Silicon Hybrid EPDM Composite with High Thermal Protection Performance

Abstract

1. Introduction

2. Experimental Section

2.1. Materials

2.2. Preparation of Samples

2.2.1. Preparation of Silicon Hybrid EPDM

2.2.2. Preparation of Silicon Hybrid EPDM Composites

2.3. Characterization

2.3.1. Thermogravimetric Analysis (TGA)

2.3.2. Burn-Through Test

2.3.3. Thermal Conductivity

2.3.4. Field-Emission Scanning Electron Microscope (FSEM)

2.3.5. High-Performance Fully Automatic Mercury Injection

2.3.6. Scanning Electron Microscopy (SEM)

2.3.7. Mechanical Properties

2.3.8. X-ray Photoelectron Spectroscopy (XPS)

2.3.9. TG-FTIR

3. Results and Discussion

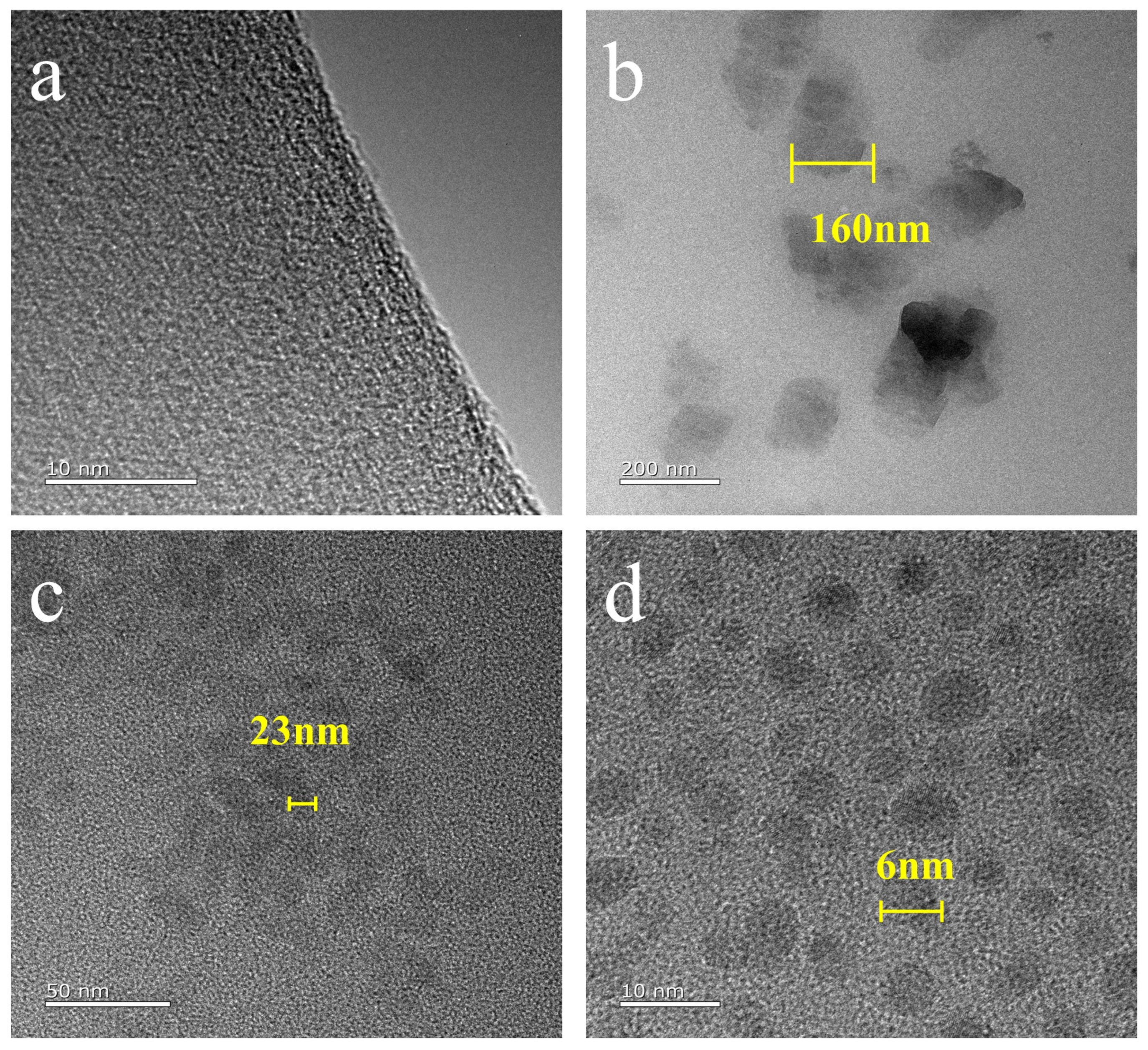

3.1. Morphology of Fillers in Silicon Hybrid EPDM

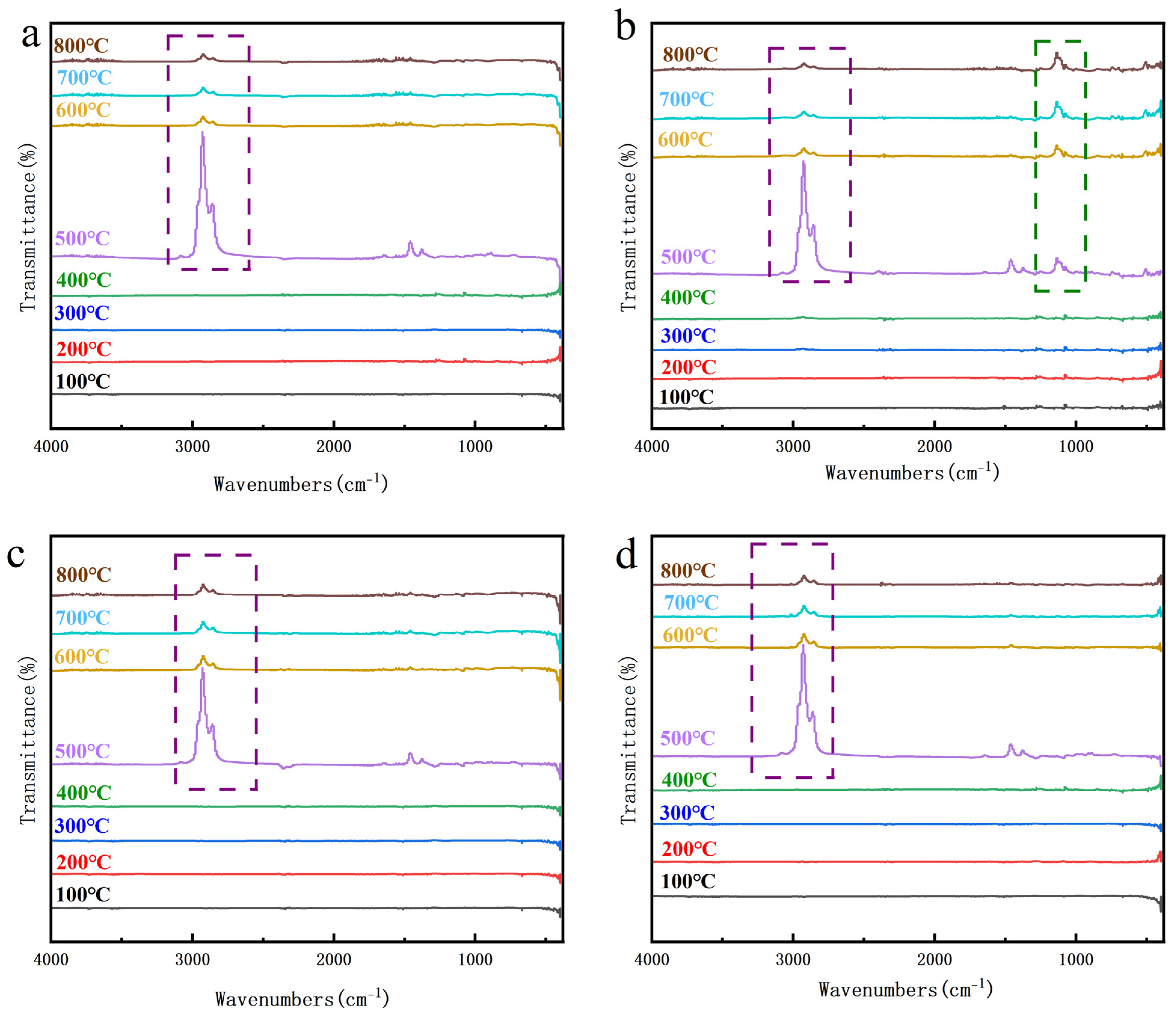

