Sustainable Innovation: Fabrication and Characterization of Mycelium-Based Green Composites for Modern Interior Materials Using Agro-Industrial Wastes and Different Species of Fungi

Abstract

1. Introduction

2. Materials and Methods

2.1. Source of Substrate and Initial Preparation

2.2. Mycelium Cultivation

2.3. Preparation of Substrate for Mycelium Culture

2.3.1. Preparing an Inoculum for Fungal Mycelia

2.3.2. Preparing the Substrate for Mycelial Growth

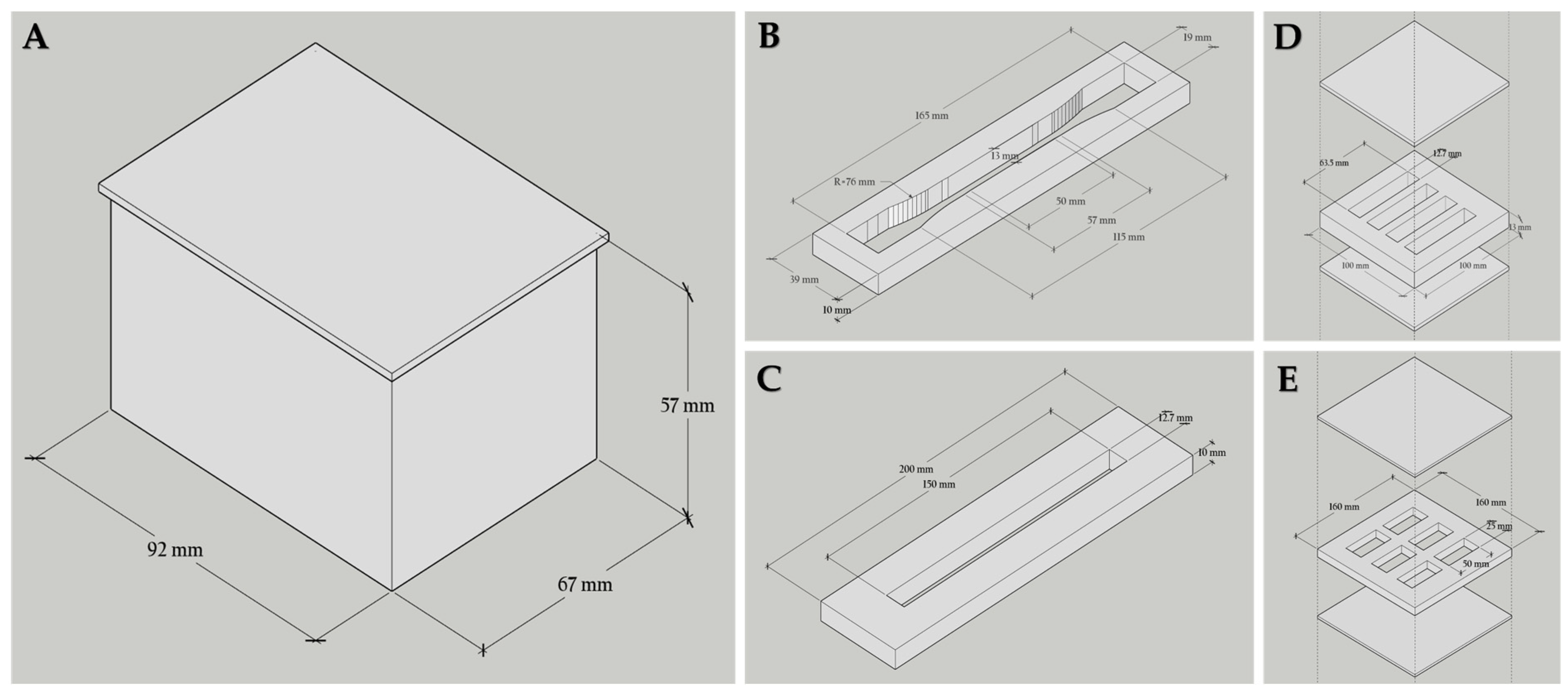

2.4. Mold Design and Sterilization

2.5. Mycelium-Based Bio-Composites Fabrication and Preparation for Testing

2.6. Determination of Physical Properties

2.6.1. Moisture Content and Shrinkage

2.6.2. Density Measurements

2.6.3. Water Absorption and Volumetric Swelling

2.6.4. Thermal Degradation

2.7. Scanning Electron Microscope Observations

2.8. Determination of Mechanical Properties

2.8.1. Bending Strength

2.8.2. Compression Strength

2.8.3. Impact Strength

2.8.4. Impact Strength

2.9. Biodegradability Test

2.10. Statistical Analysis

3. Results and Discussion

3.1. Determination of Physical Properties

3.1.1. Moisture Content and Shrinkage

3.1.2. Density

3.1.3. Water Absorption and Volumetric Swelling

3.1.4. Thermal Degradation

3.2. Scanning Electron Microscope Observations

3.3. Determination of Mechanical Properties

