Strong and Durable Wood Designed by Cell Wall Bulking Combined with Cell Lumen Filling

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of MAN-Wood

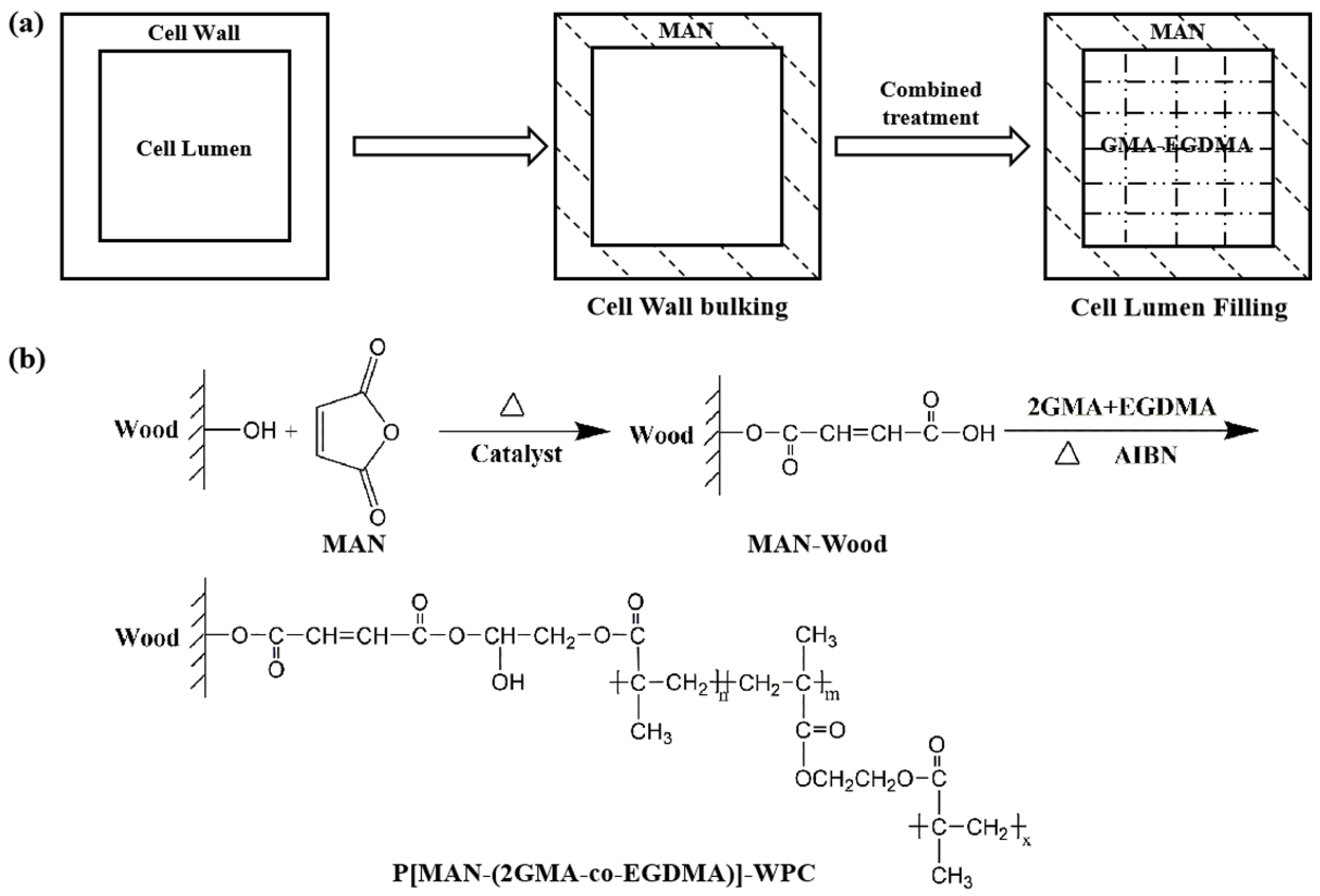

2.3. Preparation of P[MAN-(2GMA-co-EGDMA)]-WPC

2.4. Characterization

2.5. Properties Evaluation

3. Results

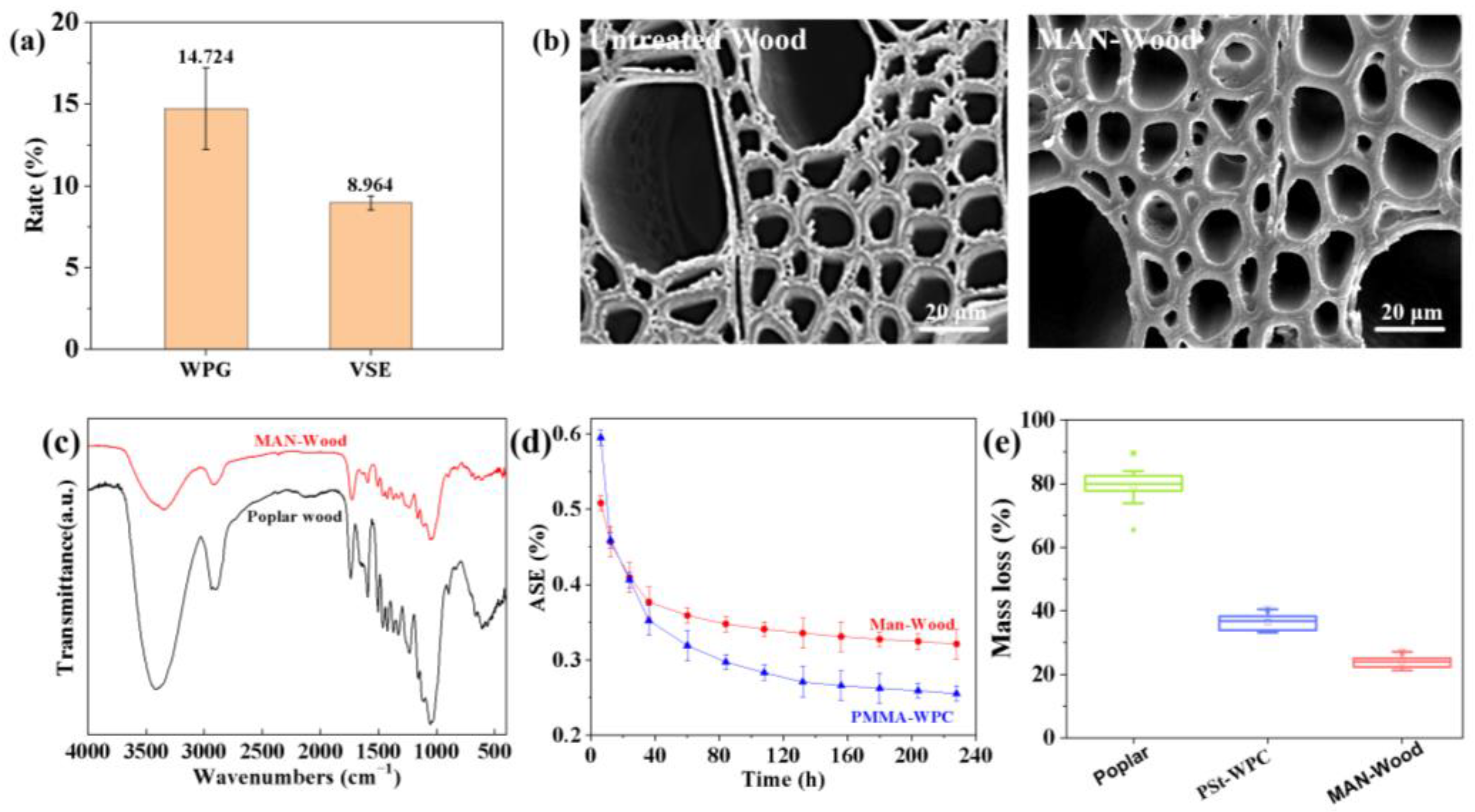

3.1. Cell Wall Bulking

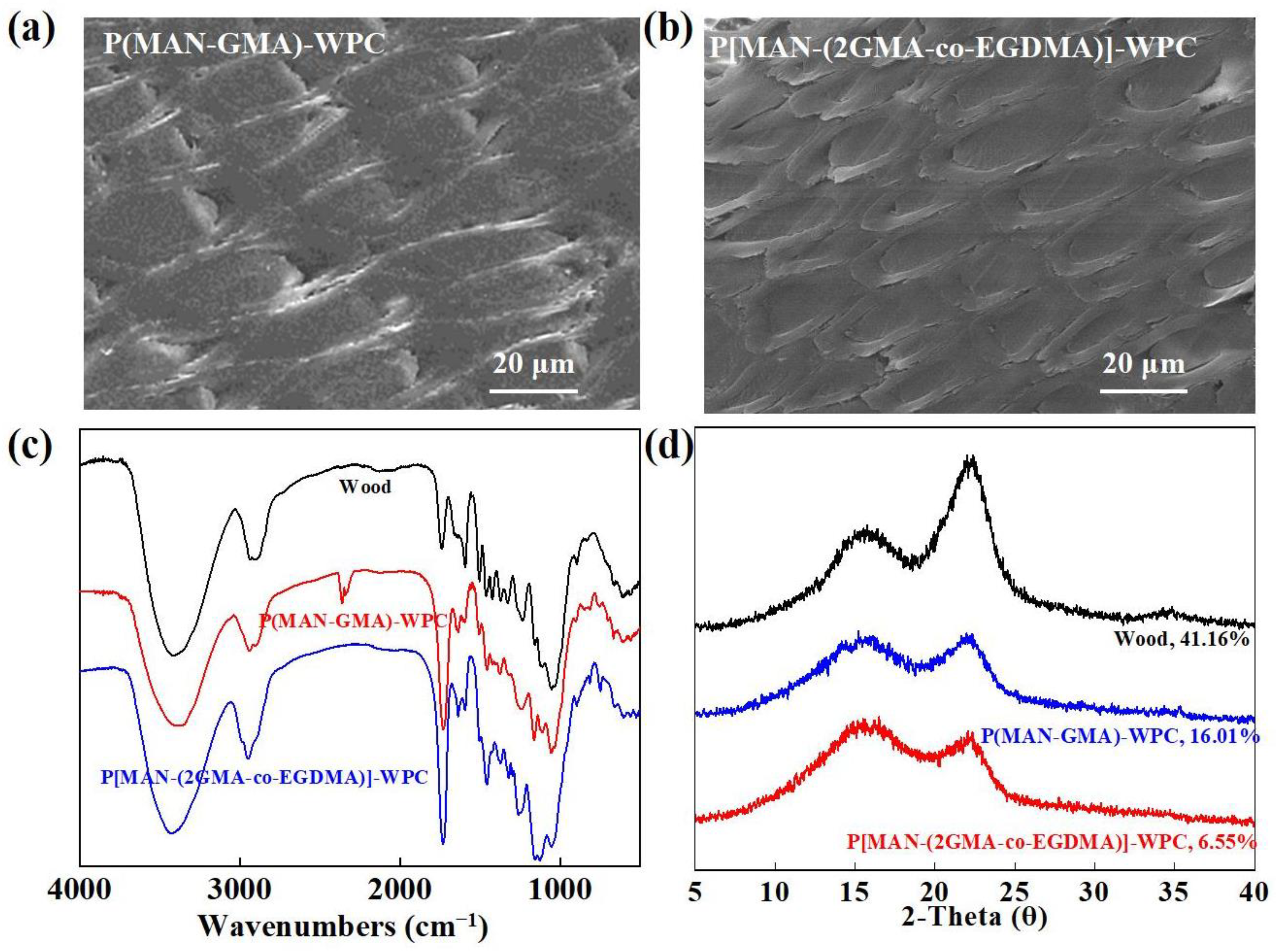

