Application Progress of Multi-Functional Polymer Composite Nanofibers Based on Electrospinning: A Brief Review

Abstract

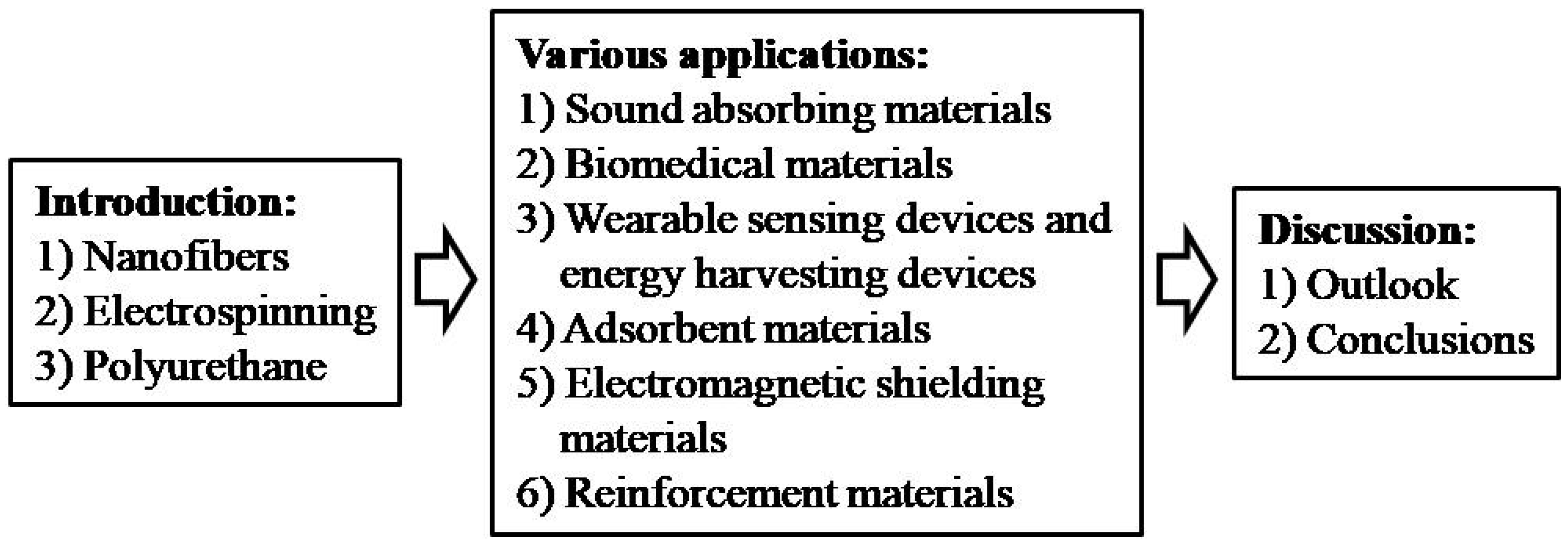

1. Introduction

2. Numerous Applications of Polymer Composite Nanofibers and Their Thin Membranes

2.1. Sound-Absorbing Materials

2.2. Biomedical Materials

2.2.1. Implantable Materials for Tissue Engineering

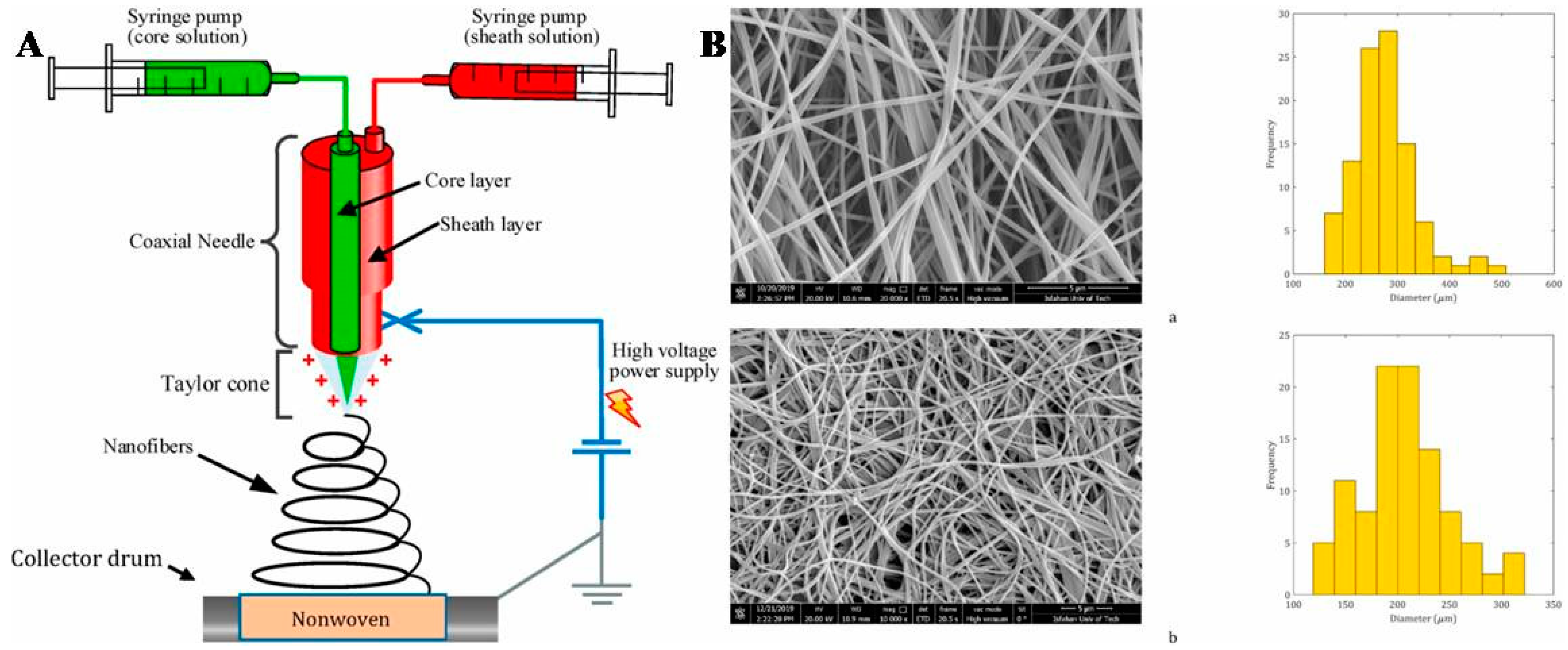

2.2.2. Drug Delivery System

2.2.3. Wound Dressings and Other Anti-Bacterial Materials

2.2.4. Health Materials

2.3. Wearable Sensing Devices and Energy-Harvesting Devices

2.3.1. Wearable Sensing Devices

2.3.2. Energy Harvester

2.4. Adsorbent Materials

2.5. Electromagnetic Shielding Materials

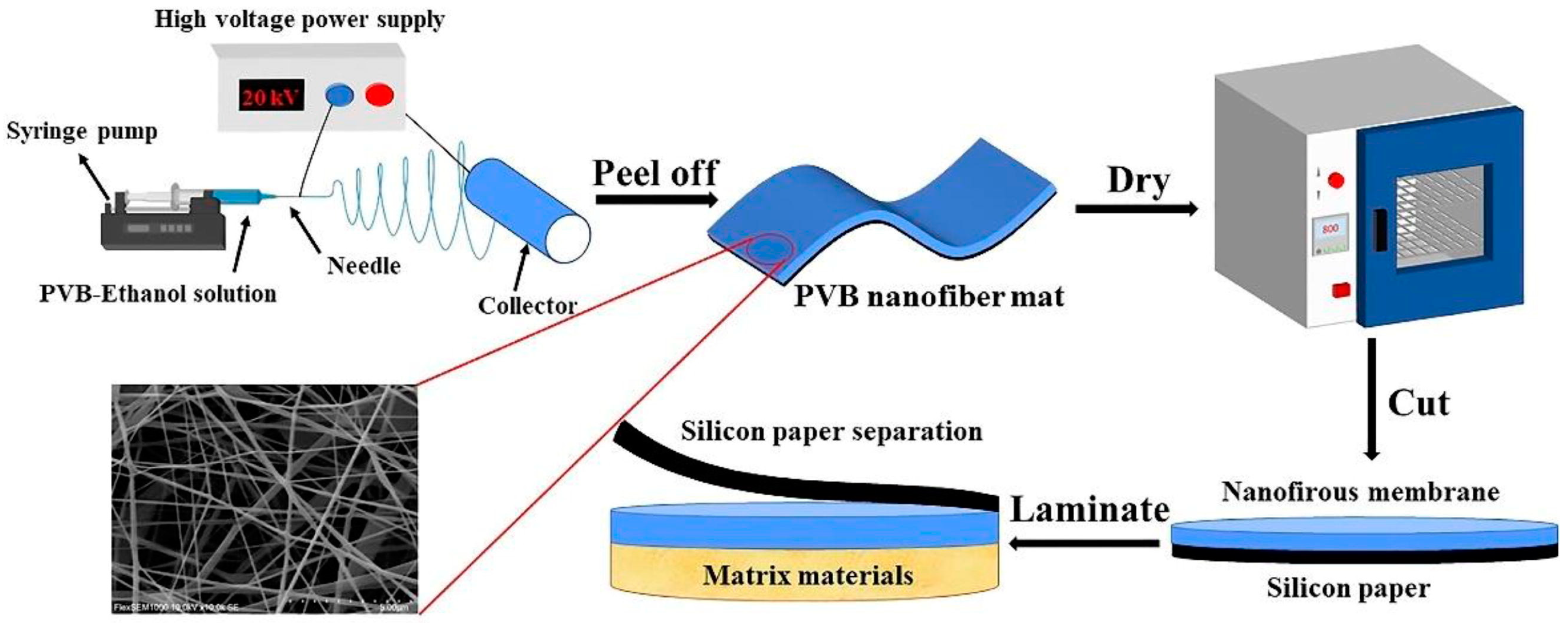

2.6. Reinforcement Materials

3. Discussion and Outlook

- (1)

- n terms of the product cost of PU-based nanofibers, although PU belongs to a cheaper category compared to other polymer materials, its preparation process is still relatively expensive because it requires the use of a large amount of organic solvents, e.g., DMAc and DMF, which are usually not cheap. Moreover, due to the relatively low production efficiency of electrospinning compared to other preparation processes, the equipment occupation time and energy consumption are usually costly. All of these factors contribute to the relatively high price of PU-based nanofibers compared to other polymer products. Therefore, further development of electrospinning technology is still needed, such as upgrading needleless and multi-needle electrospinning technology and multi-material co-spinning.

- (2)

- The typically large amount of usually corrosive and toxic organic solvents for the electrospinning polymer solutions are prone to environmental pollution. Therefore, much more effort should also be made to develop environmentally friendly solvents, such as water-soluble solvents and recyclable solvents. The combination of the electrospinning method and other related technologies will also be one of the strategies for achieving significant breakthroughs in preparation efficiency. Moreover, water-soluble polymers and eco-friendly melt electrospinning are also excellent choices. According to statistics, the total amount of PU waste accounts for about 30% of the total volume of all waste plastics, which has caused serious environmental problems. Fortunately, most PU materials have both hydrolytic and biodegradable abilities, mainly due to their unique chemical structure. Among them, polyester-type PU has better biodegradability than polyether-type PU. Intentionally selecting the chemical structure can significantly increase PU’s hydrolysis rate. Of course, both hydrolysis and biodegradation require huge storage spaces and take a long time. Therefore, how to further improve the hydrolysis and biodegradation ability of PU remains an important research direction.