3.3.1. Bending Strength

3.3.2. Compression Strength

3.3.3. Impact Strength

3.3.4. Tensile Strength

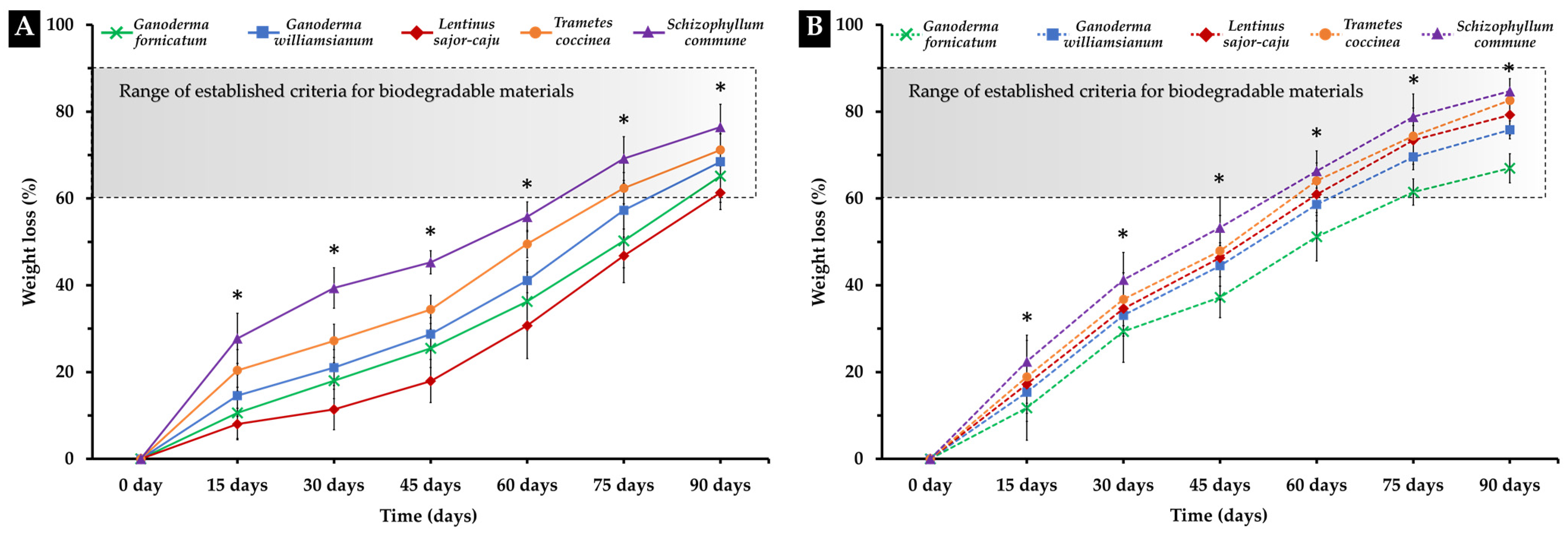

3.4. Biodegradability Test

3.5. Determination of Mechanical Properties

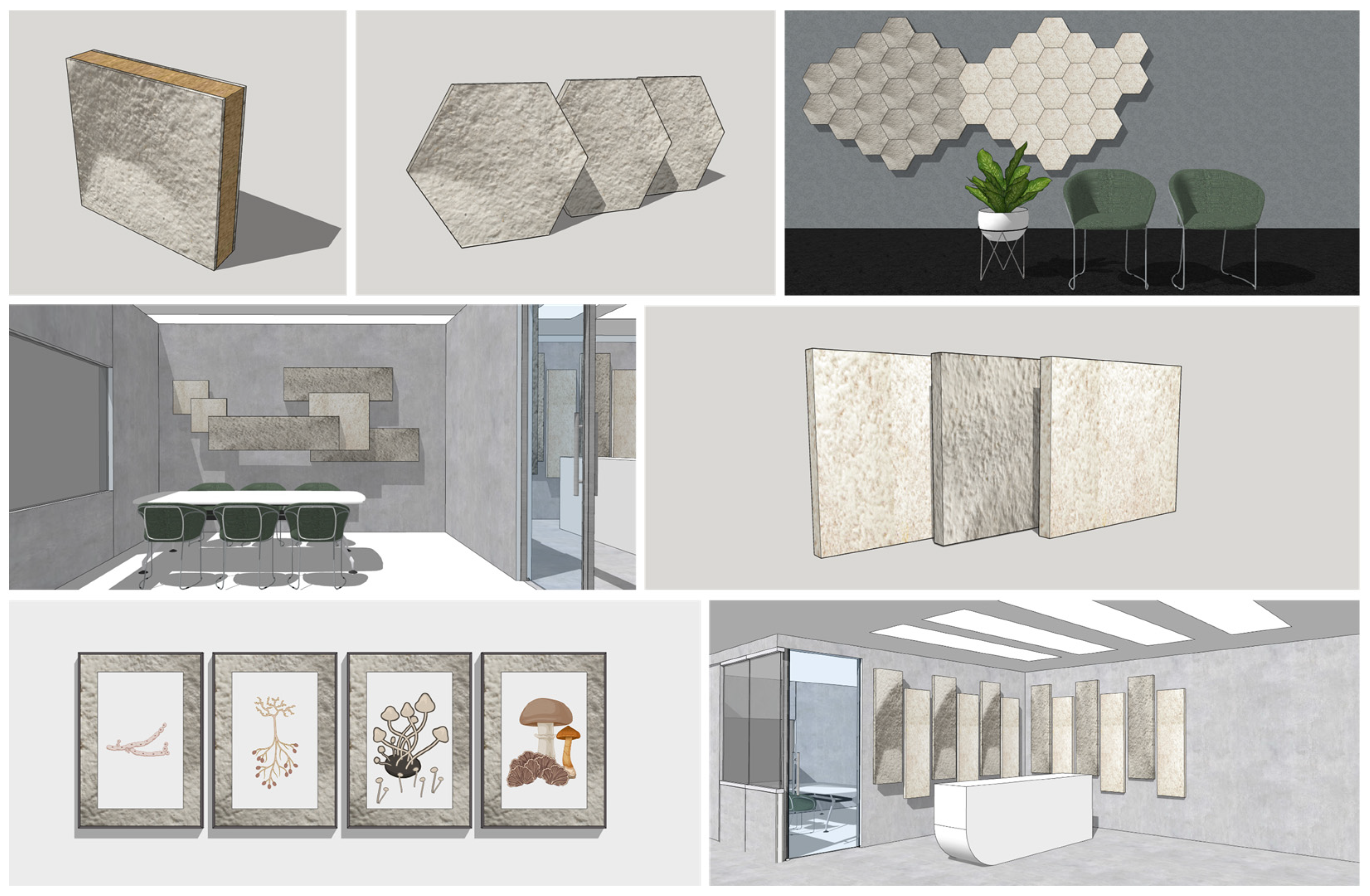

3.6. Challenges, Future Perspectives, and Development Approaches in Terms of Applications and Modern Interior Prototypes

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Rendón-Villalobos, R.; Ortíz-Sánchez, A.; Tovar-Sánchez, E.; Flores-Huicochea, E. The role of biopolymers in obtaining environmentally friendly materials. In Composites from Renewable and Sustainable Materials; Matheus, P., Ed.; InTechOpen: London, UK, 2016; p. 151. [Google Scholar]

- Garcia-Garcia, D.; Quiles-Carrillo, L.; Balart, R.; Torres-Giner, S.; Arrieta, M.P. Innovative solutions and challenges to increase the use of Poly (3-hydroxybutyrate) in food packaging and disposables. Eur. Polym. J. 2022, 178, 111505. [Google Scholar] [CrossRef]

- Zhang, L.; Xu, M.; Chen, H.; Li, Y.; Chen, S. Globalization, green economy and environmental challenges: State of the art review for practical implications. Front. Environ. Sci. 2022, 10, 870271. [Google Scholar] [CrossRef]

- Mohamed, F.; Jamil, M.; Zain, M.F.M. Sustainable material: Challenges and prospect. J. Adv. Res. Mater. Sci. 2019, 57, 7–18. [Google Scholar]

