Tribological Properties of Polyimide Composites Modified with Diamondoid Metal–Organic Frameworks

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of MOFs

2.3. Preparation of PI and MOFs/PI Composites

2.4. Test Methods

2.4.1. Mechanical Tests

2.4.2. Tribological Properties of PI and MOFs/PI Composites

2.5. Analysis and Characterization Techniques

3. Results and Discussion

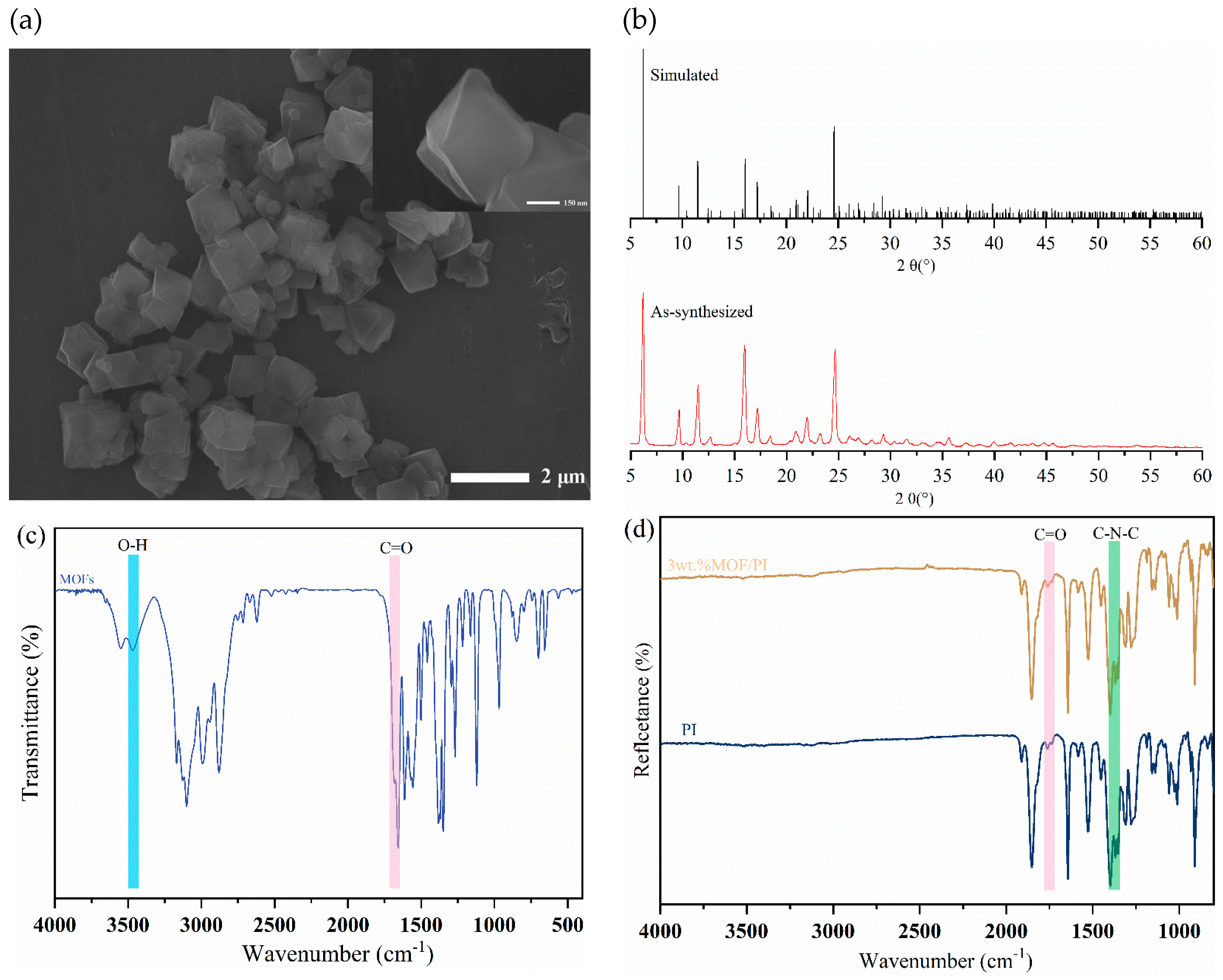

3.1. Morphology and Structure of the Materials

3.2. Mechanical Properties of MOFs/PI Composites

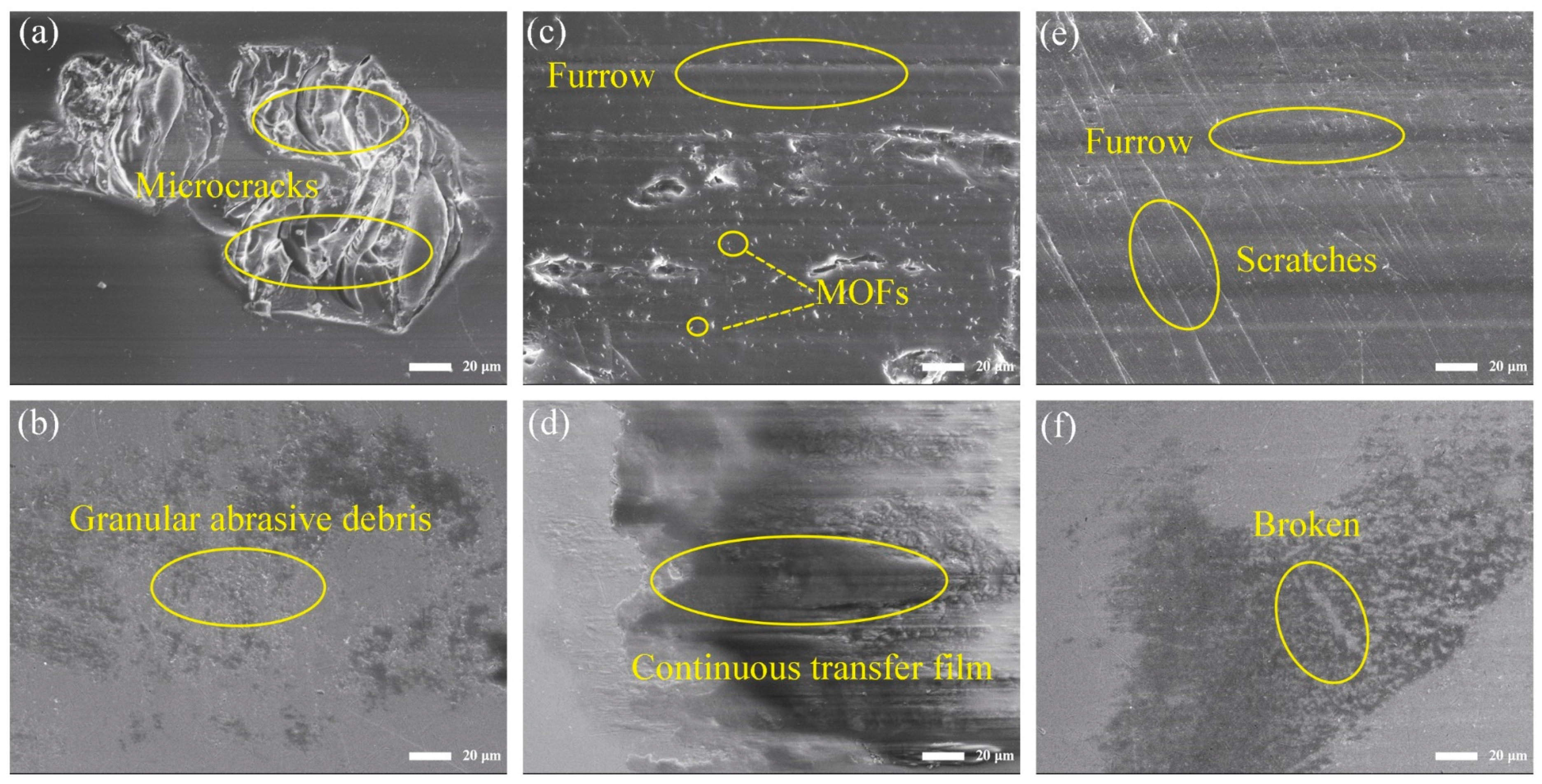

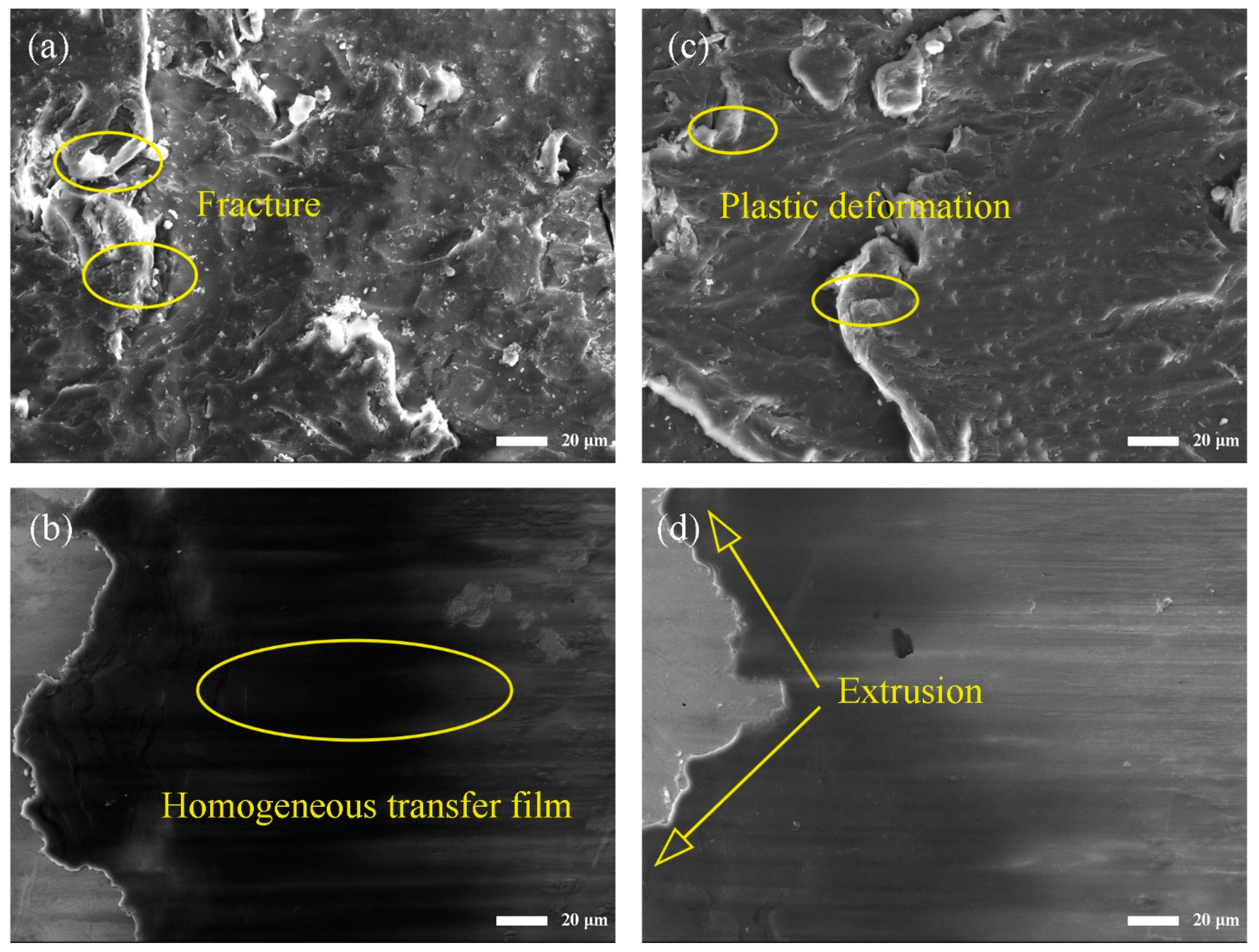

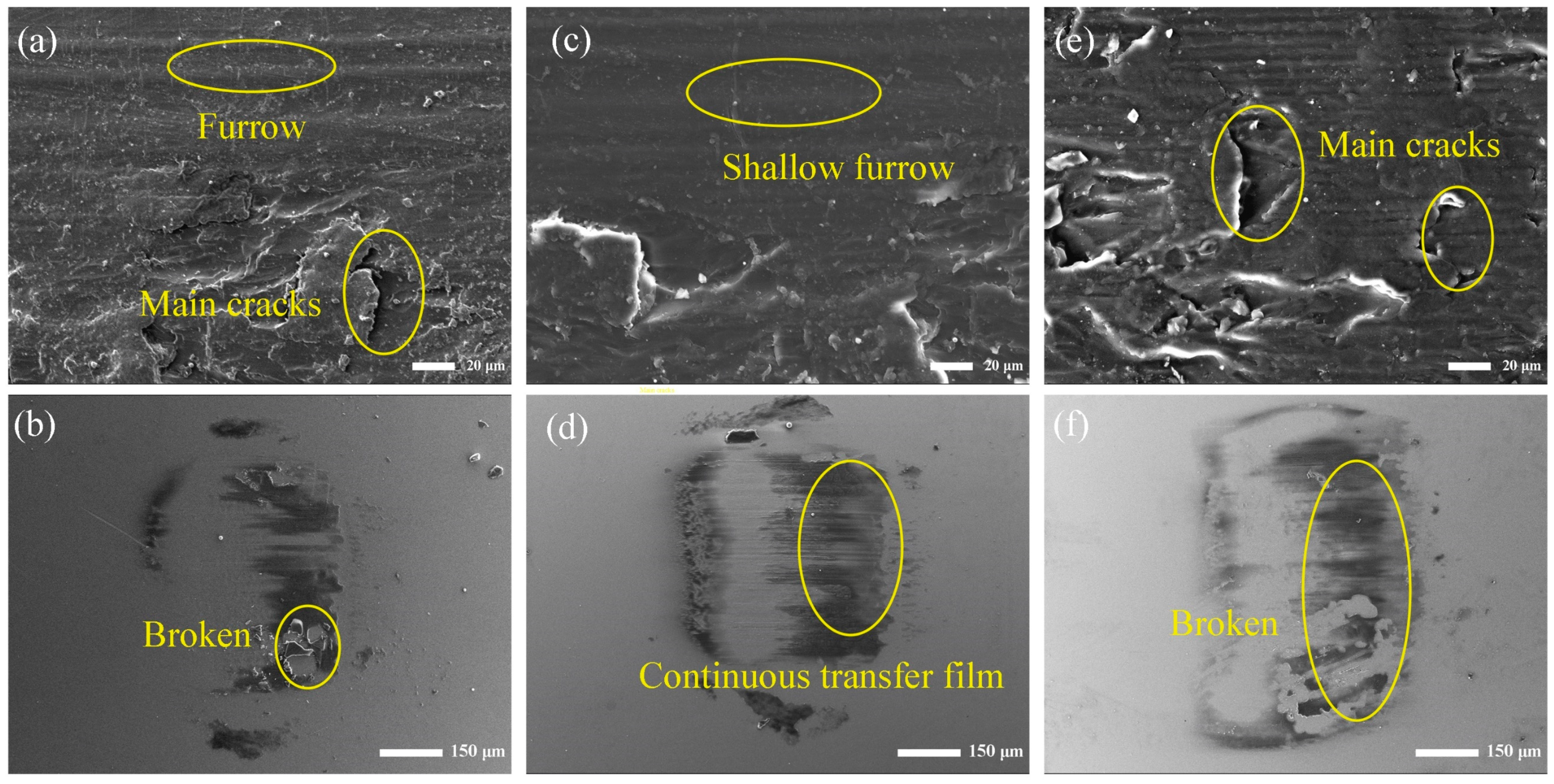

3.3. Tribological Properties of MOFs/PI Composites

4. Conclusions

