Behavior of a Precast Bridge Pier with Basalt Fiber-Reinforced Polymer (BFRP)-Strengthened Segments under Seismic Loading

Abstract

1. Introduction

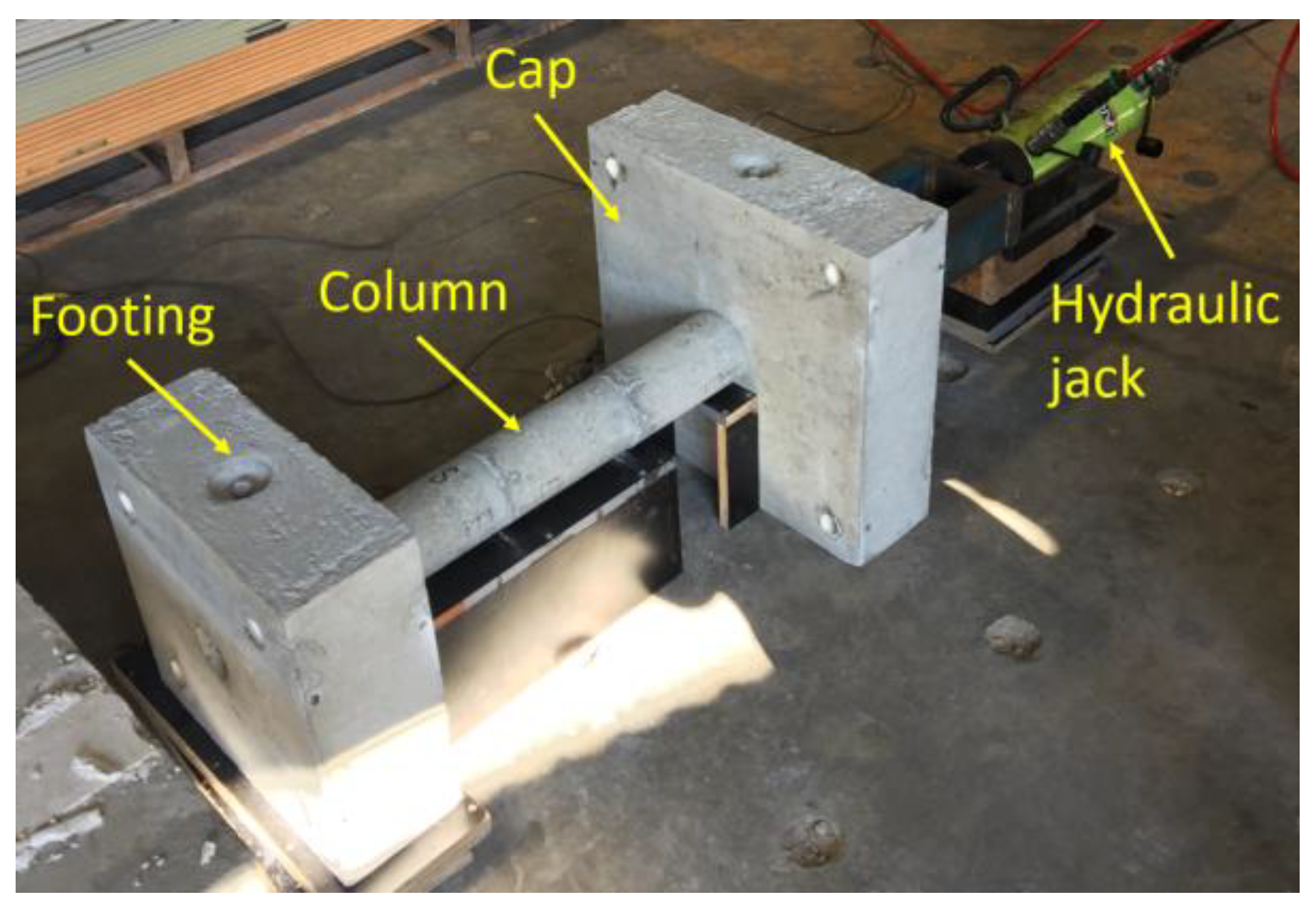

2. Specimen Designs and Constructions

2.1. Design of Specimens

2.2. Preparation of Specimens

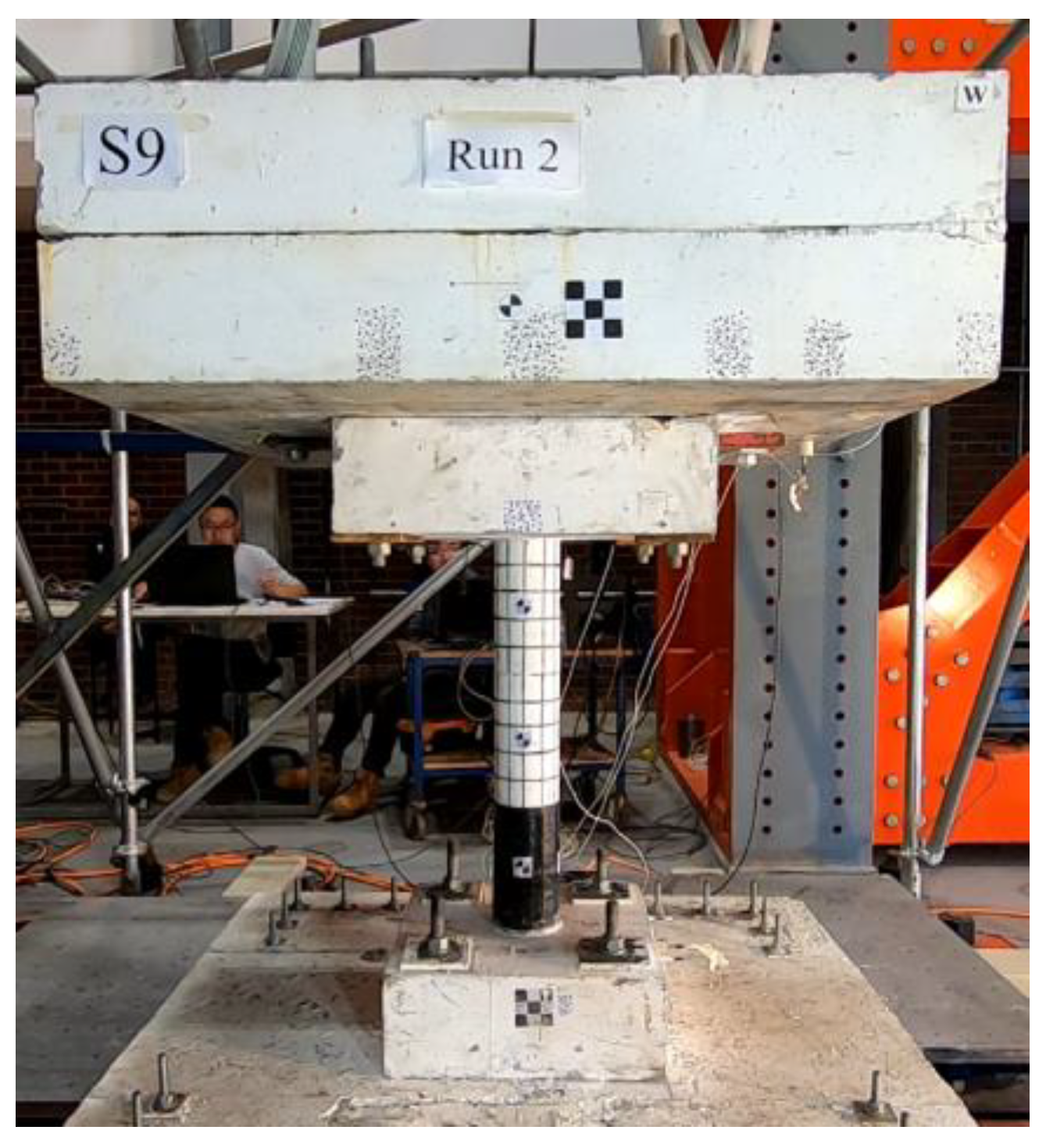

3. Test Setup

