Mold Fungal Resistance of Loose-Fill Thermal Insulation Materials Based on Processed Wheat Straw, Corn Stalk and Reed

Abstract

1. Introduction

2. Materials and Methods

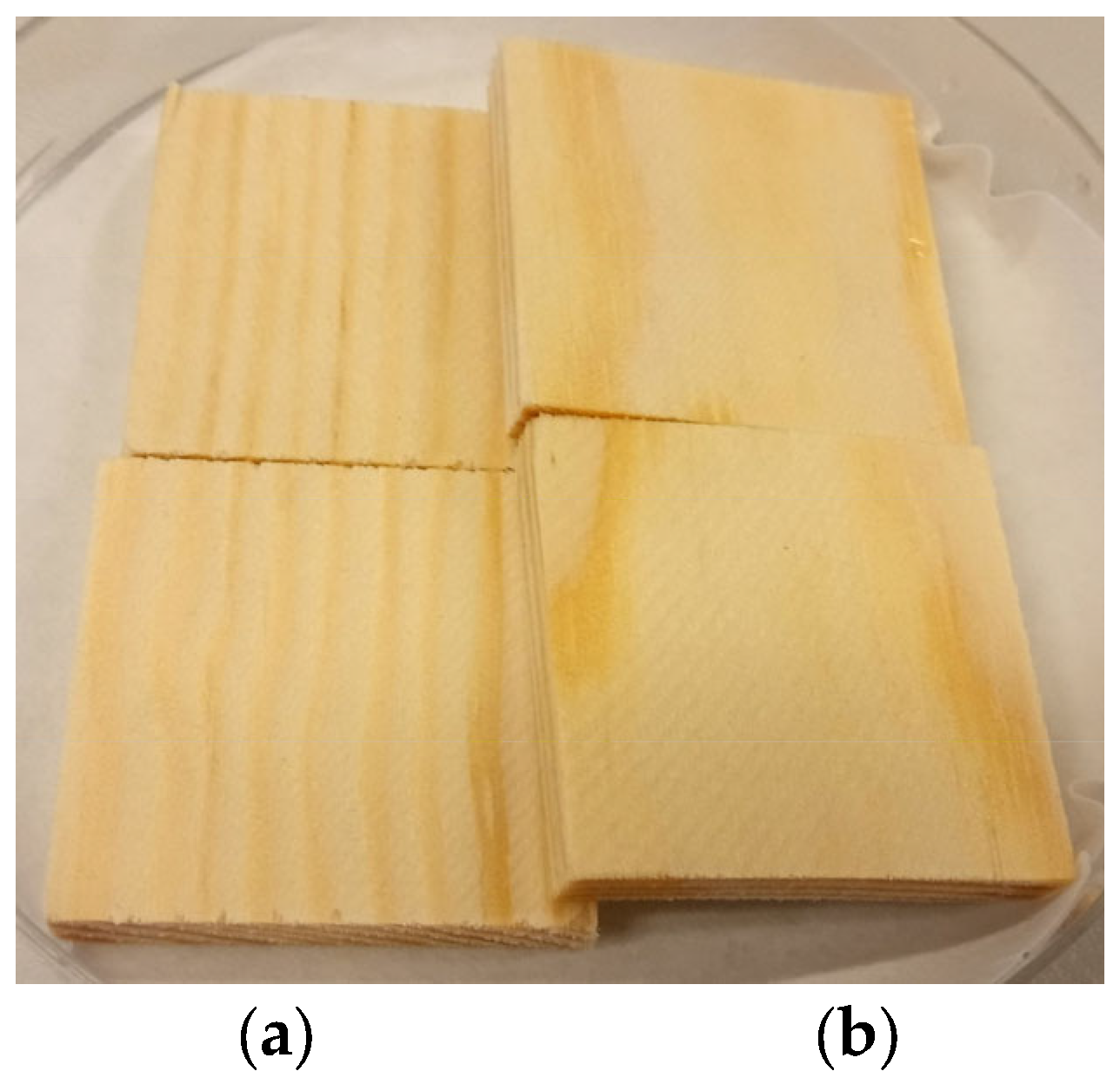

2.1. Raw LCB

2.2. Processing of Raw LCB

2.2.1. Steam Explosion Pulping (SEP)

2.2.2. Thermo-Mechanical Pulping (TMP)

2.2.3. Mechanical Foaming of Processed LCB

2.2.4. Admixture of Fire Retarder and Fungicide

2.3. Mold Growth Tests

2.4. Evaluation of Mold Fungal Growth

- 0—no detectable growth;

- 1—small growth with ~20% colonization;

- 2—sparse growth with ~40% colonization;

- 3—moderate growth with ~60% colonization;

- 4—heavy growth with ~80% colonization;

- 5—very heavy colonization across the entire material surface (~100%).

