Synergistic Reinforcement with SEBS-g-MAH for Enhanced Thermal Stability and Processability in GO/rGO-Filled PC/ABS Composites

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

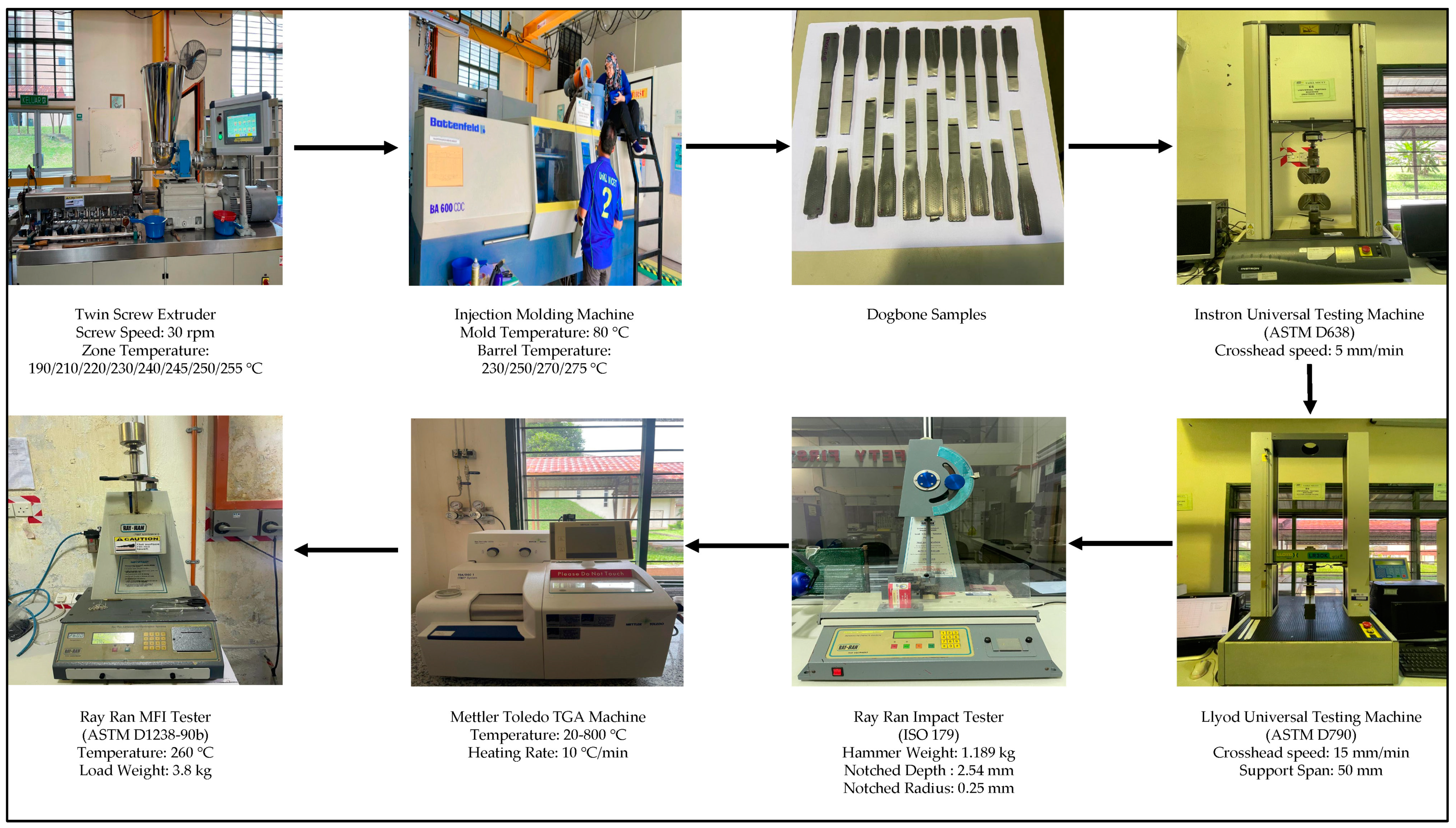

2.2. Methods

2.2.1. Fabrication of Samples

2.2.2. Mechanical Properties Analysis

Tensile Testing