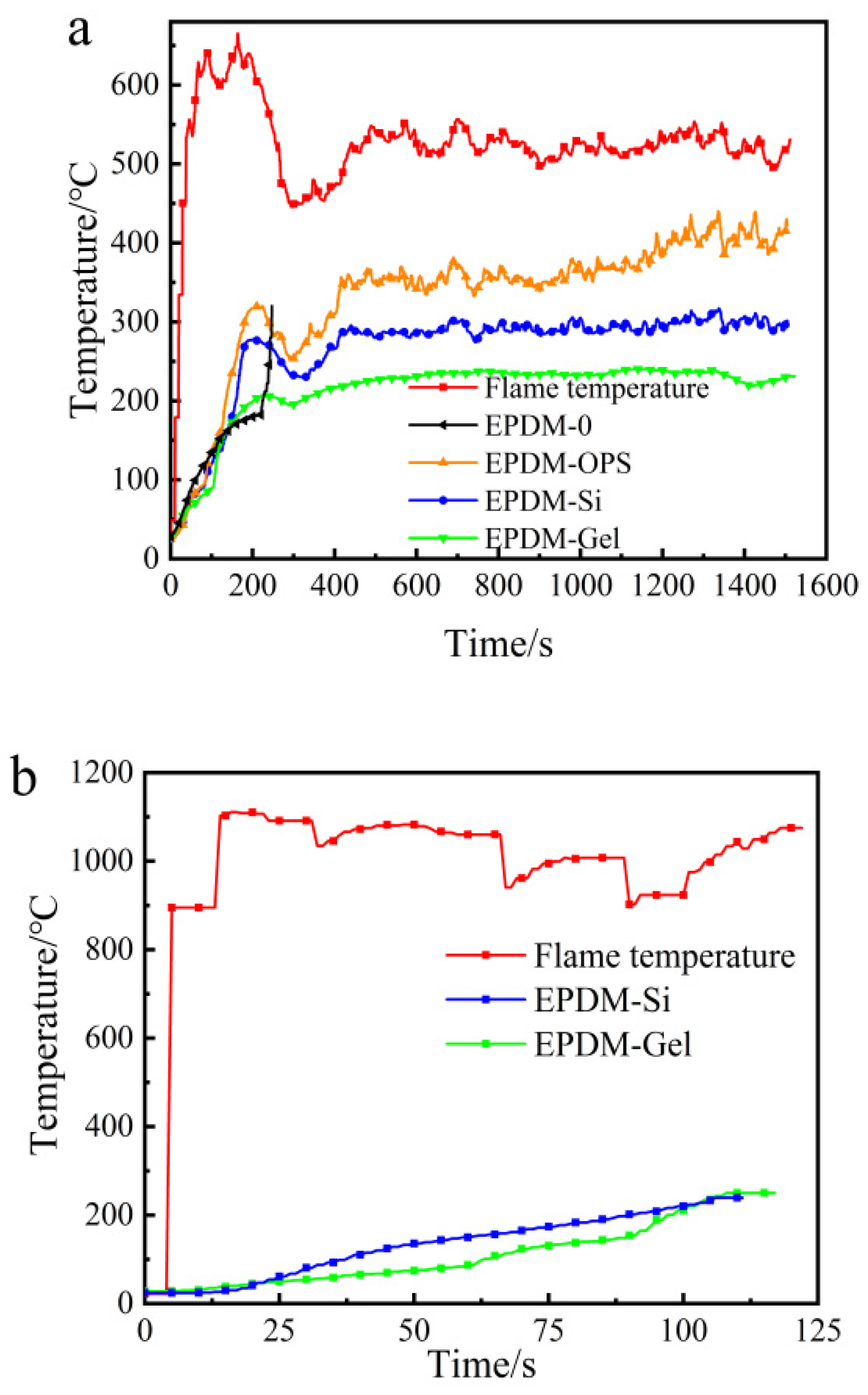

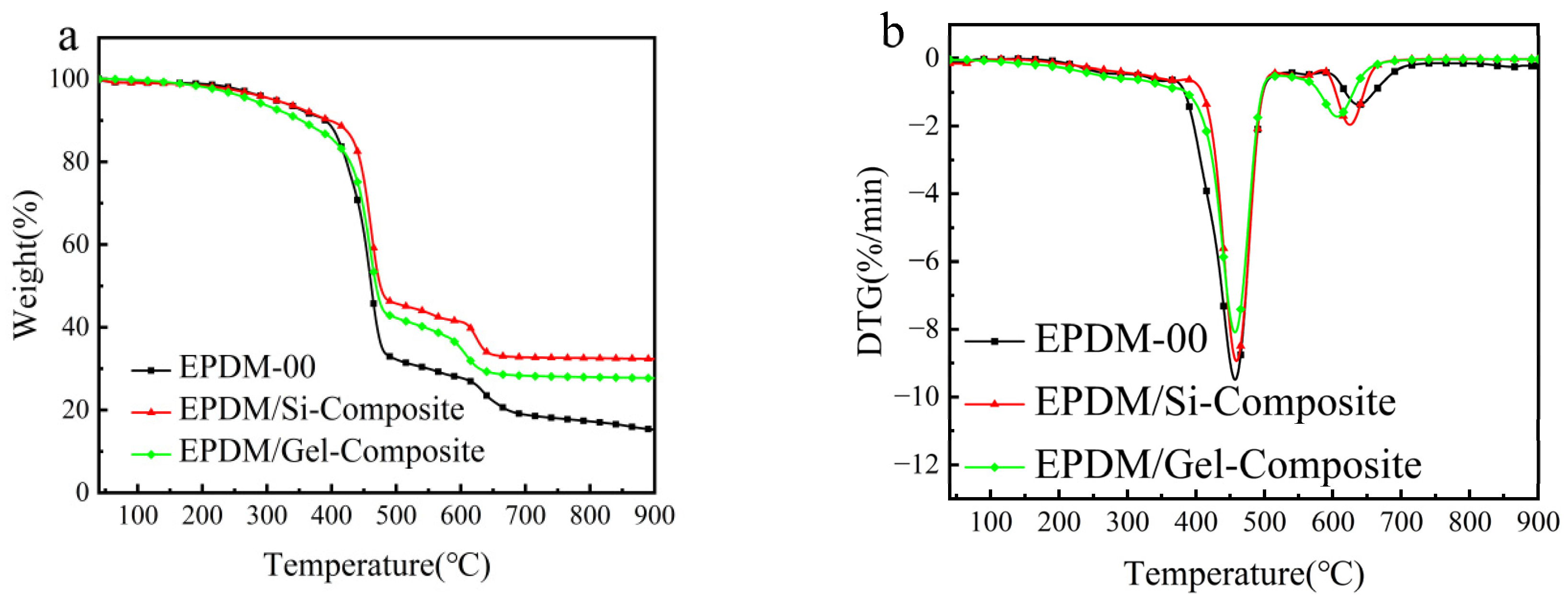

3.2. Thermal Degradation and Insulation of Silicon Hybrid EPDM

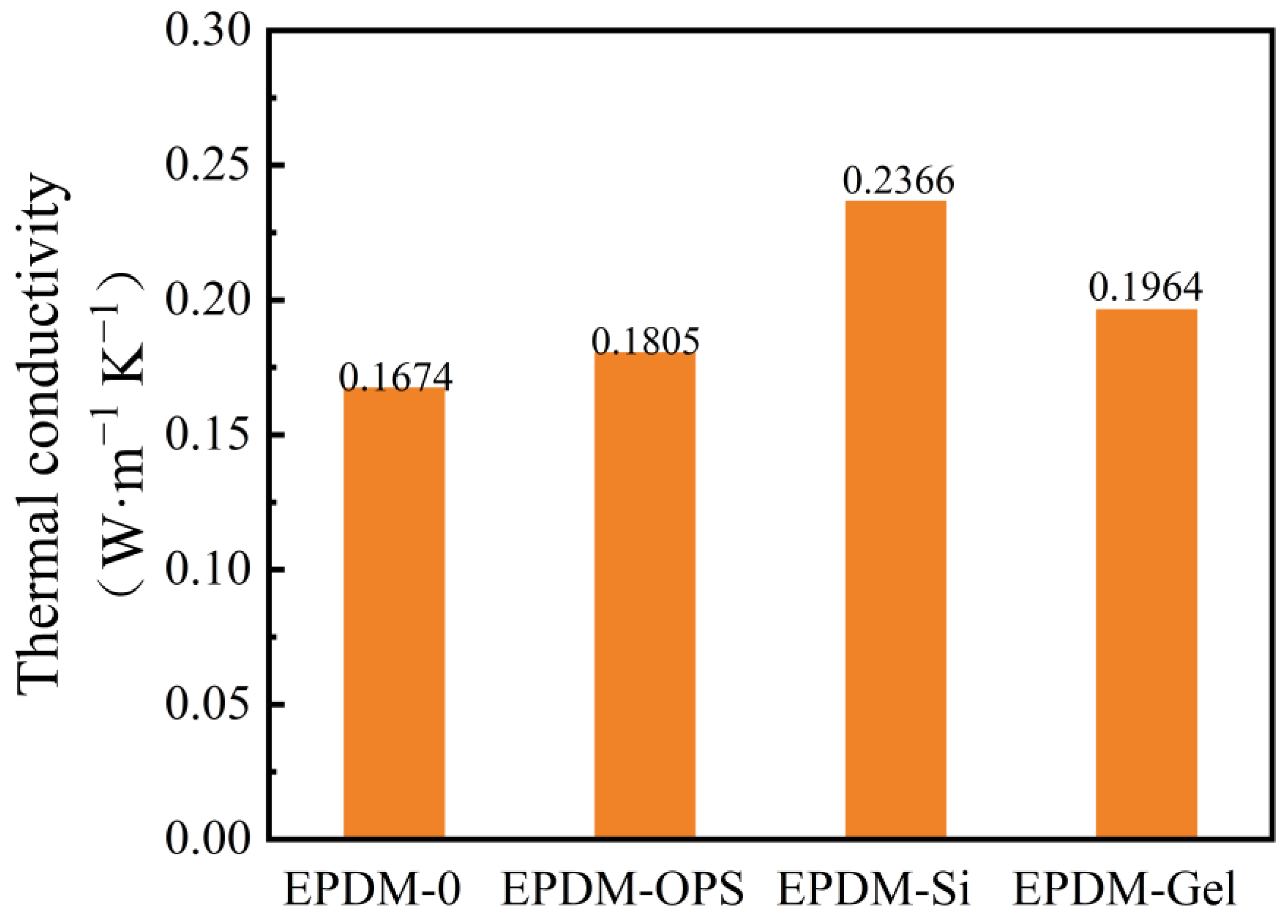

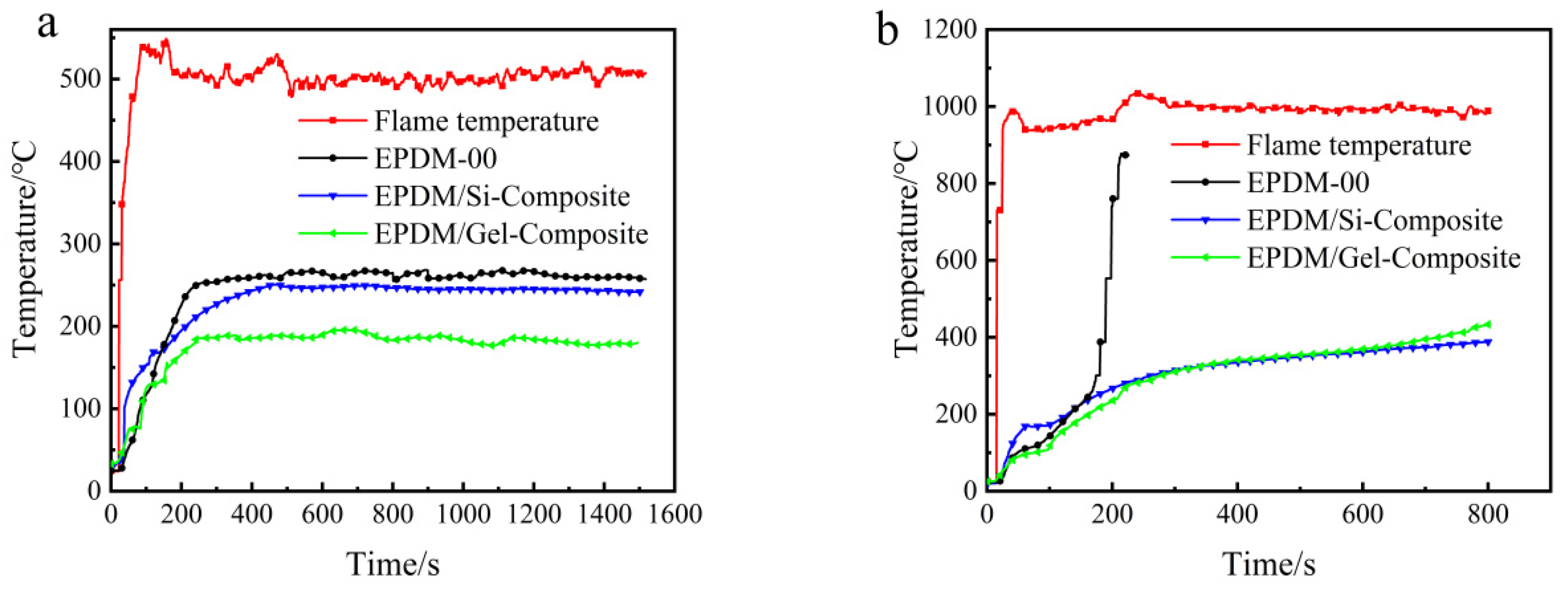

