Surface Modification of Flax Fibers with TMCTS-Based PECVD for Improved Thermo-Mechanical Properties of PLA/Flax Fiber Composites

Abstract

1. Introduction

2. Experimental

2.1. Materials and Method

2.2. Sample Preparation for Plasma-Modified Flax Fibers

2.3. Composite Processing

2.4. Characterization Methods

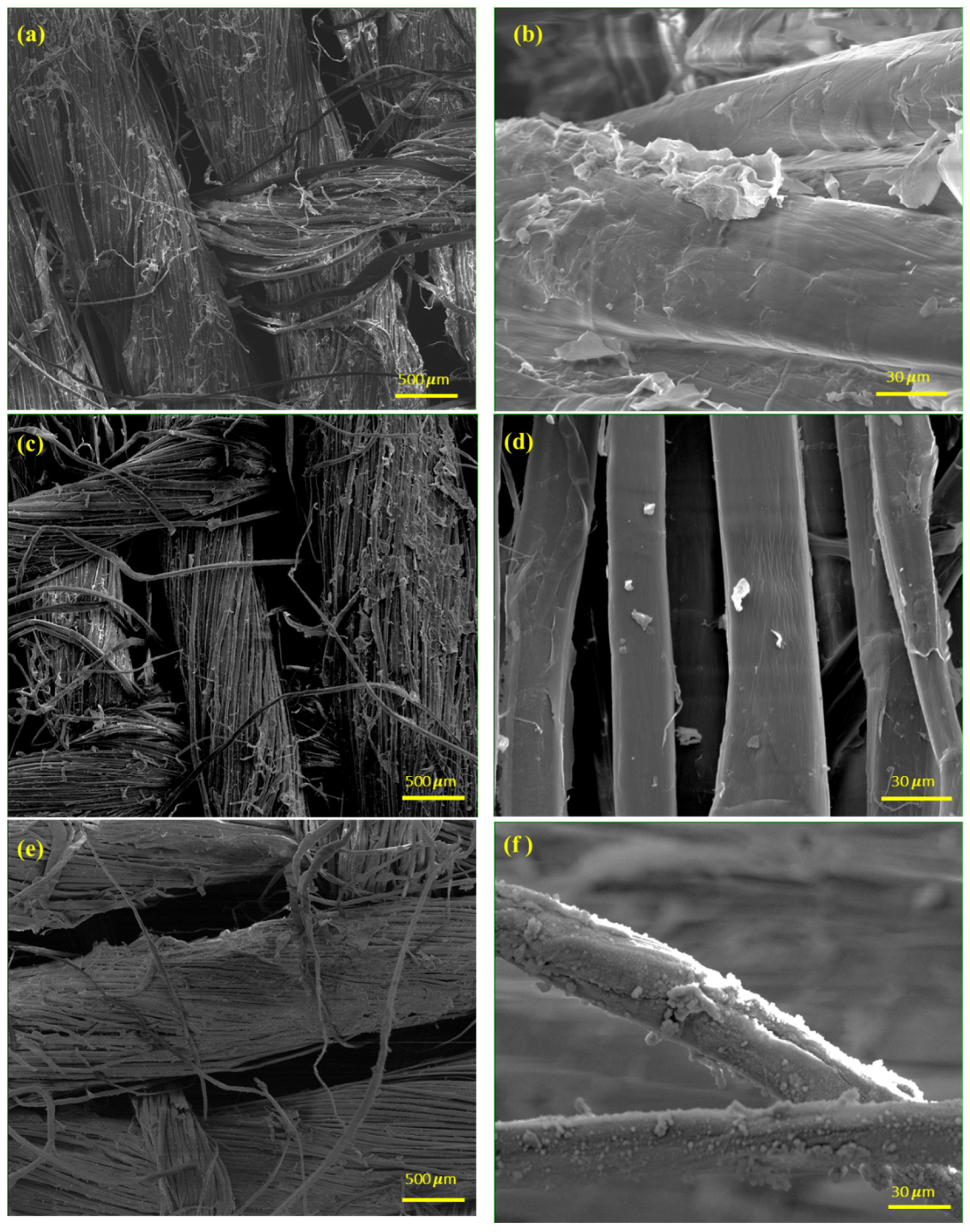

2.4.1. Scanning Electron Microscopy (SEM)

2.4.2. Fourier-Transform Infrared Spectroscopy (FTIR)