- Obeidat, I.; Obeidat, S.; Rumman, S.A.; Al-Jubouri, F. The role of sustainable interior design and its impact on customer’s behavior in commercial environments. In Proceedings of the IOP Conference Series: Earth and Environmental Science, Riyadh, Saudi Arabia, 19–22 February 2022. [Google Scholar]

- Paulraj, P.; Ilangovan, P.; Subramanian, K.; Nagarajan, M.R.; Suthan, R.; Sakthimurugan, V.; Madhu, S.; Varuvel, E.G.; Lenin, H. Environmentally conscious manufacturing and life cycle analysis: A state-of-the-art survey. J. Nanomater. 2023, 2022, 8438462. [Google Scholar] [CrossRef]

- Khalil, H.A.; Bhat, A.H.; Yusra, A.I. Green composites from sustainable cellulose nanofibrils: A review. Carbohydr. Polym. 2012, 87, 963–979. [Google Scholar] [CrossRef]

- Abdur Rahman, M.; Haque, S.; Athikesavan, M.M.; Kamaludeen, M.B. A review of environmental friendly green composites: Production methods, current progresses, and challenges. Environ. Sci. Pollut. Res. 2023, 30, 16905–16929. [Google Scholar] [CrossRef] [PubMed]

- Livne, A.; Wösten, H.A.; Pearlmutter, D.; Gal, E. Fungal mycelium bio-composite acts as a CO2-sink building material with low embodied energy. ACS Sustain. Chem. Eng. 2022, 10, 12099–12106. [Google Scholar] [CrossRef]

- Sydor, M.; Cofta, G.; Doczekalska, B.; Bonenberg, A. Fungi in mycelium-based composites: Usage and recommendations. Materials 2022, 15, 6283. [Google Scholar] [CrossRef] [PubMed]

- Manan, S.; Ullah, M.W.; Ul-Islam, M.; Atta, O.M.; Yang, G. Synthesis and applications of fungal mycelium-based advanced functional materials. J. Bioresour. Bioprod. 2021, 6, 1–10. [Google Scholar] [CrossRef]

- Rajendran, R.C. Packaging Applications of Fungal Mycelium-Based Biodegradable Composites. In Fungal Biopolymers and Biocomposites: Prospects and Avenues; Sunil, K.D., Mukund, V.D., Kandikere, R.S., Eds.; Springer Nature Singapore: Singapore, 2022; pp. 189–208. [Google Scholar]

- Alemu, D.; Tafesse, M.; Mondal, A.K. Mycelium-based composite: The future sustainable biomaterial. Int. J. Biomater. 2020, 2022, 8401528. [Google Scholar] [CrossRef]

- Kundanati, L. Fungi-based biomimetic approach to address plastic pollution: A developing nation’s perspective. Preprints 2022, 2022090255. [Google Scholar] [CrossRef]

- Attias, N.; Danai, O.; Tarazi, E.; Pereman, I.; Grobman, Y.J. Implementing bio-design tools to develop mycelium-based products. Des. J. 2019, 22, 1647–1657. [Google Scholar] [CrossRef]

- Aiduang, W.; Kumla, J.; Srinuanpan, S.; Thamjaree, W.; Lumyong, S.; Suwannarach, N. Mechanical, physical, and chemical properties of mycelium-based composites produced from various lignocellulosic residues and fungal species. J. Fungi 2022, 8, 1125. [Google Scholar] [CrossRef]

- Kupradi, C.; Khongla, C.; Musika, S.; Ranok, A.; Tamaruay, K.; Woraratphoka, J.; Mangkalanan, S. Cultivation of Lentinus squarrosulus and Pleurotus ostreatus on cassava bagasse based substrates. Int. J. Agric. Technol. 2017, 13, 883–892. [Google Scholar]

- ISO 846:2000; Evaluation of the Action of Microorganisms on Plastics. International Organization for Standardization: Geneva, Switzerland, 2000.

- Juanga-Labayen, J.P.; Yuan, Q. Making biodegradable seedling pots from textile and paper waste—Part B: Development and evaluation of seedling pots. Int. J. Environ. Res. Public Health 2021, 18, 7609. [Google Scholar] [CrossRef] [PubMed]

- McGowan, M.J.; Shimoda, L.M.; Woolsey, G.D. Effects of sodium hypochlorite on denture base metals during immersion for short-term sterilization. J. Prosthet. Dent. 1988, 60, 212–218. [Google Scholar] [CrossRef] [PubMed]

- ASTM D644; Standard Test Method for Moisture Content of Paper and Paperboard by Oven Drying. ASTM, American Society for Testing and Materials, ATSM: West Conshohocken, PA, USA, 1999.

- Zimele, Z.; Irbe, I.; Grinins, J.; Bikovens, O.; Verovkins, A.; Bajare, D. Novel mycelium-based biocomposites (Mbb) as building materials. J. Renew. Mater. 2020, 8, 1067–1076. [Google Scholar] [CrossRef]

- Elsacker, E.; Vandelook, S.; Brancart, J.; Peeters, E.; Laet, L.D. Mechanical, physical and chemical characterisation of myce-lium–based composites with different types of lignocellulosic substrates. PLoS ONE. 2019, 7, e0213954. [Google Scholar]

- Appels, F.V.W.; Camere, S.; Montalti, M.; Karana, E.; Jansen, K.M.B.; Dijksterhuis, J.; Krijgsheld, P.; Wosten, H.A.B. Fabrication factors influencing mechanical, moisture and water related properties of mycelium-based composites. Mater. Des. 2019, 161, 64–71. [Google Scholar] [CrossRef]

- Sandak, A.; Sandak, J.; Modzelewska, I. Manufacturing fit-for-purpose paper packaging containers with controlled biodegradation rate by optimizing addition of natural fillers. Cellulose 2019, 26, 2673–2688. [Google Scholar] [CrossRef]

- Yang, L.; Park, D.; Qin, Z. Material function of mycelium-based bio-composite: A review. Front. Mater. Sci. 2021, 8, 737377. [Google Scholar] [CrossRef]

- Deacon, J.W. Fungal Biology; Blackwell-Wiley: Oxford, UK, 2006; pp. 1–95. [Google Scholar]

- Velasco, P.M.; Ortiz, M.P.M.; Giro, M.A.M.; Castelló, M.C.J.; Velasco, L.M. Development of better insulation bricks by adding mushroom compost wastes. Energy Build. 2014, 80, 17–22. [Google Scholar] [CrossRef]

