Development of PLA–Waste Paper Biocomposites with High Cellulose Content

Abstract

1. Introduction

2. Materials and Methods

2.1. Biocomposite Components

2.2. Biocomposite Manufacturing Process

2.3. Characterisation of Components and Manufactured Biocomposites

2.3.1. WP

2.3.2. Characterisation of Biocomposites

3. Results

3.1. WP Characterisation

3.1.1. Morphology

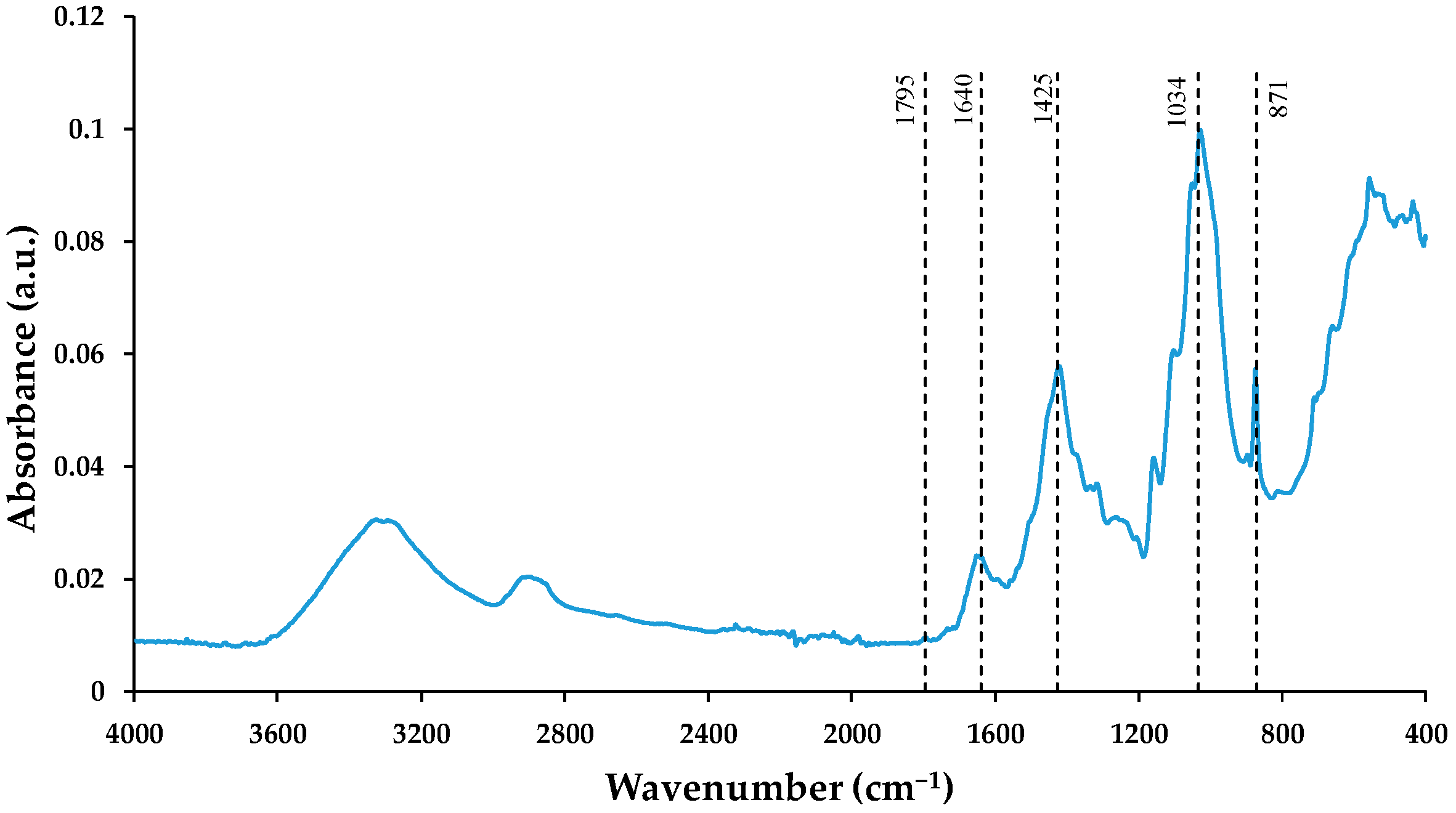

3.1.2. FT-IR

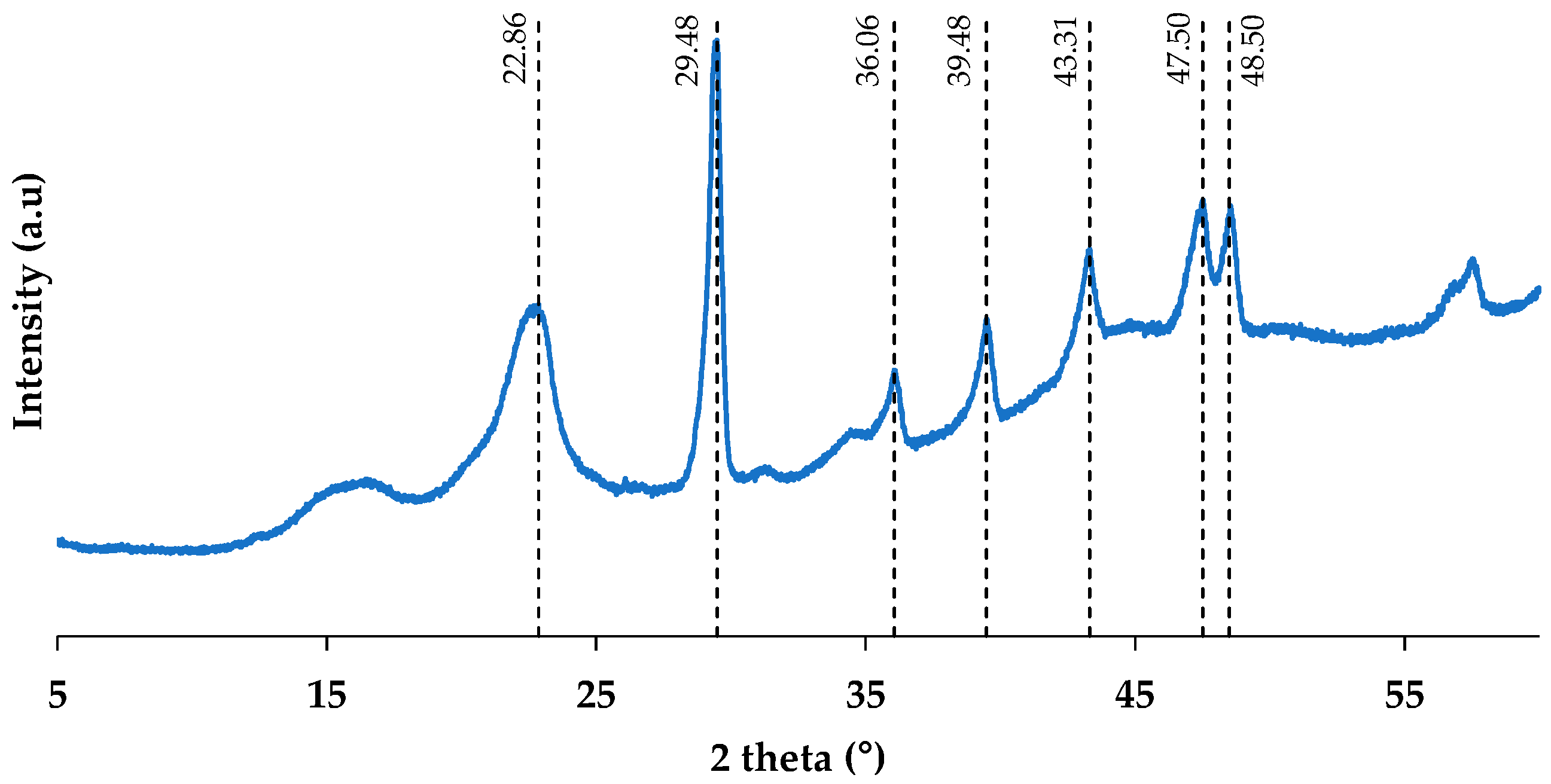

3.1.3. XRD

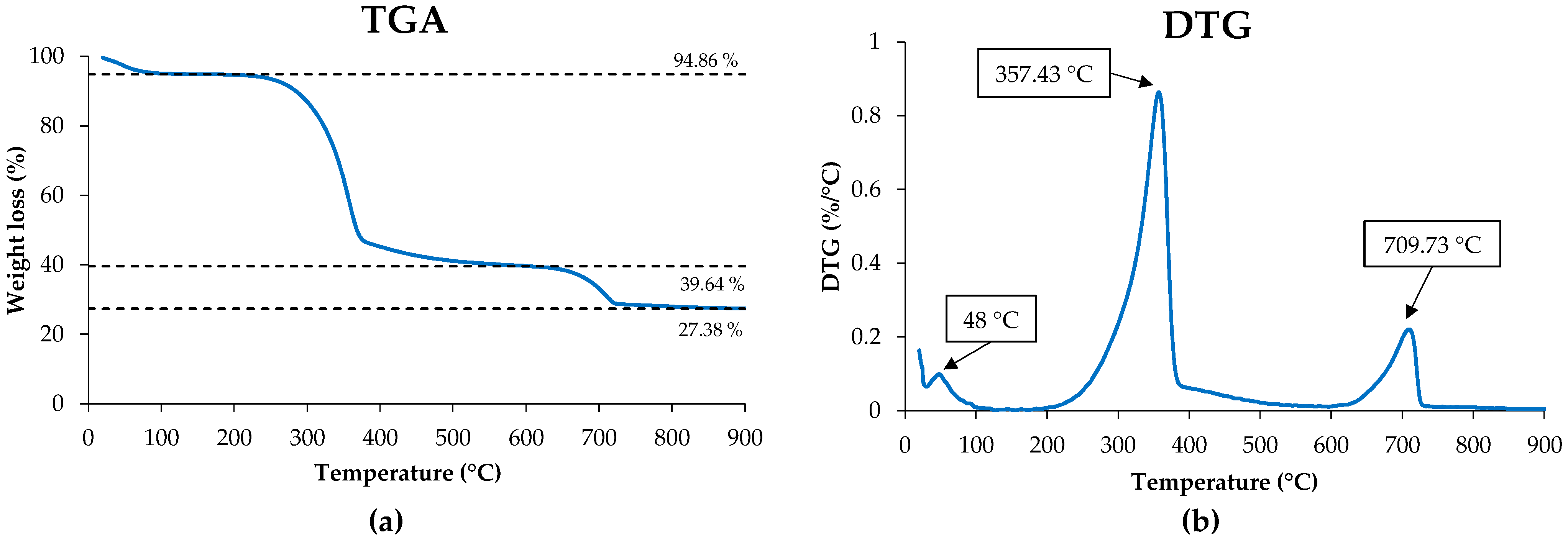

3.1.4. Thermal Analysis

3.2. Characterisation of Biocomposites