3. Results

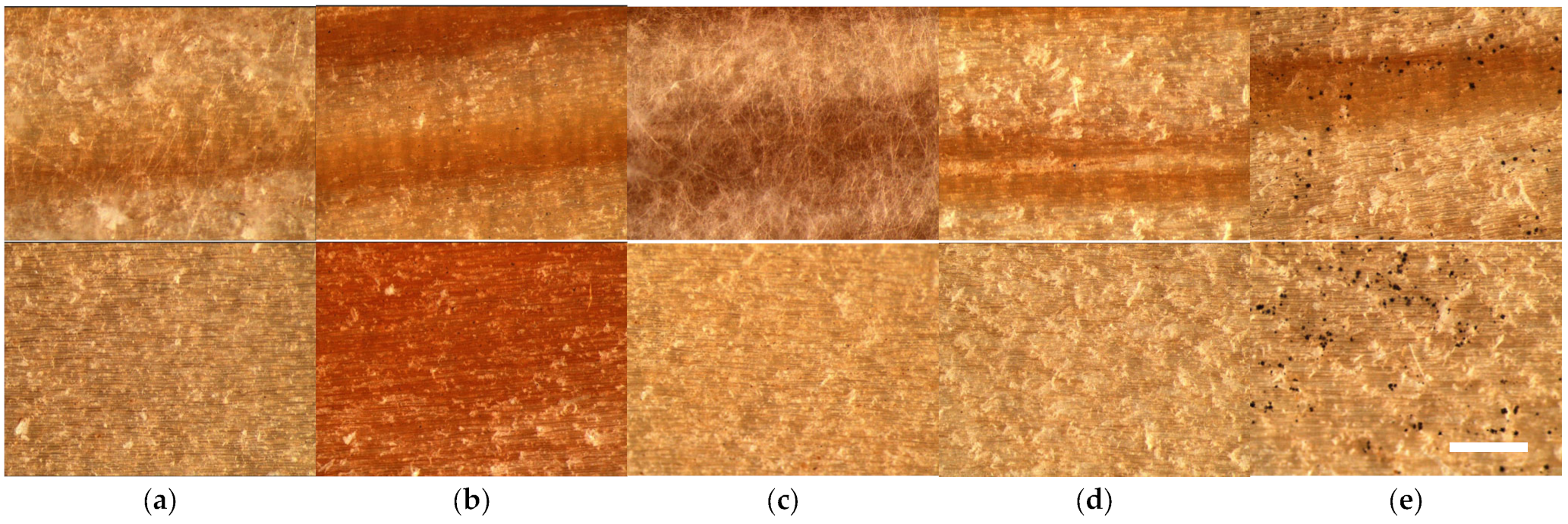

3.1. Mold Fungal Colonization on Wood Controls

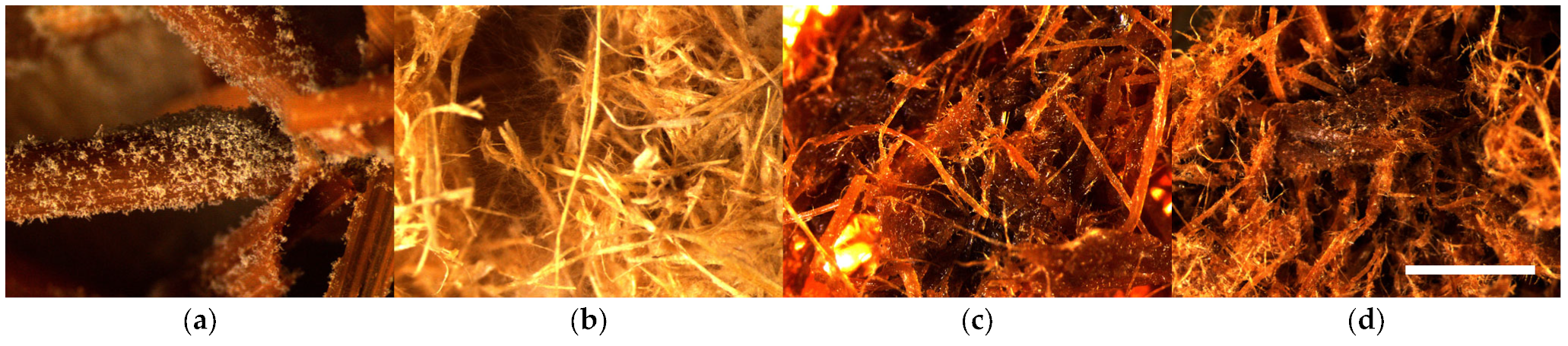

3.2. Mold Fungal Colonization on Loose-Fill LCB