3.2. Preparation and Characterization of Bulking–Filling Wood Composite Materials

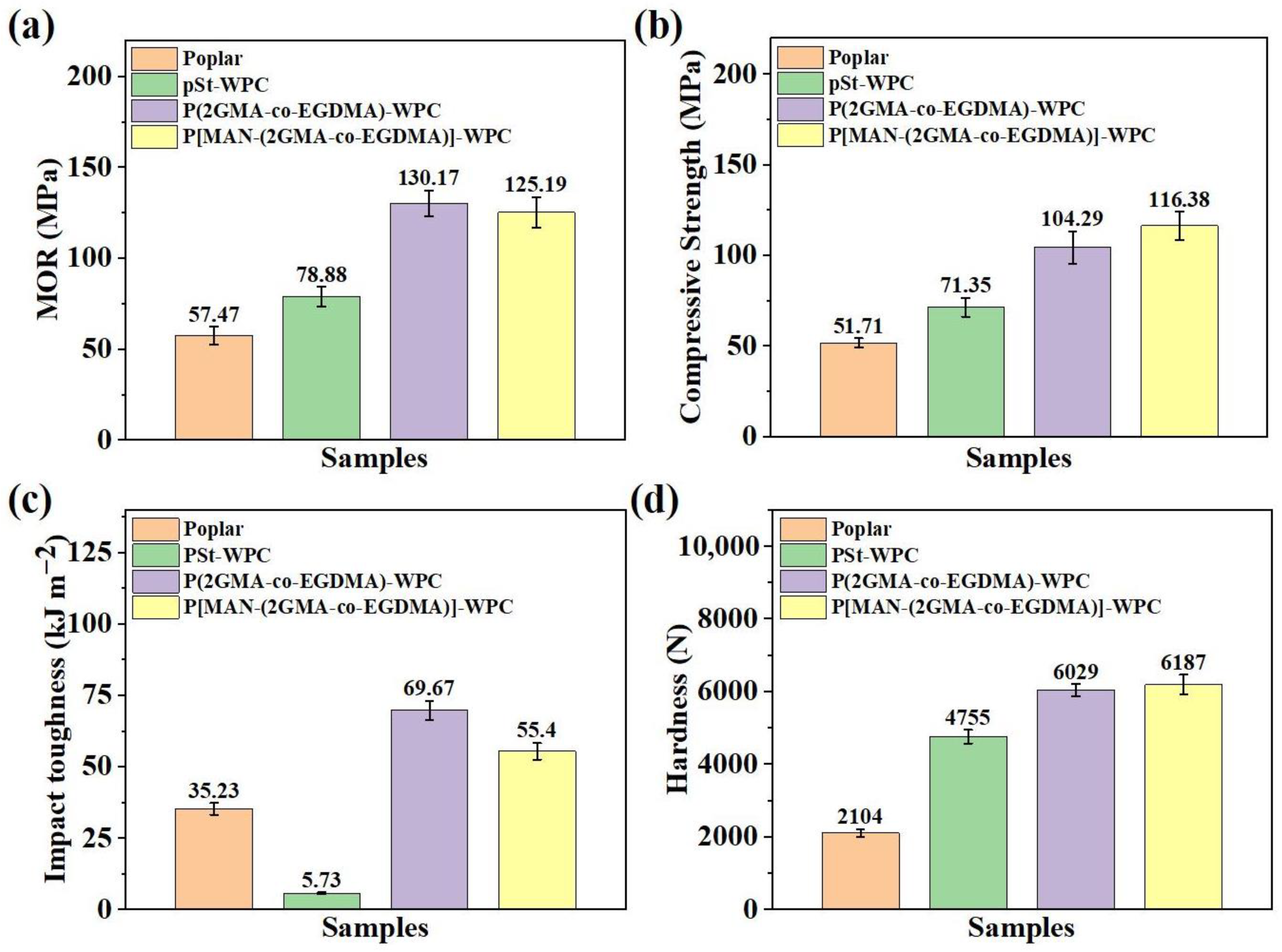

3.3. Mechanical Properties of Bulking–Filling Wood Composite Materials

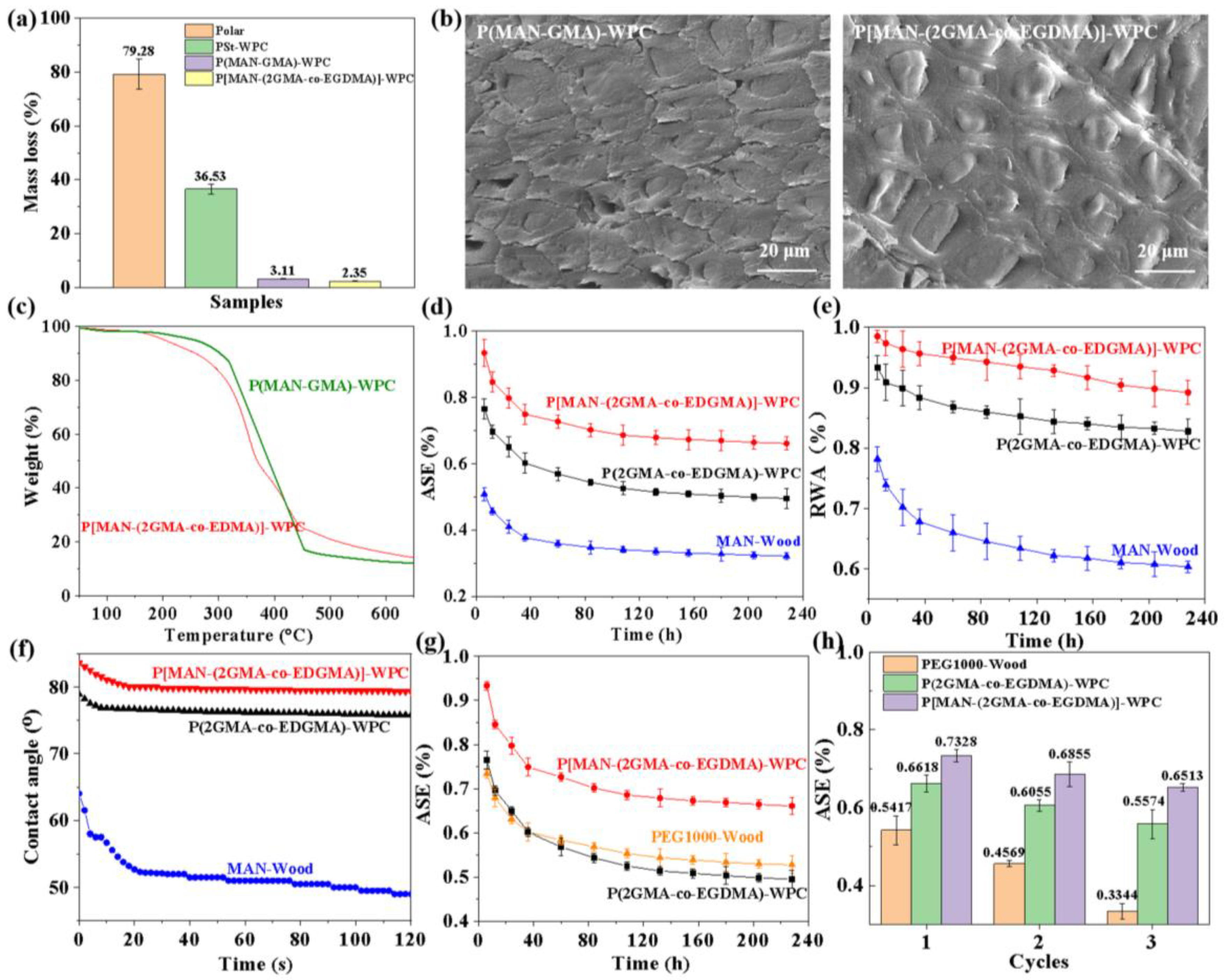

3.4. Durability and Dimensional Stability of Bulking–Filling Wood Composite Materials

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Savov, V.; Antov, P.; Zhou, Y.; Bekhta, P. Eco-Friendly