Effects of C-S-H Seed Prepared by Wet Grinding on the Properties of Cement Containing Large Amounts of Silica Fume

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Sample Preparation

2.2.1. Preparation of C-S-H Seed

2.2.2. Concrete Sample Preparation

2.3. Experiment Method

2.3.1. Particle Size Distribution Test

2.3.2. Viscosity Test

2.3.3. Fourier Transform Infrared Spectroscopy (FTIR) Test

2.3.4. Zeta Potential Test

2.3.5. X-ray Diffraction (XRD) Test

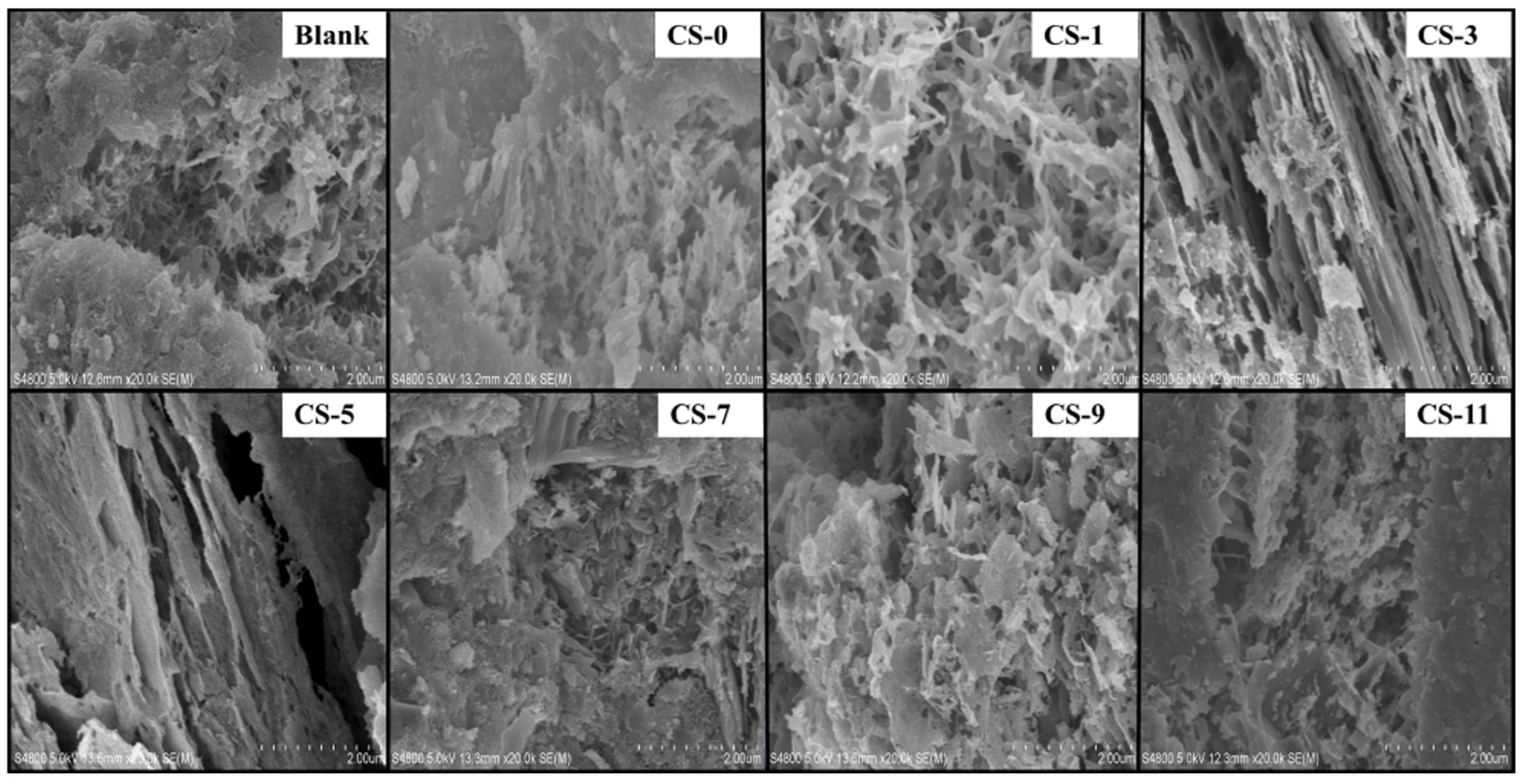

2.3.6. Scanning Electron Microscope (SEM) Test

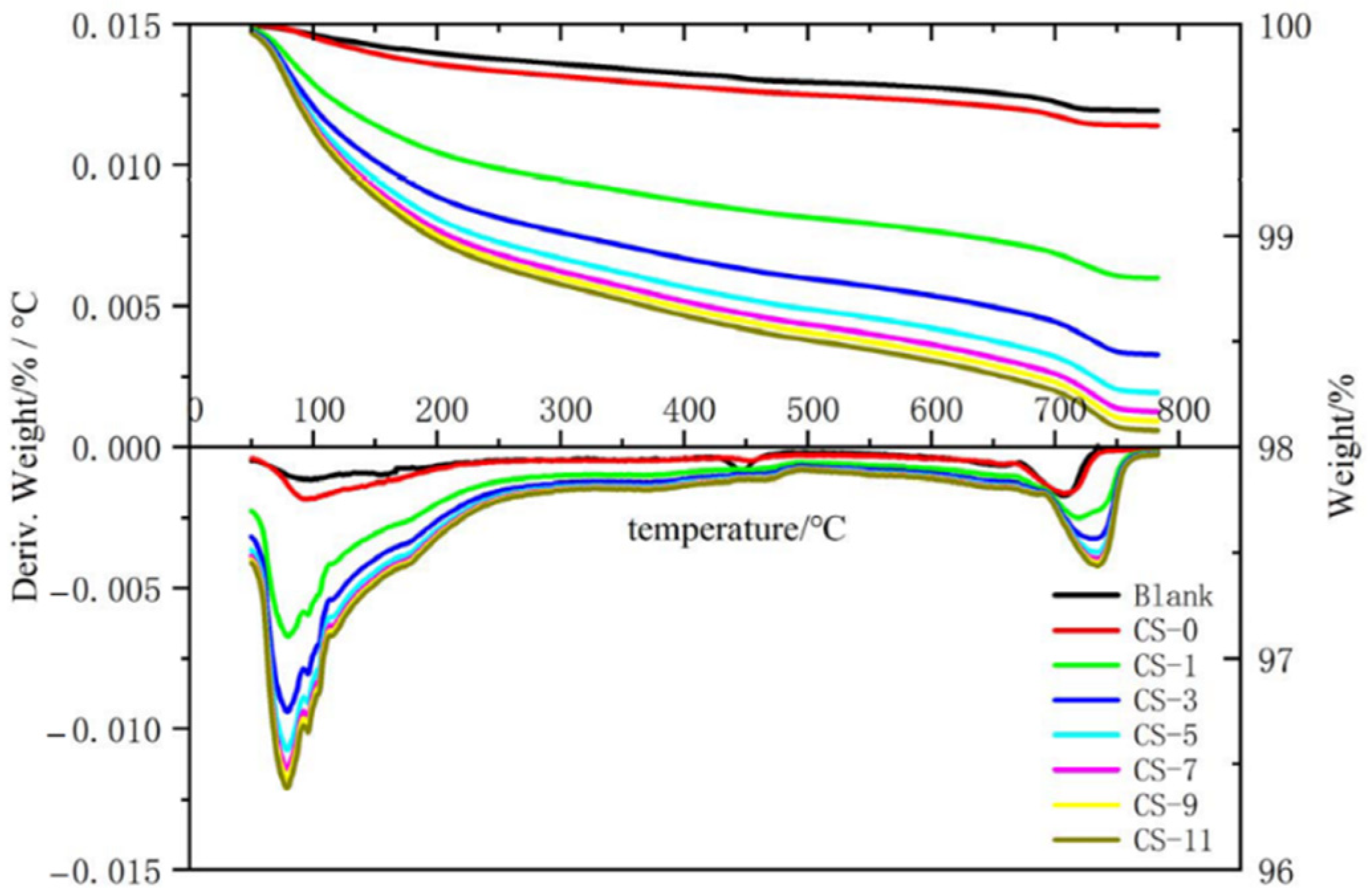

2.3.7. Thermogravimetry–Differential Scanning Calorimetry (TD) Analysis

2.3.8. Concrete Compressive Strength

3. Results

3.1. C-S-H Seed Properties

3.1.1. Particle Size (PS) Distribution

3.1.2. FTIR

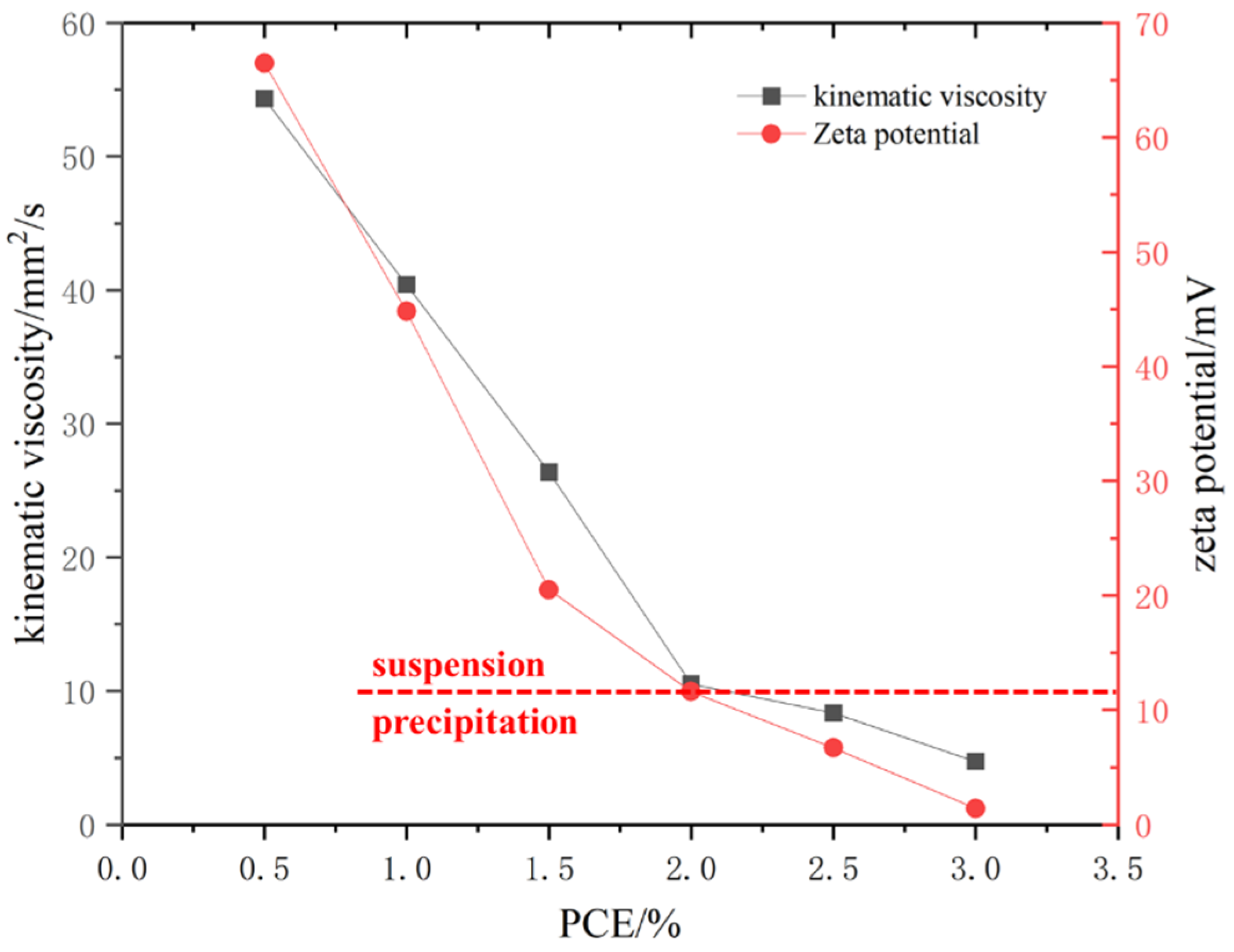

3.1.3. Viscosity and Zeta Potential

3.1.4. XRD

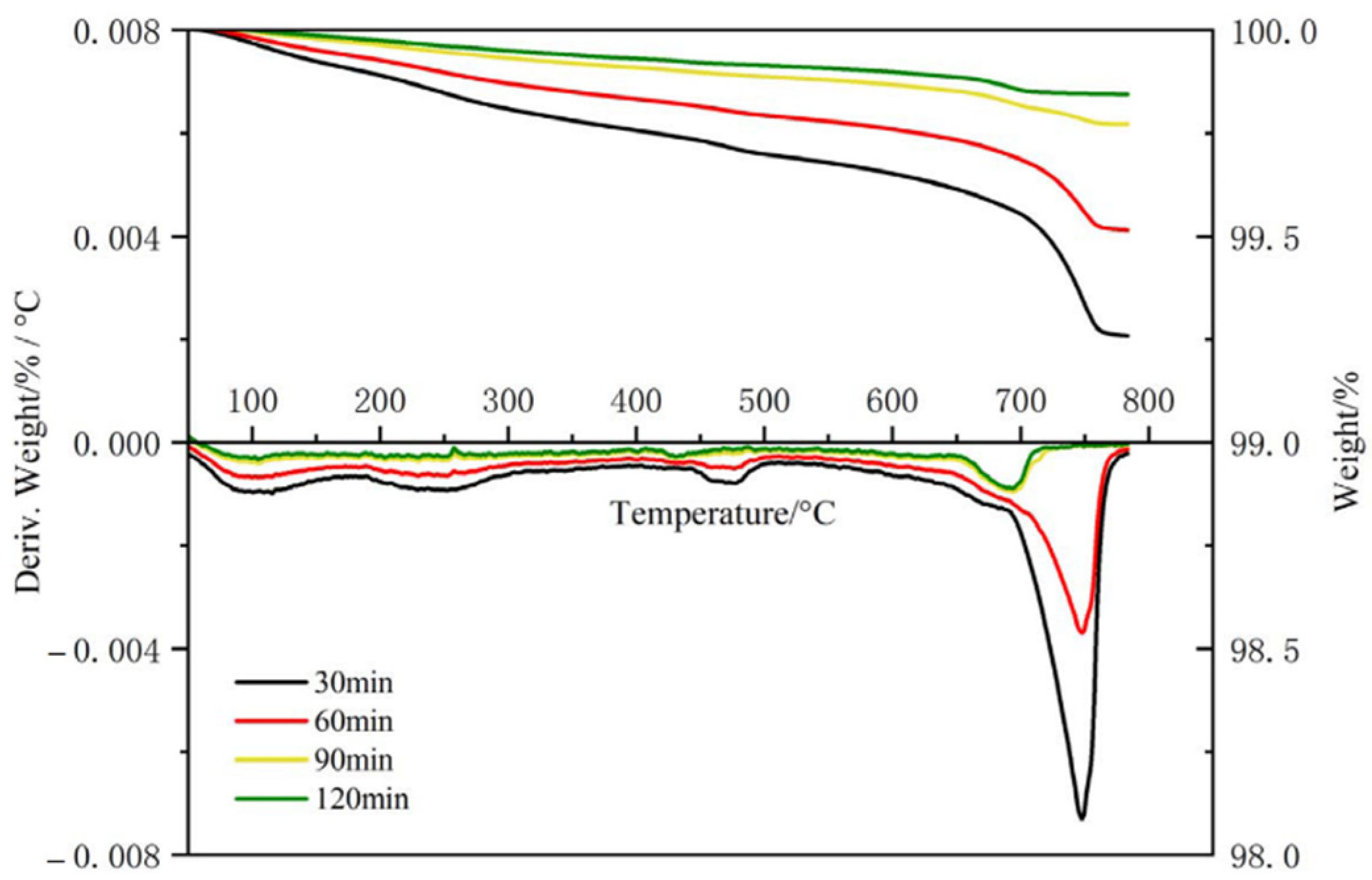