- De Lima, G.G.; Schoenherr, Z.C.P.; Magalhães, W.L.E.; Tavares, L.B.B.; Helm, C.V. Enzymatic activities and analysis of a mycelium-based composite formation using peach palm (Bactris gasipaes) residues on Lentinula edodes. Bioresour. Bioprocess 2020, 7, 58. [Google Scholar] [CrossRef]

- Aiduang, W.; Chanthaluck, A.; Kumla, J.; Jatuwong, K.; Srinuanpan, S.; Waroonkun, T.; Oranratmanee, W.; Lumyong, S.; Suwannarach, N. Amazing fungi for eco-friendly composite materials: A comprehensive review. J. Fungi 2022, 8, 842. [Google Scholar] [CrossRef] [PubMed]

- Houette, T.; Maurer, C.; Niewiarowski, R.; Gruber, P. Growth and mechanical characterization of mycelium-based composites towards future bioremediation and food production in the material manufacturing cycle. Biomimetics 2022, 7, 103. [Google Scholar] [CrossRef] [PubMed]

- Aiduang, W.; Suwannarach, N.; Kumla, J.; Thamjaree, W.; Lumyong, S. Valorization of agricultural waste to produce myco-composite materials from mushroom mycelia and their physical properties. Agric. Nat. Resour. 2022, 56, 1083–1090. [Google Scholar]

- Holt, G.A.; Mcintyre, G.; Flagg, D.; Bayer, E.; Wanjura, J.D.; Pelletier, M.G. Fungal mycelium and cotton plant materials in the manufacture of biodegradable molded packaging material: Evaluation study of select blends of cotton byproducts. J. Biobased Mater. 2012, 6, 431–439. [Google Scholar] [CrossRef]

- Rigobello, A.; Ayres, P. Compressive behaviour of anisotropic mycelium-based composites. Sci. Rep. 2022, 12, 6846. [Google Scholar] [CrossRef]

- Butu, A.; Rodino, S.; Miu, B.; Butu, M. Mycelium-based materials for the ecodesign of bioeconomy. Dig. J. Nanomater. Biostructures 2020, 15, 1129–1140. [Google Scholar] [CrossRef]

- Gou, L.; Li, S.; Yin, J.; Li, T.; Liu, X. Morphological and physico-mechanical properties of mycelium biocomposites with natural reinforcement particles. Constr. Build. Mater. 2021, 304, 124656. [Google Scholar] [CrossRef]

- Tacer-Caba, Z.; Varis, J.J.; Lankinen, P.; Mikkonen, K.S. Comparison of novel fungal mycelia strains and sustainable growth substrates to produce humidity-resistant biocomposites. Mater. Des. 2020, 192, 108728. [Google Scholar] [CrossRef]

- Joshi, K.; Meher, M.K.; Poluri, K.M. Fabrication and characterization of bioblocks from agricultural waste using fungal mycelium for renewable and sustainable applications. ACS Appl. Bio Mater. 2020, 3, 1884–1892. [Google Scholar] [CrossRef] [PubMed]

- Angelova, G.; Brazkova, M.; Stefanova, P.; Blazheva, D.; Vladev, V.; Petkova, N.; Slavov, A.; Denev, P.; Karashanova, D.; Zaharieva, R.; et al. Waste rose flower and lavender straw biomass—An innovative lignocellulose feedstock for mycelium bio-materials development using newly isolated Ganoderma resinaceum GA1M. J. Fungi 2021, 7, 866. [Google Scholar] [CrossRef] [PubMed]

- Chan, X.Y.; Saeidi, N.; Javadian, A.; Hebel, D.E.; Gupta, M. Mechanical properties of dense mycelium-bound composites under accelerated tropical weathering conditions. Sci. Rep. 2021, 11, 22112. [Google Scholar] [CrossRef] [PubMed]

- Jones, M.; Mautner, A.; Luenco, S.; Bismarck, A.; John, S. Engineered mycelium composite construction materials from fungal biorefineries: A critical review. Mater. Des. 2020, 187, 108397. [Google Scholar] [CrossRef]

- Pishan, S.; Ghofrani, M.; Kermanian, H. Study on mechanical properties of lightweight panels made of honeycomb and polyurethane cores. Lignocellulose 2014, 3, 59–68. [Google Scholar]

- Paperonweb. Typical Density and Bulk of Paper. Available online: https://www.paperonweb.com/density.htm#a (accessed on 18 November 2023).

- Alaneme, K.K.; Anaele, J.U.; Oke, T.M.; Kareem, S.A.; Adediran, M.; Ajibuwa, O.A.; Anabaranze, Y.O. Mycelium based composites: A review of their bio-fabrication procedures, material properties and potential for green building and construction applications. Alex. Eng. J. 2023, 83, 234–250. [Google Scholar] [CrossRef]

- Kim, D. Physico-chemical conversion of lignocellulose: Inhibitor effects and detoxification strategies: A mini review. Molecules 2018, 23, 309. [Google Scholar] [CrossRef]

- Ibrahim, M.I.; Sapuan, S.M.; Zainudin, E.S.; Zuhri, M.Y.M. Extraction, chemical composition, and characterization of potential lignocellulosic biomasses and polymers from corn plant parts. Bioresources 2019, 14, 6485–6500. [Google Scholar] [CrossRef]

- Zhai, Q.; Long, F.; Hse, C.Y.; Wang, F.; Shupe, T.F.; Jiang, J.; Xu, J. Facile fractionation of bamboo wood toward biomass valorization by p-TsOH-based methanolysis pretreatment. ACS Sustain. Chem. Eng. 2019, 7, 19213–19224. [Google Scholar] [CrossRef]

- Zhang, K.; Li, H.; Xiao, L.P.; Wang, B.; Sun, R.C.; Song, G. Sequential utilization of bamboo biomass through reductive catalytic fractionation of lignin. Bioresour. Technol. 2019, 285, 121335. [Google Scholar] [CrossRef]

- Pantamanatsopa, P.; Ariyawiriyanan, W.; Sungsanit, K.; Ekgasit, S. Physicochemical characterization of acid-treated nanocrystal cellulose and amorphous cellulose from bamboo sawdust. J. Nat. Fibers 2023, 20, 2286323. [Google Scholar] [CrossRef]

- Peeters, S.S. Assessing Modifications on Mycelium-Based Composites and the Effects on Fungal Degradation and Material Properties. Master’s Thesis, Eindhoven University of Technology, Eindhoven, The Netherlands, 2023. [Google Scholar]

