Tribological Characterization of a Novel Ceramic–Epoxy–Kevlar Composite

Abstract

1. Introduction

2. Material and Methods

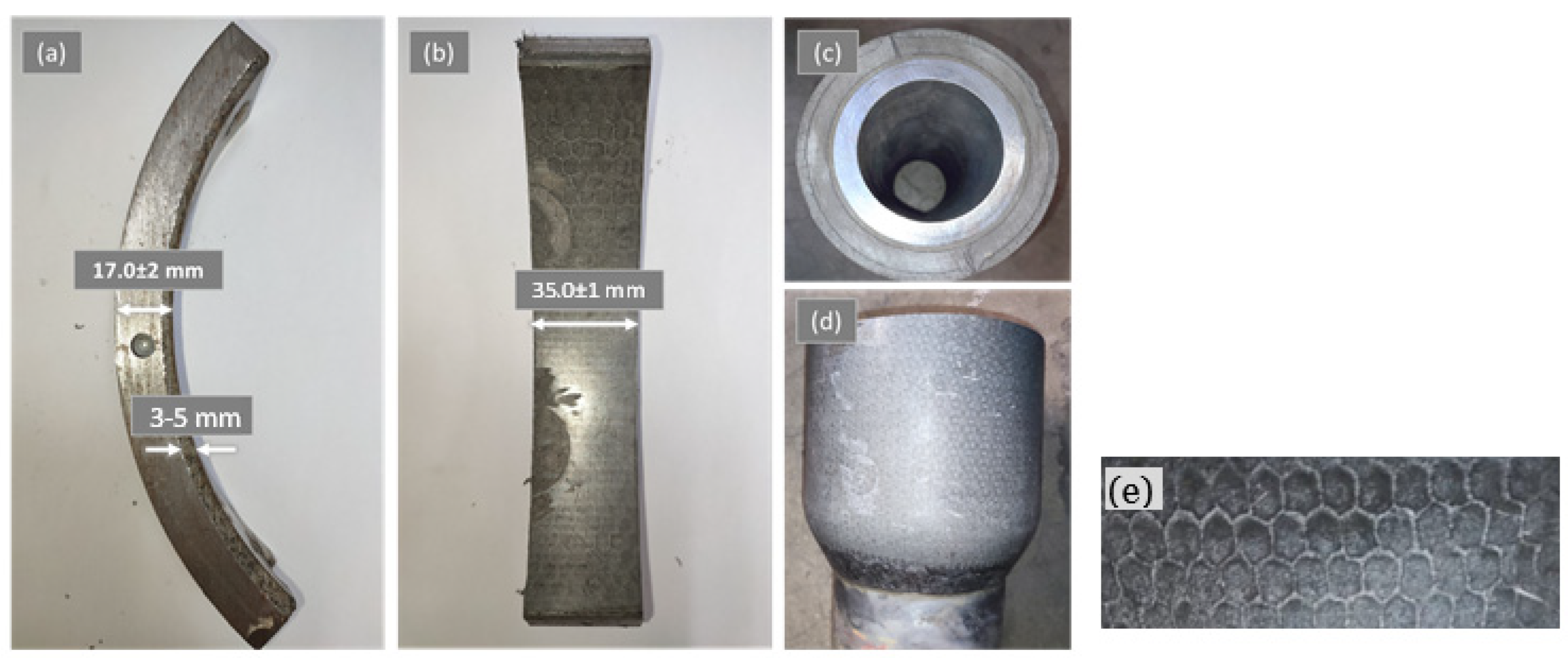

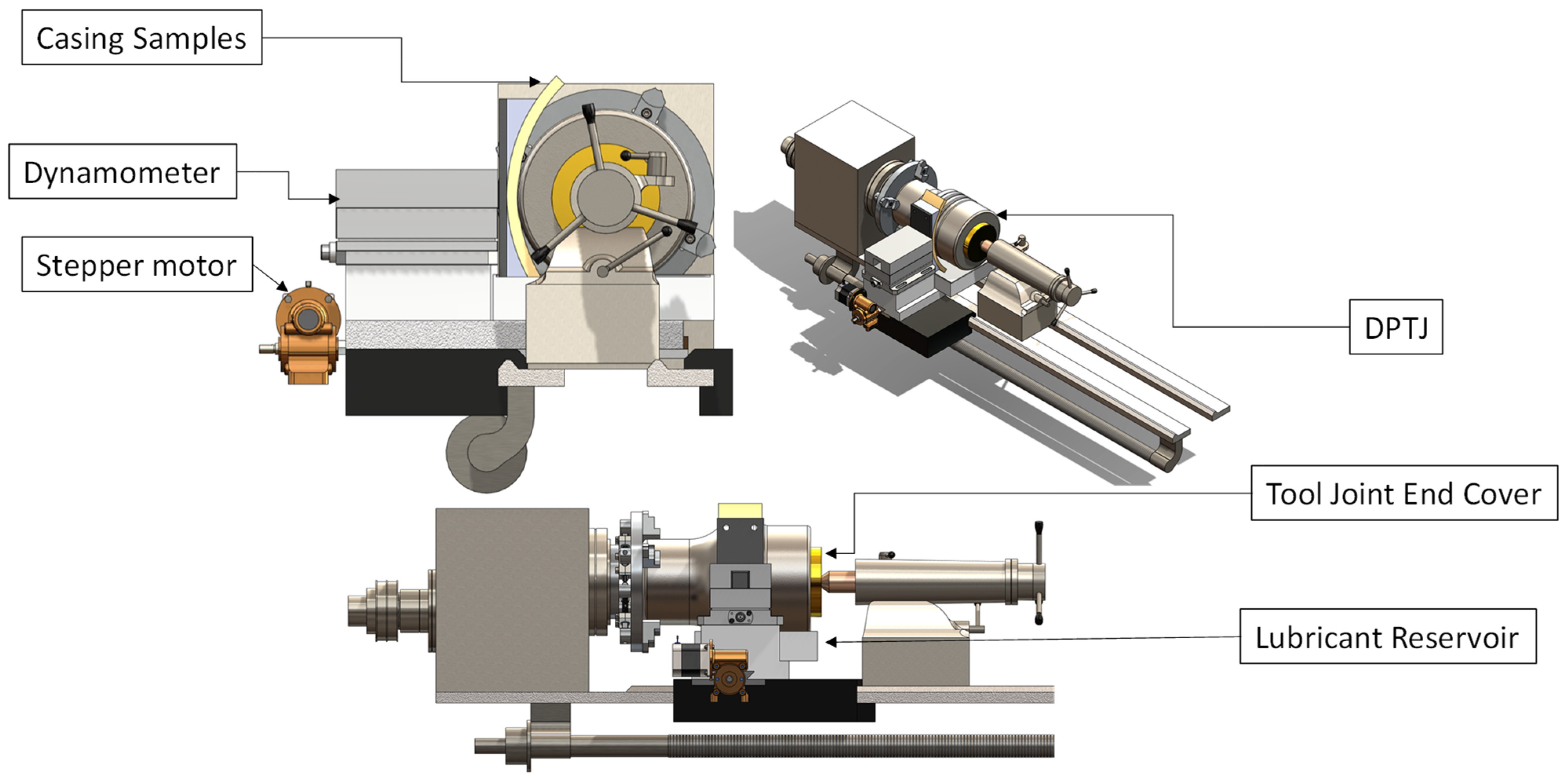

2.1. Materials and Equipment

2.2. Experimental Procedure

2.3. Characterization

3. Results and Discussion

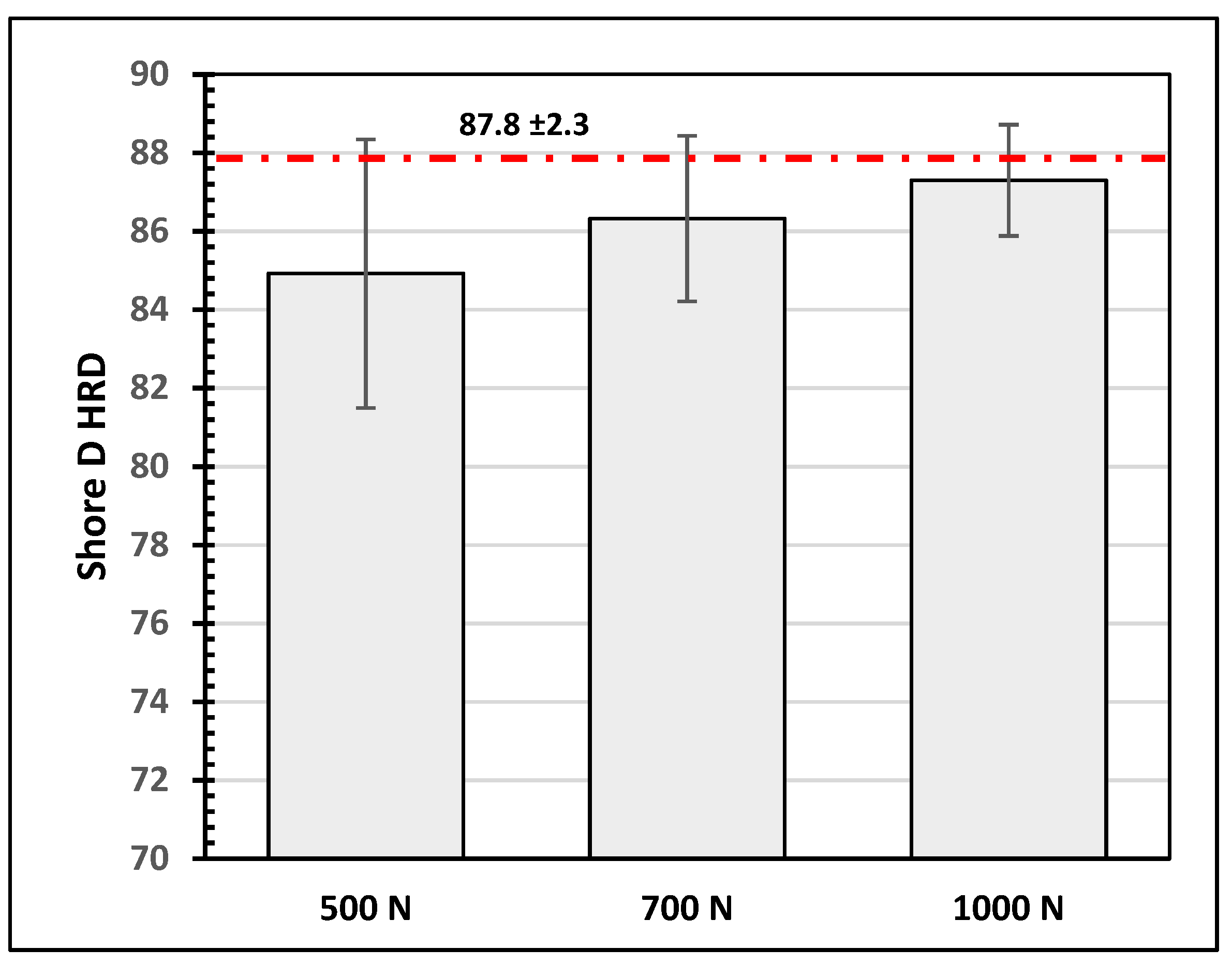

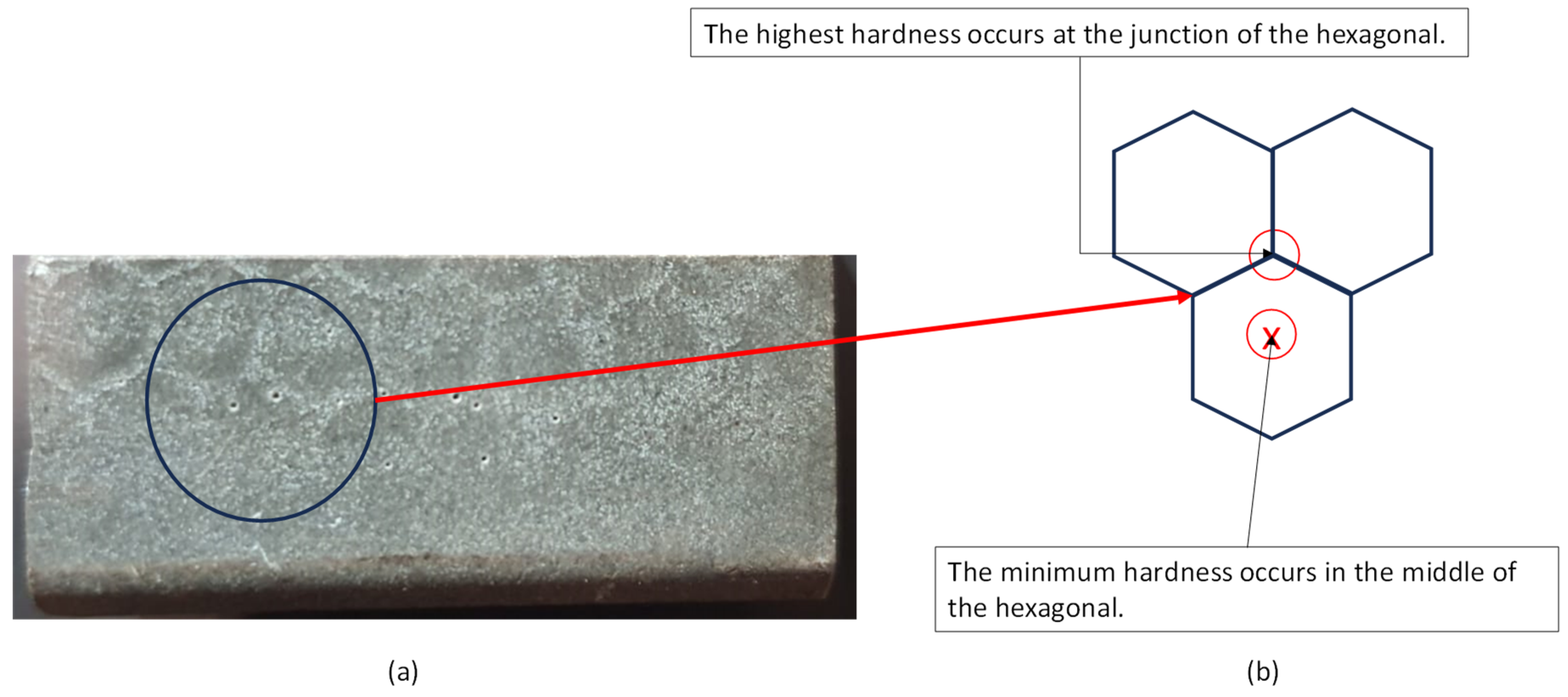

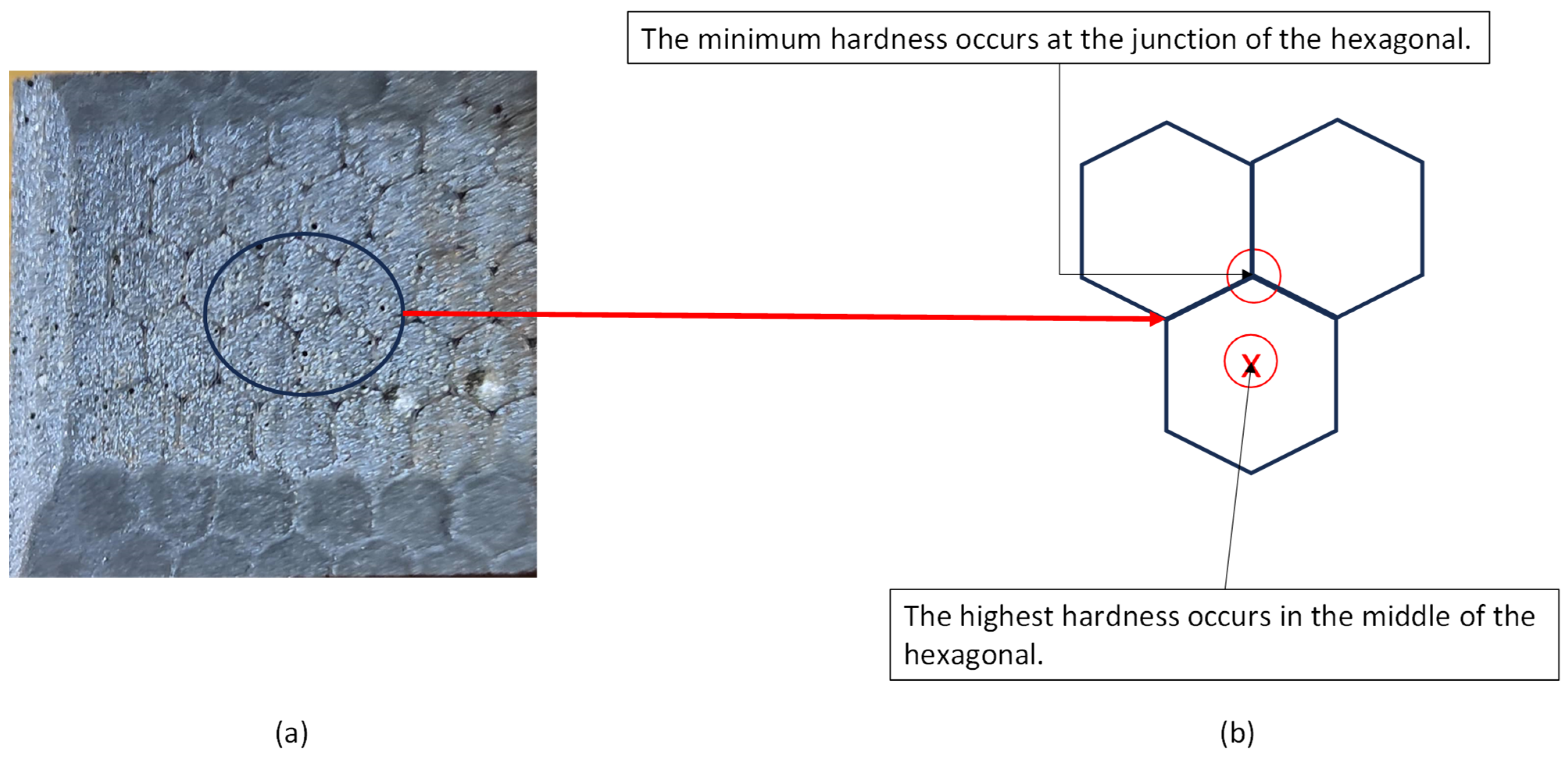

3.1. Hardness Evaluation

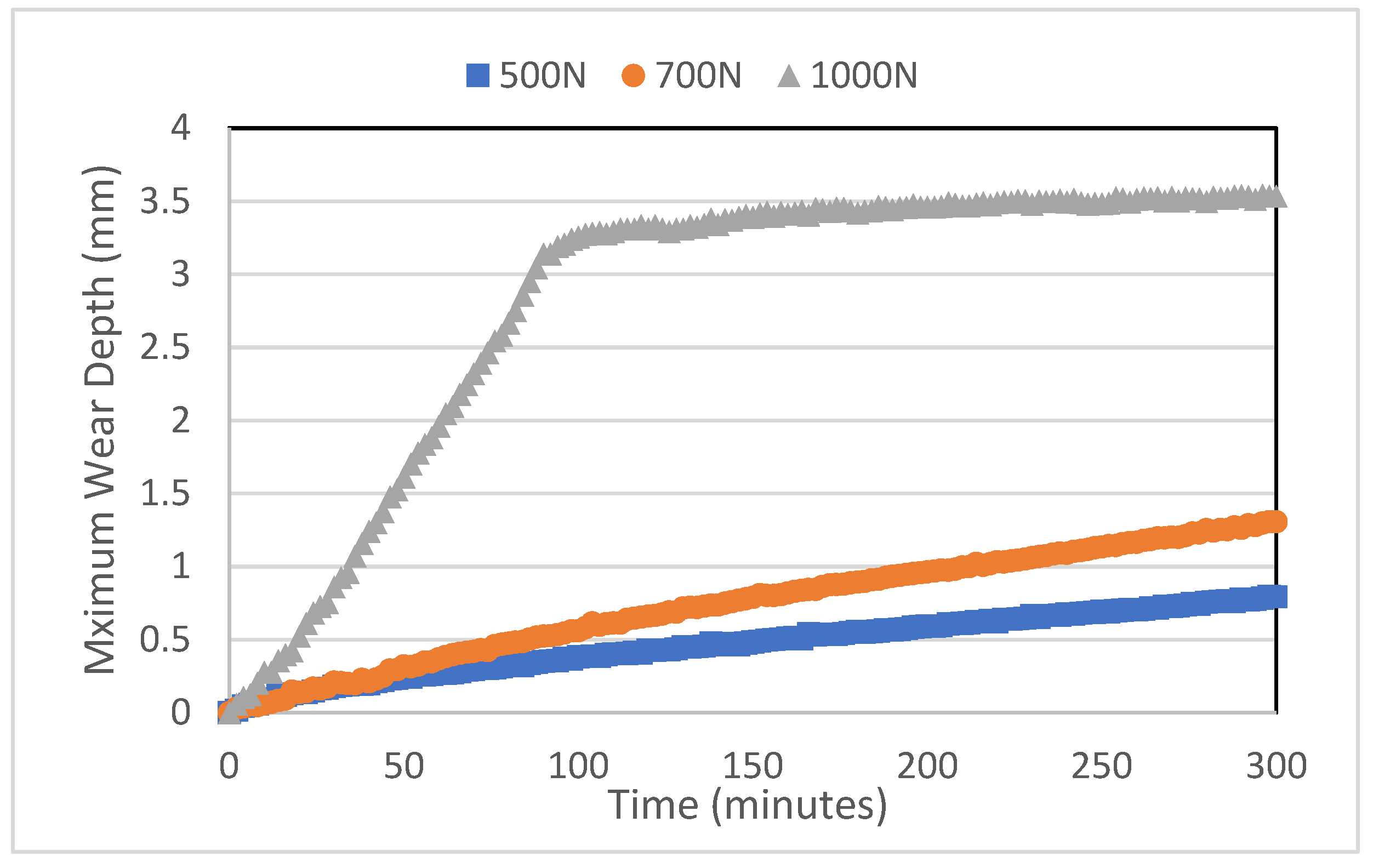

3.2. Wear Depth and Wear Volume

3.3. Specific Wear Rates

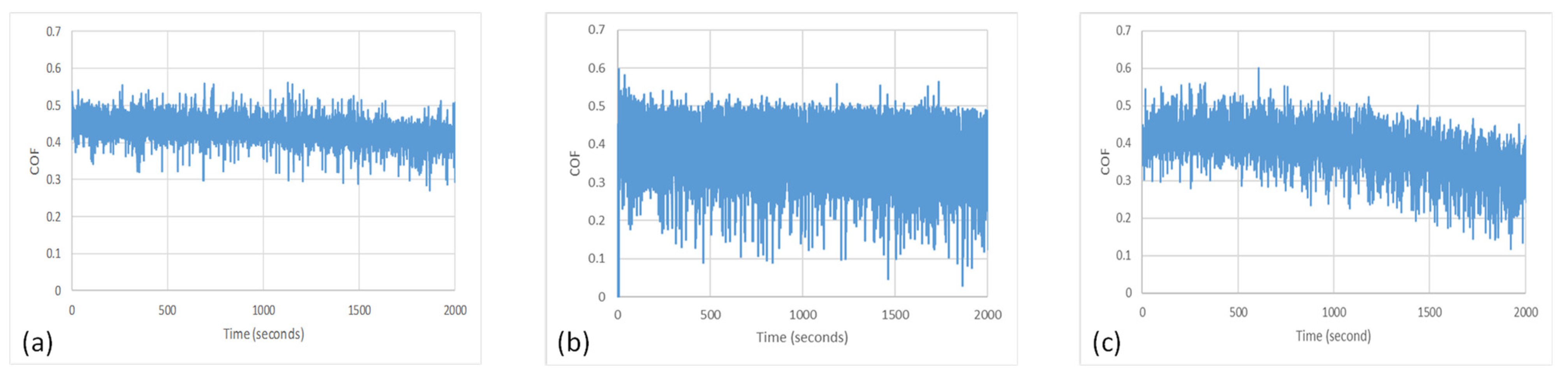