- (3)

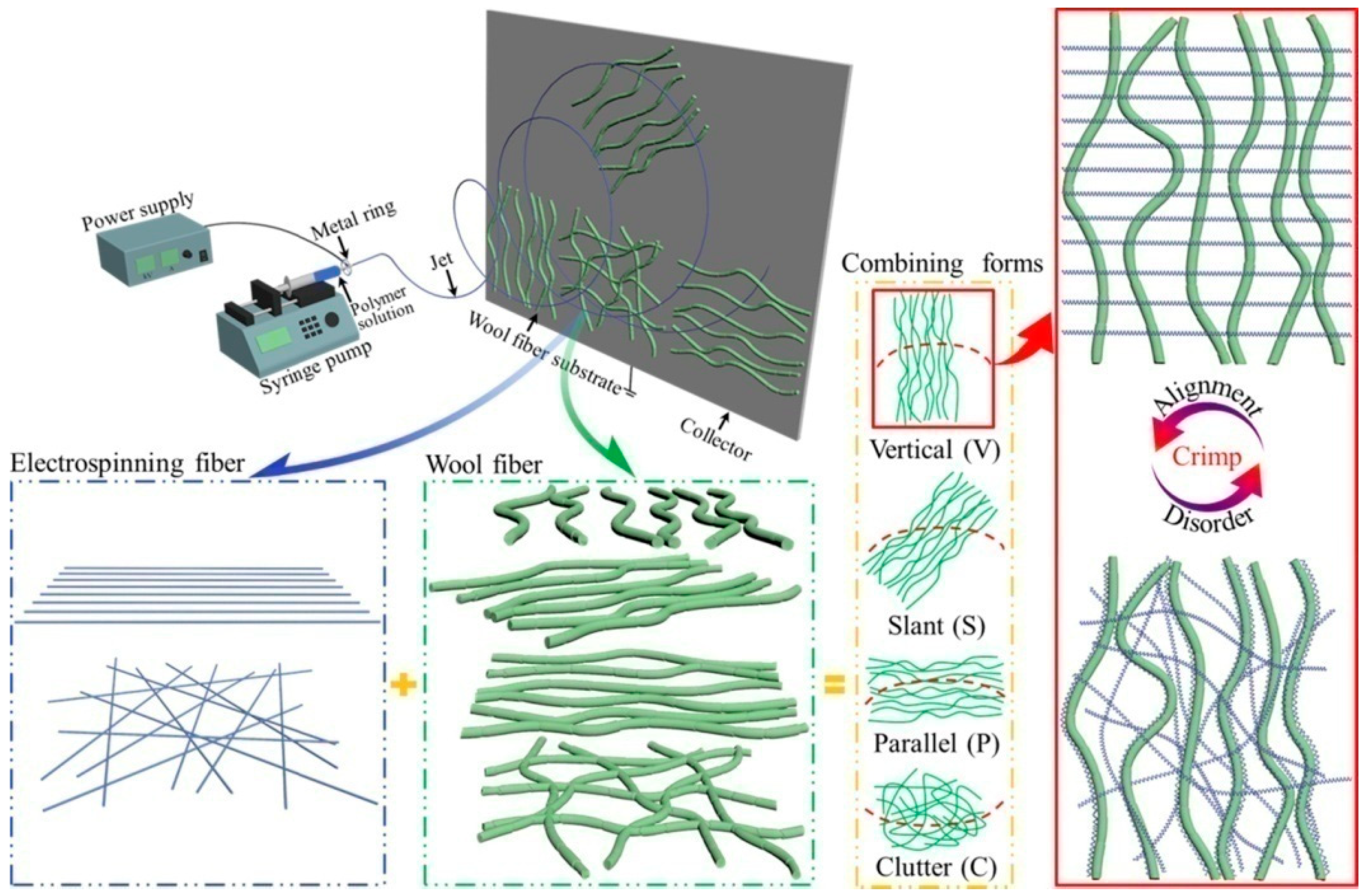

- The morphology and structure of electrospun nanofibers will still be a focus of attention in terms of product regulation. For example, the crimped morphology and fine structures, such as core–shell and hollow structures of nanofibers, have a significant impact on the performance and function of their membranes. Multi-material co-spinning provides large space for the fine design of multi-layer structures and regulation of multi-phase structures, making it an important research and development direction worthy of attention.

- (4)

- The mechanical properties of electrospun nanofibers and their thin membranes still have some obvious shortcomings. Therefore, how to improve the mechanical properties of single nanofibers by improving their continuity, orientation, crystallinity, etc., and how to increase the interaction force between single fibers to improve the mechanical properties of fiber membranes will still be a focus of research and development. The anti-bacterial, hydrophobic, biocompatible, and biodegradable properties of electrospun nanofibers are the basis of their functional performance, and further improvement and more precise regulation are definitely needed. Among them, the dispersion problem of inorganic, metal, and organic nanofillers in the polymer nanofiber matrix is still one of the technical difficulties and needs to be better solved.

- (5)

- Concerning the disadvantages of PU, such as easy aging (susceptible to UV radiation, oxygen, temperature changes, and other factors) and low mechanical strength and modulus, not only physical treatment but also chemical modification is needed to improve its comprehensive properties. The combination with nanotechnology, e.g., adding nano-size fillers, is one of the most feasible strategies to overcome the disadvantages of PU as the matrix of nanofiber composites.

4. Conclusions

- (1)

- In response to noise pollution, especially low-frequency noises below 500 Hz and intermediate-frequency noises of 500–2500 Hz, nanofiber membranes have excellent sound absorption ability due to their involvement in both porous and resonant mechanisms. Combining nanofiber membranes with traditional microfibers can solve the problem of poor sound absorption performance in the low frequency range, achieving the best comprehensive sound absorption effect. Moreover, the addition of nanofiber membranes will barely increase the materials’ thickness and weight.

- (2)

- The application of electrospun nanofibers in the biomedical field mainly includes implantable materials (such as scaffolds) in tissue engineering, controlled drug release, wound dressings, and health materials. The anisotropic structure of both bone tissue and blood vessels can be achieved by utilizing the highly oriented properties of electrospun nanofibers. The polymer nanofibers prepared by electrospinning have more advantages than other nanoparticles when used in targeted drug delivery systems. The bioactive wound dressing prepared by the electrospinning nanofiber membrane has good anti-bacterial properties and can help with wound healing. The electrospinning nanofibers combined with functional materials such as tourmaline can also be used for health materials such as negative ions. For the biomedical applications of electrospun nanofiber membranes, such as wound dressings, traditional materials such as gauze and nonwoven fabrics are used as benchmarks. Although the preparation efficiency of electrospun nanofiber membranes is lower and the price per unit volume and weight is higher, they have some special properties that other materials do not have, so they still have their application market. Of course, combining electrospun nanofiber membranes with traditional materials may achieve synergistic effects in terms of functionality and economy.

