Mechanistic Fatigue Performance Evaluation of Stone Mastic Asphalt Mixtures: Effect of Asphalt Performance Grade and Elastic Recovery

Abstract

1. Introduction

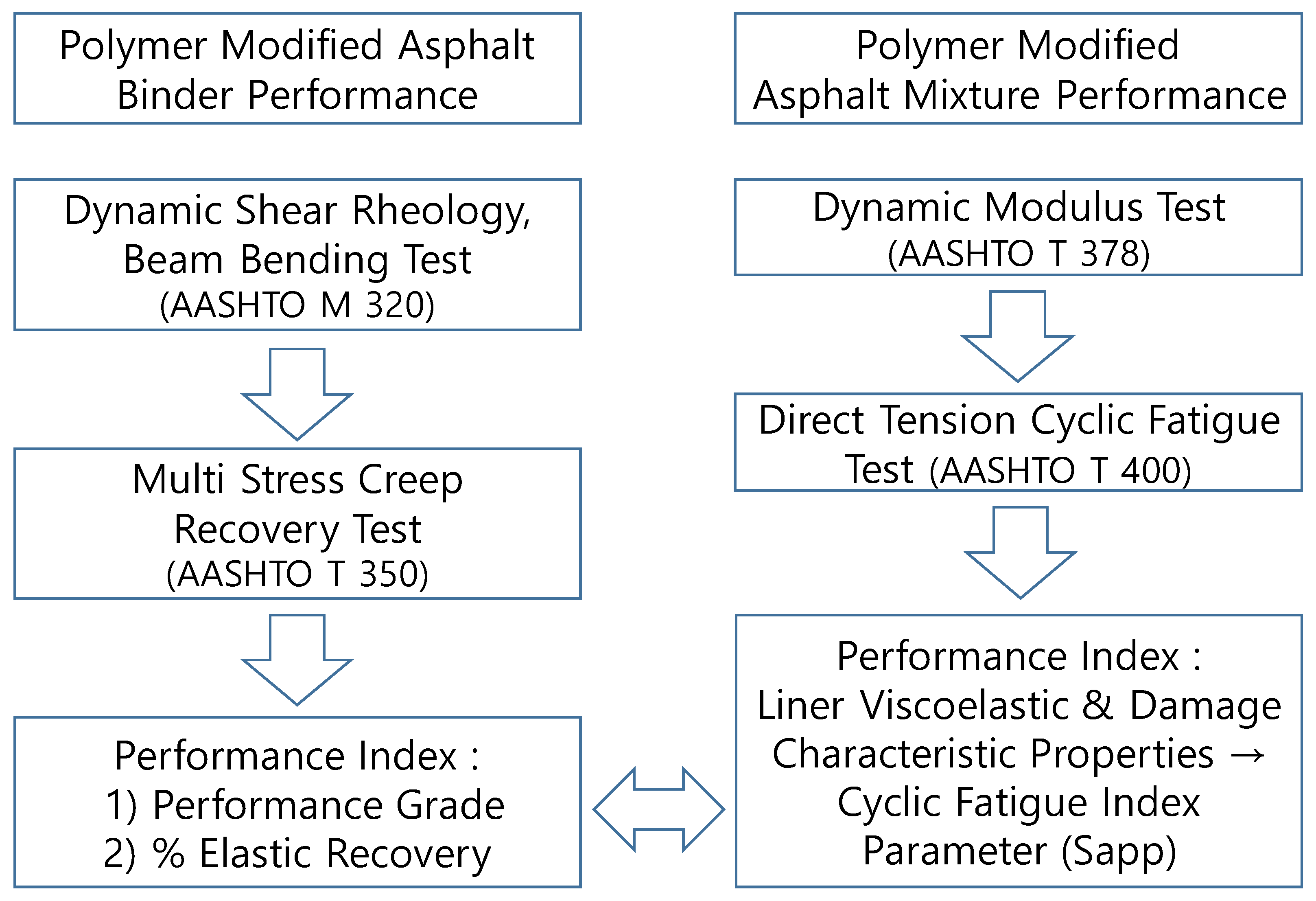

2. Experimental Program and Analysis Methods

2.1. Material and Mix Design

2.2. Testing Protocol and Analysis Methods

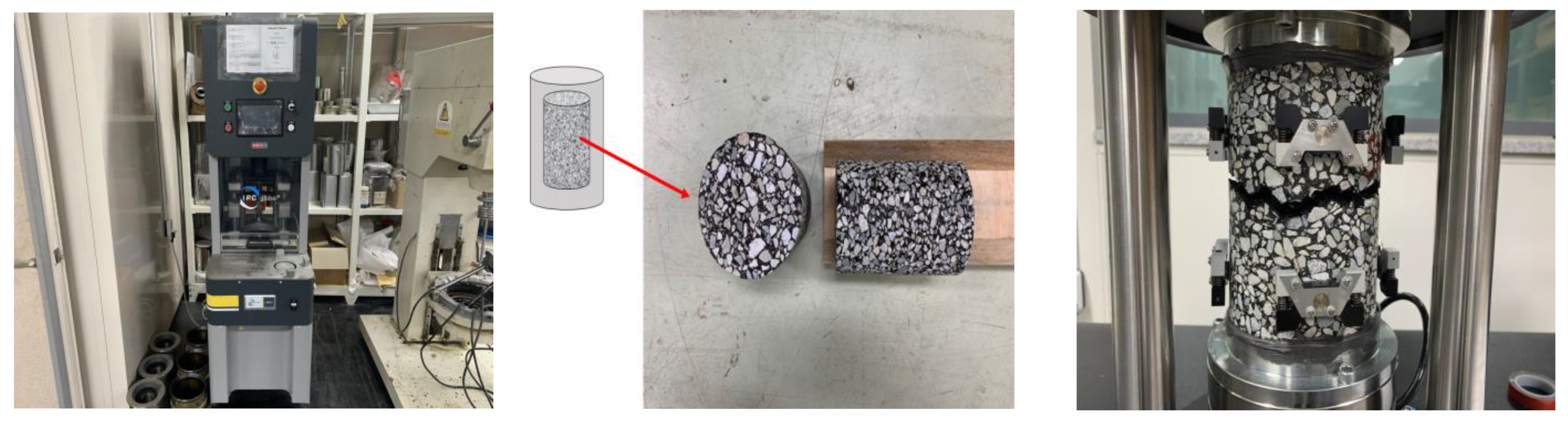

2.3. Specimen Preparation

2.4. Testing Protocol

2.5. Analysis Method

3. Discussion of Results