3.1.5. TD

3.2. Concrete Properties

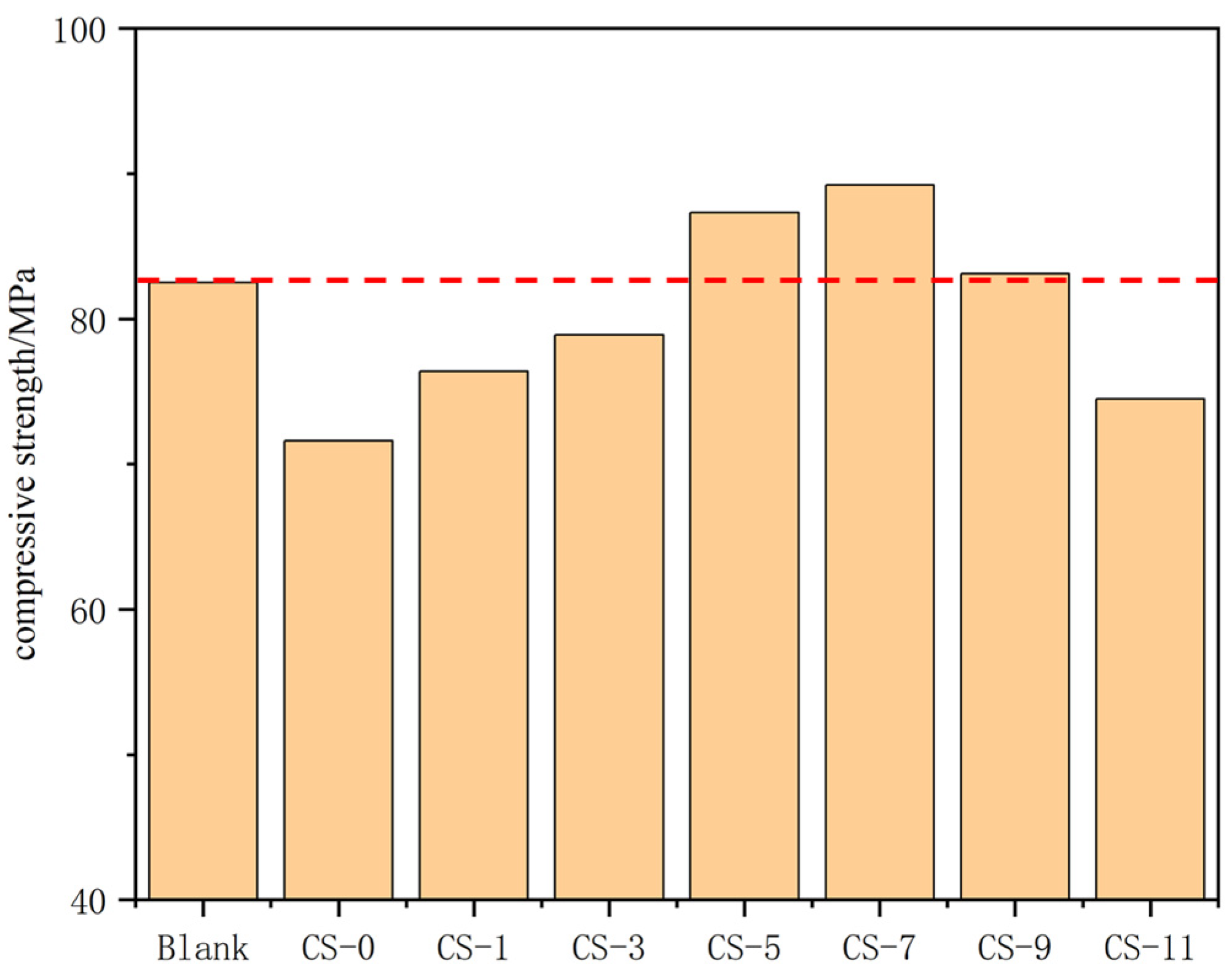

3.2.1. Compressive Strength

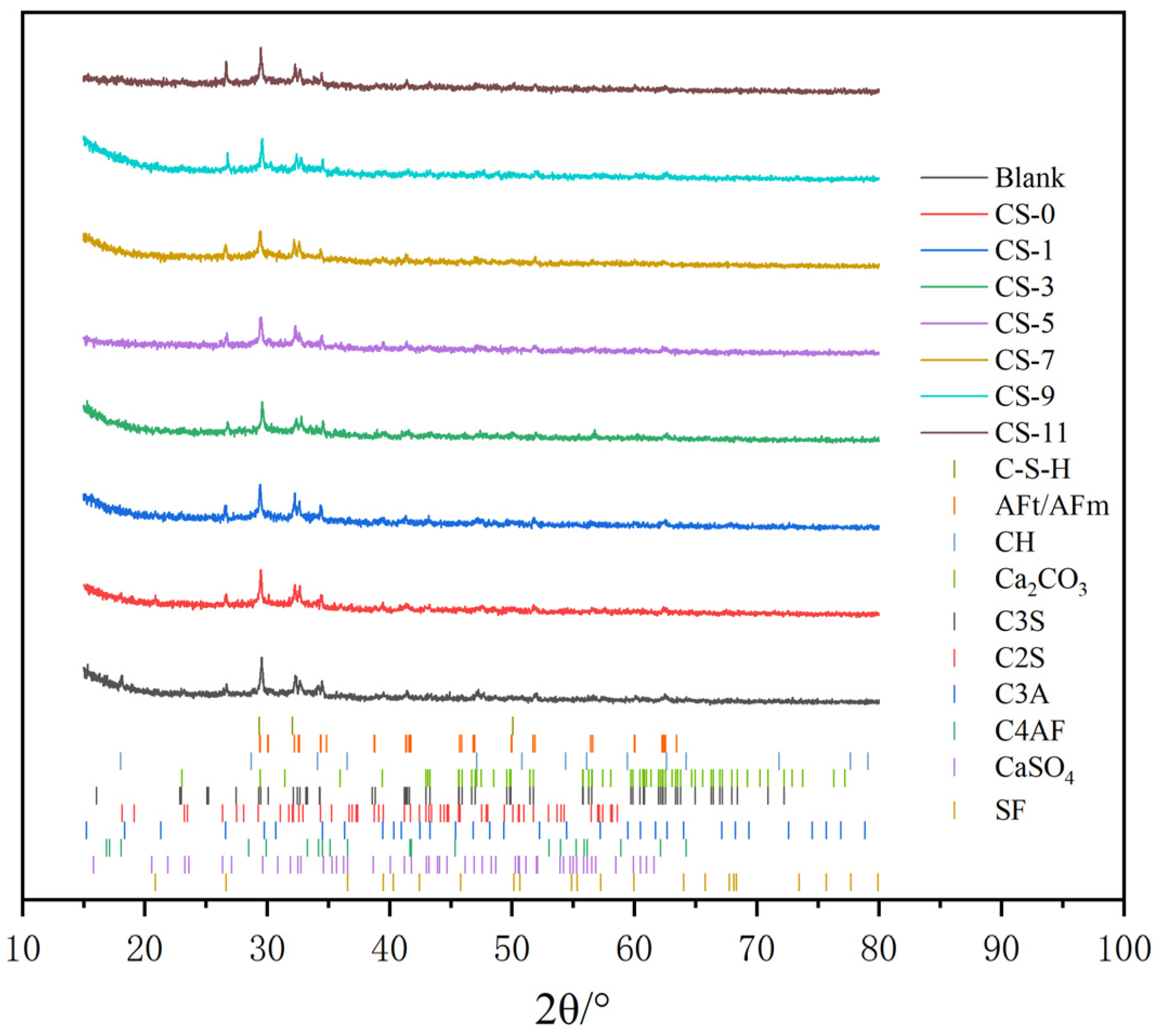

3.2.2. XRD

3.2.3. TD

4. Conclusions

- The wet grinding process can reduce the PS of C-S-H seed and promote its hydration degree. With the increase in wet grinding time, the PS of the C-S-H seed agent continued to decrease, and the hydration degree continued to increase. When the wet grinding time exceeded 90 min, the PS and hydration degree of the C-S-H seed agent no longer increased. There are few reports on the study of wet grinding of C-S-H seed, and its key parameters are not yet clear. Further research on this is necessary.

- The addition of PCE can reduce the dynamic viscosity of the C-S-H seed suspension and make it have good fluidity. When the amount of PCE increased to 1.5%, the dynamic viscosity of the C-S-H seed suspension was significantly reduced. When the amount exceeds 2%, the dynamic viscosity decreased slowly, that is, the amount of PCE in the C-S-H seed suspension should not be less than 1.5%.