- Zhang, X.; Fan, X.; Han, C.; Wang, C.; Yu, X. Improving soil surface erosion resistance by fungal mycelium. In Proceedings of the Geo-Congress 2020, VA: American Society of Civil Engineers, Minneapolis, MN, USA, 25–28 February 2020; pp. 523–531. [Google Scholar]

- Robertson, O.; Høgdal, F.; Mckay, L.; Lenau, T. Fungal Future: A review of mycelium biocomposites as an ecological alter-native insulation material. In Proceedings of the Nord Design 2020, Lyngby, Denmark, 12–14 August 2020; pp. 1–13. [Google Scholar]

- Sun, W.; Tajvidi, M.; Hunt, C.G.; McIntyre, G.; Gardner, D.J. Fully bio-based hybrid composites made of wood, fungal mycelium and cellulose nanofibrils. Sci. Rep. 2019, 9, 3766. [Google Scholar] [CrossRef]

- Sun, W. Understanding the Adhesion Mechanism in Mycelium-Assisted Wood Bonding. Ph.D. Thesis, The University of Maine, Orono, ME, USA, 2021. [Google Scholar]

- Charpentier-Alfaro, C.; Benavides-Hernández, J.; Poggerini, M.; Crisci, A.; Mele, G.; Della Rocca, G.; Emiliani, G.; Frascella, A.; Torrigiani, T.; Palanti, S. Wood-decaying fungi: From timber degradation to sustainable insulating biomaterials production. Materials 2023, 16, 3547. [Google Scholar] [CrossRef]

- Bruscato, C.; Malvessi, E.; Brandalise, R.N.; Camassola, M. High performance of macrofungi in the production of mycelium-based biofoams using sawdust—Sustainable technology for waste reduction. J. Clean. Prod. 2019, 234, 225–232. [Google Scholar] [CrossRef]

- Waters, C.L.; Janupala, R.R.; Mallinson, R.G.; Lobban, L.L. Staged thermal fractionation for segregation of lignin and cellulose pyrolysis products: An experimental study of residence time and temperature effects. J. Anal. Appl. Pyrolysis 2017, 126, 380–389. [Google Scholar] [CrossRef]

- Agarwal, G.A.U.R.A.V.; Liu, G.; Lattimer, B.R.I.A.N. Pyrolysis and oxidation of cardboard. Fire Saf. Sci. 2014, 11, 124–137. [Google Scholar] [CrossRef]

- Chen, N.; Zhang, S.; Pan, X.; Zhou, S.; Zhao, M. Foaming mechanism and optimal process conditions of foamed glass based on thermal analysis. J. Porous Mater. 2020, 27, 621–626. [Google Scholar] [CrossRef]

- Ma, Y.; Song, D.; Cao, J. Preparation of activated carbon monolith from waste corrugated cardboard box via catalytic pyrolysis and gasification under CO2 atmosphere for adsorption and solar steam generation. J. Porous Mater. 2020, 27, 1711–1726. [Google Scholar] [CrossRef]

- Nazir, M.T.; Phung, B.T.; Yeoh, G.H.; Yasin, G.; Akram, S.; Bhutta, M.S.; Mehmood, M.A.; Hussain, S.; Yu, S.; Kabir, I. Enhanced dielectric and thermal performance by fabricating coalesced network of alumina trihydrate/boron nitride in silicone rubber for electrical insulation. Bull. Mater. Sci. 2020, 43, 220. [Google Scholar] [CrossRef]

- Rasid, Z.A. The Thermal Stability Property of Bio-composites: A Review. In InCIEC 2014: Proceedings of the International Civil and Infrastructure Engineering Conference 2014; Springer: Singapore, 2015; pp. 667–680. [Google Scholar]

- Sun, W.; Tajvidi, M.; Howell, C.; Hunt, C.G. Insight into mycelium-lignocellulosic bio-composites: Essential factors and properties. Compos. A Appl. Sci. Manuf. 2022, 161, 107125. [Google Scholar] [CrossRef]

- Raimbault, M. General and microbiological aspects of solid substrate fermentation. Electron. J. Biotechnol. 2003, 1, 26–27. [Google Scholar] [CrossRef]

- Wösten, H.A. Filamentous fungi for the production of enzymes, chemicals and materials. Curr. Opin. Biotechnol. 2019, 59, 65–70. [Google Scholar] [CrossRef]

- Elsacker, E.; Vandelook, S.; Damsin, B.; Van Wylick, A.; Peeters, E.; De Laet, L. Mechanical characteristics of bacterial cellulose-reinforced mycelium composite materials. Fungal Biol. Biotechnol. 2021, 8, 18. [Google Scholar] [CrossRef] [PubMed]

- Akromah, S.; Chandarana, N.; Eichhorn, S.J. Mycelium composites for sustainable development in developing countries: The case for Africa. Adv. Sustain. Syst. 2023, 8, 2300305. [Google Scholar] [CrossRef]

- MatWeb LLC. Material Property Data. Available online: https://www.matweb.com/search/AdvancedSearch.aspx (accessed on 20 October 2023).

- Javadian, A.; Le Ferrand, H.; Hebel, D.E.; Saeidi, N. Application of mycelium-bound composite materials in construction industry: A short review. SOJ Mater. Sci. Eng. 2020, 7, 1–9. [Google Scholar] [CrossRef]

- Pohl, C.; Schmidt, B.; Nunez Guitar, T.; Klemm, S.; Gusovius, H.J.; Platzk, S.; Kruggel-Emden, H.; Klunker, A.; Völlmecke, C.; Fleck, C.; et al. Establishment of the basidiomycete Fomes fomentarius for the production of composite materials. Fungal Biol. Biotechnol. 2022, 9, 4. [Google Scholar] [CrossRef] [PubMed]

- Kohphaisansombat, C.; Jongpipitaporn, Y.; Laoratanakul, P.; Tantipaibulvut, S.; Euanorasetr, J.; Rungjindamai, N.; Chuaseeharonnachaid, C.; Kwantong, P.; Somrithipol, S.; Boonyuen, N. Fabrication of mycelium (oyster mushroom)-based composites derived from spent coffee grounds with pineapple fibre reinforcement. Mycology 2023. [Google Scholar] [CrossRef]

- Vašatko, H.; Gosch, L.; Jauk, J.; Stavric, M. Basic research of material properties of mycelium-based composites. Biomimetics 2022, 7, 51. [Google Scholar] [CrossRef] [PubMed]

