Investigation of the Effectiveness of Silicon Nitride as a Reinforcement Agent for Polyethylene Terephthalate Glycol in Material Extrusion 3D Printing

Abstract

1. Introduction

- Examine the ability of Si3N4 to enhance the mechanical properties and reinforce the performance of the PETG polymer.

- Determine the contribution of Si3N4 to the electrical/dielectric properties of the PETG polymer.

- Investigate and provide evidence for the suitability of PETG/Si3N4 composites for use as 3D printable materials for the fabrication of various parts that can serve a constantly increasing variety of applications in demanding and extreme environments.

2. Materials and Methods

2.1. Materials

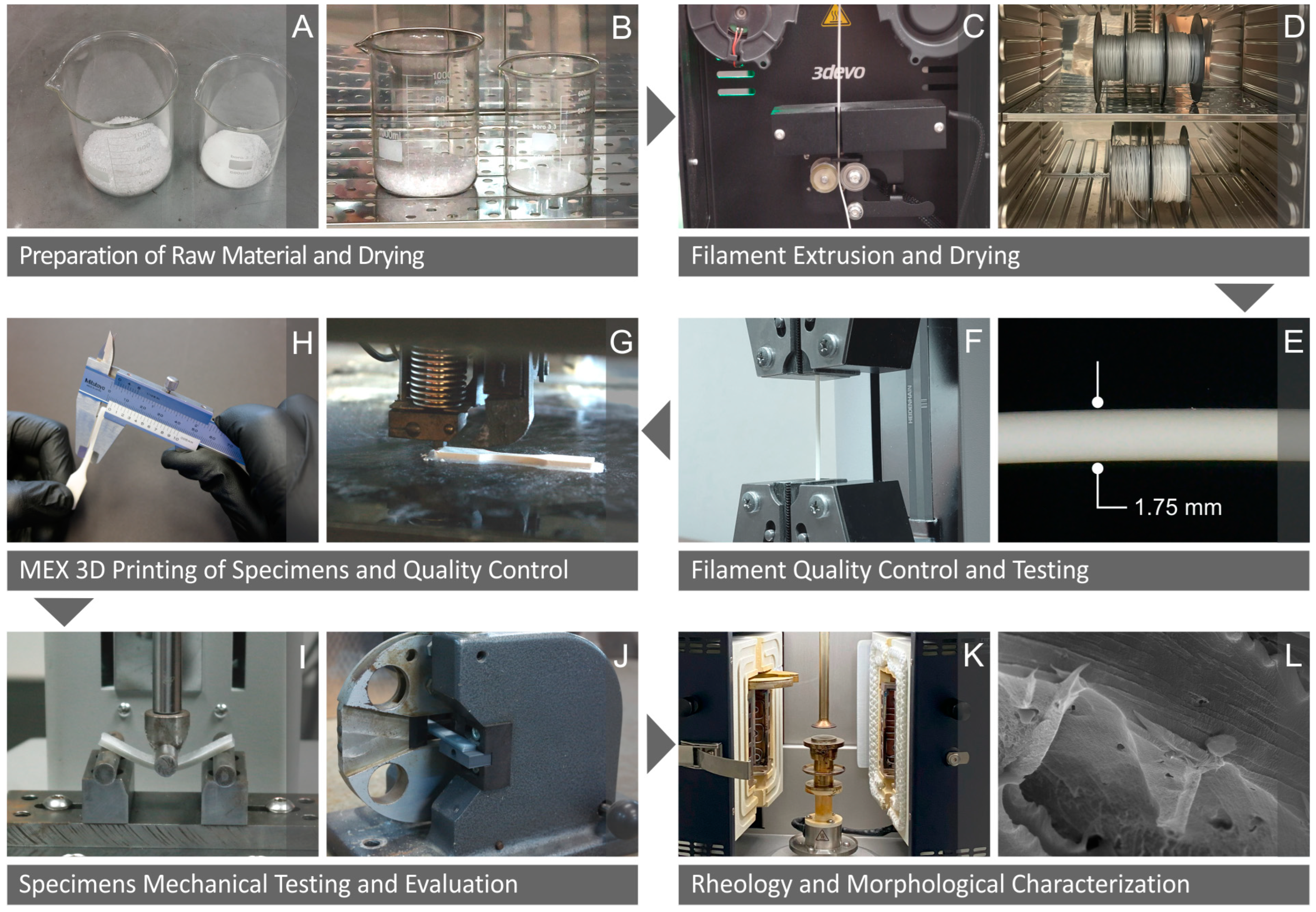

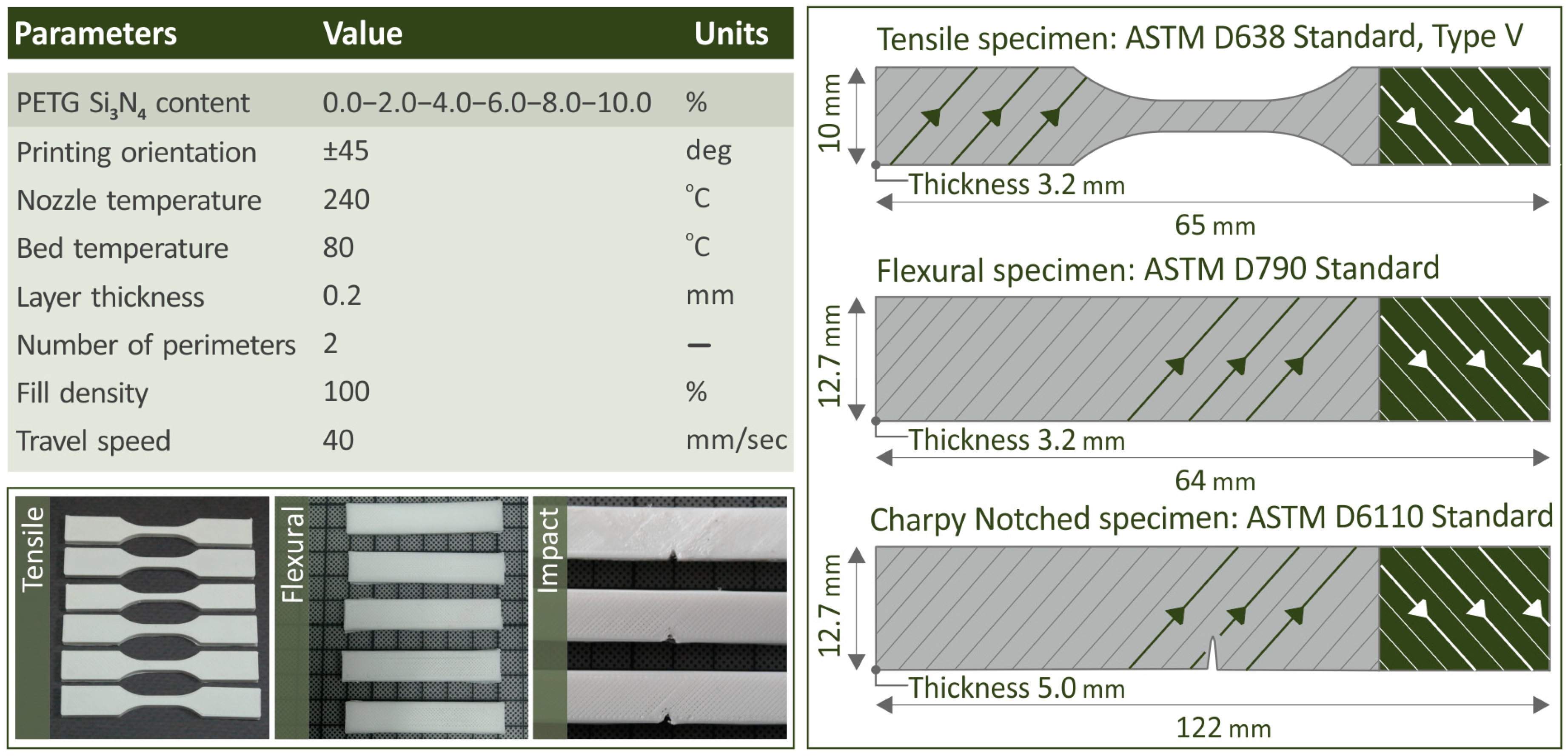

2.2. Preparation of the PETG/Si3N4 Filament and 3D Printing

2.3. SEM of Si3N4 and EDS Analysis

2.4. Mechanical Tests

2.5. Raman Spectroscopy

- Measurement spectral sensitivity range (50 up to 3900 cm−1);

- Spectral resolution (2 cm−1);

- Spectrometer grating (600 grooves/mm);

- Exposure time at each measurement point (10 s);

- Measurement accumulations per point (5);

- Measurement point dimensions (1.7 μm laterally and 2 μm axially).

