Recognition and Characterization of Nanoscale Phases: Modulus Mapping of Asphalt Film in Pavement Mixture Cores

Abstract

1. Introduction

2. Materials and Research Methods

2.1. Materials

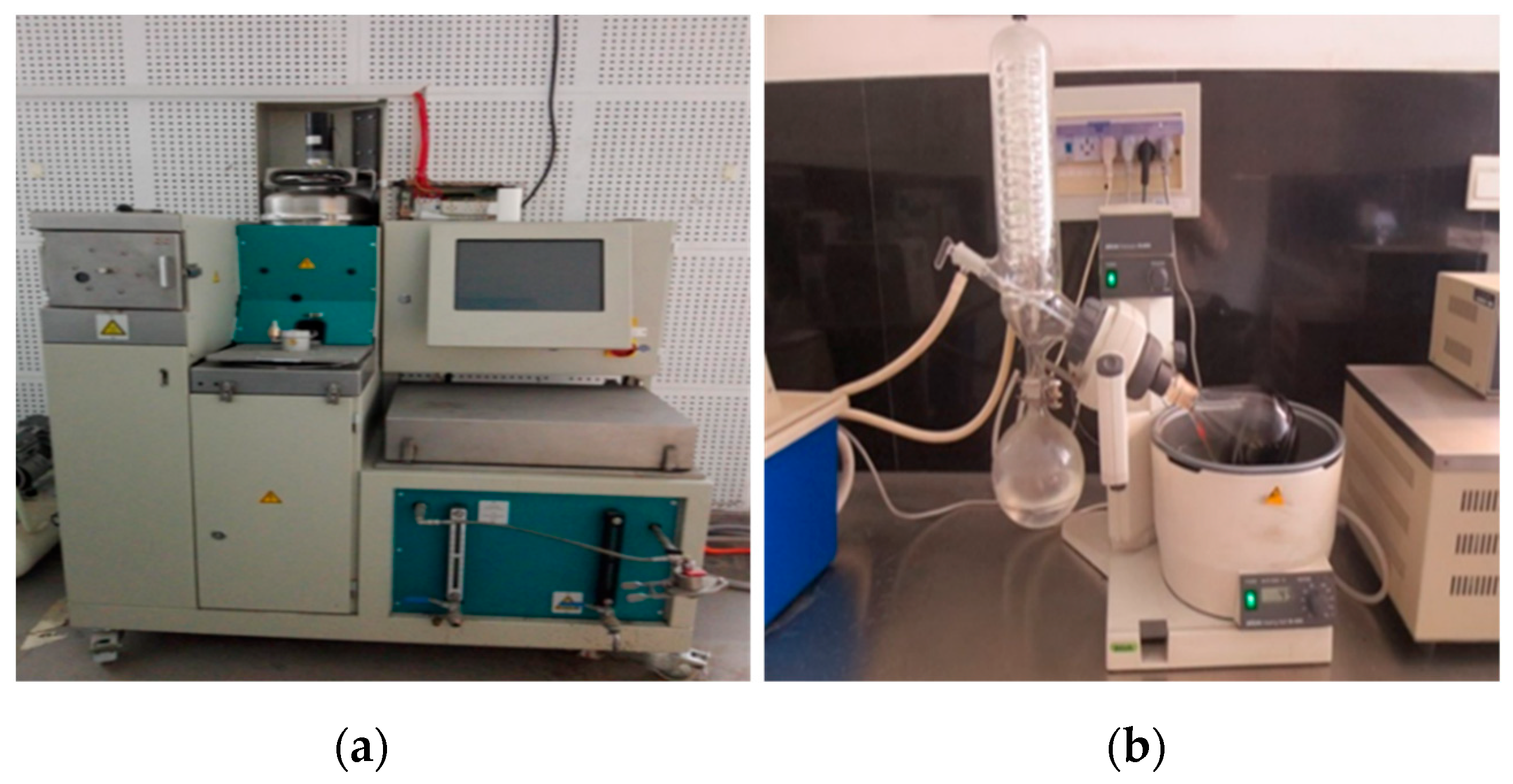

2.2. Test Methods

2.2.1. AFM-QNM Technology

2.2.2. Technology for Extracting and Recovering Asphalt from Cored Samples