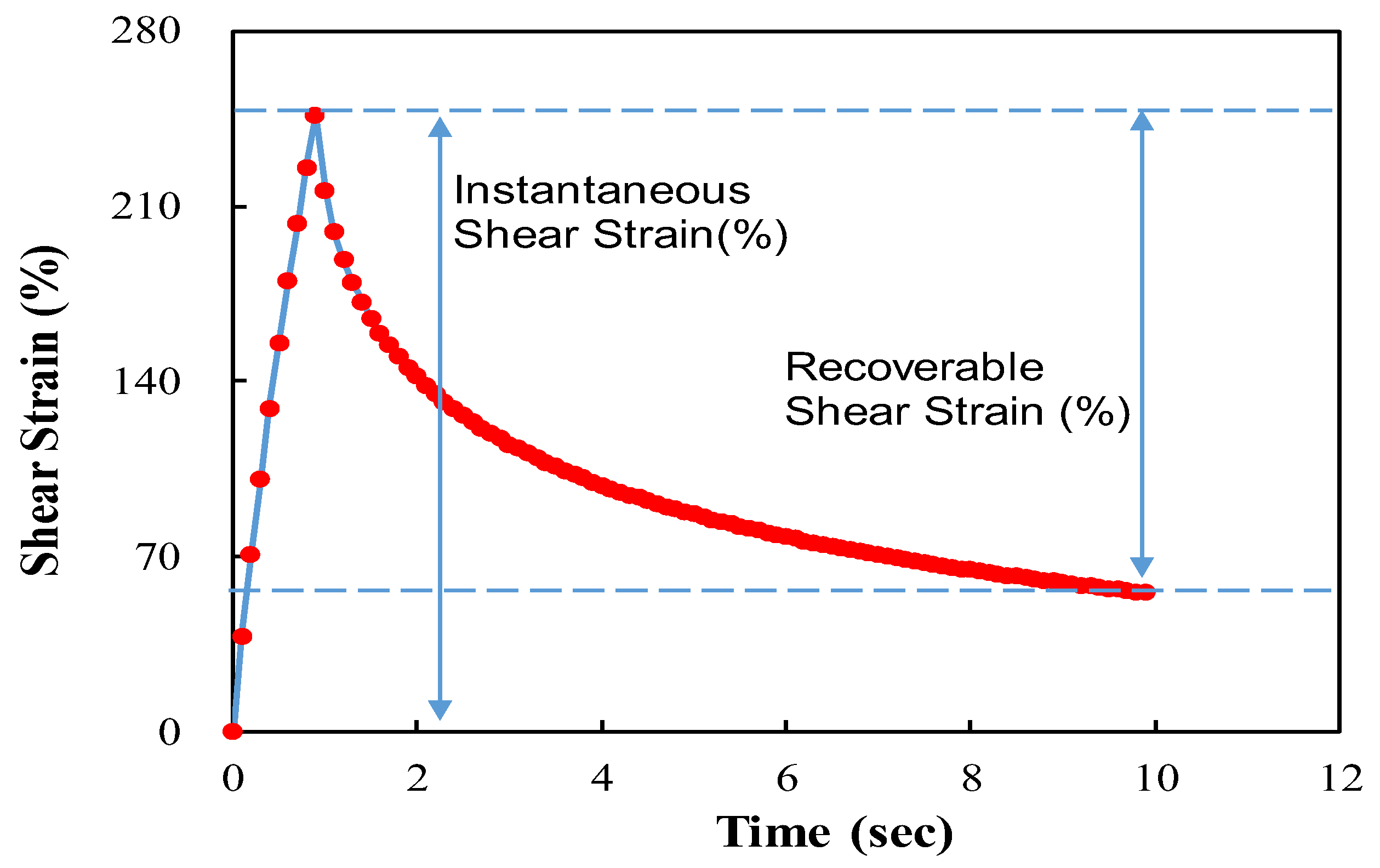

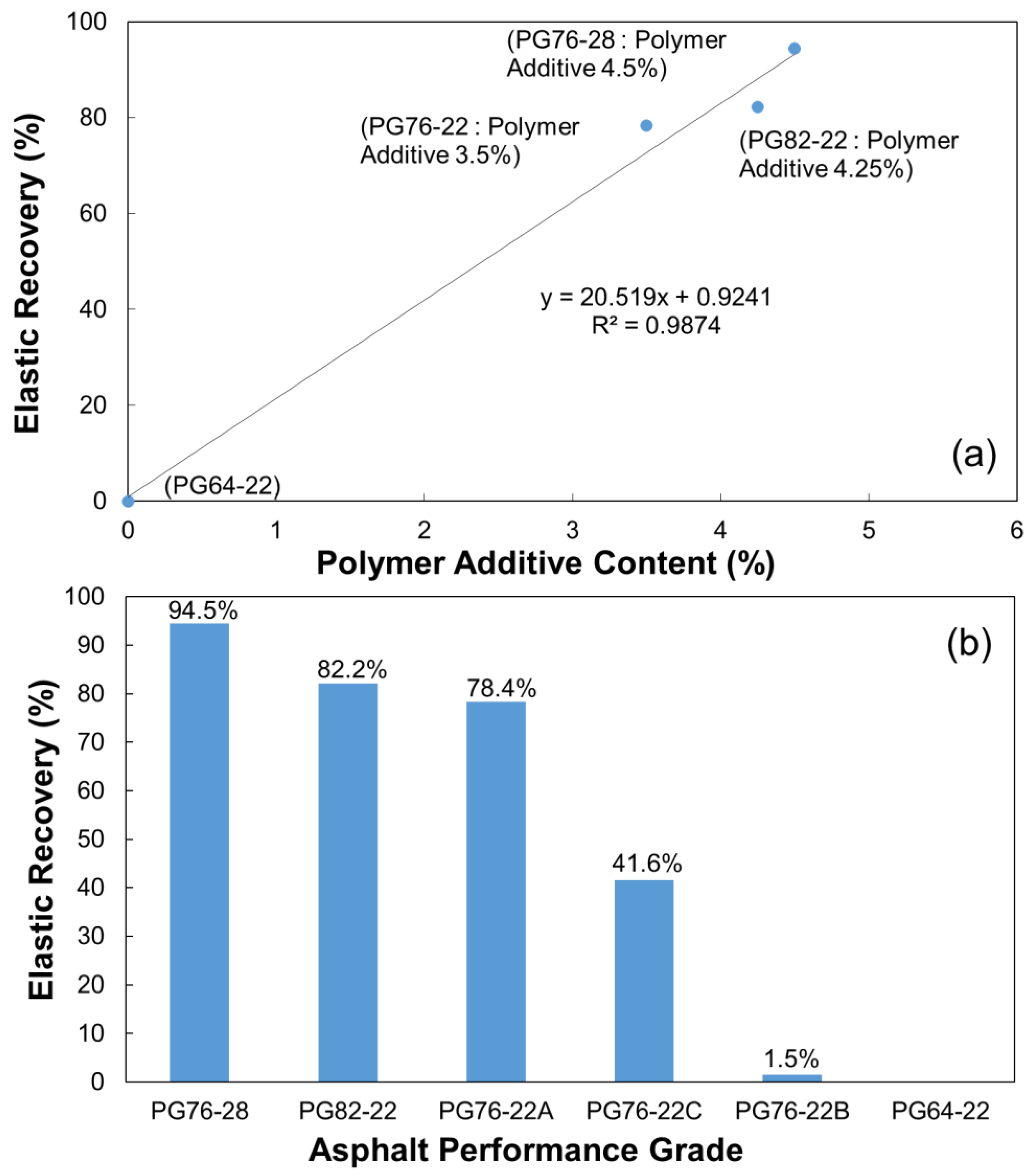

3.1. Asphalt Elastic Recovery

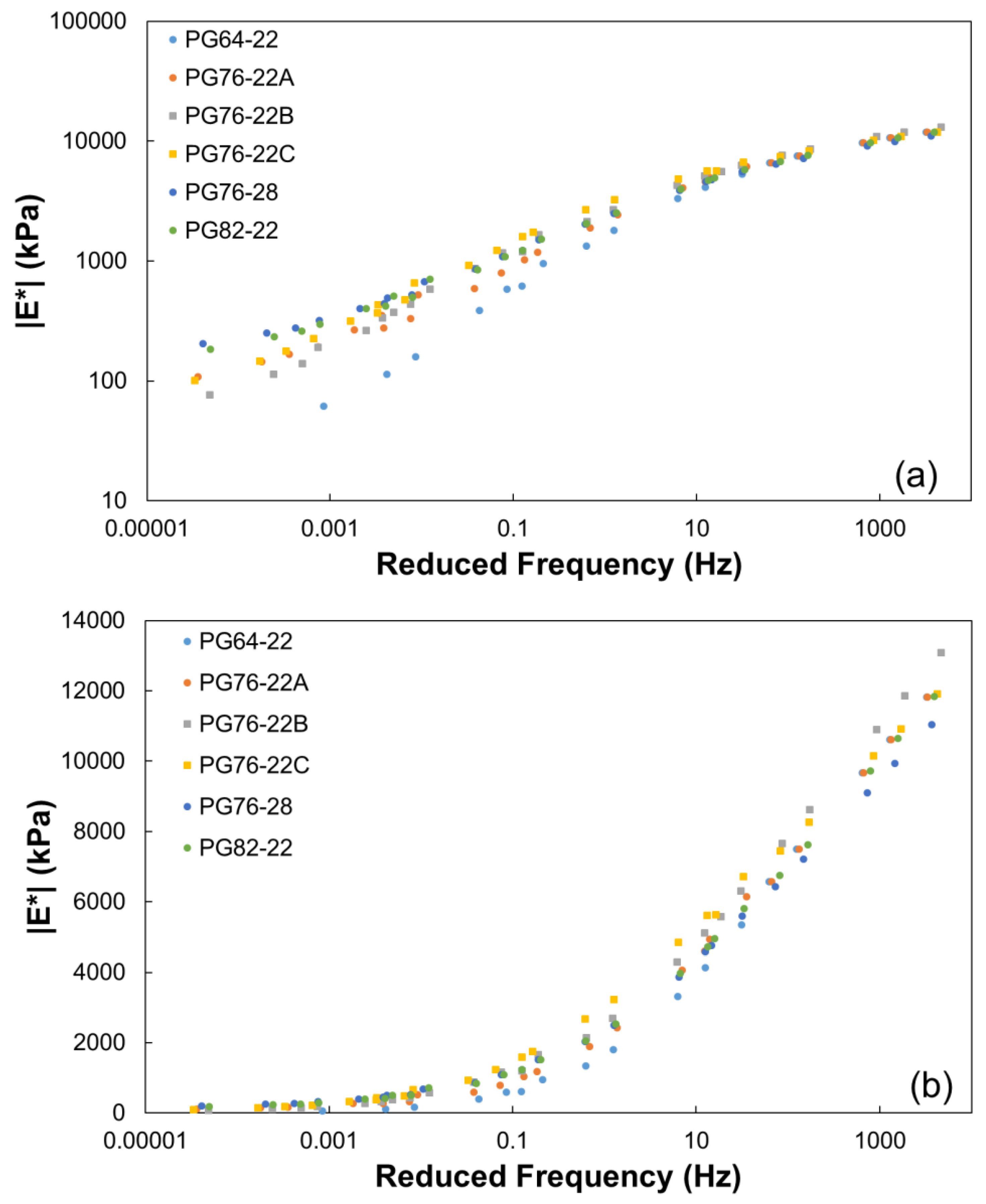

3.2. Dynamic Modulus Test of the SMA Mixtures

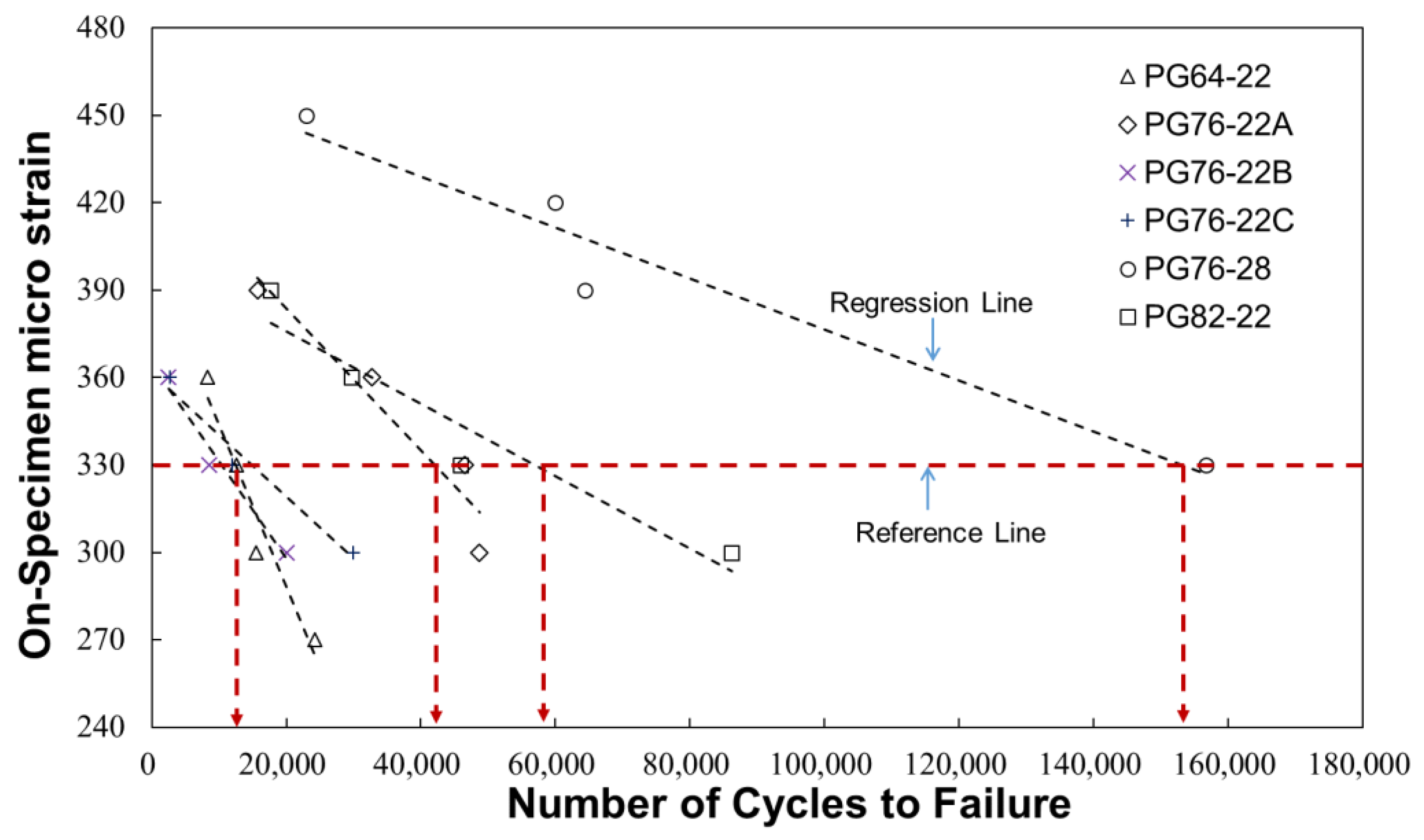

3.3. Direct Tension Cyclic Fatigure Test of SMA Mixtures

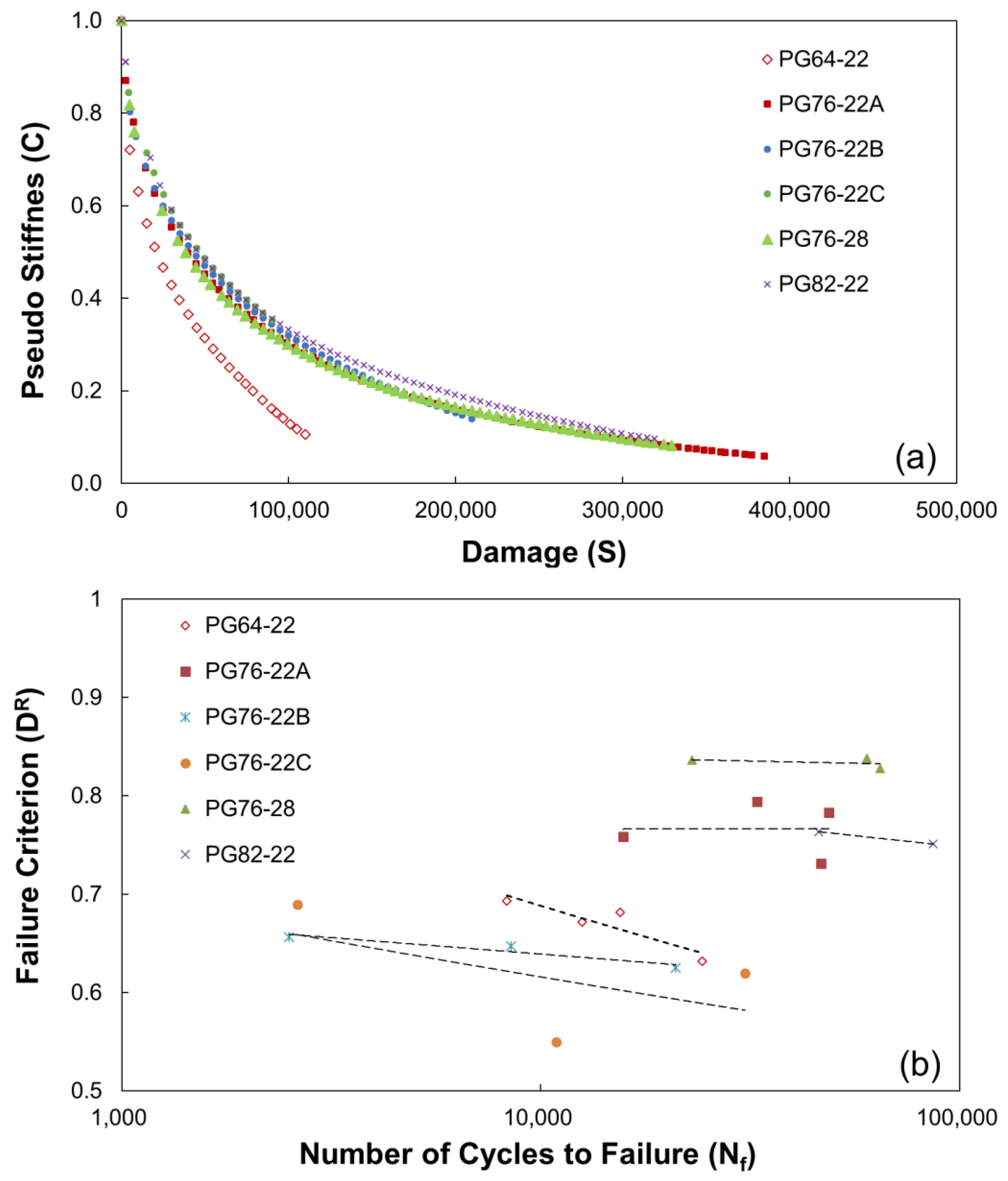

3.4. Damage Characteristic Curve and Failure Criteria of SMA Mixtures

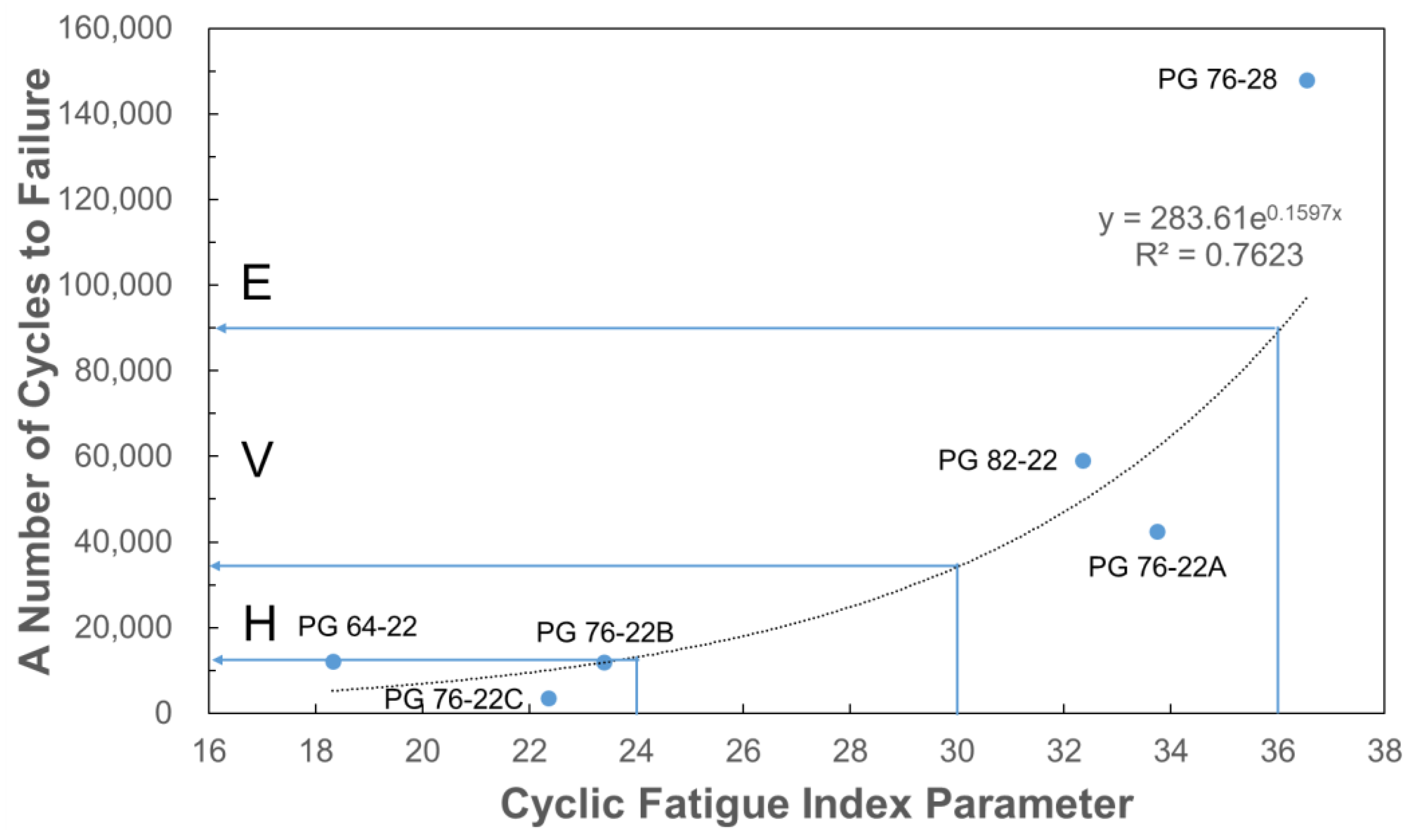