2.6. Thermogravimetric and Differential Scanning Calorimetry Analyses

2.7. Investigation of the Rheometric Behavior

2.8. Broadband Dielectric Spectroscopy (BDS) Examination

2.9. Micro-Computed Tomography

3. Results

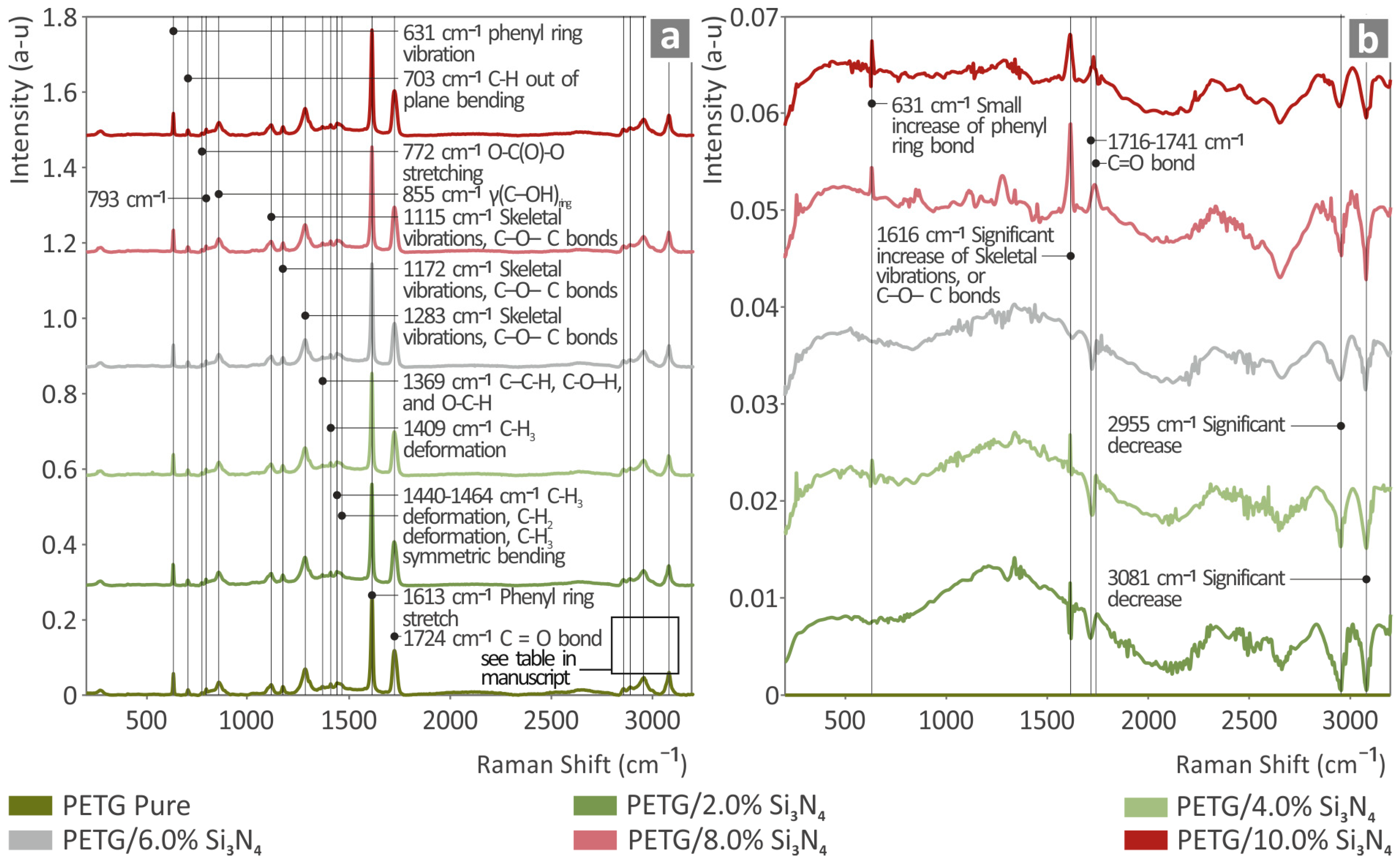

3.1. Raman Results for PETG/x wt.% Si3N4 Composites

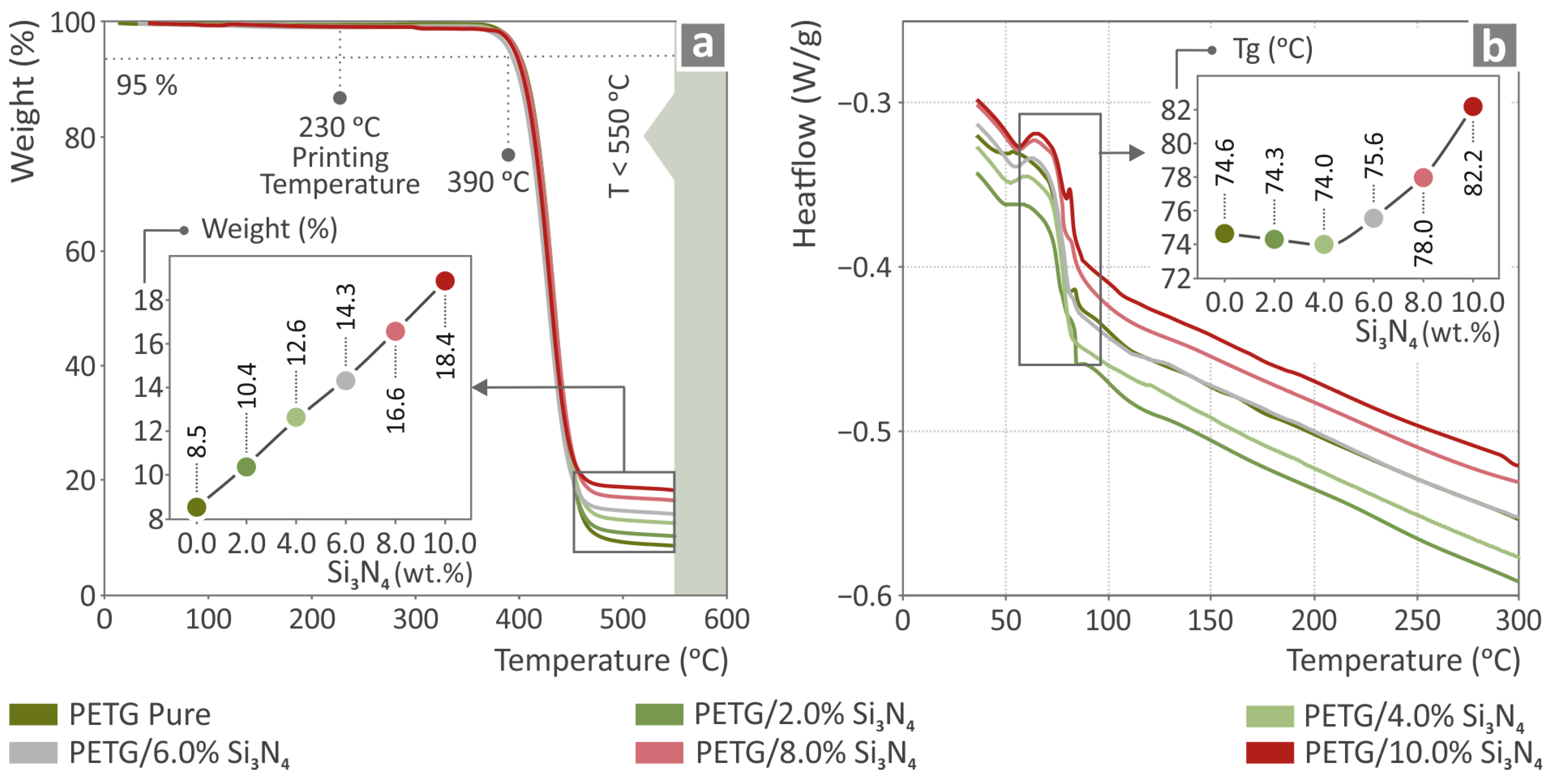

3.2. Thermogravimetric and Differential Scanning Calorimetry Analysis

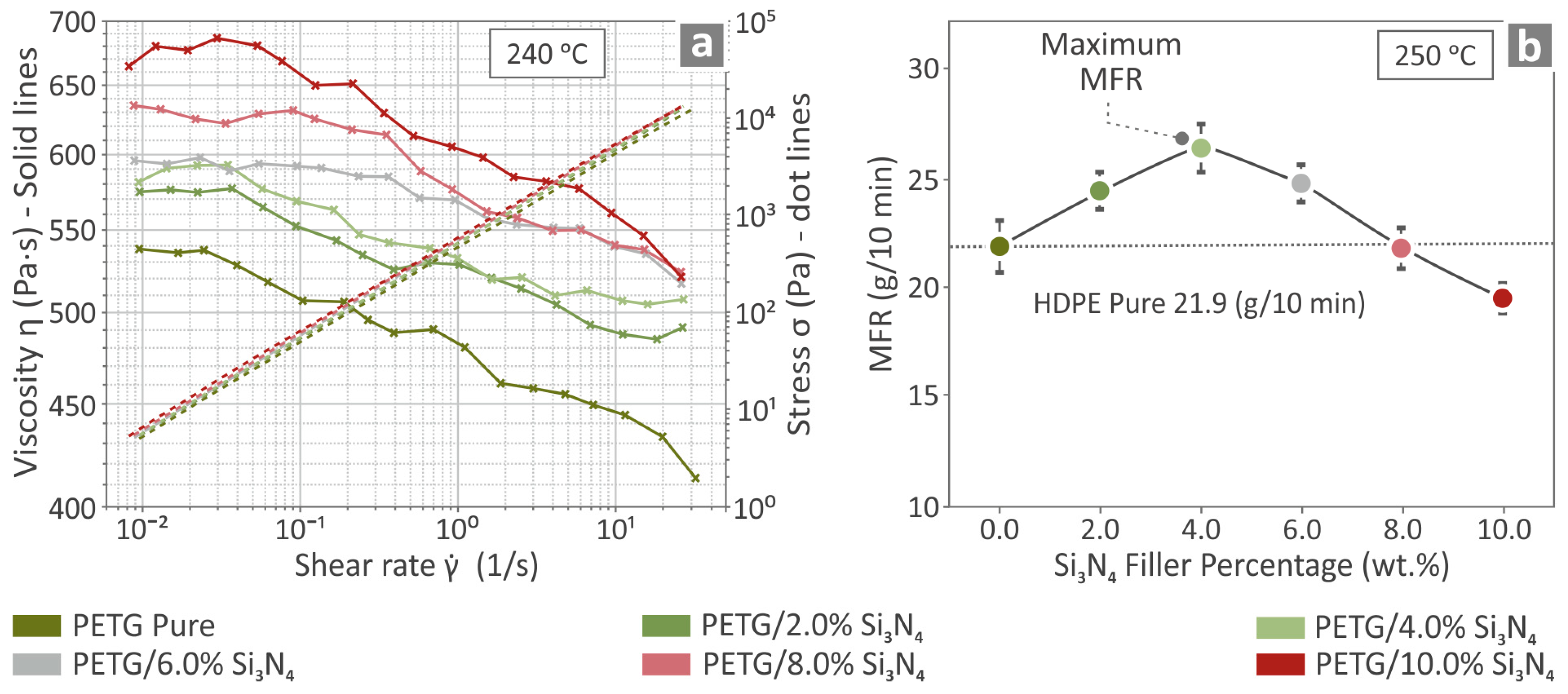

3.3. Viscosity and MFR Analysis

3.4. Monitoring of the Filament