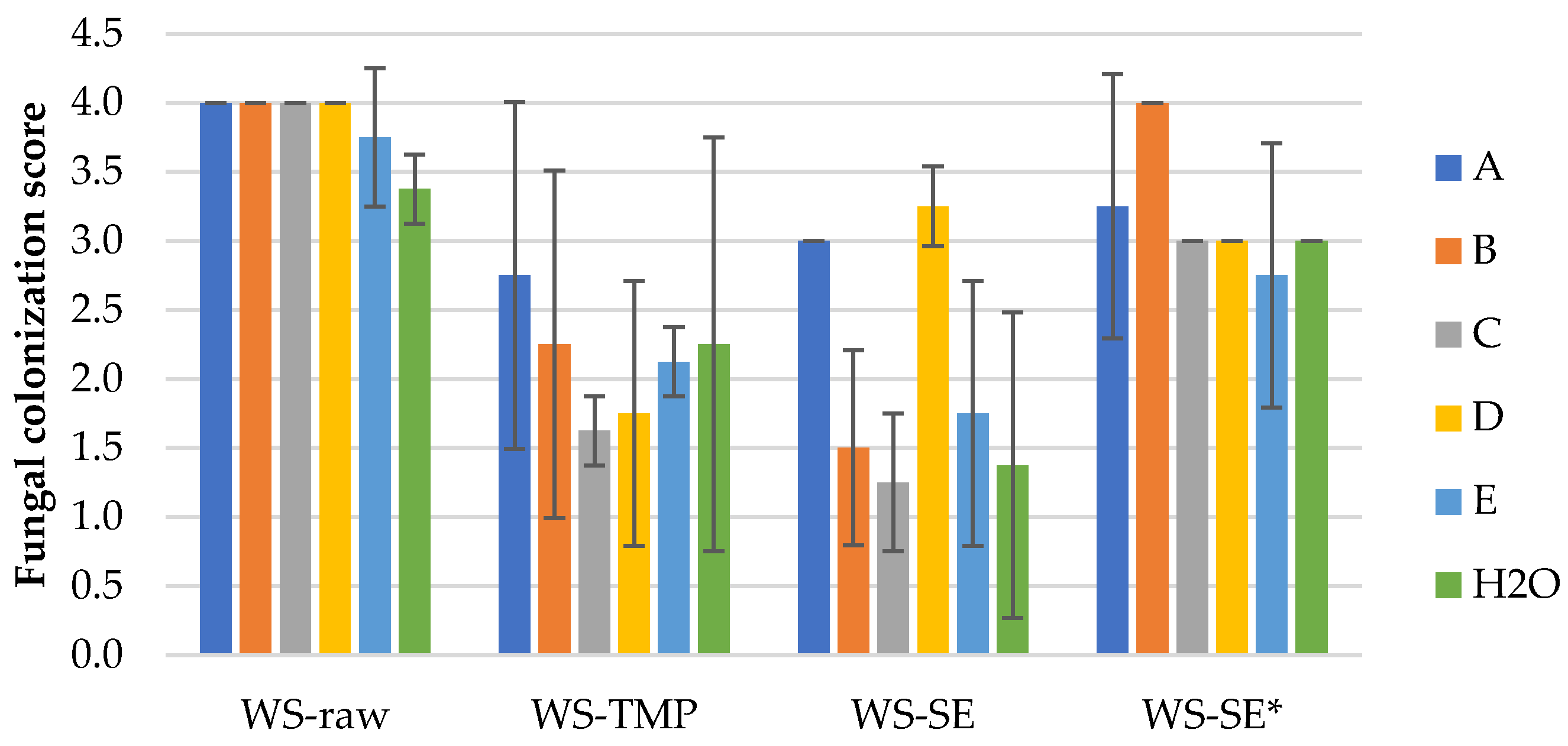

3.2.1. Fungal Colonization on Wheat Straw LCB Samples

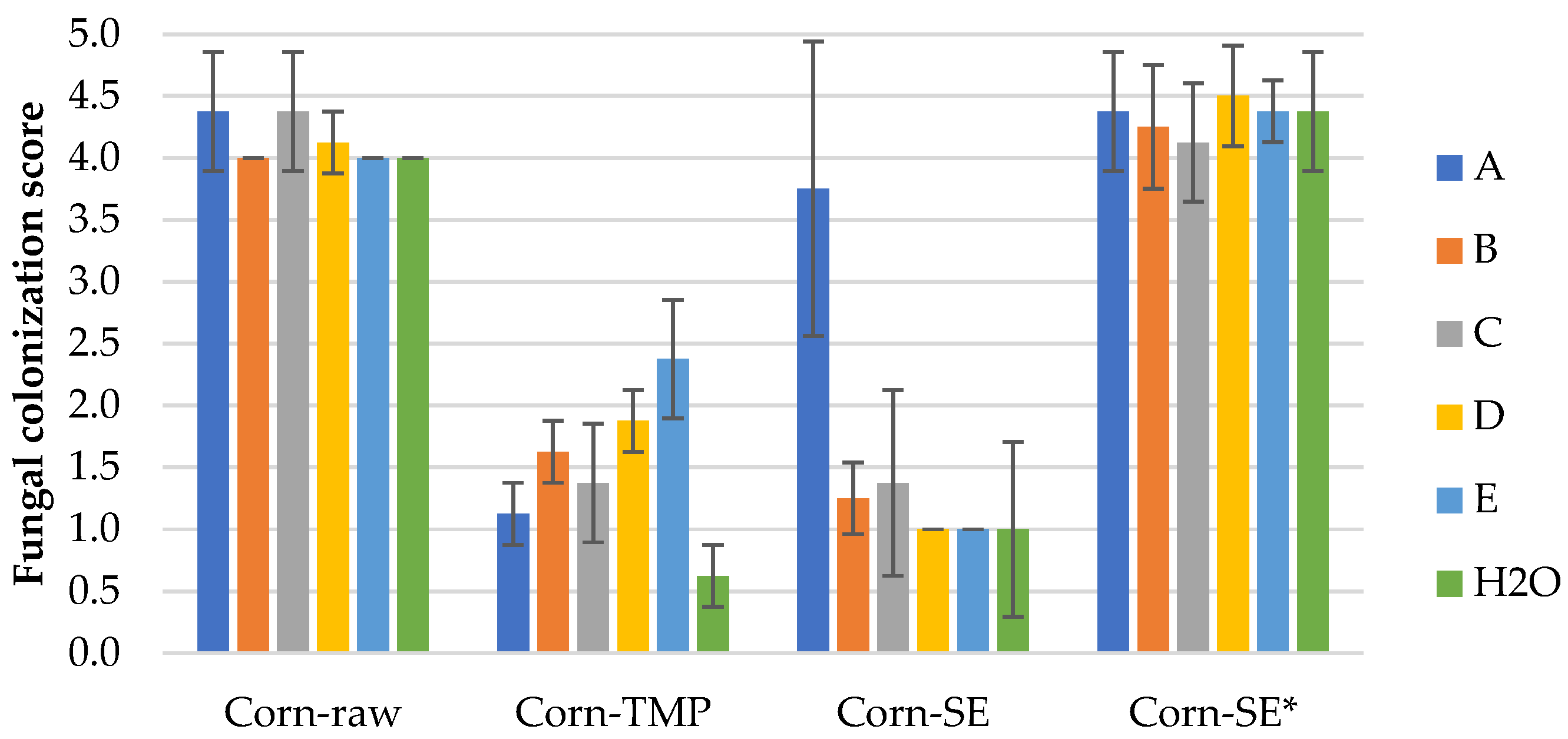

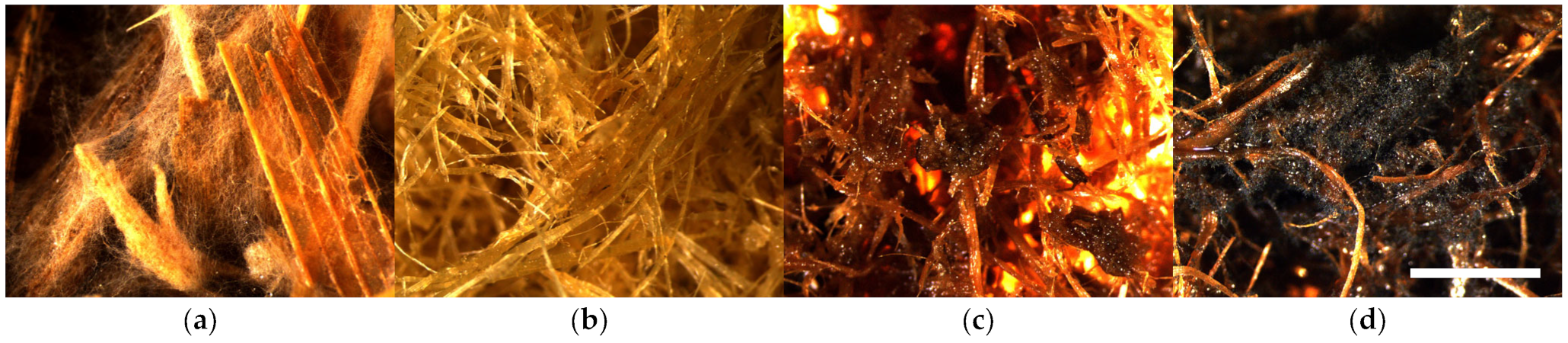