- PCE can cause the C-S-H seed suspension to agglomerate and precipitate; With the increase in the amount of PCE, the zeta potential of the C-S-H seed gradually decreased. When the amount of PCE in the crystal seed was greater than 2%, the zeta potential was less than 20 mV, precipitate formed in the C-S-H seed suspension, and the amount of PCE in the C-S-H seed suspension should not be greater than 2.0%. PCE affects the viscosity and zeta potential of C-S-H seed suspension by adsorbing C-S-H seeds and the influence of –COOH group on the surface charge of C-S-H seeds. Further research is needed to investigate how the molecular structure of PCE and the –COO– group affect C-S-H seed suspension, which will help design PCE for C-S-H seed suspension.

- C-S-H seed can improve the early performance of concrete while adding silica fume to replace cement, making the concrete denser and improving the strength of concrete. When the amount of C-S-H seed agent was less than 5%, the concrete strength increased less. When the amount of C-S-H seed agent was higher than 7%, due to the small particle size of C-S-H seed, this will increase the unit water consumption of concrete, making the concrete workability worse and causing the concrete strength to decrease. Therefore, the amount of C-S-H seed agent should be controlled at 5%~7%.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Blotevogel, S.; Doussang, L.; Poirier, M.; André, L.; Canizarès, A.; Simon, P.; Montouillout, V.; Kaknics, J.; Patapy, C.; Cyr, M. The influence of Al2O3, CaO, MgO and TiO2 content on the early-age reactivity of GGBS in blended cements, alkali-activated materials and supersulfated cements. Cem. Concr. Res. 2024, 178, 107439. [Google Scholar] [CrossRef]

- Jiang, J.; Miao, Y.; Wang, H.; Dong, X.; Li, Y.; Lin, J.; Lu, Z. In-situ dispersion of nano-TiO2 to highly reinforce cement paste. Constr. Build. Mater. 2023, 409, 133962. [Google Scholar] [CrossRef]

- Abo-El-Enein, S.; El-Hosiny, F.; El-Gamal, S.; Amin, M.S.; Ramadan, M. Gamma radiation shielding, fire resistance and physicochemical characteristics of Portland cement pastes modified with synthesized Fe2O3 and ZnO nanoparticles. Constr. Build. Mater. 2018, 706, 173687. [Google Scholar] [CrossRef]

- Han, B.; Wang, Z.; Zeng, S.; Zhou, D.; Yu, X.; Cui, X.; Ou, J. Properties and modification mechanisms of nano-zirconia filled reactive powder concrete. Constr. Build. Mater. 2017, 434, 141426. [Google Scholar] [CrossRef]

- Marrero, R.; Corr, J.; Espinosa, H.; Shah, S. Characterization of adhesion strength between carbon nanotubes and cementitious materials. Cem. Concr. Compos. 2023, 138, 104953. [Google Scholar] [CrossRef]