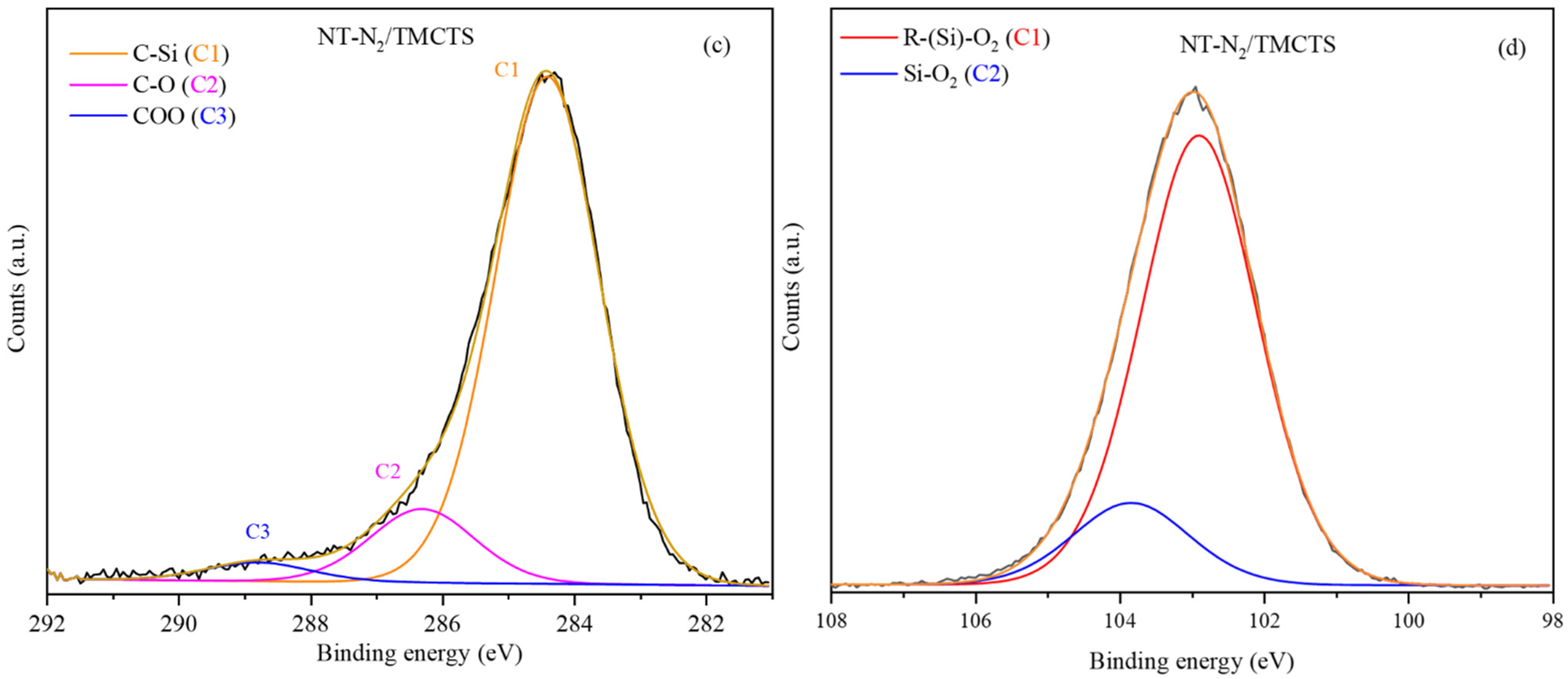

2.4.3. X-ray Photoelectron Spectroscopy (XPS)

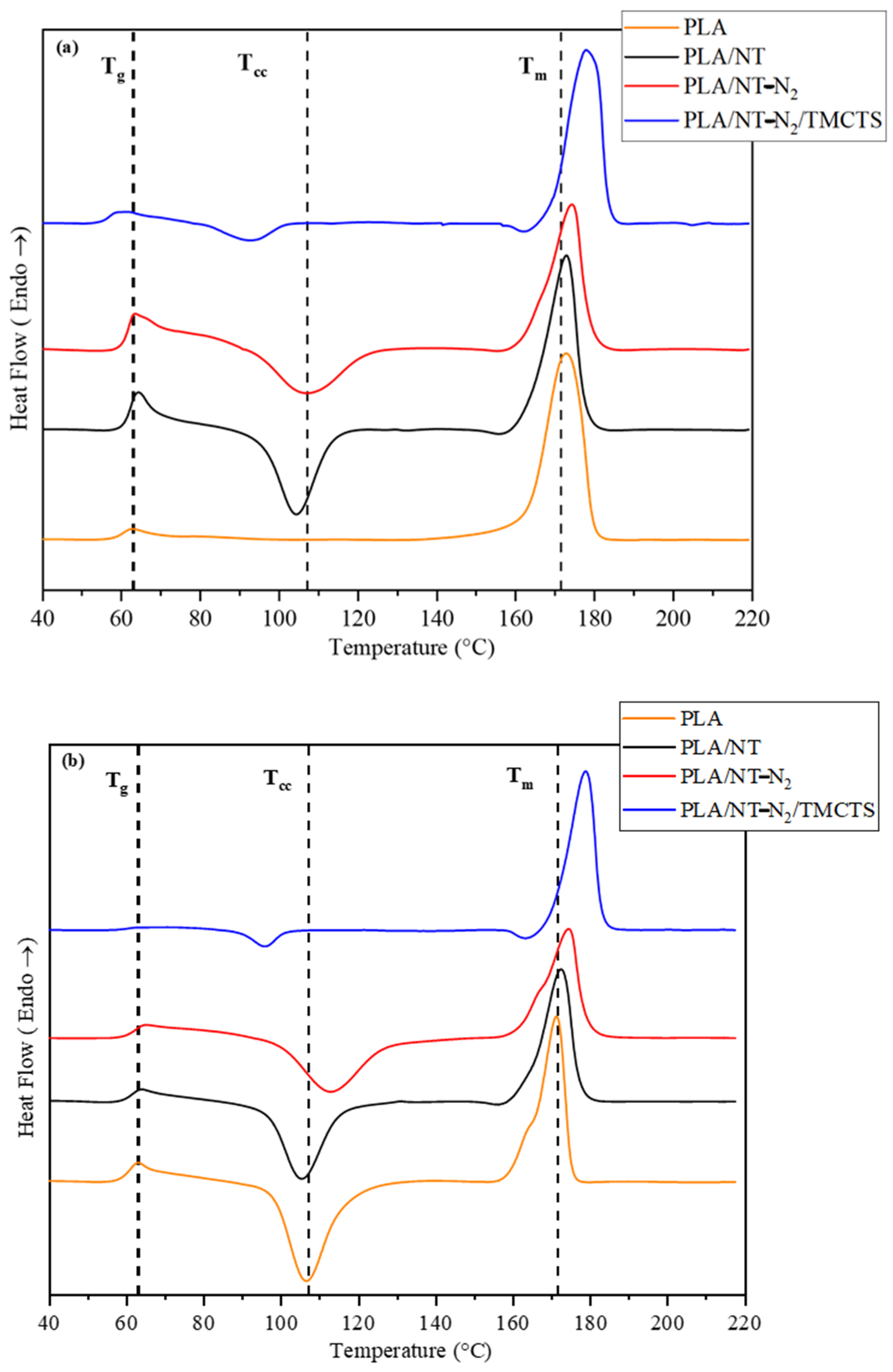

2.4.4. Differential Scanning Calorimetry (DSC)

2.4.5. Dynamic Mechanical Analysis (DMA)

3. Results and Discussion

3.1. Comparative Images of Flax Fibers Pre and Post Treatments

3.2. FTIR of Non-Treated and Treated Flax Fiber

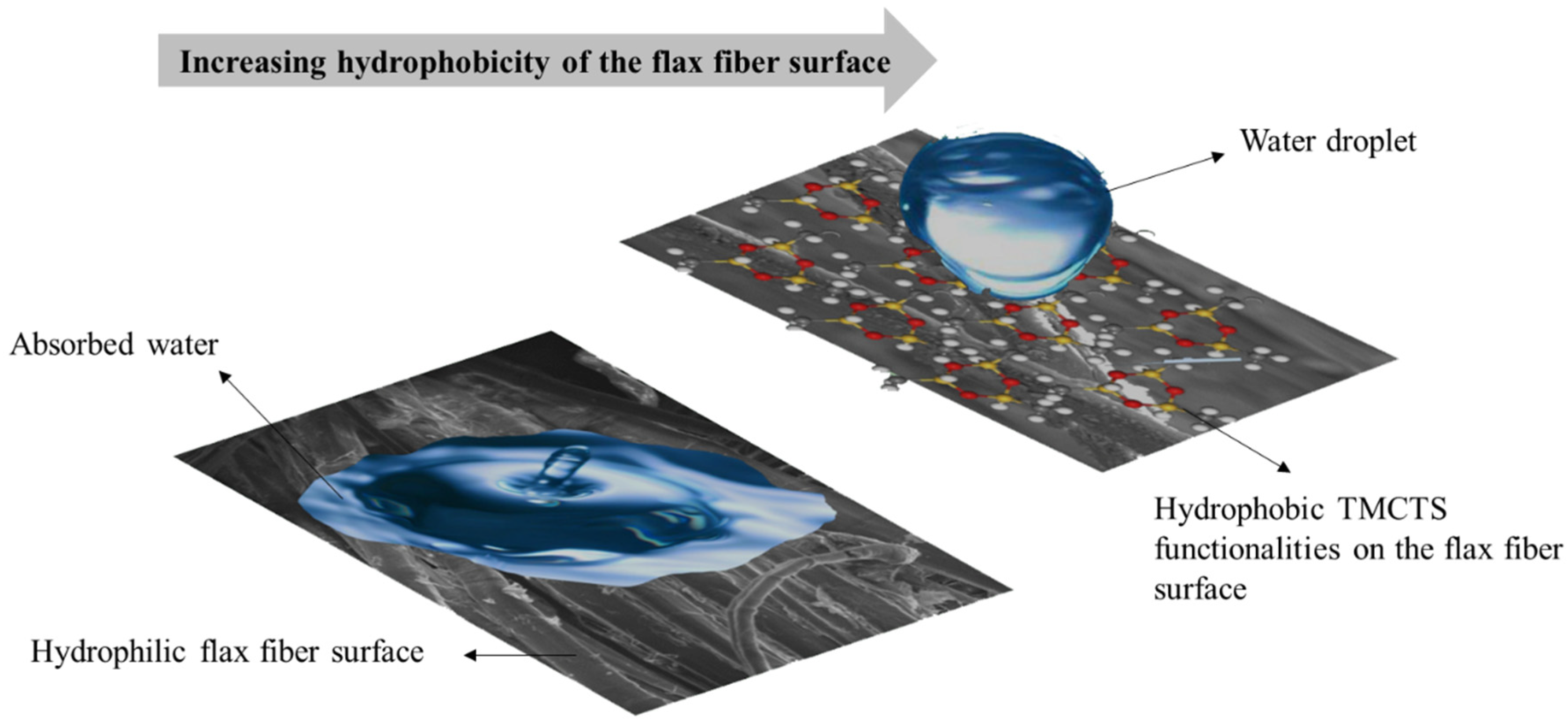

3.3. Contact Angle

3.4. XPS Spectroscopy Examination: Investigating the Surface of Flax Fibers

3.5. Thermal Characterization of PLA/Flax Fiber Composites

3.6. Thermal Mechanical Analysis of PLA/Flax Fiber Composites

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ravindran, G.; Mahesh, V.; Bheel, N.; Chittimalla, S.; Srihitha, K.; Sushmasree, A. Usage of Natural Fibre Composites for Sustainable Material Development: Global Research Productivity Analysis. Buildings 2023, 13, 1260. [Google Scholar] [CrossRef]

- Andrew, J.J.; Dhakal, H. Sustainable biobased composites for advanced applications: Recent trends and future opportunities–A critical review. Compos. Part C Open Access 2022, 7, 100220. [Google Scholar] [CrossRef]

- Samant, L.; Goel, A.; Mathew, J.; Jose, S.; Thomas, S. Effect of surface treatment on flax fiber reinforced natural rubber green composite. J. Appl. Polym. Sci. 2023, 140, e53651. [Google Scholar] [CrossRef]