3.1. Installation of the Columns

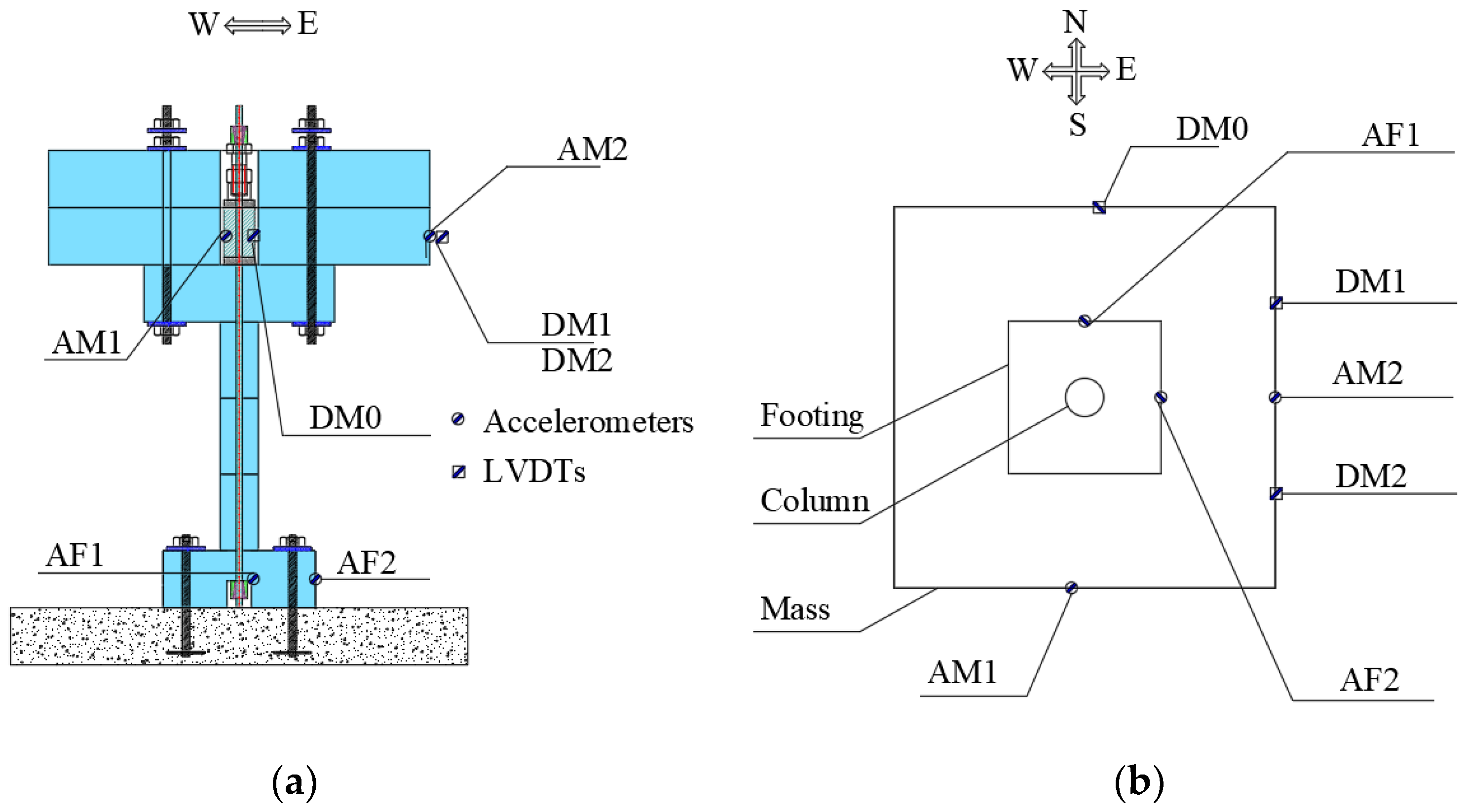

3.2. Arrangement of Sensors

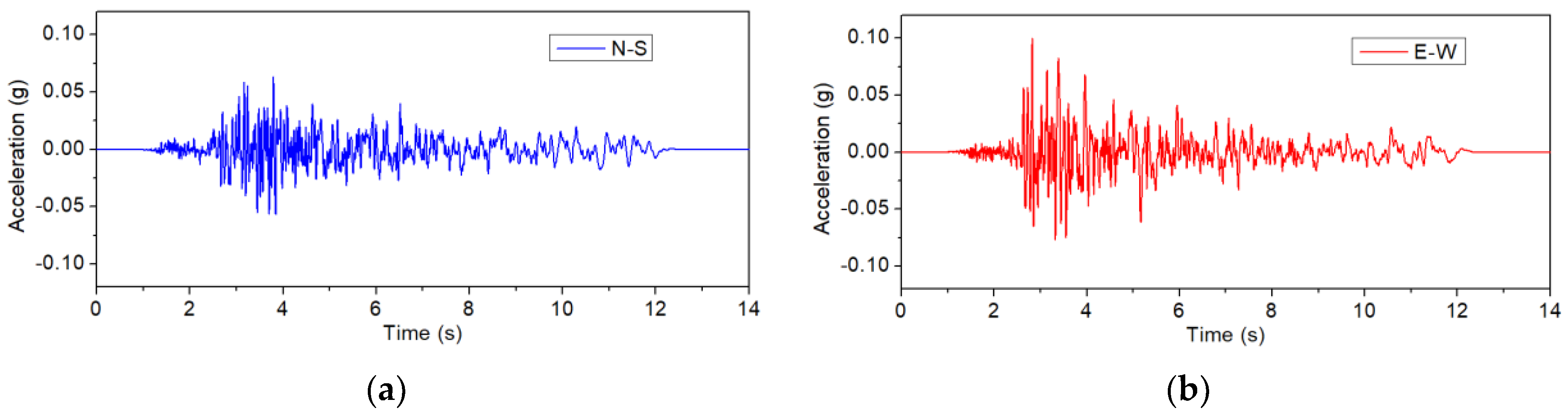

3.3. Input Motions

4. Test Results

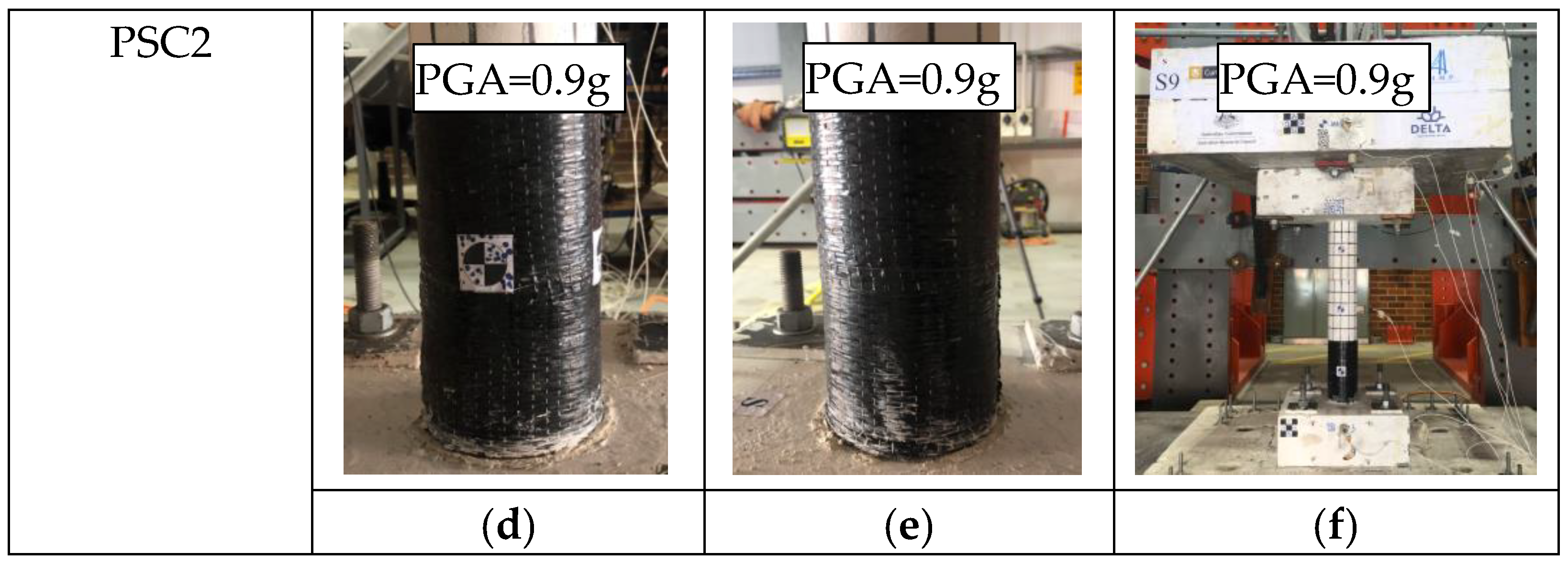

4.1. Observed Damage Patterns

4.2. Change of Vibration Periods

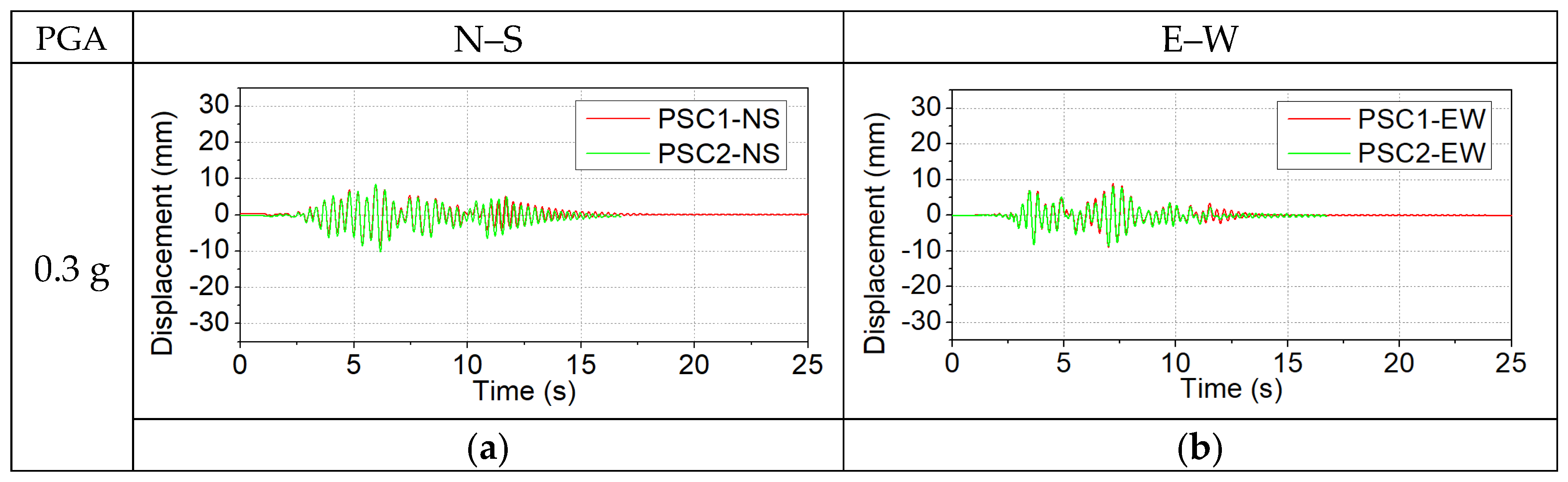

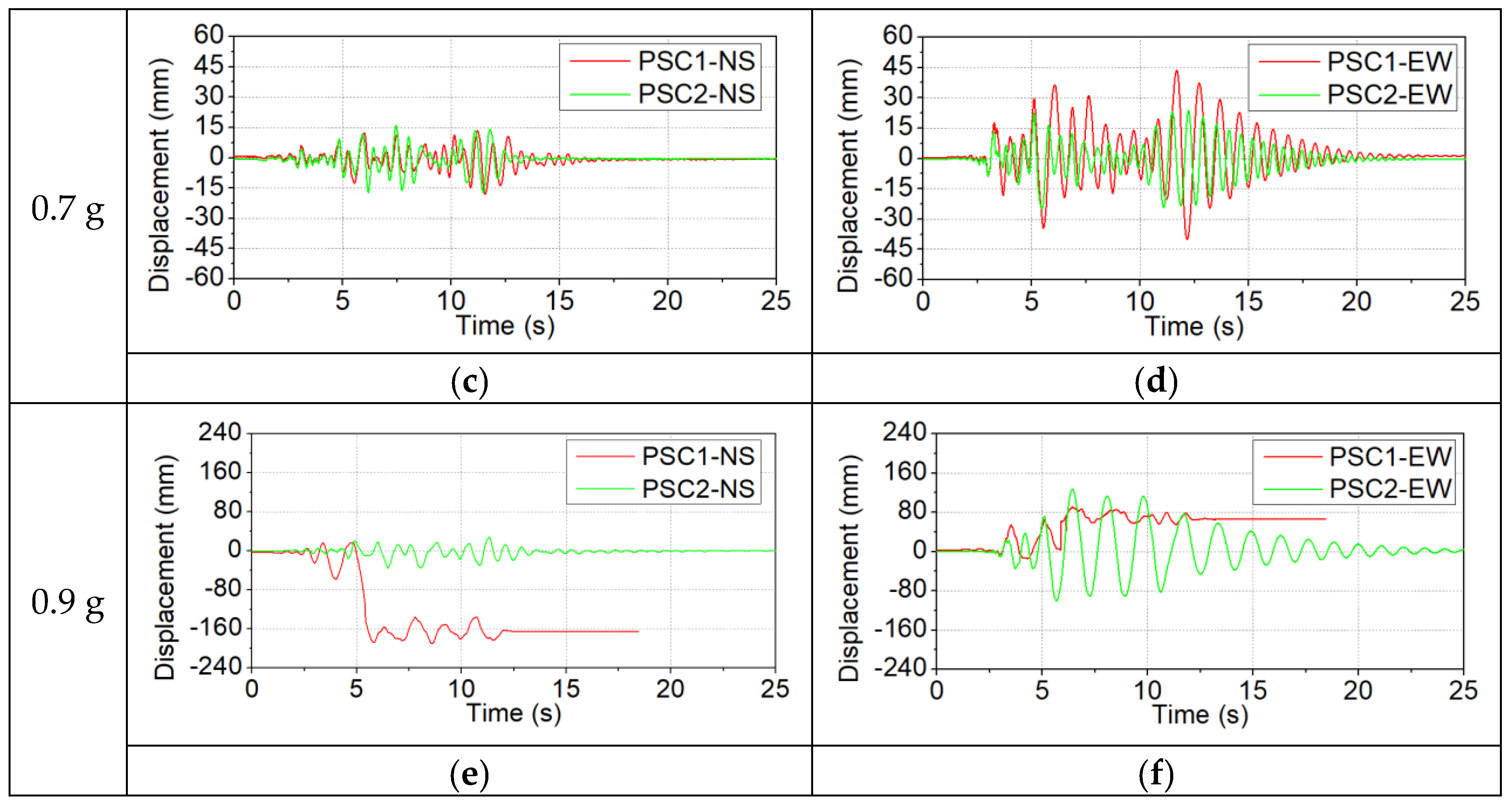