Flexural Testing

Impact Testing

2.2.3. Thermal Properties Analysis

2.2.4. FTIR Analysis

2.2.5. Rheological Properties Analysis

3. Results and Discussion

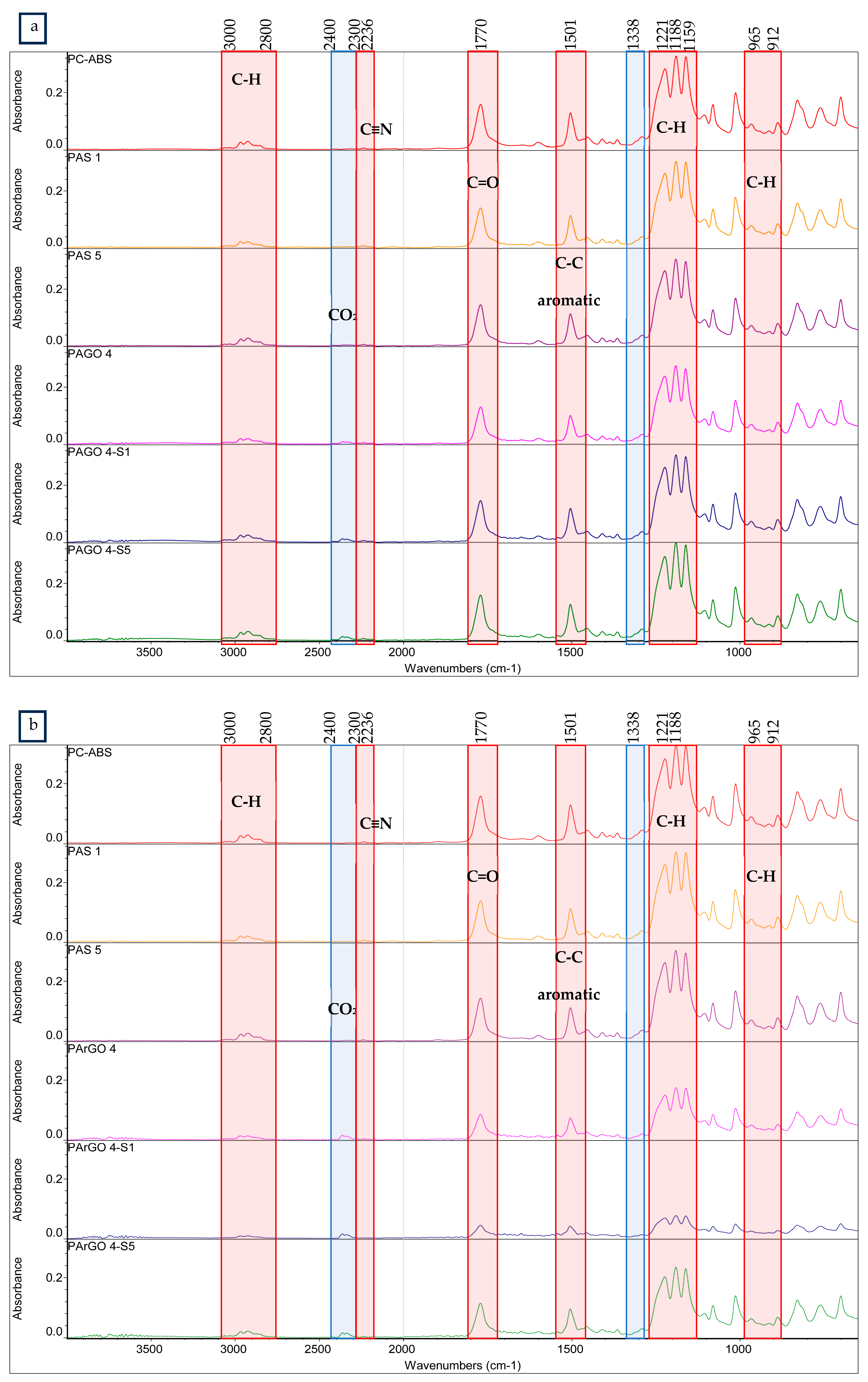

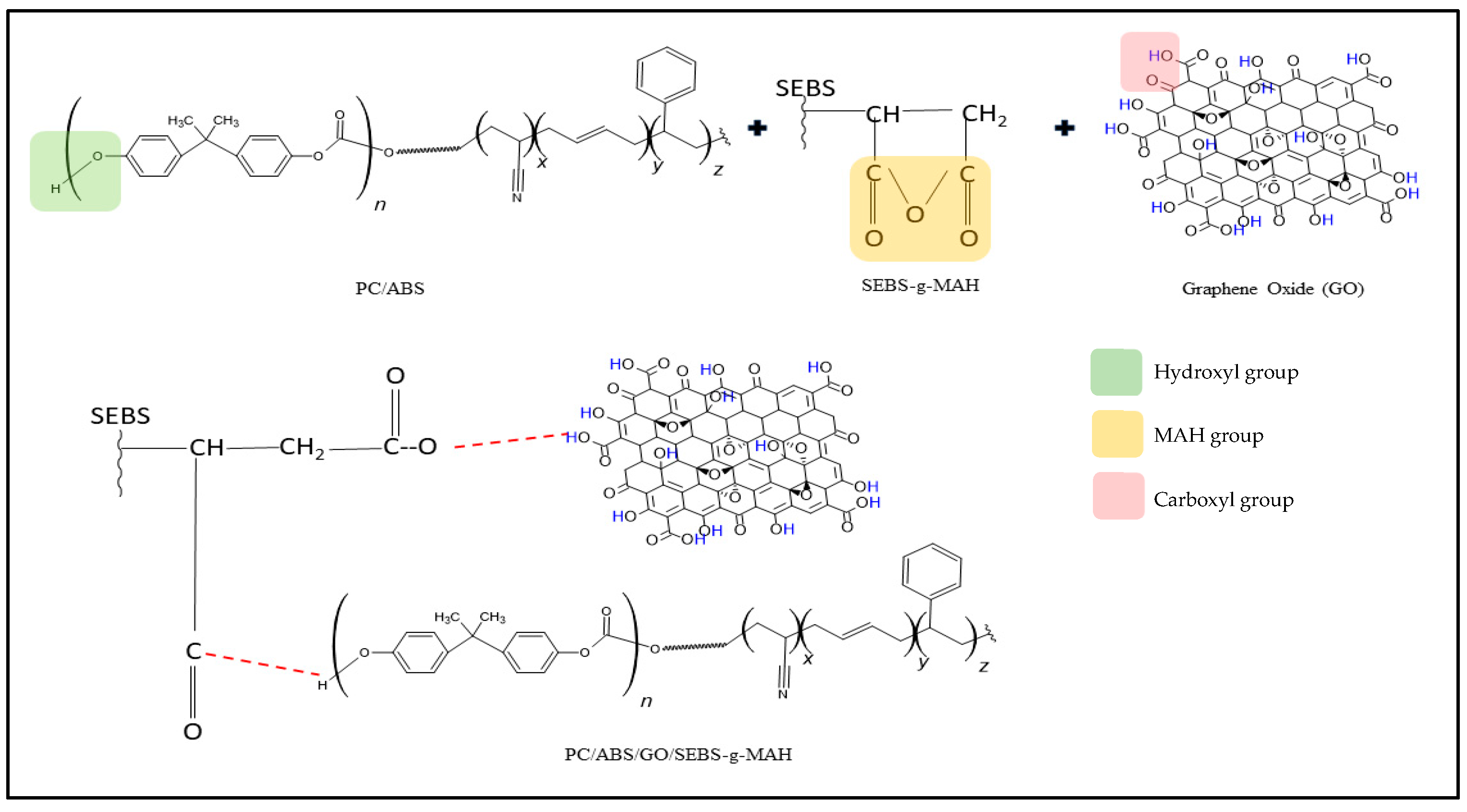

3.1. FTIR

3.2. Rheological Analysis

3.3. Mechanical Analysis