- Sanivada, U.K.; Mármol, G.; Brito, F.; Fangueiro, R. PLA composites reinforced with flax and jute fibers—A review of recent trends, processing parameters and mechanical properties. Polymers 2020, 12, 2373. [Google Scholar] [CrossRef]

- Shuvo, I.I. Fibre attributes and mapping the cultivar influence of different industrial cellulosic crops (cotton, hemp, flax, and canola) on textile properties. Bioresour. Bioprocess. 2020, 7, 51. [Google Scholar] [CrossRef]

- Teklal, F.; Djebbar, A.; Allaoui, S.; Hivet, G.; Joliff, Y.; Kacimi, B. A review of analytical models to describe pull-out behavior–Fiber/matrix adhesion. Compos. Struct. 2018, 201, 791–815. [Google Scholar] [CrossRef]

- Abdollahiparsa, H.; Shahmirzaloo, A.; Teuffel, P.; Blok, R. A review of recent developments in structural applications of natural fiber-Reinforced composites (NFRCs). Compos. Adv. Mater. 2023, 32, 26349833221147540. [Google Scholar] [CrossRef]

- Thapliyal, D.; Verma, S.; Sen, P.; Kumar, R.; Thakur, A.; Tiwari, A.K.; Singh, D.; Verros, G.D.; Arya, R.K. Natural Fibers Composites: Origin, Importance, Consumption Pattern, and Challenges. J. Compos. Sci. 2023, 7, 506. [Google Scholar] [CrossRef]

- El Hawary, O.; Boccarusso, L.; Ansell, M.P.; Durante, M.; Pinto, F. An overview of natural fiber composites for marine applications. J. Mar. Sci. Eng. 2023, 11, 1076. [Google Scholar] [CrossRef]

- Nassar, M.M.; Alzebdeh, K.I.; Pervez, T.; Al-Hinai, N.; Munam, A. Progress and challenges in sustainability, compatibility, and production of eco-composites: A state-of-art review. J. Appl. Polym. Sci. 2021, 138, 51284. [Google Scholar] [CrossRef]

- Sanjeevi, S.; Shanmugam, V.; Kumar, S.; Ganesan, V.; Sas, G.; Johnson, D.J.; Shanmugam, M.; Ayyanar, A.; Naresh, K.; Neisiany, R.E. Effects of water absorption on the mechanical properties of hybrid natural fibre/phenol formaldehyde composites. Sci. Rep. 2021, 11, 13385. [Google Scholar] [CrossRef]

- Pankaj; Jawalkar, C.; Kant, S. Critical Review on Chemical Treatment of Natural Fibers to Enhance Mechanical Properties of Bio Composites. Silicon 2022, 14, 5103–5124. [Google Scholar] [CrossRef]

- Kathuria, A.; Zhang, S. Sustainable and repulpable barrier coatings for fiber-based materials for food packaging: A review. Front. Mater. 2022, 9, 929501. [Google Scholar] [CrossRef]

- Srinivasa, C.; Ani, A.S.; Prasad, B.J. Protective Coatings for Bio-Composites—A Review; IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2020; p. 012048. [Google Scholar]

- Cech, V.; Marek, A.; Knob, A.; Valter, J.; Branecky, M.; Plihal, P.; Vyskocil, J. Continuous surface modification of glass fibers in a roll-to-roll plasma-enhanced CVD reactor for glass fiber/polyester composites. Compos. Part A Appl. Sci. Manuf. 2019, 121, 244–253. [Google Scholar] [CrossRef]

- Rodríguez-Tobías, H.; Morales, G.; Grande, D. Comprehensive review on electrospinning techniques as versatile approaches toward antimicrobial biopolymeric composite fibers. Mater. Sci. Eng. C 2019, 101, 306–322. [Google Scholar] [CrossRef]

- Natarajan, K.; Krishnasamy, K.; Devarajan, B. Coating of natural fiber composite envisaging through the patent landscape: An overview. J. Appl. Polym. Sci. 2023, 140, e53783. [Google Scholar] [CrossRef]

- Liu, Z.; Tisserat, B.H. Coating applications to natural fiber composites to improve their physical, surface and water absorption characters. Ind. Crops Prod. 2018, 112, 196–199. [Google Scholar] [CrossRef]

