Enhanced Feedstock Processability for the Indirect Additive Manufacturing of Metals by Material Extrusion through Ethylene–Propylene Copolymer Modification

Abstract

1. Introduction

2. Experimental Section

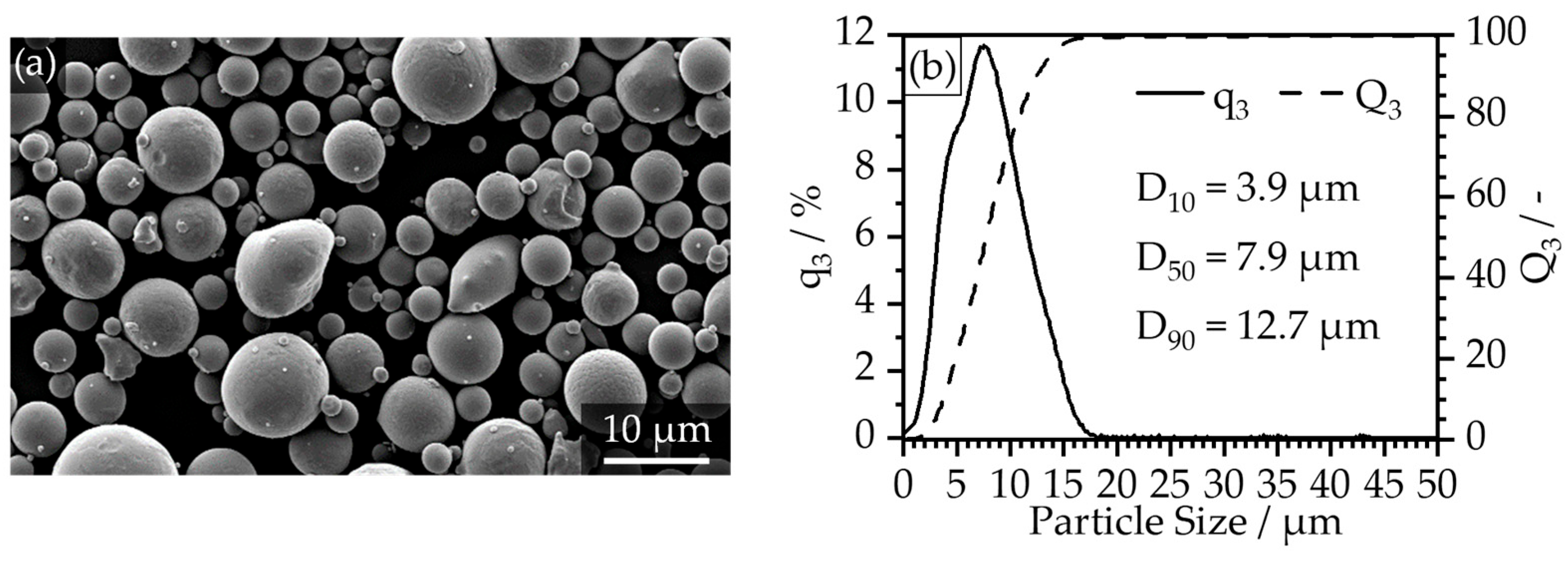

2.1. Materials

2.2. Processing

2.3. Methods

3. Results and Discussion

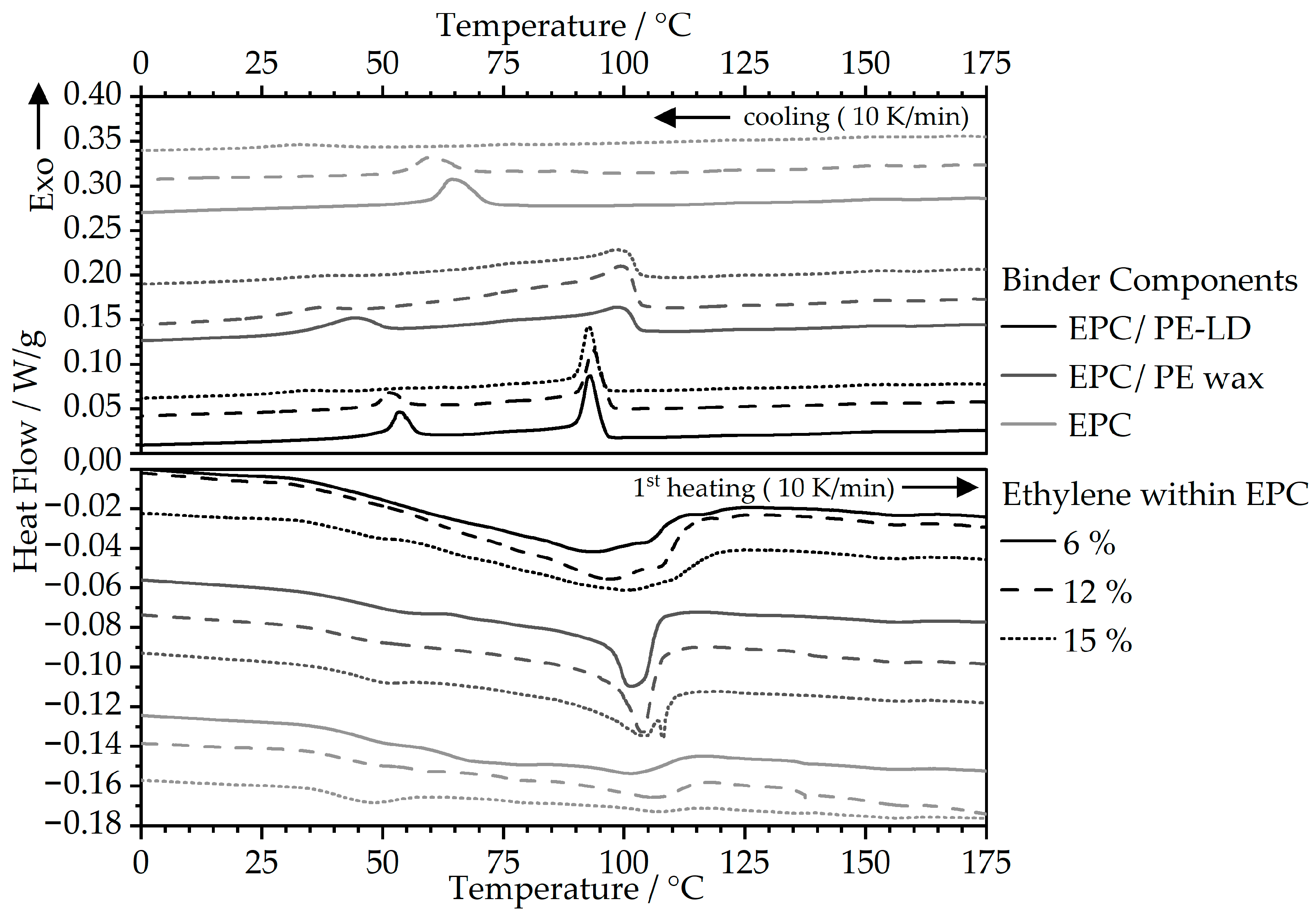

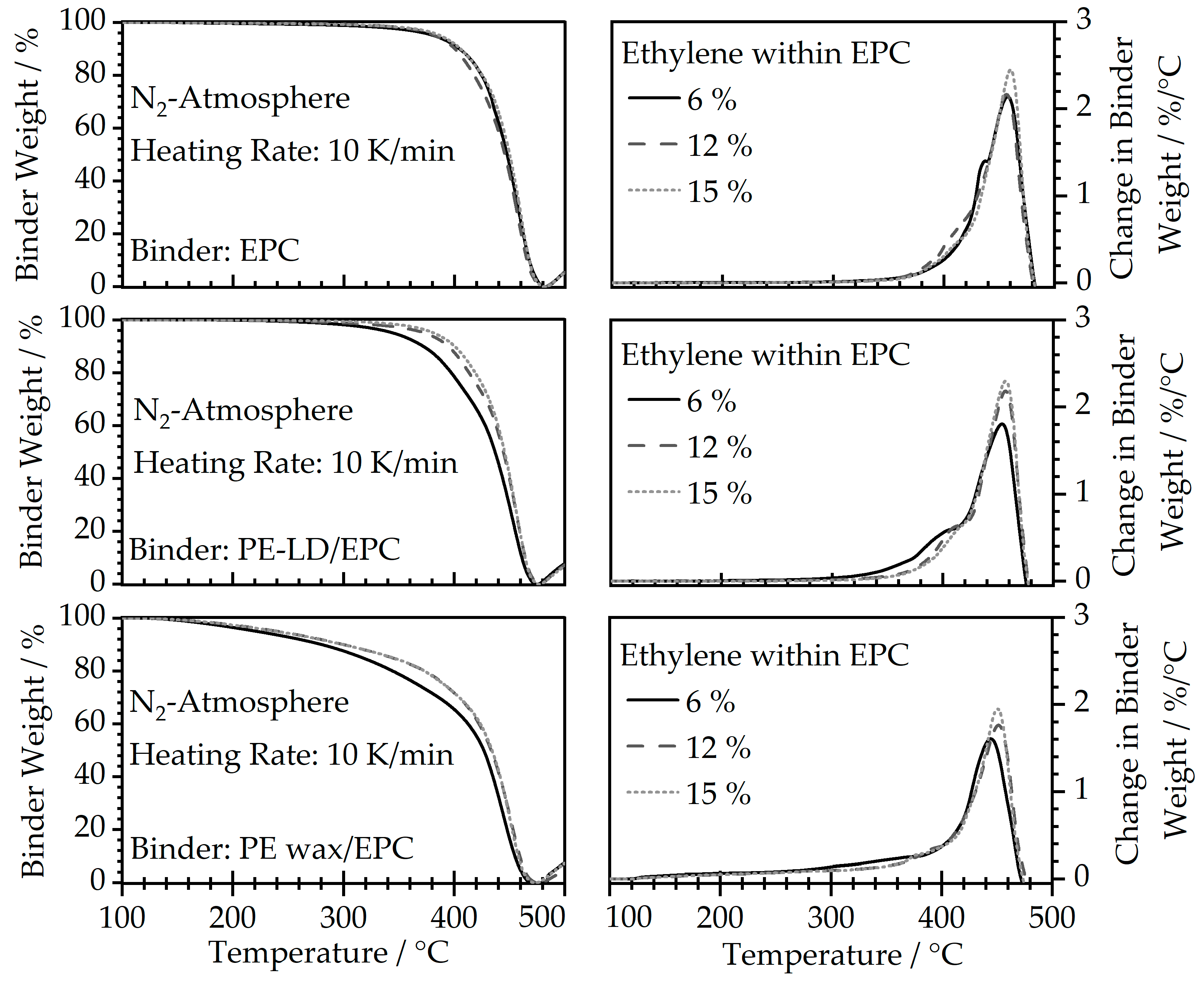

3.1. Thermal Behavior

3.2. Mechanical Properties

