Developing Eco-Friendly 3D-Printing Composite Filament: Utilizing Palm Midrib to Reinforce High-Density Polyethylene Matrix in Design Applications

Abstract

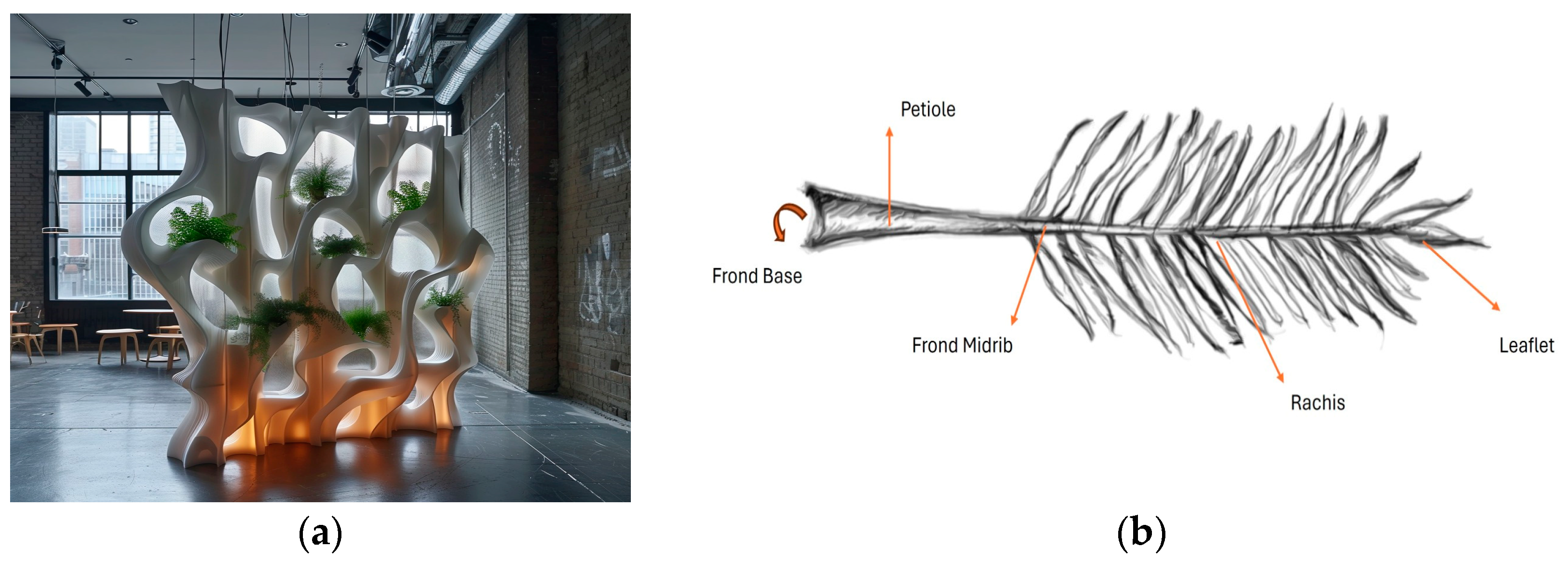

1. Introduction

2. Materials and Methods

2.1. Fabrication of the Filament

2.2. Characterizations

2.3. Three-Dimensional-Printing Pen

3. Results

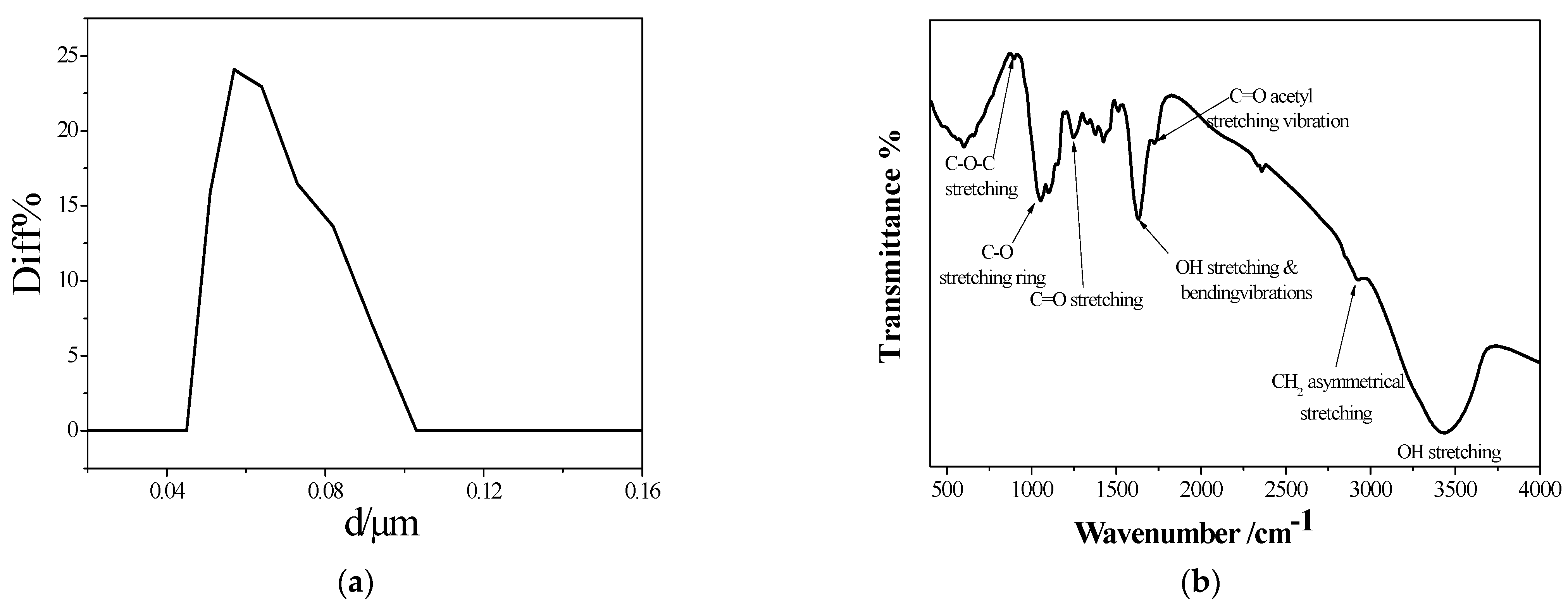

3.1. DPFNP Characterization

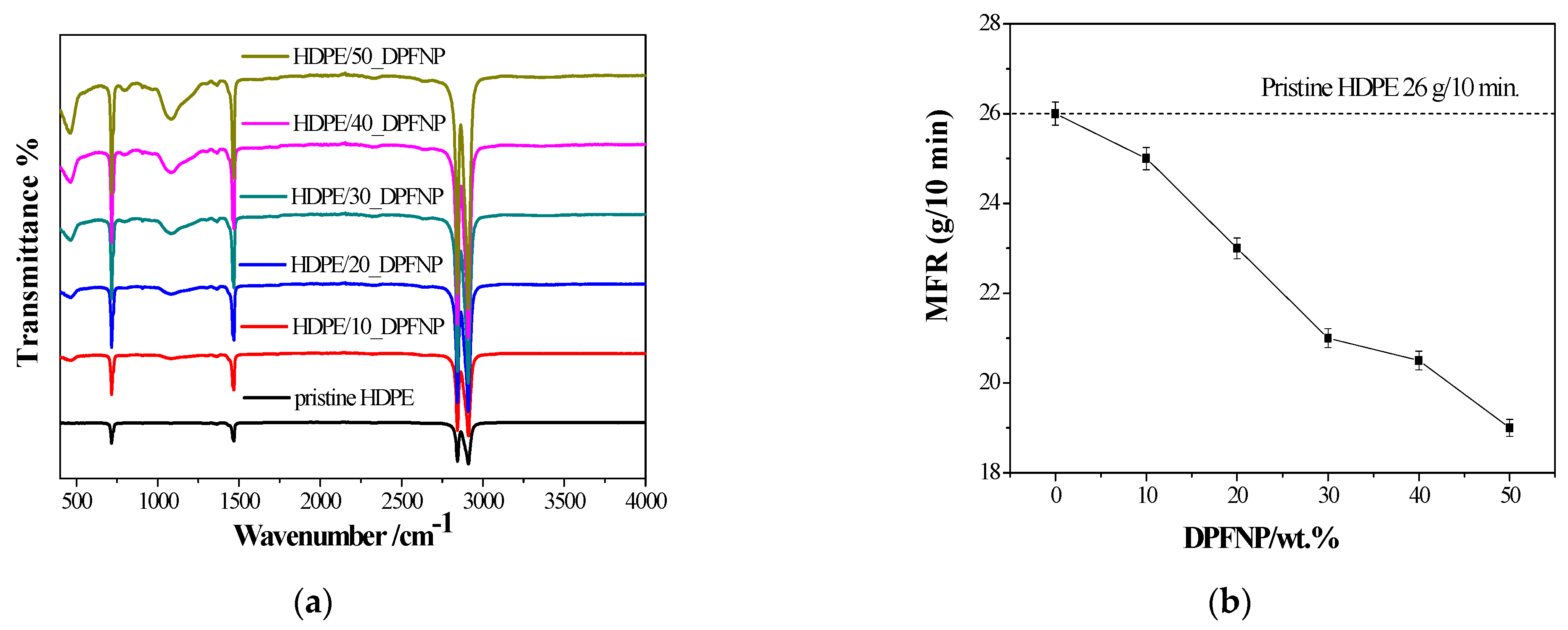

3.2. Filament Characterization

3.3. Three-Dimensional-Printing Pen

- Mechanical performance and impact resistance were the main topics of Caminero et al.’s investigation into the impact performance of continuous fiber-reinforced thermoplastic composites (CFRTPCs) made utilizing FDM. They discovered that the impact strength of these composites increased with the amount of fiber, with samples reinforced with glass fiber showing the highest impact strength. In comparison to traditional materials, this work highlights how fiber reinforcements can improve the mechanical and impact properties of thermoplastic composites [39].