Wood Composites: Design, Characterization and Applications. Polymers 2023, 15, 892. [Google Scholar] [CrossRef] [PubMed]

- Hu, J.; Wang, X. Modification Mechanisms and Properties of Poplar Wood via Grafting with 2-Hydroxyethyl Methacrylate/N, N′-methylenebis (acrylamide) onto Cell Walls. Polymers 2023, 15, 1861. [Google Scholar] [CrossRef] [PubMed]

- Elsayed, H.; Farag, M.; Megahed, H.; Mehanny, S. Influence of flax fibers on properties of starch-based composites. In Proceedings of the ASME International Mechanical Engineering Congress and Exposition, Houston, TX, USA, 9–15 November 2012; American Society of Mechanical Engineers: New York, NY, USA, 2012; Volume 45196, pp. 1397–1408. [Google Scholar]

- Souissi, S.; Lachtar, F.; Elloumi, A.; Bergeret, A. Properties of Wood Polymer Composites Based on Polypropylene/Olive Wood Flour: Effects of Fiber Treatment and Compatibilizer. Iran. Polym. J. 2022, 31, 1511–1521. [Google Scholar] [CrossRef]

- Kumar, V.; Gulati, K.; Lal, S.; Sanjiv, A. Effect of Gamma Irradiation on Tensile and Thermal Properties of Poplar Wood Flour-Linear Low Density Polyethylene Composites. Radiat. Phys. Chem. 2020, 174, 108922. [Google Scholar] [CrossRef]