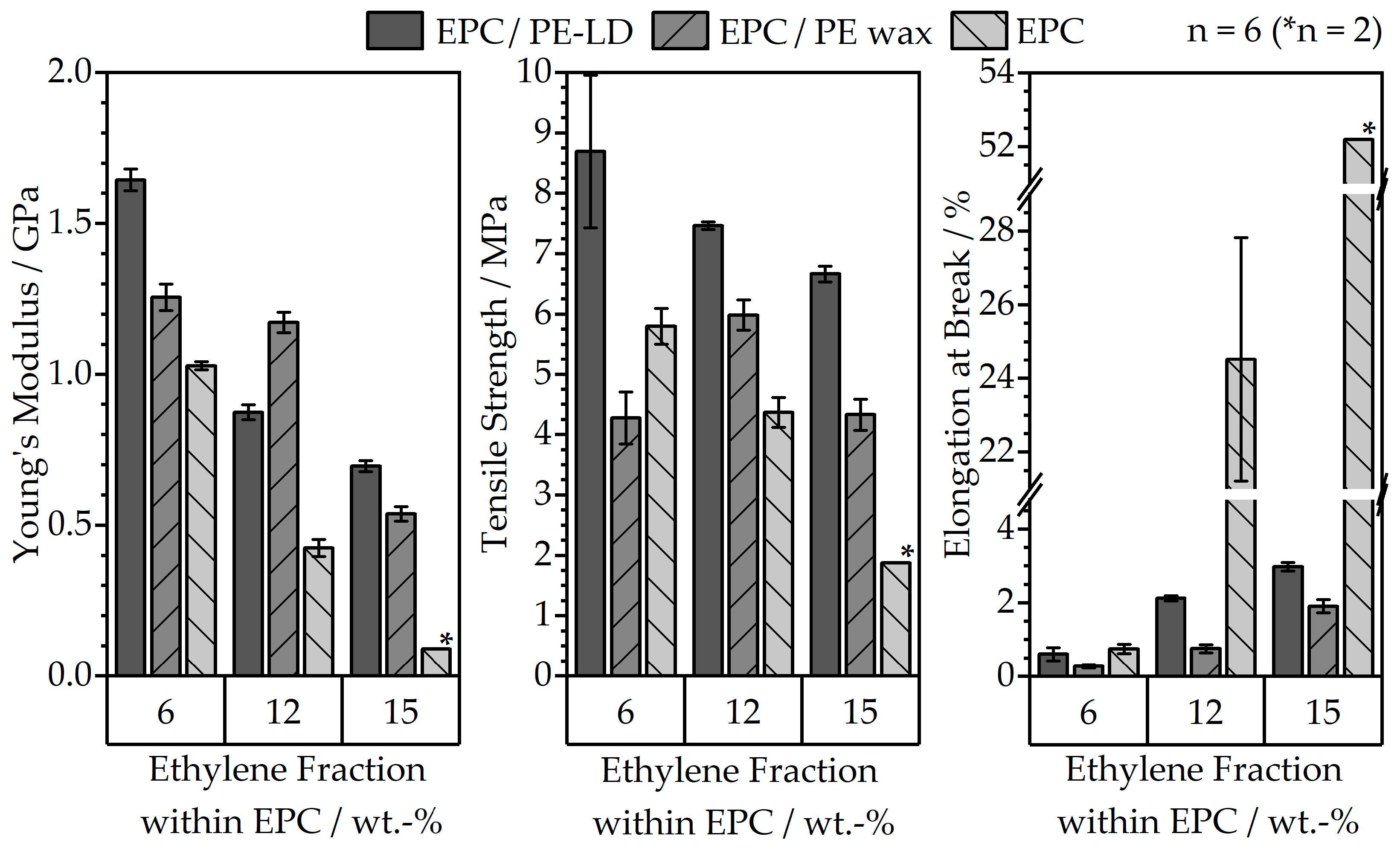

3.2.1. Tensile Properties

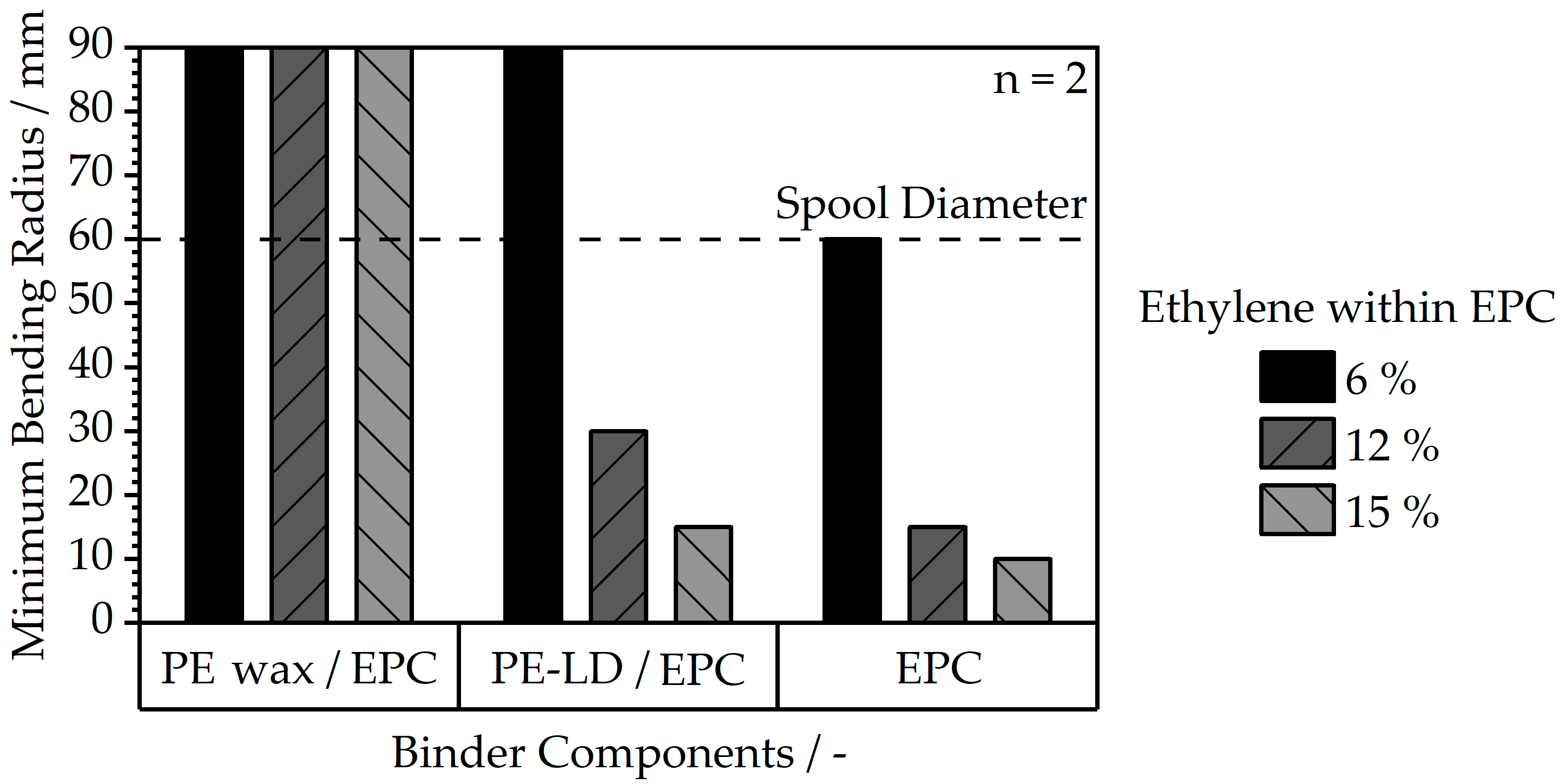

3.2.2. Filament Flexibility

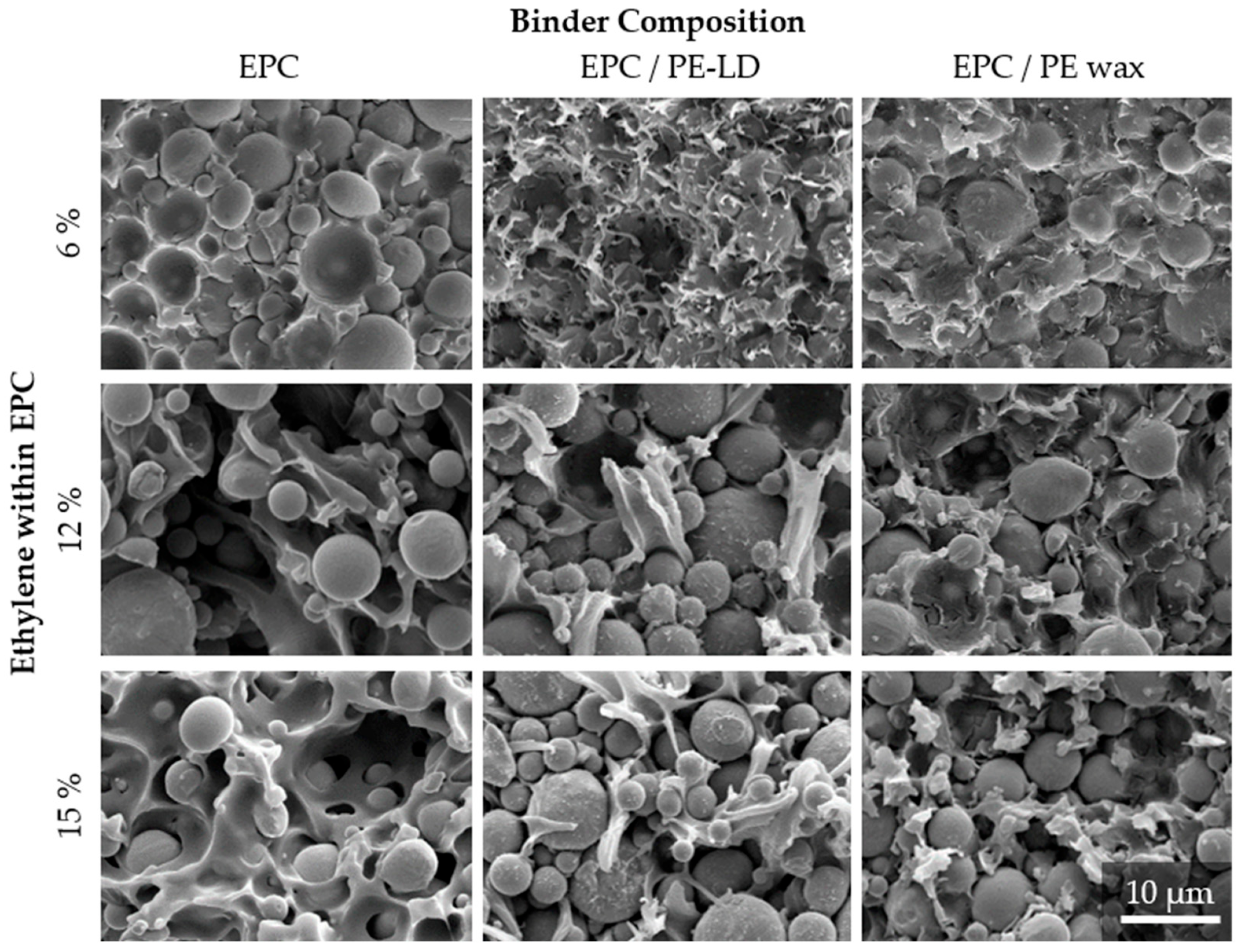

3.2.3. Fracture Morphology