3.5. Cyclic Fatigue Index Parameter (Sapp) of SMA Mixtures

3.6. Relationship between Asphalt Elastic Recovery, Nf, and Sapp

4. Conclusions

- (1)

- When a modifier was added to straight asphalt, the initial shear strain decreased, and the recoverable shear strain increased. The sensitivity analysis showed that elastic recovery increased by approximately 21% for each 1% increase in polymer additive content.

- (2)

- The rubber-based PG 76-28 asphalt was evaluated to have the lowest initial strain (245) and the highest elastic recovery (83.67%) among the six types of asphalt.

- (3)

- Even with the modified asphalt of the same PG 76-22 rating, a significant difference was observed in the elastic recovery depending on the performance of the modifier.

- (4)

- Determining the appropriate modifier amount for elastic recovery testing was possible when rubber-based modifiers were used. Thus, this can be utilized as a quality control test for modified asphalt.

- (5)

- When a rubber-based modifier was used in straight asphalt, the elastic modulus increased at high temperatures and decreased at low temperatures, thereby enhancing resistance to plastic deformation in the summer and reducing low-temperature cracking in the winter.

- (6)

- In the Sapp evaluation according to the PG of the 10 mm SMA mixture, PG 76-28 was rated as the highest with an E-grade of 36.5, while PG 76-22A and PG 82-22 were rated as V-grade with 33.7 and 32.3, respectively. The remaining PGs, PG 76-22B, PG 76-22C, and PG 64-22, were evaluated as S-grade with the lowest scores of 23.4, 22.3, and 17.0, respectively.

- (7)

- The correlations between the Sapp and the modified asphalt elastic recovery, and between the Sapp and the number of direct tension cycles to failure of the mixture, were evaluated to be 0.87 and 0.76, respectively.