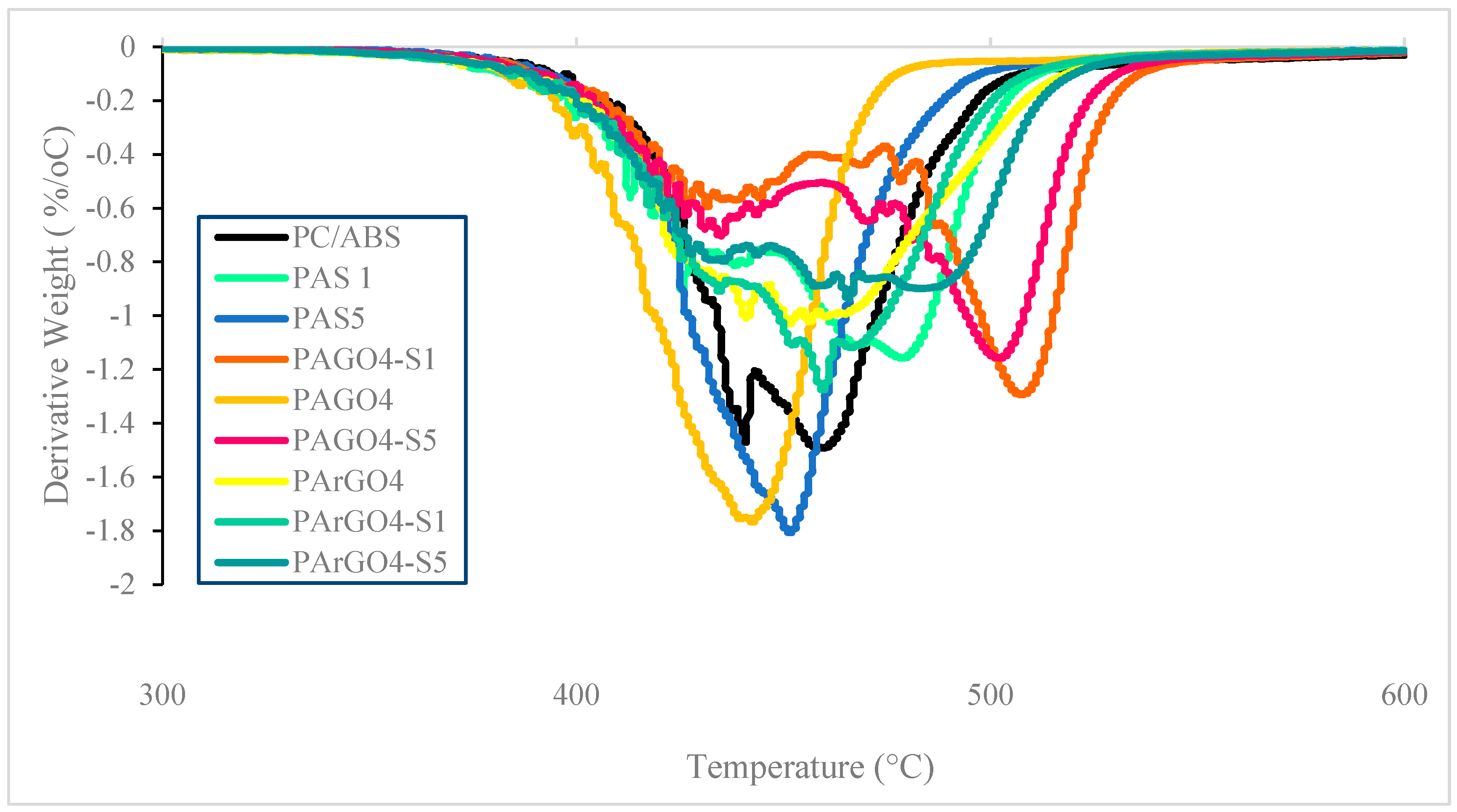

3.4. Thermal Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Hassan, A.; Yean Jwu, W. Mechanical Properties of High Impact ABS/PC Blends-Effect of Blend Ratio. In Proceedings of the Simposium Polimer Kebangsaan ke-V, Hotel Residence, Selangor, Malaysia, 23–24 August 2005; pp. 65–76. [Google Scholar]