- Printing quality and mechanical properties with nanocellulose: HDPE and chemically altered cellulose nanofibrils were combined to create a bio-based filament by Dalloul et al. [40]. Because the modified cellulose nanofibrils were fillers, the mechanical characteristics and print quality of this composite improved. This demonstrates how natural fillers, including palm midrib, can be used to improve HDPE composites and increase their characteristics for 3D printing.

- Sustainability and environmental impact: With the growing need for environmentally friendly materials in additive manufacturing, attention is being paid to the use of sustainable and renewable fillers, like cellulose nanofibrils and palm midrib. By using bio-based fillers, these composites not only have enhanced qualities but also support environmental sustainability.

- Enhanced printability with modified fibers: In contrast, modified cellulose nanofibrils were used to address the significant shrinkage and warping issues with HDPE in 3D printing [40]. Better printability and mechanical qualities result from this alteration, which also improves compatibility and dispersion within the HDPE matrix. This method emphasis the benefit of palm midrib in enhancing the characteristics and printability of HDPE composites.

- Comparison with other reinforcements: Comparing CFRTPCs and nanocellulose-based filaments with other reinforcements has shown the advantages of both fiber reinforcement and natural fillers [41,42]. However, HDPE/DPFNP composites offer a new material choice that combines the benefits of bio-based reinforcement with the well-known properties of HDPE. In terms of mechanical characteristics, sustainability, and prospective applications in 3D printing, this comparison is intriguing.

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Mehrpouya, M.; Dehghanghadikolaei, A.; Fotovvati, B.; Vosooghnia, A.; Emamian, S.S.; Gisario, A. The potential of additive manufacturing in the smart factory industrial 4.0: A review. Appl. Sci. 2019, 9, 3865. [Google Scholar] [CrossRef]

- Saad, R. The revolution of materials used in 3D printing applications in furniture and interior design. Int. Des. J. 2016, 6, 143–163. [Google Scholar] [CrossRef]

- Kokkinis, D.; Schaffner, M.; Studart, A. Multimaterial magnetically assisted 3D printing of composite materials. Nat. Commun. 2015, 6, 8643. [Google Scholar] [CrossRef] [PubMed]