- (8)

- When applying the permissible heavy vehicle traffic and congestion rating criteria of Sapp, the elastic recoveries of modified asphalt in the H, V, and E sections of a 10 mm SMA mixture were approximately 30%, 65%, and 98% respectively. The number of direct tension cycles to failure of the mixture was evaluated to be at least 13,000, 34,000, and 89,000 cycles or higher, respectively, for 330 µε using an on-specimen LVDT.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Federal Highway Administration. Asphalt Production and Oil Refining. 2024. Available online: https://pavementinteractive.org/reference-desk/materials/asphalt/asphalt-production-and-oil-refining/ (accessed on 23 June 2024).

- Volumetric Requirements for Superpave Mix Design; NCHRP 567 Final Report; Transportation Research Board of the National Academies: Washington, DC, USA, 2006.

- AASHTO M320; Standard Specification for Performance-Graded Asphalt Binder. AASHTO: Washington, DC, USA, 2023.

- AASHTO T350; Standard Method of Test for Multiple Stress Creep Recovery (MSCR) Using a Dynamic Shear Rheometer (DSR). AASHTO: Washington, DC, USA, 2023.

- The Multiple Stress Creep Recovery Procedure; FHWA Tech Brief; U.S. Department of Transportation, Federal Highway Administration: Washington, DC, USA, 2011.

- Yan, C.; Yuan, L.; Yu, X.; Ji, S. Characterizing the Fatigue Resistance of Multiple Modified Asphalts Using Time Sweep Test, LAS Test and Elastic Recovery Test. Constr. Build. Mater. 2022, 332, 125806. [Google Scholar] [CrossRef]

- Rieksts, K.; Pettinari, M.; Haritonovs, V. The influence of filler type and gradation on the rheological performance of mastics. Road Mater. Pavement Des. 2018, 20, 964–978. [Google Scholar] [CrossRef]

- Simple Performance Tester for Superpave Mix Design; NCHRP 9-29 Report; Transportation Research Board of the National Academies: Washington, DC, USA, 2011.

- Superpave Support and Performance Models Management; NCHRP 9-19 Report; Transportation Research Board of the National Academies: Washington, DC, USA, 2006.

- Cyclic Fatigue Index Parameter (Sapp) for Asphalt Performance Engineered Mixture Design; FHWA Tech Brief; U.S. Department of Transportation, Federal Highway Administration: Washington, DC, USA, 2019.

- Korea Expressway Corporation. Improvement Plan for Asphalt Overlay on Concrete Pavements. 2013. Available online: https://www.codil.or.kr/viewDtlCostSave.do?gubun=costsave&pMetaCode=EDGCODA00933 (accessed on 8 August 2024).

- KCS 44 55 15; Aggregates. Korean Construction Specification: Goyang-si, Republic of Korea, 2016.

- AASHTO R83; Standard Practice for Preparation of Cylindrical Performance Test Specimens Using the Superpave Gyratory Compactor (SGC). AASHTO: Washington, DC, USA, 2022.

- Lee, J.S.; Norouzi, A.; Kim, Y.R. Determining Specimen Geometry of Cylindrical Specimens for Direct Tension Fatigue Testing of Asphalt Concrete. J. Test. Eval. 2017, 45, 613–623. [Google Scholar] [CrossRef]

- AASHTO T378; Standard Method of Test for Determining Dynamic Modulus and Flow Number for Asphalt Mixtures Using the Asphalt Mixture Performance Tester (AMPT). AASHTO: Washington, DC, USA, 2017.

- AASHTO T 400; Standard Method of Test for Determining the Damage Characteristic Curve of Asphalt Mixtures from Direct Tension Cyclic Fatigue Tests. AASHTO: Washington, DC, USA, 2023.

- Kim, Y.R.; Lee, Y.; Lee, H.J. Correspondence Principle for Characterization of Asphalt Concrete. J. Mater. Civ. Eng. 1995, 7, 59–68. [Google Scholar] [CrossRef]

- Chehab, G.; Kim, Y.R.; Schapery, R.A.; Witczack, M.; Bonaquist, R. Time-Temperature Superposition Principle for Asphalt Concrete Mixtures with Growing Damage in Tension State. J. Assoc. Asphalt. Paving Technol. 2002, 71, 559–593. [Google Scholar]

- Underwood, B.S.; Kim, Y.R.; Guddati, M.N. Improved Calculation Method of Damage Parameter in Viscoelastic Continuum Damage Model. Int. J. Pavement Eng. 2010, 11, 459–476. [Google Scholar] [CrossRef]

- Kim, Y.R.; Guddati, M. Hot Mix Asphalt Performance-related Specifications Based on Viscoelastoplastic Continuum Damage (VEPCD) Models; Project Number DTFH61-080H-00005; FHWA Quarterly Research Progress Report; U.S. Department of Transportation, Federal Highway Administration: Washington, DC, USA, 2012. [Google Scholar]

- Wang, Y.D.; Underwood, S. Development of a Fatigue Index Parameter, Sapp, for Asphalt Mixtures using Viscoelastic Continuum Damage Theory. Int. J. Pavement Eng. 2020, 20, 438–452. [Google Scholar]