3.2.2. Mold Fungal Colonization on Corn Stalk LCB Samples

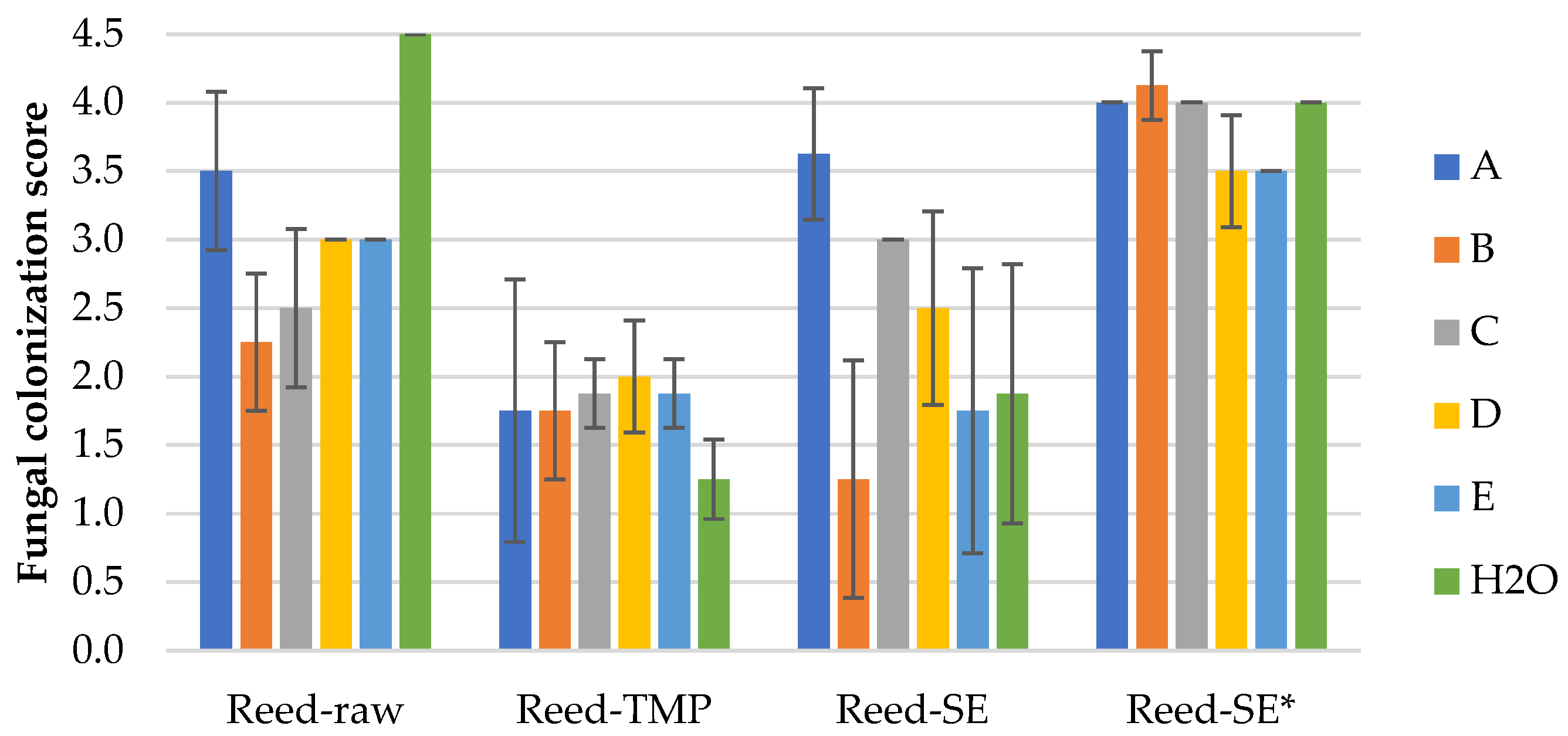

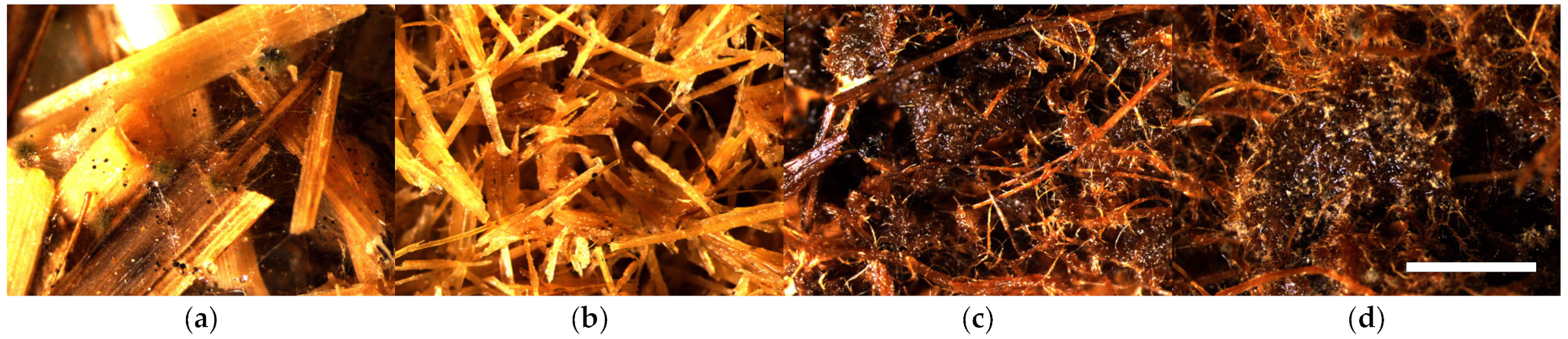

3.2.3. Mold Fungal Colonization on Water Reed LCB Samples

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Danish; Zhang, B.; Wang, Z.; Wang, B. Energy Production, Economic Growth and CO2 Emission: Evidence from Pakistan. Nat. Hazards 2018, 90, 27–50. [Google Scholar] [CrossRef]