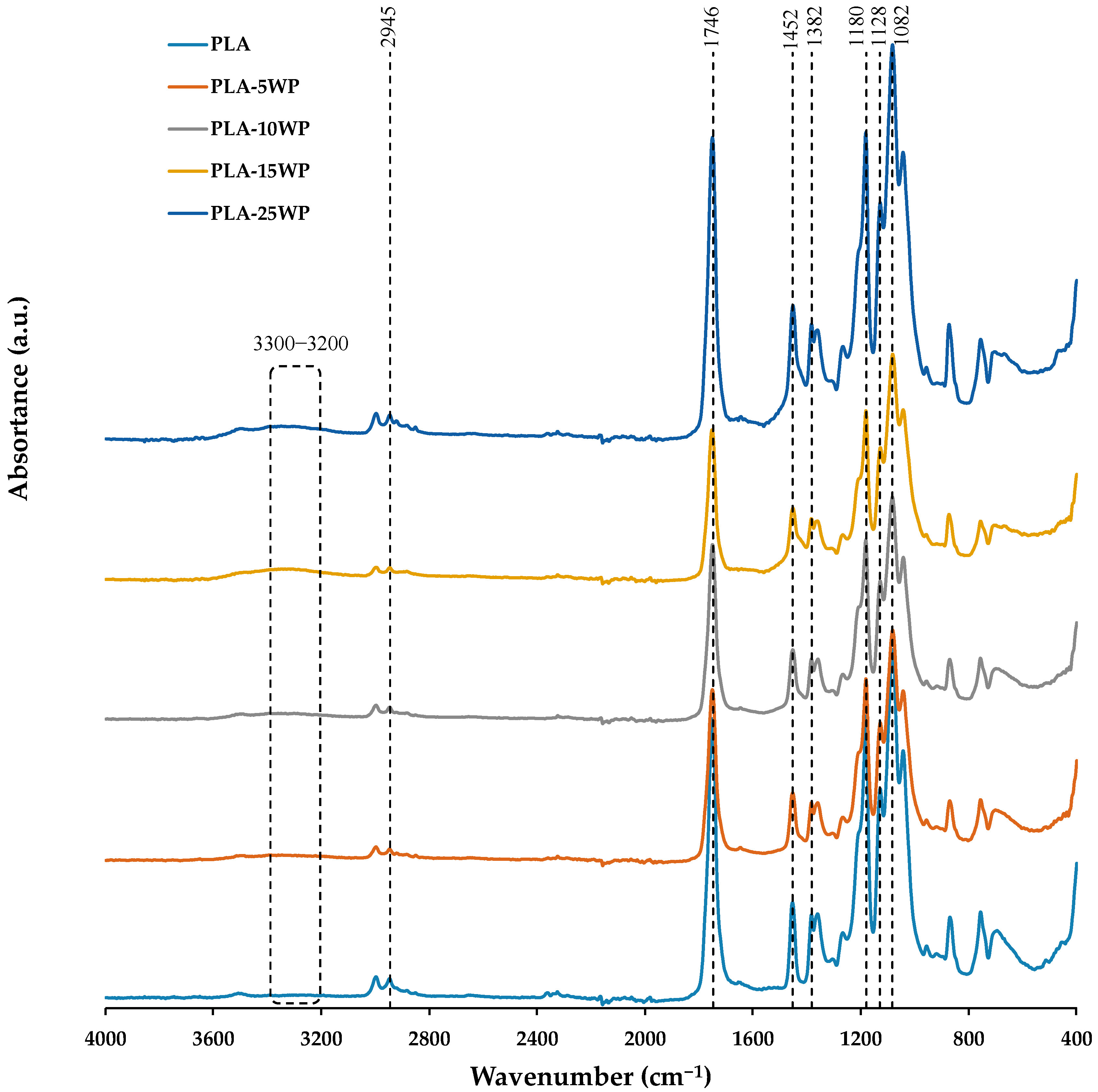

3.2.1. FT-IR

3.2.2. XRD

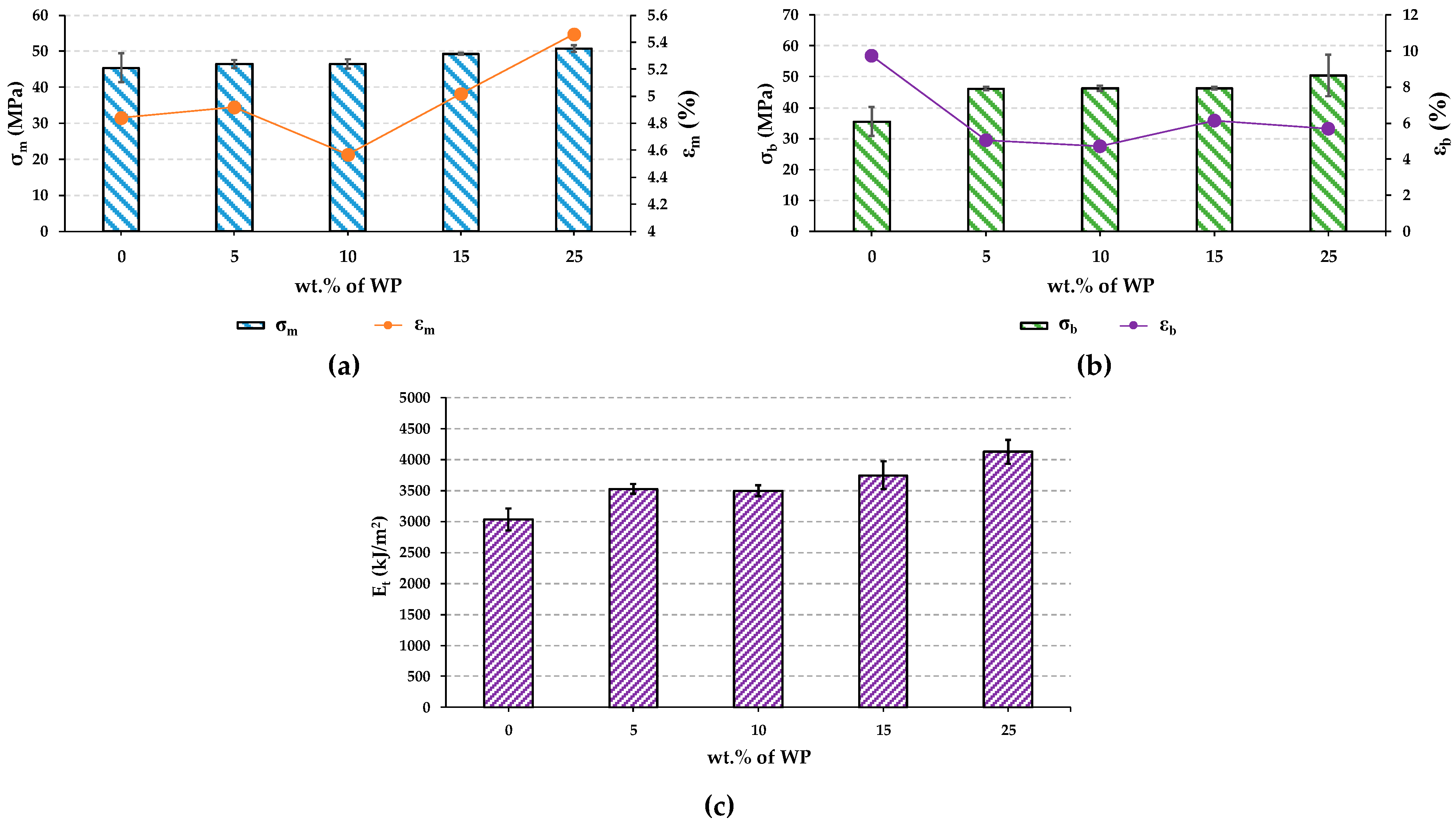

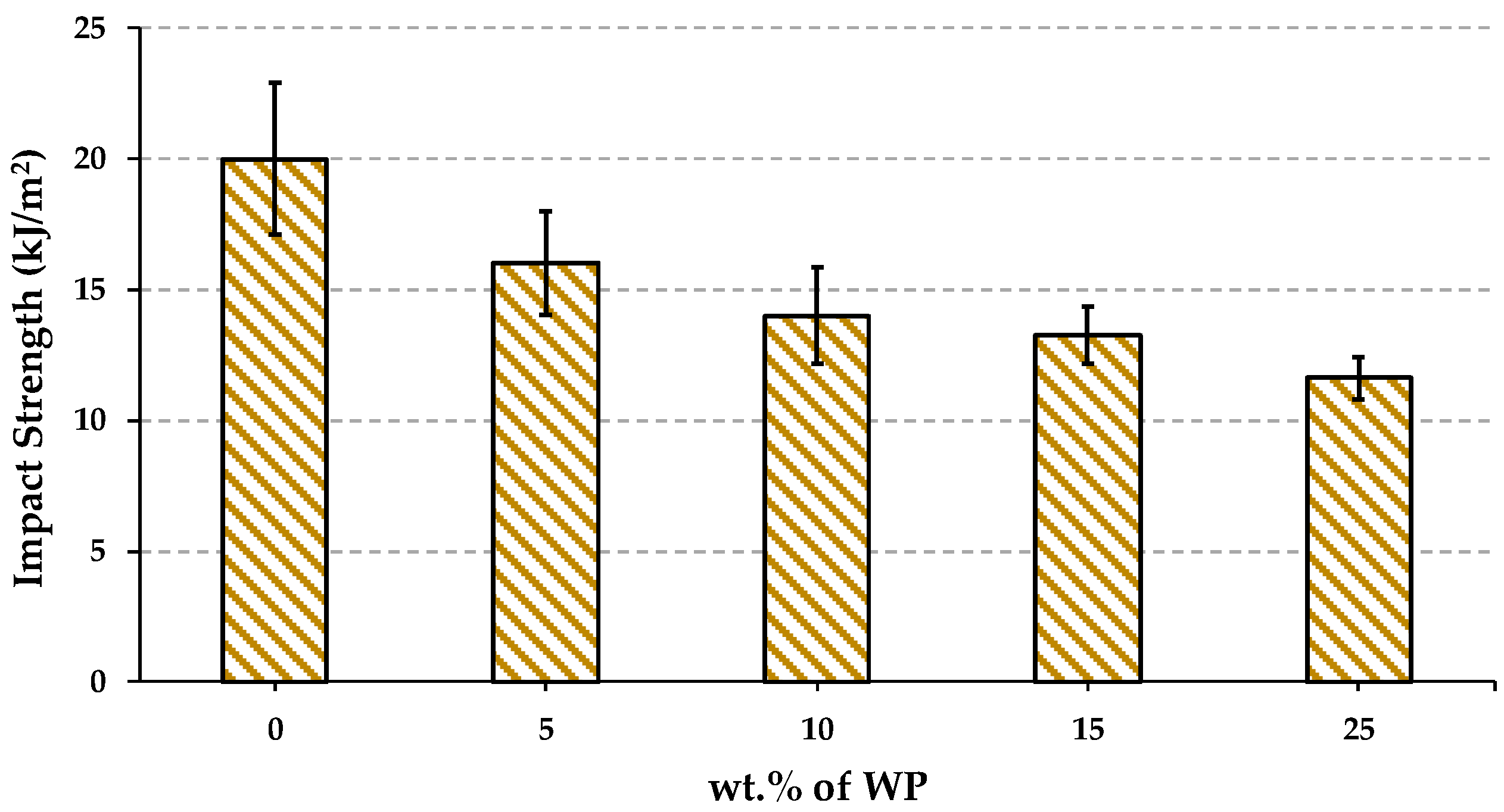

3.2.3. Mechanical Properties

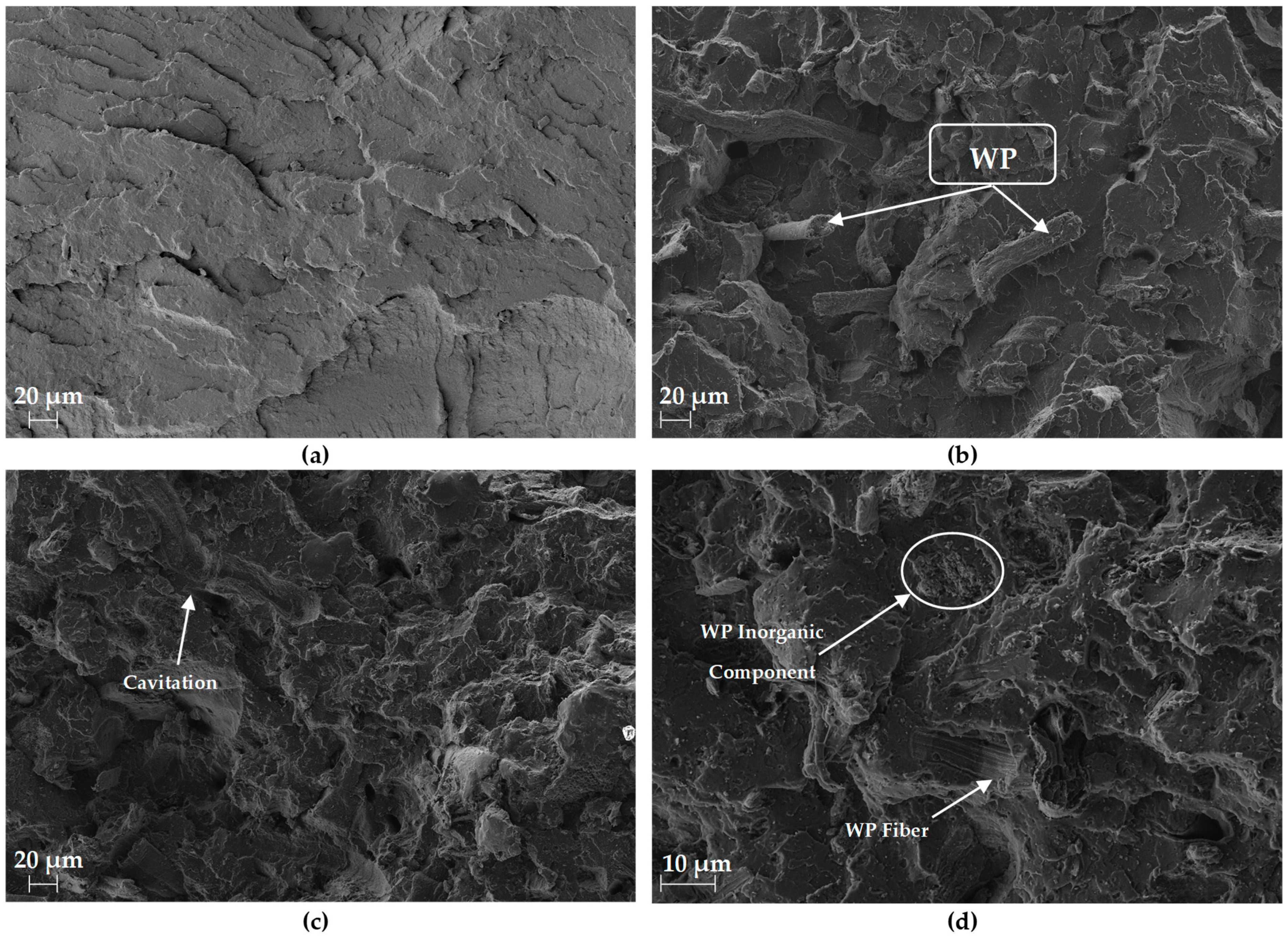

3.2.4. SEM

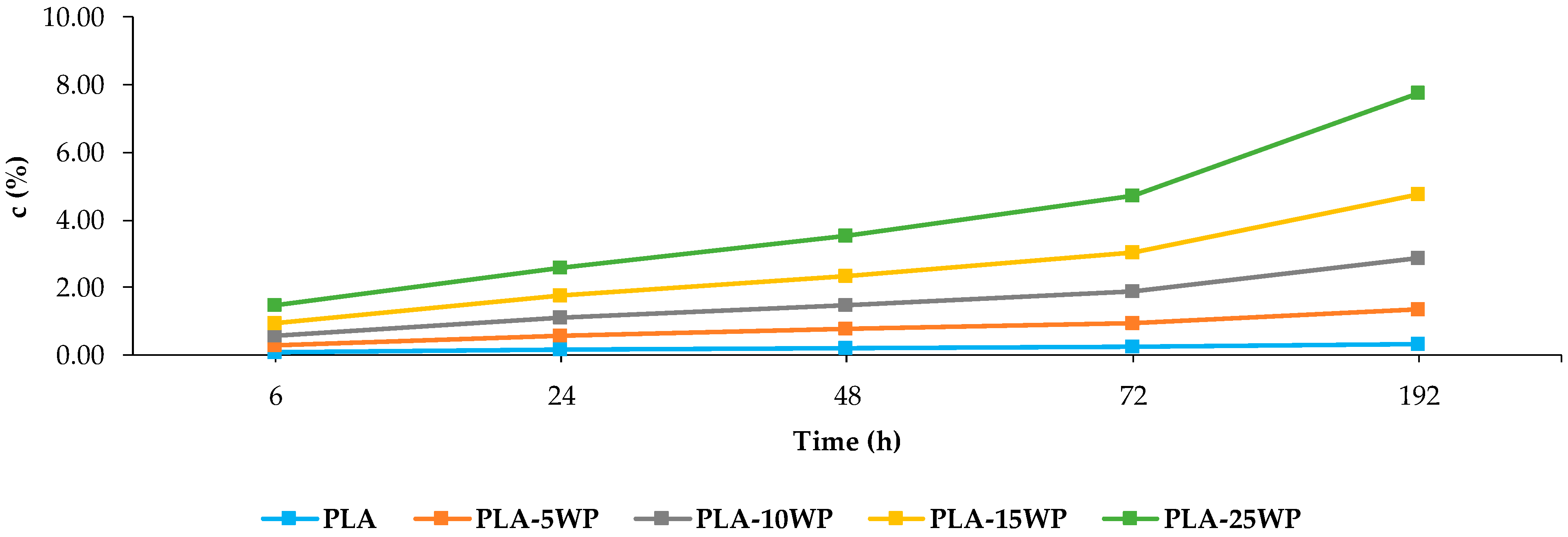

3.2.5. Water Absorption

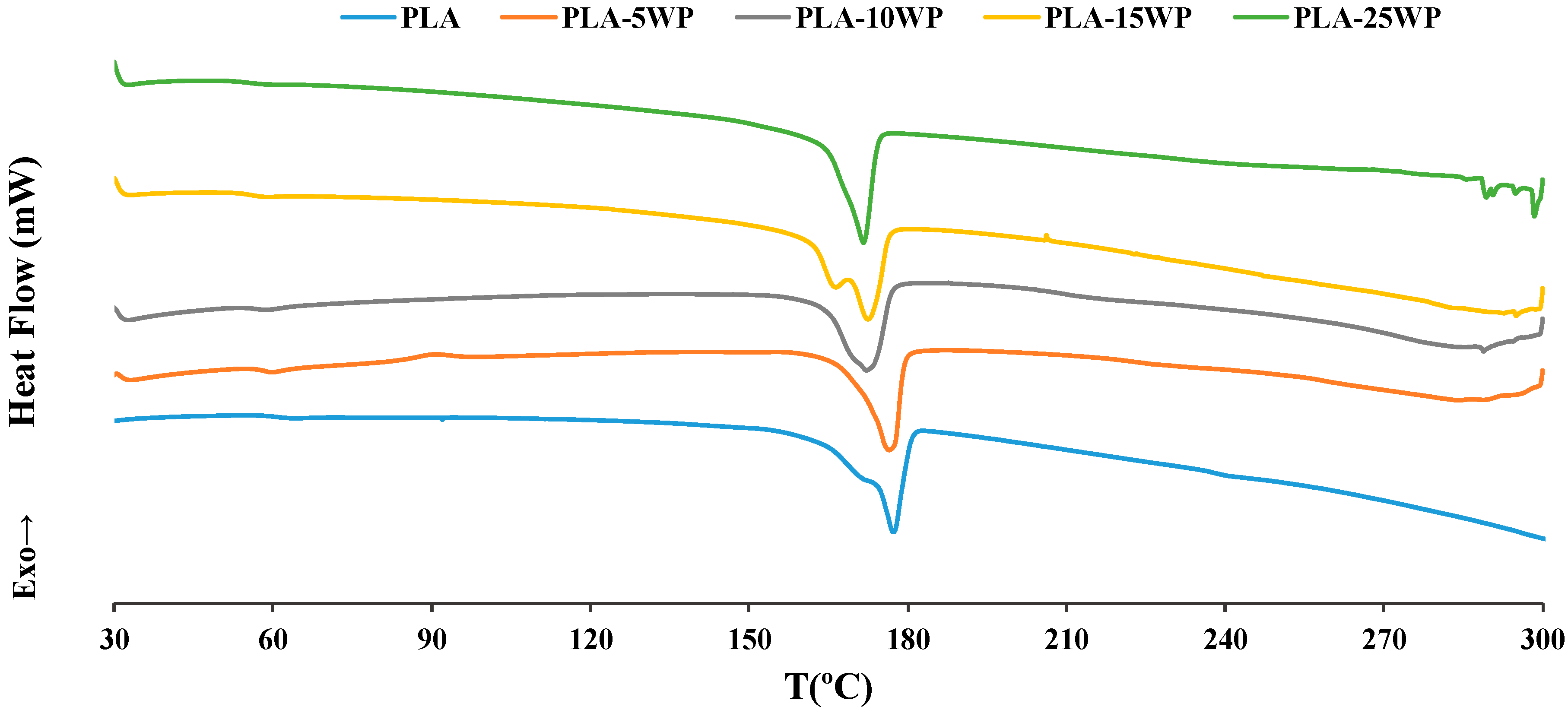

3.2.6. DSC

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Garrido, L.; Soares, E.; Oliveira, M. Development of bio-based expanded cork polymer composites (eCPC) with poly(lactic acid) (PLA). Mater. Sci. Eng. B 2023, 298, 116873. [Google Scholar] [CrossRef]