- Reches, Y. Nanoparticles as concrete additives: Review and perspectives. Constr. Build. Mater. 2018, 495, 175483. [Google Scholar] [CrossRef]

- Uthaman, S.; Vishwakarma, V.; George, R.; Ramachandran, D.; Kumari, K.; Preetha, R.; Premila, M.; Rajaraman, R.; Mudali, U.K.; Amarendra, G. Enhancement of strength and durability of fly ash concrete in seawater environments: Synergistic effect of nanoparticles. Constr. Build. Mater. 2018, 459, 187448. [Google Scholar] [CrossRef]

- Tao, M.; Qiang, Y.; Hu, A.; Xu, C.; Lin, L. Effect of compound nano-CaCO3 addition on strength development and microstructure of cement-stabilized soil in the marine environment. Constr. Build. Mater. 2017, 81, 151775. [Google Scholar]

- Li, W.; Wang, R.; Wang, Y.; Zuo, W.; Hong, J.; Luo, S.; Wang, P. The acceleration effect of nano C-S-H-PCE on the microstructure formation and evolution at early age of cement paste. Mater. Struct. 2023, 56, 4. [Google Scholar] [CrossRef]

- Shen, X.; Feng, P.; Zhang, Y.; de Souza, F.B.; Duan, W. Multi-step nucleation of C-S-H: DFT simulation on silicate oligomerization and Si(Qn) evolution dynamics. Constr. Build. Mater. 2024, 439, 137372. [Google Scholar] [CrossRef]

- Yu, J.; Wang, K.; Yang, P.; Li, M.; Dong, B.; Jin, Z.; Hong, S.; Ma, H. Simulation of calcium carbonate nucleation processes in confined C-S-H nanopores with different calcium-silicon ratios. Constr. Build. Mater. 2024, 438, 137157. [Google Scholar] [CrossRef]

- Li, Y.; Tang, E. Research on C-S-H and C-S-H Dehydration Relative to Cement Stone Structure Modification. J. Ceram. 1991, 4, 373–380. [Google Scholar]

- Li, J.; Tang, E. Effect of synthetic C-S-H gel on the interface zone between cement stone and aggregate. J. Wuhan Univ. Technol. 1997, 2, 9–12. [Google Scholar]

- Thomas, J.; Hamlin, M.; Jennings, J. Influence of Nucleation Seeding on the Hydration Mechanisms of Tricalcium Silicate and Cement. J. Phys. Chem. 2009, 113, 4327–4334. [Google Scholar] [CrossRef]

- Wiroonpochit, P.; Boonmee, P.; Kerdlap, W.; Chisti, Y.; Hansupalak, N. Synthesis of low crystalline thermally insulating calcium silicate hydrate via a simple template-assisted sol–gel method. Constr. Build. Mater. 2022, 353, 129081. [Google Scholar] [CrossRef]

- Tian, H.; Stephan, D.; Lothenbach, B.; Lehmann, C. Influence of foreign ions on calcium silicate hydrate under hydrothermal conditions: A review. Constr. Build. Mater. 2021, 301, 124071. [Google Scholar] [CrossRef]

- Chen, G.; Lin, M.; Chen, Y.; Kong, G.; Geng, Z. Alkali-reinforced hydrothermal solidification of waste soil. Mater. Chem. Phys. 2022, 289, 126505. [Google Scholar] [CrossRef]

- Li, M.; Tan, H.; He, X.; Jian, S.; Zheng, Z.; Su, Y.; Yang, J.; Wang, Y.; Luo, Z. Preparation of nano cement particles by wet-grinding and its effect on hydration of cementitious system. Constr. Build. Mater. 2021, 307, 125051. [Google Scholar] [CrossRef]

- Ji, G.; Peng, X.; Wang, S.; Li, J.; Sun, K.; Chi, H. Influence of ground quartz sand finesses on the formation of poorly ordered calcium silicate hydrate prepared by dynamically hydrothermal synthesis. Case Stud. Constr. Mater. 2024, 20, e02746. [Google Scholar] [CrossRef]

- Gu, X.; Tan, H.; He, X.; Zhang, J.; Li, M.; Su, Y.; Yang, J. Nano C-S-H seeds prepared from ground granulated blast-furnace slag-carbide slag and its application in Portland cement. Constr. Build. Mater. 2022, 329, 127204. [Google Scholar] [CrossRef]

- Yang, J.; Zeng, J.; He, X.; Zhang, Y.; Su, Y.; Tan, H. Sustainable clinker-free solid waste binder produced from wet-ground granulated blast-furnace slag, phosphogypsum and carbide slag. Constr. Build. Mater. 2022, 330, 127218. [Google Scholar] [CrossRef]

- Li, Y.; Fang, J.; Cheng, L.; He, X.; Su, Y.; Tan, H. Mechanical performance, hydration characteristics and microstructures of high volume blast furnace ferronickel slag cement mortar by wet grinding activation. Constr. Build. Mater. 2022, 320, 126148. [Google Scholar] [CrossRef]

- Wang, Y.; Tan, H.; Gu, X.; He, X.; Zhang, J. Preparation of nano-kaolin by wet-grinding process and its application as accelerator in Portland cement. J. Build. Eng. 2021, 44, 103401. [Google Scholar] [CrossRef]

- Liu, X.; Ma, B.; Tan, H.; He, X.; Zhao, R.; Chen, P.; Su, Y.; Yang, J. Preparation of ultrafine fly ash by wet grinding and its utilization for immobilizing chloride ions in cement paste. Waste Manag. 2020, 113, 456–468. [Google Scholar] [CrossRef] [PubMed]

