A Study on the Properties of Composite Modified Mortar with Styrene–Butadiene Rubber Latex and Silica Fume

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Mix Design

2.3. Testing Methods

2.3.1. Fluidity

2.3.2. Drying Shrinkage

2.3.3. Mechanical Properties

2.3.4. Abrasion Resistance

2.3.5. Microscopic Testing

2.3.6. FT-IR

2.3.7. BET

3. Results and Discussion

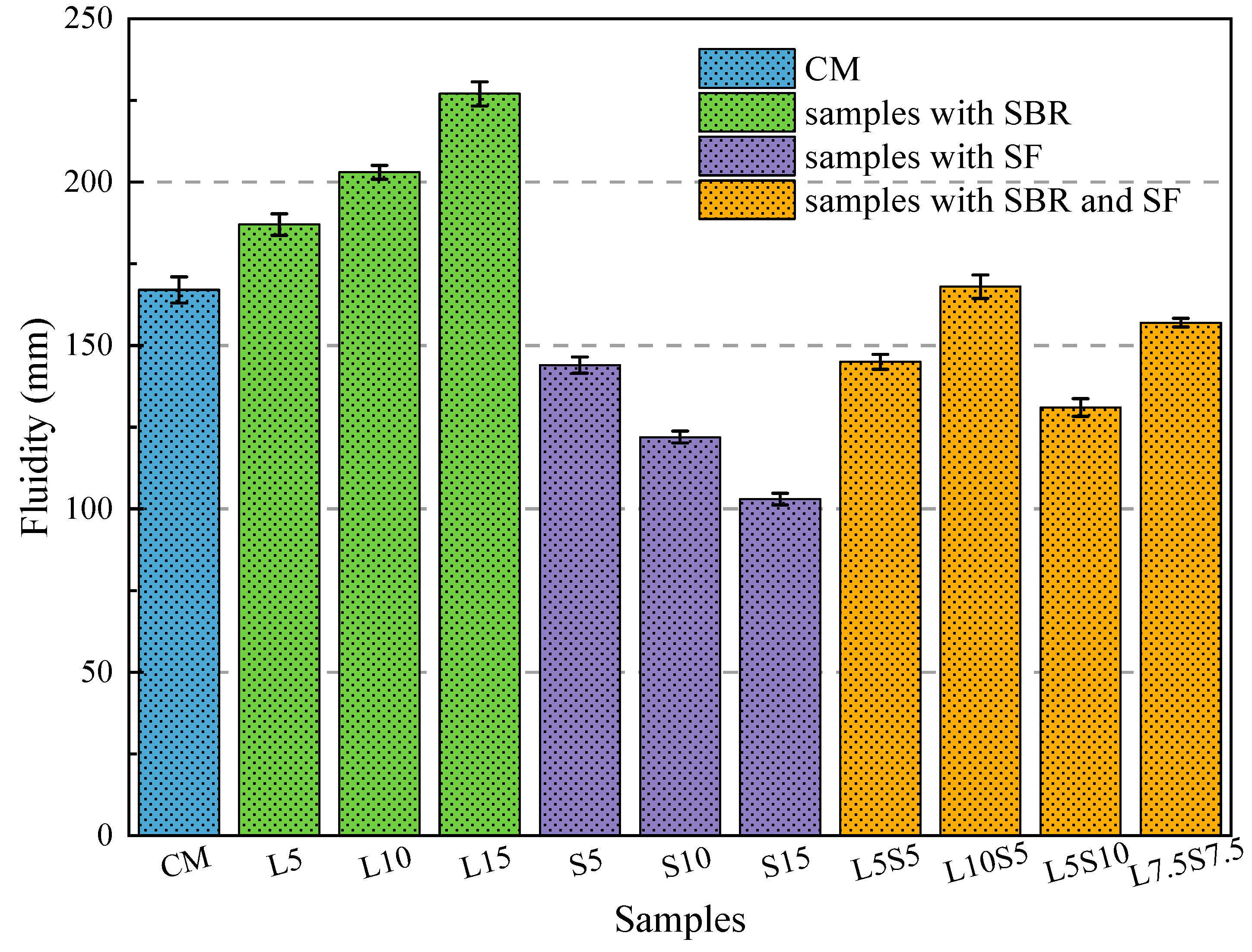

3.1. Fluidity