- (1)

- An appropriate amount of diamondoid MOFs can improve the hardness and elastic modulus of the PI matrix due to the restricted molecular movement and enhanced interfacial bonding between MOFs and PI molecules. The modifying role of MOFs became impaired at excessive incorporations of them, and a content of 3 wt.% was recommended according to the present study.

- (2)

- The MOF particles helped increase the anti-shear performance of the PI surface and can bear the load during friction, during which relatively homogeneous and continuous transfer films were formed on the counterpart surface. As a combinational consequence, the wear rate of PI was decreased effectively, while the friction coefficient was increased slightly.

- (3)

- At the optimal content of 3 wt.%, the MOFs/PI composite still exhibited excellent tribological properties under high load or high velocity. This can mainly be attributed to the formation of uniform and continuous transfer films on the counterpart surface, which were promoted by the decomposition of MOFs.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Chen, S.; Guo, F.; Cheng, G.; Xiang, C.; Wang, Y. Evolution of the low-temperature tribological performance of polychlorotrifluoroethylene and polyimide. Tribol. Int. 2023, 180, 108271. [Google Scholar] [CrossRef]

- Zha, J.-W.; Tian, Y.; Zheng, M.-S.; Wan, B.; Yang, X.; Chen, G. High-temperature energy storage polyimide dielectric materials: Polymer multiple-structure design. Mater. Today Energy 2023, 31, 101217. [Google Scholar] [CrossRef]