- Mubaslat, A. Introduction to Waste Management; International Youth Ambassadors Foundation: Amman, Jordan, 2021. [Google Scholar]

- Das, O.; Babu, K.; Shanmugam, V.; Sykam, K.; Tebyetekerwa, M.; Esmaeely, R.E.; Försth, M.; Sas, G.; Gonzalez-Libreros, J.; Capezza, A.J.; et al. Natural and industrial wastes for sustainable and renewable polymer composites. Renew. Sustain. Energy Rev. 2022, 158, 112054. [Google Scholar] [CrossRef]

- Fei, B.; Yang, H.; Yang, J.; Wang, D.; Guo, H.; Hou, H.; Melhi, S.; Bin, B.; Khamees, H.; Guo, Z.; et al. Sustainable compression-molded bamboo fibers/poly(lactic acid) green composites with excellent UV shielding performance. J. Mater. Sci. Technol. 2024, 205, 247–257. [Google Scholar] [CrossRef]

- Iyer, K.A.; Lechanski, J.; Torkelson, J.M. Green polypropylene/waste paper composites with superior modulus and crystallization behavior: Optimizing specific energy in solid-state shear pulverization for filler size reduction and dispersion. Compos. Part. A-Appl. Sci. Manuf. 2016, 83, 47–55. [Google Scholar] [CrossRef]

- Ferrari, F.; Striani, R.; Fico, D.; Alam, M.M.; Greco, A.; Esposito Corcione, C. An Overview on Wood Waste Valorization