Enhancing Tensile Modulus of Polyurethane-Based Shape Memory Polymers for Wound Closure Applications through the Addition of Palm Oil

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Synthesis of PU and Sample Preparation

2.3. Characterizations

3. Results and Discussion

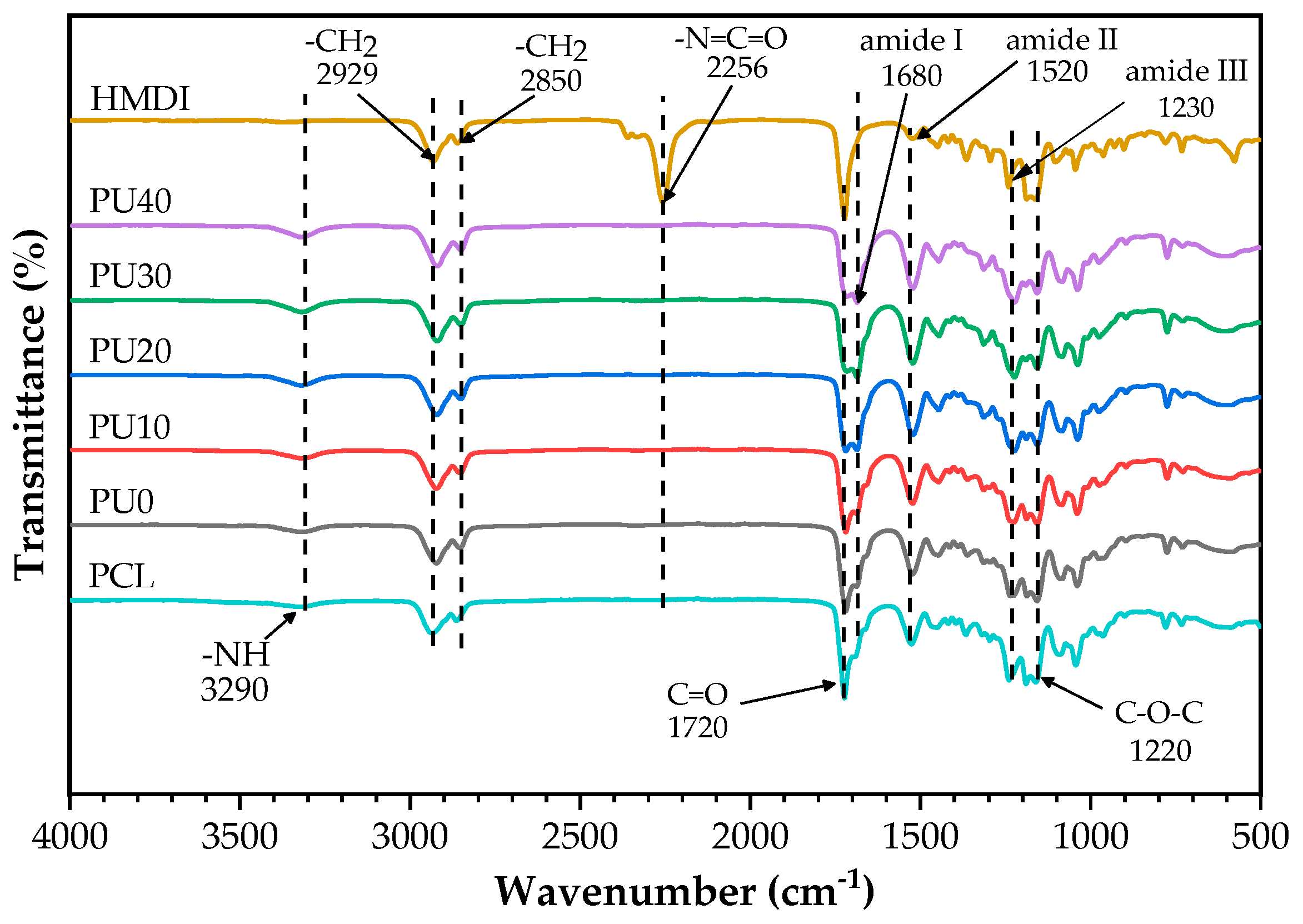

3.1. FT-IR Analysis

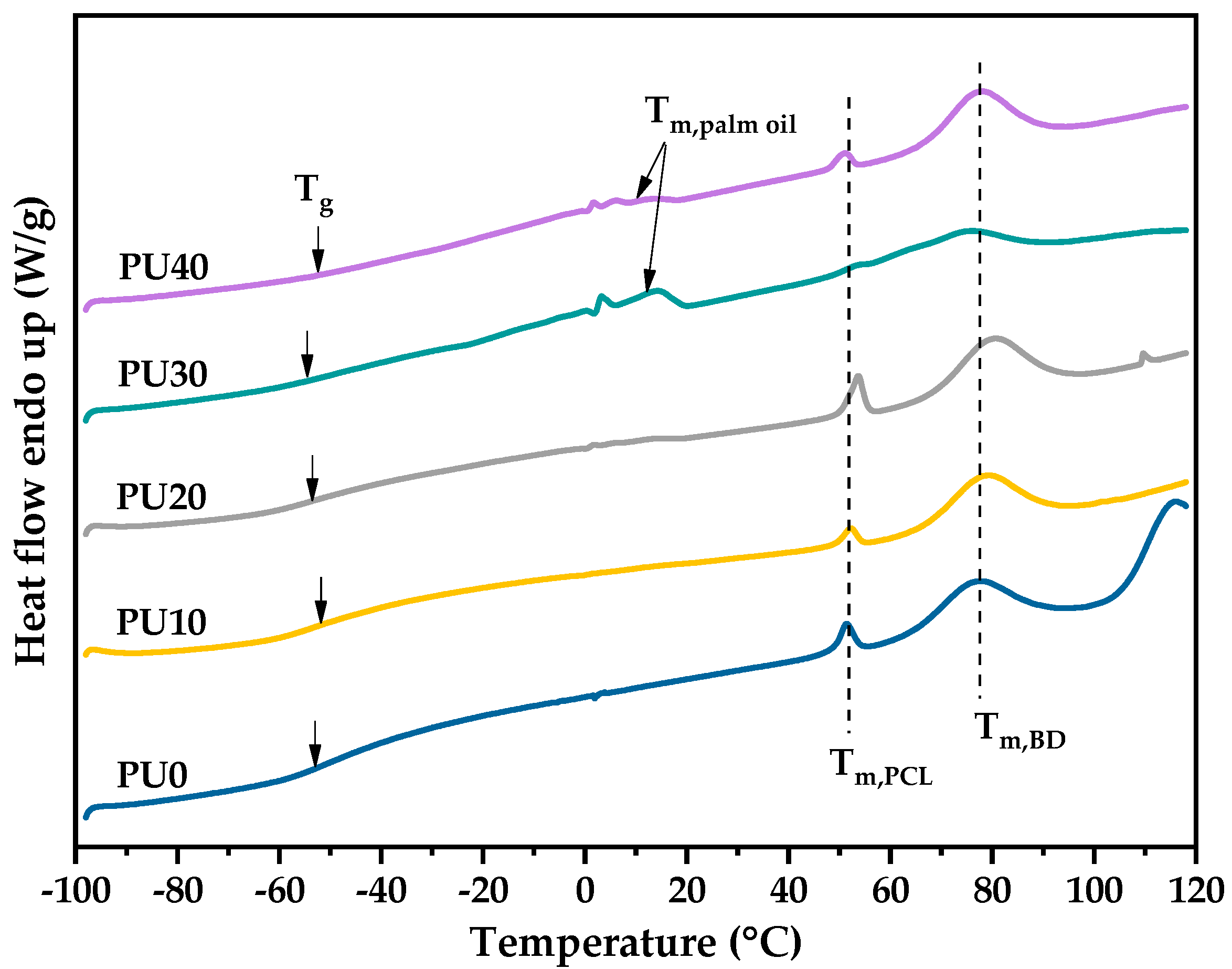

3.2. DSC Analysis

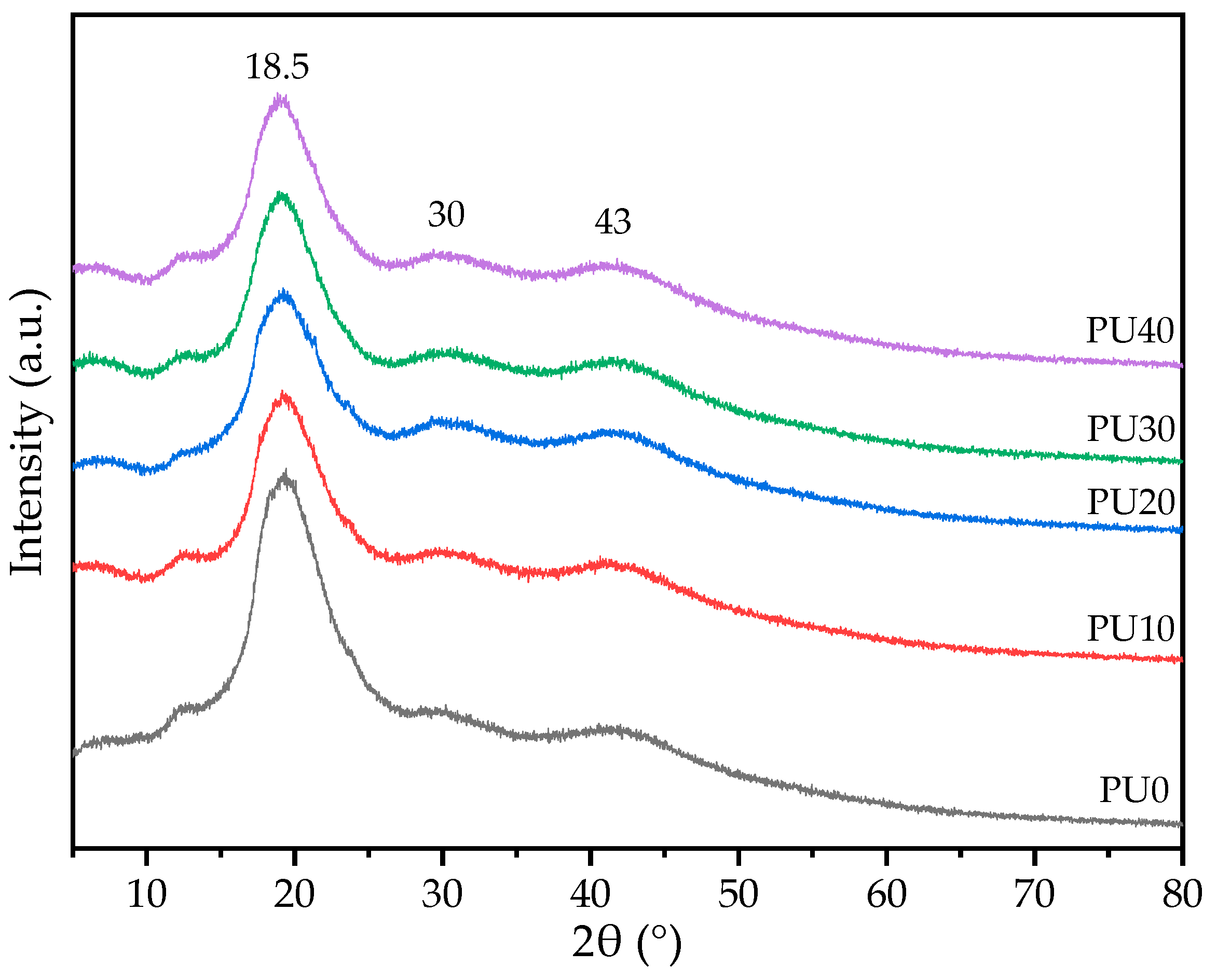

