlin, Germany, 2022.

- Hilbig, K.; Nowka, M.; Redeker, J.; Watschke, H.; Friesen, V.; Duden, A.; Vietor, T. Data-driven design support for additively manufactured heating elements. Proc. Des. Soc. 2022, 2, 1391–1400. [Google Scholar] [CrossRef]

- Hampel, B.; Monshausen, S.; Schilling, M. Properties and applications of electrically conductivethermoplastics for additive manufacturing of sensors. TM—Tech. Mess. 2017, 84, 593–599. [Google Scholar] [CrossRef]

- Nassar, H.; Dahiya, R. Fused deposition modeling-based 3d-printed electrical interconnects and Circuits. Adv. Intell. Syst. 2021, 3, 2100102. [Google Scholar] [CrossRef]

- Kim, H.; Lee, S. Characterization of electrical heating of graphene/PLA honeycomb structure composite manufactured by CFDM 3D printer. Fash. Text. 2020, 7, 8. [Google Scholar] [CrossRef]

- Drücker, S.; Voormann, H.; von Berg, K.-P.; Ahrens, M.W.; Wisniewski, V.K.; Schröder, E.; Kehne, A.; Detjen, S.; Kaysser, S.; Keun, C.-A.; et al. Solid epoxy for functional 3D printing with isotropic mechanical properties by material extrusion. Addit. Manuf. 2022, 55, 102797. [Google Scholar] [CrossRef]

- Truman, L.; Whitwam, E.; Nelson-Cheeseman, B.B.; Koerner, L.J. Conductive 3D printing: Resistivity dependence upon infill pattern and application to EMI shielding. J. Mater. Sci. Mater. Electron. 2020, 31, 14108–14117. [Google Scholar] [CrossRef]

- Scholle, P.; Rüther, S.; Sinapius, M. Comparison of Electrical Contacting Techniques to Carbon Fiber Reinforced Plastics for Self-Strain-Sensing Applications. C 2021, 7, 81. [Google Scholar] [CrossRef]

- Marion, S.; Joffre, T.; Jaxel, J.; Pigeonneau, F. Improved printability and electrical conductivity of carbon black polymer composite with a customized nozzle of material extrusion process. Addit. Manuf. 2024, 79, 103939. [Google Scholar] [CrossRef]

- Heller, B.P.; Smith, D.E.; Jack, D.A. Effects of extrudate swell and nozzle geometry on fiber orientation in fused filament fab-rication nozzle flow. Addit. Manuf. 2016, 12, 252–264. [Google Scholar] [CrossRef]

- Kanarska, Y.; Duoss, E.B.; Lewicki, J.P.; Rodriguez, J.N.; Wu, A. Fiber motion in highly confined flows of carbon fiber and non-Newtonian polymer. J. Non-Newton. Fluid Mech. 2019, 265, 41–52. [Google Scholar] [CrossRef]

- Abdalla, A.; Hamzah, H.H.; Keattch, O.; Covill, D.; Patel, B.A. Augmentation of conductive pathways in carbon black/PLA 3D-printed electrodes achieved through varying printing parameters. Electrochim. Acta 2020, 354, 136618. [Google Scholar] [CrossRef]

| Study | Kumar et al. [12] | Bajpai et al. [14,15] | Georgopoulou et al. [16] | Georgopoulou et al. [13] | Watschke et al. [10] | Sanchez et al. [17] | Gao and Meisel [18] | Zhang et al. [19] | Dembek et al. [20] | Yang et al. [21] | Paz et al. [22] | Nowka et al. [4] | Stankevich et al. [11] | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Material and feedstock processing | Commercially available | ◆ | ◆ | ◆ | ◆ | ◆ | ||||||||

| Matrix polymer | EVA | EVA | TPE | TPE | PLA, PCL | PLA | PLA | ABS | PLA | PVA | ABS | PLA | PLA PVDF | |

| Fillers (legend below) | GR | G, CNT | CB | CB | CB, CNT, CP | GR, G | CB, GnP | CB | CNT | GnP | GnP | CB, CNT | G, CB | |