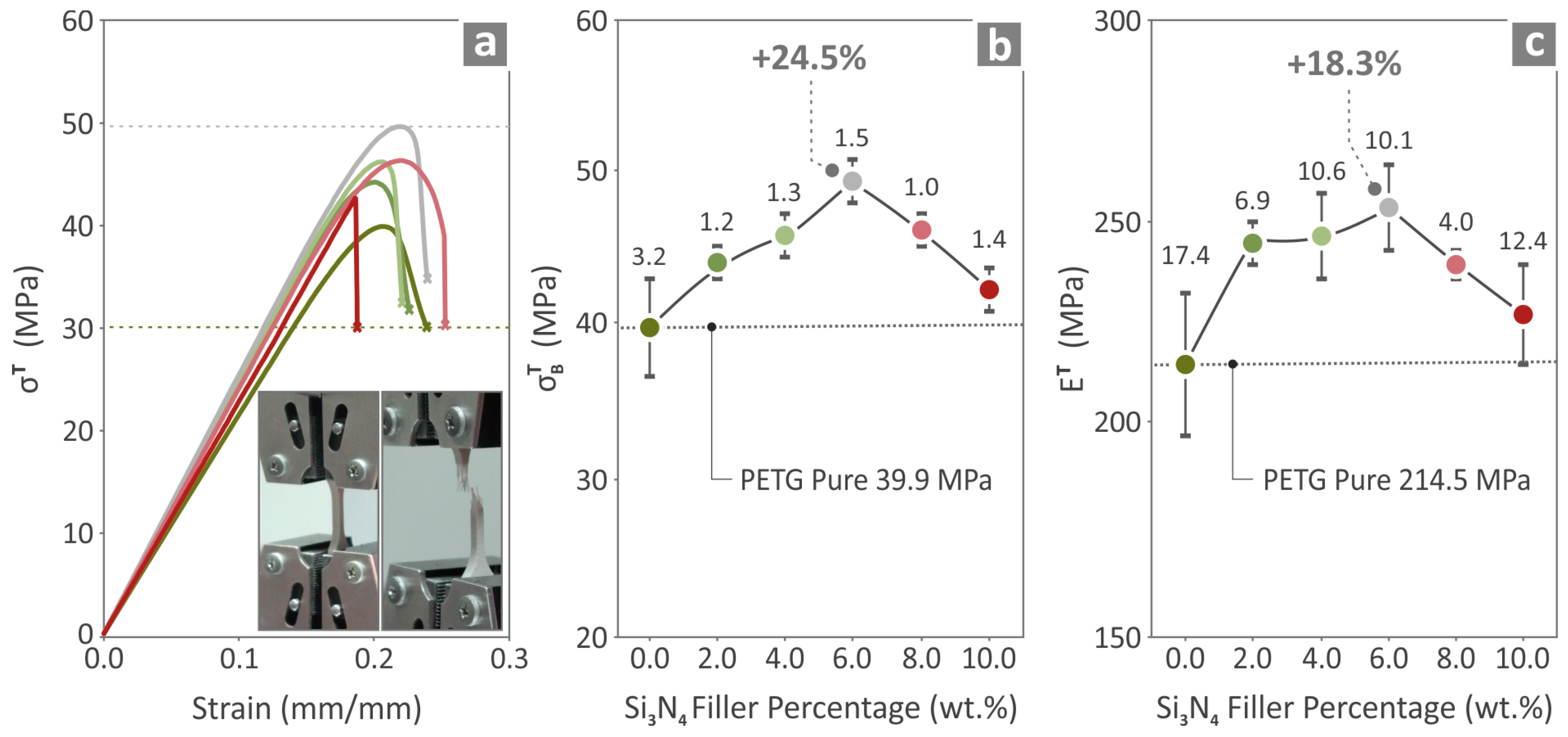

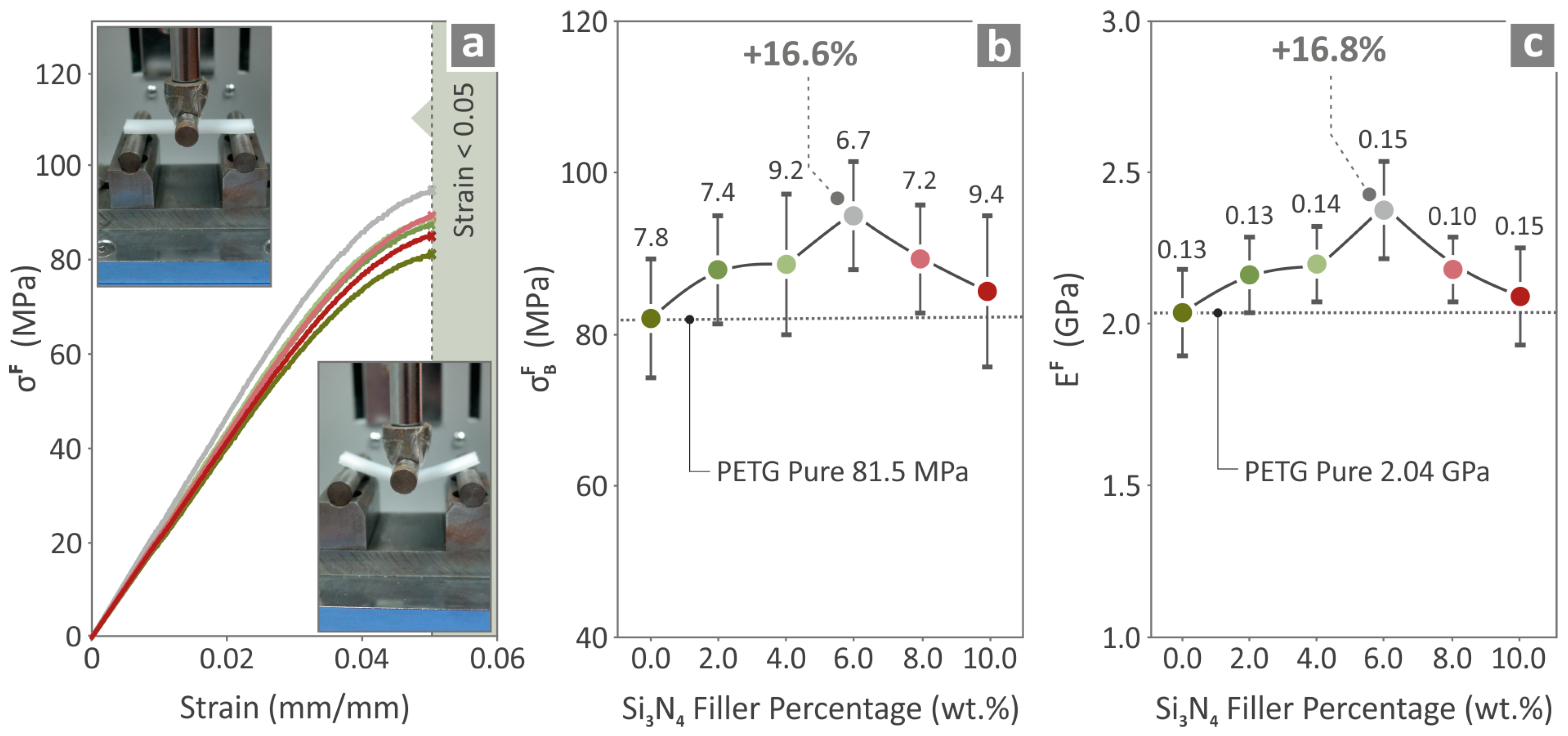

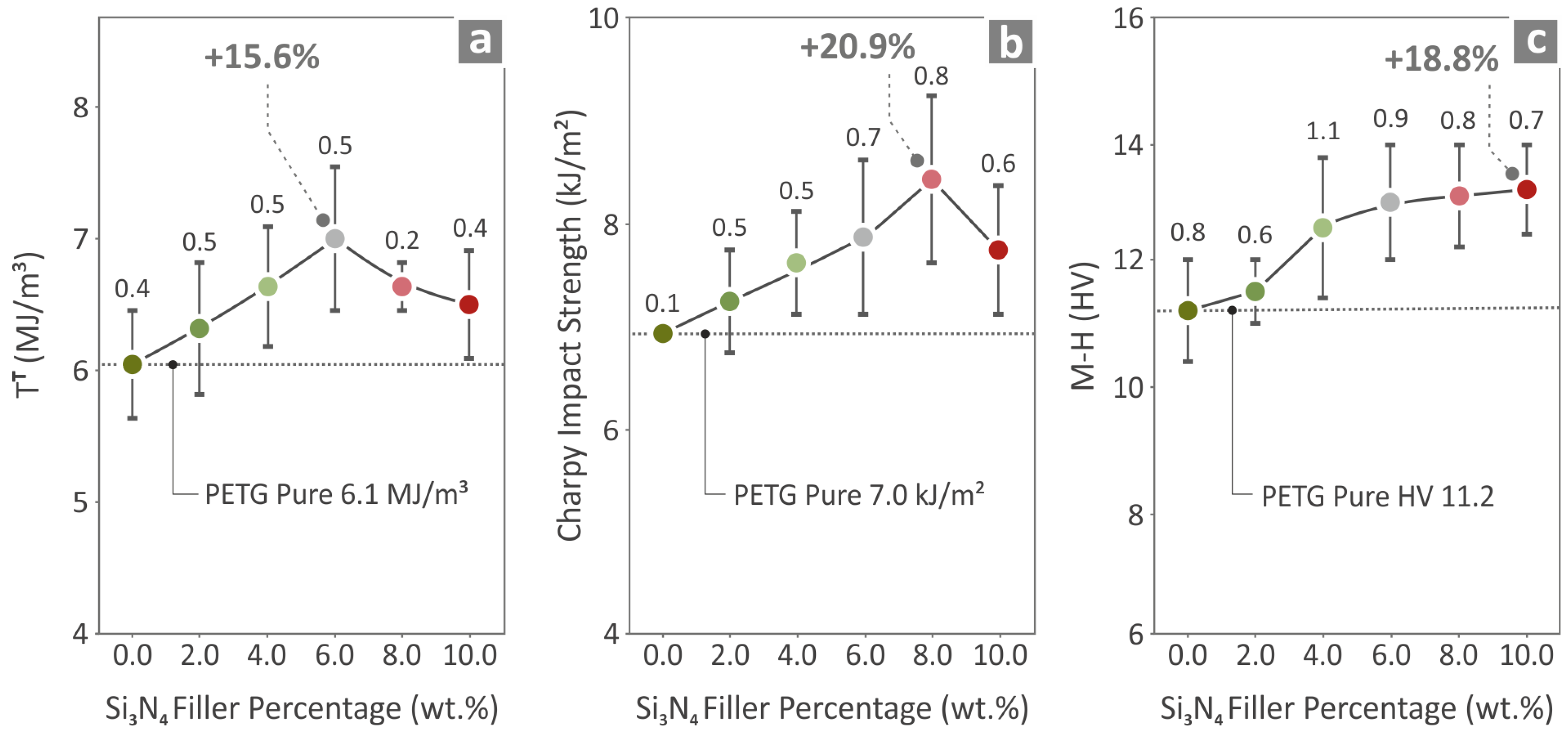

3.5. Mechanical Tests

3.6. Electrical/Dielectric Characterization

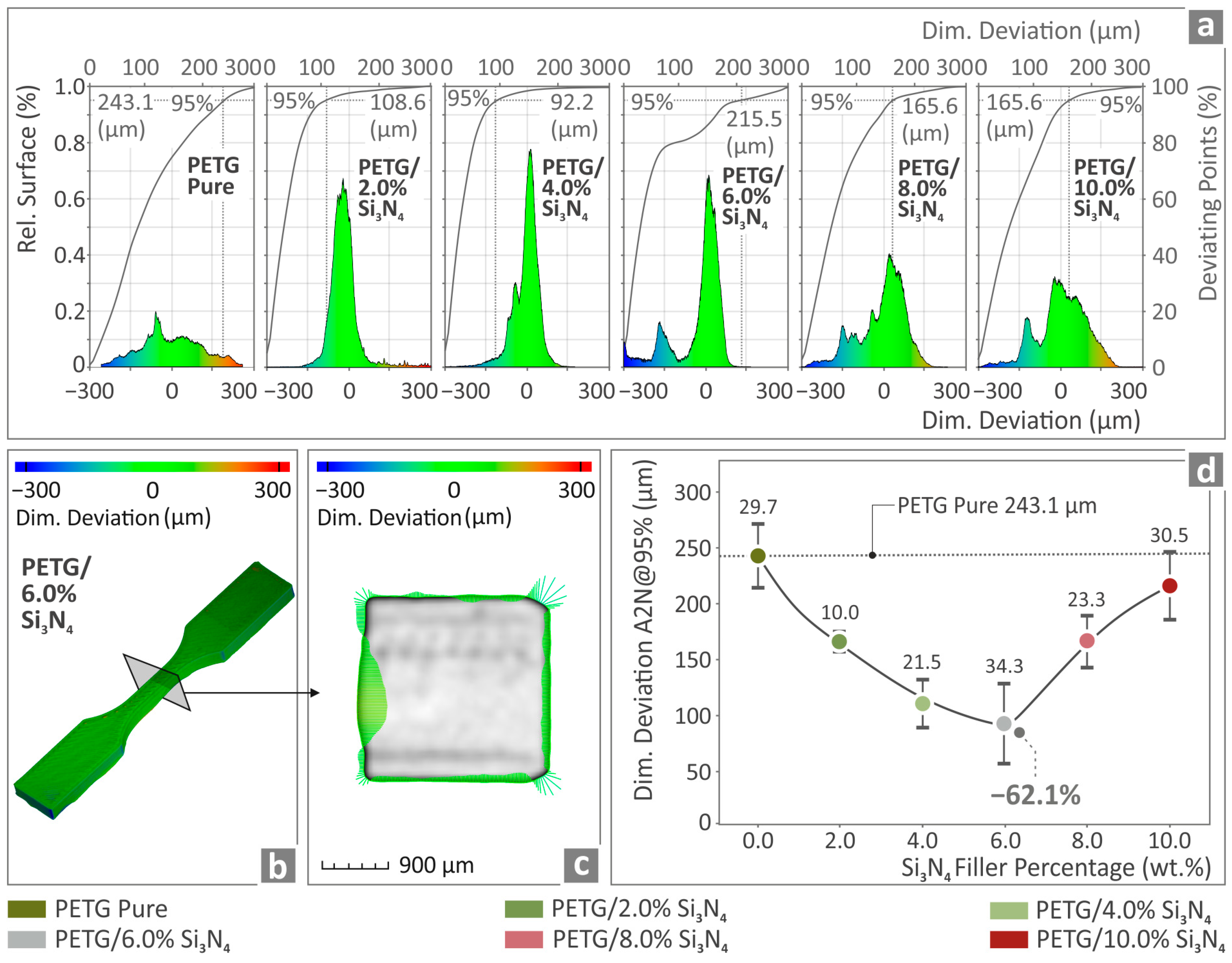

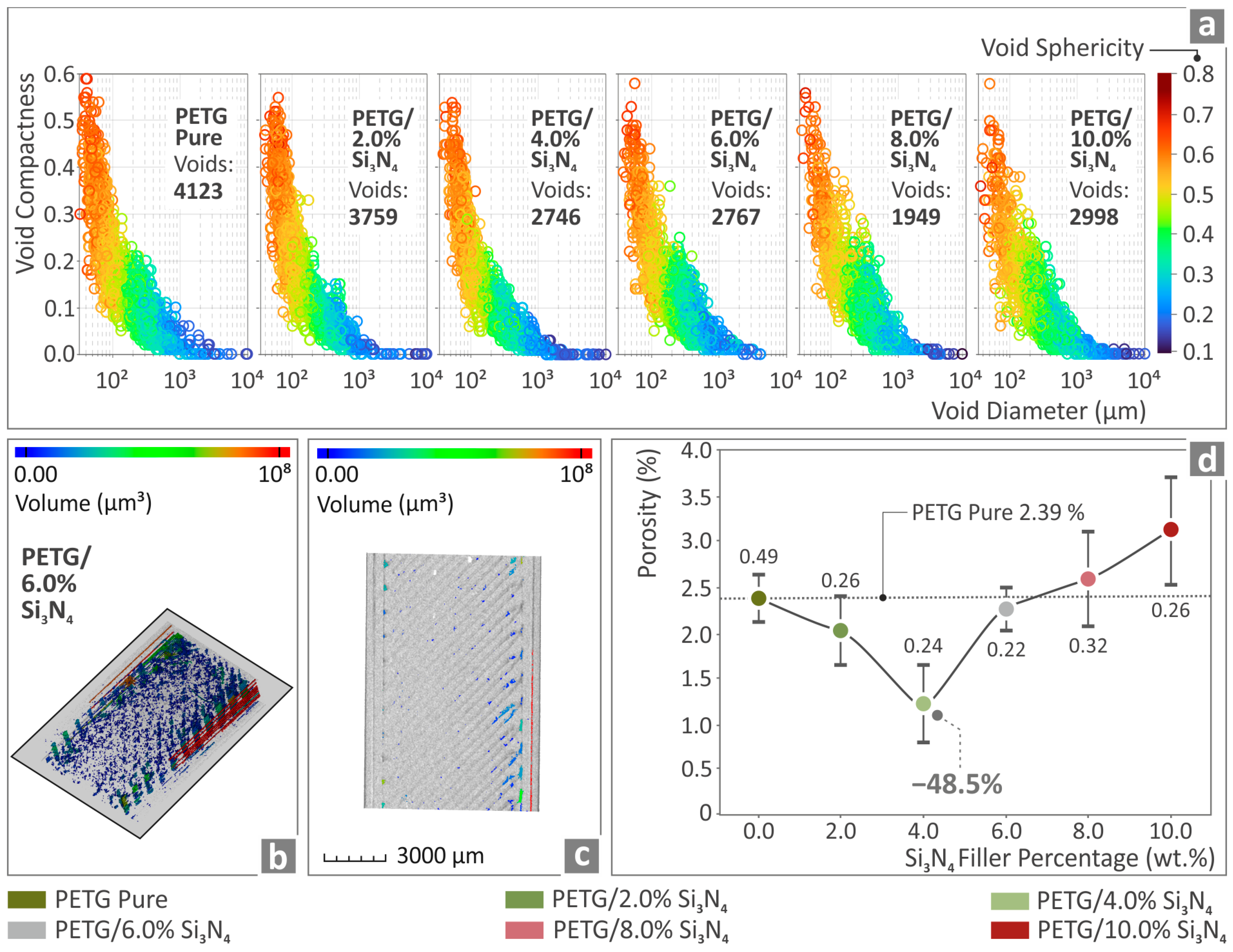

3.7. Analysis of Specimens through Micro Computed Tomography (μ-CT) Scanning

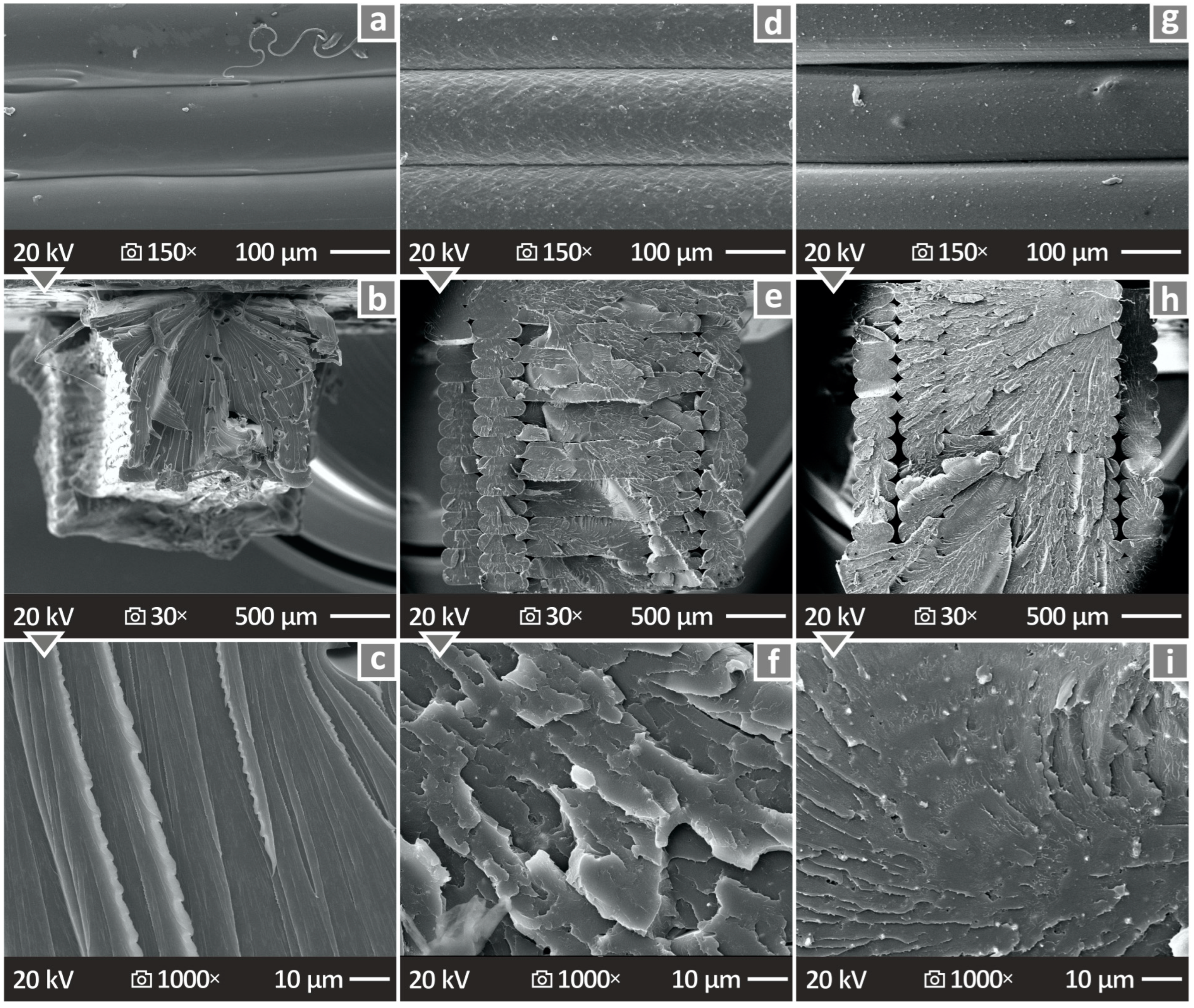

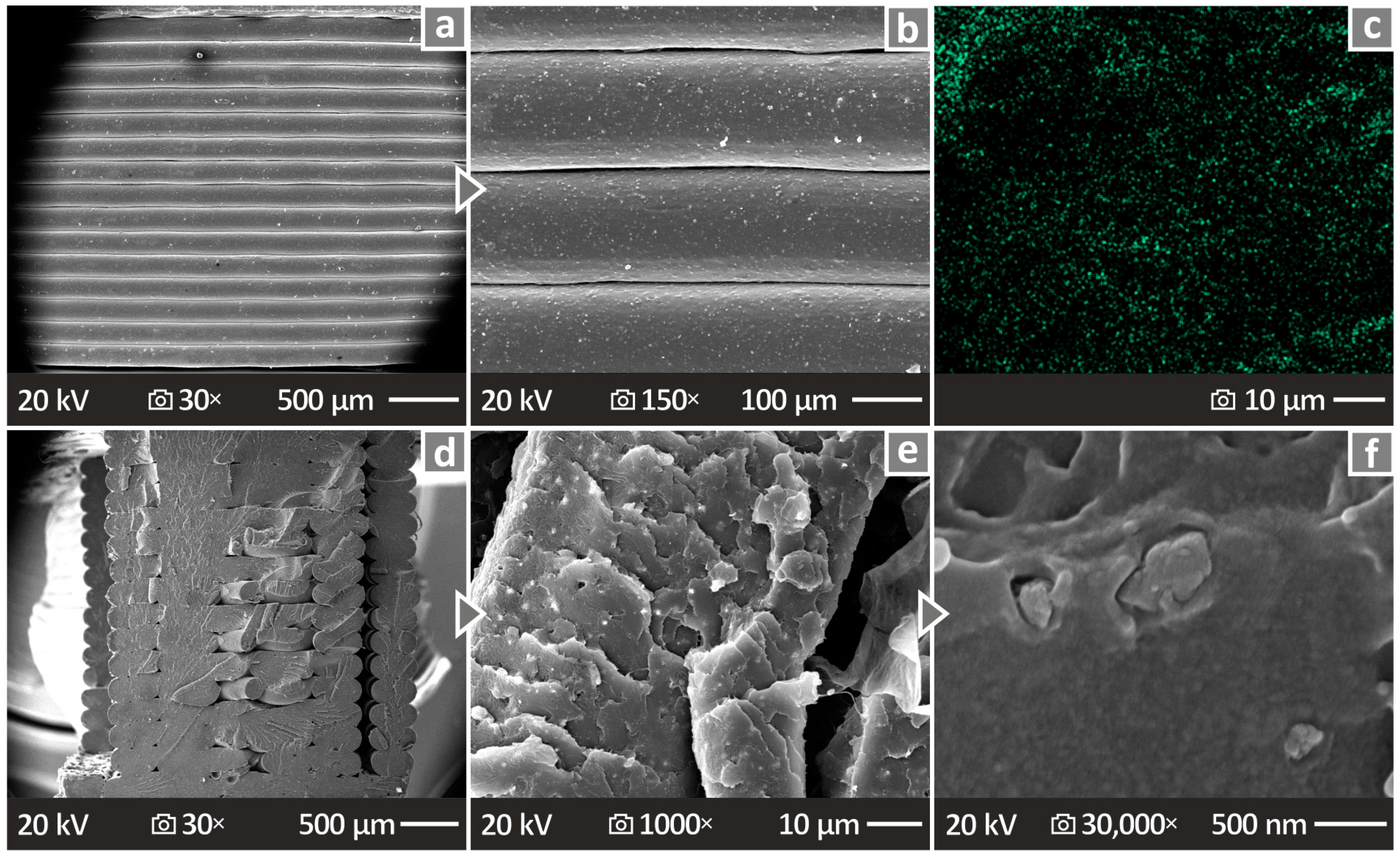

3.8. Analysis of Specimens through Scanning Electron Microscopy