- Ishak, A.; Sonnier, R.; Otazaghine, B.; Longuet, C. Silazanes, a novel flax fibers functionalization: Effect on silicone-based composites. Compos. Part A Appl. Sci. Manuf. 2023, 166, 107382. [Google Scholar] [CrossRef]

- Sawangrat, C.; Thipchai, P.; Kaewapai, K.; Jantanasakulwong, K.; Suhr, J.; Wattanachai, P.; Rachtanapun, P. Surface Modification and Mechanical Properties Improvement of Bamboo Fibers Using Dielectric Barrier Discharge Plasma Treatment. Polymers 2023, 15, 1711. [Google Scholar] [CrossRef]

- Mohammed, M.; Rahman, R.; Mohammed, A.M.; Adam, T.; Betar, B.O.; Osman, A.F.; Dahham, O.S. Surface treatment to improve water repellence and compatibility of natural fiber with polymer matrix: Recent advancement. Polym. Test. 2022, 115, 107707. [Google Scholar] [CrossRef]

- Gupta, U.S.; Dhamarikar, M.; Dharkar, A.; Chaturvedi, S.; Kumrawat, A.; Giri, N.; Tiwari, S.; Namdeo, R. Plasma modification of natural fiber: A review. Mater. Today Proc. 2021, 43, 451–457. [Google Scholar] [CrossRef]

- Kocaman, S.; Karaman, M.; Gursoy, M.; Ahmetli, G. Chemical and plasma surface modification of lignocellulose coconut waste for the preparation of advanced biobased composite materials. Carbohydr. Polym. 2017, 159, 48–57. [Google Scholar] [CrossRef]

- Pillai, R.; Batra, N.; Manocha, L.; Machinewala, N. Deposition of silicon carbide interface coating on carbon fibre by PECVD for advanced composites. Surf. Interfaces 2017, 7, 113–115. [Google Scholar] [CrossRef]

- Samanta, K.K.; Joshi, A.G.; Jassal, M.; Agrawal, A.K. Study of hydrophobic finishing of cellulosic substrate using He/1, 3-butadiene plasma at atmospheric pressure. Surf. Coat. Technol. 2012, 213, 65–76. [Google Scholar] [CrossRef]

- Özdoğan, E.; Karaca Uğural, B.; Demir, A.; Kurt, A. Effects of alkaline and atmospheric plasma treatments on mechanical properties and CO2 emissions of flax/polypropylene composites. J. Text. Inst. 2023, 114, 656–663. [Google Scholar] [CrossRef]

- Téraube, O.; Gratier, L.; Agopian, J.-C.; Pucci, M.F.; Liotier, P.-J.; Hajjar-Garreau, S.; Petit, E.; Batisse, N.; Bousquet, A.; Charlet, K. Elaboration of hydrophobic flax fibers through fluorine plasma treatment. Appl. Surf. Sci. 2023, 611, 155615. [Google Scholar] [CrossRef]

- Moradkhani, G.; Profili, J.; Robert, M.; Laroche, G.; Elkoun, S. Effects of Wet and Dry Treatments on Surface Functional Groups and Mechanical Properties of Flax Fiber Composites. Coatings 2023, 13, 1036. [Google Scholar] [CrossRef]

- Profili, J.; Asadollahi, S.; Vinchon, P.; Dorris, A.; Beck, S.; Sarkassian, A.; Stafford, L. Recent progress on organosilicon coatings deposited on bleached unrefined Kraft paper by non-thermal plasma process at atmospheric pressure. Prog. Org. Coat. 2020, 147, 105865. [Google Scholar] [CrossRef]

- Denes, A.R.; Tshabalala, M.A.; Rowell, R.; Denes, F.; Young, R.A. Hexamethyldisiloxane-plasma coating of wood surfaces for creating water repellent characteristics. Holzforschung 1999, 53, 318–326. [Google Scholar] [CrossRef]

- Vârban, R.; Crișan, I.; Vârban, D.; Ona, A.; Olar, L.; Stoie, A.; Ștefan, R. Comparative FT-IR prospecting for cellulose in stems of some fiber plants: Flax, velvet leaf, hemp and jute. Appl. Sci. 2021, 11, 8570. [Google Scholar] [CrossRef]