- Yang, J.; Yang, M.; He, X.; Ma, M.; Fan, M.; Su, Y.; Tan, H. Green reaction-type nucleation seed accelerator prepared from coal fly ash ground in water environment. Constr. Build. Mater. 2021, 306, 124840. [Google Scholar] [CrossRef]

- Tan, H.; Du, C.; He, X.; Li, M.; Zhang, J.; Zheng, Z.; Su, Y.; Yang, J.; Deng, X.; Wang, Y. Enhancement of compressive strength of high-volume fly ash cement paste by wet grinded cement: Towards low carbon cementitious materials. Constr. Build. Mater. 2022, 323, 126458. [Google Scholar] [CrossRef]

- Feng, X.; Zhuo, C.; Yin, S. Synthesizing high-quality C-S-H seeds using the impinging stream precipitation method. J. Sustain. Cem.-Based Mater. 2024, 13, 841–853. [Google Scholar] [CrossRef]

- Deng, X.; Tan, H.; Yang, Z.; He, X.; Wang, J.; Jian, S.; Huang, J.; Yang, J. C-S-H based nucleation seed prepared from waste glass powder and carbide slag and its application in Portland cement. Constr. Build. Mater. 2024, 416, 135258. [Google Scholar] [CrossRef]

- Cohen, S. Colloid Science; Science Press: Alexandria, Australia, 2012. [Google Scholar]

- Xu, R.; Li, X.; Zuo, D. Flow Field Simulation of Ball-milling Impact towards Dispersion of Nano-suspension and Experimental Verification. J. Mater. Sci. Eng. 2013, 31, 737–742. [Google Scholar]

- Chwadaka, P.; Damodhara, R. Modeling the particle size of nanomaterials synthesized in a planetary ball mill. OpenNano 2023, 14, 100191. [Google Scholar]

- GB/T 50081-2019; Standard Test Methods for Physical and Mechanical Properties of Concrete. Standardization Administration of China: Beijing, China, 2019.

- GB/T 13476-2023; Pretensioned Spun Concrete Piles. Standardization Administration of China: Beijing, China, 2023.

- GB/T 17671-2021; Test Method of Cement Mortar Strength. Standardization Administration of China: Beijing, China, 2021.

- GB/T 30514-2014; Glass Capillary Kinematic Viscometer-Specifications and Operating Instructions. Standardization Administration of China: Beijing, China, 2014.

- Guan, J.; Liu, S.; Liu, X.; Zhang, G.; Lai, G.; Gao, R.; Zhu, H.; Huang, M.; Wang, Z.; Cui, S. Effect of side chain ionizability of polycarboxylate superplasticizer on cement hydration. Constr. Build. Mater. 2024, 436, 136940. [Google Scholar] [CrossRef]

- Plank, J.; Hirsch, C. Impact of zeta potential of early cement hydration phases on superplasticizer adsorption. Cem. Concr. Res. 2007, 37, 537–542. [Google Scholar] [CrossRef]

- Luc, N.; Alexander, E.; Matthias, K. A kinetic analysis of the role of polymers in mineral nucleation. The exampleof gypsum. Cem. Concr. Res. 2019, 124, 105837. [Google Scholar]

- Made, J.; Muthukannan, V.; Camellia, P.; Ferry, F. Dispersion of amorphous silica nanoparticles via beads milling processand their particle size analysis, hydrophobicity and anti-bacterial activity. Adv. Powder Technol. 2020, 31, 370–380. [Google Scholar] [CrossRef]

- Fenda, F.; Ferry, F.; Sparisoma, V. Experimental and simulation study of solid flows in beads mill. Adv. Powder Technol. 2021, 32, 2703–2711. [Google Scholar]

- Tao, Y.; Jae, W.; Xiong, S. Physicochemical properties of nano fish bone prepared by wet media milling. LWT—Food Sci. Technol. 2015, 64, 367–373. [Google Scholar]

- Liu, H.; Sun, X.; Du, H.; Lu, H.; Ma, Y.; Shen, W.; Tian, Z. Effects and threshold of water film thickness on multi-mineral cement paste. Cem. Concr. Compos. 2020, 112, 103677. [Google Scholar] [CrossRef]

- Zhang, Z.; Feng, Q.; Zhu, W.; Lin, X.; Chen, K.; Yin, W.; Lu, C. Influence of Sand-Cement Ratio and Polycarboxylate Superplasticizer on the Basic Properties of Mortar Based on Water Film Thickness. Materials 2021, 14, 4850. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Ma, Y.; Wang, J.; Gao, N.; Hu, Z.; Liu, J.; Wang, K. A novel shrinkage-reducing polycarboxylate superplasticizer for cement-based materials: Synthesis, performance and mechanisms. Constr. Build. Mater. 2022, 321, 126342. [Google Scholar] [CrossRef]

- Kanchanason, V.; Plank, J. Role of pH on the structure, composition and morphology of C-S-H-PCE nanocomposites and their effect on early strength development of Portland cement. Cem. Concr. Res. 2017, 102, 98. [Google Scholar] [CrossRef]

- Abbas, S.N.; Qureshi, M.I.; Alkharisi, M.K.; Alturki, M.; Ahmad, Z. Combined effect of silica fume and various fibers on fresh and hardened properties of concrete incorporating HDPE aggregates. Cem. Concr. Res. 2024, 445, 137940. [Google Scholar] [CrossRef]