3.2. Drying Shrinkage

3.3. Mechanical Properties

3.3.1. Compressive Strength

3.3.2. Flexural Strength

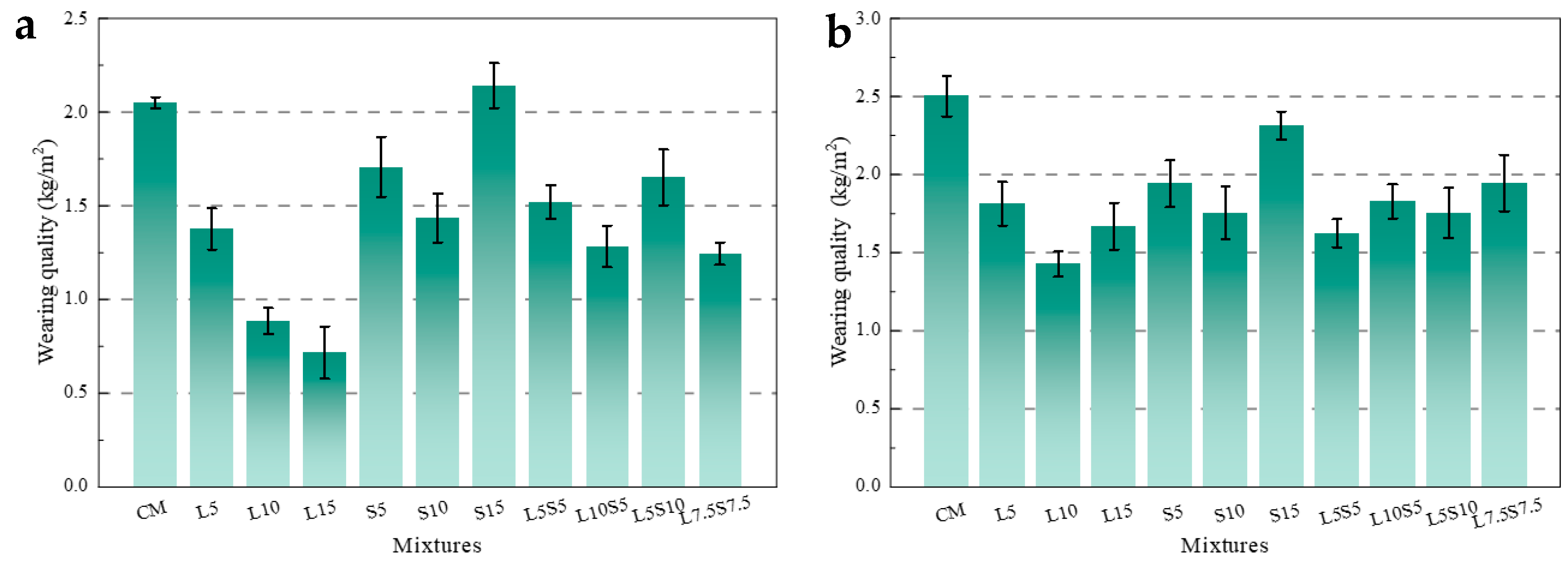

3.4. Abrasion Resistance

3.5. Composition and Pore Structure