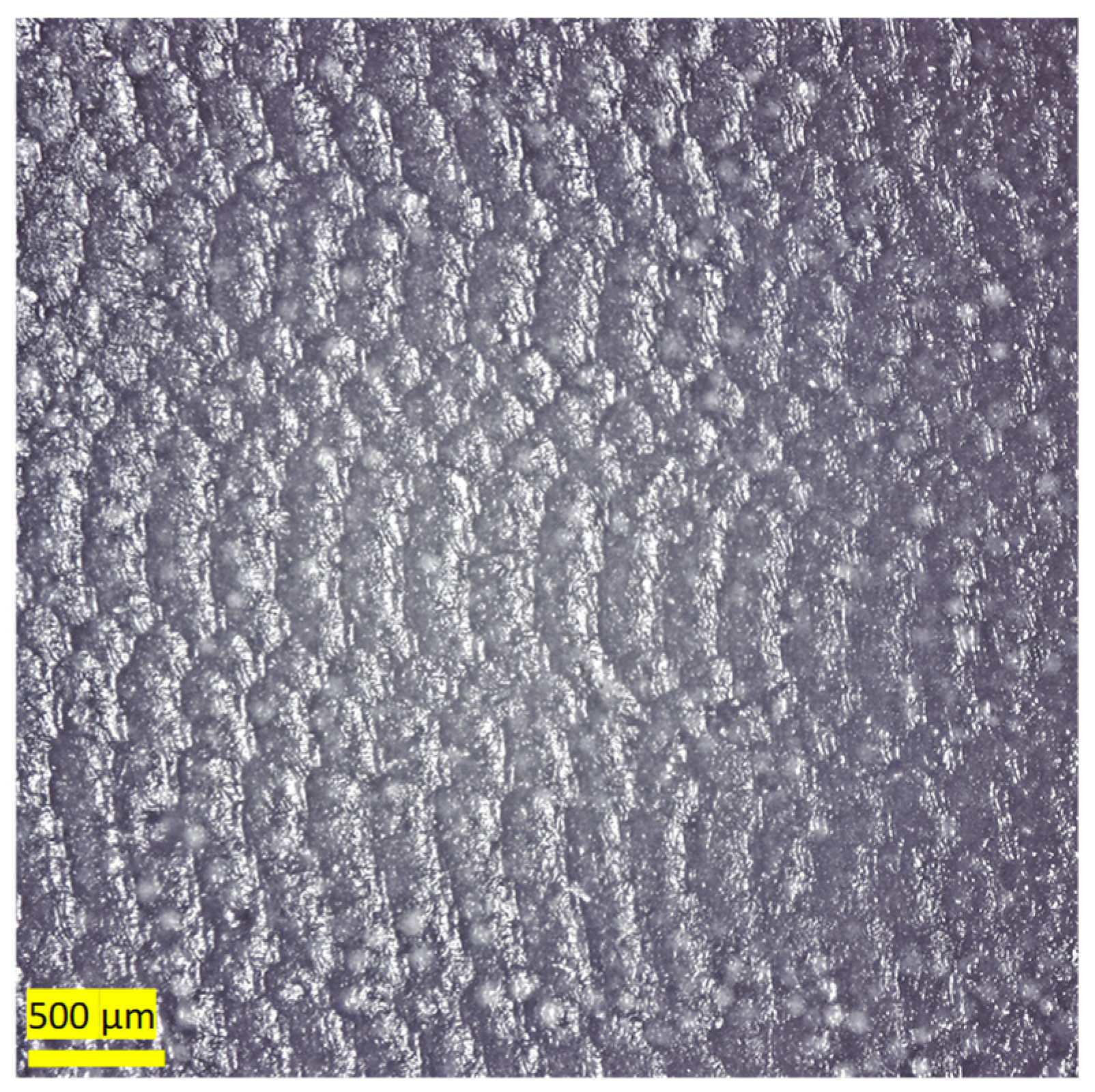

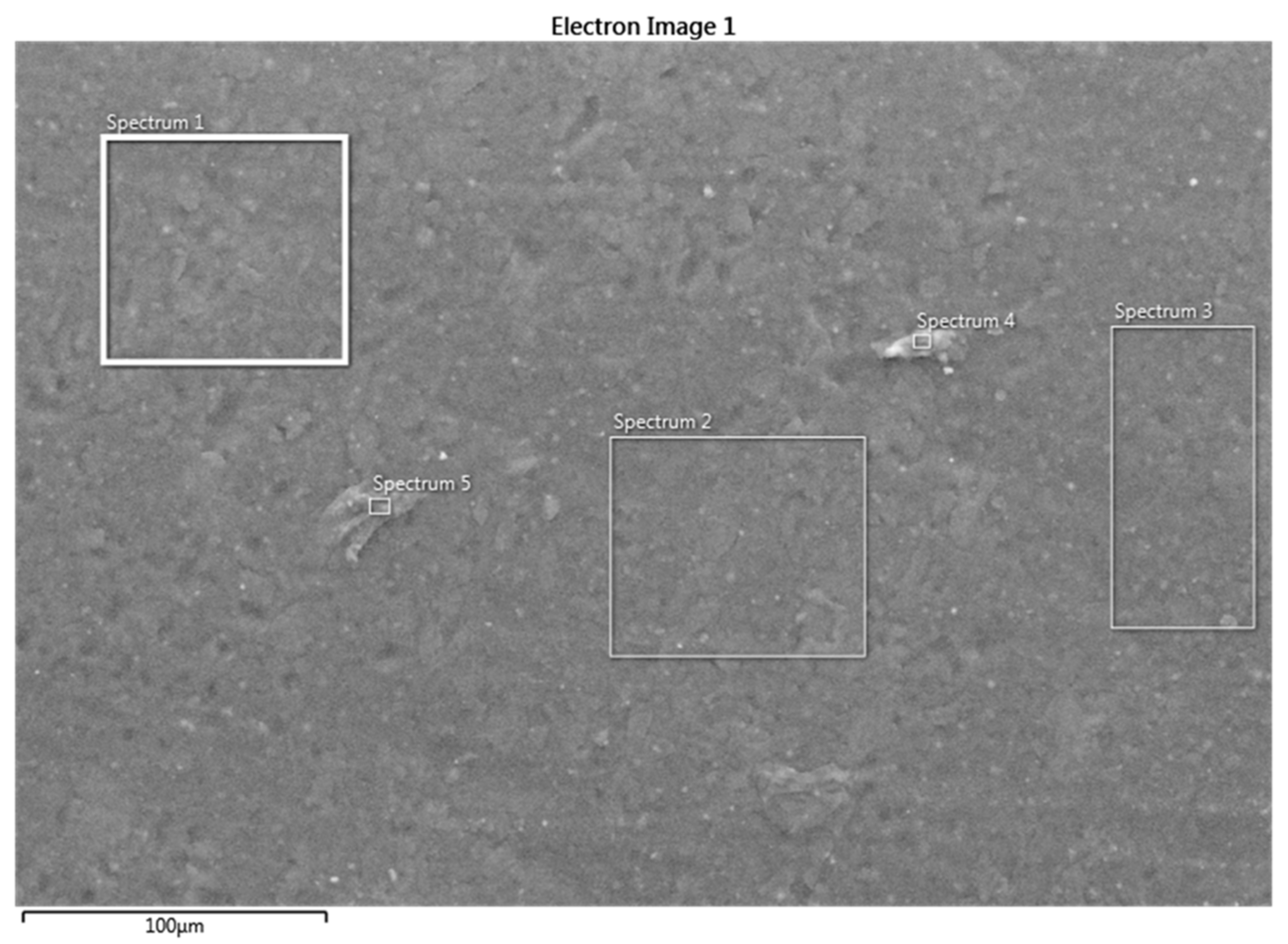

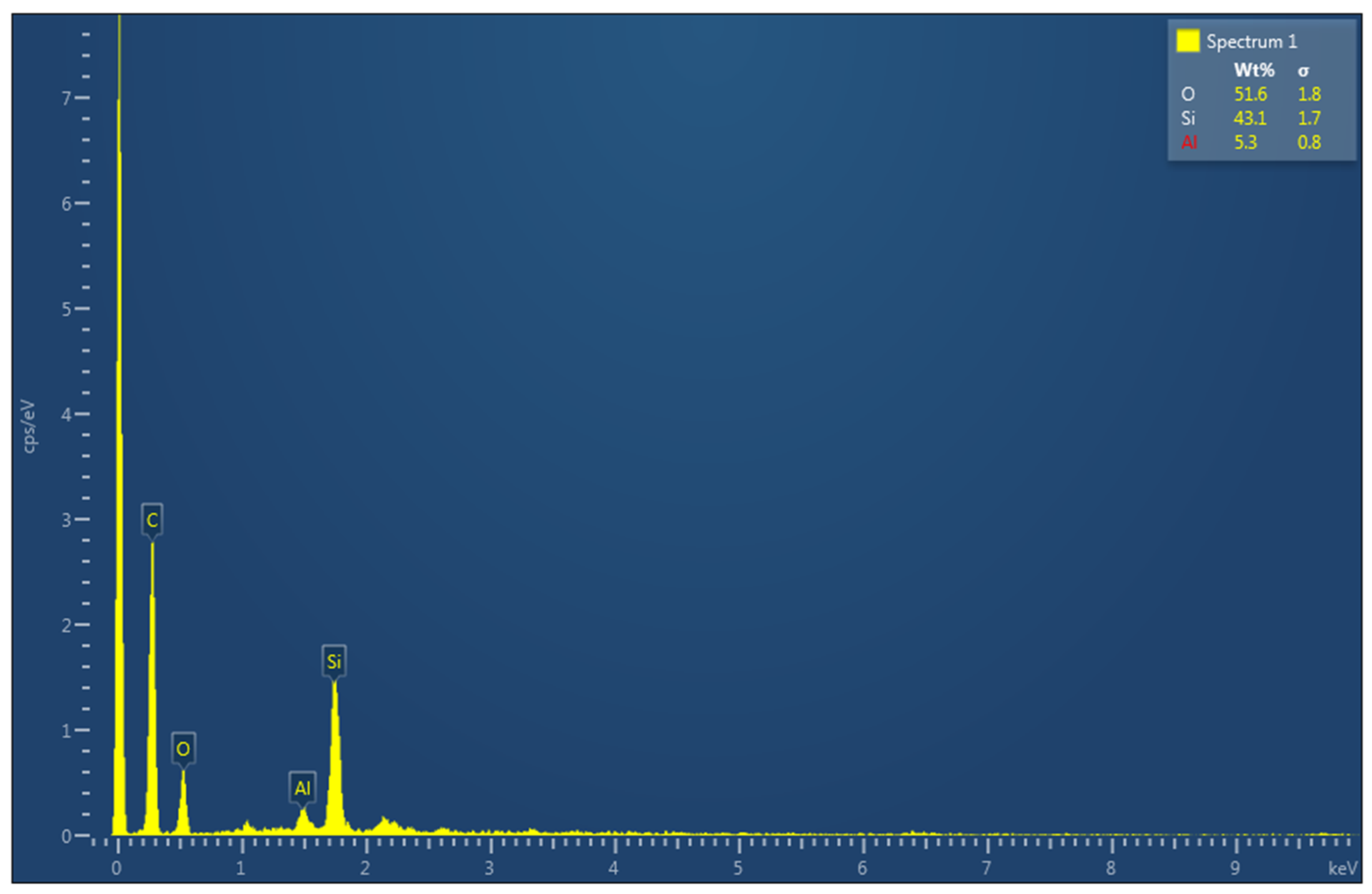

3.4. Wear Mechanisms

4. Conclusions

- The specific wear rate increases with contact load because of the increase in contact pressure and the presence of more asperities.

- The specific wear rate was significantly affected by the rotation speed with the minimum wear at the intermediate speed of 115 rpm. The primary cause of this behavior is the probable change in the lubrication regime from thin to thick film. The presence of zirconia tribofilms may also be contributing to the observed improvement in K.