- Triquet, J.; Blanchet, P.; Landry, V. Chemical Surface Densification of Hardwood Through Lateral Monomer Impregnation and in Situ Electron Beam Polymerization, Part I: Density Profile and Surface Hardness of Three Hardwood Species. J. Mater. Sci. 2021, 56, 11309–11323. [Google Scholar] [CrossRef]

- Khan, M.Z.R.; Srivastava, S.K.; Gupta, M.K. A State-Of-The-Art Review on Particulate Wood Polymer Composites: Processing, Properties and Applications. Polym. Test. 2020, 89, 106721. [Google Scholar] [CrossRef]

- Hadi, Y.S.; Hermawan, D.; Sulastiningsih, I.M.; Basri, E.; Pari, G.; Pari, R.; Abdillah, I.B. Color Change and Physical-Mechanical Properties of Polystyrene-Impregnated Glulam from Three Tropical Fast-Growing Wood Species. Forests 2021, 12, 1420. [Google Scholar] [CrossRef]

- Stolf, D.O.; Bertolini, M.S.; Christoforo, A.L.; Panzera, T.H.; Filho, S.L.M.R.; Lahr, F.A.R. Pinus Caribaea Var. Hondurensis Wood Impregnated with Methyl Methacrylate. J. Mater. Civ. Eng. 2017, 29, 05016004. [Google Scholar] [CrossRef]

- Yildiz, Ü.C.; Yildiz, S.; Gezer, E.D. Mechanical Properties and Decay Resistance of Wood–Polymer Composites Prepared from Fast Growing Species in Turkey. Bioresour. Technol. 2005, 96, 1003–1011. [Google Scholar] [CrossRef]

- Pandey, K.K.; Jayashree; Nagaveni, H.C. Study of Dimensional Stability, Decay Resistance, and Light Stability of Phenylisothiocyanate Modified Rubberwood. Bioresources 2009, 4, 257–267. [Google Scholar] [CrossRef]

- Zhang, Y.; He, Y.; Yu, J.; Lu, Y.; Zhang, X.; Fang, L. Fabrication and Characterization of EVA Resins as Adhesives in Plywood. Polymers 2023, 15, 1834. [Google Scholar] [CrossRef] [PubMed]

- Liu, X.; Fu, Z.; Zhang, F.; Wu, M.; Dong, Y. Synthesis of Silica Janus Nanosheets and Their Application to The Improvement of Interfacial Interaction in Wood Polymer Composites. J. Mater. Res. Technol. 2021, 15, 4652–4661. [Google Scholar] [CrossRef]

- Habu, N.; Nagasawa, Y.; Samejima, M.; Nakanishi, T.M. The Effect of Substituent Distribution on The Decay Resistance of Chemically Modified Wood. Int. Biodeterior. Biodegrad. 2006, 57, 57–62. [Google Scholar] [CrossRef]

- Rao, A.N.S.; Nagarajappa, G.B.; Nair, S.; Chathoth, A.M.; Pandey, K.K. Flexible Transparent Wood Prepared from Poplar Veneer and Polyvinyl Alcohol. Compos. Sci. Technol. 2019, 182, 107719. [Google Scholar]

- Ghorbani, M.; Poorzahed, N.; Amininasab, S.M. Morphological, Physical, and Mechanical Properties of Silanized Wood-Polymer Composite. J. Compos. Mater. 2020, 54, 1403–1412. [Google Scholar] [CrossRef]

- Ghorbani, M.; Shahmirzadi, A.N.; Amininasab, S.M. Physical and Morphological Properties of Combined Treated Wood Polymer Composites by Maleic Anhydride and Methyl Methacrylate. J. Wood Chem. Technol. 2017, 37, 443–450. [Google Scholar] [CrossRef]

- Ermeydan, M.; Cabane, E.; Gierlinger, N.; Koetzd, J.; Burgert, I. Improvement of Wood Material Properties via in Situ Polymerization of Styrene into Tosylated Cell Walls. RSC Adv. 2014, 4, 12981. [Google Scholar] [CrossRef]

- Test Methods for Physical and Mechanical Properties of Small Clear Wood Specimens—Part 2: Sampling Methods and General Requirements; GB/T 1927.2-2021. China Standard Publishing: Beijing, China, 2021.

- LYT1283-2011; Method of Laboratory Test for Toxicity of Wood Preservatives to Decay Fungi. China Standard Publishing: Beijing, China, 2011.

