Role of Minor Phase Morphology on Mechanical and Shape-Memory Properties of Polylactide/Bio-Polyamide Nanocomposite

Abstract

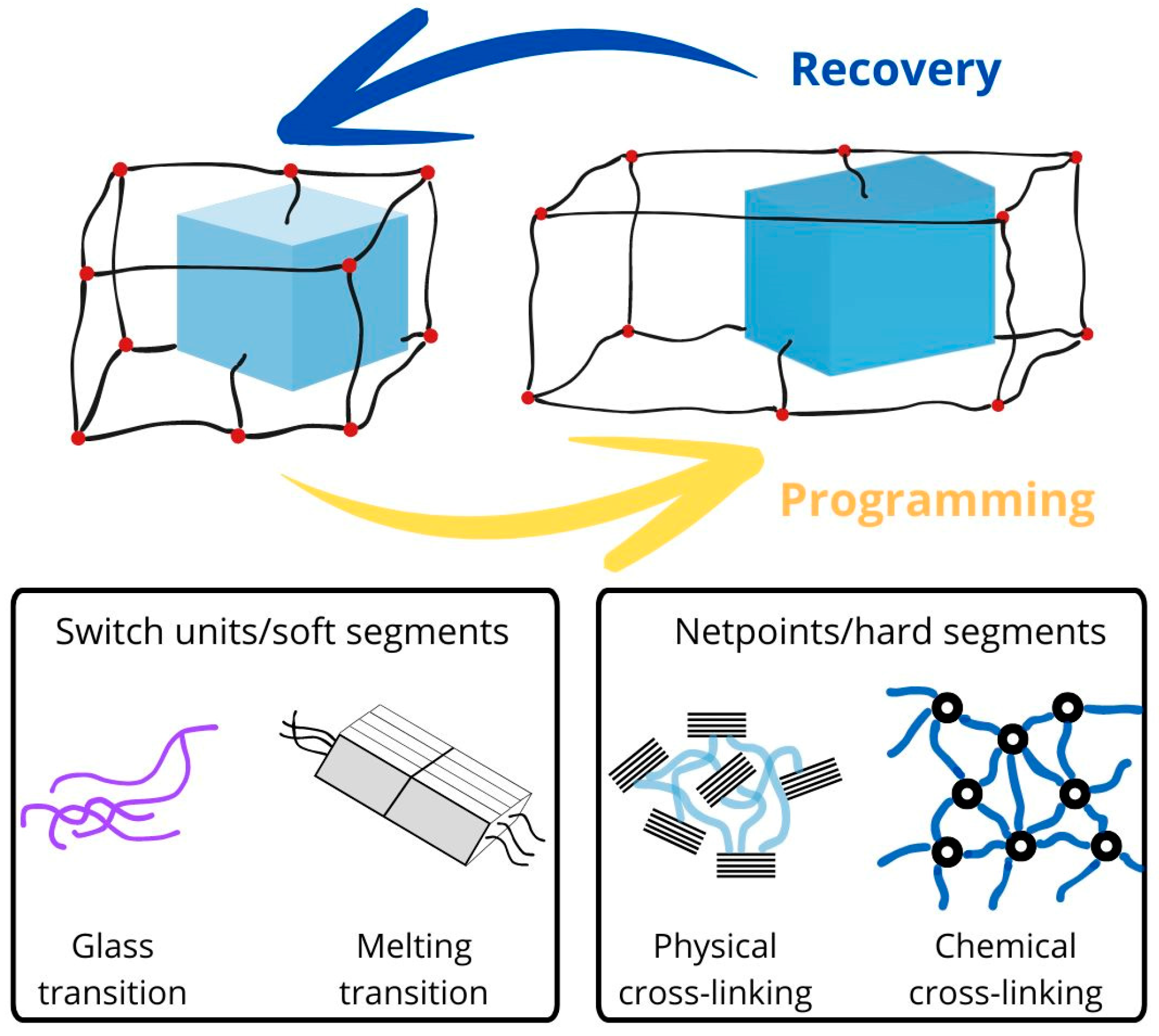

1. Introduction

2. Experimental

2.1. Materials

2.2. Sample Preparation

2.3. Mechanical and Thermal Properties

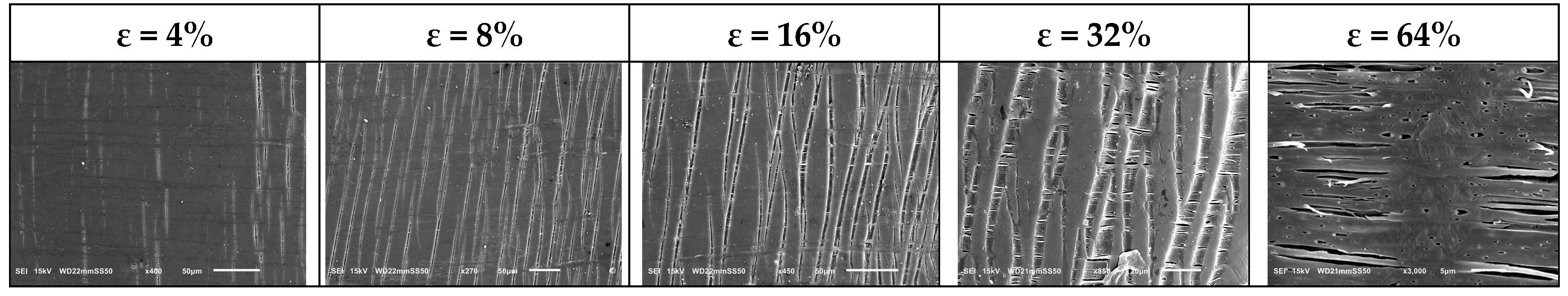

2.4. Scanning Electronic Microscopy (SEM)

2.5. Shape-Memory Characterization Test

2.6. In Situ 2D Small-Angle X-ray Scattering (SAXS)

3. Results and Discussion

3.1. Morphology

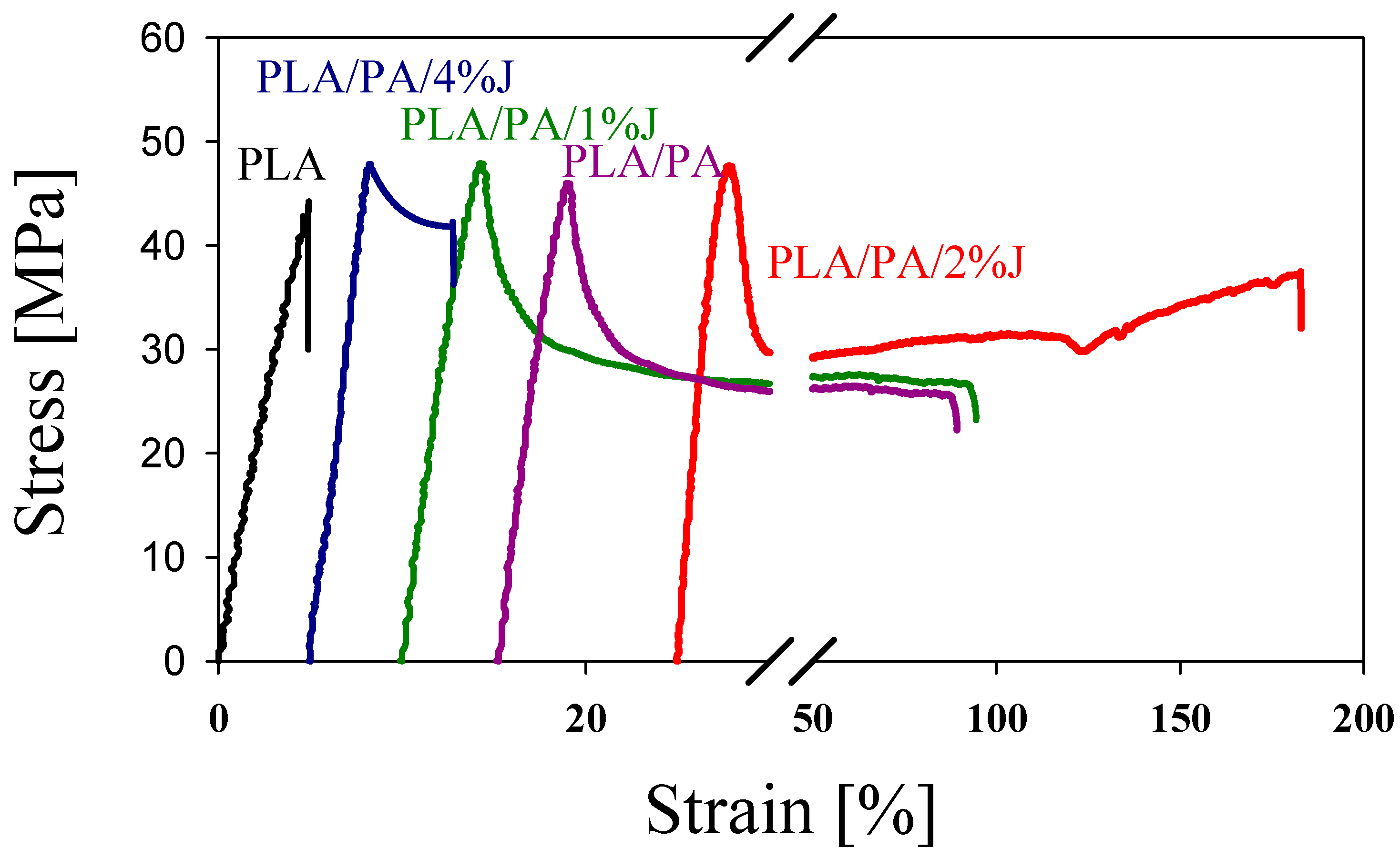

3.2. Mechanical Properties

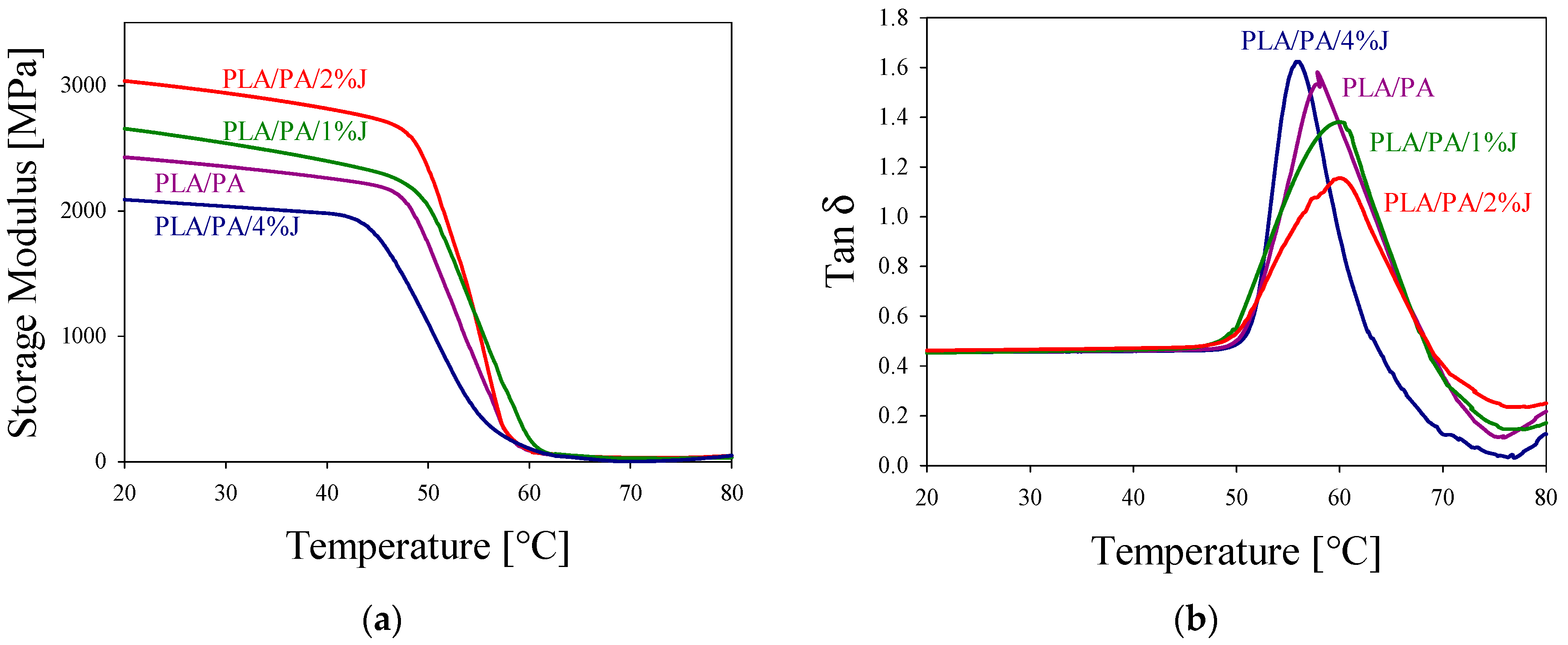