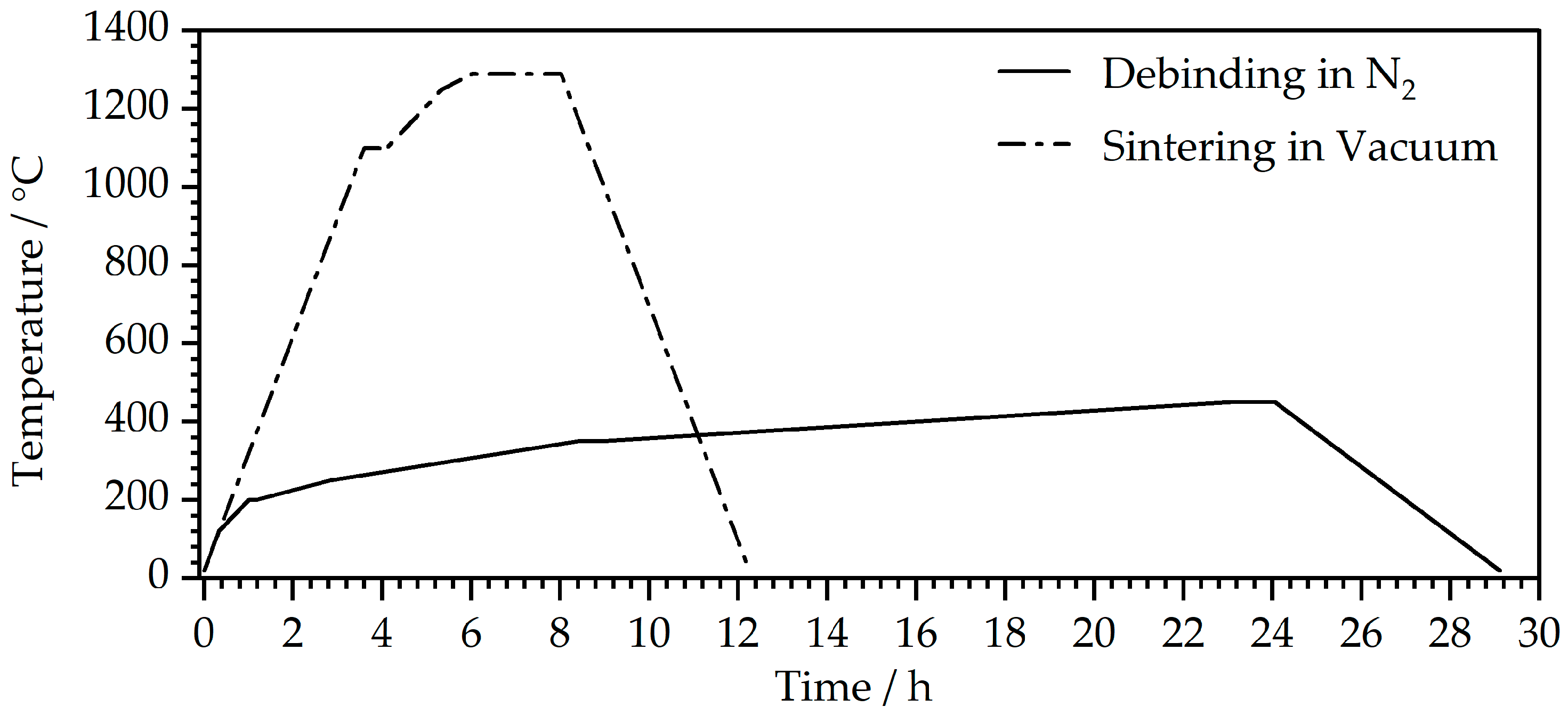

3.3. Debinding Behavior

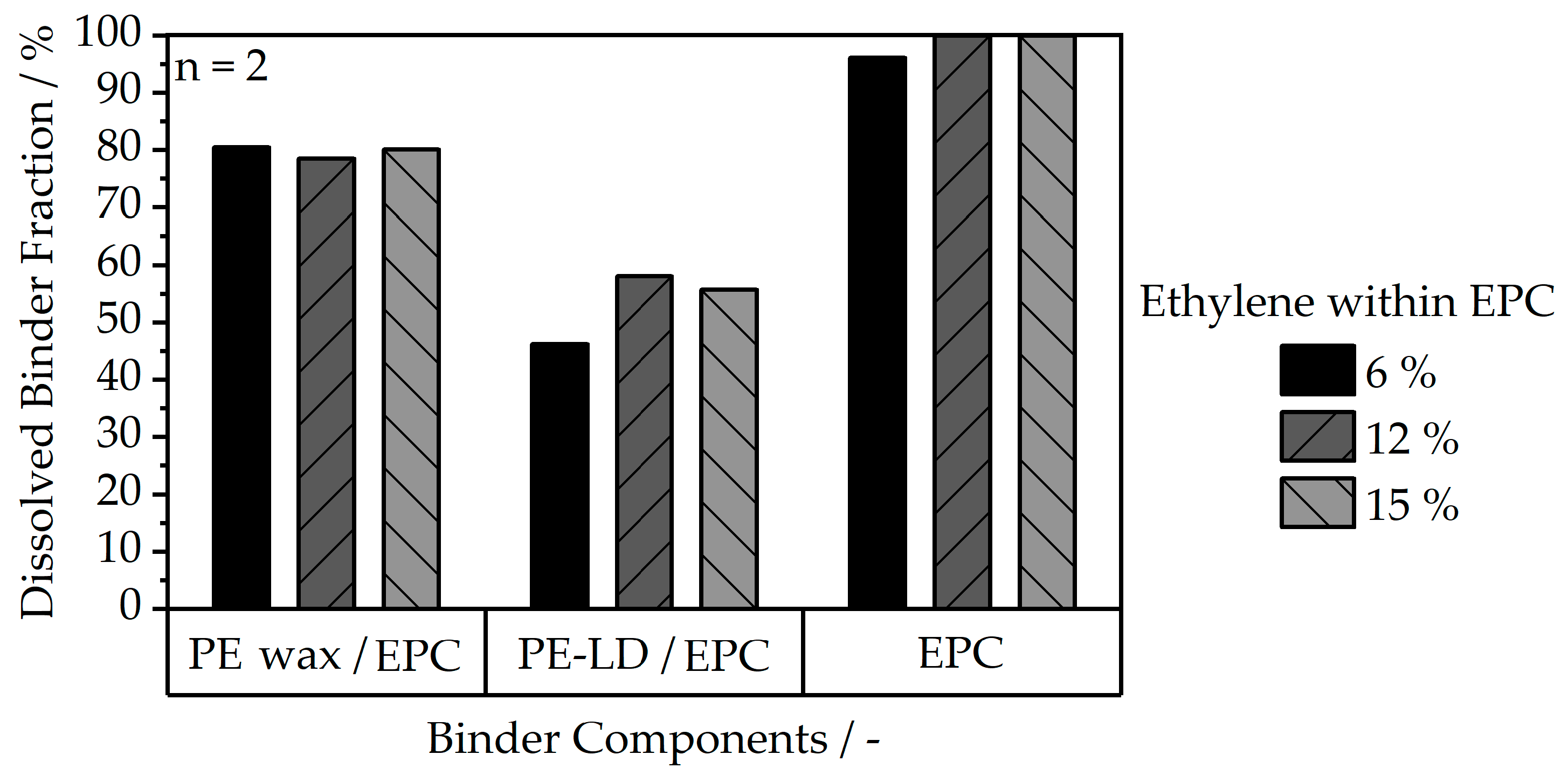

3.3.1. Solvent Debinding

3.3.2. Thermal Debinding

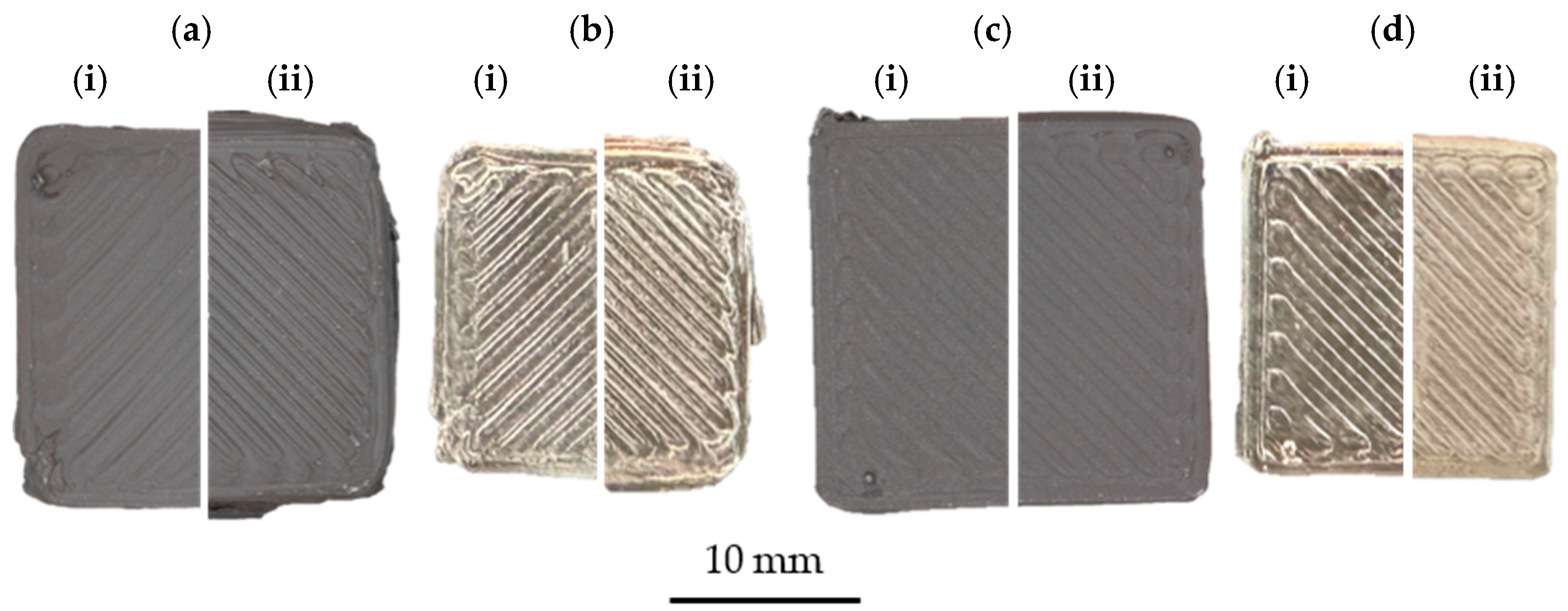

3.4. Processability in MEX

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wohlers, T.; Campbell, R.I.; Diegel, O.; Huff, R.; Kowen, J. Wohlers Report 2023: 3D Printing and Additive Manufacturing: Global State of the Industry; Wohlers Associates: Washington, DC, USA; ASTM International: Fort Collins, CO, USA, 2023; ISBN 9781622049660. [Google Scholar]

- DIN EN ISO ASTM 52900:2021; Additive Fertigun—Terminologie. Beuth Verlag GmbH: Berlin, Germany, 2022.