- Hou, D.; Li, H.; Zhang, L.; Zhang, J. Nano-scale mechanical properties investigation of C-S-H from hydratedtri-calcium silicate by nano-indentation and molecular dynamics simulation. Cem. Concr. Res. 2018, 189, 265–275. [Google Scholar]

- Wang, Y.; Wang, X.; Yao, F.; Lin, C.; Xu, S.; Li, Y.; Du, J.; Pan, L. What are the mechanisms of functional monomers’ effect on air entrainment of polycarboxylate superplasticizers in cement paste and mortar. Constr. Build. Mater. 2024, 442, 137038. [Google Scholar] [CrossRef]

- Chen, Y.; Chen, Y.; Xie, Y.; Liu, Y.; Tao, J.; Liu, R.; Li, Z.; Liu, F.; Li, M. The effect of alkyl acrylate ester side chain length of polycarboxylate superplasticizer on the flow behaviour of concrete. Constr. Build. Mater. 2024, 443, 137691. [Google Scholar] [CrossRef]

- Mehmet, S.; Egemen, T.; Jale, Y.; Malayoglu, U. The effect of nano-biochar produced from various raw materials on flow and mechanical properties of mortar. Constr. Build. Mater. 2024, 416, 135404. [Google Scholar]

- Kim, G.; Cho, S.; Moon, J.; Suh, H.; Her, S.; Sim, S.; Bae, S. Investigation of the hydrate formation and mechanical performance of limestone calcined clay cement paste incorporating nano-CaCO3 and nano-SiO2 as partial limestone substitutes. Constr. Build. Mater. 2024, 418, 135335. [Google Scholar] [CrossRef]

- Yun, J.; Zhao, C.; Li, X.; Zhang, W.; Liu, H.; Liu, B. Rheological properties and early mechanical strength of oil-well cement modified by hybrid nano-silica and nano-hexagonal boron nitride. Constr. Build. Mater. 2022, 356, 129291. [Google Scholar] [CrossRef]

- Zhang, Y.; Guo, L.; Shi, J.; Luo, Q.; Jiang, J.; Hou, D. Full process of calciumsilicate hydrate decalcification: Molecular structure, dynamics. and mechanical properties. Cem. Concr. Res. 2022, 161, 106964. [Google Scholar] [CrossRef]

- Tennis, P.; Jennings, H. A model for two types of calcium silicate hydrate in the microstructure of Portland cement pastes. Cem. Concr. Res. 2000, 30, 855–863. [Google Scholar] [CrossRef]

| Sample | SiO2 | Al2O3 | CaO | Fe2O3 | SO3 | MgO | LOI |

|---|---|---|---|---|---|---|---|

| Cement | 22.84 | 4.53 | 61.98 | 3.41 | 2.83 | 2.61 | 1.80 |

| GGBS | 34.13 | 13.52 | 40.88 | 0.51 | 2.36 | 6.79 | 1.81 |

| SF | 98.31 | 0.14 | 0.56 | 0.21 | 0.12 | 0.31 | 0.35 |

| Sample | Cement | GGBS | SF | Sand | Aggregate | Water | C-S-H Seed |

|---|---|---|---|---|---|---|---|

| Blank | 320 | 85 | 40 | 620 | 1380 | 110 | 0 |

| CS-0 | 250 | 85 | 110 | 620 | 1380 | 110 | 0 |

| CS-1 | 246 | 85 | 110 | 620 | 1380 | 110 | 18 |

| CS-3 | 237 | 85 | 110 | 620 | 1380 | 110 | 54 |

| CS-5 | 228 | 85 | 110 | 620 | 1380 | 110 | 89 |

| CS-7 | 219 | 85 | 110 | 620 | 1380 | 110 | 125 |

| CS-9 | 210 | 85 | 110 | 620 | 1380 | 110 | 160 |

| CS-11 | 201 | 85 | 110 | 620 | 1380 | 110 | 196 |

| Sample | Cement | GGBS | SF | Water | C-S-H Seed |

|---|---|---|---|---|---|

| Blank | 320 | 85 | 40 | 110 | 0 |

| CS-0 | 250 | 85 | 110 | 110 | 0 |

| CS-1 | 246 | 85 | 110 | 110 | 18 |

| CS-3 | 237 | 85 | 110 | 110 | 54 |

| CS-5 | 228 | 85 | 110 | 110 | 89 |

| CS-7 | 219 | 85 | 110 | 110 | 125 |

| CS-9 | 210 | 85 | 110 | 110 | 160 |

| CS-11 | 201 | 85 | 110 | 110 | 196 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, S.; Zhao, P.; Tian, Y.; Liu, J. Effects of C-S-H Seed Prepared by Wet Grinding on the Properties of Cement Containing Large Amounts of Silica Fume. Polymers 2024, 16, 2769. https://doi.org/10.3390/polym16192769

Wang S, Zhao P, Tian Y, Liu J. Effects of C-S-H Seed Prepared by Wet Grinding on the Properties of Cement Containing Large Amounts of Silica Fume. Polymers. 2024; 16(19):2769. https://doi.org/10.3390/polym16192769

Chicago/Turabian StyleWang, Shiheng, Peng Zhao, Yaogang Tian, and Jianan Liu. 2024. "Effects of C-S-H Seed Prepared by Wet Grinding on the Properties of Cement Containing Large Amounts of Silica Fume" Polymers 16, no. 19: 2769. https://doi.org/10.3390/polym16192769

APA StyleWang, S., Zhao, P., Tian, Y., & Liu, J. (2024). Effects of C-S-H Seed Prepared by Wet Grinding on the Properties of Cement Containing Large Amounts of Silica Fume. Polymers, 16(19), 2769. https://doi.org/10.3390/polym16192769