3.3. Thermal and Dynamic Mechanical Analysis

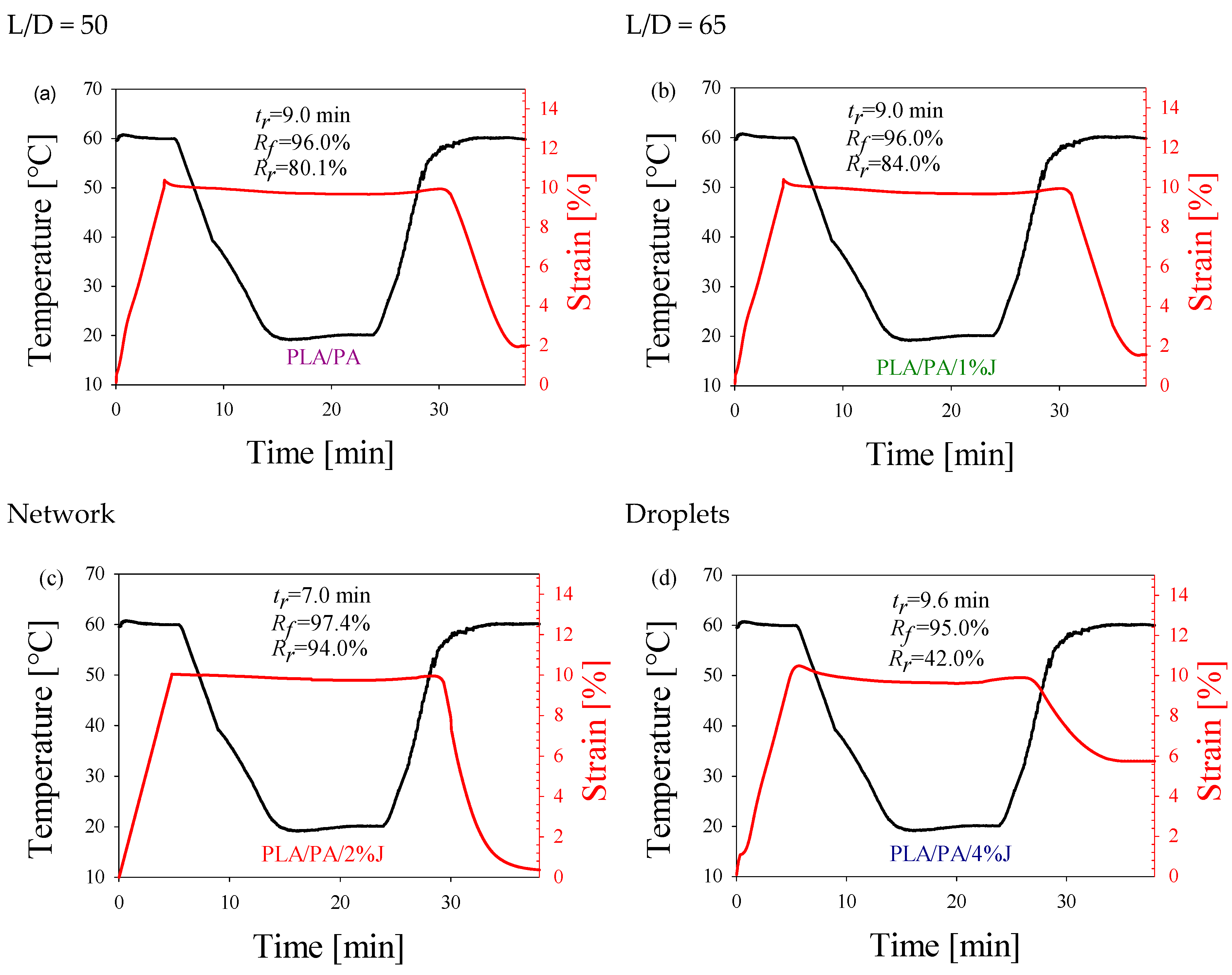

3.4. Shape-Memory Properties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Behl, M.; Lendlein, A. Shape-memory polymers. Mater. Today 2007, 10, 20–28. [Google Scholar] [CrossRef]

- Mazurek-Budzynska, M.; Razzaq, M.Y.; Behl, M.; Lendlein, A. Shape-memory polymers. In Functional Polymers; Mazumder, M.A.J., Sheardown, H., Al Ahmed, A., Eds.; Springer: Cham, Switzerland, 2019; pp. 605–663. [Google Scholar]

- Hager, M.D.; Bode, S.; Weber, C.; Schubert, U.S. Shape memory polymers: Past, present and future developments. Prog. Polym. Sci. 2015, 49, 3–33. [Google Scholar] [CrossRef]