- Dua, R.; Rashad, Z.; Spears, J.; Dunn, G.; Maxwell, M. Applications of 3D-Printed PEEK via Fused Filament Fabrication: A Systematic Review. Polymers 2021, 13, 4046. [Google Scholar] [CrossRef] [PubMed]

- Jiang, D.; Smith, D.E. Anisotropic mechanical properties of oriented carbon fiber filled polymer composites produced with fused filament fabrication. Addit. Manuf. 2017, 18, 84–94. [Google Scholar] [CrossRef]

- Naranjo-Lozada, J.; Ahuett-Garza, H.; Orta-Castañón, P.; Verbeeten, W.M.H.; Sáiz-González, D. Tensile properties and failure behavior of chopped and continuous carbon fiber composites produced by additive manufacturing. Addit. Manuf. 2019, 26, 227–241. [Google Scholar] [CrossRef]

- Cai, Z.; Thirunavukkarasu, N.; Diao, X.; Wang, H.; Wu, L.; Zhang, C.; Wang, J. Progress of Polymer-Based Thermally Conductive Materials by Fused Filament Fabrication: A Comprehensive Review. Polymers 2022, 14, 4297. [Google Scholar] [CrossRef]

- Tan, J.C.; Low, H.Y. Embedded electrical tracks in 3D printed objects by fused filament fabrication of highly conductive composites. Addit. Manuf. 2018, 23, 294–302. [Google Scholar] [CrossRef]

- Schmitz, D.P.; Dul, S.; Ramoa, S.D.A.S.; Soares, B.G.; Barra, G.M.O.; Pegoretti, A. Effect of printing parameters on the electromagnetic shielding efficiency of ABS/carbonaceous-filler composites manufactured via filament fused fabrication. J. Manuf. Process. 2021, 65, 12–19. [Google Scholar] [CrossRef]

- Gonzalez-Gutierrez, J.; Cano, S.; Schuschnigg, S.; Kukla, C.; Sapkota, J.; Holzer, C. Additive Manufacturing of Metallic and Ceramic Components by the Material Extrusion of Highly-Filled Polymers: A Review and Future Perspectives. Materials 2018, 11, 840. [Google Scholar] [CrossRef]

- Heaney, D.F. (Ed.) Handbook of Metal Injection Molding; Elsevier: Amsterdam, The Netherlands, 2019; ISBN 9780081021521. [Google Scholar]

- Thompson, Y.; Gonzalez-Gutierrez, J.; Kukla, C.; Felfer, P. Fused filament fabrication, debinding and sintering as a low cost additive manufacturing method of 316L stainless steel. Addit. Manuf. 2019, 30, 100861. [Google Scholar] [CrossRef]

- Singh, P.; Shaikh, Q.; Balla, V.K.; Atre, S.V.; Kate, K.H. Estimating Powder-Polymer Material Properties Used in Design for Metal Fused Filament Fabrication (DfMF3). JOM 2020, 72, 485–495. [Google Scholar] [CrossRef]

- Kantaros, A.; Soulis, E.; Petrescu, F.I.T.; Ganetsos, T. Advanced Composite Materials Utilized in FDM/FFF 3D Printing Manufacturing Processes: The Case of Filled Filaments. Materials 2023, 16, 6210. [Google Scholar] [CrossRef]

- German, R.M. Powder Injection Molding; Metal Powder Industries Federation: Princeton, NJ, USA, 1990; ISBN 0-918404-95-9. [Google Scholar]

- Bek, M.; Gonzalez-Gutierrez, J.; Kukla, C.; Pušnik Črešnar, K.; Maroh, B.; Slemenik Perše, L. Rheological Behaviour of Highly Filled Materials for Injection Moulding and Additive Manufacturing: Effect of Particle Material and Loading. Appl. Sci. 2020, 10, 7993. [Google Scholar] [CrossRef]

- Ren, L.; Zhou, X.; Song, Z.; Zhao, C.; Liu, Q.; Xue, J.; Li, X. Process Parameter Optimization of Extrusion-Based 3D Metal Printing Utilizing PW-LDPE-SA Binder System. Materials 2017, 10, 305. [Google Scholar] [CrossRef] [PubMed]

- Shivashankar, T.S.; Enneti, R.K.; Park, S.-J.; German, R.M.; Atre, S.V. The effects of material attributes on powder–binder separation phenomena in powder injection molding. Powder Technol. 2013, 243, 79–84. [Google Scholar] [CrossRef]

- Forstner, T.; Cholewa, S.; Drummer, D. Influence of wax addition on feedstock processing behavior in additive manufacturing of metals by material extrusion. Prog. Addit. Manuf. 2024, 9, 625–632. [Google Scholar] [CrossRef]

- Kopping, J.T.; Hermant, M.-C.; Schmidt, K.; Nestle, K.; Koehler, A. Filaments for Us as Support Material in Fused Deposition Modeling. U.S. Patent No. 11,434,587, 6 September 2022. [Google Scholar]

- Zhang, Z.; Gao, X. Polypropylene Random Copolymer Based Composite Used for Fused Filament Fabrication: Printability and Properties. Polymers 2022, 14, 1106. [Google Scholar] [CrossRef]

- Gahleitner, M.; Tranninger, C.; Doshev, P. Heterophasic copolymers of polypropylene: Development, design principles, and future challenges. J. Appl. Polym. Sci 2013, 130, 3028–3037. [Google Scholar] [CrossRef]