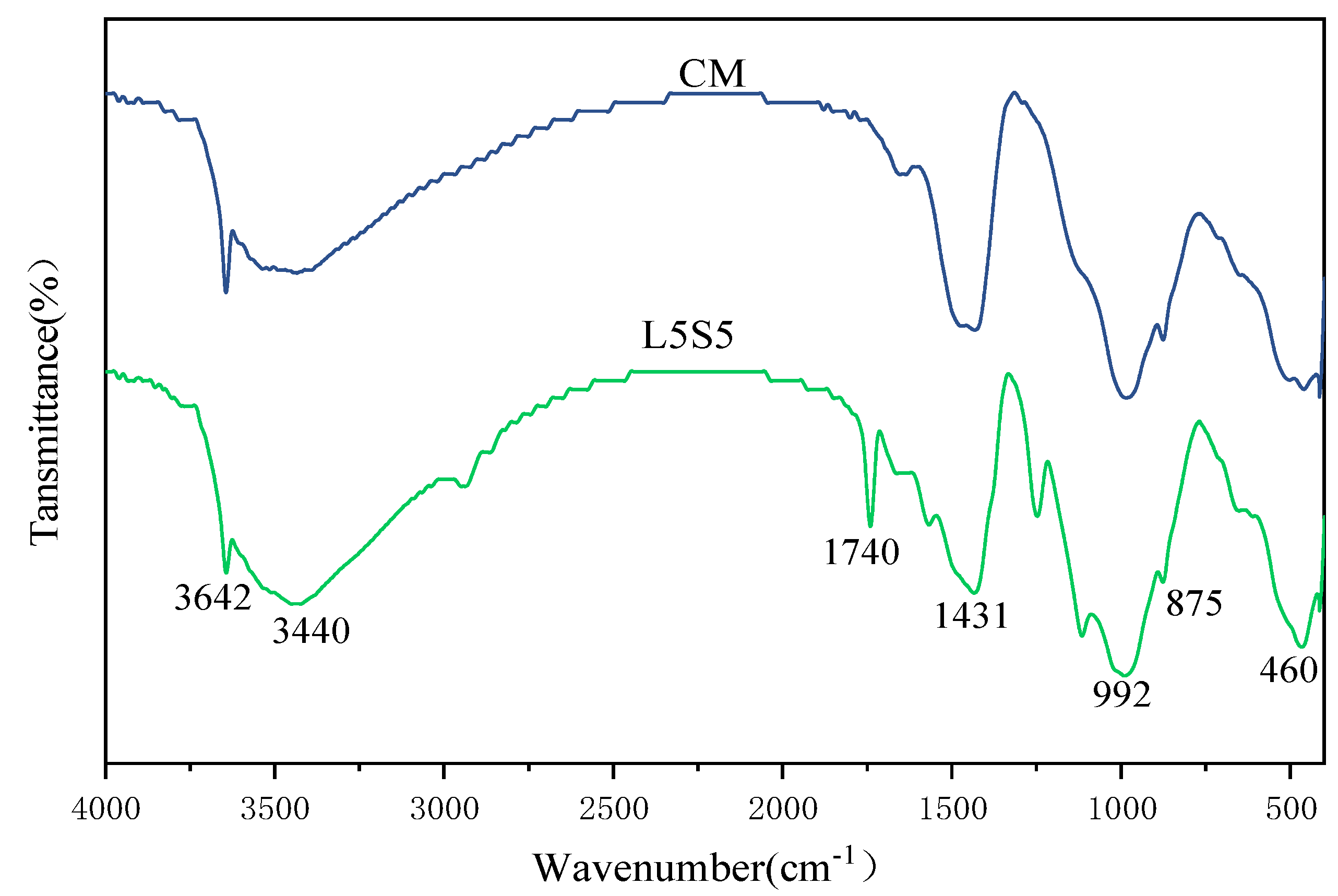

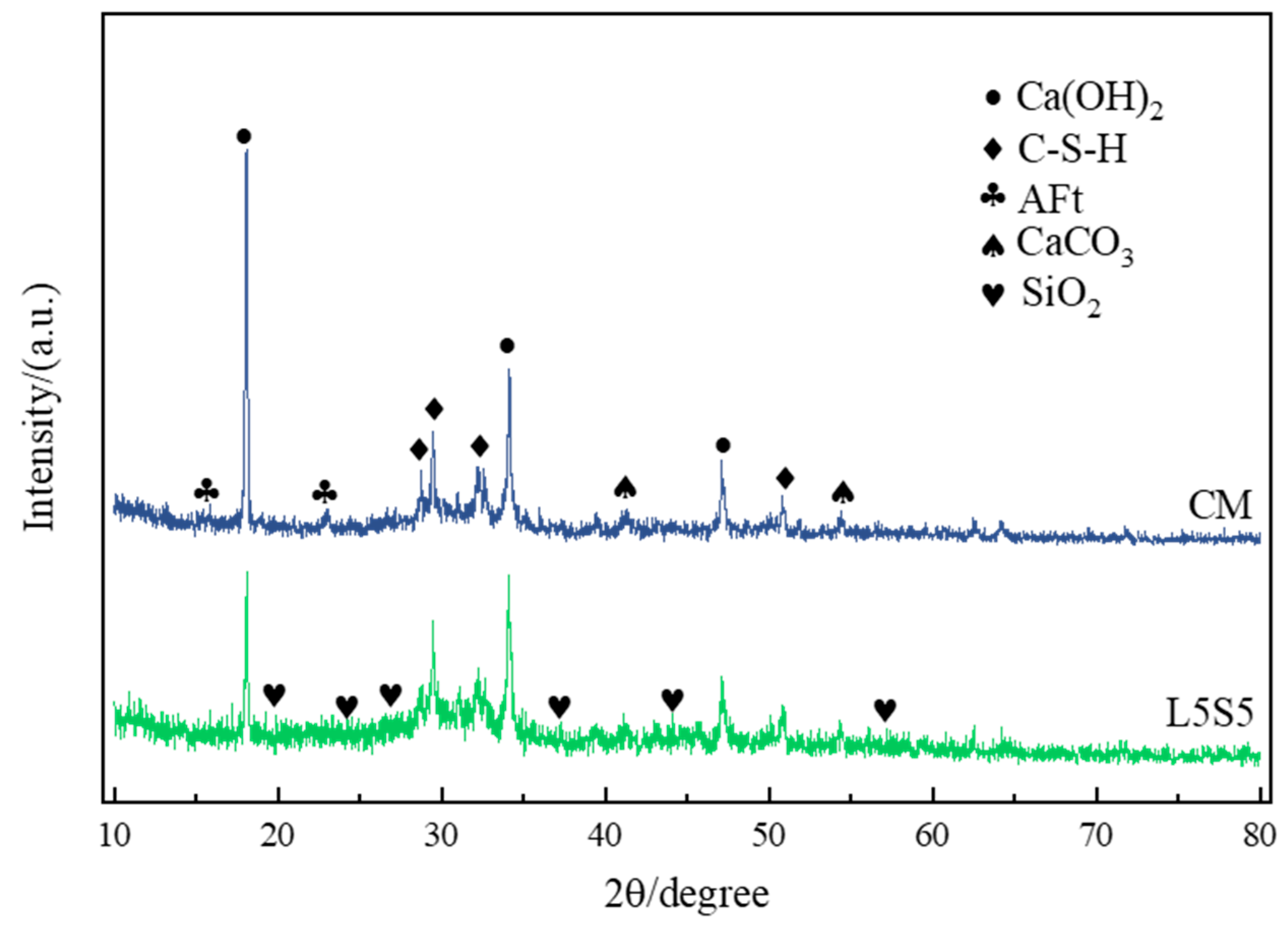

3.5.1. FT-IR and XRD

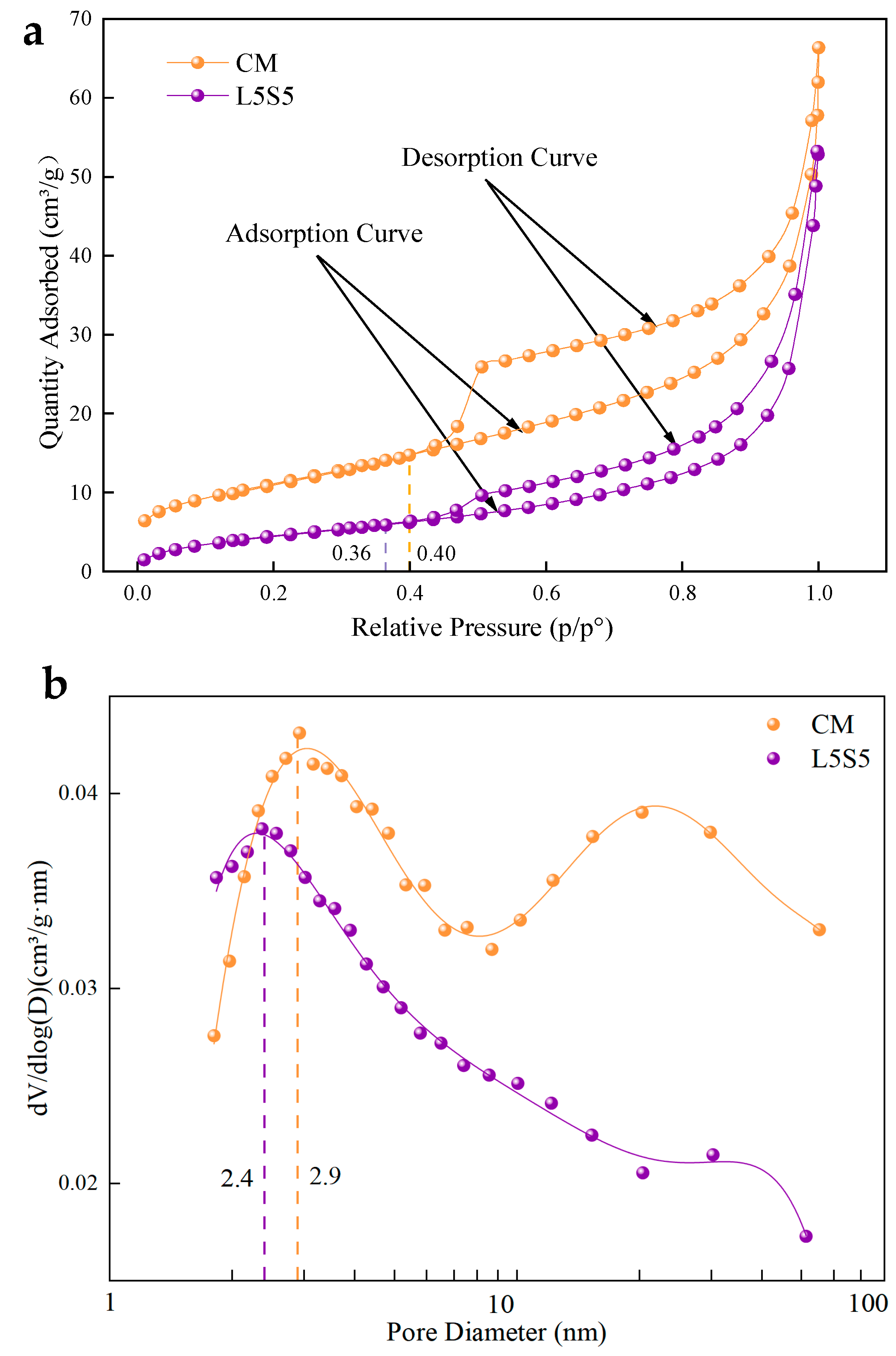

3.5.2. BET

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Ghoddousi, P.; Zareechian, M.; Shirzadi Javid, A.A.; Habibnejad Korayem, A. Microstructural study and surface properties of concrete pavements containing nanoparticles. Constr. Build. Mater. 2020, 262, 120103. [Google Scholar] [CrossRef]