- Luo, L.; Zhang, F.; Wang, L.; Liu, Y.; Leng, J. Recent Advances in shape memory polymers: Multifunctional materials, multiscale structures, and applications. Adv. Funct. Mater. 2024, 34, 2312036. [Google Scholar] [CrossRef]

- Toncheva, A.; Khelifa, F.; Paint, Y.; Voué, M.; Lambert, P.; Dubois, P.; Raquez, J.-M. Fast IR-actuated shape-memory polymers using in situ silver nanoparticle-grafted cellulose nanocrystals. ACS Appl. Mater. Interfaces 2018, 10, 29933–29942. [Google Scholar] [CrossRef] [PubMed]

- Sessini, V.; Raquez, J.-M.; Lourdin, D.; Maigret, J.-E.; Kenny, J.M.; Dubois, P.; Peponi, L. Humidity-activated shape memory effects on thermoplastic starch/EVA blends and their compatibilized nanocomposites. Macromol. Chem. Phys. 2017, 218, 1700388. [Google Scholar] [CrossRef]

- Beloshenko, V.A.; Varyukhin, V.N.; Voznyak, Y.V. Electrical properties of carbon containing epoxy compositions under shape memory effect realization. Compos. Part A 2005, 36, 65–70. [Google Scholar] [CrossRef]

- Kalita, V.M.; Dzhezherya, Y.I.; Cherepov, S.V.; Skirta, Y.B.; Bodnaruk, A.V.; Levchenko, G.G. Critical bending and shape memory effect in magnetoactive elastomers. Smart Mater. Struct. 2021, 30, 025020. [Google Scholar] [CrossRef]

- Gunes, I.S.; Cao, F.; Jana, S.C. Evaluation of nanoparticulate fillers for development of shape memory polyurethane nanocomposites. Polymer 2008, 49, 2223–2234. [Google Scholar] [CrossRef]

- Lan, X.; Liu, Y.; Lv, H.; Wang, X.; Leng, J.; Du, S. Fiber reinforced shape-memory polymer composite and its application in a deployable hinge. Smart Mater. Struct. 2009, 18, 024002. [Google Scholar] [CrossRef]

- Nishikawa, M.; Wakatsuki, K.; Yoshimura, A.; Takeda, N. Effect of fiber arrangement on shape fixity and shape recovery in thermally activated shape memory polymer-based composites. Compos. Part A 2012, 43, 165–173. [Google Scholar] [CrossRef]