- Yulvan, Y. 3D printing in the learning process of furniture design. In Proceedings of the 1st Conference of Visual Art, Design, and Social Humanities by Faculty of Art and Design, CONVASH 2019, Surakarta, Indonesia, 2 November 2019. [Google Scholar] [CrossRef]

- Vo, H. Design creativity in Industry 4.0: Gravity Sketch and 3D printing in a luminaire design project. J. Eng. Des. Technol. 2022; ahead-of-print. [Google Scholar] [CrossRef]

- Mitchell, A.; Lafont, U.; Hołyńska, M.; Semprimoschnig, C. Additive manufacturing—A review of 4D printing and future applications. Addit. Manuf. 2018, 24, 606–626. [Google Scholar] [CrossRef]

- Archello. The World’s First 3D Printed, Irrigated Green Wall. Available online: https://archello.com/it/news/the-worlds-first-3d-printed-irrigated-green-wall (accessed on 10 March 2024).

- Der Klift, F.V.; Koga, Y.; Todoroki, A.; Ueda, M.; Hirano, Y.; Matsuzaki, R. 3D printing of continuous carbon fibre reinforced thermo-plastic (CFRTP) tensile test specimens. Open J. Compos. Mater. 2016, 6, 18–27. [Google Scholar] [CrossRef]

- Nicolau, A.; Pop, M.; Coșereanu, C. 3D printing application in wood furniture components assembling. Materials 2022, 15, 2907. [Google Scholar] [CrossRef] [PubMed]

- Shi, Q. Research status and development trend of polylactic acid matrix composites applied to 3D printed furniture. Int. J. Front. Sociol. 2021, 3, 3–11. [Google Scholar] [CrossRef]

- Hsieh, C.; Ku, S. The research on the characteristics of furniture hardware design through 3D printing. In HCI International 2019—Posters; Stephanidis, C., Ed.; Springer: Cham, Switzerland, 2019. [Google Scholar] [CrossRef]

- Lee, S.H.; Lee, T.; Lim, H. A study on the importance and application of 3D printing technology for street furniture manufacturing. J. Korea Acad. Ind. Coop. Soc. 2020, 21, 509–517. [Google Scholar]

- Paramés-González, A.; Prieto-Lage, I.; Gutiérrez-Santiago, A. 3D printing in fitting furniture to student anthropometry. ESHPA Educ. Sport Health Phys. Act. 2021, 5, 76–89. [Google Scholar] [CrossRef]

- Greenhalgh, S. The effects of 3D printing in design thinking and design education. J. Eng. Des. Technol. 2016, 14, 752–769. [Google Scholar] [CrossRef]

- Ngo, T.; Kashani, A.; Imbalzano, G.; Nguyen, K.; Hui, D. Additive manufacturing (3D printing): A review of materials, methods, applications and challenges. Compos. Part B Eng. 2018, 143, 172–196. [Google Scholar] [CrossRef]

- Jiang, Z.; Diggle, B.; Tan, M.; Viktorova, J.; Bennett, C.W.; Connal, L. Extrusion 3D printing of polymeric materials with advanced properties. Adv. Sci. 2020, 7, 2001379. [Google Scholar] [CrossRef] [PubMed]

- Sadik, W.A.; El-Demerdash, A.M.; Abokhateeb, E.A.A.; Elessawy, N.A. Innovative high-density polyethylene/waste glass powder composite with remarkable mechanical, thermal and recyclable properties for technical applications. Heliyon 2021, 7, e06627. [Google Scholar] [CrossRef] [PubMed]

- Sun, Y.; Qin, J. Introduction of a new line of high-density polyethylene (HDPE) based furniture. Int. J. Innov. Manag. Technol. 2023, 14, 7–12. [Google Scholar] [CrossRef]

- Jabasingh, S.A.; Kumar, B.; Kumar, G. Preparation of high density polyethylene (HDPE) blended lignocellulosic composite. Polym. Test. 2012, 31, 880–888. [Google Scholar] [CrossRef]

- Choi, K.; Ray, W. Recent developments in transition metal catalyzed olefin polymerization—A survey. I. Ethylene polymerization. J. Macromol. Sci.—Rev. Macromol. Chem. Phys. 1985, 25, 1–55. [Google Scholar] [CrossRef]