- Kartal, S.N.; Yoshimura, T.; Imamura, Y. Modification of Wood with Si Compounds to Limit Boron Leaching from Treated Wood and to Increase Termite and Decay Resistance. Int. Biodeterior. Biodegrad. 2009, 63, 187–190. [Google Scholar] [CrossRef]

- Vieira, A.P.; Santana, S.A.A.; Bezerra, C.W.B.; Silva, H.A.S.; Santos, K.C.A.; Melo, J.C.P.; Silva Filho, E.C.; Airoldi, C. High Performance Maleated Lignocellulose Epicarp Fibers for Copper Ion Removal. Braz. J. Chem. Eng. 2014, 31, 183–193. [Google Scholar] [CrossRef]

- Li, Y.; Wu, Q.; Li, J.; Liu, Y.; Wang, X.M.; Liu, Z. Improvement of Dimensional Stability of Wood via Combination Treatment: Swelling with Maleic Anhydride and Grafting with Glycidyl Methacrylate and Methyl Methacrylate. Holzforschung 2012, 66, 59–66. [Google Scholar] [CrossRef]

- Li, Y.; Dong, X.; Liu, Y.; Li, J.; Wang, F. Improvement of Decay Resistance of Wood via Combination Treatment on Wood Cell Wall: Swell-Bonding with Maleic Anhydride and Graft Copolymerization with Glycidyl Methacrylate and Methyl Methacrylate. Int. Biodeterior. Biodegrad. 2011, 65, 1087–1094. [Google Scholar] [CrossRef]

- Poletto, M.; Zattera, A.J.; Forte, M.M.; Santan, R.M. Thermal decomposition of wood: Influence of wood components and cellulose crystallite size. Bioresour. Technol. 2012, 109, 148–153. [Google Scholar] [CrossRef] [PubMed]

| Number | Temperature (°C) | Time (h) | ASE (%) |

|---|---|---|---|

| 1 | 80 | 2 | 58.92 ± 3.56 |

| 2 | 90 | 4 | 65.40 ± 5.28 |

| 3 | 100 | 6 | 70.22 ± 1.77 |

| 4 | 110 | 8 | 78.10 ± 3.21 |

| 5 | 90 | 6 | 66.98 ± 2.64 |

| 6 | 80 | 8 | 64.33 ± 4.53 |

| 7 | 110 | 2 | 67.07 ± 2.33 |

| 8 | 100 | 4 | 68.46 ± 3.37 |

| 9 | 100 | 8 | 73.55 ± 4.26 |

| 10 | 110 | 6 | 76.44 ± 1.75 |

| 11 | 80 | 4 | 60.35 ± 0.98 |

| 12 | 90 | 2 | 62.65 ± 1.54 |

| 13 | 110 | 4 | 71.92 ± 2.09 |

| 14 | 100 | 2 | 64.07 ± 1.17 |

| 15 | 90 | 8 | 68.57 ± 2.82 |

| 16 | 80 | 6 | 61.73 ± 4.97 |

| DEVSQ | Degree Freedom | Mean Square | F | Significance | |

|---|---|---|---|---|---|

| Temperature | 0.0446 | 3 | 0.0149 | 29.80 | ** |

| Time | 0.0546 | 3 | 0.0182 | 36.40 | ** |

| Error | 0.0046 | 9 | 0.0005 | ||

| Sum | 10.38% | 15 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dong, Y.; Qi, Y.; Dong, X.; Li, Y. Strong and Durable Wood Designed by Cell Wall Bulking Combined with Cell Lumen Filling. Polymers 2024, 16, 93. https://doi.org/10.3390/polym16010093

Dong Y, Qi Y, Dong X, Li Y. Strong and Durable Wood Designed by Cell Wall Bulking Combined with Cell Lumen Filling. Polymers. 2024; 16(1):93. https://doi.org/10.3390/polym16010093

Chicago/Turabian StyleDong, Yaoyao, Yanran Qi, Xiaoying Dong, and Yongfeng Li. 2024. "Strong and Durable Wood Designed by Cell Wall Bulking Combined with Cell Lumen Filling" Polymers 16, no. 1: 93. https://doi.org/10.3390/polym16010093

APA StyleDong, Y., Qi, Y., Dong, X., & Li, Y. (2024). Strong and Durable Wood Designed by Cell Wall Bulking Combined with Cell Lumen Filling. Polymers, 16(1), 93. https://doi.org/10.3390/polym16010093