- The abrasive wear mechanism was found to be dominant at lower speeds and loads, while both abrasive and adhesive wear were present at higher speeds. The effect of side load on the wear mechanisms is not very important.

- The EDS analyses showed that the material is composed of two different layers, where the surface is mostly aluminum and silica mixed with an epoxy matrix. The predominant elements in the lower layers are a mix of alumina, zirconia, and silica embedded in an epoxy matrix.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kato, K. Classification of wear mechanisms/models. Proc. Inst. Mech. Eng. Part. J J. Eng. Tribol. 2002, 216, 349–356. [Google Scholar] [CrossRef]

- Mohammed, A.I.; Oyeneyin, B.; Atchison, B.; Njuguna, J. Casing structural integrity and failure modes in a range of well types—A review. J. Nat. Gas. Sci. Eng. 2019, 68, 102898. [Google Scholar] [CrossRef]

- Liu, Y.; Feng, M.; Sun, G.; Liu, Z.; Ma, C.; Zhong, X.; Wang, L.; Liao, Y. Casing Failure Characteristics, Prevention and Control Strate gies for Mature Oilfields. IOP Conf. Ser. Earth Environ. Sci. 2019, 267, 042153. [Google Scholar] [CrossRef]

- Tan, L.; Gao, D.; Zhou, J. A Prediction Model of Casing Wear in Extended-Reach Drilling with Buckled Drillstring. J. Appl. Mech. Trans. ASME 2019, 85, 021001. [Google Scholar] [CrossRef]

- Fischer, A.; Bobzin, K. Friction, Wear and Wear Protection; Wiley-VGH: Weinheim, Germany, 2008. [Google Scholar]

- Zhang, H.; Goltsberg, R.; Etsion, I. Modeling Adhesive Wear in Asperity and Rough Surface Contacts: A Review. Materials 2022, 15, 6855. [Google Scholar] [CrossRef]

- Swain, B.; Bhuyan, S.; Behera, R.; Mohapatra, S.S.; Behera, A. Wear: A Serious Problem in Industry. In Tribology in Materials and Manufacturing—Wear, Friction and Lubrication; IntechOpen Limited: London, UK, 2020. [Google Scholar] [CrossRef]

- Sow, L.; Idrac, J.; Mora, P.; Font, E. Influence of environmental parameters on corrosion mechanisms of steels used in oil field. Mater. Corros. 2015, 66, 1245–1249. [Google Scholar] [CrossRef]

- Perez, T.E. Corrosion in the oil and gas industry: An increasing challenge for materials. JOM 2013, 65, 1033–1042. [Google Scholar] [CrossRef]

- Figueiredo-Pina, C.G.; Neves, A.A.M.; Neves, B.M.B.D. Corrosion-wear evaluation of a UHMWPE/Co–Cr couple in sliding contact under relatively low contact stress in physiological saline solution. Wear 2011, 271, 665–670. [Google Scholar] [CrossRef]