- Schirmeister, C.G.; Hees, T.; Licht, E.H.; Mülhaupt, R. 3D printing of high-density polyethylene by fused filament fabrication. Addit. Manuf. 2019, 28, 152–159. [Google Scholar] [CrossRef]

- Tang, W.; Santare, M.; Advani, S. Melt processing and mechanical property characterization of multi-walled carbon nanotube/high. Carbon 2003, 41, 2779–2785. [Google Scholar] [CrossRef]

- Palaniyandi, V.; Simonsen, J. Effect of compatibilizers on the crystallization kinetics of cellulose-filled high-density polyethylene. Compos. Interfaces 2007, 14, 73–83. [Google Scholar] [CrossRef]

- Kang, B.; Kim, S.; Song, H.A.; Lee, T. Accelerating the biodegradation of high-density polyethylene (HDPE) using Bjerkandera adusta TBB-03 and lignocellulose substrates. Microorganisms 2019, 7, 304. [Google Scholar] [CrossRef] [PubMed]

- Juan, R.; Domínguez, C.; Robledo, N.; Paredes, B.; García-Muñoz, R.A. Incorporation of recycled high-density polyethylene to polyethylene pipe grade resins to increase close-loop recycling and underpin the circular economy. J. Clean. Prod. 2020, 276, 124081. [Google Scholar] [CrossRef]

- University of Florida Gardening Solutions. Palm Leaf Structure. UF/IFAS Extension. Available online: https://gardeningsolutions.ifas.ufl.edu/plants/trees-and-shrubs/palms-and-cycads/palm-leaf-structure.html (accessed on 1 March 2024).

- ASTM D 638-14; Standard Test Method for Tensile Properties of Plastics. ASTM International: West Conshohocken, PA, USA, 2014.

- Yang, W.; Ding, H.; Puglia, D.; Kenny, J.M.; Liu, T.; Guo, J.; Wang, Q.; Ou, R.; Xu, P.; Ma, P.; et al. Bio-renewable polymers based on lignin-derived phenol monomers: Synthesis, applications, and perspectives. SusMat 2022, 2, 535–568. [Google Scholar] [CrossRef]

- Ahmad, T.; Danish, M.; Rafatullah, M.; Ghazali, A.; Sulaiman, O.; Hashim, R.; Ibrahim, M.N.M. The use of date palm as a potential adsorbent for wastewater treatment: A review. Environ. Sci. Pollut. Res. 2012, 19, 1464–1484. [Google Scholar] [CrossRef] [PubMed]

- Hahn, A.; Gerdts, G.; Völker, C.; Niebühr, V. Using FTIRS as pre-screening method for detection of microplastic in bulk sediment samples. Sci. Total Environ. 2019, 689, 341–346. [Google Scholar] [CrossRef]

- Zhang, J.; Koubaa, A.; Xing, D.; Liu, W.; Wang, Q.; Wang, X.; Wang, H. Improving lignocellulose thermal stability by chemical modification with boric acid for incorporating into polyamide. Mater. Des. 2020, 191, 108589. [Google Scholar] [CrossRef]

- Shah AU, R.; Jalil, A.; Sadiq, A.; Alzaid, M.; Naseem, M.S.; Alanazi, R.; Alanazi, S.; Alanzy, A.O.; Alsohaimi, I.H.; Malik, R.A. Effect of Rice Husk and Wood Flour on the Structural, Mechanical, and Fire-Retardant Characteristics of Recycled High-Density Polyethylene. Polymers 2023, 15, 4031. [Google Scholar] [CrossRef] [PubMed]

- de Carvalho, M.S.; Azevedo, J.B.; Barbosa, J.D.V. Effect of the melt flow index of an HDPE matrix on the properties of composites with wood particles. Polym. Test. 2020, 90, 106678. [Google Scholar] [CrossRef]

- Tisserat, B.; Reifschneider, L.; Joshee, N.; Finkenstadt, V.L. Properties of high density polyethylene–Paulownia wood flour composites via injection molding. BioResources 2013, 8, 4440–4458. [Google Scholar] [CrossRef]