- Qiu, J.; Ma, J.; Han, W.; Wang, X.; Wang, X.; Heini, M.; Li, B.; Sun, D.; Zhang, R.; Shi, Y.; et al. Effects of electron irradiation and temperature on mechanical properties of polyimide film. Polymers 2023, 15, 3805. [Google Scholar] [CrossRef]

- Wu, Y.T.; Wang, Y.X.; Li, Y. Combining the good tribological properties with the high adhesion strength of the amorphous carbon films in situ grown on PI. Front. Mater. 2023, 10, 1138854. [Google Scholar] [CrossRef]

- Liu, Y.; Mo, S.; Xu, X.; Du, X.; He, M.; Zhai, L.; Fan, L. Organic/inorganic hybrid polyimide matrix resins with high temperature resistance. Acta Mater. Compos. Sin. 2023, 40, 62–71. [Google Scholar]

- Pan, Z.; Wang, X.; Du, X.; Ren, X.; Zhang, Y.; Yang, C.; Wang, X.; Dai, S.; Liu, J. Progress on the research and application of polyimide films in triboelectric nanogenerators. New Chem. Mater. 2023, 51, 1–8. [Google Scholar]

- Akhdar, H.; Alotaibi, R. Geant4 simulation of the effect of different composites on polyimide photon and neutron shielding properties. Polymers 2023, 15, 1973. [Google Scholar] [CrossRef]

- Chen, B.; Wang, J.; Liu, N.; Yan, F. Synergism of several carbon series additions on the microstructures and tribological behaviors of polyimide-based composites under sea water lubrication. Mater. Des. 2014, 63, 325–332. [Google Scholar] [CrossRef]