- Khun, N.W.; Liu, E. Thermal, Mechanical and Tribological Properties of Polycarbonate/Acrylonitrile-Butadiene-Styrene Blends. J. Polym. Eng. 2013, 33, 535–543. [Google Scholar] [CrossRef]

- Masud, M.; Khan, K.; Gupta, R.; Agarwal, S.; Khan, M.M.K.; Liang, R.F.; Gupta, R.K.; Agarwal, S. Rheological and Mechanical Properties of ABS/PC Blends. Korea-Aust. Rheol. J. 2005, 17, 1–7. [Google Scholar]

- Dal Lago, E.; Cagnin, E.; Boaretti, C.; Roso, M.; Lorenzetti, A.; Modesti, M. Influence of Different Carbon-Based Fillers on Electrical and Mechanical Properties of a PC/ABS Blend. Polymers 2020, 12, 29. [Google Scholar] [CrossRef] [PubMed]

- dos Anjos, E.G.R.; Braga, N.F.; Ribeiro, B.; Escanio, C.A.; Cardoso, A.d.M.; Marini, J.; Antonelli, E.; Passador, F.R. Influence of Blending Protocol on the Mechanical, Rheological, and Electromagnetic Properties of PC/ABS/ABS-g-MAH Blend-Based MWCNT Nanocomposites. J. Appl. Polym. Sci. 2022, 139, 51946. [Google Scholar] [CrossRef]

- Razaq, A.; Bibi, F.; Zheng, X.; Papadakis, R.; Jafri, S.H.M.; Li, H. Review on Graphene-, Graphene Oxide-, Reduced Graphene Oxide-Based Flexible Composites: From Fabrication to Applications. Materials 2022, 15, 1012. [Google Scholar] [CrossRef]

- Morales-Zamudio, L.; Lozano, T.; Caballero-Briones, F.; Zamudio, M.A.M.; Angeles-San Martin, M.E.; de Lira-Gomez, P.; Martinez-Colunga, G.; Rodriguez-Gonzalez, F.; Neira, G.; Sanchez-Valdes, S. Structure and Mechanical Properties of Graphene Oxide-Reinforced Polycarbonate. Mater. Chem. Phys. 2021, 261, 124180. [Google Scholar] [CrossRef]

- Smith, A.T.; LaChance, A.M.; Zeng, S.; Liu, B.; Sun, L. Synthesis, Properties, and Applications of Graphene Oxide/Reduced Graphene Oxide and Their Nanocomposites. Nano Mater. Sci. 2019, 1, 31–47. [Google Scholar] [CrossRef]

- Zhu, Y.; Murali, S.; Cai, W.; Li, X.; Suk, J.W.; Potts, J.R.; Ruoff, R.S. Graphene and Graphene Oxide: Synthesis, Properties, and Applications. Adv. Mater. 2010, 22, 3906–3924. [Google Scholar] [CrossRef]

- Joy, A.; Unnikrishnan, G.; Megha, M.; Haris, M.; Thomas, J.; Deepti, A.; Baby Chakrapani, P.S.; Kolanthai, E.; Muthuswamy, S. A Novel Combination of Graphene Oxide/Palladium Integrated Polycaprolactone Nanocomposite for Biomedical Applications. Diam. Relat. Mater. 2023, 136, 110033. [Google Scholar] [CrossRef]

- Esmaeili, E.; Eslami-Arshaghi, T.; Hosseinzadeh, S.; Elahirad, E.; Jamalpoor, Z.; Hatamie, S.; Soleimani, M. The Biomedical Potential of Cellulose Acetate/Polyurethane Nanofibrous Mats Containing Reduced Graphene Oxide/Silver Nanocomposites and Curcumin: Antimicrobial Performance and Cutaneous Wound Healing. Int. J. Biol. Macromol. 2020, 152, 418–427. [Google Scholar] [CrossRef]

- Banerjee, A.N. Graphene and Its Derivatives as Biomedical Materials: Future Prospects and Challenges. Interface Focus 2018, 8, 20170056. [Google Scholar] [CrossRef] [PubMed]

- Ibrahim, A.; Klopocinska, A.; Horvat, K.; Hamid, Z.A. Graphene-Based Nanocomposites: Synthesis, Mechanical Properties, and Characterizations. Polymers 2021, 13, 2869. [Google Scholar] [CrossRef] [PubMed]

- Wu, X.H.; Then, Y.Y. Fabrication and Characterization of Superhydrophobic Graphene/Titanium Dioxide Nanoparticles Composite. Polymers 2021, 14, 122. [Google Scholar] [CrossRef] [PubMed]

- Aradhana, R.; Mohanty, S.; Nayak, S.K. Comparison of Mechanical, Electrical and Thermal Properties in Graphene Oxide and Reduced Graphene Oxide Filled Epoxy Nanocomposite Adhesives. Polymer 2018, 141, 109–123. [Google Scholar] [CrossRef]

