Material Performance Evaluation for Customized Orthoses: Compression, Flexural, and Tensile Tests Combined with Finite Element Analysis

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials Production

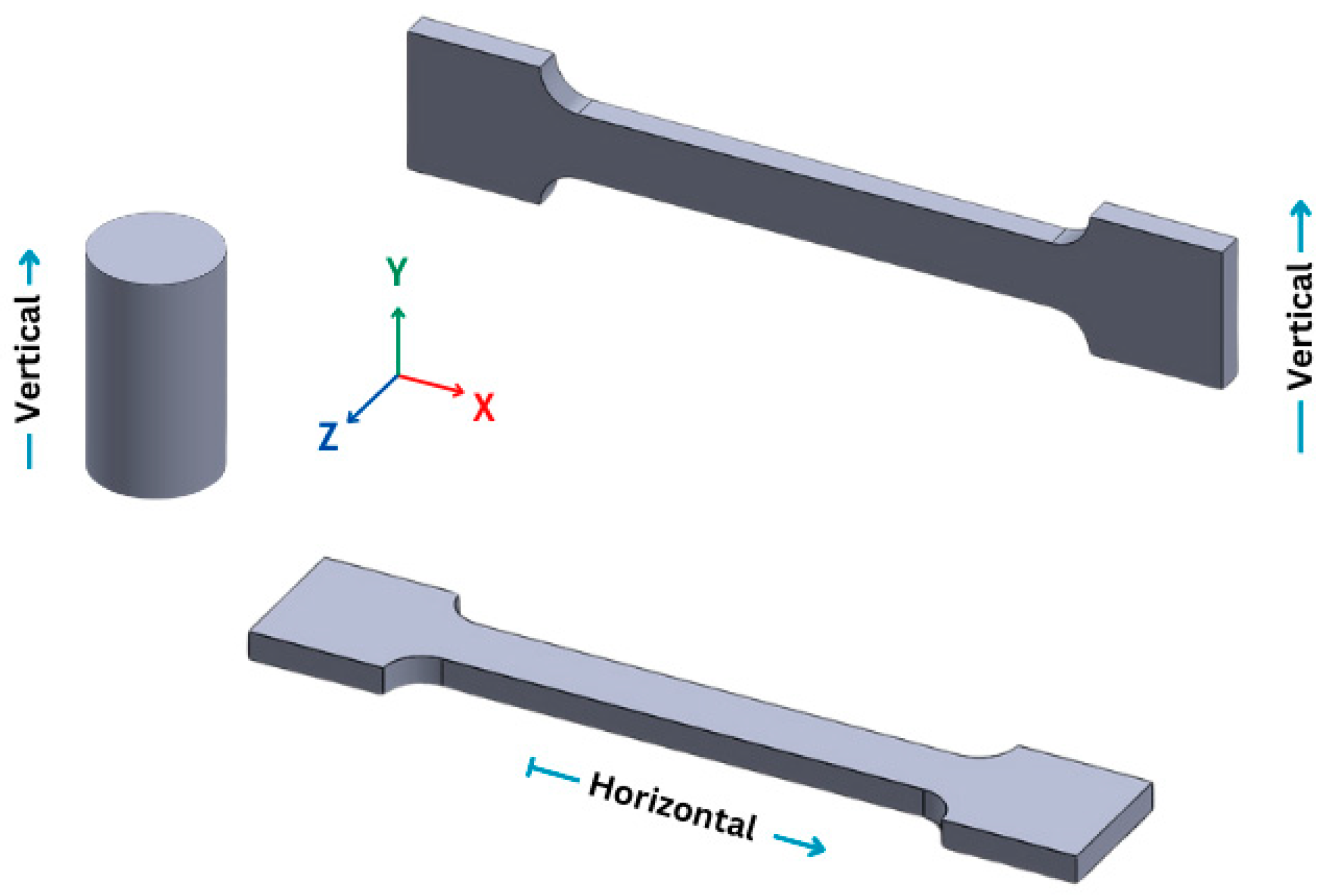

2.2. Tensile Testing

2.3. Flexural Testing

2.4. Compression Testing

2.5. Data Analysis of the Mechanical Assays

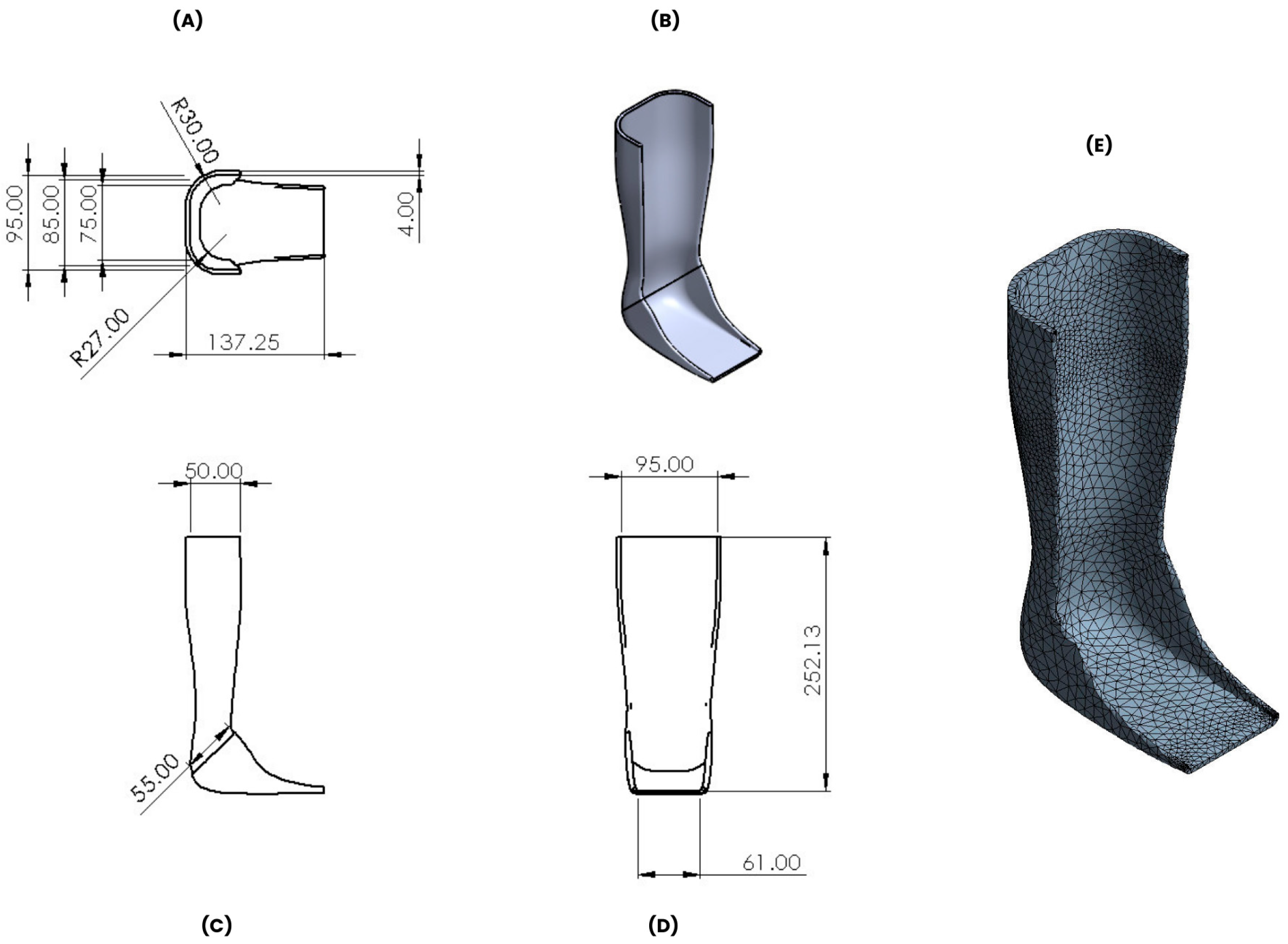

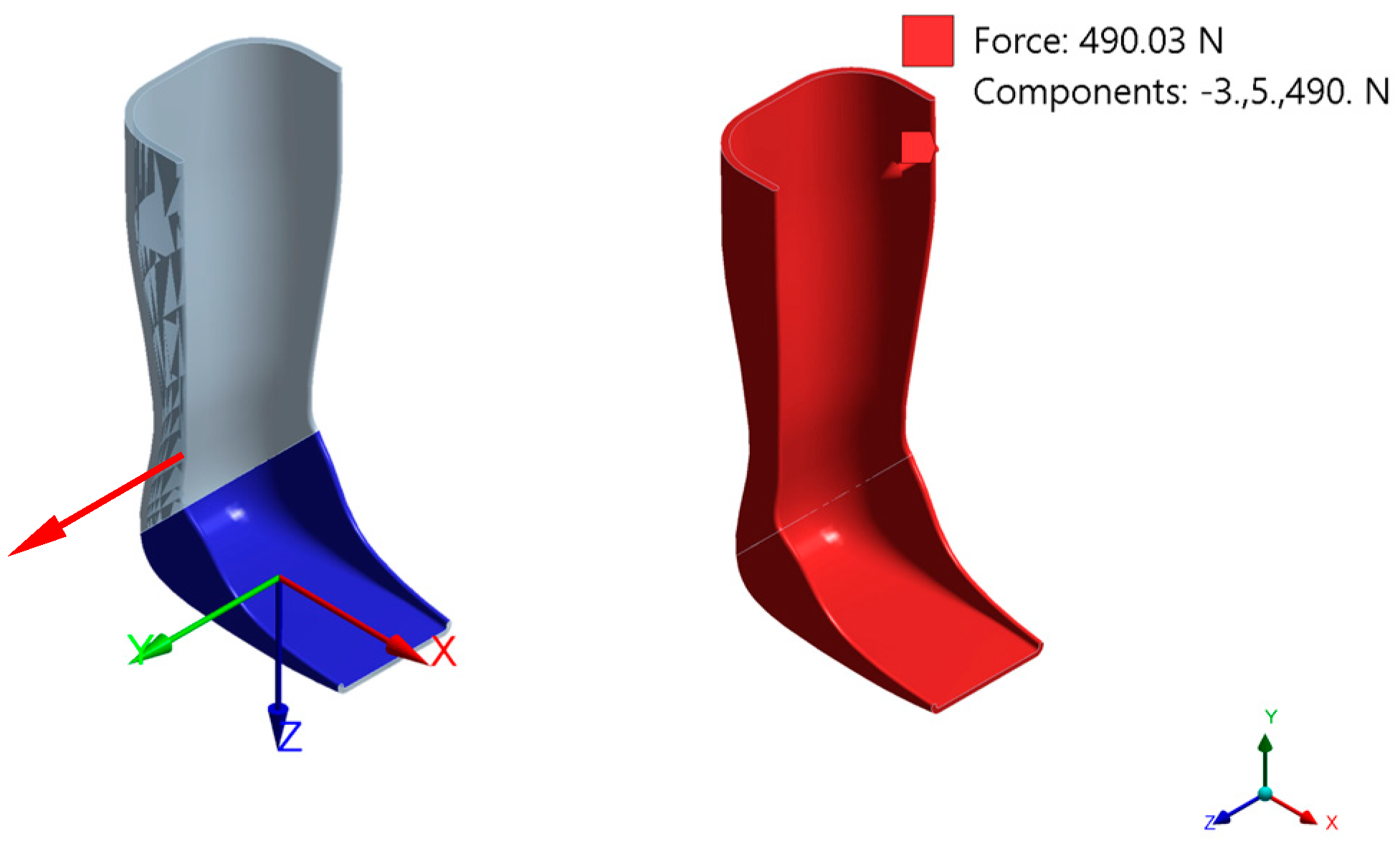

2.6. Static Structural Test

3. Results

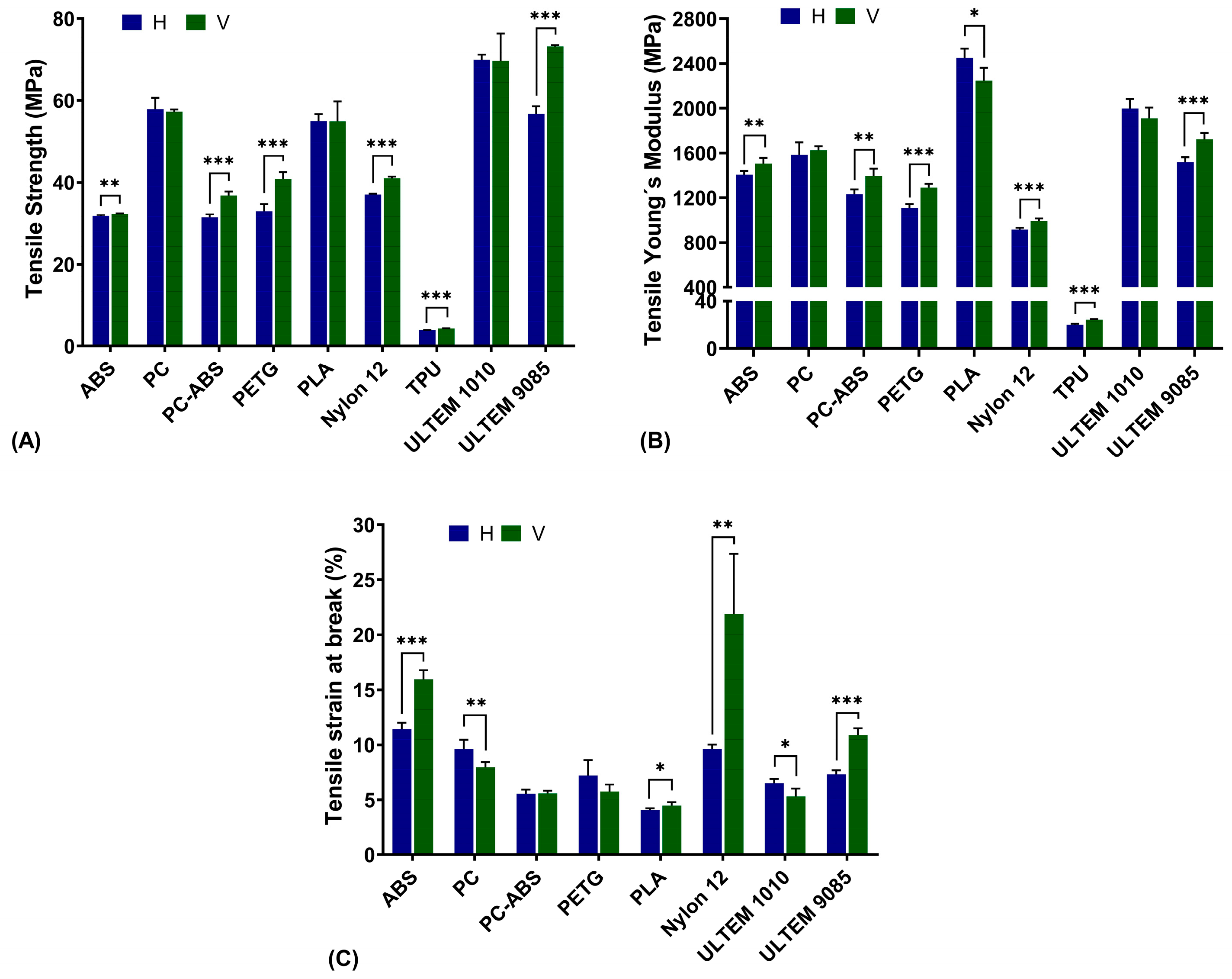

3.1. Tensile Tests

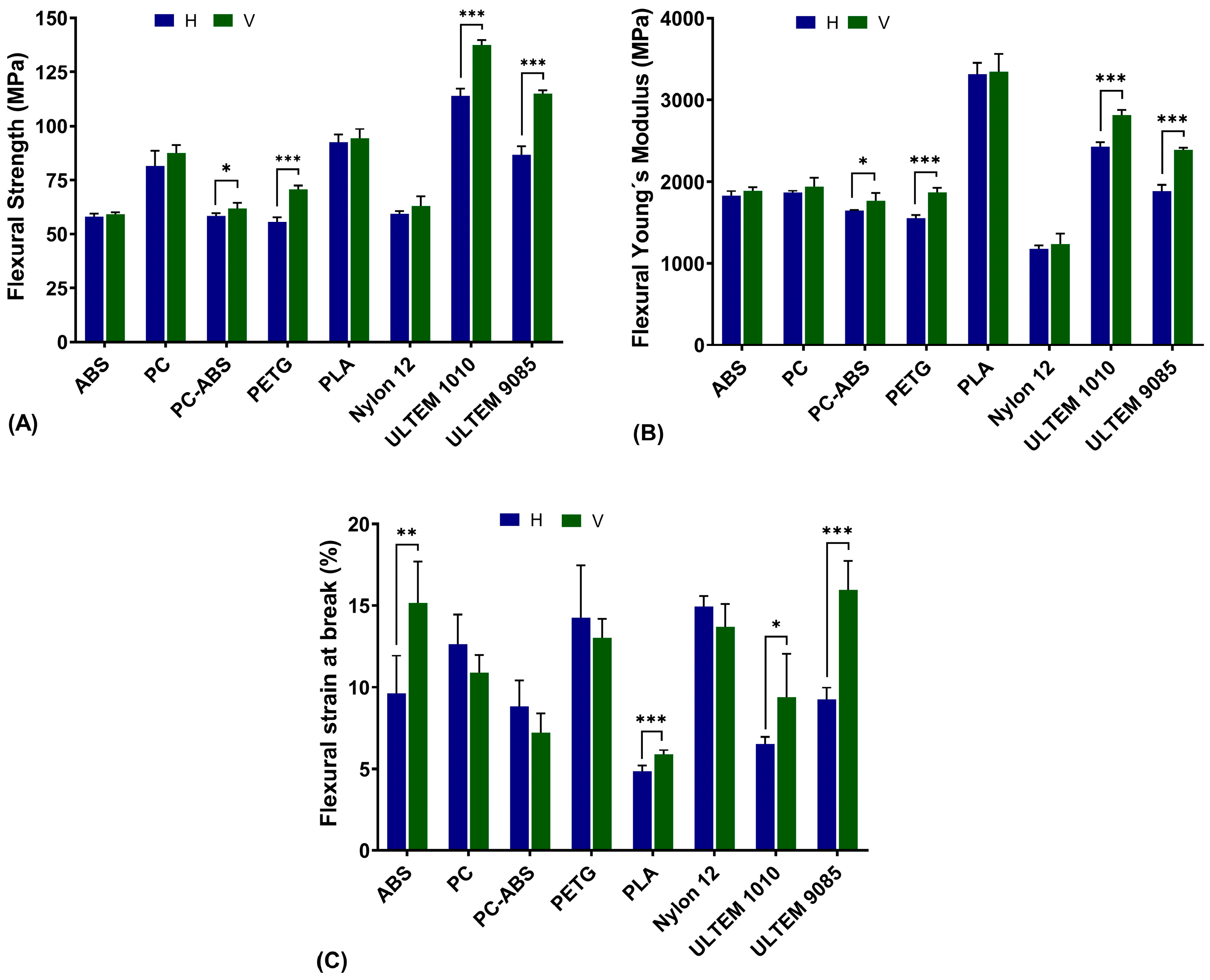

3.2. Flexural Tests

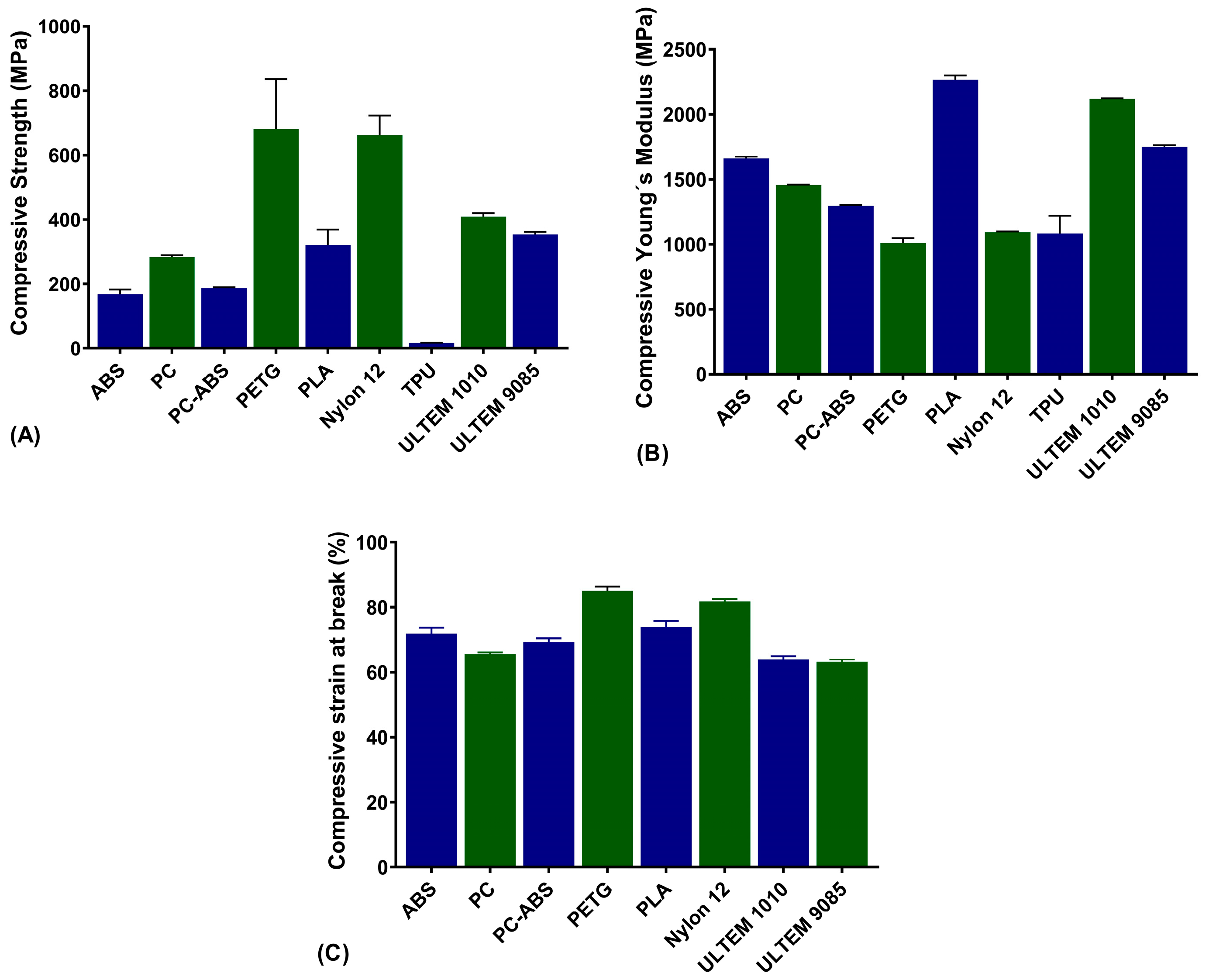