- Lee, J.; Lee, J.; Kwon, S.; Kim, Y.R. Use of Cyclic Direct Tension Tests and Digital Imaging Analysis to Evaluate Moisture Susceptibility of Warm Mix Asphalt Concrete. Transp. Res. Rec. J. Transp. Res. Board 2013, 2372, 61–71. [Google Scholar] [CrossRef]

| Item | True Density (g/cm3) | Density in Saturated Surface Dry Condition (g/cm3) | Density in Absolute Dry Condition (g/cm3) | Absorption Rate (%) | Abrasion Loss (%) |

|---|---|---|---|---|---|

| Criterion | - | - | Above 2.5 | Below 3.0 | Below 30 |

| Coarse Aggregate | 2.706 | 2.659 | 2.631 | 1.061 | 21.5 |

| Fine Aggregate | 2.614 | 2.600 | 2.591 | 0.328 | - |

| List of Mix Design | Criteria | Results | ||

|---|---|---|---|---|

| PG64-22 | PG76-22/28 | PG82-22 | ||

| Asphalt Binder Content (%) | above 6.6 | 6.9 | ||

| Design Air Void (%) | 2–4 | 3.2 | 3.0 | 2.8 |

| Design VMA (%) | above 18 | 18.9 | 18.8/18.7 | 18.0 |

| Design VFA (%) | above 75 | 83.2 | 84.0 | 88.3 |

| Drain Down (%) | below 0.3 | 0.12 | 0.14 | 0.18 |

| Dynamic Stability (cycles/mm) | above 2500 | 352 | 6721/7417 | 12,378 |

| Aged (Criterion) | Unit | PG62-22 | PG76-22A | PG76-22B | PG76-22C | PG76-28 | PG82-22 |

|---|---|---|---|---|---|---|---|

| Orig. G*/sinδ (1.0 ↑) | kPa | 1.35 (64 °C) | 1.57 (76 °C) | 1.29 (76 °C) | 2.26 (76 °C) | 1.91 (76 °C) | 2.45 (82 °C) |

| 0.64 (70 °C) | 1.00 (82 °C) | 0.78 (82 °C) | 1.22 (82 °C) | 1.26 (82 °C) | 1.08 (88 °C) | ||

| RTFO G*/sinδ (2.2 ↑) | kPa | 2.43 (64 °C) | 2.33 (76 °C) | 2.28 (76 °C) | 2.77 (76 °C) | 2.32 (76 °C) | 4.32 (82 °C) |

| 1.14 (70 °C) | 1.42 (82 °C) | 1.36 (82 °C) | 1.57 (82 °C) | 1.50 (82 °C) | 2.66 (88 °C) | ||

| PAV G* × sinδ (5000 ↓) | kPa | 2815 (25 °C) | 1266 (31 °C) | 1926 (31 °C) | 2748 (31 °C) | 542 (28 °C) | 1998 (34 °C) |

| Stiffness (300 ↓) | MPa | 145 (−12 °C) | 175 (−12 °C) | 224 (−12 °C) | 174 (−12 °C) | 40 (−18 °C) | 152 (−12 °C) |

| m-value (0.3 ↑) | - | 0.33 (−12 °C) | 0.31 (−12 °C) | 0.30 (−12 °C) | 0.32 (−12 °C) | 0.32 (−18 °C) | 0.33 (−12 °C) |

| Sapp Parameters | PG62-22 | PG76-22A | PG76-22B | PG76-22C | PG76-28 | PG82-22 |

|---|---|---|---|---|---|---|

| 3.03 | 3.71 | 3.54 | 3.75 | 4.17 | 4.22 | |

| 2.408 | 2.444 | 2.546 | 2.551 | 2.424 | 2.499 | |

| 5,773,000 | 6,739,000 | 6,163,000 | 6,330,000 | 4,344,000 | 5,788,000 | |

| C11 | 0.0147 | 0.0143 | 0.0068 | 0.0057 | 0.0154 | 0.0071 |

| C12 | 0.352 | 0.332 | 0.399 | 0.416 | 0.336 | 0.387 |

| 0.67 | 0.77 | 0.66 | 0.69 | 0.83 | 0.76 |

| Traffic (Million ESALs) | Saap Limits | Grade | Designation |

|---|---|---|---|

| <10 | Saap > 8 | Standard | S |

| 10≤, ≤30 | Saap > 24 | Heavy | H |

| >30 | Saap > 30 | Very Heavy | V |

| >30, slow traffic | Saap > 36 | Extremely Heavy | E |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, J.; Lee, S.; Hwang, Y.; Kwon, O.; Yeon, G. Mechanistic Fatigue Performance Evaluation of Stone Mastic Asphalt Mixtures: Effect of Asphalt Performance Grade and Elastic Recovery. Polymers 2024, 16, 2414. https://doi.org/10.3390/polym16172414

Lee J, Lee S, Hwang Y, Kwon O, Yeon G. Mechanistic Fatigue Performance Evaluation of Stone Mastic Asphalt Mixtures: Effect of Asphalt Performance Grade and Elastic Recovery. Polymers. 2024; 16(17):2414. https://doi.org/10.3390/polym16172414

Chicago/Turabian StyleLee, Jongsub, Sungjin Lee, Yujoong Hwang, Ohsun Kwon, and Gyumin Yeon. 2024. "Mechanistic Fatigue Performance Evaluation of Stone Mastic Asphalt Mixtures: Effect of Asphalt Performance Grade and Elastic Recovery" Polymers 16, no. 17: 2414. https://doi.org/10.3390/polym16172414

APA StyleLee, J., Lee, S., Hwang, Y., Kwon, O., & Yeon, G. (2024). Mechanistic Fatigue Performance Evaluation of Stone Mastic Asphalt Mixtures: Effect of Asphalt Performance Grade and Elastic Recovery. Polymers, 16(17), 2414. https://doi.org/10.3390/polym16172414