| Filament MEX | ◆ | ◆ | ◆ | ◆ | ◆ | ◆ | ◆ | ◆ | ◆ | |||||

| Granule MEX | ◆ | ◆ | ◆ | ◆ | ||||||||||

| MEX parameters | Layer height | ⊛ | ⊛ | ⊛ | ⊛ | ⊛ | ⊛ | |||||||

| Deposition speed | ⊛ | ⊛ | ⊛ | |||||||||||

| Extrusion temperature | ⊛ | ⊛ | ⊛ | ⊛ | ⊛ | |||||||||

| Build platform temp. | ||||||||||||||

| Infill pattern | ⊛ | ⊛ | ⊛ | |||||||||||

| Infill pattern orientation | ⊛ | ⊛ | ⊛ | |||||||||||

| Infill percentage | ⊛ | |||||||||||||

| Line width | ⊛ | ⊛ | ||||||||||||

| Nozzle diameter | ⊛ | |||||||||||||

| Flow rate | ⊛ | ⊛ | ||||||||||||

| Cooling | ⊛ | |||||||||||||

| Characterization | Electrical bonding | Ag, Cu | Ag | Ag | Ag | Ag | Ag | Ag | ||||||

| Resistivity filament | ◎ | ◉ | ◉ | ◎ | ◉ | |||||||||

| Resistivity MEX specimen | ◉ | ◎ | ◎ | ◎ | ◉ | ◎ | ◉ | ◉ | ◎ | ◎ | ◉ | ◉ | ||

| SEM | ◆ | ◆ | ◆ | ◆ | ◆ | ◆ | ◆ |

| DoE Input Factor | Lower Limit | Increment | Upper Limit |

|---|---|---|---|

| Extrusion temperature [°C] | 190 | 10 | 220 |

| Deposition speed [mm/s] | 10 | 20 | 70 |

| MEX manufacturing process | Filament MEX | - | Granule MEX |

| Filament MEX | Granule MEX | ||

|---|---|---|---|

| Model | S [Ωcm] | 0.482835 | 0.696061 |

| R2 [%] | 51.50 | 71.39 | |

| R2 (predicted) [%] | 45.11 | 68.03 | |

| p-Value | Extr. temperature [°C] | 0.000 | 0.000 |

| Deposition speed [mm/s] | 0.125 | 0.068 | |

| Extr. temperature [°C] · extr. temperature [°C] | 0.000 | 0.000 | |

| Extr. temperature [°C] · deposition speed [mm/s] | 0.080 | 0.092 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nowka, M.; Hilbig, K.; Schulze, L.; Heller, T.; Goutier, M.; Vietor, T. Influence of Manufacturing Process on the Conductivity of Material Extrusion Components: A Comparison between Filament- and Granule-Based Processes. Polymers 2024, 16, 1134. https://doi.org/10.3390/polym16081134

Nowka M, Hilbig K, Schulze L, Heller T, Goutier M, Vietor T. Influence of Manufacturing Process on the Conductivity of Material Extrusion Components: A Comparison between Filament- and Granule-Based Processes. Polymers. 2024; 16(8):1134. https://doi.org/10.3390/polym16081134

Chicago/Turabian StyleNowka, Maximilian, Karl Hilbig, Lukas Schulze, Timo Heller, Marijn Goutier, and Thomas Vietor. 2024. "Influence of Manufacturing Process on the Conductivity of Material Extrusion Components: A Comparison between Filament- and Granule-Based Processes" Polymers 16, no. 8: 1134. https://doi.org/10.3390/polym16081134

APA StyleNowka, M., Hilbig, K., Schulze, L., Heller, T., Goutier, M., & Vietor, T. (2024). Influence of Manufacturing Process on the Conductivity of Material Extrusion Components: A Comparison between Filament- and Granule-Based Processes. Polymers, 16(8), 1134. https://doi.org/10.3390/polym16081134