3.3. Compressive Tests

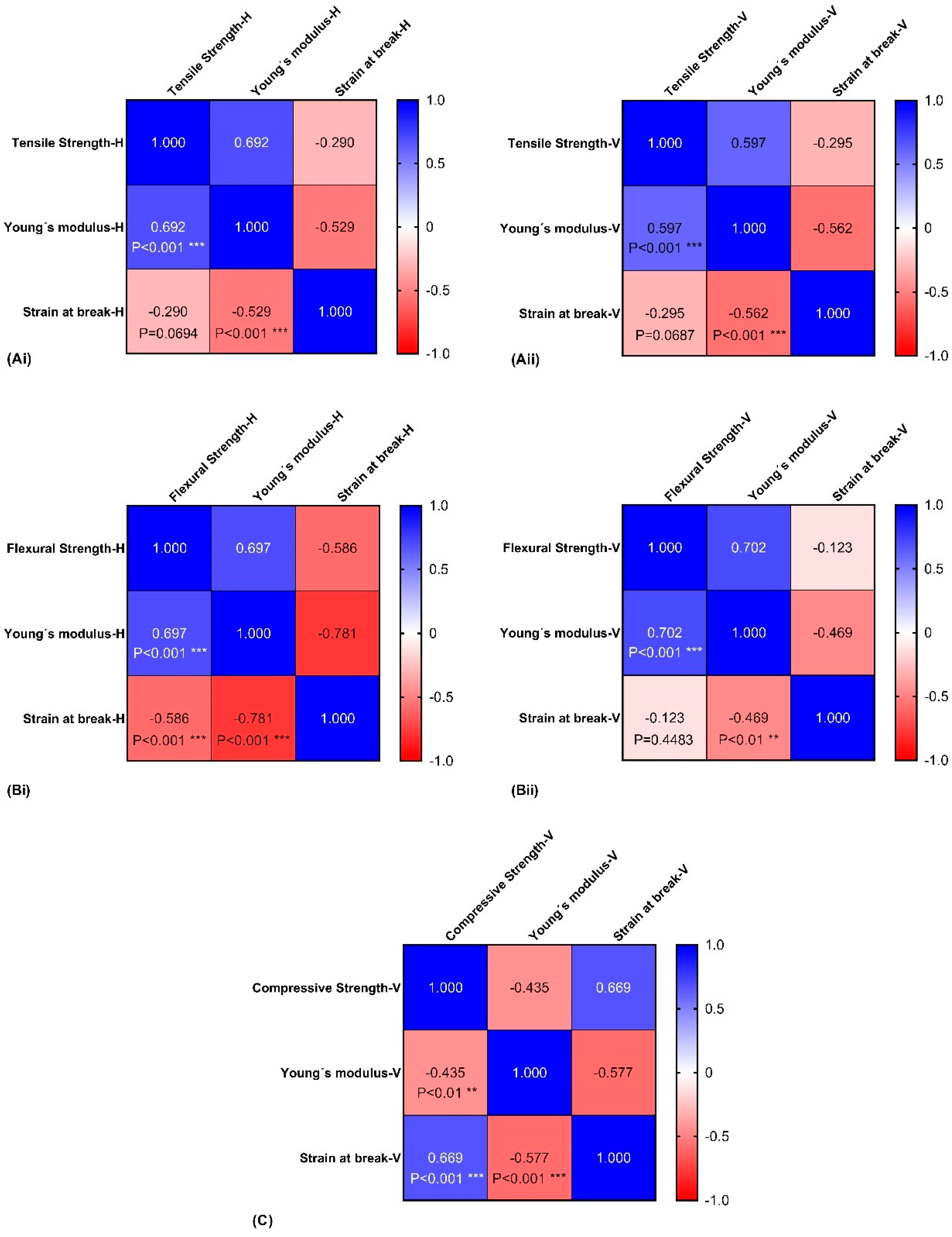

3.4. Correlation Assays

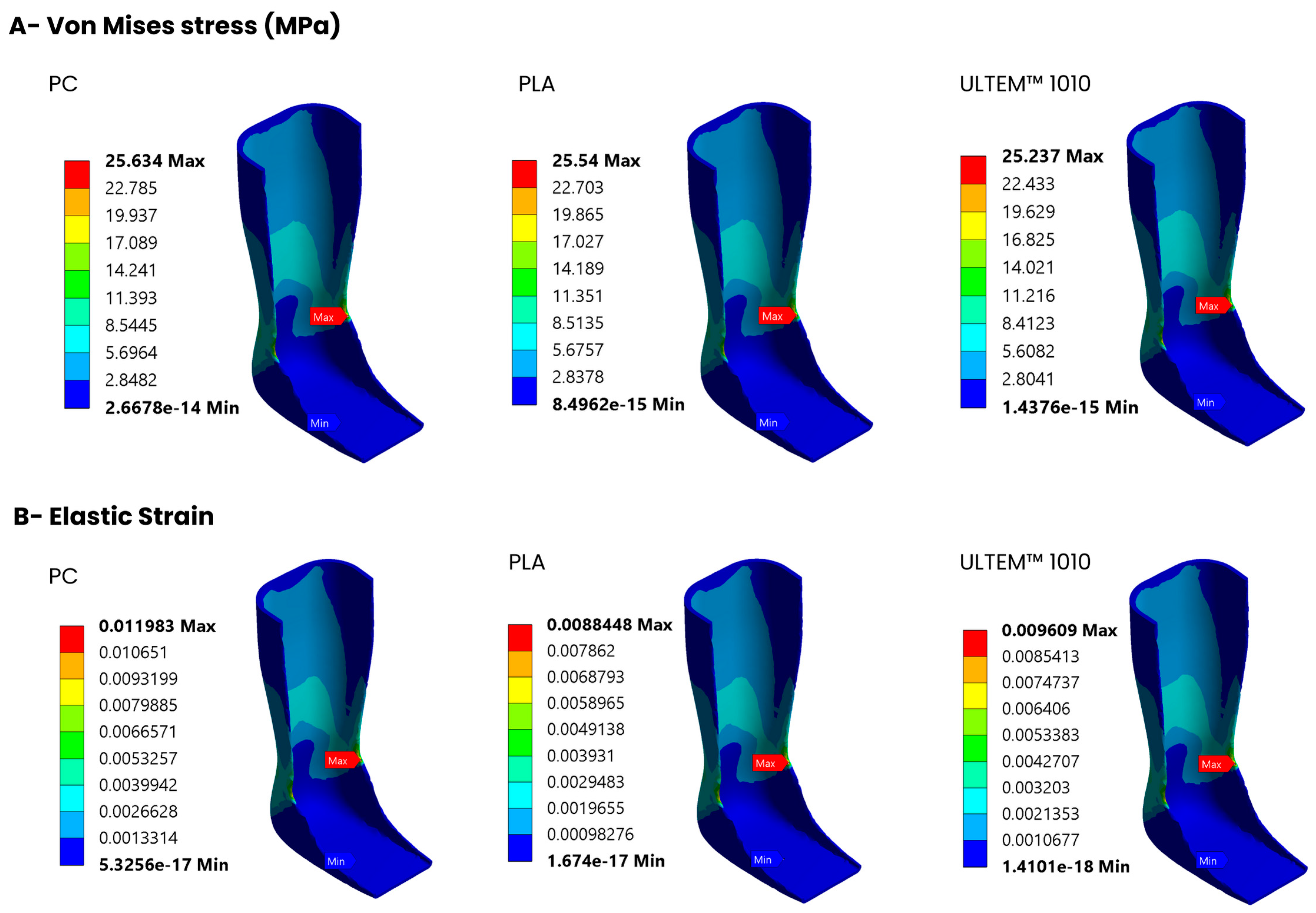

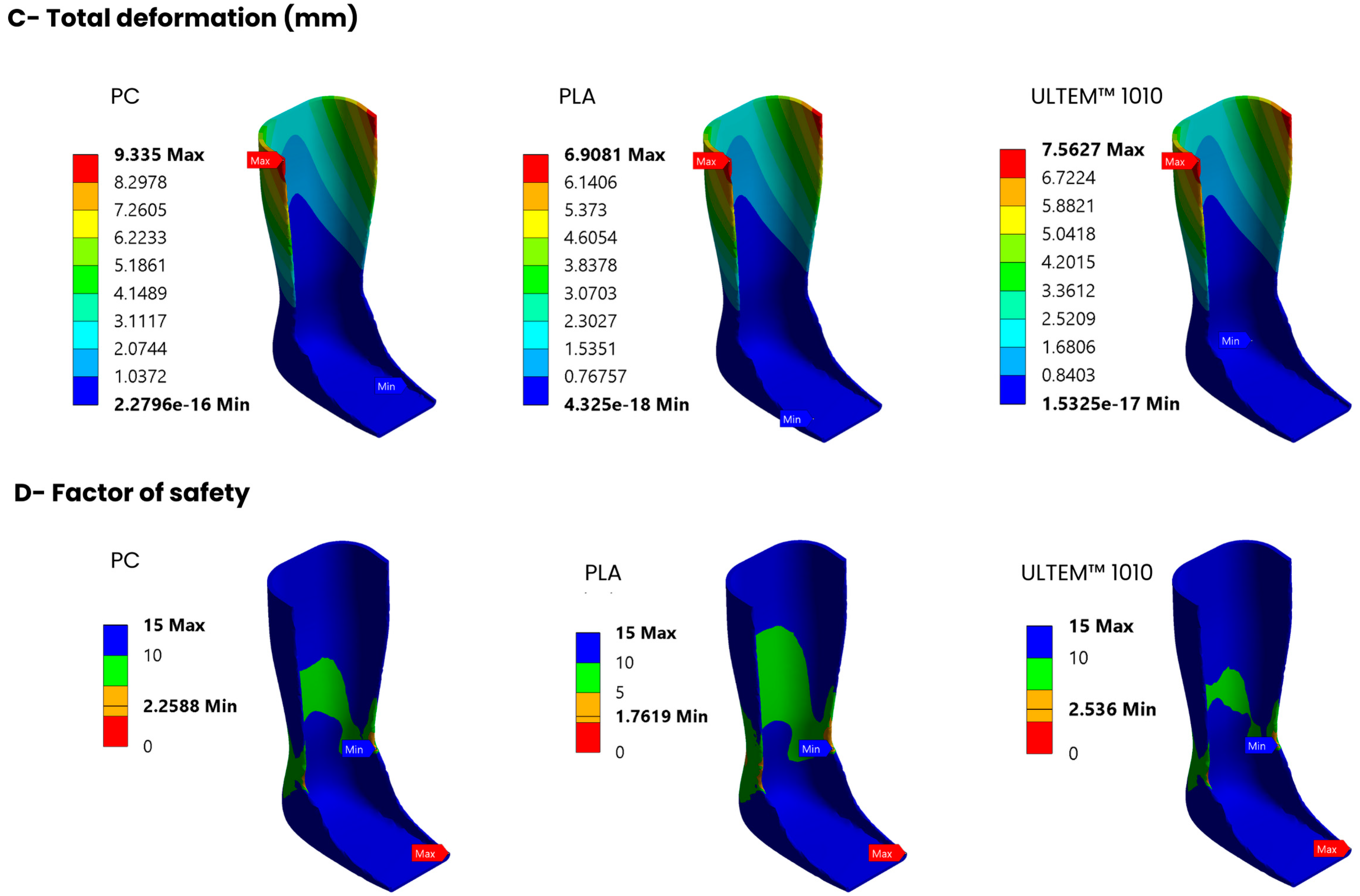

3.5. Static Structural Analysis

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Alqahtani, M.S.; Al-Tamimi, A.; Almeida, H.; Cooper, G.; Bartolo, P. A Review on the Use of Additive Manufacturing to Produce Lower Limb Orthoses. Prog. Addit. Manuf. 2020, 5, 85–94. [Google Scholar] [CrossRef]

- Hensen, J.C.D.; Foggiatto, J.A.; Ulbricht, L.; Stadnik, A.M.W. Additive Manufacturing of Customized Lower Limb Orthoses—A Review. Int. J. Innov. Educ. Res. 2018, 6, 141–152. [Google Scholar] [CrossRef]