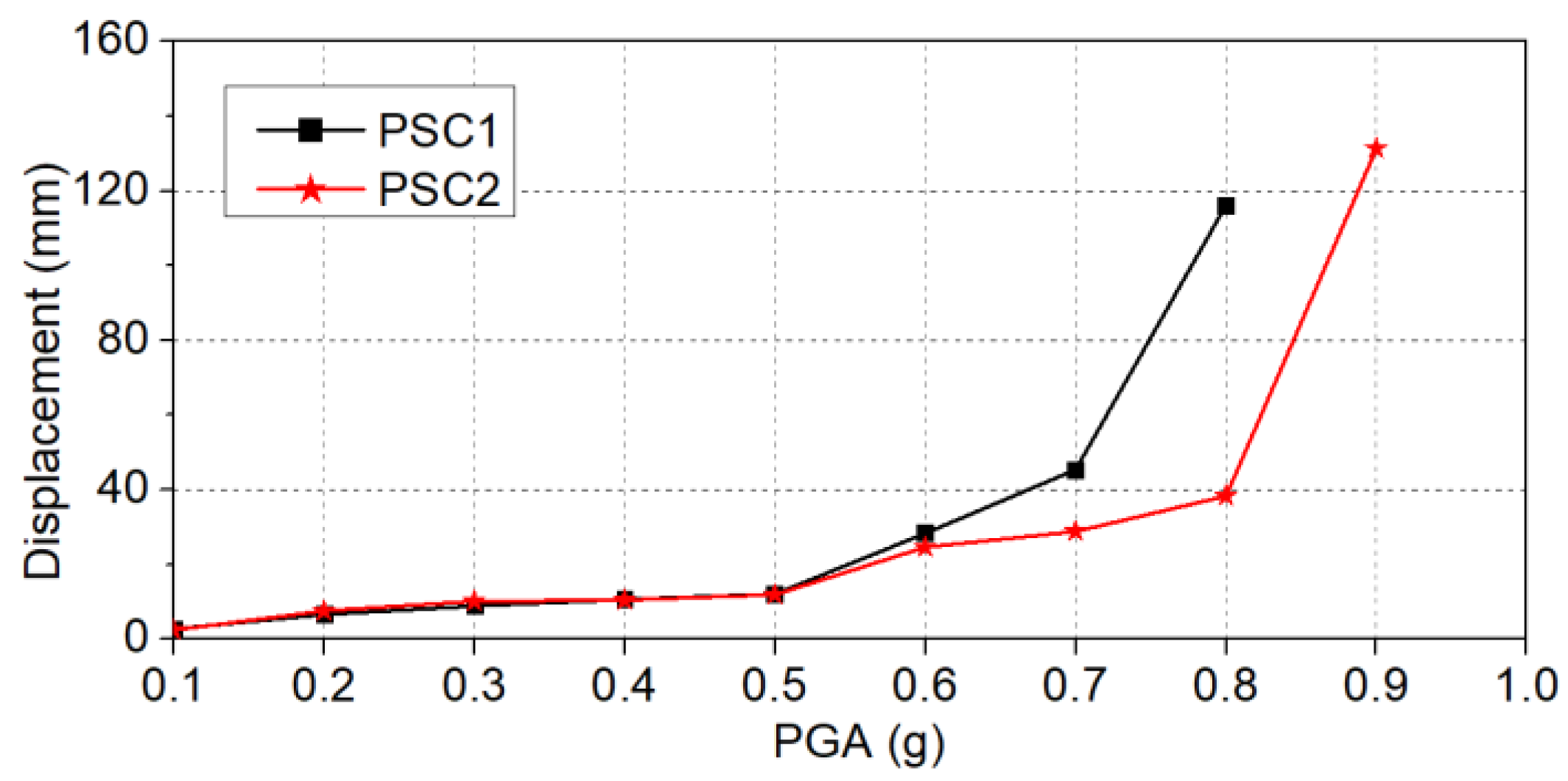

4.3. Displacement Responses

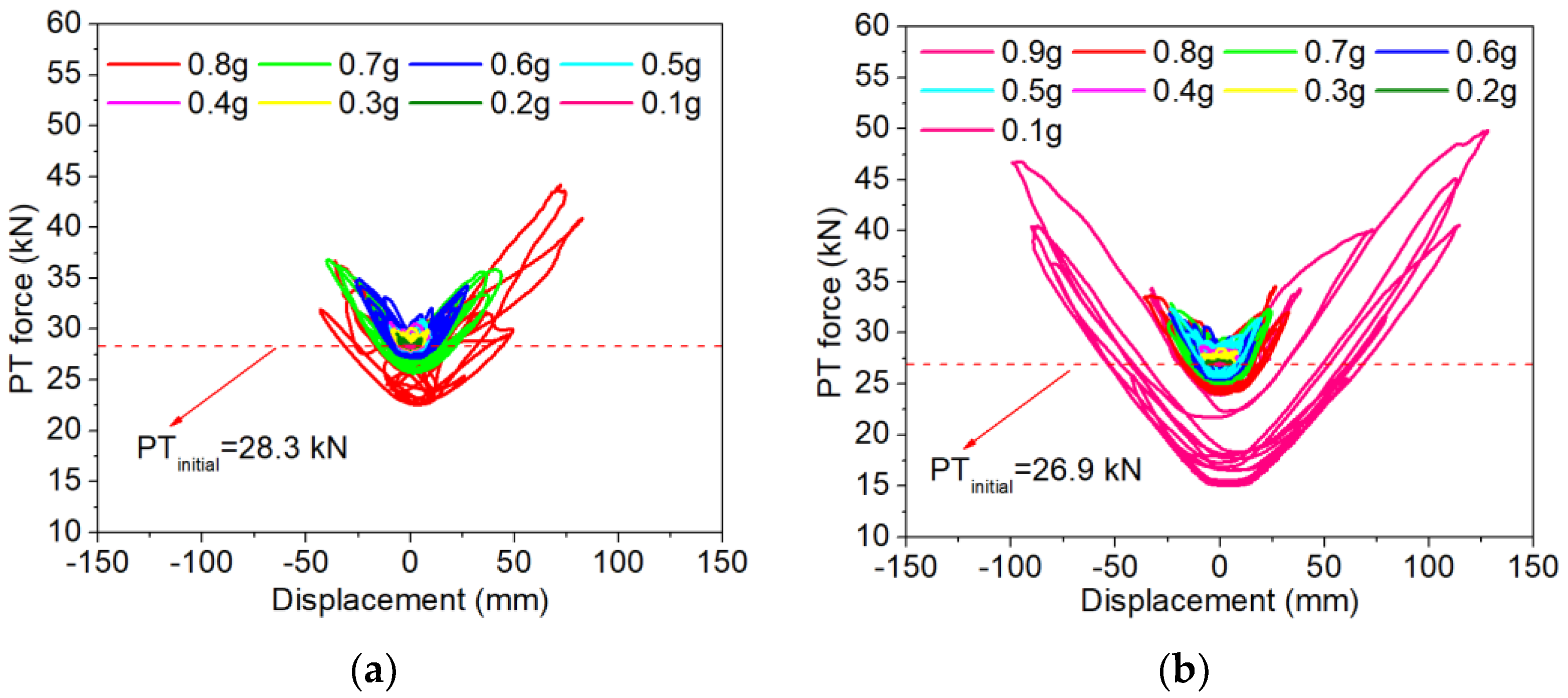

4.4. Histories of PT Forces

4.5. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Luo, W.; Sandanayake, M.; Hou, L.; Tan, Y.; Zhang, G. A systematic review of green construction research using scientometrics methods. J. Clean. Prod. 