- Zhou, C.; Chen, L.; Zheng, S.; Xu, Y.; Feng, D. Rheological, mechanical, and abrasion characteristics of polymer-modified cement mortar and concrete. Can. J. Civ. Eng. 2020, 47, 1226–1237. [Google Scholar] [CrossRef]

- Kılıç, A.; Atiş, C.D.; Teymen, A.; Karahan, O.; Özcan, F.; Bilim, C.; Özdemir, M. The influence of aggregate type on the strength and abrasion resistance of high strength concrete. Cem. Concr. Compos. 2008, 30, 290–296. [Google Scholar] [CrossRef]

- Nazeer, M.; Kapoor, K.; Singh, S.P. Strength, durability and microstructural investigations on pervious concrete made with fly ash and silica fume as supplementary cementitious materials. J. Build. Eng. 2023, 69, 106275. [Google Scholar] [CrossRef]

- Omoding, N.; Cunningham, L.S.; Lane-Serff, G.F. Effect of using recycled waste glass coarse aggregates on the hydrodynamic abrasion resistance of concrete. Constr. Build. Mater. 2021, 268, 121177. [Google Scholar] [CrossRef]

- Wu, F.; Chen, X.; Chen, J. Abrasion resistance enhancement of concrete using surface treatment methods. Tribol. Int. 2023, 179, 108180. [Google Scholar] [CrossRef]

- Silva, C.V.; Zorzi, J.E.; Cruz, R.C.D.; Dal Molin, D.C.C. Experimental evidence that micro and macrostructural surface properties markedly influence on abrasion resistance of concretes. Wear 2019, 422, 191–200. [Google Scholar] [CrossRef]

- Deng, Q.; Zhang, R.; Liu, C.; Duan, Z.; Xiao, J. Influence of fiber properties on abrasion resistance of recycled aggregate concrete: Length, volume fraction, and types of fibers. Constr. Build. Mater. 2023, 362, 129750. [Google Scholar] [CrossRef]

- Zhai, S.; Liu, G.; Pang, B.; Liu, C.; Zhang, Z.; Zhang, L.; Liu, L.; Yang, Y.; Liu, Z.; Zhang, Y. Investigation on the influence of modified waste rubber powder on the abrasion resistance of concrete. Constr. Build. Mater. 2022, 357, 129409. [Google Scholar] [CrossRef]

- Wu, F.; Yu, Q.; Chen, X. Effects of steel fibre type and dosage on abrasion resistance of concrete against debris flow. Cem. Concr. Compos. 2022, 134, 104776. [Google Scholar] [CrossRef]

- Rajput, B.L.; Pimplikar, S.S. Abrasion and impact resistance of concrete produced with nano-silica. Mater. Today Proc. 2022, 59, 115–119. [Google Scholar] [CrossRef]

- He, Z.; Chen, X.; Cai, X. Influence and mechanism of micro/nano-mineral admixtures on the abrasion resistance of concrete. Constr. Build. Mater. 2019, 197, 91–98. [Google Scholar] [CrossRef]

- Yön, M.Ş.; Arslan, F.; Karatas, M.; Benli, A. High-temperature and abrasion resistance of self-compacting mortars incorporating binary and ternary blends of silica fume and slag. Constr. Build. Mater. 2022, 355, 129244. [Google Scholar] [CrossRef]

- Jain, B.; Sancheti, G. Influence of silica fume and iron dust on mechanical properties of concrete. Constr. Build. Mater. 2023, 409, 133910. [Google Scholar] [CrossRef]