- Margariti, C. The application of FTIR microspectroscopy in a non-invasive and non-destructive way to the study and conservation of mineralised excavated textiles. Herit. Sci. 2019, 7, 63. [Google Scholar] [CrossRef]

- Makarem, M.; Lee, C.M.; Kafle, K.; Huang, S.; Chae, I.; Yang, H.; Kubicki, J.D.; Kim, S.H. Probing cellulose structures with vibrational spectroscopy. Cellulose 2019, 26, 35–79. [Google Scholar] [CrossRef]

- Makhlouf, A.; Belaadi, A.; Amroune, S.; Bourchak, M.; Satha, H. Elaboration and characterization of flax fiber reinforced high density polyethylene biocomposite: Effect of the heating rate on thermo-mechanical properties. J. Nat. Fibers 2022, 19, 3928–3941. [Google Scholar] [CrossRef]

- Paukshtis, E.A.; Yaranova, M.A.; Batueva, I.S.; Bal’zhinimaev, B.S. A FTIR study of silanol nests over mesoporous silicate materials. Microporous Mesoporous Mater. 2019, 288, 109582. [Google Scholar] [CrossRef]

- Babaei, S.; Profili, J.; Al Rashidi, M.; Dorris, A.; Beck, S.; Asadollahi, S.; Sarkissian, A.; Stafford, L. Permeation properties of a plasma-processed organosilicon–carboxymethylcellulose bilayer on fibrillated cellulosic films for sustainable packaging applications. Cellulose 2023, 30, 7889–7904. [Google Scholar] [CrossRef]

- Blanchard, N.E.; Naik, V.V.; Geue, T.; Kahle, O.; Hegemann, D.; Heuberger, M. Response of plasma-polymerized hexamethyldisiloxane films to aqueous environments. Langmuir 2015, 31, 12944–12953. [Google Scholar] [CrossRef]

- Levasseur, O.; Kumar Gangwar, R.; Profili, J.; Naudé, N.; Gherardi, N.; Stafford, L. Influence of substrate outgassing on the plasma properties during wood treatment in He dielectric barrier discharges at atmospheric pressure. Plasma Process. Polym. 2017, 14, 1600172. [Google Scholar] [CrossRef]

- Profili, J.; Babaei, S.; Al Rashidi, M.; Dorris, A.; Asadollahi, S.; Sarkissian, A.; Stafford, L. Plasma-Deposited Organosilicon Hydrophobic Coatings on Cellulosic Materials for Wet Packaging Applications. Coatings 2023, 13, 924. [Google Scholar] [CrossRef]

- Asadollahi, S.; Profili, J.; Farzaneh, M.; Stafford, L. Development of organosilicon-based superhydrophobic coatings through atmospheric pressure plasma polymerization of HMDSO in nitrogen plasma. Materials 2019, 12, 219. [Google Scholar] [CrossRef]

- Liu, H.; Song, W.; Chen, F.; Guo, L.; Zhang, J. Interaction of microstructure and interfacial adhesion on impact performance of polylactide (PLA) ternary blends. Macromolecules 2011, 44, 1513–1522. [Google Scholar] [CrossRef]

- Pilla, S.; Kramschuster, A.; Lee, J.; Auer, G.K.; Gong, S.; Turng, L.-S. Microcellular and solid polylactide–flax fiber composites. Compos. Interfaces 2009, 16, 869–890. [Google Scholar] [CrossRef]

- Xia, X.; Shi, X.; Liu, W.; Zhao, H.; Li, H.; Zhang, Y. Effect of flax fiber content on polylactic acid (PLA) crystallization in PLA/flax fiber composites. Iran. Polym. J. 2017, 26, 693–702. [Google Scholar] [CrossRef]

- Kaseem, M.; Ur Rehman, Z.; Hossain, S.; Singh, A.K.; Dikici, B. A review on synthesis, properties, and applications of polylactic acid/silica composites. Polymers 2021, 13, 3036. [Google Scholar] [CrossRef] [PubMed]