2.2.3. Temperature Sweep Test and Penetration Test

3. Mapping Recognition and Characterization of Asphalt Phase Modulus

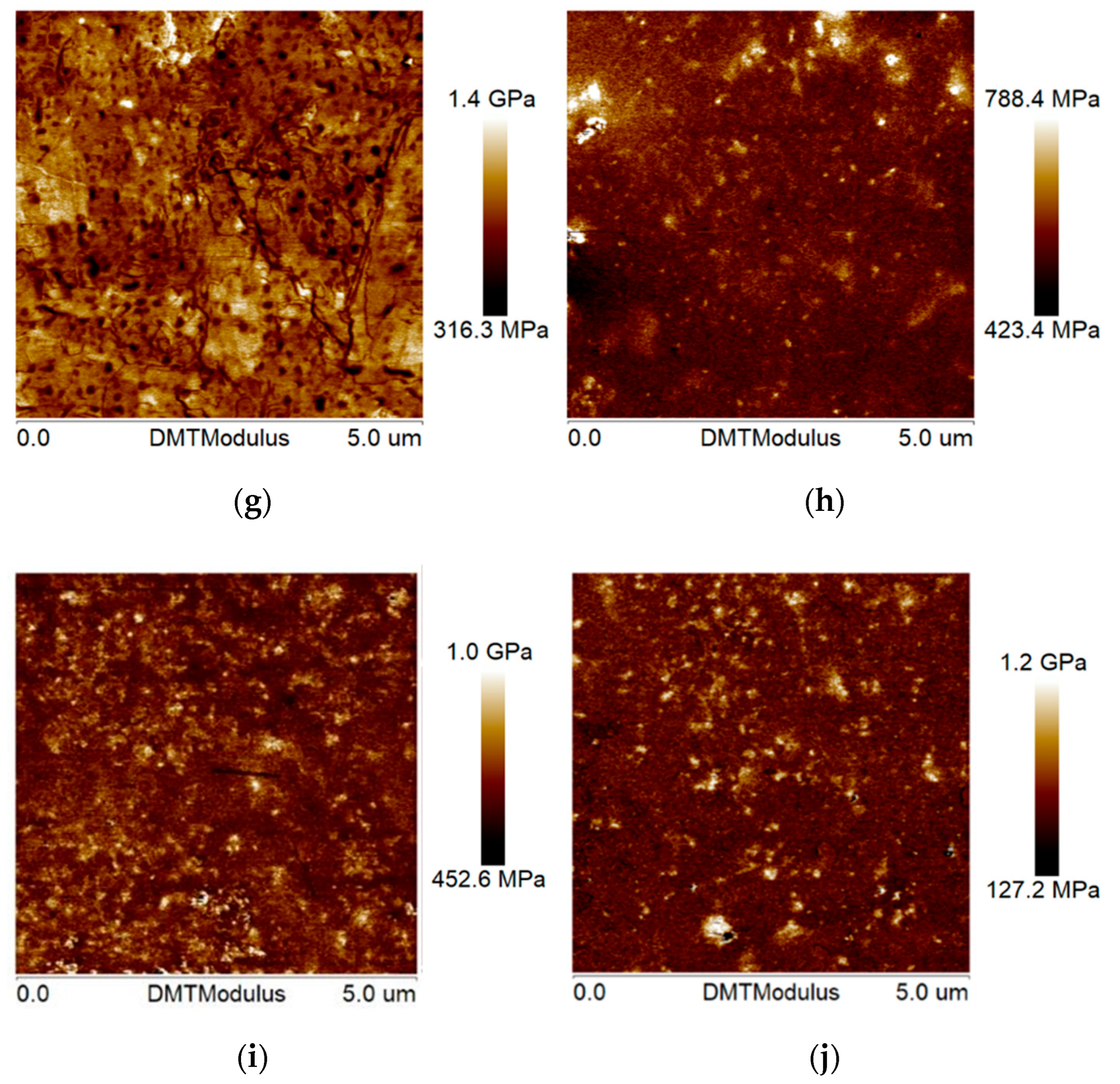

3.1. Phase Modulus Mappings Recognition

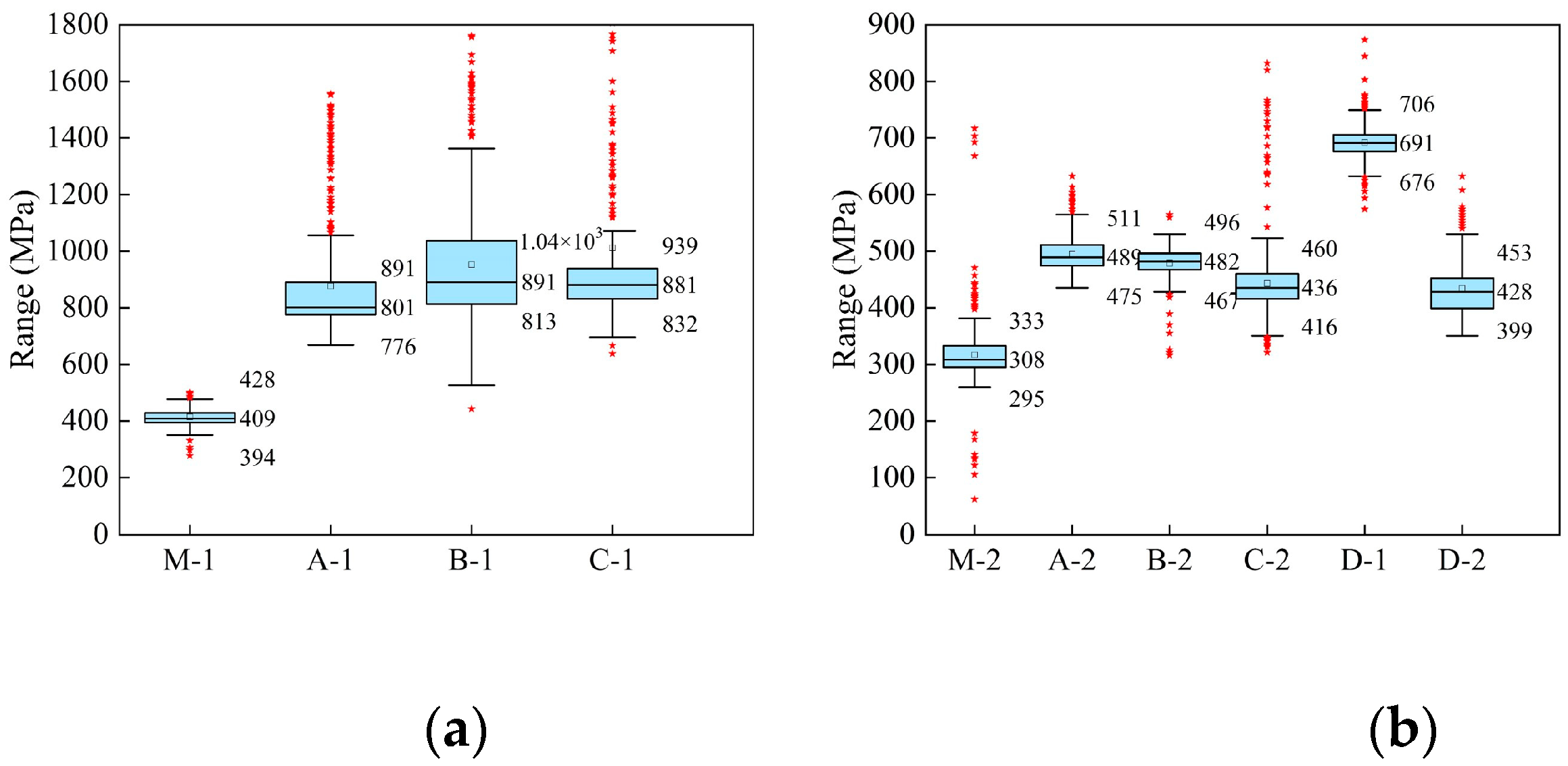

3.2. Phase Modulus Quantization Method

4. Macroscopic Properties of Asphalt Recovered from Mixtures