2022, 366, 132710. [Google Scholar] [CrossRef]

- Mander, J.B.; Cheng, C.-T. Seismic Resistance of Bridge Piers Based on Damage Avoidance Design; NCEER-97-0014; National Center for Earthquake Engineering Research: Buffalo, NY, USA, 1997. [Google Scholar]

- Hewes, J.T.; Priestley, M.N. Seismic Design and Performance of Precast Concrete Segmental Bridge Columns; SSRP-2001/25; University of California: San Diego, CA, USA, 2002. [Google Scholar]

- Zhong, C.; Christopoulos, C. Self-centering seismic-resistant structures: Historical overview and state-of-the-art. Earthq. Spectra 2021, 38, 1321–1356. [Google Scholar] [CrossRef]

- Piras, S.; Palermo, A.; Saiid Saiidi, M. State-of-the-Art of Posttensioned Rocking Bridge Substructure Systems. J. Bridge Eng. 2022, 27, 03122001. [Google Scholar] [CrossRef]

- Raza, S.; Triantafyllidis, Z.; Anton, A.; Dillenburger, B.; Shahverdi, M. Seismic performance of Fe-SMA prestressed segmental bridge columns with 3D printed permanent concrete formwork. Eng. Struct. 2024, 302, 117423. [Google Scholar] [CrossRef]