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Jacobs, P.F. Rapid Prototyping & Manufacturing: Fundamentals of Stereolithography; Society of Manufacturing Engineers: Dearborn, MI, USA, 1992. [Google Scholar]

- Comb, J.W.; Priedeman, W.R.; Turley, P.W. FDM® Technology Process Improvements. In Proceedings of the 1994 International Solid Freeform Fabrication Symposium, Austin, TX, USA; Available online: http://hdl.handle.net/2152/68588 (accessed on 20 December 2023).

- Sachs, E.M.; Haggerty, J.S.; Cima, M.J.; Williams, P.A. Three-Dimensional Printing Techniques. U.S. Patent 5,204,055, 20 April 1993. [Google Scholar]

- Beaman, J.J.; Barlow, J.W.; Bourell, D.L.; Crawford, R.H.; Marcus, H.L.; McAlea, K.P. Solid Freeform Fabrication: A New Direction in Manufacturing; Springer: Boston, MA, USA, 1997; ISBN 978-0-7923-9834-9. [Google Scholar]

- Feygin, M.; Hsieh, B. Laminaled Objecf Manufacturing (Lom): A Simpler Process. In Proceedings of the 1991 International Solid Freeform Fabrication Symposium, Austin, TX, USA; Available online: http://hdl.handle.net/2152/64325 (accessed on 20 December 2023).