- Benduski, M. Paris Agreement vs. Kyoto Protocol [Comparison Chart]. Available online: https://www.careaboutclimate.org/blog/paris-agreement-vs-kyoto-protocol-comparison-chart (accessed on 17 January 2024).

- European Comission. A European Green Deal. Available online: https://ec.europa.eu/info/strategy/priorities-2019-2024/european-green-deal_en (accessed on 17 January 2024).

- Asdrubali, F.; D’Alessandro, F.; Schiavoni, S. A Review of Unconventional Sustainable Building Insulation Materials. Sustain. Mater. Technol. 2015, 4, 1–17. [Google Scholar] [CrossRef]

- Cintura, E.; Nunes, L.; Esteves, B.; Faria, P. Agro-Industrial Wastes as Building Insulation Materials: A Review and Challenges for Euro-Mediterranean Countries. Ind. Crops Prod. 2021, 171, 113833. [Google Scholar] [CrossRef]

- Elbashiry, E.M.A.; Chen, J.; Tuo, W.; Ren, Y.; Guo, Z. Review of the Pretreatment Methods for Wheat Straw Building Materials. J. Reinf. Plast. Compos. 2018, 37, 35–48. [Google Scholar] [CrossRef]

- Nasir, M.; Khali, D.P.; Jawaid, M.; Tahir, P.M.; Siakeng, R.; Asim, M.; Khan, T.A. Recent Development in Binderless Fiber-Board Fabrication from Agricultural Residues: A Review. Constr. Build. Mater. 2019, 211, 502–516. [Google Scholar] [CrossRef]

- Chougan, M.; Hamidreza, S.; Al-kheetan, M.J.; Gecevicius, M. Wheat Straw Pre-Treatments Using Eco-Friendly Strategies for Enhancing the Tensile Properties of Bio-Based Polylactic Acid Composites. Ind. Crops Prod. 2020, 155, 11. [Google Scholar] [CrossRef]

- Sun, W.; Tajvidi, M.; Hunt, C.G.; Cole, B.J.W.; Howell, C.; Gardner, D.J.; Wang, J. Fungal and Enzymatic Pretreatments in Hot-Pressed Lignocellulosic Bio-Composites: A Critical Review. J. Clean. Prod. 2022, 353, 131659. [Google Scholar] [CrossRef]

- Schritt, H.; Pleissner, D. Recycling of Organic Residues to Produce Insulation Composites: A Review. Clean. Waste Syst. 2022, 3, 100023. [Google Scholar] [CrossRef]

- Godish, T.J.; Godish, D.R. Mold Infestation of Wet Spray-Applied Cellulose Insulation. J. Air Waste Manag. Assoc. 2006, 56, 90–95. [Google Scholar] [CrossRef] [PubMed]

- Herrera, J. Assessment of Fungal Growth on Sodium Polyborate-Treated Cellulose Insulation. J. Occup. Environ. Hyg. 2006, 2, 626–632. [Google Scholar] [CrossRef] [PubMed]

- Nguyen, D.M.; Grillet, A.-C.; Diep, T.M.H.; Thuc, C.N.H.; Woloszyn, M. Hygrothermal Properties of Bio-Insulation Building Materials Based on Bamboo Fibers and Bio-Glues. Constr. Build. Mater. 2017, 155, 852–866. [Google Scholar] [CrossRef]

- Hellová, K.E.; Unčík, S.; Cabanová, T. Sorption Properties of Thermal Insulation Composed of Flax or Hemp Fibers. Slovak J. Civ. Eng. 2020, 28, 47–52. [Google Scholar] [CrossRef]

- Feng, J.; Li, C.; Chen, J.; Chen, M.; Shu, X.; Shi, Q. Evaluation of the Association between Natural Mold Resistance and Chemical Components of Nine Wood Species. Bioresouces 2018, 13, 6524–6541. [Google Scholar] [CrossRef]

- Feng, J.; Dong, P.; Li, R.; Li, C.; Xie, X.; Shi, Q. Effects of Wood Fiber Properties on Mold Resistance of Wood Polypropylene Composites. Int. Biodeterior. Biodegrad. 2019, 140, 152–159. [Google Scholar] [CrossRef]