- Yang, J.; Xiao, Q.F.; Lin, Z.; Li, Y.; Jia, X.H.; Song, H.J. Growth of ultra-dense MoS2 nanosheets on carbon fibers to improve the mechanical and tribological properties of polyimide composites. Friction 2021, 9, 1150–1162. [Google Scholar] [CrossRef]

- Ye, X.; Liu, X.; Yang, Z.; Wang, Z.; Wang, H.; Wang, J.; Yang, S. Tribological properties of fluorinated graphene reinforced polyimide composite coatings under different lubricated conditions. Compos. Part A Appl. Sci. Manuf. 2016, 81, 282–288. [Google Scholar] [CrossRef]

- Shi, Y.J.; Mu, L.W.; Feng, X.; Lu, X.H. The tribological behavior of nanometer and micrometer TiO2 particle-filled polytetrafluoroethylene/polyimide. Mater. Mater. Des. 2011, 32, 964–970. [Google Scholar] [CrossRef]

- Friedrich, K.; Zhang, Z.; Schlarb, A.K. Effects of various fillers on the sliding wear of polymer composites. Compos. Sci. Technol. 2005, 65, 2329–2343. [Google Scholar] [CrossRef]

- Song, Q.; Shi, S.; Liu, B. Metal-Organic Framework-based colloidal particle synthesis, assembly, and application. ChemPlusChem 2023, 88, e202200396. [Google Scholar] [CrossRef] [PubMed]

- Wang, C.X.; Zhou, M.A.; Cao, H.; Lin, H.L.; Han, S. Recent advances in metal-organic frameworks for lubrication. Mol. Syst. Des. Eng. 2024, 9, 243–253. [Google Scholar] [CrossRef]

- Baig, U.; Waheed, A.; Jillani, S.M.S. Recent advancements in Metal-Organic Framework-based membranes for hydrogen separation: A review. Chem. Asian J. 2023, e202300619. [Google Scholar] [CrossRef] [PubMed]

- Xin, Z.; Wang, Y.-R.; Chen, Y.; Li, W.-L.; Dong, L.-Z.; Lan, Y.-Q. Metallocene implanted metalloporphyrin organic framework for highly selective CO2 electroreduction. Nano Energy 2020, 67, 104233. [Google Scholar] [CrossRef]

- Park, C.; Baek, J.W.; Shin, E.; Kim, I.-D. Two-Dimensional electrically conductive Metal-Organic Frameworks as chemiresistive sensors. ACS Nanosci. Au 2023, 3, 353–374. [Google Scholar] [CrossRef]

- Jiang, S.; Lv, T.; Peng, Y.; Pang, H. MOFs containing solid-state electrolytes for batteries. Adv. Sci. 2023, 10, 2206887. [Google Scholar] [CrossRef]

- Wu, W.; Liu, J.; Li, Z.; Zhao, X.; Liu, G.; Liu, S.; Ma, S.; Li, W.; Liu, W. Surface-functionalized nanoMOFs in oil for friction and wear reduction and antioxidation. Chem. Eng. J. 2021, 410, 128306. [Google Scholar] [CrossRef]

- Sui, T.; Li, L.; Lin, B.; Zhang, Y.; Zhang, B.; Yan, S. Study on lubrication and friction reduction properties of ZIF-8 nanoparticles as Si3N4 ceramic water lubrication additives. Front. Chem. 2021, 9, 802375. [Google Scholar] [CrossRef]

- Dawson, R.; Cooper, A.I.; Adams, D.J. Nanoporous organic polymer networks. Prog. Polym. Sci. 2012, 37, 530–563. [Google Scholar] [CrossRef]

- Hu, C.; Huang, Q.; Zhai, Y. Thermal, mechanical investigation and neutron shielding analysis for Gd-MOF/polyimide materials. RSC Adv. 2021, 11, 40148–40158. [Google Scholar] [CrossRef]