- Wang, Y.; Tan, Q.; Pu, F.; Boone, D.; Zhang, M. A Review of the Application of Additive Manufacturing in Prosthetic and Orthotic Clinics from a Biomechanical Perspective. Engineering 2020, 6, 1258–1266. [Google Scholar] [CrossRef]

- Aydin, L.; Kucuk, S. A Method for More Accurate FEA Results on a Medical Device Developed by 3D Technologies. Polym. Adv. Technol. 2018, 29, 2281–2286. [Google Scholar] [CrossRef]

- Barrios-Muriel, J.; Romero-Sánchez, F.; Alonso-Sánchez, F.J.; Rodríguez Salgado, D. Advances in Orthotic and Prosthetic Manufacturing: A Technology Review. Materials 2020, 13, 295. [Google Scholar] [CrossRef] [PubMed]

- Mian, S.H.; Abouel Nasr, E.; Moiduddin, K.; Saleh, M.; Alkhalefah, H. An Insight into the Characteristics of 3D Printed Polymer Materials for Orthoses Applications: Experimental Study. Polymers 2024, 16, 403. [Google Scholar] [CrossRef] [PubMed]

- Pallari, J.H.P.; Dalgarno, K.W.; Munguia, J.; Muraru, L.; Peeraer, L.; Telfer, S.; Woodburn, J. Design and Additive Fabrication of Foot and Ankle-Foot Orthoses. In Proceedings of the 21st Annual International Solid Freeform Fabrication Symposium—An Additive Manufacturing Conference, Austin, TX, USA, 9–11 August 2010; pp. 9–11. [Google Scholar]