- Wood, R.J.K. Tribo-corrosion of coatings: A review. J. Phys. D Appl. Phys. 2007, 40, 5502–5521. [Google Scholar] [CrossRef]

- Stachowiak, G.W.; Batchelor, A.W. Wear of Non-Metallic Materials. In Engineering Tribology; Elsevier: Amsterdam, The Netherlands, 2006; pp. 651–704. [Google Scholar] [CrossRef]

- Briscoe, B.J.; Sinha, S.K. Wear of polymers. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2002, 216, 401–413. [Google Scholar] [CrossRef]

- Abdelbary, A. Wear of Polymers and Composites. In Proceedings of the International Conference on Applied Mechanics and Mechanical Engineering, Changsha, China, 13–15 March 2015; Volume 17. [Google Scholar] [CrossRef]

- Sampath, V. Studies on mechanical, friction, and wear characteristics of Kevlar and glass fiber-reinforced friction materials. Mater. Manuf. Process. 2006, 21, 47–57. [Google Scholar] [CrossRef]

- Krishna, K.G.; Divakar, C.; Venkatesh, K.; Mohan, C.B.; Lohith, K.S.M. Tribological studies of polymer based ceramic-metal composites processed at ambient temperature. Wear 2009, 266, 878–883. [Google Scholar] [CrossRef]

- Hareland, G.; Lyons, W.C.; Baldwin, D.D.; Briggs, G.M.; Bratli, R.K. Extended reach composite materials drill pipe. SPE Drill. Complet. 1998, 13, 114–120. [Google Scholar] [CrossRef]

- Al-Furjan, M.S.H.; Shan, L.; Shen, X.; Zarei, M.S.; Hajmohammad, M.H.; Kolahchi, R. A review on fabrication techniques and tensile properties of glass, carbon, and Kevlar fiber reinforced rolymer composites. J. Mater. Res. Technol. 2022, 19, 2930–2959. [Google Scholar] [CrossRef]

- Nair, A.N.; Sundharesan, S.; Al Tubi, I.S.M. Kevlar-based Composite Material and its Applications in Body Armour: A Short Literature Review. IOP Conf. Ser. Mater. Sci. Eng. 2020, 987, 012003. [Google Scholar] [CrossRef]

- Liu, J.; Lu, F.; Du, S.; Pang, X.; Zhang, Y. Friction and Wear Behaviors of Kevlar/Polytetrafluoroethylene Braided Composite in Oscillatory Contacts. J. Mater. Eng. Perform. 2020, 29, 2605–2611. [Google Scholar] [CrossRef]

- Yang, Q.; Senda, T.; Kotani, N.; Hirose, A. Sliding wear behavior and tribofilm formation of ceramics at high temperatures. Surf. Coat. Technol. 2004, 184, 270–277. [Google Scholar] [CrossRef]

- Denape, J.; Lamon, J. Sliding friction of ceramics: Mechanical action of the wear debris. J. Mater. Sci. 1990, 25, 3592–3604. [Google Scholar] [CrossRef]

- Kurahatti, R.V.; Surendranathan, A.O.; Srivastava, S.; Singh, N.; Kumar, A.V.R.; Suresha, B. Role of zirconia filler on friction and dry sliding wear behaviour of bismaleimide nanocomposites. Mater. Des. 2011, 32, 2644–2649. [Google Scholar] [CrossRef]

- Kurahatti, R.V.; Surendranathan, A.O.; Kumar, A.V.R.; Wadageri, C.S.; Auradi, V.; Kori, S.A. Dry Sliding Wear Behaviour of Epoxyreinforced with nanoZrO2 Particles. Procedia Mater. Sci. 2014, 5, 274–280. [Google Scholar] [CrossRef]

- Wang, S.; Zhou, S.; Huang, J.; Zhao, G.; Liu, Y. Attaching ZrO2 nanoparticles onto the surface of graphene oxide via electrostatic self-assembly for enhanced mechanical and tribological performance of phenolic resin composites. J. Mater. Sci. 2019, 54, 8247–8261. [Google Scholar] [CrossRef]

- Yi, J.; Yang, Y.; Zhang, Y.; Cao, M.; Wang, T.; Guan, J.; Xiao, Y.; Zhang, Y.; Tang, B.; Shen, X. Improved tribological and thermo-mechanical properties of epoxy resin with micro-nano structured ZrO2/Ti3C2 particles. J. Appl. Polym. Sci. 2021, 138, 51209. [Google Scholar] [CrossRef]

- Shivanand, H.K.; Kumar, P.J. Studies on Wear and hardness Properties of Kevlar/E-Glass/Epoxy with SiC Reinforced Polymer Matrix Composites. Int. Adv. Res. J. Sci. Eng. Technol. 2021, 8. [Google Scholar] [CrossRef]

- Osman, O.A.; Merah, N.; Abdul Samad, M.; Baig, M.M.; Samuel, R.; Alshalan, M.; Alshaarawi, A. Casing Wear and Wear Factors: New Experimental Study and Analysis. Materials 2022, 5, 6544. [Google Scholar] [CrossRef]

- Osman, O.A.; Merah, N.; Samuel, R.; Alshalan, M.; Alshaarawi, A. Casing Wear Tests for Precise Wear Factor Evaluation. In Proceedings of the SPE—International Association of Drilling Contractors Drilling Conference Proceedings 2022, Bangkok, Thailand, 9–10 August 2022. [Google Scholar] [CrossRef]

- Osman, O.; Merah, N.; Samad, M.A.; Al-Shaarawi, A.; Alshalan, M. Effects of Drilling Parameters and Mud Types on Wear Factors and Mechanisms of SM2535 Casings. Lubricants 2023, 11, 420. [Google Scholar] [CrossRef]

- Osman, O.A.; Merah, N.; Samad, M.A.; Baig, M.M.; Samuel, R.; Alshalan, M.; Alshaarawi, A. Wear factors and mechanisms of L-80 steel casings. Eng. Res. Express 2023, 5, 025076. [Google Scholar] [CrossRef]

- ASTM D2240-15; Standard Test Method for Rubber Property—Durometer Hardness. ASTM: West Conshohocken, PA, USA, 2015.