- Ou, Y.C.; Wang, P.H.; Tsai, M.S.; Chang, K.C.; Lee, G.C. Large-scale experimental study of precast segmental unbonded posttensioned concrete bridge columns for seismic regions. J. Struct. Eng. 2009, 136, 255–264. [Google Scholar] [CrossRef]

- Li, C.; Xiang, Y.; Cai, C. Performance of a seismic-resilient precast segmental column with UHPC segments and CFRP tendon. Eng. Struct. 2023, 282, 115833. [Google Scholar] [CrossRef]

- Billington, S.L.; Yoon, J. Cyclic response of unbonded posttensioned precast columns with ductile fiber-reinforced concrete. J. Bridge Eng. 2004, 9, 353–363. [Google Scholar] [CrossRef]

- Chou, C.C.; Chen, Y.C. Cyclic tests of post-tensioned precast CFT segmental bridge columns with unbonded strands. Earthq. Eng. Struct. Dynam. 2006, 35, 159–175. [Google Scholar] [CrossRef]

- ElGawady, M.; Sha’lan, A. Seismic behavior of self-centering precast segmental bridge bents. J. Bridge Eng. 2010, 16, 328–339. [Google Scholar] [CrossRef]

- Li, C.; Xiang, Y.; He, X.; Yang, P.; Zhou, H.; Cai, C. Investigation of the seismic performance of a precast CFDST column with internal SMA and external energy dissipating devices. Structures 2024, 61, 106000. [Google Scholar] [CrossRef]

- Tazarv, M.; Hart, K.; Khan, A. Rocking Bridge Columns with External Replaceable Tendons. J. Bridge Eng. 2024, 29, 04024008. [Google Scholar] [CrossRef]

- Shen, Y.; Freddi, F.; Li, Y.; Li, J. Shaking table tests of seismic-resilient post-tensioned reinforced concrete bridge piers with enhanced bases. Eng. Struct. 2024, 305, 117690. [Google Scholar] [CrossRef]

- McLellan, B.C.; Williams, R.P.; Lay, J.; Van Riessen, A.; Corder, G.D. Costs and carbon emissions for geopolymer pastes in comparison to ordinary portland cement. J. Clean. Prod. 2011, 19, 1080–1090. [Google Scholar] [CrossRef]

- Singh, B.; Ishwarya, G.; Gupta, M.; Bhattacharyya, S.K. Geopolymer concrete: A review of some recent developments. Constr. Build. Mater. 2015, 85, 78–90. [Google Scholar] [CrossRef]

- Nguyễn, H.H.; Lương, Q.-H.; Choi, J.-I.; Ranade, R.; Li, V.C.; Lee, B.Y. Ultra-ductile behavior of fly ash-based engineered geopolymer composites with a tensile strain capacity up to 13.7%. Cem. Concr. Compos. 2021, 122, 104133. [Google Scholar] [CrossRef]

- Maranan, G.B.; Manalo, A.C.; Benmokrane, B.; Karunasena, W.; Mendis, P. Behavior of concentrically loaded geopolymer-concrete circular columns reinforced longitudinally and transversely with GFRP bars. Eng. Struct. 2016, 117, 422–436. [Google Scholar] [CrossRef]

- Saranya, P.; Nagarajan, P.; Shashikala, A. Seismic performance of geopolymer concrete beam-column joints under reverse cyclic loading. Innov. Infrastruct. Solut. 2021, 6, 92. [Google Scholar] [CrossRef]

- Alashker, Y.; Raza, A. Seismic performance of recycled aggregate geopolymer concrete-filled double skin tubular columns with internal steel and external FRP tube. Polymers 2022, 14, 5204. [Google Scholar] [CrossRef] [PubMed]

- Maniarasan, S.K.; Chandrasekaran, P.; Jayaprakash, S.; Ravindran, G. Influence of slag-based geopolymer concrete on the seismic behavior of exterior beam column joints. Sustainability 2023, 15, 2327. [Google Scholar] [CrossRef]

- Raza, A.; Selmi, A.; El Ouni, M.H.; Arshad, M.; Kahla, N.B. Rapid repair of geopolymer concrete members reinforced with polymer composites: Parametric study and analytical modeling. Eng. Struct. 2024, 299, 117143. [Google Scholar] [CrossRef]

- AlAjarmeh, O.S.; Manalo, A.C.; Benmokrane, B.; Karunasena, W.; Mendis, P.; Nguyen, K.T.Q. Compressive behavior of axially loaded circular hollow concrete columns reinforced with GFRP bars and spirals. Constr. Build. Mater. 2019, 194, 12–23. [Google Scholar] [CrossRef]

- Issa, M.A.; Ovitigala, T.; Ibrahim, M. Shear behavior of basalt fiber reinforced concrete beams with and without basalt FRP stirrups. J. Compos. Constr. 2016, 20, 04015083. [Google Scholar] [CrossRef]

- Monaldo, E.; Nerilli, F.; Vairo, G. Basalt-based fiber-reinforced materials and structural applications in civil engineering. Compos. Struct. 2019, 214, 246–263. [Google Scholar] [CrossRef]

- Fan, X.; Zhang, M. Behaviour of inorganic polymer concrete columns reinforced with basalt FRP bars under eccentric compression: An experimental study. Compos. Part B Eng. 2016, 104, 44–56. [Google Scholar] [CrossRef]

- Moustafa, A.; ElGawady, M.A. Performance of double skin FRP-concrete-steel self-centered segmental bridge piers subjected to forward-directivity near-fault ground motion. Eng. Struct. 2020, 221, 111065. [Google Scholar] [CrossRef]