- Jakab, E.; Faix, O.; Till, F. Thermal decomposition of milled wood lignins studied by thermogravimetry/mass spectrometry. J. Anal. Appl. Pyrolysis 1997, 40–41, 171–186. [Google Scholar] [CrossRef]

- Gouda, M.H.; Konsowa, A.H.; Farag, H.A.; Elessawy, N.A.; Tamer, T.M.; Mohy Eldin, M.S. Development novel eco-friendly proton exchange membranes doped with nano sulfated zirconia for direct methanol fuel cells. J. Polym. Res. 2021, 28, 263. [Google Scholar] [CrossRef]

- Tajeddin, B.; Rahman, R.A.; Abdulah, L.C.; Ibrahim, N.A.; Yusof, Y.A. Thermal Properties of Low Density Polyethylene—Filled Kenaf Cellulose Composites. Eur. J. Sci. Res. 2009, 32, 223–230. [Google Scholar]

- Facca, A.G.; Kortschot, M.T.; Yan, N. Predicting the tensile strength of natural fibre reinforced thermoplastics. Compos. Sci. Technol. 2007, 67, 2454–2466. [Google Scholar] [CrossRef]

- Caminero, M.; Chacón, J.M.; García-Moreno, I.; Rodríguez, G. Impact damage resistance of 3D printed continuous fibre reinforced thermoplastic composites using fused deposition modelling. Compos. Part B Eng. 2018, 148, 93–103. [Google Scholar] [CrossRef]

- Dalloul, F.; Mietner, J.B.; Navarro, J.R.G. Production and 3D Printing of a Nanocellulose-Based Composite Filament Composed of Polymer-Modified Cellulose Nanofibrils and High-Density Polyethylene (HDPE) for the Fabrication of 3D Complex Shapes. Fibers 2022, 10, 91. [Google Scholar] [CrossRef]

- Zhang, H.; Lei, X.; Hu, Q.; Wu, S.; Aburaia, M.; Gonzalez-Gutierrez, J.; Lammer, H. Hybrid Printing Method of Polymer and Continuous Fiber-Reinforced Thermoplastic Composites (CFRTPCs) for Pipes through Double-Nozzle Five-Axis Printer. Polymers 2022, 14, 819. [Google Scholar] [CrossRef]

- Yang, Y.; Yang, B.; Chang, Z.; Duan, J.; Chen, W. Research Status of and Prospects for 3D Printing for Continuous Fiber-Reinforced Thermoplastic Composites. Polymers 2023, 15, 3653. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

El Shakhs, A.; Elessawy, N.A.; El-Saka, M.F.; Hassan, G.E.; Ali, M.A.M. Developing Eco-Friendly 3D-Printing Composite Filament: Utilizing Palm Midrib to Reinforce High-Density Polyethylene Matrix in Design Applications. Polymers 2024, 16, 1135. https://doi.org/10.3390/polym16081135

El Shakhs A, Elessawy NA, El-Saka MF, Hassan GE, Ali MAM. Developing Eco-Friendly 3D-Printing Composite Filament: Utilizing Palm Midrib to Reinforce High-Density Polyethylene Matrix in Design Applications. Polymers. 2024; 16(8):1135. https://doi.org/10.3390/polym16081135

Chicago/Turabian StyleEl Shakhs, Ahmed, Noha A. Elessawy, Mohamed Fahmy El-Saka, Gasser E. Hassan, and May A. Malek Ali. 2024. "Developing Eco-Friendly 3D-Printing Composite Filament: Utilizing Palm Midrib to Reinforce High-Density Polyethylene Matrix in Design Applications" Polymers 16, no. 8: 1135. https://doi.org/10.3390/polym16081135

APA StyleEl Shakhs, A., Elessawy, N. A., El-Saka, M. F., Hassan, G. E., & Ali, M. A. M. (2024). Developing Eco-Friendly 3D-Printing Composite Filament: Utilizing Palm Midrib to Reinforce High-Density Polyethylene Matrix in Design Applications. Polymers, 16(8), 1135. https://doi.org/10.3390/polym16081135