- Spikes, H.; Granick, S. Equation for Slip of Simple Liquids at Smooth Solid Surfaces. Langmuir 2003, 19, 5065–5071. [Google Scholar] [CrossRef]

- Zhu, Y.; Granick, S. No-slip boundary condition switches to partial slip when fluid contains surfactant. Langmuir 2002, 18, 10058–10063. [Google Scholar] [CrossRef]

- Vinogradova, O.I. Drainage of a Thin Liquid Film Confined between Hydrophobic Surfaces. Langmuir 1995, 11, 2213–2220. [Google Scholar] [CrossRef]

- Yamaguchi, T.; Ando, J.; Tsuda, T.; Takahashi, N.; Tohyama, M.; Murase, A.; Ohmori, T.; Hokkirigawa, K. Sliding velocity dependency of the friction coefficient of Si-containing diamond-like carbon film under oil lubricated condition. Tribol. Int. 2011, 44, 1296–1303. [Google Scholar] [CrossRef]

- Velkavrh, I.; Kalin, M.; Vižintin, J. The influence of viscosity on the friction in lubricated DLC contacts at various sliding velocities. Tribol. Int. 2009, 42, 1752–1757. [Google Scholar] [CrossRef]

- Bhushan, B. Principles and Applications of Tribology; Wiley: New York, NY, USA, 1999. [Google Scholar]

- Che, Y.; Sun, Z.; Zhan, R.; Wang, S.; Zhou, S.; Huang, J. Effects of graphene oxide sheets-zirconia spheres nanohybrids on mechanical, thermal and tribological performances of epoxy composites. Ceram. Int. 2018, 44, 18067–18077. [Google Scholar] [CrossRef]

| Outer Diameter | Inner Diameter | Sample Width | Composite Layer | |

|---|---|---|---|---|

| Casing | 244.5 | 211.5 | 35 ± 1 | 3–5 |

| DP-TJ | 137.2 | 78.0 | 146.0 | 35.6 |

| Tensile Strength (MPa) | 134.19 |

| Compressive strength (MPa) | 78.13 |

| Bending Strength (MPa) | 88.44 |

| Shear Strength (MPa) | 118.66 |

| Shear Modulus (GPa) | 3.2 |

| Modulus of Elasticity (GPa) | 6.8 |

| Hardness | Shore D > 90 |

| Water | As needed |

| Caustic Soda, ppb | 0.5 |

| Potato Starch, ppb | 5 |

| XC Polymer, ppb | 0.75 |

| Biocide (B-54 or equivalent), ppb | 0.3 |

| Marble Fine, pcf | Up to 67 |

| Test No. | Speed (rpm) | Force (N) |

|---|---|---|

| 1 | 65 | 500 |

| 2 | 65 | 500 |

| 3 | 65 | 700 |

| 4 | 65 | 700 |

| 5 | 65 | 1000 |

| 6 | 115 | 500 |

| 7 | 115 | 700 |

| 8 | 115 | 1000 |

| 9 | 154 | 500 |

| 10 | 154 | 500 |

| 11 | 154 | 700 |

| 12 | 154 | 1000 |

| Test Number | Speed (rpm) | Side Load (N) | Total Wear Depth (mm) | Loss in DP-TJ Thickness (mm) | Wear Volume (mm3) | Casing Specific Wear Rate K × 10−8 (MPa−1) |

|---|---|---|---|---|---|---|

| 1 | 65 | 500 | 0.180 | 0.05 | 70.04 | 0.929 |

| 2 | 65 | 500 | 0.103 | 0.06 | 31.33 | 0.276 |

| 3 | 65 | 700 | 0.826 | 0.15 | 683.95 | 8.62 |

| 4 | 65 | 700 | 0.637 | 0.151 | 474.76 | 5.43 |

| 5 | 65 | 1000 | 3.001 | 0.15 | 4525.7 | 115.16 |

| 6 | 115 | 500 | 0.339 | 0.15 | 186.9 | 1.046 |

| 7 | 115 | 700 | 0.760 | 0.15 | 621.76 | 4.398 |

| 8 | 115 | 1000 | 1.329 | 0.1 | 1599.95 | 14.439 |

| 9 | 154 | 500 | 0.792 | 0.125 | 647.86 | 5.125 |

| 10 | 154 | 500 | 1.140 | 0.2 | 1127.98 | 8.5683 |

| 11 | 154 | 700 | 1.305 | 0.15 | 1372.17 | 8.289 |

| 12 | 154 | 1000 | 3.137 | 0.24 | 4803 | 75.33 |

| Element | Spectrum 1 (wt.%) | Spectrum 2 (wt.%) | Spectrum 3 (wt.%) | Spectrum 4 (wt.%) | Spectrum 5 (wt.%) |

|---|---|---|---|---|---|

| O | 51.6 | 54.5 | 54.4 | 57.8 | 65.2 |

| Si | 43.1 | 38.8 | 37.1 | 30.3 | 29.8 |

| Al | 5.3 | 6.7 | 8.5 | 11.9 | 5.0 |

| Element | Spectrum 1 (wt.%) | Spectrum 2 (wt.%) | Spectrum 3 (wt.%) | Spectrum 4 (wt.%) | Spectrum 5 (wt.%) | Spectrum 6 (wt.%) |

|---|---|---|---|---|---|---|

| O | 50 | 42.9 | 38.5 | 23.4 | 30.6 | 44.4 |

| C | 24.1 | 18.4 | 33.2 | 75.5 | 64.9 | 16.0 |

| Zr | 18.3 | 29.3 | 21.0 | - | - | 28.8 |

| Si | 5.7 | 7.6 | 5.9 | 1.1 | 3.1 | 8.5 |

| Al | 1.8 | 1.8 | 1.4 | - | 1.4 | 2.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fouad, Y.; Aleid, A.A.; Osman, O.; Merah, N.; Shaarawi, A.; Hijles, A.; Waluyo, F. Tribological Characterization of a Novel Ceramic–Epoxy–Kevlar Composite. Polymers 2024, 16, 785. https://doi.org/10.3390/polym16060785

Fouad Y, Aleid AA, Osman O, Merah N, Shaarawi A, Hijles A, Waluyo F. Tribological Characterization of a Novel Ceramic–Epoxy–Kevlar Composite. Polymers. 2024; 16(6):785. https://doi.org/10.3390/polym16060785

Chicago/Turabian StyleFouad, Yassin, Abdulrahman A. Aleid, Omer Osman, Necar Merah, Amjad Shaarawi, Ali Hijles, and Fawzia Waluyo. 2024. "Tribological Characterization of a Novel Ceramic–Epoxy–Kevlar Composite" Polymers 16, no. 6: 785. https://doi.org/10.3390/polym16060785

APA StyleFouad, Y., Aleid, A. A., Osman, O., Merah, N., Shaarawi, A., Hijles, A., & Waluyo, F. (2024). Tribological Characterization of a Novel Ceramic–Epoxy–Kevlar Composite. Polymers, 16(6), 785. https://doi.org/10.3390/polym16060785