3.3. Thermal Degradation and Insulation of Silicon Hybrid EPDM Composites

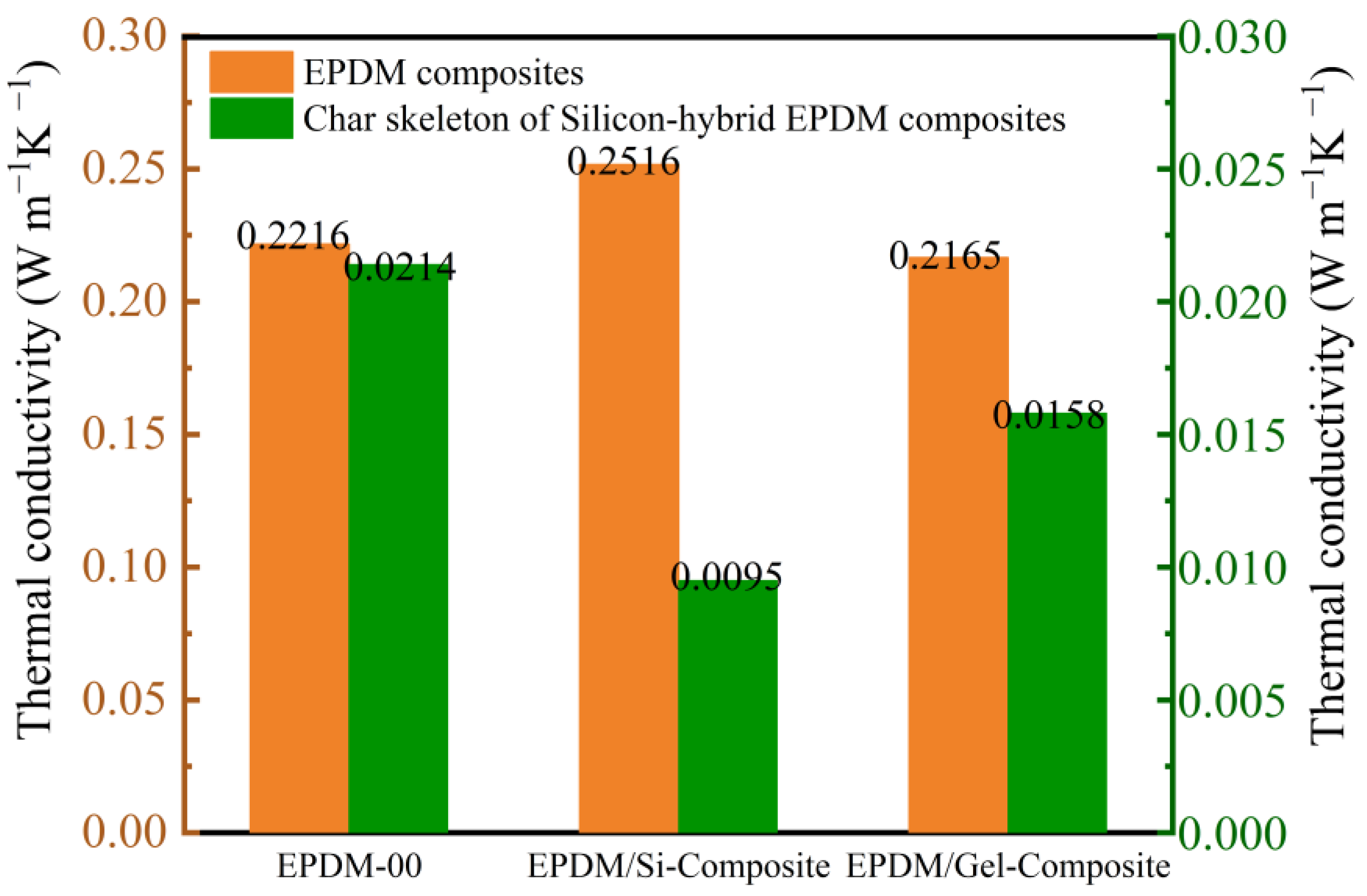

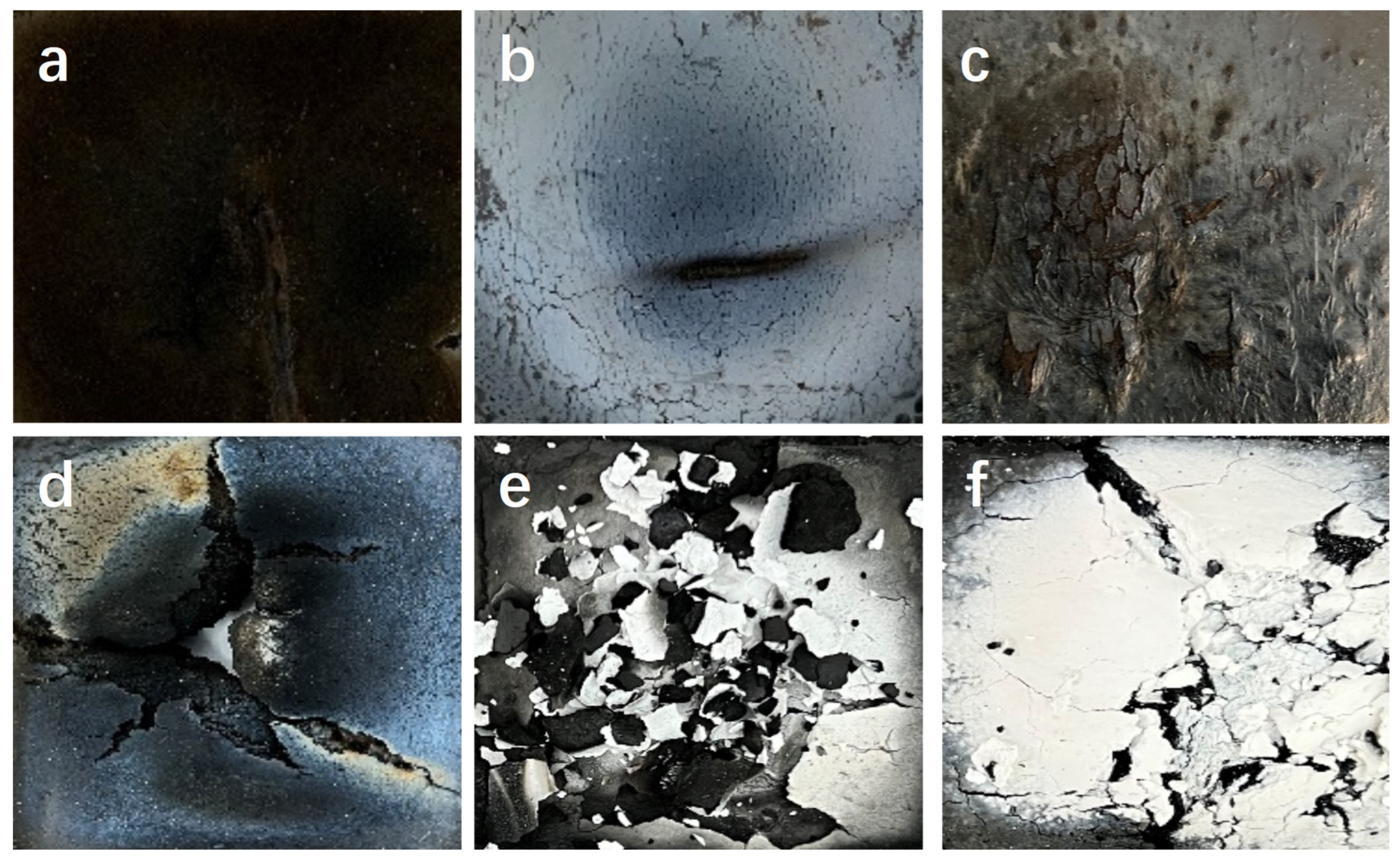

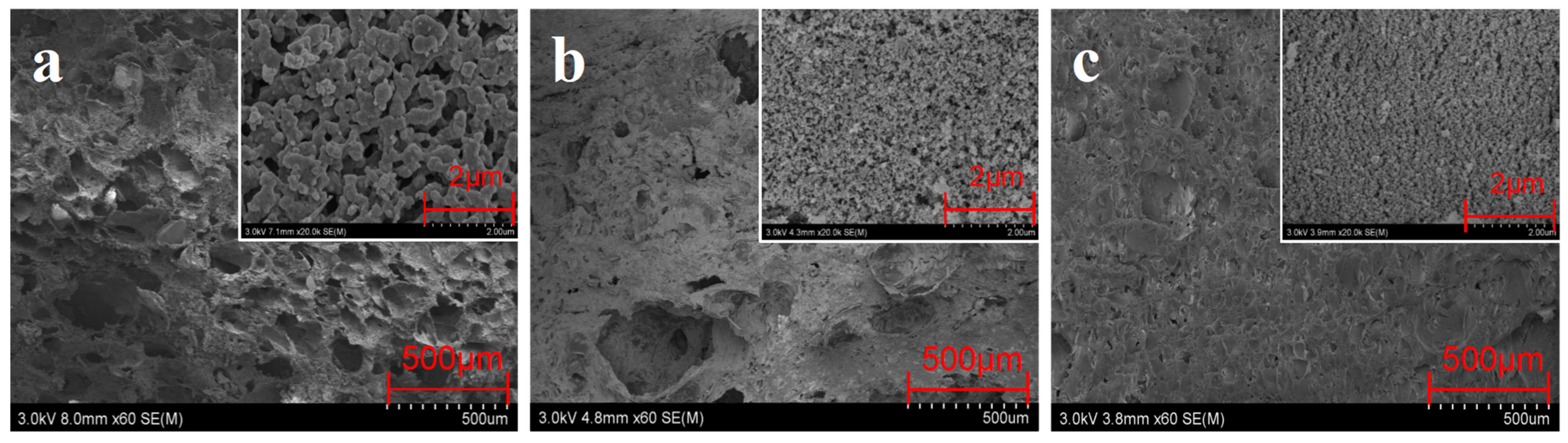

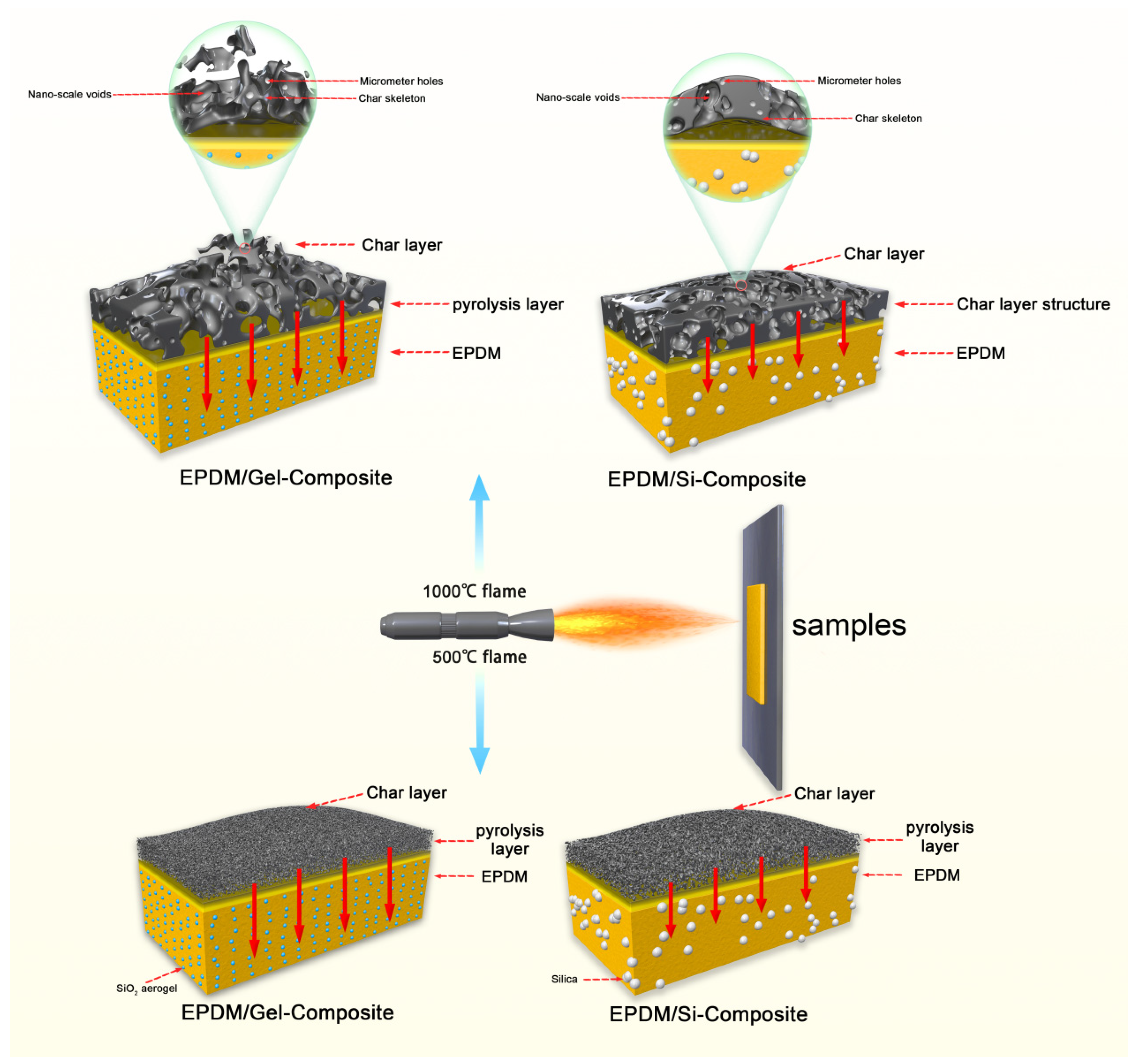

3.4. Char of Silicon Hybrid EPDM Composites

3.5. Thermal Insulation Mechanism

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Liu, H.; Zhu, G.; Zhang, C. Promoted ablation resistance of polydimethylsiloxane via crosslinking with multi-ethoxy POSS. Compos. Part B Eng. 2020, 190, 107901. [Google Scholar] [CrossRef]