- Sivakumar, D.; Kathiravan, S.; Ng, L.F.; Ali, M.B.; Selamat, M.Z.; Sivaraos, S.; Bapokutty, O. Experimental investigation on charpy impact response of kenaf bast fibre reinforced metal laminate system. ARPN J. Eng. Appl. Sci. 2018, 13, 822–827. [Google Scholar]

- Abidin, N.M.Z.; Sultan, M.T.H.; Shah, A.U.M.; Safri, S.N.A. Charpy and Izod impact properties of natural fibre composites. In Proceedings of the 6th International Conference on Applications and Design in Mechanical Engineering, Penang Island, Malaysia, 26–27 August 2019; IOP Conference Series: Materials Science and Engineering; p. 012031. [Google Scholar]

- Barboutis, I.; Vassiliou, V. Strength properties of lightweight paper honeycomb panels for the furniture. In Proceedings of the International Scientific Conference, Stockholm, Sweden, 24–28 July 2005; pp. 17–18. [Google Scholar]

- Ashby, M.F. Materials and the Environment: Eco-Informed Material Choice; Butterworth Heinemann: Oxford, UK, 2012. [Google Scholar]

- Keskisaari, A.; Kärki, T.; Vuorinen, T. Mechanical properties of recycled polymer composites made from side-stream materials from different industries. Sustainability 2019, 11, 6054. [Google Scholar] [CrossRef]

- Baca Lopez, D.M.; Ahmad, R. Tensile mechanical behaviour of multi-polymer sandwich structures via fused deposition modelling. Polymers 2020, 12, 651. [Google Scholar] [CrossRef]

- Gauvin, F.; Vette, I.J. Characterization of Mycelium-Based Composites as Foam-Like Wall Insulation Material. Master’s Thesis, Eindhoven University of Technology, Eindhoven, The Netherlands, 2020. [Google Scholar]

- Travaglini, S.; Noble, J.; Ross, P.G.; Dharan, C.K.H. Mycology matrix composites. In Proceedings of the Annual Technical Conference 28th American Society for Composites, State College, PA, USA, 9–11 September 2013. [Google Scholar]

- Kopal, I.; Labaj, I.; Harničárová, M.; Valíček, J.; Hrubý, D. Prediction of the tensile response of carbon black filled rubber blends by artificial neural network. Polymers 2018, 10, 644. [Google Scholar] [CrossRef]

- Czechowski, L.; Śmiechowicz, W.; Kmita-Fudalej, G.; Szewczyk, W. Flexural damage of honeycomb paperboard—A numerical and experimental study. Materials 2020, 13, 2601. [Google Scholar] [CrossRef]

- Pohl, A. Strengthened Corrugated Paper Honeycomb for Application in Structural Elements. Ph.D. Thesis, Eidgenössische Technische Hochschule Zürich, Zürich, Switzerland, 2009. [Google Scholar]

- Sisti, L.; Gioia, C.; Totaro, G.; Verstichel, S.; Cartabia, M.; Camere, S.; Celli, A. Valorization of wheat bran agro-industrial byproduct as an upgrading filler for mycelium-based composite materials. Ind. Crops Prod. 2021, 170, 113742. [Google Scholar] [CrossRef]

- Van Wylick, A.; Elsacker, E.; Yap, L.L.; Peeters, E.; De Laet, L. Mycelium composites and their biodegradability: An exploration on the disintegration of mycelium-based materials in soil. Constr. Technol. Archit. 2022, 1, 652–659. [Google Scholar]

- Ly, L.; Jitjak, W. Biocomposites from agricultural wastes and mycelia of a local mushroom, Lentinus squarrosulus (Mont.) Singer. Open Agric. 2022, 7, 634–643. [Google Scholar] [CrossRef]

- Kjeldsen, A.; Price, M.; Lilley, C.; Guzniczak, E.; Archer, I. A review of standards for biodegradable plastics. Ind. Biotechnol. Innov. Cent. 2018, 33, 1–33. [Google Scholar]

- Fairus, M.J.B.M.; Bahrin, E.K.; Arbaain, E.N.N.; Ramli, N.O.R.H.A.Y.A.T.I.; Enis, N. Mycelium-based composite: A way forward for renewable material. J. Sustain. Sci. Manag. 2022, 17, 271–280. [Google Scholar] [CrossRef]

- Bian, J.; Cao, W.; Yang, L.; Xiong, C. Experimental research on the mechanical properties of tailing microcrystalline foam glass. Material 2018, 11, 2048. [Google Scholar] [CrossRef] [PubMed]

- Armstrong, S. Foamglas Cellular Glass Insulation Is Proven Value; Pittsburgh Corning Corporation: Pittsburgh, PA, USA, 2016; pp. 1–13. [Google Scholar]

- Şahin, A.; Kılıç, Y.; Kara, M.; Sarı, A.; Duymaz, B. An investigation of raw material effects on nano sic based foam glass production. In Proceedings of the Conference: SERES’18 IV International Ceramic, Glass, Porcelain Enamel, Glaze and Pigment Congress, Eskişehir, Turkey, 18 October 2018. [Google Scholar]

- Scarinci, G.; Brusatin, D.; Bernardo, E. Glass Foams. In Cellular Ceramics: Structure, Manufacturing, Properties and Applications; Michael, S., Paolo, C., Eds.; Wiley-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2005; pp. 158–176. [Google Scholar]

- Yang, L.; Gao, J.; Liu, Y.; Zhuang, G.; Peng, X.; Wu, W.M.; Zhuang, X. Biodegradation of expanded polystyrene and low-density polyethylene foams in larvae of Tenebrio molitor Linnaeus (Coleoptera: Tenebrionidae): Broad versus limited extent depolymerization and microbe-dependence versus independence. Chemosphere 2021, 262, 127818. [Google Scholar] [CrossRef]

- Maghfouri, M.; Alimohammadi, V.; Gupta, R.; Saberian, M.; Azarsa, P.; Hashemi, M.; Asadi, I.; Roychand, R. Drying shrinkage properties of expanded polystyrene (EPS) lightweight aggregate concrete: A review. Case Stud. Constr. Mater. 2022, 16, e00919. [Google Scholar] [CrossRef]

- Zegardło, B.; Kobyliński, K. Analysis of the possibility of using extruded polystyrene (xps) wastes to make lightweight cement composites. J. Ecol. Eng. 2021, 22, 123–131. [Google Scholar]

- Plascams. Phenolic PF Phenol Formaldehyde Foam. Available online: https://www.azom.com/article.aspx?ArticleID=728 (accessed on 18 November 2023).