- Lin, Y.; He, R.; Xu, Y.; Zhang, J.; Wetzel, B.; Zhang, G. Significance of nickel particles on reducing friction and wear of polyimide subjected to harsh boundary lubrication conditions. Tribol. Int. 2023, 178, 108063. [Google Scholar] [CrossRef]

- Taghipour, A.; Rahimpour, A.; Rastgar, M.; Sadrzadeh, M. Ultrasonically synthesized MOFs for modification of polymeric membranes: A critical review. Ultrason. Sonochem 2022, 90, 106202. [Google Scholar] [CrossRef] [PubMed]

- Zou, R.Q.; Yamada, Y.; Xu, Q. Strong fluorescent emission of a new fourfold-interpenetrated diamondoid metal-organic framework of zinc(II) urocanate with one-dimensional open channels. Microporous Mesoporous Mater. 2006, 91, 233–237. [Google Scholar] [CrossRef]

- Takahashi, T.; Takabayashi, S.; Inoue, H. Preparation of polyimide films from a-BPDA/ODA by one-pot and two-step imidization methods. High. Perform. Polym. 1998, 10, 33–44. [Google Scholar] [CrossRef]

- Duan, Y.B.; Jiang, D.Y.; Hu, J. Determination of the load-independent hardness by analyzing the nanoindentation loading curves: A case study on fused silica. J. Adv. Ceram. 2019, 8, 583–586. [Google Scholar] [CrossRef]

- Ma, S.; Li, H.; Li, C.; Tian, H.; Tao, M.; Fei, J.; Qi, L. Metal-organic frameworks/polydopamine synergistic interface enhancement of carbon fiber/phenolic composites for promoting mechanical and tribological performances. Nanoscale 2021, 13, 20234–20247. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Y.; Pan, B.; Wang, M.; Feng, Y.; Nie, P.; He, X. Tribological properties of differently shaped zinc-based metal-organic framework particles reinforced epoxy resin composites. J. Appl. Polym. 2023, 140, e54738. [Google Scholar] [CrossRef]

- Ma, S.; Fei, J.; Yan, J.; Liu, L.; Huang, Q.; Zhou, M.; Li, H. Organic-inorganic interface enhancement for boosting mechanical and tribological performances of carbon fiber reinforced composites. J. Appl. Polym. 2023, 141, e54855. [Google Scholar] [CrossRef]

- Wang, H.; Yan, L.; Liu, D.; Wang, C.; Zhu, Y.; Zhu, J. Investigation of the tribological properties: Core-shell structured magnetic Ni@NiO nanoparticles reinforced epoxy nanocomposites. Tribol. Int. 2015, 83, 139–145. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yu, Z.; Pei, X.; Pei, Q.; Wang, Y.; Zhang, Z.; Zhang, Y.; Wang, Q.; Wang, T. Tribological Properties of Polyimide Composites Modified with Diamondoid Metal–Organic Frameworks. Polymers 2024, 16, 806. https://doi.org/10.3390/polym16060806

Yu Z, Pei X, Pei Q, Wang Y, Zhang Z, Zhang Y, Wang Q, Wang T. Tribological Properties of Polyimide Composites Modified with Diamondoid Metal–Organic Frameworks. Polymers. 2024; 16(6):806. https://doi.org/10.3390/polym16060806

Chicago/Turabian StyleYu, Zihui, Xianqiang Pei, Qianyao Pei, Yan Wang, Zhancheng Zhang, Yaoming Zhang, Qihua Wang, and Tingmei Wang. 2024. "Tribological Properties of Polyimide Composites Modified with Diamondoid Metal–Organic Frameworks" Polymers 16, no. 6: 806. https://doi.org/10.3390/polym16060806

APA StyleYu, Z., Pei, X., Pei, Q., Wang, Y., Zhang, Z., Zhang, Y., Wang, Q., & Wang, T. (2024). Tribological Properties of Polyimide Composites Modified with Diamondoid Metal–Organic Frameworks. Polymers, 16(6), 806. https://doi.org/10.3390/polym16060806