- Odent, J.; Raquez, J.-M.; Samuel, C.; Barrau, S.; Enotiadis, A.; Dubois, P.; Giannelis, E.P. Shape-Memory Behavior of Polylactide/Silica Ionic Hybrids. Macromolecules 2017, 50, 2896–2905. [Google Scholar] [CrossRef]

- Vozniak, I.; Zaïri, F.; Hosseinnezhad, R.; Morawiec, J.; Galeski, A. Design of hybrid PLA/PBS/POM composite based on in-situ formation of interpenetrating fiber networks, Compos. Part A Appl. Sci. Manuf. 2021, 151, 106667. [Google Scholar] [CrossRef]

- Fakirov, S. In situ nano- and microfibrillar polymer-polymer composites: The concept of micro- or nanofibrils reinforced polymerpolymer composites. In Synthetic Polymer-Polymer Composites; Bhattacharyya, D., Fakirov, S.S., Eds.; Hanser Publications: Munich, Germany, 2012; pp. 353–400. [Google Scholar]

- Hosseinnezhad, R.; Vozniak, I.; Morawiec, J.; Galeski, A. Evolution of green in-situ generated polyamide nanofibers controlled by viscoelasticity. Express Polym. Lett. 2021, 15, 250–261. [Google Scholar] [CrossRef]

- Kakroodia, A.R.; Kazemia, Y.; Rodrigueb, D.; Park, C.H.B. Facile production of biodegradable PCL/PLA in situ nanofibrillar composites with unprecedented compatibility between the blend components. Chem. Eng. J. 2018, 351, 976–984. [Google Scholar] [CrossRef]

- Ding, W.; Chen, Y.; Liu, Z.H.; Yang, S. In situ nano-fibrillation of microinjection molded poly (lactic acid)/poly(e-caprolactone) blends and comparison with conventional injection molding. RSC Adv. 2015, 5, 92905–92917. [Google Scholar] [CrossRef]

- Hosseinnezhad, R.; Vozniak, I.; Morawiec, J.; Galeski, A. Nanofibrillar green composites of polylactide/polyamide produced in situ due to shear induced crystallization. Compos. Commun. 2020, 22, 100512. [Google Scholar] [CrossRef]

- Vozniak, I.; Hosseinnezhad, R.; Morawiec, J.; Galeski, A. Nanofibrillar green composites of polylactide/polyhydroxyalkanoate produced in situ due to shear induced crystallization. Polymers 2019, 11, 1811. [Google Scholar] [CrossRef] [PubMed]

- Vozniak, I.; Hosseinnezhad, R.; Morawiec, J.; Galeski, A. Microstructural evolution of poly(ε-caprolactone), its immiscible blend, and in situ generated nanocomposites. Polymers 2020, 12, 2587. [Google Scholar] [CrossRef] [PubMed]

- Hosseinnezhad, R.; Vozniak, I.; Zaïri, F. In situ generation of green hybrid nanofibrillar polymer-polymer composites—A novel approach to the triple shape memory polymer formation. Polymers 2021, 13, 1900. [Google Scholar] [CrossRef]

- Jinlian, H.; Chen, S. A review of actively moving polymers in textile applications. J. Mater. Chem. 2010, 17, 3346–3355. [Google Scholar]

- Wang, L.S.; Chen, H.C.; Xiong, Z.C.; Pang, X.B.; Xiong, C.D. A completely biodegradable Poly[(L-lactide)-co-(ε-caprolactone)] elastomer reinforced by in situ Poly(glycolic acid) fibrillation: Manufacturing and shape-memory effects. Macromol. Mater. Eng. 2010, 295, 381–385. [Google Scholar] [CrossRef]

- Hosseinnezhad, R.; Elumalai, D.; Vozniak, I. Approaches to control crazing deformation of PHA-based biopolymeric blends. Polymers 2023, 15, 4234. [Google Scholar] [CrossRef] [PubMed]

- ISO 527; Plastics—Determination of Tensile Properties—Part 2: Test Conditions for Moulding and Extrusion Plastics. ISO: Geneva, Switzerland, 2012.