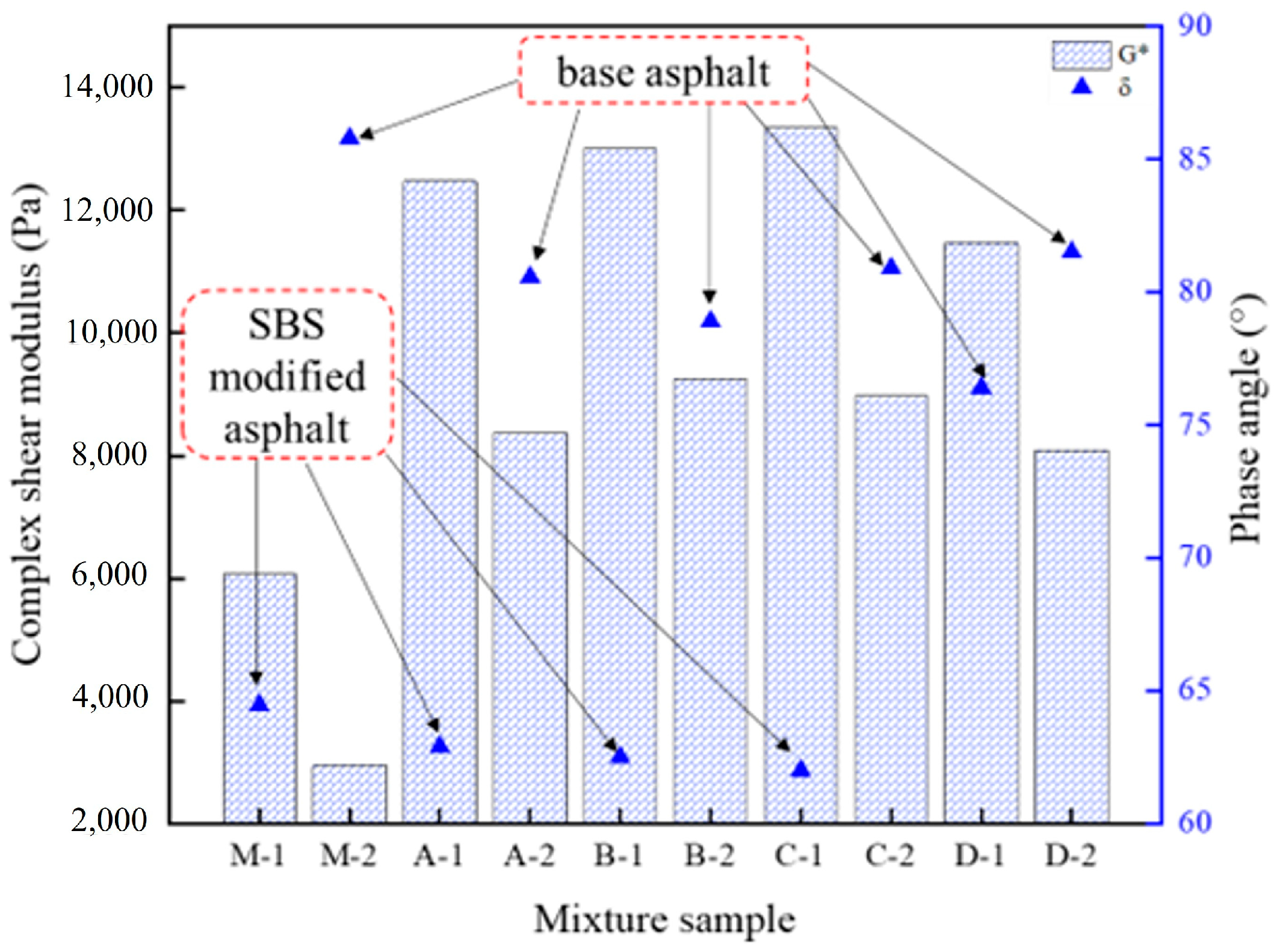

4.1. Rheological Properties Test

4.2. Penetration Test

5. The Correlation between Phase Modulus and Macroscopic Properties

6. Conclusions

- (1)

- Compared with the laboratory samples (namely, M), the characteristics of the multi-phase and diversified phase of the pavement core samples (namely, A, B, C, and D) were more significant. This phenomenon indicates that the asphalt in the pavement core samples had an obvious phase separation phenomenon due to aging. Further, the phase similar to black spots was found in the phase modulus mappings of the SBS-modified asphalt, but this phenomenon was not obvious for base asphalt.