- (3)

- In terms of wearable sensing devices, the conductive electrospun nanofibers using nanocomposite technology are suitable for the key components of flexible electronic devices due to their excellent comprehensive performance and can be used to detect the health status of the body and the movement status of different human parts. In terms of energy-harvesting devices, electrospun nanofibers can be used to prepare nanogenerators based on electrostatic induction and contact electrification mechanisms, providing electricity for wearable devices.

- (4)

- In terms of the adsorbent materials, the treatment of oil pollution caused by offshore oil exploration and transportation accidents requires cost-effective oil adsorbents, such as magnetic electrospun composite nanofiber membranes.

- (5)

- In terms of electromagnetic shielding materials, reducing electromagnetic radiation pollution requires the development of high-performance electromagnetic shielding materials, such as conductive polymer composites, which replace traditional metal materials due to their numerous advantages. The conductive electrospun composite nanofiber membrane is one of the outstanding types.

- (6)

- In terms of the reinforcing materials, the high modulus, strength, and ultra-high specific surface area of electrospun polymer nanofibers make them suitable as nanofillers for polymer composites. Their high specific surface area is especially conducive to the impregnation of fillers by the matrix, thus forming a good interface with tight contact and strong bonding. The biggest difference between this review and other reviews related to electrospinning is the emphasis on the combination of composite material technology and electrospinning technology. The introduction of nanofillers can not only improve the mechanical strength of electrospun nanofibers but also endow the material with more functions. This is undoubtedly extremely important for its practical application.

- (7)

- There is still a significant gap in the preparation efficiency, production scale, and product price of electrospun nanofibers compared to the microfibers prepared by traditional methods. Therefore, much more effort in material synthesis, structure design, technique improvement, and so on is still needed for the wider applications of such novel materials.

Funding

Conflicts of Interest

Abbreviations

| 1D | one-dimensional |

| 3D | three-dimensional |

| AC | alternating current |

| CNT | carbon nanotube |

| DC | direct current |

| DMAc | N,N-dimethylacetamide |

| DMF | dimethylformamide |

| GO | graphene oxide |

| MOF | metal–organic framework |

| MWCNT | multi-wall carbon nanotube |

| MXene | two-dimensional transition metal carbon nitrides |

| PA | polyamide |

| PAN | polyacrylonitrile |

| PCL | polycaprolactone |

| PDA | polydopamine |

| PDLA | poly(D-lactic acid) |

| PDMS | polydimethyl siloxane |

| PEG | polyethylene glycol |

| PEO | polyethylene oxide |

| PFDT | 1H,1H,2H,2H-perfluorododecanethiol |

| PET | polyethylene terephthalate |

| PK | polyketone |

| PLA | polylactic acid |

| PLLA | poly(L-lactic acid) |

| PMMA | polymethyl methacrylate |

| PP | polypropylene |

| PS | polystyrene |

| PTFE | polytetrafluoroethylene |

| PU | polyurethane |

| PUA | polyurethane acrylate |

| PVA | polyvinyl alcohol |

| PVAc | polyvinyl acetate |

| PVB | polyvinyl butyral |

| PVDF | polyvinylidene fluoride |

| PZT | lead zirconate titanate |

| SEM | scanning electron microscope |

| TENG | triboelectric nanogenerator |

| TM | tourmaline |

| TN | tourmaline nanoparticles |

| TPU | thermoplastic polyurethane |

| UV | ultraviolet |

References

- Li, L.; Wang, T.; Zhong, Y.; Li, R.; Deng, W.; Xiao, X.; Xu, Y.; Zhang, J.; Hu, X.; Wang, Y. A review of nanomaterials for biosensing applications. J. Mater. Chem. B 2024, 12, 1168–1193. [Google Scholar] [CrossRef] [PubMed]

- Kalluri, L.; Duan, Y.; Janorkar, A.V. Electrospun polymeric nanofibers for dental applications. J. Appl. Polym. Sci. 2024, 141, e55224. [Google Scholar] [CrossRef]

- Formhals, A. Process and Apparatus for Preparing Artificial Threads. U.S. Patents Specification 1975504, 10 February 1934. [Google Scholar]

- Chen, Z.; Guan, M.; Bian, Y.; Yin, X. Multifunctional electrospun nanofibers for biosensing and biomedical engineering applications. Biosensors 2024, 14, 13. [Google Scholar] [CrossRef]

- Chen, X.; Liu, Z.; Ma, R.; Lu, J.; Zhang, L. Electrospun nanofibers applications in caries lesions: Prevention, treatment and regeneration. J. Mater. Chem. B 2024, 12, 1429–1445. [Google Scholar] [CrossRef] [PubMed]

- Zhang, C.; Li, J.; Chen, Y.; Zou, Z.; Zhang, Y.; Liu, Y.; Wu, B. Stretchable, flexible, and breathable MXene/dopamine/thermoplastic polyurethane nanofiber membrane with outstanding strain sensing and electromagnetic interference shielding performances. Mater. Today Commun. 2024, 38, 107968. [Google Scholar] [CrossRef]

- Xiong, C.; Wang, L.; Yu, J.; Qin, X.; Wang, R.; Yu, J. Continuous self-crimped micro-nanofiber via one-step electrospinning. Compos. Part A 2022, 158, 106959. [Google Scholar] [CrossRef]

- Nan, Z.; Wei, W.; Lin, Z.; Chang, J.; Hao, Y. Flexible nanocomposite conductors for electromagnetic interference shielding. Nano-Micro Lett. 2023, 15, 172. [Google Scholar] [CrossRef]

- Lee, Y.S.; Kim, M.-S.; Kim, D.W.; Pang, C. Intelligent structured nanocomposite adhesive for bioelectronics and soft robots. Nano Res. 2024, 17, 534–549. [Google Scholar] [CrossRef]