- Hidayah, N.M.S.; Liu, W.W.; Lai, C.W.; Noriman, N.Z.; Khe, C.S.; Hashim, U.; Lee, H.C. Comparison on Graphite, Graphene Oxide and Reduced Graphene Oxide: Synthesis and Characterization. AIP Conf. Proc. 2017, 1892, 150002. [Google Scholar] [CrossRef]

- Ray, S.C. Application and Uses of Graphene Oxide and Reduced Graphene Oxide. In Applications of Graphene and Graphene-Oxide Based Nanomaterials; Elsevier: Amsterdam, The Netherlands, 2015; pp. 39–55. [Google Scholar]

- Qiao, Y.; Fring, L.D.; Pallaka, M.R.; Simmons, K.L. A Review of the Fabrication Methods and Mechanical Behavior of Continuous Thermoplastic Polymer Fiber–Thermoplastic Polymer Matrix Composites. Polym. Compos. 2023, 44, 694–733. [Google Scholar] [CrossRef]

- Shi, H.; Shi, D.; Li, C.; Luan, S.; Yin, J.; Li, R.K.Y. Preparation of Functionalized Graphene/SEBS-g-MAH Nanocomposites and Improvement of Its Electrical, Mechanical Properties. Mater. Lett. 2014, 133, 200–203. [Google Scholar] [CrossRef]

- Rafiee, M.; Nitzsche, F.; Laliberte, J.; Hind, S.; Robitaille, F.; Labrosse, M.R. Thermal Properties of Doubly Reinforced Fiberglass/Epoxy Composites with Graphene Nanoplatelets, Graphene Oxide and Reduced-Graphene Oxide. Compos. B Eng. 2019, 164, 1–9. [Google Scholar] [CrossRef]

- Ucpinar Durmaz, B.; Atılgan, M.G.; Aytac, A. A Comparative Study of Graphene Oxide or Chemically Reduced Graphene Oxide Filled Poly(Ethylene Terephthalate)/Poly(Butylene Terephthalate)/Graphene Nanocomposites. Iran. Polym. J. 2022, 31, 991–1002. [Google Scholar] [CrossRef]

- Inuwa, I.M.; Arjmandi, R.; Ibrahim, A.N.; Haafiz, M.K.M.; Wong, S.L.; Majeed, K.; Hassan, A. Enhanced Mechanical and Thermal Properties of Hybrid Graphene Nanoplatelets/Multiwall Carbon Nanotubes Reinforced Polyethylene Terephthalate Nanocomposites. Fibers Polym. 2016, 17, 1657–1666. [Google Scholar] [CrossRef]

- Wei, L.; Chen, X.; Hong, K.; Yuan, Z.; Wang, L.; Wang, H.; Qiao, Z.; Wang, X.; Li, Z.; Wang, Z. Enhancement in Mechanical Properties of Epoxy Nanocomposites by Styrene-Ethylene-Butadiene-Styrene Grafted Graphene Oxide. Compos. Interfaces 2019, 26, 141–156. [Google Scholar] [CrossRef]

- Wang, C.; Ge, H.; Ma, X.; Liu, Z.; Wang, T.; Zhang, J. Effect of Graphene Oxide Mixed Epoxy on Mechanical Properties of Carbon Fiber/Acrylonitrile-Butadiene-Styrene Composites. J. Nanosci. Nanotechnol. 2018, 18, 2513–2520. [Google Scholar] [CrossRef] [PubMed]

- Ajitha, A.R.; Thomas, S. Introduction: Polymer Blends, Thermodynamics, Miscibility, Phase Separation, and Compatibilization. In Compatibilization of Polymer Blends: Micro and Nano Scale Phase Morphologies, Interphase Characterization, and Properties; Elsevier: Amsterdam, The Netherlands, 2019; pp. 1–29. ISBN 9780128160060. [Google Scholar]

- Ajitha, A.R.; Mathew, L.P.; Thomas, S. Compatibilization of Polymer Blends by Micro and Nanofillers. In Compatibilization of Polymer Blends: Micro and Nano Scale Phase Morphologies, Interphase Characterization, and Properties; Elsevier: Amsterdam, The Netherlands, 2019; pp. 179–203. ISBN 9780128160060. [Google Scholar]

- Olongal, M.; Raphael, L.R.; Raghavan, P.; Mohamed Nainar, M.A.; Athiyanathil, S. Maleic Anhydride Grafted Acrylonitrile Butadiene Styrene (ABS)/Zinc Oxide Nanocomposite: An Anti-Microbial Material. J. Polym. Res. 2021, 28, 284. [Google Scholar] [CrossRef]

- Zhang, X.L.; Wu, H.; Guo, S.Y. The Molecular Structure of SEBS Grafted with Maleic Anhydride through Ultrasound Initiation. Chin. J. Polym. Sci. (Engl. Ed.) 2015, 33, 988–999. [Google Scholar] [CrossRef]

- Cai, H.; Lu, T.; Jiang, Y.; Chen, J.; Xiao, Y.; Han, B.; Gao, W.; Ju, J. Experimental and Computational Investigation on Performances of the Thermoplastic Elastomer SEBS/Poly(Lactic Acid) Blends. Mater. Today Commun. 2023, 35, 105600. [Google Scholar] [CrossRef]