- Xu, Y.; Guo, L.; Zhang, H.; Zhai, H.; Ren, H. Research status, industrial application demand and prospects of phenolic resin. RSC Adv. 2019, 9, 28924–28935. [Google Scholar] [CrossRef] [PubMed]

- Lampé, I.; Hegedús, C. Comparative evaluation of the shrinkage of addition-type silicone impression material using hand-mix and cartridge-mix technique. Fogorv. Sz. 2002, 95, 249–252. [Google Scholar] [PubMed]

- Russ, A.; Schwartz, J.; Boháček, Š.; Lübke, H.; Ihnat, V.; Pažitný, A. Reuse of old corrugated cardboard in constructional and thermal insulating boards. Wood Res. 2013, 58, 505–510. [Google Scholar]

- Łątka, J.F.; Jasiołek, A.; Karolak, A.; Niewiadomski, P.; Noszczyk, P.; Klimek, A.; Zielińska, S.; Misiurka, S.; Jezierska, D. Properties of paper-based products as a building material in architecture–An interdisciplinary review. J. Build. Eng. 2022, 50, 104135. [Google Scholar] [CrossRef]

- Elliott, O. The Benefits of Cardboard Packaging. 2022. Available online: https://www.bigdug.co.uk/blog/benefits-of-cardboard-packaging/ (accessed on 25 November 2023).

- Mahakalkar, S.G.; Sambare, R.; Sunheriya, N. Effect of environmental conditions on performance of corrugated sheet boxes manufacturing process. Int. J. Recent. Technol. Eng. 2019, 8, 339–343. [Google Scholar]

- Tungsangprateep, S.; Kulchan, R.; Toonkham, W.; Tuntawiroon, O.; Meaktrong, W.; Praditniyakul, B.; Maneesin, P.; Sansupa, S. Development of consumer packaging for fresh persimmons. Agric. Nat. Resour. 2006, 40, 172–181. [Google Scholar]

- Wendler, S. Washboarding of Corrugated Cardboard. Ph.D. Thesis, RMIT University, Melbourne, Australia, 2006. [Google Scholar]

- Ralph, A. Swelling of Corrugated Boxes. Available online: https://askralph-aiccbox.org/2015/03/02/swelling-of-corrugated-boxes/ (accessed on 25 November 2023).

- Fadiji, T.; Berry, T.; Coetzee, C.J.; Opara, L. Investigating the mechanical properties of paperboard packaging material for handling fresh produce under different environmental conditions: Experimental analysis and finite element modelling. J. Appl. Packag. Res. 2017, 9, 3. [Google Scholar]

- Zulaikah, S.; Triawan, F.; Budiman, B.A.; Romadhon, Y.; Kamaludin, D. Study on the mechanical properties and behavior of corrugated cardboard under tensile and compression loads. In Materials Science Forum; Juraj, M., Gregor, P., Ulrike, G., Faisal, M., Eds.; Trans Tech Publications Ltd.: Baech, Switzerland, 2023; pp. 45–54. [Google Scholar]

- Allaoui, S.; Aboura, Z.; Benzeggagh, M.L. Phenomena governing uni-axial tensile behaviour of paperboard and corrugated cardboard. Compos. Struct. 2009, 87, 80–92. [Google Scholar] [CrossRef]

- Korte, I.; Albrecht, A.; Mittler, M.; Waldhans, C.; Kreyenschmidt, J. Influence of different bio-based and conventional packaging trays on the quality loss of fresh cherry tomatoes during distribution and storage. Packag Technol. Sci. 2023, 36, 569–583. [Google Scholar] [CrossRef]

- Fefco. The Study Biodegradability and Compostability Fefco. 2020. Available online: https://www.gifco.it/wp-content/uploads/2020/11/Fefco_ppt_report_biodegradability_and_compostability_2020.pdf (accessed on 22 October 2023).

- Odusote, J.K.; Onowuma, S.A.; Fodeke, E.A. Production of paperboard briquette using waste paper and sawdust. J. Eng. Res. 2016, 13, 80–88. [Google Scholar] [CrossRef]

- Larsson, P.A. Dimensional Stability of Paper: Influence of Fibre-Fibre Joints and Fibre Wall Oxidation. Ph.D. Thesis, KTH Royal Institute of Technology, Stockholm, Sweden, 2008. [Google Scholar]

- Odusote, J.K.; Dosunmu, K.S. Development of chicken feather reinforced insulation paperboard from waste carton and Portland cement. J. Eng. Res. 2019, 16, 44–52. [Google Scholar]

- Ataguba, C.O. Properties of ceiling boards produced from a composite of waste paper and rice husk. Int. J. Adv. Sci. Eng. Technol. 2016, 2, 117–121. [Google Scholar]

- Marin, G.; Nygårds, M.; Östlund, S. Experimental quantification of differences in damage due to in-plane tensile test and bending of paperboard. Packag. Technol. Sci. 2022, 35, 69–80. [Google Scholar] [CrossRef]

- Naitzel, T.D.C.; Garcia, V.A.D.S.; Lourenço, C.A.M.; Vanin, F.M.; Yoshida, C.M.P.; Carvalho, R.A.D. Properties of paperboard coated with natural polymers and polymer blends: Effect of the number of coating layers. Foods 2023, 12, 2745. [Google Scholar] [CrossRef] [PubMed]

- Rhim, J.W.; Lee, J.H.; Hong, S.I. Increase in water resistance of paperboard by coating with poly (lactide). Packag. Technol. Sci. 2007, 20, 393–402. [Google Scholar] [CrossRef]

- Sridach, W.; Retulainen, E.; Nazhad, M.M.; Kuusipalo, J.; Parkpian, P. Biodegradable barrier coating on paperboard: Effects on biodegradation, recycling and incineration. Pap. Ja Puu 2006, 88, 115–120. [Google Scholar]

- Semple, K.E.; Sam-Brew, S.; Deng, J.; Cote, F.; Yan, N.; Chen, Z.; Smith, G.D. Properties of commercial kraft paper honeycomb furniture stock panels conditioned under 65 and 95 percent relative humidity. For. Prod. J. 2015, 65, 106–122. [Google Scholar] [CrossRef]

- Ayrilmis, N.; Kuzman, M.K. Properties of honeycomb paperboards faced with heat-treated thin medium-density fiberboards. Bioresources 2016, 11, 7803–7810. [Google Scholar] [CrossRef][Green Version]

- Fu, Y.; Sadeghian, P. Bio-based sandwich beams made of paper honeycomb cores and flax FRP facings: Flexural and shear characteristics. Structures 2023, 54, 446–460. [Google Scholar] [CrossRef]

- Słonina, M.; Dziurka, D.; Molińska-Glura, M.; Smardzewski, J. Influence of impregnation with modified starch of a paper core on bending of wood-based honeycomb panels in changing climatic conditions. Materials 2022, 15, 395. [Google Scholar] [CrossRef] [PubMed]

- Bewi. Honeycomb. 2023. Available online: https://bewi.com/material/honeycomb/ (accessed on 25 November 2023).