as Biopolymers and Biocomposites: Definition, Classification, Production, Properties and Applications. Polymers 2022, 14, 5519. [Google Scholar] [CrossRef]

- Awad, A.H.; Hazem, M. Assessment of mechanical and physical properties of LDPE reinforced with marble dust. Compos. B Eng. 2019, 173, 106948. [Google Scholar] [CrossRef]

- Sundum, T.; Mészáros, K.; Kaewtatip, K. Preparation and characterization of thermoplastic starch composites with fly ash modified by planetary ball milling. Carbohydr. Polym. 2018, 191, 198–204. [Google Scholar] [CrossRef] [PubMed]

- Chen, C.; Yihe, Z.; Wanjia, H.; Cheng, Q.; Yongfan, L.; Na, Z. Incorporation of Xuan-paper waste residue in red mud/waste polyethylene composites. J. Hazard. Mater. 2020, 399, 123051. [Google Scholar] [CrossRef]

- Anguruwa, G.T.; Oluwadare, A.O.; Odega, O.A. Evaluation of pulp making properties and kraft lignin precipitation from Ficus exasperate (Vahl.). J. For. Res. 2024, 16, 124–136. [Google Scholar]

- National Statistics Institute (INE). (2022, 23 November). Environmental Accounts: Waste Account Year 2020 [Press Release]. Available online: https://ine.es/prensa/cma_2020_res.pdf (accessed on 23 November 2022).