- Jelleab, B.P. Air-filled nanopore based high-performance thermal insulation materials. Energy Build. 2011, 43, 2549–2563. [Google Scholar]

- Li, C.; Wu, G.; Li, M.; Hu, C.; Wei, J. A heat transfer model for aluminum droplet/wall impact. Aerosp. Sci. Technol. 2020, 97, 105639. [Google Scholar] [CrossRef]

- Hao, H.; Zhou, X.; Shen, Z.; He, J.; Yang, R. Study on the ablative properties of ethylene propylene diene terpolymer/silsesquioxane insulation materials. J. Appl. Polym. Sci. 2020, 137, 48365. [Google Scholar] [CrossRef]

- Rivier, M.; Lachaud, J.; Congedo, P.M. Ablative thermal protection system under uncertainties including pyrolysis gas composition. Aerosp. Sci. Technol. 2019, 84, 1059–1069. [Google Scholar] [CrossRef]

- Guo, M.; Li, J.; Xi, K.; Liu, Y.; Ji, J. Effect of multi-walled carbon nanotubes on thermal stability and ablation properties of EPDM insulation materials for solid rocket motors. Acta Astronaut. 2019, 159, 508–516. [Google Scholar] [CrossRef]

- Iqbal, N.; Sagar, S.; Khan, M.B.; Rafique, H.M. Ablation and thermo-mechanical tailoring of EPDM rubber using carbon fibers. Polym. Eng. Sci. 2014, 54, 255–263. [Google Scholar] [CrossRef]

- Gao, G.; Zhang, Z.; Li, X.; Meng, Q.; Zheng, Y. An excellent ablative composite based on PBO reinforced EPDM. Polym. Bull. 2010, 64, 607–622. [Google Scholar] [CrossRef]

- Natali, M.; Rallini, M.; Kenny, J.; Torre, L. Effect of Wollastonite on the ablation resistance of EPDM based elastomeric heat shielding materials for solid rocket motors. Polym. Degrad. Stab. 2016, 130, 47–57. [Google Scholar] [CrossRef]

- Natali, M.; Monti, M.; Kenny, J.M.; Torre, L. A nanostructured ablative bulk molding compound: Development and characterization. Compos. Part A Appl. Sci. Manuf. 2011, 42, 1197–1204. [Google Scholar] [CrossRef]

- Singh, S.; Guchhait, P.K.; Bandyopadhyay, G.G.; Chaki, T.K. Development of polyimide–nanosilica filled EPDM based light rocket motor insulator compound: Influence of polyimide–nanosilica loading on thermal, ablation, and mechanical properties. Compos. Part A Appl. Sci. Manuf. 2013, 44, 8–15. [Google Scholar] [CrossRef]

- Khan, H.; Amin, M.; Yasin, M.; Ali, M.; Ahmad, A. Structure and properties of particles/rubber composites applied on functionally graded lapping and polishing plate. J. Polym. Eng. 2016, 37, 671–680. [Google Scholar] [CrossRef]

- Morselli, D.; Bondioli, F.; Luyt, A.S.; Mokhothu, T.H.; Messori, M. Preparation and characterization of EPDM rubber modified with in situ generated silica. J. Appl. Polym. Sci. 2013, 128, 2525–2532. [Google Scholar] [CrossRef]

- Jiang, X.; Zhao, Z.; Zhou, S.; Zou, H.; Liu, P. Anisotropic and lightweight carbon/graphene composite aerogels for efficient thermal insulation and electromagnetic interference shielding. Appl. Mater. Interfaces 2022, 14, 45844–45852. [Google Scholar] [CrossRef] [PubMed]

- Shi, S.; Lei, B.; Li, M.; Cui, X.; Wang, X.; Fan, X.; Tang, S.; Shen, J. Thermal decomposition behavior of a thermal protection coating composite with silicone rubber: Experiment and modeling. Prog. Org. Coat. Int. Rev. J. 2020, 143, 105609. [Google Scholar] [CrossRef]

- Jin, R.; Zhou, Z.; Liu, J.; Shi, B.; Zhou, N.; Wang, X.; Jia, X.; Guo, D.; Xu, B. Aerogels for Thermal Protection and Their Application in Aerospace. Gels 2023, 9, 606. [Google Scholar] [CrossRef] [PubMed]

- Serge, B.; Johan, S.; Tsilla, B. Intumescent polypropylene in extreme fire conditions. Fire Saf. J. 2020, 120, 103082. [Google Scholar]

- GB/T 528-2009; Determination of Tensile Stress-Strain Properties of Vulcanized or Thermoplastic Rubber. China Standardization Press: Beijing, China, 2009.