- (2)

- The phase modulus of each sample was distributed across a relatively wide numerical range, and there were also many numerical points with large fluctuations. Especially for the mixture sample containing SBS-modified asphalt, the phase modulus distribution mappings presented a multi-peak phenomenon. Hence, considering the distribution characteristics of the data, the box plot method was introduced in this study.

- (3)

- Compared with the quantified results from the laboratory samples, the phase modulus of SBS-modified asphalt increased by 0.96 times, 1.18 times, and 1.15 times, and that of base asphalt increased by 0.59 times, 0.56 times, 0.42 times, 1.24 times, and 0.39 times, respectively. This showed that the aging degree of asphalt in the upper layer was generally greater than that in the middle layer. This finding also suggests that there was an aging gradient in the direction of pavement depth.

- (4)

- It can be clearly seen that all points were within the 95% confidence band, indicating that the phase modulus and the complex shear modulus, as well as the phase modulus and penetration, showed a better fitting effect. Moreover, it was noted that the fitting points of the phase modulus and the complex shear modulus were farther from the fitting line, whereas the fitting points of the phase modulus and penetration were closer to the fitting line. This showed a better fit between the phase modulus and penetration.

- (5)

- However, limited by the sample quantity and test conditions, as well as by other factors, the universality of this conclusion is still questionable. It should be noted that this study achieved the goal of identifying the phase mechanical properties of asphalt film in the mixture in situ. In addition, this study also suggests that advanced characterization techniques, such as nano-infrared, should be applied to the testing and characterization of asphalt film properties in the mixture, and the test results should be combined with those from this study. This may provide an innovative way to identify the degree of asphalt aging in older pavement mixtures.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ni, H.T.; Hu, M.J.; Sun, D.Q.; Xu, L.; Ling, S.L.; Lu, T.; Deng, Y. Degradation characteristics of SBS polymer and its contribution to weathering aging of modified asphalt. Constr. Build. Mater. 2023, 369, 130549. [Google Scholar] [CrossRef]

- Chen, M.Y.; Geng, J.G.; Xia, C.Y.; He, L.L.; Liu, Z. A review of phase structure of SBS modified asphalt: Affecting factors, analytical methods, phase models and improvements. Constr. Build. Mater. 2021, 294, 22. [Google Scholar] [CrossRef]

- Xing, C.W.; Liu, L.P.; Li, M.C. Chemical Composition and Aging Characteristics of Linear SBS Modified Asphalt Binders. Energy Fuels 2020, 34, 4194–4200. [Google Scholar] [CrossRef]

- Cui, Y.N.; Guo, L.D.; Chen, D.S. Composite aging mechanism of SBS modified asphalt. J. Build. Mater 2020, 23, 1183–1191. [Google Scholar] [CrossRef]

- He, Z.Y. Aging Mechanism and Regeneration Technology of Asphalt; Science Press: Beijing, China, 2021; ISBN 9787030618948. [Google Scholar]

- Wang, M. Study on In-situ Determination Method of Asphalt Aging Degree in Old Materials. Ph.D. Thesis, Tongji University, Shanghai, China, 2017. [Google Scholar]

- Sun, L.; Wang, Y.Y.; Zhang, Y.M. Aging mechanism and effective recycling ratio of SBS modified asphalt. Constr. Build. Mater. 2014, 70, 26–35. [Google Scholar] [CrossRef]

- Liu, Q.; Wu, J.T.; Xie, L.L.; Zhang, Z.Y.; Ma, X.Y.; Oeser, M. Micro-scale investigation of aging gradient within bitumen film around air-binder interface. Fuel 2021, 286, 119404. [Google Scholar] [CrossRef]

- Guo, M.; Tan, Y.Q.; Wei, J.M. Using molecular dynamics simulation to study concentration distribution of asphalt binder on aggregate surface. J. Mater. Civ. Eng. 2018, 30, 04018075. [Google Scholar] [CrossRef]