- Chhikara, K.; Singh, G.; Gupta, S.; Chanda, A. Progress of Additive Manufacturing in Fabrication of Foot Orthoses for Diabetic Patients: A Review. Ann. 3D Print. Med. 2022, 8, 100085. [Google Scholar] [CrossRef]

- Butt, J.; Bhaskar, R.; Mohaghegh, V. Investigating the Influence of Material Extrusion Rates and Line Widths on FFF-Printed Graphene-Enhanced PLA. J. Manuf. Mater. Process. 2022, 6, 57. [Google Scholar] [CrossRef]

- Walbran, M.; Turner, K.; McDaid, A.J. Customized 3D Printed Ankle-Foot Orthosis with Adaptable Carbon Fibre Composite Spring Joint. Cogent Eng. 2016, 3, 1227022. [Google Scholar] [CrossRef]

- Rengier, F.; Mehndiratta, A.; von Tengg-Kobligk, H.; Zechmann, C.M.; Unterhinninghofen, R.; Kauczor, H.-U.; Giesel, F.L. 3D Printing Based on Imaging Data: Review of Medical Applications. Int. J. Comput. Assist. Radiol. Surg. 2010, 5, 335–341. [Google Scholar] [CrossRef]

- Wong, M.S.; Hassan Beygi, B.; Zheng, Y. Materials for Exoskeletal Orthotic and Prosthetic Systems. In Encyclopedia of Biomedical Engineering; Narayan, R., Ed.; Elsevier: Amsterdam, The Netherlands, 2019; pp. 352–367. [Google Scholar]

- Sarma, T.; Pandey, D.; Sahai, N.; Tewari, R.P. Material Selection and Development of Ankle Foot Orthotic Device. Mater. Today Proc. 2019, 18, 2509–2514. [Google Scholar] [CrossRef]