- Zhu, N.; Gao, X.; Liang, J.; Wang, Y.; Hou, R.; Ni, Z. Finely Modulated LDPE/PS Blends via Synergistic Compatibilization with SEBS-g-MAH and OMMT. Symmetry 2022, 14, 974. [Google Scholar] [CrossRef]

- Debbah, I.; Krache, R.; Aranburu, N.; Fernández, M.; Etxeberria, A. Effect of SEBS-g-MAH Addition on the Mechanical, Rheological, and Morphological Properties of Polycarbonate/Acrylonitrile–Butadiene–Styrene Blends. J. Elastomers Plast. 2018, 50, 611–633. [Google Scholar] [CrossRef]

- Chow, W.S.; Tham, W.L.; Poh, B.T.; Mohd Ishak, Z.A. Mechanical and Thermal Oxidation Behavior of Poly(Lactic Acid)/Halloysite Nanotube Nanocomposites Containing N,N′-Ethylenebis(Stearamide) and SEBS-g-MA. J. Polym. Environ. 2018, 26, 2973–2982. [Google Scholar] [CrossRef]

- Taghavi, S.K.; Shahrajabian, H.; Hosseini, H.M. Detailed Comparison of Compatibilizers MAPE and SEBS-g-MA on the Mechanical/Thermal Properties, and Morphology in Ternary Blend of Recycled PET/HDPE/MAPE and Recycled PET/HDPE/SEBS-g-MA. J. Elastomers Plast. 2018, 50, 13–35. [Google Scholar] [CrossRef]

- Song, L.; Cong, F.; Wang, W.; Ren, J.; Chi, W.; Yang, B.; Zhang, Q.; Li, Y.; Li, X.; Wang, Y. The Effect of Functionalized SEBS on the Properties of PP/SEBS Blends. Polymers 2023, 15, 3696. [Google Scholar] [CrossRef]

- ASTM D638-14; Standard Test Method for Tensile Properties of Plastics. ASTM: West Conshohocken, PA, USA, 2022.

- ASTM D790-17; Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials. ASTM: West Conshohocken, PA, USA, 2017.

- ISO 179-2:2020; Plastics—Determination of Charpy Impact Properties—Part 2: Instrumented Impact Test. International Organization for Standardization: Geneva, Switzerland, 2020.

- ASTM E168-16; Standard Practices for General Techniques of Infrared Quantitative Analysis. ASTM: West Conshohocken, PA, USA, 2023.

- ASTM D1238-90b; Standard Test Method for Flow Rates of Thermoplastics by Extrusion Plastometer. ASTM: West Conshohocken, PA, USA, 2017.

- Rodrigues, P.V.; Ramoa, B.; Torres, A.R.; Castro, M.C.R.; Machado, A.V. Enhancing the Interface Behavior on Polycarbonate/Elastomeric Blends: Morphological, Structural, and Thermal Characterization. Polymers 2023, 15, 1773. [Google Scholar] [CrossRef] [PubMed]

- Tejada-Oliveros, R.; Balart, R.; Ivorra-Martinez, J.; Gomez-Caturla, J.; Montanes, N.; Quiles-Carrillo, L. Improvement of Impact Strength of Polylactide Blends with a Thermoplastic Elastomer Compatibilized with Biobased Maleinized Linseed Oil for Applications in Rigid Packaging. Molecules 2021, 26, 240. [Google Scholar] [CrossRef] [PubMed]

- Jamaludin, N.A.; Hassan, A.; Othman, N.; Jawaid, M. Effects of Halloysite Nanotubes on Mechanical and Thermal Stability of Poly(Ethylene Terephthalate)/Polycarbonate Nanocomposites. Appl. Mech. Mater. 2015, 735, 8–12. [Google Scholar] [CrossRef]

- Asyadi, F.; Jawaid, M.; Hassan, A.; Wahit, M.U. Mechanical Properties of Mica-Filled Polycarbonate/Poly(Acrylonitrile-Butadiene-Styrene) Composites. Polym.-Plast. Technol. Eng. 2013, 52, 727–736. [Google Scholar] [CrossRef]

- Pour, R.H.; Hassan, A.; Soheilmoghaddam, M.; Bidsorkhi, H.C. Mechanical, Thermal, and Morphological Properties of Graphene Reinforced Polycarbonate/Acrylonitrile Butadiene Styrene Nanocomposites. Polym. Compos. 2016, 37, 1633–1640. [Google Scholar] [CrossRef]

- de Sousa Filho, V.A.; de Albuquerque Filho, M.A.; de Alencar Lira, M.C.; Pedrosa, T.C.; da Fonseca, L.S.; Araújo, S.S.; Henrique, M.A.; da Silva Barbosa Ferreira, E.; Araújo, E.M.; Luna, C.B.B. Efficiency Assessment of the SEBS, SEP, and SBS Copolymers in the Compatibilization of the PS/ABS Blend. J. Polym. Res. 2023, 30, 425. [Google Scholar] [CrossRef]

- Matei, E.; Râpă, M.; Andras, Á.A.; Predescu, A.M.; Pantilimon, C.; Pica, A.; Predescu, C. Recycled Polypropylene Improved with Thermoplastic Elastomers. Int. J. Polym. Sci. 2017, 2017, 7525923. [Google Scholar] [CrossRef]