- Shen, Y.; Tan, J.; Fernandes, L.; Qu, Z.; Li, Y. Dynamic mechanical analysis on delaminated flax fiber reinforced composites. Materials 2019, 12, 2559. [Google Scholar] [CrossRef] [PubMed]

| Peak Location (cm−1) | Bond | Component |

|---|---|---|

| 3650–3700 | Si-OH | Isolated silanol |

| 3344 | ν (OH) | Hydrogen bonds |

| 2915, 2850 | ν (CH2) | Waxes |

| 1640 | δ (OH) | Adsorbed water within the fibre |

| 1432 | δ (CH3) | Aromatic lignin |

| 1370 | δ (CH) | Cellulose |

| 1335, 1315 | δ (CH2) | Cellulose |

| 1270 | ν (Si–CH3) | Silicon methyl group |

| 1160 | ν (C–C) | Polysaccharides in cellulose |

| 1108 | ν (C–O–C) | Polysaccharides in cellulose |

| 1056, 1033 | ν (C–OH) | Cellulose |

| 900 | ν (C–O–C) | Cellulose |

| 796 | ν (Si–O) | Silicone |

| Sample Name | Atomic Percentage | Relative Atomic% | ||||

|---|---|---|---|---|---|---|

| C | O | N | Si | [Si]/[C] | [O]/[Si] | |

| NT | 75.12 | 24.26 | 0.36 | 0.25 | 0 | 97.04 |

| NT/N2 | 64.76 | 31.26 | 1.74 | 2.23 | 0.03 | 14.01 |

| NT/N2-TMCTS | 25.29 | 52 | 0 | 22.71 | 0.9 | 2.29 |

| Name | First Heating | Second Heating | ||||||

|---|---|---|---|---|---|---|---|---|

| Tg (°C) | Tcc (°C) | Tm (°C) | XC (%) | Tg (°C) | Tcc (°C) | Tm (°C) | XC (%) | |

| PLA | 63 | - | 173 | 57.81 | 63.1 | 106.6 | 171.4 | 48.41 |

| PLA/NT | 64.3 | 104.4 | 173.2 | 76.35 | 63.1 | 106.7 | 171.5 | 78.75 |

| PLA/NT-N2 | 63.7 | 107.0 | 174.4 | 69.25 | 65.1 | 113 | 174.5 | 78.99 |

| PLA/NT-N2-TMCTS | 59.46 | 93.03 | 178 | 79.93 | 62.0 | 96 | 179 | 83.17 |

| Sample | (Tg) | (E′) | (E″) | Tanδ at Tg |

|---|---|---|---|---|

| PLA | 68.65 | 3428 | 236 | 70.43 |

| PLA/NT | 59.25 | 6468 | 498 | 69.24 |

| PLA/NT-N2 | 64.77 | 6729 | 1226 | 65.76 |

| PLA/NT-N2-TMCTS | 61.66 | 8051 | 1464 | 64.77 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Moradkhani, G.; Profili, J.; Robert, M.; Laroche, G.; Elkoun, S.; Mighri, F. Surface Modification of Flax Fibers with TMCTS-Based PECVD for Improved Thermo-Mechanical Properties of PLA/Flax Fiber Composites. Polymers 2024, 16, 360. https://doi.org/10.3390/polym16030360

Moradkhani G, Profili J, Robert M, Laroche G, Elkoun S, Mighri F. Surface Modification of Flax Fibers with TMCTS-Based PECVD for Improved Thermo-Mechanical Properties of PLA/Flax Fiber Composites. Polymers. 2024; 16(3):360. https://doi.org/10.3390/polym16030360

Chicago/Turabian StyleMoradkhani, Ghane, Jacopo Profili, Mathieu Robert, Gaétan Laroche, Saïd Elkoun, and Frej Mighri. 2024. "Surface Modification of Flax Fibers with TMCTS-Based PECVD for Improved Thermo-Mechanical Properties of PLA/Flax Fiber Composites" Polymers 16, no. 3: 360. https://doi.org/10.3390/polym16030360

APA StyleMoradkhani, G., Profili, J., Robert, M., Laroche, G., Elkoun, S., & Mighri, F. (2024). Surface Modification of Flax Fibers with TMCTS-Based PECVD for Improved Thermo-Mechanical Properties of PLA/Flax Fiber Composites. Polymers, 16(3), 360. https://doi.org/10.3390/polym16030360