- Mazumder, J.; Schifferer, A.; Choi, J. Direct Materials Deposition: Designed Macro and Microstructure. Mater. Res. Innov. 1999, 3, 118–131. [Google Scholar] [CrossRef]

- Guo, N.; Leu, M.C. Additive Manufacturing: Technology, Applications and Research Needs. Front. Mech. Eng. 2013, 8, 215–243. [Google Scholar] [CrossRef]

- Attaran, M. The Rise of 3-D Printing: The Advantages of Additive Manufacturing over Traditional Manufacturing. Bus. Horiz. 2017, 60, 677–688. [Google Scholar] [CrossRef]

- Sepasgozar, S.M.E.; Shi, A.; Yang, L.; Shirowzhan, S.; Edwards, D.J. Additive Manufacturing Applications for Industry 4.0: A Systematic Critical Review. Buildings 2020, 10, 231. [Google Scholar] [CrossRef]

- Thomas, C.L.; Gaffney, T.M.; Kaza, S.; Lee, C.H. Rapid Prototyping of Large Scale Aerospace Structures. In Proceedings of the 1996 IEEE Aerospace Applications Conference, Aspen, CO, USA, 10 February 1996; pp. 219–230. [Google Scholar]

- Bacciaglia, A.; Ceruti, A.; Liverani, A. Towards Large Parts Manufacturing in Additive Technologies for Aerospace and Automotive Applications. Procedia Comput. Sci. 2022, 200, 1113–1124. [Google Scholar] [CrossRef]

- Mohanavel, V.; Ashraff Ali, K.S.; Ranganathan, K.; Allen Jeffrey, J.; Ravikumar, M.M.; Rajkumar, S. The Roles and Applications of Additive Manufacturing in the Aerospace and Automobile Sector. Mater. Today Proc. 2021, 47, 405–409. [Google Scholar] [CrossRef]

- Najmon, J.C.; Raeisi, S.; Tovar, A. Review of Additive Manufacturing Technologies and Applications in the Aerospace Industry. In Additive Manufacturing for the Aerospace Industry; Elsevier: Amsterdam, The Netherlands, 2019; pp. 7–31. [Google Scholar]

- Tepylo, N.; Huang, X.; Patnaik, P.C. Laser-Based Additive Manufacturing Technologies for Aerospace Applications. Adv. Eng. Mater. 2019, 21, 1900617. [Google Scholar] [CrossRef]

- de Leon, A.C.; Chen, Q.; Palaganas, N.B.; Palaganas, J.O.; Manapat, J.; Advincula, R.C. High Performance Polymer Nanocomposites for Additive Manufacturing Applications. React. Funct. Polym. 2016, 103, 141–155. [Google Scholar] [CrossRef]

- Song, Y.; Yan, Y.; Zhang, R.; Xu, D.; Wang, F. Manufacture of the Die of an Automobile Deck Part Based on Rapid Prototyping and Rapid Tooling Technology. J. Mater. Process Technol. 2002, 120, 237–242. [Google Scholar] [CrossRef]

- Vasco, J.C. Additive Manufacturing for the Automotive Industry. In Additive Manufacturing; Elsevier: Amsterdam, The Netherlands, 2021; pp. 505–530. [Google Scholar]

- Sun, C.; Wang, Y.; McMurtrey, M.D.; Jerred, N.D.; Liou, F.; Li, J. Additive Manufacturing for Energy: A Review. Appl. Energy 2021, 282, 116041. [Google Scholar] [CrossRef]

- Cramer, C.L.; Ionescu, E.; Graczyk-Zajac, M.; Nelson, A.T.; Katoh, Y.; Haslam, J.J.; Wondraczek, L.; Aguirre, T.G.; LeBlanc, S.; Wang, H.; et al. Additive Manufacturing of Ceramic Materials for Energy Applications: Road Map and Opportunities. J. Eur. Ceram. Soc. 2022, 42, 3049–3088. [Google Scholar] [CrossRef]

- Goh, G.L.; Zhang, H.; Chong, T.H.; Yeong, W.Y. 3D Printing of Multilayered and Multimaterial Electronics: A Review. Adv. Electron. Mater. 2021, 7, 141–155. [Google Scholar] [CrossRef]

- Zhang, Z.; Yuan, X. Applications and Future of Automated and Additive Manufacturing for Power Electronics Components and Converters. IEEE J. Emerg. Sel. Top. Power Electron. 2022, 10, 4509–4525. [Google Scholar] [CrossRef]

- Colorado, H.A.; Cardenas, C.A.; Gutierrez-Velazquez, E.I.; Escobedo, J.P.; Monteiro, S.N. Additive Manufacturing in Armor and Military Applications: Research, Materials, Processing Technologies, Perspectives, and Challenges. J. Mater. Res. Technol. 2023, 27, 3900–3913. [Google Scholar] [CrossRef]

- Busachi, A.; Erkoyuncu, J.; Colegrove, P.; Martina, F.; Watts, C.; Drake, R. A Review of Additive Manufacturing Technology and Cost Estimation Techniques for the Defence Sector. CIRP J. Manuf. Sci. Technol. 2017, 19, 117–128. [Google Scholar] [CrossRef]

- Giannatsis, J.; Dedoussis, V. Additive Fabrication Technologies Applied to Medicine and Health Care: A Review. Int. J. Adv. Manuf. Technol. 2009, 40, 116–127. [Google Scholar] [CrossRef]

- Ovsianikov, A. Additive Manufacturing Technologies for Biomedical Applications. Professorial Dissertation, Technische Universität Wien, Vienna, Austria, 2017. Available online: http://hdl.handle.net/20.500.12708/159459 (accessed on 20 December 2023).

- Chauhan, I.; Chattopadhyay, S.; Mohanty, P. Fabrication of Titania Nanowires Incorporated Paper Sheets and Study of Their Optical Properties. Mater. Express 2013, 3, 343–349. [Google Scholar] [CrossRef]

- Hwa, L.C.; Uday, M.B.; Ahmad, N.; Noor, A.M.; Rajoo, S.; Zakaria, K. Bin Integration and Fabrication of the Cheap Ceramic Membrane through 3D Printing Technology. Mater. Today Commun. 2018, 15, 134–142. [Google Scholar] [CrossRef]

- Fichou, D.; Morlock, G.E. Open-Source-Based 3D Printing of Thin Silica Gel Layers in Planar Chromatography. Anal. Chem. 2017, 89, 2116–2122. [Google Scholar] [CrossRef] [PubMed]

- Ahmed, W.; Siraj, S.; Al-Marzouqi, A.H. Embracing Additive Manufacturing Technology through Fused Filament Fabrication for Antimicrobial with Enhanced Formulated Materials. Polymers 2021, 13, 1523. [Google Scholar] [CrossRef] [PubMed]

- Velu, R.; Jayashankar, D.K.; Subburaj, K. Additive Processing of Biopolymers for Medical Applications. In Additive Manufacturing; Elsevier: Amsterdam, The Netherlands, 2021; pp. 635–659. [Google Scholar]

- Yasa, E.; Ersoy, K. Dimensional Accuracy and Mechanical Properties of Chopped Carbon Reinforced Polymers Produced by Material Extrusion Additive Manufacturing. Materials 2019, 12, 3885. [Google Scholar] [CrossRef] [PubMed]

- Vidakis, N.; Mangelis, P.; Petousis, M.; Mountakis, N.; Papadakis, V.; Moutsopoulou, A.; Tsikritzis, D. Mechanical Reinforcement of ABS with Optimized Nano Titanium Nitride Content for Material Extrusion 3D Printing. Nanomaterials 2023, 13, 669. [Google Scholar] [CrossRef] [PubMed]

- Vidakis, N.; Petousis, M.; Tzounis, L.; Velidakis, E.; Mountakis, N.; Grammatikos, S.A. Polyamide 12/Multiwalled Carbon Nanotube and Carbon Black Nanocomposites Manufactured by 3D Printing Fused Filament Fabrication: A Comparison of the Electrical, Thermoelectric, and Mechanical Properties. C 2021, 7, 38. [Google Scholar] [CrossRef]

- García Plaza, E.; Núñez López, P.; Caminero Torija, M.; Chacón Muñoz, J. Analysis of PLA Geometric Properties Processed by FFF Additive Manufacturing: Effects of Process Parameters and Plate-Extruder Precision Motion. Polymers 2019, 11, 1581. [Google Scholar] [CrossRef] [PubMed]

- Bouzaglou, O.; Golan, O.; Lachman, N. Process Design and Parameters Interaction in Material Extrusion 3D Printing: A Review. Polymers 2023, 15, 2280. [Google Scholar] [CrossRef] [PubMed]

- Devsingh, D.; Dev, A.D.; Avala, B.; Reddy, R.; Arjula, S. Characterization of Additive Manufactured PETG and Carbon Fiber-PETG. Int. J. Res. Eng. Appl. Manag. (IJREAM) 2018, 4, 2. [Google Scholar] [CrossRef]

- Valvez, S.; Silva, A.P.; Reis, P.N.B. Optimization of Printing Parameters to Maximize the Mechanical Properties of 3D-Printed PETG-Based Parts. Polymers 2022, 14, 2564. [Google Scholar] [CrossRef] [PubMed]