- Yousfi, M.; Dadouche, T.; Chomat, D.; Samuel, C.; Soulestin, J.; Lacrampe, M.F.; Krawczak, P. Development of nanofibrillar morphologies in poly(L-lactide)/poly(amide) blends: Role of the matrix elasticity and identification of the critical shear rate for the nodular/fibrillar transition. RSC Adv. 2018, 8, 22023–22041. [Google Scholar] [CrossRef] [PubMed]

- Ashida, M.; Noguchi, T. Effect of matrix’s type on the dynamic properties for short fiber-elastomer composite. J. Appl. Polym. Sci. 1985, 30, 1011–1021. [Google Scholar] [CrossRef]

- Hao, X.; Kaschta, J.; Liu, X.H.; Pan, Y.; Schubert, D.W. Entanglement network formed in miscible PLA/PMMA blends and its role in rheological and thermo-mechanical properties of the blends. Polymer 2015, 80, 38–45. [Google Scholar] [CrossRef]

- Vozniak, A.; Beloshenko, V.; Zaïri, F.; Galeski, A.; Rozanski, A. Interfaces generation via severe plastic deformation—A new way to multiple shape memory polymer composites. Polymer 2023, 267, 125653. [Google Scholar] [CrossRef]

- Liu, H.; He, H.; Huang, B. Favorable thermoresponsive shape memory effects of 3D printed Poly(Lactic Acid)/Poly(ε-Caprolactone) blends fabricated by fused deposition modeling. Macromol. Mater. Eng. 2020, 305, 2000295. [Google Scholar] [CrossRef]

| Composite | Modulus of Elasticity, GPa | Yield Stress, MPa | Stress at Break, MPa | Strain at Break, % |

|---|---|---|---|---|

| PLA | 1.50 | 42.1 | 30.0 | 5 |

| PLA/PA | 1.90 | 43.4 | 25.8 | 70 |

| PLA/PA/1%J | 1.98 | 49.2 | 27.9 | 80 |

| PLA/PA/2%J | 2.12 | 49.5 | 39.8 | 150 |

| PLA/PA/4%J | 1.72 | 48.2 | 43.3 | 13 |

| Composite | α | χc, Degree of Crystallinity, % |

|---|---|---|

| PLA/PA | 3.63 | 15.0 |

| PLA/PA/1%J | 5.34 | 15.9 |

| PLA/PA/2%J | 8.13 | 19.2 |

| PLA/PA/4%J | 2.12 | 12.8 |

| Material | Shape-Fixity Ratio Rf, % | Shape-Recovery Ratio Rr, % | Shape-Recovery Time, min |

|---|---|---|---|

| PLA | 80.2 | 15.5 | 9.7 |

| PLA/PA | 96.0 | 80.1 | 9.0 |

| PLA/PA/1%J | 96.0 | 84.0 | 9.0 |

| PLA/PA/2%J | 97.4 | 94.0 | 7.0 |

| PLA/PA/4%J | 95.0 | 42.0 | 9.6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bondarenko, V.; Hosseinnezhad, R.; Voznyak, A. Role of Minor Phase Morphology on Mechanical and Shape-Memory Properties of Polylactide/Bio-Polyamide Nanocomposite. Polymers 2024, 16, 2413. https://doi.org/10.3390/polym16172413

Bondarenko V, Hosseinnezhad R, Voznyak A. Role of Minor Phase Morphology on Mechanical and Shape-Memory Properties of Polylactide/Bio-Polyamide Nanocomposite. Polymers. 2024; 16(17):2413. https://doi.org/10.3390/polym16172413

Chicago/Turabian StyleBondarenko, Vladislav, Ramin Hosseinnezhad, and Andrei Voznyak. 2024. "Role of Minor Phase Morphology on Mechanical and Shape-Memory Properties of Polylactide/Bio-Polyamide Nanocomposite" Polymers 16, no. 17: 2413. https://doi.org/10.3390/polym16172413

APA StyleBondarenko, V., Hosseinnezhad, R., & Voznyak, A. (2024). Role of Minor Phase Morphology on Mechanical and Shape-Memory Properties of Polylactide/Bio-Polyamide Nanocomposite. Polymers, 16(17), 2413. https://doi.org/10.3390/polym16172413