- Wei, Z.; Gong, P.; Kong, X.; Li, M.; Cheng, J.; Zhou, H.; Li, D.; Ye, Y.; Lu, X.; Yu, J.; et al. Enhanced thermal conductivity of nanodiamond nanosheets/polymer nanofiber composite films by uniaxial and coaxial electrospinning: Implications for thermal management of nanodevices. ACS Appl. Nano Mater. 2023, 6, 8358–8366. [Google Scholar] [CrossRef]

- Ren, S.; Liu, Y.; Sun, W.; Wang, H.; Lei, Y.; Wang, H.; Zeng, X. Broadband low-frequency sound absorbing metastructures composed of impedance matching coiled-up cavity and porous materials. Appl. Acoust. 2022, 200, 109061. [Google Scholar] [CrossRef]

- Li, X.; Peng, Y.; He, Y.; Zhang, C.; Zhang, D.; Liu, Y. Research progress on sound absorption of electrospun fibrous composite materials. Nanomaterials 2022, 12, 1123. [Google Scholar] [CrossRef] [PubMed]

- Ozkal, A.; Callioglu, F.C. Effect of nanofiber spinning duration on the sound absorption capacity of nonwovens produced from recycled polyethylene terephthalate fibers. Appl. Acoust. 2020, 169, 107468. [Google Scholar] [CrossRef]

- Selvaraj, S.; Ramalingam, S.; Parida, S.; Rao, J.R.; Nishter, N.F. Chromium containing leather trimmings valorization: Sustainable sound absorber from collagen hydrolysate intercalated electrospun nanofibers. J. Hazard. Mater. 2021, 405, 124231. [Google Scholar] [CrossRef]

- Wu, D.-Y.; Wang, S.-S.; Wu, C.-S. Textile fabrics containing recycled poly(ethylene terephthalate), oyster shells, and silica aerogels with superior heat insulation, water resistance, and antibacterial properties. ACS Appl. Polym. Mater. 2021, 3, 3175–3184. [Google Scholar] [CrossRef]

- Shao, X.; Yan, X. Sound absorption properties of nanofiber membrane-based multi-layer composites. Appl. Acoust. 2022, 200, 109029. [Google Scholar] [CrossRef]

- Hajimohammadi, M.; Soltani, P.; Semnani, D.; Taban, E.; Fashandi, H. Nonwoven fabric coated with core-shell and hollow nanofiber membranes for efficient sound absorption in buildings. Build. Environ. 2022, 213, 108887. [Google Scholar] [CrossRef]

- Karaca, N.; Yuksek, I.O.; Ucar, N.; Onen, A.; Baydogan, M.; Kirbas, C. Experimental analysis of sound absorption effect of specially developed elastomeric thin thermoplastic polyurethane sub-micron fibre web layers placed on rigid layer and flexible layers. Plast. Rubber Compos. 2021, 50, 507–515. [Google Scholar] [CrossRef]

- Karaca, N.; Yuksek, I.O.; Ucar, N.; Onen, A.; Kirbas, C. Sound absorption and thermal insulation properties of composite thermoplastic polyurethane/polystyrene (TPU/PS) nanofiber web and TPU nanofiber web and PS-extracted TPU/PS microfiber web. J. Ind. Text. 2022, 51, 7963S–7982S. [Google Scholar] [CrossRef]

- Sakamoto, S.; Hasegawa, T.; Ikeda, K. Estimation of sound transmission loss in nanofiber nonwoven fabrics: Comparison of conventional models and the simplified limp frame model. Nanomaterials 2023, 13, 2947. [Google Scholar] [CrossRef]

- Mammana, M.; Bonis, A.; Verzeletti, V.; Dell’Amore, A.; Rea, F. Tracheal tissue engineering: Principles and state of the art. Bioengineering 2024, 11, 198. [Google Scholar] [CrossRef]

- Eom, S.; Park, S.M.; Hwang, D.G.; Kim, H.W.; Jang, J.; Kim, D.S. Fabrication of an align-random distinct, heterogeneous nanofiber mat endowed with bifunctional properties for engineered 3D cardiac anisotropy. Compos. Part B 2021, 226, 109336. [Google Scholar] [CrossRef]

- Jin, Q.; Fu, Y.; Zhang, G.; Xu, L.; Jin, G.; Tang, L.; Ju, J.; Zhao, W.; Hou, R. Nanofiber electrospinning combined with rotary bioprinting for fabricating small-diameter vessels with endothelium and smooth muscle. Compos. Part B 2022, 234, 109691. [Google Scholar] [CrossRef]

- Chuan, D.; Fan, R.; Wang, Y.; Ren, Y.; Wang, C.; Du, Y.; Zhou, L.; Yu, J.; Gu, Y.; Chen, H.; et al. Stereocomplex poly(lactic acid)-based composite nanofiber membranes with highly dispersed hydroxyapatite for potential bone tissue engineering. Compos. Sci. Technol. 2020, 192, 108107. [Google Scholar] [CrossRef]

- Yan, S.; Na, J.; Liu, X.; Wu, P. Different targeting ligands-mediated drug delivery systems for tumor therapy. Pharmaceutics 2024, 16, 248. [Google Scholar] [CrossRef]

- Aminu, N.; Ilyasu, S.; Hassan, M.A.-K.; Kurfi, F.S.; Jatau, A.I.; Chan, S.-Y.; Alfred-Ugbenbo, D. Applications of nanofibers drug delivery system in cancer therapy. J. Drug Deliv. Sci. Technol. 2023, 90, 105128. [Google Scholar] [CrossRef]

- Rad, F.; Davaran, S.; Babazadeh, M.; Akbarzadeh, A.; Pazoki-Toroudi, H. Biodegradable electrospun polyester-urethane nanofiber scaffold: Codelivery investigation of doxorubicin-ezetimibe and its synergistic effect on prostate cancer cell line. J. Nanomater. 2022, 2022, 8818139. [Google Scholar] [CrossRef]