- Fariha, S.; Chowdhury, F.I.; Rahman, M.R.; Khusairy, M. 3-Development of pulp and paper waste-recycled plastic biocomposites. In Recycled Plastic Biocomposites; Rahman, M.R., Khusairy, M., Eds.; Woodhead Publishing: Sawston, UK, 2022; pp. 51–79. [Google Scholar] [CrossRef]

- Ye, H.; Jiang, J.; Yang, Y.; Shi, J.; Sun, H.; Zhang, L.; Ge, S.; Zhang, Y.; Zhou, Y.; Liew, R.K.; et al. Ultra-strong and environmentally friendly waste polyvinyl chloride/paper biocomposites. Adv. Compos. Hybrid Mater. 2023, 6, 81. [Google Scholar] [CrossRef]

- Ilyas, R.A.; Sapuan, S. Biopolymers and Biocomposites: Chemistry and Technology. Curr. Anal. Chem. 2020, 16, 500–503. [Google Scholar] [CrossRef]

- Loureiro, N.C.; Esteves, J.L.; Viana, J.C.; Ghosh, S. Development of polyhydroxyalkanoates/poly(lactic acid) composites reinforced with cellulosic fibers. Compos. B Eng. 2014, 60, 603–611. [Google Scholar] [CrossRef]

- Jamaluddin, N.; Kanno, T.; Asoh, T.; Uyama, H. Surface modification of cellulose nanofiber using acid anhydride for poly(lactic acid) reinforcement. Mater. Today Commun. 2019, 21, 100587. [Google Scholar] [CrossRef]

- Sun, J.; Zhao, Z.; Pang, Y.; Liu, J.; Zhang, W.; Wang, B.; Xu, L.; Guo, H.; Liu, Y. The Facile and Efficient Fabrication of Rice Husk/poly (lactic acid) Foam Composites by Coordinated the Interface Combination and Bubble Hole Structure. Int. J. Biol. Macromol. 2023, 234, 123734. [Google Scholar] [CrossRef] [PubMed]

- Manshor, M.R.; Anuar, H.; Nur, M.N.; Ahmad, M.I.; Wan, W.B.; Sapuan, S.M.; El-Shekeil, Y.A.; Wahit, M.U. Mechanical, thermal and morphological properties of durian skin fibre reinforced PLA biocomposites. Mater. Des. 2014, 59, 279–286. [Google Scholar] [CrossRef]

- Zhou, L.; Ke, K.; Yang, M.; Yang, W. Recent progress on chemical modification of cellulose for high mechanical-performance Poly(lactic acid)/Cellulose composite: A review. Compos. Commun. 2021, 23, 100548. [Google Scholar] [CrossRef]

- Segal, L.; Creely, J.; Martin, A.E.J.; Conrad, C. An Empirical Method for Estimating the Degree of Crystallinity of Native Cellulose Using the X-Ray Diffractometer. Text. Res. J. 1959, 29, 786–794. [Google Scholar] [CrossRef]

- ISO 527-2:2012; Plastics-Determination of Tensile Properties-Part 2: Test Conditions for Moulding and Extrusion Plastics. ISO: Geneva, Switzerland, 2012.

- ISO 179-1:2024; Plastics-Determination of Charpy Impact Properties-Part 1: Noninstrumented Impact Test. ISO: Geneva, Switzerland, 2024.

- ISO 62:2008; Plastics—Determination of Water Absorption. ISO: Geneva, Switzerland, 2008.

- Zhang, Q.; Usman, M.; Lin, X.; Yi, W.; Lei, H. Green-composites produced from waste residue in pulp and paper industry: A sustainable way to manage industrial wastes. J. Clean. Prod. 2020, 262, 121251. [Google Scholar] [CrossRef]

- Ahmad, N.D.; Kusmono; Wildan, M.W.; Herianto. Preparation and properties of cellulose nanocrystals-reinforced Poly (lactic acid) composite filaments for 3D printing applications. Results Eng. 2023, 17, 100842. [Google Scholar] [CrossRef]

- De Souza, A.G.; Kano, F.; Bonvent, J.; Rosa, D. Cellulose Nanostructures Obtained from Waste Paper Industry: A Comparison of Acid and Mechanical Isolation Methods. Mater. Res. 2017, 20, 209–214. [Google Scholar] [CrossRef]

- Zhang, X.; Di, J.; Xu, L.; Lv, J.; Duan, J.; Zhu, X.; Li, X.; Bo, X. High-value utilization method of digital printing waste paper fibers-Co-blending filled HDPE composites and performance improvement. Polym. Test. 2022, 116, 107790. [Google Scholar] [CrossRef]

- Zhu, W.; Chen, T.; He, R.; Ding, Y.; Duan, T.; Xiao, B. Understanding the interfacial interactions of bioinspired chitosan-calcite nanocomposites by first principles molecular dynamics simulations and experimental FT-IR spectroscopy. Carbohydr. Polym. 2019, 223, 115054. [Google Scholar] [CrossRef] [PubMed]

- Liu, S.; Zhang, C.; Du, J.; Huang, H.; Fang, S.; Li, X.; DuanS, M. Effect of dispersants on the stability of calcite in non-polar solutions. Colloids Surf. A Physicochem. Eng. Asp. 2023, 672, 131730. [Google Scholar] [CrossRef]

- Mondal, K.; Sakurai, S.; Okahisa, Y.; Goud, V.V.; Katiyar, V. Effect of cellulose nanocrystals derived from Dunaliella tertiolecta marine green algae residue on crystallization behaviour of poly(lactic acid). Carbohydr. Polym. 2021, 261, 117881. [Google Scholar] [CrossRef]

- Ngo, T.; Phan, T.; Le, T.; Le Tan, N.T.; Huynh, Q.; Phan, T.; Hoang, M.; Vo, T.; Nguyen, Q. Producing bacterial cellulose from industrial recycling paper waste sludge. Heliyon 2023, 9, e17663. [Google Scholar] [CrossRef]