- Onuaguluchi, O. Effects of surface pre-coating and silica fume on crumb rubber-cement matrix interface and cement mortar properties. J. Clean. Prod. 2015, 104, 339–345. [Google Scholar] [CrossRef]

- Rao, G.A. Influence of silica fume replacement of cement on expansion and drying shrinkage. Cem. Concr. Res. 1998, 28, 1505–1509. [Google Scholar] [CrossRef]

- Al-Amoudi, O.S.B.; Maslehuddin, M.; Shameem, M.; Ibrahim, M. Shrinkage of plain and silica fume cement concrete under hot weather. Cem. Concr. Compos. 2007, 29, 690–699. [Google Scholar] [CrossRef]

- Hamada, H.M.; Abed, F.; Binti Katman, H.Y.; Humada, A.M.; Al Jawahery, M.S.; Majdi, A.; Yousif, S.T.; Thomas, B.S. Effect of silica fume on the properties of sustainable cement concrete. J. Mater. Res. Technol. 2023, 24, 8887–8908. [Google Scholar] [CrossRef]

- Zhang, X.; Du, M.; Fang, H.; Shi, M.; Zhang, C.; Wang, F. Polymer-modified cement mortars: Their enhanced properties, applications, prospects, and challenges. Constr. Build. Mater. 2021, 299, 124290. [Google Scholar] [CrossRef]

- Shi, C.; Zou, X.; Wang, P. Influences of ethylene-vinyl acetate and methylcellulose on the properties of calcium sulfoaluminate cement. Constr. Build. Mater. 2018, 193, 474–480. [Google Scholar] [CrossRef]

- Jo, Y.-K. Adhesion in tension of polymer cement mortar by curing conditions using polymer dispersions as cement modifier. Constr. Build. Mater. 2020, 242, 118134. [Google Scholar] [CrossRef]

- Zhao, J.; Hu, M.; Liu, W.; Feng, J.; Zhang, H.; Liu, M.; Guo, J. Toughening effects of well-dispersed carboxylated styrene-butadiene latex powders on the properties of oil well cement. Constr. Build. Mater. 2022, 340, 127768. [Google Scholar] [CrossRef]

- Chen, H.; Ma, C.; Zhang, H.; Yin, Y. Study on skid resistance and skid-resistance durability of polymer modified cement mortar based on surface texture properties. Constr. Build. Mater. 2023, 370, 130645. [Google Scholar] [CrossRef]

- Moodi, F.; Kashi, A.; Ramezanianpour, A.A.; Pourebrahimi, M. Investigation on mechanical and durability properties of polymer and latex-modified concretes. Constr. Build. Mater. 2018, 191, 145–154. [Google Scholar] [CrossRef]

- Yuan, P.; Zhang, B.; Yang, Y.; Jiang, T.; Li, J.; Qiu, J.; He, H. Application of polymer cement repair mortar in underground engineering: A review. Case Stud. Constr. Mater. 2023, 19, e02555. [Google Scholar] [CrossRef]

- JTG 3420-2020; Testing Methods of Cement and Concrete for Highway Engineering. Ministry of Transport of the People’s Republic of China: Beijing, China, 2020.

- Li, X.; Liu, R.; Li, S.; Zhang, C.; Li, J.; Cheng, B.; Liu, Y.; Ma, C.; Yan, J. Effect of SBR and XSBRL on water demand, mechanical strength and microstructure of cement paste. Constr. Build. Mater. 2022, 332, 127309. [Google Scholar] [CrossRef]

- Eren, F.; Gödek, E.; Keskinateş, M.; Tosun-Felekoğlu, K.; Felekoğlu, B. Effects of latex modification on fresh state consistency, short term strength and long term transport properties of cement mortars. Constr. Build. Mater. 2017, 133, 226–233. [Google Scholar] [CrossRef]

- Bhattacharya, M.; Harish, K.V. An integrated approach for studying the hydration of portland cement systems containing silica fume. Constr. Build. Mater. 2018, 188, 1179–1192. [Google Scholar] [CrossRef]