- Moustafa, A.; ElGawady, M.A. Shaking Table Testing of Segmental Hollow-Core FRP-Concrete-Steel Bridge Columns. J. Bridge Eng. 2018, 23, 04018020. [Google Scholar] [CrossRef]

- Schoettler, M.; Restrepo, J.; Guerrini, G.; Duck, D.; Carrea, F. A Full-Scale, Single-Column Bridge Bent Tested by Shake-Table Excitation; Center for Civil Engineering Earthquake Research, Department of Civil Engineering, University of Nevada: Berkeley, CA, USA, 2012. [Google Scholar]

- Motaref, S.; Saiidi, M.S.; Sanders, D. Shake table studies of energy-dissipating segmental bridge columns. J. Bridge Eng. 2013, 19, 186–199. [Google Scholar] [CrossRef]

| Physical Items | Scale Rules | Scale Factors | |

|---|---|---|---|

| Geometry | Length (l) | Sl | 12 |

| Displacement (δ) | Sl | 12 | |

| Material properties | Elastic modulus (E) | SE | 1 |

| Stress (σ) | SE | 1 | |

| Strain (ε) | 1 | 1 | |

| Poisson’s Ratio (ν) | 1 | 1 | |

| Dynamic properties | Acceleration (a) | Sa | 1 |

| Mass (m) | SESl2/Sa | 144 | |

| Frequency (ω) | (Sa/Sl)0.5 | 0.29 | |

| Velocity (v) | (SlSa)0.5 | 3.46 | |

| Time (t) | (Sl/Sa)0.5 | 3.46 | |

| Loadings | Force (F) | SESl2 | 144 |

| Moment (M) | SESl3 | 1728 | |

| Mixed Concrete | Aggregates | Sand | Fly Ash | Slag | Na2SiO3 Solution | NaOH Solution |

|---|---|---|---|---|---|---|

| GPC | 1196 | 644 | 360 | 40 | 173.7 | 59.4 |

| Material | Diameter | Elastic Modulus | Yield Strength | Ultimate Strength |

|---|---|---|---|---|

| (mm) | (GPa) | (MPa) | (MPa) Steel/BFRP | |

| Longitudinal rebar | 6 | 55 | - | 1100 |

| Stirrup | 3 | 55 | - | 1100 |

| Tendon | 9.3 | 195 | 1674 | 1860 |

| BFRP fabric | - | 105 | - | 2100 |

| Device | Name | Note |

|---|---|---|

| Accelerometers | AM1 | Acceleration at mass (N–S) |

| AM2 | Acceleration at mass (E–W) | |

| AF1 | Acceleration at footing (N–S) | |

| AF2 | Acceleration at footing (E–W) | |

| LVDTs | DM0 | Displacement at mass (N–S) |

| DM1 | Displacement at mass (E–W) | |

| DM2 | Displacement at mass (E–W) | |

| Load Cell | FT | Force in the tendon |

| PGA (g) | PSC1 | PSC2 | ||||

|---|---|---|---|---|---|---|

| Max (kN) | Min (kN) | Loss (%) | Max (kN) | Min (kN) | Loss (%) | |

| 0 | 28.28 | 28.28 | 0.00 | 26.90 | 26.90 | 0.00 |

| 0.1 | 28.37 | 28.27 | 0.07 | 27.03 | 26.90 | 0.01 |

| 0.2 | 29.53 | 28.16 | 0.44 | 27.35 | 26.88 | 0.05 |

| 0.3 | 30.08 | 28.04 | 0.88 | 28.44 | 26.84 | 0.21 |

| 0.4 | 30.66 | 27.95 | 1.17 | 28.65 | 26.72 | 0.67 |

| 0.5 | 30.91 | 27.86 | 1.51 | 29.96 | 26.58 | 1.18 |

| 0.6 | 34.92 | 27.20 | 3.83 | 31.86 | 25.93 | 3.60 |

| 0.7 | 36.82 | 25.75 | 8.94 | 32.88 | 25.02 | 7.00 |

| 0.8 | 44.18 | 22.57 | 20.19 | 34.53 | 24.01 | 10.72 |

| 0.9 | - | - | - | 49.83 | 15.00 | 44.22 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, C.; Peng, Y.; Yang, P.; Zhou, H.; Wang, N. Behavior of a Precast Bridge Pier with Basalt Fiber-Reinforced Polymer (BFRP)-Strengthened Segments under Seismic Loading. Polymers 2024, 16, 2018. https://doi.org/10.3390/polym16142018

Li C, Peng Y, Yang P, Zhou H, Wang N. Behavior of a Precast Bridge Pier with Basalt Fiber-Reinforced Polymer (BFRP)-Strengthened Segments under Seismic Loading. Polymers. 2024; 16(14):2018. https://doi.org/10.3390/polym16142018

Chicago/Turabian StyleLi, Chao, Yaowei Peng, Pengyu Yang, Hao Zhou, and Ningbo Wang. 2024. "Behavior of a Precast Bridge Pier with Basalt Fiber-Reinforced Polymer (BFRP)-Strengthened Segments under Seismic Loading" Polymers 16, no. 14: 2018. https://doi.org/10.3390/polym16142018

APA StyleLi, C., Peng, Y., Yang, P., Zhou, H., & Wang, N. (2024). Behavior of a Precast Bridge Pier with Basalt Fiber-Reinforced Polymer (BFRP)-Strengthened Segments under Seismic Loading. Polymers, 16(14), 2018. https://doi.org/10.3390/polym16142018