- Nykter, M. Microbial Quality of Hemp (Cannabis sativa L.) and Flax (Linum usitatissimum L.) from Plants to Thermal Insulation. Ph.D. Thesis, University of Helsinki, Helsinki, Finland, 2006; p. 97. [Google Scholar]

- Viel, M.; Collet, F.; Lecieux, Y.; François, M.L.M.; Colson, V.; Lanos, C.; Hussain, A.; Lawrence, M. Resistance to Mold Development Assessment of Bio-Based Building Materials. Compos. Part B Eng. 2019, 158, 406–418. [Google Scholar] [CrossRef]

- Klamer, M.; Morsing, E.; Husemoen, T. Fungal Growth on Different Insulation Materials Exposed to Different Moisture Regimes. Int. Biodeterior. Biodegrad. 2004, 54, 277–282. [Google Scholar] [CrossRef]

- Palumbo, M.; Lacasta, A.M.; Navarro, A.; Giraldo, M.P.; Lesar, B. Improvement of Fire Reaction and Mould Growth Resistance of a New Bio-Based Thermal Insulation Material. Constr. Build. Mater. 2017, 139, 531–539. [Google Scholar] [CrossRef]

- Nykter, M.; Kymalainen, H.-R.; Thomsen, A.B.; Lilholt, H.; Koponen, H.; Sjober, A.-M.; Thygesen, A. Effects of Thermal and Enzymatic Treatments and Harvesting Time on the Microbial Quality and Chemical Composition of Fibre Hemp (Cannabis sativa L.). Biomass Bioenergy 2008, 32, 392–399. [Google Scholar] [CrossRef]

- Ogar, A.; Tylko, G.; Turnau, K. Antifungal Properties of Silver Nanoparticles against Indoor Mould Growth. Sci. Total Environ. 2015, 521–522, 305–314. [Google Scholar] [CrossRef]

- Sun, F.; Zhou, Y.; Bao, B.; Chen, A.; Du, C. Influence of Solvent Treatment on Mould Resistance of Bamboo. BioResources 2011, 6, 2091–2100. [Google Scholar] [CrossRef]

- Garzón-Barrero, N.M.; Shirakawa, M.A.; Brazolin, S.; de Lara, I.A.R.; Savastano, H. Evaluation of Mold Growth on Sugarcane Bagasse Particleboards in Natural Exposure and in Accelerated Test. Int. Biodeterior. Biodegrad. 2016, 115, 266–276. [Google Scholar] [CrossRef]

- Imken, A.A.P.; Brischke, C.; Kögel, S.; Krause, K.C.; Mai, C. Resistance of Different Wood-Based Materials against Mould Fungi: A Comparison of Methods. Eur. J. Wood Wood Prod. 2020, 78, 661–671. [Google Scholar] [CrossRef]

- Zheng, C.; Li, D.; Ottenhall, A.; Ek, M. Cellulose Fiber Based Fungal and Water Resistant Insulation Materials. Holzforschung 2017, 71, 633–639. [Google Scholar] [CrossRef]

- Berzins, A.; Tupciauskas, R.; Andzs, M.; Pavlovichs, G. Development of Thermal Insulation Materials from Plant Fibres by Steam Explosion Pre-Treatment. In Proceedings of the 18th Annual Meeting of the Northern European Network for Wood Science and Engineering, Göttingen, Germany, 22 September 2022; Brischke, C., Buschalsky, A., Eds.; University of Göttingen: Göttingen, Germany, 2022; pp. 177–180. [Google Scholar]

- Berzins, A.; Tupciauskas, R.; Andzs, M.; Pavlovichs, G. Potential of Some Latvian Industrial Crops Residuals for Conversion to Bio-Based Thermal Insulation Material. Mater. Sci. Forum 2022, 1071, 139–146. [Google Scholar] [CrossRef]

- Tupciauskas, R.; Berzins, A.; Pavlovics, G.; Bikovens, O.; Filipova, I.; Andze, L.; Andzs, M. Optimization of Thermal Conductivity vs Bulk Density of Steam Exploded Loose-Fill Annual Lignocellulosics. Materials 2023, 16, 3654. [Google Scholar] [CrossRef] [PubMed]

- EN 15101-1+A1; Thermal Insulation Products for Buildings—In-Situ Formed Loose Fill Cellulose (LFCI) Products—Part 1: Specification for the Products before Installation. European Standard: Brussels, Belgium, 2019.