- Guo, M.; Tan, Y.Q.; Wang, L.B.; Hou, Y. A state-of-the-art review on interfacial behavior between asphalt binder and mineral aggregate. Front. Struct. Civ. Eng. 2018, 12, 248–259. [Google Scholar] [CrossRef]

- Xu, W.Y. Multi-scale Characterization of Asphalt-filler Interaction Behavior and Molecular Dynamic Simulation of Interfacial Adhesion Mechanism. Master’s Thesis, Zhejiang Normal University, Jinhua, China, 2021. [Google Scholar]

- Tao, J.L. Research on Characteristics of Mineral Aggregate and Its Effect on High and Low Temperature Viscoelastic Performance of Asphalt Mixture. Ph.D. Thesis, Jilin University, Changchun, China, 2017. [Google Scholar]

- Xing, C.W.; Tang, S.X.; Chang, Z.B.; Han, Z.C.; Li, H.Z.Y.; Zhu, B.H. A comprehensive review on the plant-mixed cold recycling technology of emulsified asphalt: Raw materials and factors affecting performances. Constr. Build. Mater. 2024, 439, 137344. [Google Scholar] [CrossRef]

- Tarefder, R.A.; Zaman, A.M.; Uddin, W. Determining hardness and elastic modulus of asphalt by nanoindentation. Int. J. Geomech. 2010, 10, 106–116. [Google Scholar] [CrossRef]

- Yao, Z.H.; Lu, G.L.; Yang, J.; Gong, M.H.; Tang, Z.Y.; Xue, J.Y.; Zhang, X.R. Nanoindentation characterization of aging gradient of mastic in asphalt mixtures. Constr. Build. Mater. 2019, 214, 187–195. [Google Scholar] [CrossRef]

- Zhu, X.Y.; Yuan, Y.; Li, L.H.; Du, Y.C.; Li, F. Identification of interfacial transition zone in asphalt concrete based on nano-scale metrology techniques. Mater. Des. 2017, 129, 91–102. [Google Scholar] [CrossRef]

- Katsuki, D.; Gutierrez, M. Nanoindentation approach characterizing strain rate sensitivity of compressive response of asphalt concrete. Acta Geotech. 2014, 9, 887–901. [Google Scholar] [CrossRef]

- Young, T.; Monclus, M.; Burnett, T.; Broughton, W.; Ogin, S.; Smith, P. The use of the PeakForceTM quantitative nanomechanical mapping AFM-based method for high-resolution Young’s modulus measurement of polymers. Meas. Sci. Technol. 2011, 22, 125703. [Google Scholar] [CrossRef]

- Ouyang, Q.J.; Xie, Z.W.; Liu, J.H.; Gong, M.H.; Yu, H.Y. Application of atomic force microscopy as advanced asphalt testing technology: A comprehensive review. Polymers 2022, 14, 2851. [Google Scholar] [CrossRef]

- Das, P.K.; Kringos, N.; Birgisson, B. Microscale investigation of thin film surface ageing of bitumen. J. Microsc. 2014, 254, 95–107. [Google Scholar] [CrossRef]

- Poulikakos, L.D.; dos Santos, S.; Bueno, M.; Kuentzel, S.; Hugener, M.; Partl, M.N. Influence of short and long term aging on chemical, microstructural and macro-mechanical properties of recycled asphalt mixtures. Constr. Build. Mater. 2014, 51, 414–423. [Google Scholar] [CrossRef]

- XU, Z.Y.; SHEN, J.N.; LIU, Y.; SHI, P.C.; SONG, X.Y.; LI, X.S. Nonlinear model of asphalt weathering based on atomic force microscopy technology. J. Mater. Sci. Eng. 2021, 39, 288–293+316. [Google Scholar] [CrossRef]

- Fischer, H.; Stadler, H.; Erina, N. Quantitative temperature-depending mapping of mechanical properties of bitumen at the nanoscale using the AFM operated with PeakForce TappingTM mode. J. Microsc. 2013, 250, 210–217. [Google Scholar] [CrossRef]

- Nahar, S.; Schmets, A.; Scarpas, A.; Schitter, G. Temperature and thermal history dependence of the microstructure in bituminous materials. Eur. Polym. J. 2013, 49, 1964–1974. [Google Scholar] [CrossRef]