- Bitting, S.; Derme, T.; Lee, J.; Van Mele, T.; Dillenburger, B.; Block, P. Challenges and opportunities in scaling up architectural applications of mycelium-based materials with digital fabrication. Biomimetics 2022, 7, 44. [Google Scholar] [CrossRef]

- Protopapadaki, I.; Kalika, S. Insights into Mycelium. Available online: https://criticalconcrete.com/insights-mycelium/ (accessed on 22 October 2023).

- Bonenberg, A.; Sydor, M.; Cofta, G.; Doczekalska, B.; Grygorowicz-Kosakowska, K. Mycelium-based composite materials: Study of acceptance. Materials 2023, 16, 2164. [Google Scholar] [CrossRef]

- Teeraphantuvat, T.; Jatuwong, K.; Jinanukul, P.; Thamjaree, W.; Lumyong, S.; Aiduang, W. Improving the physical and mechanical properties of mycelium-based green composites using paper waste. Polymers 2024, 16, 262. [Google Scholar] [CrossRef]

| Types | Properties * | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| D (kg/m3) | AS (%) | WP (%) | VS (%) | TD (%) | CS (%) | BS (%) | IS (%) | TS (%) | EAB (%) | B (%) | ||

| Mycelium-Based Bio-Composites | This study | 212.31–281.33 | 3.14–16.66 | 104.89–224.08 | 3.67–10.10 | 180–325 | 400–952 | 52.79–205.28 | 0.29–2.96 | 4.1–61.85 | 0.41–1.51 | 61.31–84.72 |

| Previous studies | 25–954 | 6.2–16.31 | 24.5–560 | 0.28–21 | 225–375 | 30–4400 | 50–4400 | 0.21–2.7 | 10–1550 | 0.7–4.7 | 19–70 | |

| Synthetic Foams | Foamed Glass | 100–400 | 0.01–2 | 0.8–11 | – | 300–450 | 400–3000 | < 300–3000 | 0.001–5 | < 660–1590 | < 1.7–11 | NB |

| Expanded Polystyrene foam | 11–32 | 0.2–5 | 0.03–9.00 | – | 318–440 | 100–180 | 75–3000 | 0.22–0.245 | < 80–170 | < 5–13.4 | NB | |

| Extruded Polystyrene foam | 28–50 | 0.2–1.5 | 0.25– 0.9 | – | 318–440 | 200–700 | 500–1000 | 0.16–2.14 | < 200–520 | 1–70 | NB | |

| Phenolic Formaldehyde Resin foam | 35–120 | 0.1–1 | 1–15 | – | 270–475 | 200–550 | < 380–780 | 0.26–1.63 | < 190–460 | 0.2–15.7 | – | |

| Polypropylene foam | 895–920 | 1.0–2.5 | 0.01–0.8 | – | 360–460 | < 31,190–48,290 | < 20,000–23,200 | 0.02–3 | < 9000–41,400 | < 2.4–900 | NB | |

| Polyurethane foam | 30–100 | 0.59–2 | 0.3–20.0 | – | 278–379 | 2–48,000 | < 210–56,500 | 0.38–1.2 | < 80–103,000 | < 3.2–760 | NB | |

| Silicone foam | 104–164 | 0.15–1 | 0.2–12.0 | – | 250–350 | 8–170 | – | – | 55.2–2800 | < 49–300 | NB | |

| Paper-Based materials | Corrugated Cardboard | 98.3–691 | 5.36–13.45 | 98–161 | 0.52–4 | 260–347 | 7.94–1345.7 | < 770–2510 | – | < 400–3000 | < 6.7–7.7 | 80–88 |

| Paperboard | 200–800 | 1.4–12 | 43–146.4 | 0.5–9 | 250–350 | 591–10,000 | < 60–3200 | 2–4 | < 427–15,000 | 1–3.5 | 80–100 | |

| Paper Honeycomb | 10–321 | 1–20 | 16.6–100 | 0.05–4.5 | – | 100–1680 | < 94.8–4200 | < 4.8–12 | 49.3–22,700 | – | 100 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Aiduang, W.; Jatuwong, K.; Jinanukul, P.; Suwannarach, N.; Kumla, J.; Thamjaree, W.; Teeraphantuvat, T.; Waroonkun, T.; Oranratmanee, R.; Lumyong, S. Sustainable Innovation: Fabrication and Characterization of Mycelium-Based Green Composites for Modern Interior Materials Using Agro-Industrial Wastes and Different Species of Fungi. Polymers 2024, 16, 550. https://doi.org/10.3390/polym16040550

Aiduang W, Jatuwong K, Jinanukul P, Suwannarach N, Kumla J, Thamjaree W, Teeraphantuvat T, Waroonkun T, Oranratmanee R, Lumyong S. Sustainable Innovation: Fabrication and Characterization of Mycelium-Based Green Composites for Modern Interior Materials Using Agro-Industrial Wastes and Different Species of Fungi. Polymers. 2024; 16(4):550. https://doi.org/10.3390/polym16040550

Chicago/Turabian StyleAiduang, Worawoot, Kritsana Jatuwong, Praween Jinanukul, Nakarin Suwannarach, Jaturong Kumla, Wandee Thamjaree, Thana Teeraphantuvat, Tanut Waroonkun, Rawiwan Oranratmanee, and Saisamorn Lumyong. 2024. "Sustainable Innovation: Fabrication and Characterization of Mycelium-Based Green Composites for Modern Interior Materials Using Agro-Industrial Wastes and Different Species of Fungi" Polymers 16, no. 4: 550. https://doi.org/10.3390/polym16040550

APA StyleAiduang, W., Jatuwong, K., Jinanukul, P., Suwannarach, N., Kumla, J., Thamjaree, W., Teeraphantuvat, T., Waroonkun, T., Oranratmanee, R., & Lumyong, S. (2024). Sustainable Innovation: Fabrication and Characterization of Mycelium-Based Green Composites for Modern Interior Materials Using Agro-Industrial Wastes and Different Species of Fungi. Polymers, 16(4), 550. https://doi.org/10.3390/polym16040550