- Correia, C.; Oliveira, L.; Valera, T. The Influence of Bleached Jute Fiber Filler on the Properties of Vulcanized Natural Rubber. Mater. Res. 2017, 20, 466–471. [Google Scholar] [CrossRef]

- Lu, T.; Liu, S.; Jiang, M.; Xu, X.; Wang, Y.; Wang, Z.; Gou, J.; Hui, D.; Zhou, Z. Effects of modifications of bamboo cellulose fibers on the improved mechanical properties of cellulose reinforced poly(lactic acid) composites. Compos. B Eng. 2014, 62, 191–197. [Google Scholar] [CrossRef]

- Irfan, T.N.M.; George, T.S.; Sainul, K.M.; Parambath, B.; George, N.; Balachandrakurup, V.; Midhun, C.D.; Nair, A.B. Waste paper as a viable sustainable source for cellulosic extraction by chlorine free bleaching and acid hydrolysis method for the production of PVA-starch/cellulose based biocomposites. Mater. Today Proc. 2023. [Google Scholar] [CrossRef]

- Koutsomitopoulou, A.F.; Bénézet, J.C.; Bergeret, A.; Papanicolaou, G.C. Preparation and characterization of olive pit powder as a filler to PLA-matrix bio-composites. Powder Technol. 2014, 255, 10–16. [Google Scholar] [CrossRef]

- Kassab, Z.; Abdellaoui, Y.; Salim, M.H.; Bouhfid, R.; Qaiss, A.E.K.; El Achaby, M. Micro- and nano-celluloses derived from hemp stalks and their effect as polymer reinforcing materials. Carbohydr. Polym. 2020, 245, 116506. [Google Scholar] [CrossRef]

- Karunadasa, K.S.; Manoratne, C.H.; Pitawala, H.M.; Rajapakse, R.M. Thermal decomposition of calcium carbonate (calcite polymorph) as examined by in-situ high-temperature X-ray powder diffraction. J. Phys. Chem. Solids 2019, 134, 21–28. [Google Scholar] [CrossRef]

- Chaudhary, V.; Dwivedi, S.; Das, P.; Gupta, P.; Sharma, B. An investigation of fatigue, creep, and dynamic mechanical behavior of bio-fiber-reinforced PLA and their hybrid biocomposites. Biomass Convers. Biorefinery 2024, 1–11. [Google Scholar] [CrossRef]

- Syamani, F.; Kurniawan, Y.; Suryanegara, L. Cellulose fibers from oil palm fronds reinforced polylactic acid composite. In Proceedings of the Conference: The International Conference on Materials Science and Technology by ASEAN SCMST, Bogor, Indonesia, 18–27 August 2014. [Google Scholar]

- Jałbrzykowski, M.; Oksiuta, Z.; Obidziński, S.; Czyżewska, U.; Osiecki, T.; Kroll, L.; Yildiz, M.J. Assessment of innovative PLA biopolymer compositions with plant waste fillers. Eng. Fail. Anal. 2022, 139, 106496. [Google Scholar] [CrossRef]

- Benyahia, A.; Merrouche, A.; Rahmouni, Z.E.A.; Rokbi, M.; Serge, W.; Kouadri, Z. Study of the alkali treatment effect on the mechanical behavior of the composite unsaturated polyester-Alfa fibers. Mech. Ind. 2014, 15, 69–73. [Google Scholar] [CrossRef]

- Yaghoobi, H.; Fereidoon, A. An experimental investigation and optimization on the impact strength of kenaf fiber biocomposite: Application of response surface methodology. Polym. Bull. 2018, 75, 3283–3309. [Google Scholar] [CrossRef]

- Tao, Y.; Liu, M.; Han, W.; Li, P. Waste office paper filled polylactic acid composite filaments for 3D printing. Compos. B Eng. 2021, 221, 108998. [Google Scholar] [CrossRef]

| Reference | PLA | WP | AD |

|---|---|---|---|

| PLA | 98.5 | - | 1.5 |

| 5WP/PLA | 93.5 | 5 | 1.5 |

| 10WP/PLA | 88.5 | 10 | 1.5 |

| 15WP/PLA | 83.5 | 15 | 1.5 |

| 25WP/PLA | 73.5 | 25 | 1.5 |

| Reference | Tg (°C) | Tm (°C) | ΔHm (J/g) | ΔHg (J/g) | Wc (%) |

|---|---|---|---|---|---|

| PLA | 62.51 | 170.60 | 36.18 | 1.66 | 17.83 |

| 5WP/PLA | 59.75 | 176.74 | 44.15 | 0.72 | 21.98 |

| 10WP/PLA | 59.26 | 172.45 | 45.43 | 0.98 | 23.09 |

| 15WP/PLA | 58.64 | 172.96 | 45.41 | 0.69 | 23.58 |

| 25WP/PLA | 58.30 | 172.23 | 44.96 | 0.25 | 23.34 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Delgado-Orti, C.; Navas-Martos, F.J.; Rodríguez-Liébana, J.A.; La Rubia, M.D.; Jurado-Contreras, S. Development of PLA–Waste Paper Biocomposites with High Cellulose Content. Polymers 2024, 16, 2000. https://doi.org/10.3390/polym16142000

Delgado-Orti C, Navas-Martos FJ, Rodríguez-Liébana JA, La Rubia MD, Jurado-Contreras S. Development of PLA–Waste Paper Biocomposites with High Cellulose Content. Polymers. 2024; 16(14):2000. https://doi.org/10.3390/polym16142000

Chicago/Turabian StyleDelgado-Orti, Concepción, Francisco J. Navas-Martos, Jose A. Rodríguez-Liébana, M. Dolores La Rubia, and Sofía Jurado-Contreras. 2024. "Development of PLA–Waste Paper Biocomposites with High Cellulose Content" Polymers 16, no. 14: 2000. https://doi.org/10.3390/polym16142000

APA StyleDelgado-Orti, C., Navas-Martos, F. J., Rodríguez-Liébana, J. A., La Rubia, M. D., & Jurado-Contreras, S. (2024). Development of PLA–Waste Paper Biocomposites with High Cellulose Content. Polymers, 16(14), 2000. https://doi.org/10.3390/polym16142000