- Ercelik, M.; Tekin, C.; Parin, F.N.; Mutlu, B.; Dogan, H.Y.; Tezcan, G.; Aksoy, S.A.; Gurbuz, M.; Yildirim, K.; Bekar, A.; et al. Co-loading of temozolomide with oleuropein or rutin into polylactic acid core-shell nanofiber webs inhibit glioblastoma cell by controlled release. Int. J. Biol. Macromol. 2023, 253, 126722. [Google Scholar] [CrossRef]

- Dai, J.; Shao, J.; Zhang, Y.; Hang, R.; Yao, X.; Bai, L.; Hang, R. Piezoelectric dressings for advanced wound healing. J. Mater. Chem. B 2024, 12, 1973–1990. [Google Scholar] [CrossRef]

- Hosseini, S.M.; Abdouss, M.; Mazinani, S.; Soltanabadi, A.; Kalaee, M. Modified nanofiber containing chitosan and graphene oxide-magnetite nanoparticles as effective materials for smart wound dressing. Compos. Part B 2022, 231, 109557. [Google Scholar] [CrossRef]

- Shi, H.; Liu, H.; Luan, S.; Shi, D.; Yan, S.; Liu, C.; Li, R.K.Y.; Yin, J. Antibacterial and biocompatible properties of polyurethane nanofiber composites with integrated antifouling and bactericidal components. Compos. Sci. Technol. 2016, 127, 28–35. [Google Scholar] [CrossRef]

- Parin, F.N.; Parin, U. Spirulina biomass-loaded thermoplastic polyurethane/polycaprolacton (TPU/PCL) nanofibrous mats: Fabrication; characterization, and antibacterial activity as potential wound healing. Chem. Sel. 2022, 7, e202104148. [Google Scholar] [CrossRef]

- Lee, S. Multifunctionality of layered fabric systems based on electrospun polyurethane/zinc oxide nanocomposite fibers. J. Appl. Polym. Sci. 2009, 114, 3652–3658. [Google Scholar] [CrossRef]

- Tijing, L.D.; Ruelo, M.T.G.; Amarjargal, A.; Pant, H.R.; Park, C.-H.; Kim, D.W.; Kim, C.S. Antibacterial and superhydrophilic electrospun polyurethane nanocomposite fibers containing tourmaline nanoparticles. Chem. Eng. J. 2012, 197, 41–48. [Google Scholar] [CrossRef]

- Han, H.S.; Jeong, G.J.; Lee, H.W.; Shim, J.H.; Seo, S.J.; Park, K.Y. Innovative use of negative air ions as an alternative therapy for acne vulgaris: A report of three cases. Ann. Dermatol. 2022, 34, 216–220. [Google Scholar] [CrossRef]

- Zhang, Y.; Hu, J. Robust effects of graphene oxide on polyurethane/tourmaline nanocomposite fiber. Polymers 2021, 13, 16. [Google Scholar] [CrossRef] [PubMed]

- Zheng, L.; Cao, M.; Du, Y.; Liu, Q.; Emran, M.Y.; Kotb, A.; Sun, M.; Ma, C.-B.; Zhou, M. Artificial enzyme innovations in electrochemical devices: Advancing wearable and portable sensing technologies. Nanoscale 2024, 16, 44–60. [Google Scholar] [CrossRef]

- Mercante, L.A.; Andre, R.S.; Facure, M.H.M.; Correa, D.S.; Mattoso, L.H.C. Recent progress in conductive electrospun materials for flexible electronics: Energy, sensing, and electromagnetic shielding applications. Chem. Eng. J. 2023, 465, 142847. [Google Scholar] [CrossRef]

- Bhattacharyya, A.; Joshi, M. Development of polyurethane based conducting nanocomposite fibers via twin screw extrusion. Fibers Polym. 2011, 12, 734–740. [Google Scholar] [CrossRef]

- Wang, L.; Chen, Y.; Lin, L.; Wang, H.; Huang, X.; Xue, H.; Gao, J. Highly stretchable, anti-corrosive and wearable strain sensors based on the PDMS/CNTs decorated elastomer nanofiber composite. Chem. Eng. J. 2019, 362, 89–98. [Google Scholar] [CrossRef]

- Li, B.; Luo, J.; Huang, X.; Lin, L.; Wang, L.; Hu, M.; Tang, L.; Xue, H.; Gao, J.; Mai, Y.-W. A highly stretchable, super-hydrophobic strain sensor based on polydopamine and graphene reinforced nanofiber composite for human motion monitoring. Compos. Part B 2020, 181, 107580. [Google Scholar] [CrossRef]

- Tang, J.; Wu, Y.; Ma, S.; Yan, T.; Pan, Z. Flexible strain sensor based on CNT/TPU composite nanofiber yarn for smart sports bandage. Compos. Part B 2022, 232, 109605. [Google Scholar] [CrossRef]

- Du, T.; Dong, F.; Xi, Z.; Zhu, M.; Zou, Y.; Sun, P.; Xu, M. Recent advances in mechanical vibration energy harvesters based on triboelectric nanogenerators. Small 2023, 19, 2300401. [Google Scholar] [CrossRef] [PubMed]

- Gunasekhar, R.; Sathiyanathan, P.; Reza, M.S.; Prasad, G.; Prabu, A.A.; Kim, H. Polyvinylidenefluoride/aromatic hyperbranched polyester of third-generation-based electrospun nanofiber as a self-powered triboelectric nanogenerator for wearable energy harvesting and health monitoring applications. Polymers 2023, 15, 2375. [Google Scholar] [CrossRef] [PubMed]

- Ni, Q.-Q.; Guan, X.; Zhu, Y.; Dong, Y.; Xia, H. Nanofiber-based wearable energy harvesters in different body motions. Compos. Sci. Technol. 2020, 200, 108478. [Google Scholar] [CrossRef]

- Anushree, C.; Rahim, F.A.; Vanithakumari, S.C.; Thinaharan, C.; Philip, J. Electrospun superparamagnetic fibrous composite nanofiber films for enhanced oil spill recovery: Effect of capping and magnetic nanoparticle loading on oil sorption efficiency. Compos. Part A 2023, 171, 107591. [Google Scholar] [CrossRef]