- Tayebi, M.; Ramazani, S.A.A.; Hamed Mosavian, M.T.; Tayyebi, A. LDPE/EVA/Graphene Nanocomposites with Enhanced Mechanical and Gas Permeability Properties. Polym. Adv. Technol. 2015, 26, 1083–1090. [Google Scholar] [CrossRef]

- Tjong, S.C.; Meng, Y.Z. Effect of Reactive Compatibilizers on the Mechanical Properties of Polycarbonate/Poly(Acrylonitrile-Butadiene-Styrene) Blends. Eur. Polym. J. 1999, 36, 123–129. [Google Scholar] [CrossRef]

- Tjong, S.C.; Bao, S.P.; Liang, G.D. Polypropylene/Montmorillonite Nanocomposites Toughened with SEBS-g-MA: Structure-Property Relationship. J. Polym. Sci. B Polym. Phys. 2005, 43, 3112–3126. [Google Scholar] [CrossRef]

- Mazlan, M.A.S.; Zakaria, Z.; Ahmad Saidi, M.A.; Hassan, A.; Xin, C.J. Effect of Graphene Oxide on Mechanical, Thermal and Physical Properties of Impact Modified Poly(Lactic Acid) Nanocomposites. PERINTIS eJournal 2020, 10, 51–67. [Google Scholar]

- Li, H.; Zhao, J.; Liu, S.; Yuan, Y. Polycarbonate–Acrylonitrile-Butadiene-Styrene Blends with Simultaneously Improved Compatibility and Flame Retardancy. RSC Adv. 2014, 4, 10395. [Google Scholar] [CrossRef]

- Hou, S.; Li, Z.; Zhang, Y.J.; Jiang, P. Phosphorous-Phosphorous Synergistic Effect on Flame Retardancy, Mechanically Reinforce and Hydrolytic Resistance for PC/ABS Blends. Polym. Degrad. Stab. 2021, 183, 109442. [Google Scholar] [CrossRef]

- Qiao, Z.; Ma, Y.; Chen, X.; Chen, M.; Hong, K.; Li, Z.; Lu, G.; Wang, Z. Mechanical and Piezo-resistive Properties of Functionalized Multi-walled Carbon Nanotubes/Styrene-ethylene-butadiene-styrene Composites. Polym. Compos. 2020, 41, 2082–2093. [Google Scholar] [CrossRef]

- Jamaludin, N.A.; Inuwa, I.M.; Hassan, A.; Othman, N.; Jawaid, M. Mechanical and Thermal Properties of SEBS-g-MA Compatibilized Halloysite Nanotubes Reinforced Polyethylene Terephthalate/Polycarbonate/Nanocomposites. J. Appl. Polym. Sci. 2015, 132, 42608. [Google Scholar] [CrossRef]

- Han, W.; Wu, M.; Rong, J.; Zhang, S.; Zhang, X.; Zhao, T.; Yu, X.; Naito, K.; Zhang, Q. Effect of Functionalized Nanodiamond on Properties of Polylactic Acid Eco-Friendly Composite Films. Diam. Relat. Mater. 2023, 133, 109717. [Google Scholar] [CrossRef]

- Kusmono; Mohd Ishak, Z.A.; Chow, W.S.; Takeichi, T. Rochmadi Influence of SEBS-g-MA on Morphology, Mechanical, and Thermal Properties of PA6/PP/Organoclay Nanocomposites. Eur. Polym. J. 2008, 44, 1023–1039. [Google Scholar] [CrossRef]

| No. | Sample | PC/ABS (phr) | GO (phr) | rGO (phr) | SEBS-g-MAH (phr) |

|---|---|---|---|---|---|

| 1 | PC/ABS | 100.0 | - | - | - |

| 2 | PAS1 | - | - | 1 | |

| 3 | PAS5 | - | - | 5 | |

| 4 | PAGO4.0 | 100.0 | 4.0 | - | - |

| 5 | PArGO4.0 | 100.0 | - | 4.0 | - |

| 6 | PAGO4.0-S1 | 100.0 | 4.0 | - | 1 |

| 7 | PAGO4.0-S5 | 100.0 | 4.0 | - | 5 |

| 8 | PArGO4.0-S1 | 100.0 | - | 4.0 | 1 |

| 9 | PArGO4.0-S5 | 100.0 | - | 4.0 | 5 |

| Samples | PC/ABS | PAS-1 | PAS-5 | PAGO4.0 | PAGO4.0-S1 | PAGO4.0-S5 | PArGO4.0 | PArGO4.0-S1 | PArGO4.0-S5 |

|---|---|---|---|---|---|---|---|---|---|

| MFI (g/10 min) 260 °C, 3.8 kg | 13.27 | 17.79 | 17.07 | 12.68 | 19.29 | 19.31 | 11.14 | 16.63 | 17.98 |

| Sample | TS (MPa) | YM (MPa) | EB (%) | FS (MPa) | FM (MPa) | ISN (kJ/m2) | ISUN (kJ/m2) |

|---|---|---|---|---|---|---|---|

| PC/ABS | 38.84 ± 1.2 c,d,e | 1041.60 ± 27.4 c,d | 29.09 ± 10.8 b | 29.55 ± 0.9 f | 421.52 ± 17.3 e | 38.68 ± 0.4 a | 54.11 ± 8.6 d,e |

| PAS-1 | 39.38 ± 0.4 b,c,d | 1049.40 ± 20.9 b,c,d | 51.33 ± 9.0 a | 29.77 ± 0.1 e,f | 433.94 ± 10.0 d,e | 37.32 ± 0.3 a | 75.14 ± 4.6 b,c |