- Wang, M.; Liu, L.P. Aging behaviors of nanoscale mechanical properties of asphalt phases. J. Traffic Transp. Eng. 2019, 19, 1–13. [Google Scholar] [CrossRef]

- Liu, L.; Xing, C.; Wang, M. A Method of Determination of Micro Scale Properties of Asphalt Components in Mixtures Based on Atomic Force Microscopy. J. Tongji Univ. (Nat. Sci.) 2018, 46, 1218–1224. [Google Scholar]

- Standard Specifications for Transportation Materials and Methods of Sampling and Testing and Provisional Standards; American Association of State Highway and Transportation Officials (AASHTO): Washington, DC, USA, 2016; Available online: https://searchworks.stanford.edu/view/12089123 (accessed on 1 July 2024).

- JTG E20-2011; Standard Test Methods of Bitumen and Bituminous Mixtures for Highway Engineering. Research Institute of Highway Ministry of Transport: Beijing, China, 2011. Available online: https://kns.cnki.net/kcms2/article/abstract?v=9koCHBfbQEdZTJrLRIO6mHCMJsXZYIng3Hoj2OAtixpHvUiddB_B1jZwo7hjk2dQbZUjJzxiDA9a2Zh6Gk-dRfQpCSTIchnNHE9GUvWi2dUwXjsXUhMUcnslRbAXz4SsPXpycBEsVtgpA28EC1fKnVL1wLrEHE2iDsk7e1zvznAP80tHzQpVTiVCQebbggmw&uniplatform=NZKPT&language=CHS (accessed on 13 September 2011).

- Xing, C.; Liu, L.; Li, M. Analysis of the nanoscale phase characteristics of bitumen and bitumen in mastics and mixtures via AFM. J. Microsc. 2020, 280, 19–29. [Google Scholar] [CrossRef] [PubMed]

- Sato, A.; Furuya, S. Development of a X-ray Exposure Dose Control Tool for CT Examination by Using Spreadsheet Software. Jpn. J. Radiol. Technol. 2023, 79, 142–150. [Google Scholar] [CrossRef] [PubMed]

| Pavement | Service Life (Years) | Asphalt Type/Designation | |

|---|---|---|---|

| Upper Layer | Middle Layer | ||

| M | 0 | SBS-modified asphalt/M-1 | Base asphalt//M-2 |

| A | 6 | SBS-modified asphalt/A-1 | Base asphalt /A-2 |

| B | 6 | SBS-modified asphalt/B-1 | Base asphalt//B-2 |

| C | 7 | SBS-modified asphalt/C-1 | Base asphalt//C-2 |

| D | 4 | Base asphalt/D-1 | Base asphalt//D-2 |

| Mixture Sample | M | A | B | C | D |

|---|---|---|---|---|---|

| Upper layer | 56.0 | 32.5 | 30.4 | 28.1 | 20.5 |

| Middle layer | 68.0 | 36.3 | 36.6 | 39.6 | 42.6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, M.; Wang, Y.; Guo, J.; Xing, C.; Zou, L.; Tian, S. Recognition and Characterization of Nanoscale Phases: Modulus Mapping of Asphalt Film in Pavement Mixture Cores. Polymers 2024, 16, 2537. https://doi.org/10.3390/polym16172537

Wang M, Wang Y, Guo J, Xing C, Zou L, Tian S. Recognition and Characterization of Nanoscale Phases: Modulus Mapping of Asphalt Film in Pavement Mixture Cores. Polymers. 2024; 16(17):2537. https://doi.org/10.3390/polym16172537

Chicago/Turabian StyleWang, Ming, Yuxuan Wang, Jingxuan Guo, Chengwei Xing, Lingyun Zou, and Shuaituan Tian. 2024. "Recognition and Characterization of Nanoscale Phases: Modulus Mapping of Asphalt Film in Pavement Mixture Cores" Polymers 16, no. 17: 2537. https://doi.org/10.3390/polym16172537

APA StyleWang, M., Wang, Y., Guo, J., Xing, C., Zou, L., & Tian, S. (2024). Recognition and Characterization of Nanoscale Phases: Modulus Mapping of Asphalt Film in Pavement Mixture Cores. Polymers, 16(17), 2537. https://doi.org/10.3390/polym16172537