- Almeida, A.E.F.d.S.; Sichieri, E.P. Mineralogical study of polymer modified mortar with silica fume. Constr. Build. Mater. 2006, 20, 882–887. [Google Scholar] [CrossRef]

- Shi, C.; Li, M.; Ma, C.; He, T. Interfacial bonding properties of styrene-butadiene rubber and ethylene vinyl acetate emulsion-modified OPC–CAC–G repair mortar. Constr. Build. Mater. 2023, 370, 130747. [Google Scholar] [CrossRef]

- Yang, Z.; Shi, X.; Creighton, A.T.; Peterson, M.M. Effect of styrene–butadiene rubber latex on the chloride permeability and microstructure of Portland cement mortar. Constr. Build. Mater. 2009, 23, 2283–2290. [Google Scholar] [CrossRef]

| Materials | SiO2 | Al2O3 | Fe2O3 | CaO | MgO | SO3 | Na2Oeq | LOSS | f-CaO |

|---|---|---|---|---|---|---|---|---|---|

| cement | 22.9 | 7.2 | 2.6 | 57.8 | 2.6 | 2.5 | 0.3 | 3.5 | 0.6 |

| silica fume | 98 | 0.7 | 0.5 | 0.2 | 0.6 | - | - | - | - |

| Sample | w/b | Water (g) | Cement (g) | SBR Latex (g) | SF (g) | Quartz Sand (g) | Defoamer (g) |

|---|---|---|---|---|---|---|---|

| CM | 0.40 | 240 | 600 | 0 | 0 | 1200 | 3.6 |

| L5 | 0.40 | 210 | 570 | 60 | 0 | 1200 | 3.6 |

| L10 | 0.40 | 180 | 540 | 120 | 0 | 1200 | 3.6 |

| L15 | 0.40 | 150 | 510 | 180 | 0 | 1200 | 3.6 |

| S5 | 0.40 | 240 | 570 | 0 | 30 | 1200 | 3.6 |

| S10 | 0.40 | 240 | 540 | 0 | 60 | 1200 | 3.6 |

| S15 | 0.40 | 240 | 510 | 0 | 90 | 1200 | 3.6 |

| L5S5 | 0.40 | 210 | 540 | 60 | 30 | 1200 | 3.6 |

| L10S5 | 0.40 | 180 | 510 | 120 | 30 | 1200 | 3.6 |

| L5S10 | 0.40 | 210 | 510 | 60 | 60 | 1200 | 3.6 |

| L7.5S7.5 | 0.40 | 195 | 510 | 90 | 45 | 1200 | 3.6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yan, R.; Wang, L.; Ni, Y.; Zhang, S.; He, Z.; Guan, B. A Study on the Properties of Composite Modified Mortar with Styrene–Butadiene Rubber Latex and Silica Fume. Polymers 2024, 16, 697. https://doi.org/10.3390/polym16050697

Yan R, Wang L, Ni Y, Zhang S, He Z, Guan B. A Study on the Properties of Composite Modified Mortar with Styrene–Butadiene Rubber Latex and Silica Fume. Polymers. 2024; 16(5):697. https://doi.org/10.3390/polym16050697

Chicago/Turabian StyleYan, Renwei, Laifa Wang, Yongjun Ni, Shuowen Zhang, Zhenqing He, and Bowen Guan. 2024. "A Study on the Properties of Composite Modified Mortar with Styrene–Butadiene Rubber Latex and Silica Fume" Polymers 16, no. 5: 697. https://doi.org/10.3390/polym16050697

APA StyleYan, R., Wang, L., Ni, Y., Zhang, S., He, Z., & Guan, B. (2024). A Study on the Properties of Composite Modified Mortar with Styrene–Butadiene Rubber Latex and Silica Fume. Polymers, 16(5), 697. https://doi.org/10.3390/polym16050697