- Sohrab, A.; Gelareh, M.; Claudiane, O.-P.; Eric, D. Performance improvement of EPDM and EPDM/Silicone rubber composites using modified fumed silica, titanium dioxide and graphene additives. Polym. Test. 2020, 84, 106281. [Google Scholar]

- Lee, S.-Y.; Singh, P.; Mahajan, R.L. Role of oxygen functional groups for improved performance of graphene-silicone composites as a thermal interface material. Carbon 2019, 145, 131–139. [Google Scholar] [CrossRef]

- Xue, B.; Yang, S.; Qin, R.; Deng, S.; Niu, M.; Zhang, L. Effect of a graphene-APP composite aerogel coating on the polyester fabric for outstanding flammability. Prog. Org. Coat. 2022, 172, 107130. [Google Scholar] [CrossRef]

| Component | EPDM (wt%) | OPS (wt%) | Fumed Silica (wt%) | Silica Aerogel (wt%) | LPW (wt%) | CZ (wt%) | D (wt%) | Si-69 (wt%) | BIPB (wt%) |

|---|---|---|---|---|---|---|---|---|---|

| EPDM-0 | 90 | / | / | / | 2.4 | 1.2 | 0.3 | 3 | 3.1 |

| EPDM-OPS | 60 | 30 | / | / | 2.4 | 1.2 | 0.3 | 3 | 3.1 |

| EPDM-Si | 60 | / | 30 | / | 2.4 | 1.2 | 0.3 | 3 | 3.1 |

| EPDM-Gel | 60 | / | / | 30 | 2.4 | 1.2 | 0.3 | 3 | 3.1 |

| Composite | EPDM-0 (wt%) | Fumed Silica (wt%) | Silica Aerogel (wt%) | Fiber Pulp (wt%) | ZB (wt%) | ADP (wt%) | Phenolic Resin (wt%) |

|---|---|---|---|---|---|---|---|

| EPDM-00 | 61.3 | 0 | 0 | 4.9 | 6.1 | 15.3 | 12.4 |

| EPDM/Si-Composite | 46.9 | 23.4 | 0 | 3.7 | 4.7 | 11.7 | 9.6 |

| EPDM/Gel-Composite | 46.9 | 0 | 23.4 | 3.7 | 4.7 | 11.7 | 9.6 |

| Samples | Tensile Strength (MPa) | Elongation at Break (%) |

|---|---|---|

| EPDM-0 | 0.94 | 431 |

| EPDM-OPS | 5.50 | 886 |

| EPDM-Si | 9.30 | 897 |

| EPDM-Gel | 9.03 | 1372 |

| Samples | T5% (°C) | Tmax1 (°C) | Tmax2 (°C) | Char Residue at 900 °C (%) | Theoretical Value Char Residue (%) |

|---|---|---|---|---|---|

| EPDM-0 | 329 | 409 | 512 | 1.9 | -- |

| EPDM-OPS | 333 | 432 | 523 | 15.5 | 16.2 |

| EPDM-Si | 321 | 354 | 509 | 31.4 | 32.3 |

| EPDM-Gel | 317 | 419 | 508 | 27.3 | 28.3 |

| Samples | C (at.%) | Si (at.%) | O (at.%) |

|---|---|---|---|

| EPDM-OPS | 52.39 | 12.99 | 34.61 |

| EPDM-Si | 7.35 | 30.64 | 62.01 |

| EPDM-Gel | 5.00 | 30.54 | 64.45 |

| Samples | 500 °C Flame | 1000 °C Flame | ||

|---|---|---|---|---|

| Ts ① (°C) | t-Ts ② (s) | Ts ① (°C) | t-Ts ② (s) | |

| EPDM-0 | __ | 210 s burn-through | __ | __ |

| EPDM-OPS | __ | 1300 s burn-through | __ | __ |

| EPDM-Si | 290~300 | 400~1500 | __ | 110 s burn-through |

| EPDM-Gel | 230~240 | 400~1500 | __ | 117 s burn-through |

| Code | T5% (°C) | Tmax1 (°C) | Rmax1 (%/min) | Tmax2 (°C) | Rmax2 (%/min) | Char Residue at 900 °C (%) |

|---|---|---|---|---|---|---|

| EPDM-00 | 310.8 | 456.8 | 9.4 | 637.8 | 1.3 | 15.2 |

| EPDM/Si-Composite | 310.0 | 458.8 | 8.9 | 624.6 | 1.9 | 32.3 |

| EPDM/Gel-Composite | 276.3 | 456.8 | 8.1 | 606.2 | 1.7 | 27.7 |

| Code | 500 °C Flame | 1000 °C Flame at Different Times | |||

|---|---|---|---|---|---|

| 100 s | 300 s | 600 s | 800 s | ||

| EPDM-00 | 255~267 °C | 144 °C | —— | —— | —— |

| EPDM/Si-Composite | 242~250 °C | 172 °C | 314 °C | 361 °C | 388 °C |

| EPDM/Gel-Composite | 176~186 °C | 118 °C | 311 °C | 369 °C | 433 °C |

| Pore Volume (mL g−1) | Total Pore Area (m2 g−1) | Average Pore Diameter (nm) | Porosity (%) | |

|---|---|---|---|---|

| EPDM-00 | 3.92 | 3.65 | 4297 | 83 |

| EPDM/Si-Composite | 3.10 | 115.04 | 108 | 76 |

| EPDM/Gel-Composite | 1.97 | 179.71 | 43 | 68 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yan, C.; Chen, B.; Li, X.; He, J.; Zhao, X.; Zhu, Y.; Yang, R. Silicon Hybrid EPDM Composite with High Thermal Protection Performance. Polymers 2024, 16, 695. https://doi.org/10.3390/polym16050695

Yan C, Chen B, Li X, He J, Zhao X, Zhu Y, Yang R. Silicon Hybrid EPDM Composite with High Thermal Protection Performance. Polymers. 2024; 16(5):695. https://doi.org/10.3390/polym16050695

Chicago/Turabian StyleYan, Chenyang, Bo Chen, Xiangmei Li, Jiyu He, Xin Zhao, Yanli Zhu, and Rongjie Yang. 2024. "Silicon Hybrid EPDM Composite with High Thermal Protection Performance" Polymers 16, no. 5: 695. https://doi.org/10.3390/polym16050695

APA StyleYan, C., Chen, B., Li, X., He, J., Zhao, X., Zhu, Y., & Yang, R. (2024). Silicon Hybrid EPDM Composite with High Thermal Protection Performance. Polymers, 16(5), 695. https://doi.org/10.3390/polym16050695