- Shahar, F.S.; Hameed Sultan, M.T.; Lee, S.H.; Jawaid, M.; Md Shah, A.U.; Safri, S.N.A.; Sivasankaran, P.N. A Review on the Orthotics and Prosthetics and the Potential of Kenaf Composites as Alternative Materials for Ankle-Foot Orthosis. J. Mech. Behav. Biomed. Mater. 2019, 99, 169–185. [Google Scholar] [CrossRef] [PubMed]

- Portnova, A.A.; Mukherjee, G.; Peters, K.M.; Yamane, A.; Steele, K.M. Design of a 3D-Printed, Open-Source Wrist-Driven Orthosis for Individuals with Spinal Cord Injury. PLoS ONE 2018, 13, e0193106. [Google Scholar] [CrossRef]

- ASTM D638-14; Standard Test Method for Tensile Properties of Plastics. ASTM International: West Conshohocken, PA, USA, 2022. [CrossRef]

- ISO 178:2019; Plastics—Determination of Flexural Properties. ISO: Geneva, Switzerland, 2019.

- ASTM D695-23; Standard Test Method for Compressive Properties of Rigid Plastics. ASTM International: West Conshohocken, PA, USA, 2023. [CrossRef]

- Ferreira, P.D.P. Development of a Two-Dimensional Biomechanical Multibody Model for the Analysis of the Human Gait with an Ankle-Foot Orthosis/Desenvolvimento de Um Modelo Biomecânico Multibody Bidimensional Para a Análise Da Marcha Humana Com Uma Ortótese Do Tornozelo. Ph.D Thesis, Universidade do Minho, Braga, Portugal, 2012. [Google Scholar]

- Marques, M.A.; Mendes, E.; Ramos, N.V.; Pinto, V.C.; Vaz, M.A. Finite-Element Analysis of Ankle-Foot Orthosis to Predict Fracture Conditions during Gait. In Proceedings of the 1st ICH Gaia, Porto, Portugal, January 2010; Available online: https://www.researchgate.net/publication/262684543_Finite_element_analysis_of_ankle_foot_orthosis_to_predict_fracture_conditions_during_gait (accessed on 30 July 2024).

- Ali, M.H.; Smagulov, Z.; Otepbergenov, T. Finite Element Analysis of the CFRP-Based 3D Printed Ankle-Foot Orthosis. Procedia Comput. Sci. 2021, 179, 55–62. [Google Scholar] [CrossRef]

- Blaya, F.; Pedro, P.S.; Silva, J.L.; D’Amato, R.; Heras, E.S.; Juanes, J.A. Design of an Orthopedic Product by Using Additive Manufacturing Technology: The Arm Splint. J. Med. Syst. 2018, 42, 54. [Google Scholar] [CrossRef]

- Chen, R.K.; Chen, L.; Tai, B.L.; Wang, Y.; Shih, A.J.; Wensman, J. Additive Manufacturing of Personalized Ankle-Foot Orthosis. Proc. NAMRI/SME 2014, 42, 381–389. [Google Scholar]

- Schrank, E.S.; Hitch, L.; Wallace, K.; Moore, R.; Stanhope, S.J. Assessment of a Virtual Functional Prototyping Process for the Rapid Manufacture of Passive-Dynamic Ankle-Foot Orthoses. J. Biomech. Eng. 2013, 135, 101011. [Google Scholar] [CrossRef]

- Varga, P.; Lorinczy, D.; Toth, L.; Pentek, A.; Nyitrai, M.; Maroti, P. Novel PLA-CaCO3 Composites in Additive Manufacturing of Upper Limb Casts and Orthotics—A Feasibility Study. Mater. Res. Express 2019, 6, 045317. [Google Scholar] [CrossRef]

- Arulmozhi, R.S.; Vaidya, M.; Poojalakshmi, M.G.; Ashok Kumar, D.; Anuraag, K. 3D design and printing of custom-fit finger splint. Biomed. Eng. Appl. Basis Commun. 2018, 30, 1850032. [Google Scholar] [CrossRef]

- Łukaszewski, K.; Wichniarek, R.; Górski, F. Determination of the Elasticity Modulus of Additively Manufactured Wrist Hand Orthoses. Materials 2020, 13, 4379. [Google Scholar] [CrossRef]

- Santos, M.A.R.D.; Tokimatsu, R.C.; Treichel, T.L.E.; Prado, T.D.D.; CDS Junior, A. Orthosis and Prosthesis Development for Large and Medium Animals Using Reverse Engineering and Additive Manufacturing Techniques. Int. J. Adv. Eng. Res. Sci. 2020, 7, 169–177. [Google Scholar] [CrossRef]

- Habiba, R.; Amaro, A.; Trindade, D.; Moura, C.; Silva, R.; Antão, A.; Martins, R.F.; Malça, C.; Branco, R. Comparative Analysis of Impact Strength among Various Polymeric Materials for Orthotic Production. Polymers 2024, 16, 1843. [Google Scholar] [CrossRef]

- Butt, J.; Oxford, P.; Sadeghi-Esfahlani, S.; Ghorabian, M.; Shirvani, H. Hybrid Manufacturing and Mechanical Characterization of Cu/PLA Composites. Arab. J. Sci. Eng. 2020, 45, 9339–9356. [Google Scholar] [CrossRef]

- Butt, J.; Bhaskar, R.; Mohaghegh, V. Non-Destructive and Destructive Testing to Analyse the Effects of Processing Parameters on the Tensile and Flexural Properties of FFF-Printed Graphene-Enhanced PLA. J. Compos. Sci. 2022, 6, 148. [Google Scholar] [CrossRef]

- Camargo, J.C.; Machado, Á.R.; Almeida, E.C.; Silva, E.F.M.S. Mechanical Properties of PLA-Graphene Filament for FDM 3D Printing. Int. J. Adv. Manuf. Technol. 2019, 103, 2423–2443. [Google Scholar] [CrossRef]

- Rebenaque, A.G.; González-Requena, I. Study of bending test of specimens obtained through fdm processes of additive manufacturing. Procedia Manuf. 2019, 41, 859–866. [Google Scholar] [CrossRef]

- Derban, P.; Negrea, R.; Rominu, M.; Marsavina, L. Influence of the Printing Angle and Load Direction on Flexure Strength in 3D Printed Materials for Provisional Dental Restorations. Materials 2021, 14, 3376. [Google Scholar] [CrossRef] [PubMed]