- Vidakis, N.; Petousis, M.; Tzounis, L.; Grammatikos, S.A.; Porfyrakis, E.; Maniadi, A.; Mountakis, N. Sustainable Additive Manufacturing: Mechanical Response of Polyethylene Terephthalate Glycol over Multiple Recycling Processes. Materials 2021, 14, 1162. [Google Scholar] [CrossRef]

- Latko-Durałek, P.; Dydek, K.; Boczkowska, A. Thermal, Rheological and Mechanical Properties of PETG/RPETG Blends. J. Polym. Env. 2019, 27, 2600–2606. [Google Scholar] [CrossRef]

- Szykiedans, K.; Credo, W.; Osiński, D. Selected Mechanical Properties of PETG 3-D Prints. Procedia Eng. 2017, 177, 455–461. [Google Scholar] [CrossRef]

- Yan, C.; Kleiner, C.; Tabigue, A.; Shah, V.; Sacks, G.; Shah, D.; DeStefano, V. PETG: Applications in Modern Medicine. Eng. Regen. 2024, 5, 45–55. [Google Scholar] [CrossRef]

- Vidakis, N.; Petousis, M.; Michailidis, N.; Papadakis, V.; Mountakis, N.; Argyros, A.; Dimitriou, E.; Charou, C.; Moutsopoulou, A. Polylactic Acid/Silicon Nitride Biodegradable and Biomedical Nanocomposites with Optimized Rheological and Thermomechanical Response for Material Extrusion Additive Manufacturing. Biomed. Eng. Adv. 2023, 6, 100103. [Google Scholar] [CrossRef]

- Antoniadis, A.; Vidakis, N.; Bilalis, N. Fatigue Fracture Investigation of Cemented Carbide Tools in Gear Hobbing, Part 2: The Effect of Cutting Parameters on the Level of Tool Stresses—A Quantitative Parametric Analysis. J. Manuf. Sci. Eng. 2002, 124, 792–798. [Google Scholar] [CrossRef]

- Bouzakis, K.-D.; Vidakis, N.; Kallinikidis, D.; Leyendecker, T.; Erkens, G.; Wenke, R.; Fuss, H.-G. Fatigue Failure Mechanisms of Multi- and Monolayer Physically Vapour-Deposited Coatings in Interrupted Cutting Processes. Surf. Coat. Technol. 1998, 108–109, 526–534. [Google Scholar] [CrossRef]

- Wang, F.; Guo, J.; Li, K.; Sun, J.; Zeng, Y.; Ning, C. High Strength Polymer/Silicon Nitride Composites for Dental Restorations. Dent. Mater. 2019, 35, 1254–1263. [Google Scholar] [CrossRef] [PubMed]

- Correa Filho, L.; Fu, L.; Engqvist, H.; Xia, W.; Persson, C. Wear Performance of a Novel Silicon Nitride Ceramic for Biomedical Applications. Biomed. Mater. Devices 2023, 1, 990–999. [Google Scholar] [CrossRef]

- Khan, A.; Puttegowda, M.; Jagadeesh, P.; Marwani, H.M.; Asiri, A.M.; Manikandan, A.; Parwaz Khan, A.A.; Ashraf, G.M.; Rangappa, S.M.; Siengchin, S. Review on Nitride Compounds and Its Polymer Composites: A Multifunctional Material. J. Mater. Res. Technol. 2022, 18, 2175–2193. [Google Scholar] [CrossRef]

- Bouzakis, K.-D.; Vidakis, N.; Lontos, A.; Mitsi, S.; David, K. Implementation of Low Temperature-Deposited Coating Fatigue Parameters in Commercial Roller Bearings Catalogues. Surf. Coat. Technol. 2000, 133–134, 489–496. [Google Scholar] [CrossRef]

- Bouzakis, K.-D.; Vidakis, N.; Mitsi, S. Fatigue Prediction of Thin Hard Coatings on the Steel Races of Hybrid Bearings Used in High Speed Machine Tool Spindles. J. Tribol. 1998, 120, 835–842. [Google Scholar] [CrossRef]

- Krstic, Z.; Krstic, V.D. Silicon Nitride: The Engineering Material of the Future. J. Mater. Sci. 2012, 47, 535–552. [Google Scholar] [CrossRef]

- Riley, F.L. Silicon Nitride and Related Materials. J. Am. Ceram. Soc. 2000, 83, 245–265. [Google Scholar] [CrossRef]

- Bodišová, K.; Kašiarová, M.; Domanická, M.; Hnatko, M.; Lenčéš, Z.; Nováková, Z.V.; Vojtaššák, J.; Gromošová, S.; Šajgalík, P. Porous Silicon Nitride Ceramics Designed for Bone Substitute Applications. Ceram. Int. 2013, 39, 8355–8362. [Google Scholar] [CrossRef]

- Yan, H.; Tang, Y.; Su, J.; Yang, X. Enhanced Thermal–Mechanical Properties of Polymer Composites with Hybrid Boron Nitride Nanofillers. Appl. Phys. A 2014, 114, 331–337. [Google Scholar] [CrossRef]

- Li, M.; Wang, M.; Hou, X.; Zhan, Z.; Wang, H.; Fu, H.; Lin, C.-T.; Fu, L.; Jiang, N.; Yu, J. Highly Thermal Conductive and Electrical Insulating Polymer Composites with Boron Nitride. Compos. B Eng. 2020, 184, 107746. [Google Scholar] [CrossRef]

- Petousis, M.; Michailidis, N.; Papadakis, V.M.; Korlos, A.; Mountakis, N.; Argyros, A.; Dimitriou, E.; Charou, C.; Moutsopoulou, A.; Vidakis, N. Optimizing the Rheological and Thermomechanical Response of Acrylonitrile Butadiene Styrene/Silicon Nitride Nanocomposites in Material Extrusion Additive Manufacturing. Nanomaterials 2023, 13, 1588. [Google Scholar] [CrossRef] [PubMed]

- Badran, Z.; Struillou, X.; Hughes, F.J.; Soueidan, A.; Hoornaert, A.; Ide, M. Silicon Nitride (Si3N4) Implants: The Future of Dental Implantology? J. Oral. Implantol. 2017, 43, 240–244. [Google Scholar] [CrossRef] [PubMed]

- Du, X.; Ronayne, S.; Lee, S.S.; Hendry, J.; Hoxworth, D.; Bock, R.; Ferguson, S.J. 3D-Printed PEEK/Silicon Nitride Scaffolds with a Triply Periodic Minimal Surface Structure for Spinal Fusion Implants. ACS Appl. Bio Mater. 2023, 6, 3319–3329. [Google Scholar] [CrossRef] [PubMed]

- Yunsheng, D.; Hui, X.; Jie, W.; Tingting, Y.; Naiqi, K.; Jiaxing, H.; Wei, C.; Yufei, L.; Qiang, Y.; Shufang, W. Sustained Release Silicon from 3D Bioprinting Scaffold Using Silk/Gelatin Inks to Promote Osteogenesis. Int. J. Biol. Macromol. 2023, 234, 123659. [Google Scholar] [CrossRef] [PubMed]

- Vidakis, N.; Michailidis, N.; Argyros, A.; Mountakis, N.; Papadakis, V.; Spiridaki, M.; Moutsopoulou, A.; Sfakiotakis, E.; Petousis, M. A Coherent Optimization Course of the Silicon Nitride Nanofiller Load in Medical Grade Isotactic Polypropylene for Material Extrusion Additive Manufacturing: Rheology, Engineering Response, and Cost-Effectiveness. Colloid. Polym. Sci. 2024. [Google Scholar] [CrossRef]

- Zgalat-Lozynskyy, O.B.; Matviichuk, O.O.; Tolochyn, O.I.; Ievdokymova, O.V.; Zgalat-Lozynska, N.O.; Zakiev, V.I. Polymer Materials Reinforced with Silicon Nitride Particles for 3D Printing. Powder Metall. Met. Ceram. 2021, 59, 515–527. [Google Scholar] [CrossRef]

- Vidakis, N.; Petousis, M.; Michailidis, N.; David, C.; Saltas, V.; Sagris, D.; Spiridaki, M.; Argyros, A.; Mountakis, N.; Papadakis, V. Interpretation of the Optimization Course of Silicon Nitride Nano-Powder Content in Biomedical Resins for Vat Photopolymerization Additive Manufacturing. Ceram. Int. 2024, 50, 14919–14935. [Google Scholar] [CrossRef]

- Wang, M.; Xie, C.; He, R.; Ding, G.; Zhang, K.; Wang, G.; Fang, D. Polymer-Derived Silicon Nitride Ceramics by Digital Light Processing Based Additive Manufacturing. J. Am. Ceram. Soc. 2019, 102, 5117–5126. [Google Scholar] [CrossRef]

- ASTM D638-02a; Standard Test Method for Tensile Properties Of Plastics. American Society for Testing and Materials (ASTM International): West Conshohocken, PA, USA, 2003.

- ASTM D790-10; Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials. American Society for Testing and Materials (ASTM International): West Conshohocken, PA, USA, 2016.

- ASTM D6110-04; Standard Test Methods for Determining the Charpy Impact Resistance of Notched Specimens of Plastics. American Society for Testing and Materials (ASTM International): West Conshohocken, PA, USA, 2017.

- ASTM E384-17; Standard Test Method for Microindentation Hardness of Materials. American Society for Testing and Materials (ASTM International): West Conshohocken, PA, USA, 2022.

- ASTM D1238-13; Standard Test Method for Melt Flow Rates of Thermoplastics by Extrusion Plastometer. American Society for Testing and Materials (ASTM International): West Conshohocken, PA, USA, 2020.