| PAS-5 | 37.80 ± 1.3 d,e | 1062.40 ± 33.0 a,b,c,d | 45.83 ± 3.4 a | 30.44 ± 0.2 d,e | 423.74 ± 4.3 e | 36.91 ± 3.0 a | 86.69 ± 13.8 b |

| PAGO-4.0 | 40.17 ± 1.1 a,b,c | 1092.40 ± 31.7 a,b | 13.14 ± 1.3 d | 31.57 ± 0.2 b,c | 456.24 ± 2.2 b,c | 9.70 ± 0.2 d | 48.75 ± 5.4 e |

| PArGO-4.0 | 42.35 ± 1.1 a | 1095.00 ± 13.4 a | 9.97 ± 1.4 d | 32.39 ± 0.2 a | 485.28 ± 3.6 a | 5.47 ± 0.2 e | 52.54 ± 1.8 e |

| PAGO4.0-S1 | 39.82 ± 0.5 b,c,d | 1067.60 ± 18.7 a,b,c,d | 15.40 ± 2.1 c,d | 31.97 ± 0.2 a,b | 460.11 ± 4.0 b | 10.50 ± 0.2 d | 79.97 ± 3.9 b,c |

| PAGO4.0-S5 | 36.60 ± 0.5 e | 1028.20 ± 12.5 d | 17.51 ± 1.4 b,c,d | 30.82 ± 0.7 c,d | 440.71 ± 4.8 c,d | 11.47 ± 0.2 d | 85.28 ± 12.3 b,c |

| PArGO4.0-S1 | 41.36 ± 0.7 a,b | 1074.80 ± 15.5 a,b,c | 10.84 ± 1.6 d | 32.04 ± 0.2 a,b | 464.16 ± 7.3 b | 4.66 ± 0.2 e | 51.18 ± 2.7 e |

| PArGO4.0-S5 | 37.93 ± 2.1 c,d,e | 1068.80 ± 11.3 a,b,c,d | 17.28 ± 1.1 b,c,d | 31.48 ± 0.1 b,c | 455.36 ± 7.1 b,c | 4.61 ± 0.3 e | 69.57 ± 4.6 c,d |

| Sample | Degradation Temperature | Inflection Point (°C) | Char Residue at 800 °C (%) | |||

|---|---|---|---|---|---|---|

| T5% | T10% | T50% | T80% | |||

| PC/ABS | 410 | 423 | 457 | 488 | 462 | 6.24 |

| PAS1 | 400 | 415 | 466 | 497 | 478 | 11.93 |

| PAS5 | 408 | 420 | 451 | 481 | 445 | 9.82 |

| PAGO04.0 | 357 | 402 | 438 | 461 | 438 | 4.80 |

| PAGO4.0-S1 | 403 | 420 | 497 | 538 | 502 | 14.66 |

| PAGO4.0-S5 | 404 | 419 | 486 | 521 | 497 | 13.63 |

| PArGO4.0 | 397 | 415 | 449 | 512 | 449 | 14.40 |

| PArGO4.0-S1 | 400 | 415 | 461 | 502 | 458 | 14.17 |

| PArGO4.0-S5 | 402 | 417 | 469 | 510 | 464 | 13.69 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Joynal Abedin, F.N.; Fizal, A.N.S.; Alkarkhi, A.F.M.; Khalil, N.A.; Ahmad Yahaya, A.N.; Hossain, M.S.; Safie, S.I.; Ismail, N.A.; Zulkifli, M. Synergistic Reinforcement with SEBS-g-MAH for Enhanced Thermal Stability and Processability in GO/rGO-Filled PC/ABS Composites. Polymers 2024, 16, 2554. https://doi.org/10.3390/polym16182554

Joynal Abedin FN, Fizal ANS, Alkarkhi AFM, Khalil NA, Ahmad Yahaya AN, Hossain MS, Safie SI, Ismail NA, Zulkifli M. Synergistic Reinforcement with SEBS-g-MAH for Enhanced Thermal Stability and Processability in GO/rGO-Filled PC/ABS Composites. Polymers. 2024; 16(18):2554. https://doi.org/10.3390/polym16182554

Chicago/Turabian StyleJoynal Abedin, Fatin Najwa, Ahmad Noor Syimir Fizal, Abbas F. M. Alkarkhi, Nor Afifah Khalil, Ahmad Naim Ahmad Yahaya, Md. Sohrab Hossain, Sairul Izwan Safie, Nurul Ain Ismail, and Muzafar Zulkifli. 2024. "Synergistic Reinforcement with SEBS-g-MAH for Enhanced Thermal Stability and Processability in GO/rGO-Filled PC/ABS Composites" Polymers 16, no. 18: 2554. https://doi.org/10.3390/polym16182554

APA StyleJoynal Abedin, F. N., Fizal, A. N. S., Alkarkhi, A. F. M., Khalil, N. A., Ahmad Yahaya, A. N., Hossain, M. S., Safie, S. I., Ismail, N. A., & Zulkifli, M. (2024). Synergistic Reinforcement with SEBS-g-MAH for Enhanced Thermal Stability and Processability in GO/rGO-Filled PC/ABS Composites. Polymers, 16(18), 2554. https://doi.org/10.3390/polym16182554