- Zanchin, G.; Leone, G. Polyolefin thermoplastic elastomers from polymerization catalysis: Advantages, pitfalls and future challenges. Prog. Polym. Sci. 2021, 113, 101342. [Google Scholar] [CrossRef]

- Gahleitner, M.; Jääskeläinen, P.; Ratajski, E.; Paulik, C.; Reussner, J.; Wolfschwenger, J.; Neißl, W. Propylene–ethylene random copolymers: Comonomer effects on crystallinity and application properties. J. Appl. Polym. Sci 2005, 95, 1073–1081. [Google Scholar] [CrossRef]

- Thompson, Y.; Polzer, M.; Gonzalez-Gutierrez, J.; Kasian, O.; Heckl, J.P.; Dalbauer, V.; Kukla, C.; Felfer, P.J. Fused Filament Fabrication-Based Additive Manufacturing of Commercially Pure Titanium. Adv. Eng. Mater. 2021, 23, 2100380. [Google Scholar] [CrossRef]

- Singh, P.; Balla, V.K.; Gokce, A.; Atre, S.V.; Kate, K.H. Additive manufacturing of Ti-6Al-4V alloy by metal fused filament fabrication (MF3): Producing parts comparable to that of metal injection molding. Prog. Addit. Manuf. 2021, 6, 593–606. [Google Scholar] [CrossRef]

- DIN EN ISO 527-1:2019-12; Kunststoffe—Bestimmung der Zugeigenschaften—Teil 1: Allgemeine Grundsätze (ISO 527-1:2019); Deutsche Fassung EN ISO 527-1:2019. Beuth Verlag GmbH: Berlin, Germany, 2019.

- VDI 3405 Blatt 4.1:2021-04; Additive Fertigungsverfahren—Ergänzungen zu ISO/ASTM 52903-1: Materialextrusion von Kunststoffbauteilen—Charakterisierung des Filaments. Beuth Verlag GmbH: Berlin, Germany, 2021.

- Alamo, R.G.; VanderHart, D.L.; Nyden, M.R.; Mandelkern, L. Morphological Partitioning of Ethylene Defects in Random Propylene−Ethylene Copolymers. Macromolecules 2000, 33, 6094–6105. [Google Scholar] [CrossRef]

- Ghasemi-Mobarakeh, L.; Cano, S.; Momeni, V.; Liu, D.; Duretek, I.; Riess, G.; Kukla, C.; Holzer, C. Effect of Increased Powder-Binder Adhesion by Backbone Grafting on the Properties of Feedstocks for Ceramic Injection Molding. Polymers 2022, 14, 3653. [Google Scholar] [CrossRef] [PubMed]

- Md Ani, S.; Muchtar, A.; Muhamad, N.; Ghani, J.A. Binder removal via a two-stage debinding process for ceramic injection molding parts. Ceram. Int. 2014, 40, 2819–2824. [Google Scholar] [CrossRef]

- Santamaria, R.; Salasi, M.; Bakhtiari, S.; Leadbeater, G.; Iannuzzi, M.; Quadir, M.Z. Microstructure and mechanical behaviour of 316L stainless steel produced using sinter-based extrusion additive manufacturing. J. Mater. Sci. 2022, 57, 9646–9662. [Google Scholar] [CrossRef]

- Carminati, M.; D’Urso, G.; Giardini, C. The enhancement of mechanical properties via post-heat treatments of AISI 630 parts printed with material extrusion. Prog. Addit. Manuf. 2023, 8, 1341–1355. [Google Scholar] [CrossRef]

- Obadimu, S.O.; Kourousis, K.I. Shrinkage behaviour of material extrusion steel 316L: Influence of primary 3D printing parameters. Rapid Prototyp. J. 2022, 28, 92–101. [Google Scholar] [CrossRef]

| Component 1 | Component 2 (EPC) | Metal Powder | ||

|---|---|---|---|---|

| Type | Share /vol. % | EPC Share /vol. % | Ethylene in EPC 1 /wt. % | Share /vol. % |

| - | - | 40 | 6 | 60 |

| PE-LD | 20 | 20 | 6 | 60 |

| PE wax | 20 | 20 | 6 | 60 |

| - | - | 40 | 12 | 60 |

| PE-LD | 20 | 20 | 12 | 60 |

| PE wax | 20 | 20 | 12 | 60 |

| - | - | 40 | 15 | 60 |

| PE-LD | 20 | 20 | 15 | 60 |

| PE wax | 20 | 20 | 15 | 60 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Forstner, T.; Cholewa, S.; Drummer, D. Enhanced Feedstock Processability for the Indirect Additive Manufacturing of Metals by Material Extrusion through Ethylene–Propylene Copolymer Modification. Polymers 2024, 16, 2658. https://doi.org/10.3390/polym16182658

Forstner T, Cholewa S, Drummer D. Enhanced Feedstock Processability for the Indirect Additive Manufacturing of Metals by Material Extrusion through Ethylene–Propylene Copolymer Modification. Polymers. 2024; 16(18):2658. https://doi.org/10.3390/polym16182658

Chicago/Turabian StyleForstner, Thomas, Simon Cholewa, and Dietmar Drummer. 2024. "Enhanced Feedstock Processability for the Indirect Additive Manufacturing of Metals by Material Extrusion through Ethylene–Propylene Copolymer Modification" Polymers 16, no. 18: 2658. https://doi.org/10.3390/polym16182658

APA StyleForstner, T., Cholewa, S., & Drummer, D. (2024). Enhanced Feedstock Processability for the Indirect Additive Manufacturing of Metals by Material Extrusion through Ethylene–Propylene Copolymer Modification. Polymers, 16(18), 2658. https://doi.org/10.3390/polym16182658