- Zimmerer, C.; Matulaitiene, I.; Niaura, G.; Reuter, U.; Janke, A.; Boldt, R.; Sablinskas, V.; Steiner, G. Nondestructive Characterization of the Polycarbonate–Octadecylamine Interface by Surface Enhanced Raman Spectroscopy. Polym. Test. 2019, 73, 152–158. [Google Scholar] [CrossRef]

- Resta, V.; Quarta, G.; Lomascolo, M.; Maruccio, L.; Calcagnile, L. Raman and Photoluminescence Spectroscopy of Polycarbonate Matrices Irradiated with Different Energy 28Si+ Ions. Vacuum 2015, 116, 82–89. [Google Scholar] [CrossRef]

- Bichara, L.C.; Alvarez, P.E.; Fiori Bimbi, M.V.; Vaca, H.; Gervasi, C.; Brandán, S.A. Structural and Spectroscopic Study of a Pectin Isolated from Citrus Peel by Using FTIR and FT-Raman Spectra and DFT Calculations. Infrared Phys. Technol. 2016, 76, 315–327. [Google Scholar] [CrossRef]

- Synytsya, A. Fourier Transform Raman and Infrared Spectroscopy of Pectins. Carbohydr. Polym. 2003, 54, 97–106. [Google Scholar] [CrossRef]

- Makarem, M.; Lee, C.M.; Kafle, K.; Huang, S.; Chae, I.; Yang, H.; Kubicki, J.D.; Kim, S.H. Probing Cellulose Structures with Vibrational Spectroscopy. Cellulose 2019, 26, 35–79. [Google Scholar] [CrossRef]

- Stuart, B.H. Temperature Studies of Polycarbonate Using Fourier Transform Raman Spectroscopy. Polym. Bull. 1996, 36, 341–346. [Google Scholar] [CrossRef]

- Lin, Z.; Guo, X.; He, Z.; Liang, X.; Wang, M.; Jin, G. Thermal Degradation Kinetics Study of Molten Polylactide Based on Raman Spectroscopy. Polym. Eng. Sci. 2021, 61, 201–210. [Google Scholar] [CrossRef]

- Badr, Y.A.; Abd El-Kader, K.M.; Khafagy, R.M. Raman Spectroscopic Study of CdS, PVA Composite Films. J. Appl. Polym. Sci. 2004, 92, 1984–1992. [Google Scholar] [CrossRef]

- Liu, X.; Zou, Y.; Li, W.; Cao, G.; Chen, W. Kinetics of Thermo-Oxidative and Thermal Degradation of Poly(d,l-Lactide) (PDLLA) at Processing Temperature. Polym. Degrad. Stab. 2006, 91, 3259–3265. [Google Scholar] [CrossRef]

- Veselý, P.; Froš, D.; Hudec, T.; Sedláček, J.; Ctibor, P.; Dušek, K. Dielectric Spectroscopy of PETG/TiO2 Composite Intended for 3D Printing. Virtual Phys. Prototyp. 2023, 18, e2170253. [Google Scholar] [CrossRef]

- Dhotel, A.; Rijal, B.; Delbreilh, L.; Dargent, E.; Saiter, A. Combining Flash DSC, DSC and Broadband Dielectric Spectroscopy to Determine Fragility. J. Therm. Anal. Calorim. 2015, 121, 453–461. [Google Scholar] [CrossRef]

- Song, Y.; Zheng, Q. Concepts and Conflicts in Nanoparticles Reinforcement to Polymers beyond Hydrodynamics. Prog. Mater. Sci. 2016, 84, 1–58. [Google Scholar] [CrossRef]

- Zhang, H.; Zhu, H.; Xu, C.; Li, Y.; Liu, Q.; Wang, S.; Yan, S. Effect of Nanoparticle Size on the Mechanical Properties of Polymer Nanocomposites. Polymer 2022, 252, 124944. [Google Scholar] [CrossRef]

- Chang, A.; Babhadiashar, N.; Barrett-Catton, E.; Asuri, P. Role of Nanoparticle–Polymer Interactions on the Development of Double-Network Hydrogel Nanocomposites with High Mechanical Strength. Polymers 2020, 12, 470. [Google Scholar] [CrossRef]

- Zare, Y.; Rhee, K.Y.; Hui, D. Influences of Nanoparticles Aggregation/Agglomeration on the Interfacial/Interphase and Tensile Properties of Nanocomposites. Compos. B Eng. 2017, 122, 41–46. [Google Scholar] [CrossRef]

- Liao, Y.; Liu, C.; Coppola, B.; Barra, G.; Di Maio, L.; Incarnato, L.; Lafdi, K. Effect of Porosity and Crystallinity on 3D Printed PLA Properties. Polymers 2019, 11, 1487. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Zhao, L.; Fuh, J.Y.H.; Lee, H.P. Effect of Porosity on Mechanical Properties of 3D Printed Polymers: Experiments and Micromechanical Modeling Based on X-Ray Computed Tomography Analysis. Polymers 2019, 11, 1154. [Google Scholar] [CrossRef] [PubMed]

- Xu, G.C.; Wang, J.; Ji, X.L.; Xiong, J.Y.; Li, F. Effect of Nano-Silicon Nitride on the Mechanical and Electric Properties of Polypropylene Nanocomposite. J. Compos. Mater. 2007, 41, 2213–2223. [Google Scholar] [CrossRef]

- Khan, M.I.; Umair, M.; Nawab, Y. 8—Use of Auxetic Material for Impact/Ballistic Applications. In Composite Solutions for Ballistics; Nawab, Y., Sapuan, S.M., Shaker, K., Eds.; Woodhead Publishing: Thorston, UK, 2021; pp. 199–228. ISBN 978-0-12-821984-3. [Google Scholar]

| Wavenumber (cm−1) | Intensity | Raman Peak Assignment |

|---|---|---|

| 631 | Strong | phenyl ring vibration [68,69] |

| 703 | Medium | C-H out-of-plane bending [68] |

| 772 | Small | O-C(O)-O stretching [69] |

| 793 | Medium | |

| 855 | Strong | γ(C–OH)ring [70,71] |

| 1115 | Strong | Skeletal vibrations, C–O–C bonds [72] |

| 1172 | Strong | Skeletal vibrations, C–O–C bonds [68,72] |

| 1283 | Strong | Skeletal vibrations, C–O–C bonds [68,72] |

| 1369 | Small | C–C–H, C–O–H, and O–C–H [72] |

| 1409 | Medium | C-H3 deformation [73] |

| 1440–1464 | Medium | C-H3 deformation [68,73]; C-H2 deformation [72]; C-H3 symmetric bending [69,73,74] |

| 1613 | Very Strong | Phenyl ring stretch [69] |

| 1724 | Very Strong | C=O bond [75] |

| 2857 | Medium | C-H2 symmetric stretching [72] |

| 2890 | Medium | CH2 symmetric stretching [72,76] |

| 2955 | Strong | CH2 asymmetric stretching [72] |

| 3081 | Strong | C-H stretching [73] |

| 631 | Peak rise | Small increase in phenyl ring bond |

| 1616 | Gradual increase | Significant increase in skeletal vibrations or C–O–C bonds |

| 1716–1741 | Inconsistent behavior | C=O bond [75] |

| 2955 | Peak drop | Significant decrease |

| 3081 | Peak drop | Significant decrease |

| Current Study | [42] (PLA Matrix) | [55] (ABS Matrix) | [59] (PP Matrix) | [85] (PP Matrix) | |

|---|---|---|---|---|---|

| Impact strength increase | 20.9% | 30.2% | Decrease | 11.1% | 25% |

| Tensile strength increase | 24.5% | 40.4% | 25.6% | 16% | Decrease |

| Flexural strength increase | 16.6% | 33.2% | 30.3% | 15.7% | - |

| microhardness | 18.8% | 20.9% | 34.9% | 33.6% | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Michailidis, N.; Petousis, M.; Saltas, V.; Papadakis, V.; Spiridaki, M.; Mountakis, N.; Argyros, A.; Valsamos, J.; Nasikas, N.K.; Vidakis, N. Investigation of the Effectiveness of Silicon Nitride as a Reinforcement Agent for Polyethylene Terephthalate Glycol in Material Extrusion 3D Printing. Polymers 2024, 16, 1043. https://doi.org/10.3390/polym16081043

Michailidis N, Petousis M, Saltas V, Papadakis V, Spiridaki M, Mountakis N, Argyros A, Valsamos J, Nasikas NK, Vidakis N. Investigation of the Effectiveness of Silicon Nitride as a Reinforcement Agent for Polyethylene Terephthalate Glycol in Material Extrusion 3D Printing. Polymers. 2024; 16(8):1043. https://doi.org/10.3390/polym16081043

Chicago/Turabian StyleMichailidis, Nikolaos, Markos Petousis, Vassilis Saltas, Vassilis Papadakis, Mariza Spiridaki, Nikolaos Mountakis, Apostolos Argyros, John Valsamos, Nektarios K. Nasikas, and Nectarios Vidakis. 2024. "Investigation of the Effectiveness of Silicon Nitride as a Reinforcement Agent for Polyethylene Terephthalate Glycol in Material Extrusion 3D Printing" Polymers 16, no. 8: 1043. https://doi.org/10.3390/polym16081043

APA StyleMichailidis, N., Petousis, M., Saltas, V., Papadakis, V., Spiridaki, M., Mountakis, N., Argyros, A., Valsamos, J., Nasikas, N. K., & Vidakis, N. (2024). Investigation of the Effectiveness of Silicon Nitride as a Reinforcement Agent for Polyethylene Terephthalate Glycol in Material Extrusion 3D Printing. Polymers, 16(8), 1043. https://doi.org/10.3390/polym16081043