- Hou, J.; Choi, J.; Yun, J.; Jang, W.; Kim, J.; Byun, H. Superoleophobic polyketone nanofiber membranes for efficient separation of oil/water emulsions. ChemNanoMat 2023, 9, e202300110. [Google Scholar] [CrossRef]

- Sundaran, S.P.; Reshmi, C.R.; Sagitha, P.; Manaf, O.; Sujith, A. Multifunctional graphene oxide loaded nanofibrous membrane for removal of dyes and coliform from water. J. Environ. Manag. 2019, 240, 494–503. [Google Scholar] [CrossRef]

- Zhang, H.; Zheng, X.; Jiang, R.; Liu, Z.; Li, W.; Zhou, X. Research progress of functional composite electromagnetic shielding materials. Eur. Polym. J. 2023, 185, 111825. [Google Scholar] [CrossRef]

- Li, T.-T.; Wang, Y.; Peng, H.-K.; Zhang, X.; Shiu, B.-C.; Lin, J.-H.; Lou, C.-W. Lightweight, flexible and superhydrophobic composite nanofiber films inspired by nacre for highly electromagnetic interference shielding. Compos. Part A 2020, 128, 105685. [Google Scholar] [CrossRef]

- Huang, A.; Liu, F.; Cui, Z.; Wang, H.; Song, X.; Geng, L.; Wang, H.; Peng, X. Novel PTFE/CNT composite nanofiber membranes with enhanced mechanical, crystalline, conductive, and dielectric properties fabricated by emulsion electrospinning and sintering. Compos. Sci. Technol. 2021, 214, 108980. [Google Scholar] [CrossRef]

- Uslu, E.; Gavgali, M.; Erdal, M.O.; Yazman, S.; Gemi, L. Determination of mechanical properties of polymer matrix composites reinforced with electrospinning N66, PAN, PVA and PVC nanofibers: A comparative study. Mater. Today Commun. 2021, 26, 101939. [Google Scholar] [CrossRef]

- Gavande, V.; Lee, S.; Im, D.; Nagappan, S.; Ha, C.-S.; Lee, W.-K. Polyketone nanofiber: An effective reinforcement for the development of novel UV-curable, highly transparent and flexible polyurethane nanocomposite films. Polym. Int. 2020, 69, 1008–1017. [Google Scholar] [CrossRef]

- Gavande, V.; Im, D.; Lee, W.-K. Development of highly transparent UV-curable nylon6 nanofiber-reinforced polyurethane acrylate nanocomposite coatings for pre-coated metals. J. Appl. Polym. Sci. 2021, 138, e50614. [Google Scholar] [CrossRef]

- Gavande, V.; Nagappan, S.; Lee, W.-K. Considering electrospun nanofibers as a filler network in electrospun nanofiber-reinforced composites to predict the tensile strength and Young’s modulus of nanocomposites: A modeling study. Polymers 2022, 14, 5425. [Google Scholar] [CrossRef] [PubMed]

- Daelemans, L.; Verschatse, O.; Heirman, L.; Van Paepegem, W.; De Clerck, K. Toughening mechanisms responsible for excellent crack resistance in thermoplastic nanofiber reinforced epoxies through in-situ optical and scanning electron microscopy. Compos. Sci. Technol. 2021, 201, 108504. [Google Scholar] [CrossRef]

- Gavande, V.; Nagappan, S.; Seo, B.; Cho, Y.-S.; Lee, W.-K. Transparent nylon 6 nanofibers-reinforced epoxy matrix composites with superior mechanical and thermal properties. Polym. Test. 2023, 122, 108002. [Google Scholar] [CrossRef]

- Zhang, X.-C.; Chen, Y.-Z.; Yu, J.; Guo, Z.-X. Thermoplastic polyurethane/silica nanocomposite fibers by electrospinning. J. Polym. Sci. Part B Polym. Phys. 2011, 49, 1683–1689. [Google Scholar] [CrossRef]

- Tang, C.; Chen, P.; Liu, H. Cocontinuous cellulose acetate/polyurethane composite nanofiber fabricated through electrospinning. Polym. Eng. Sci. 2008, 48, 1296–1303. [Google Scholar] [CrossRef]

| Sequence Number | Materials | Designed Structures | Key Properties | Potential Applications | Reference Number |

|---|---|---|---|---|---|

| 1 | PS nanofiber, wool substrate | Self-crimped micro-nanofiber | Improved flexibility, elasticity, and spatial scalability | Water conduction, heat preservation, and functional carrier | [7] |

| 2 | PU nanofiber, PET nonwoven | Nanofiber web-reinforced nonwoven and sandwich | High noise reduction coefficient | Sound absorption | [13] |

| 3 | PVB nanofiber, PET fiber, TPU film | Bi-layer or three-layer laminate | High sound absorption rate | Sound absorption | [16] |

| 4 | PAN nanofiber, PVAc nanofiber, PP nonwoven | Core-shell or hollow nanofibrous membrane | Improved acoustic performance | Sound absorption | [17] |

| 5 | PCL nanofiber | Tube with outer and inner cell layers | Good elasticity, burst resistance, and suture retention | Bionic small-diameter vascular vessel | [23] |