- Ahmed, S.A.; Yang, Q.; Sehlstedt-Persson, M.; Morén, T. Accelerated Mold Test on Dried Pine Sapwood Boards: Impact of Contact Heat Treatment. J. Wood Chem. Technol. 2013, 33, 174–187. [Google Scholar] [CrossRef]

- Montgomery, D.C. Design and Analysis of Experiments, 9th ed.; John Wiley & Sons: Hoboken, NJ, USA, 2017; ISBN 9781119113478. [Google Scholar]

- Terziev, N.; Boutelje, J. Effect of Felling Time and Kiln-Drying on Color and Susceptibility of Wood to Mold and Fungal Stain during an above-Ground Field Test. Wood Fiber Sci. 1998, 30, 360–367. [Google Scholar]

- Woloshuk, C.; Martínez, E.M. Molds and Mycotoxins in Stored Products. In Stored Product Protection. Part I: Ecology of Storage Systems; Kansas State University: Manhattan, KS, USA, 2012; pp. 1–6. [Google Scholar]

- He, C.; Yao, X.; Xue, J.; Xiong, J.; Zhao, L. Influences of Mold Fungi Colonization on Wheat Straw-Polypropylene Composites. For. Prod. J. 2016, 66, 472–479. [Google Scholar] [CrossRef]

- Malheiro, R.; Ansolin, A.; Guarnier, C.; Fernandes, J.; Amorim, M.T.; Silva, S.M.; Mateus, R. The Potential of the Reed as a Regenerative Building Material—Characterisation of Its Durability, Physical, and Thermal Performances. Energies 2021, 14, 4276. [Google Scholar] [CrossRef]

- Cang, R.; Sun, X.F. Identification and Quantitation of Lipophilic Extractives from Wheat Straw. Ind. Crops Prod. 2001, 14, 51–64. [Google Scholar]

- Beyzi, S.B.; Ülger, İ.; Konca, Y. Chemical, Fermentative, Nutritive and Anti-Nutritive Composition of Common Reed (Phragmites australis) Plant and Silage. Waste Biomass Valorization 2022, 14, 927–936. [Google Scholar] [CrossRef]

- Lv, G.; Wu, S. Analytical Pyrolysis Studies of Corn Stalk and Its Three Main Components by TG-MS and Py-GC/MS. J. Anal. Appl. Pyrolysis 2012, 97, 11–18. [Google Scholar] [CrossRef]

- Han, G.; Cheng, W.; Deng, J.; Dai, C.; Zhang, S.; Wu, Q. Effect of Pressurized Steam Treatment on Selected Properties of Wheat Straws. Ind. Crops Prod. 2009, 30, 48–53. [Google Scholar] [CrossRef]

- Li, Y.; Wadsö, L. Fungal Activities of Indoor Moulds on Wood as a Function of Relative Humidity during Desorption and Adsorption Processes. Eng. Life Sci. 2013, 13, 528–535. [Google Scholar] [CrossRef]

| Fungi/ Sample | A Trichoderma viride | B Chaetomium globulosum | C Paecilomyces variotii | D Penicillium pinophilum | E Aspergillus niger | H2O |

|---|---|---|---|---|---|---|

| LCB 1-SEP | Steam-exploded pulp of each raw LCB | |||||

| LCB-SEP* | SE pulp of each raw LCB without fire retarder and fungicide | |||||

| LCB-TMP | Thermo-mechanical pulp of each raw LCB | |||||

| LCB-raw | Untreated chopped (sieve 20 mm) raw LCB | |||||

| Control | Untreated pine sapwood (30 × 30 × 5 mm) | |||||

| Surface | A | B | C | D | E | H2O |

|---|---|---|---|---|---|---|

| Radial | 3 | 1 | 3 | 0 | 3 | 0 |

| Tangential | 0 | 1 | 0 | 0 | 3 | 0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tupciauskas, R.; Orlovskis, Z.; Blums, K.T.; Liepins, J.; Berzins, A.; Pavlovics, G.; Andzs, M. Mold Fungal Resistance of Loose-Fill Thermal Insulation Materials Based on Processed Wheat Straw, Corn Stalk and Reed. Polymers 2024, 16, 562. https://doi.org/10.3390/polym16040562

Tupciauskas R, Orlovskis Z, Blums KT, Liepins J, Berzins A, Pavlovics G, Andzs M. Mold Fungal Resistance of Loose-Fill Thermal Insulation Materials Based on Processed Wheat Straw, Corn Stalk and Reed. Polymers. 2024; 16(4):562. https://doi.org/10.3390/polym16040562

Chicago/Turabian StyleTupciauskas, Ramunas, Zigmunds Orlovskis, Karlis Trevors Blums, Janis Liepins, Andris Berzins, Gunars Pavlovics, and Martins Andzs. 2024. "Mold Fungal Resistance of Loose-Fill Thermal Insulation Materials Based on Processed Wheat Straw, Corn Stalk and Reed" Polymers 16, no. 4: 562. https://doi.org/10.3390/polym16040562

APA StyleTupciauskas, R., Orlovskis, Z., Blums, K. T., Liepins, J., Berzins, A., Pavlovics, G., & Andzs, M. (2024). Mold Fungal Resistance of Loose-Fill Thermal Insulation Materials Based on Processed Wheat Straw, Corn Stalk and Reed. Polymers, 16(4), 562. https://doi.org/10.3390/polym16040562