- Keßler, A.; Hickel, R.; Ilie, N. In Vitro Investigation of the Influence of Printing Direction on the Flexural Strength, Flexural Modulus and Fractographic Analysis of 3D-Printed Temporary Materials. Dent. Mater. J. 2021, 40, 641–649. [Google Scholar] [CrossRef] [PubMed]

- Maroti, P.; Varga, P.; Abraham, H.; Falk, G.; Zsebe, T.; Meiszterics, Z.; Mano, S.; Csernatony, Z.; Rendeki, S.; Nyitrai, M. Printing Orientation Defines Anisotropic Mechanical Properties in Additive Manufacturing of Upper Limb Prosthetics. Mater. Res. Express 2018, 6, 035403. [Google Scholar] [CrossRef]

- Dwiyati, S.T.; Kholil, A.; Riyadi, R.; Putra, S.E. Influence of Layer Thickness and 3D Printing Direction on Tensile Properties of ABS Material. J. Phys. Conf. Ser. 2019, 1402, 066014. [Google Scholar] [CrossRef]

- Zaldivar, R.J.; Witkin, D.B.; McLouth, T.; Patel, D.N.; Schmitt, K.; Nokes, J.P. Influence of Processing and Orientation Print Effects on the Mechanical and Thermal Behavior of 3D-Printed ULTEM® 9085 Material. Addit. Manuf. 2017, 13, 71–80. [Google Scholar] [CrossRef]

- Appalsamy, T.; Hamilton, S.L.; Kgaphola, M.J. Tensile Test Analysis of 3D Printed Specimens with Varying Print Orientation and Infill Density. J. Compos. Sci. 2024, 8, 121. [Google Scholar] [CrossRef]

- Liu, H.; He, H.; Peng, X.; Huang, B.; Li, J. Three-dimensional Printing of Poly(Lactic Acid) Bio-based Composites with Sugarcane Bagasse Fiber: Effect of Printing Orientation on Tensile Performance. Polym. Adv. Technol. 2019, 30, 910–922. [Google Scholar] [CrossRef]

- Akgümüş Gök, D. Determination of Optimum Printing Direction of the Polycarbonate Parts Produced by Additive Manufacturing. Mater. Res. Express 2024, 11, 045302. [Google Scholar] [CrossRef]

- Tymrak, B.M.; Kreiger, M.; Pearce, J.M. Mechanical Properties of Components Fabricated with Open-Source 3-D Printers under Realistic Environmental Conditions. Mater. Des. 2014, 58, 242–246. [Google Scholar] [CrossRef]

- Xie, X.; Bennett, J.; Saha, S.; Lu, Y.; Cao, J.; Liu, W.K.; Gan, Z. Mechanistic Data-Driven Prediction of as-Built Mechanical Properties in Metal Additive Manufacturing. NPJ Comput. Mater. 2021, 7, 86. [Google Scholar] [CrossRef]

- Long, H.; Lin, H.; Li, S.; Bai, Y.; Qin, L.; Xiao, T.; Qin, A. Nanomechanical Properties of CH4-Containing Coal during CO2 Storage under Different Injection Pressures Based on Molecule Dynamics. Appl. Surf. Sci. 2022, 590, 153126. [Google Scholar] [CrossRef]

- Parsajoo, M.; Armaghani, D.J.; Mohammed, A.S.; Khari, M.; Jahandari, S. Tensile Strength Prediction of Rock Material Using Non-Destructive Tests: A Comparative Intelligent Study. Transp. Geotech. 2021, 31, 100652. [Google Scholar] [CrossRef]

- Subramanian, S.M. Mechanical Properties of Materials: Definition, Testing and Application. Int. J. Mod. Stud. Mech. Eng. 2020, 6, 28–38. [Google Scholar] [CrossRef]

- Raj, R.; Dixit, A.R.; Łukaszewski, K.; Wichniarek, R.; Rybarczyk, J.; Kuczko, W.; Górski, F. Numerical and Experimental Mechanical Analysis of Additively Manufactured Ankle–Foot Orthoses. Materials 2022, 15, 6130. [Google Scholar] [CrossRef]

| Material | Young’s Modulus (MPa) | Poisson’s Ratio | Tensile Yield Strength (MPa) | Tensile Ultimate Strength (MPa) |

|---|---|---|---|---|

| PC | 2250 | 0.39 | 57.9 | 57.3 |

| PLA | 3039 | 0.39 | 45.0 | 48.0 |

| ULTEM™ 1010 | 2770 | 0.36 | 64.0 | 81.0 |

| Material | Maximum Von Mises Stress (MPa) | Maximum Elastic Strain (mm/mm) | Maximum Total Deformation (mm) | Minimum Safety Factor |

|---|---|---|---|---|

| PC | 25.63 | 11.98 × 10−3 | 9.34 | 2.26 |

| PLA | 25.54 | 8.85 × 10−3 | 6.91 | 1.76 |

| ULTEM™ 1010 | 25.24 | 9.61 × 10−3 | 7.56 | 2.54 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Trindade, D.; Habiba, R.; Fernandes, C.; Costa, A.A.; Silva, R.; Alves, N.; Martins, R.; Malça, C.; Branco, R.; Moura, C. Material Performance Evaluation for Customized Orthoses: Compression, Flexural, and Tensile Tests Combined with Finite Element Analysis. Polymers 2024, 16, 2553. https://doi.org/10.3390/polym16182553

Trindade D, Habiba R, Fernandes C, Costa AA, Silva R, Alves N, Martins R, Malça C, Branco R, Moura C. Material Performance Evaluation for Customized Orthoses: Compression, Flexural, and Tensile Tests Combined with Finite Element Analysis. Polymers. 2024; 16(18):2553. https://doi.org/10.3390/polym16182553

Chicago/Turabian StyleTrindade, Daniela, Rachel Habiba, Cristiana Fernandes, André A. Costa, Rui Silva, Nuno Alves, Rui Martins, Cândida Malça, Ricardo Branco, and Carla Moura. 2024. "Material Performance Evaluation for Customized Orthoses: Compression, Flexural, and Tensile Tests Combined with Finite Element Analysis" Polymers 16, no. 18: 2553. https://doi.org/10.3390/polym16182553

APA StyleTrindade, D., Habiba, R., Fernandes, C., Costa, A. A., Silva, R., Alves, N., Martins, R., Malça, C., Branco, R., & Moura, C. (2024). Material Performance Evaluation for Customized Orthoses: Compression, Flexural, and Tensile Tests Combined with Finite Element Analysis. Polymers, 16(18), 2553. https://doi.org/10.3390/polym16182553