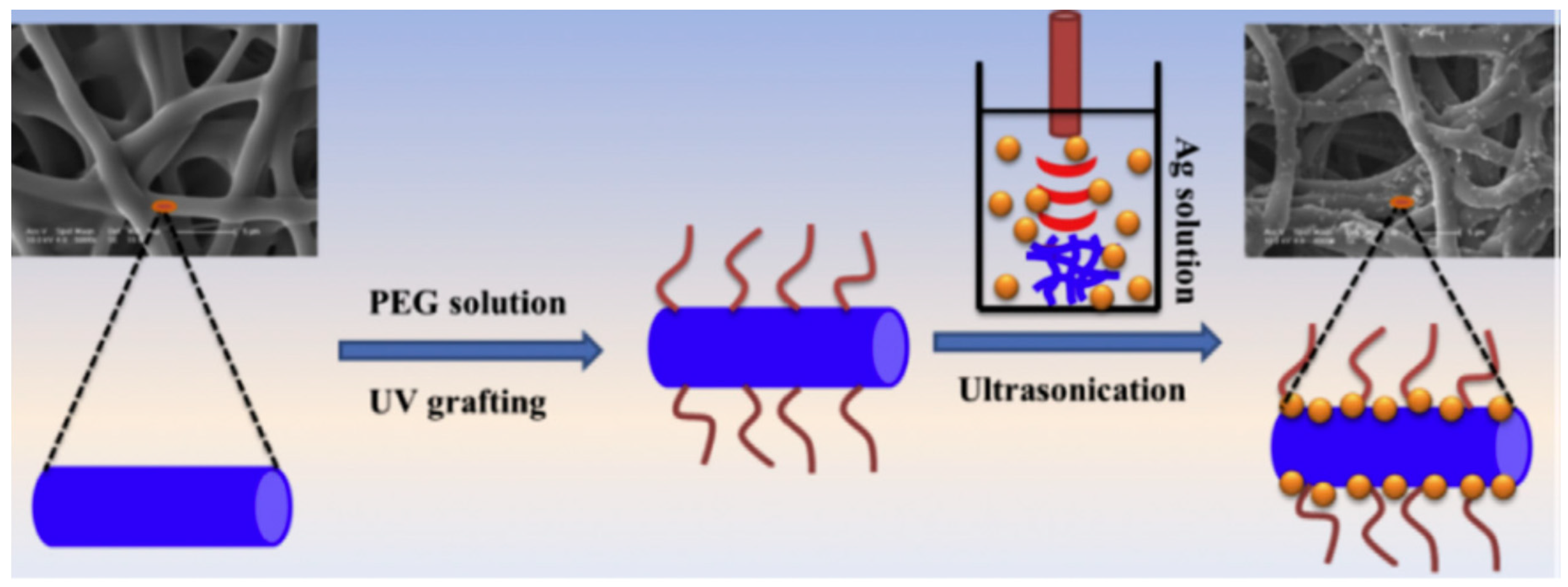

| 6 | TPU nanofiber | Nanofiber grafted by PEG and anchored by silver nanoparticles | Good anti-bacterial stability, low toxicity, and excellent hemocompatibility | Anti-bacterial use | [31] |

| 7 | PU nanofiber | Nanofiber added with TN | Improved mechanical strength, high superhydrophilicity, and high bactericidal effect | Superhydrophilic and anti-bacterial use | [34] |

| 8 | PU nanofiber | Nanofiber added with tourmaline and GO nanoparticles | Enhanced mechanical properties and negative ions release | Negative ions textiles and wearable energy therapy | [36] |

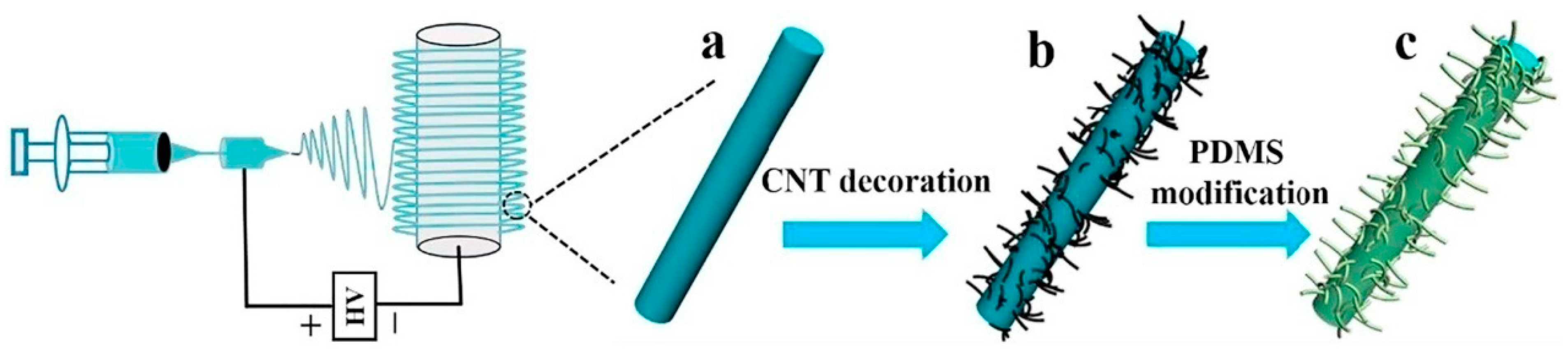

| 9 | TPU nanofiber | Nanofiber decorated with CNT and modified with PDMS | High stretchability and superhydrophobicity | Superhydrophobic strain sensor | [40] |

| 10 | TPU nanofiber | Nanofiber added with CNT | High sensitivity | Smart sports bandage | [42] |

| 11 | TPU nanofiber | Nanofiber added with GO | High anti-fouling, dye removal, and anti-bacterial properties | Adsorption of organic dyes | [48] |

| 12 | PK nanofiber, PUA film | Sandwich | UV curability, high transparency, and high flexibility | Coating for metals and optoelectronic devices | [53] |

| 13 | PA 6 nanofiber, PUA film | Bilayer | UV curability and high transparency | Protective coating | [54] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, S.; Li, A.; Pan, L. Application Progress of Multi-Functional Polymer Composite Nanofibers Based on Electrospinning: A Brief Review. Polymers 2024, 16, 2459. https://doi.org/10.3390/polym16172459

Ma S, Li A, Pan L. Application Progress of Multi-Functional Polymer Composite Nanofibers Based on Electrospinning: A Brief Review. Polymers. 2024; 16(17):2459. https://doi.org/10.3390/polym16172459

Chicago/Turabian StyleMa, Shuai, An Li, and Ligang Pan. 2024. "Application Progress of Multi-Functional Polymer Composite Nanofibers Based on Electrospinning: A Brief Review" Polymers 16, no. 17: 2459. https://doi.org/10.3390/polym16172459

APA StyleMa, S., Li, A., & Pan, L. (2024). Application Progress of Multi-Functional Polymer Composite Nanofibers Based on Electrospinning: A Brief Review. Polymers, 16(17), 2459. https://doi.org/10.3390/polym16172459