3.3. XRD Analysis

3.4. Tensile Behaviors

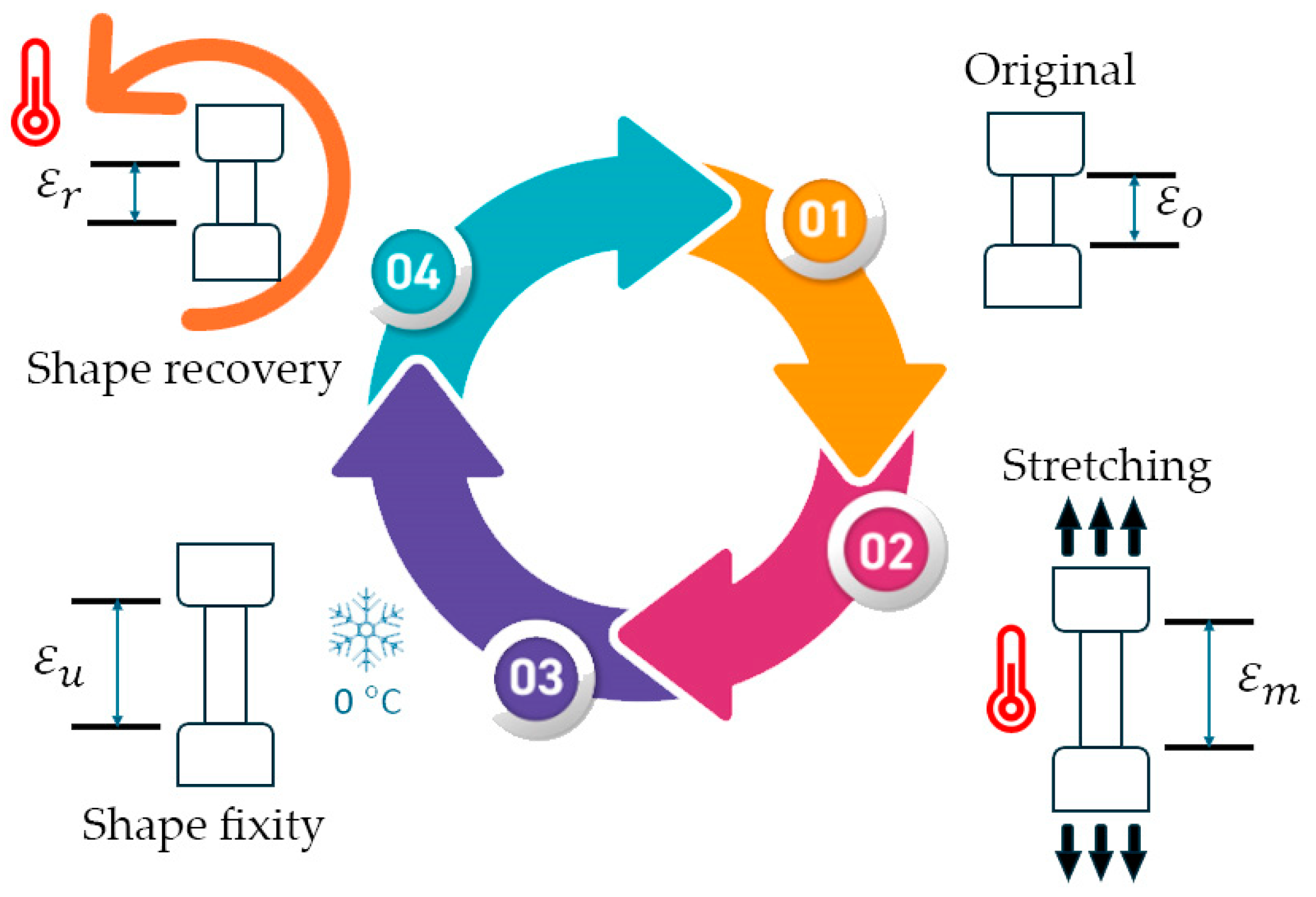

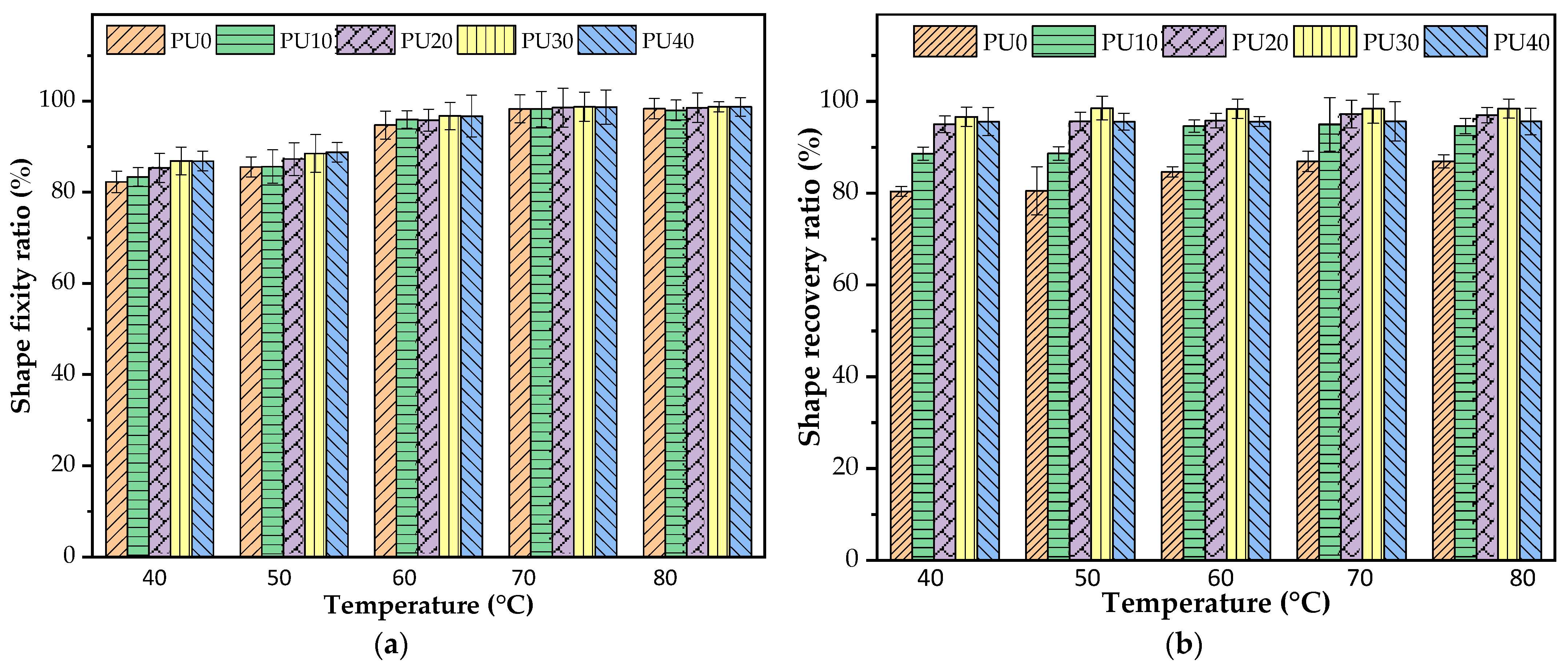

3.5. Shape Memory Properties

3.5.1. Effect of Temperature on Shape Memory Properties of PU

3.5.2. Repeatability Study of PU-Based SMPs

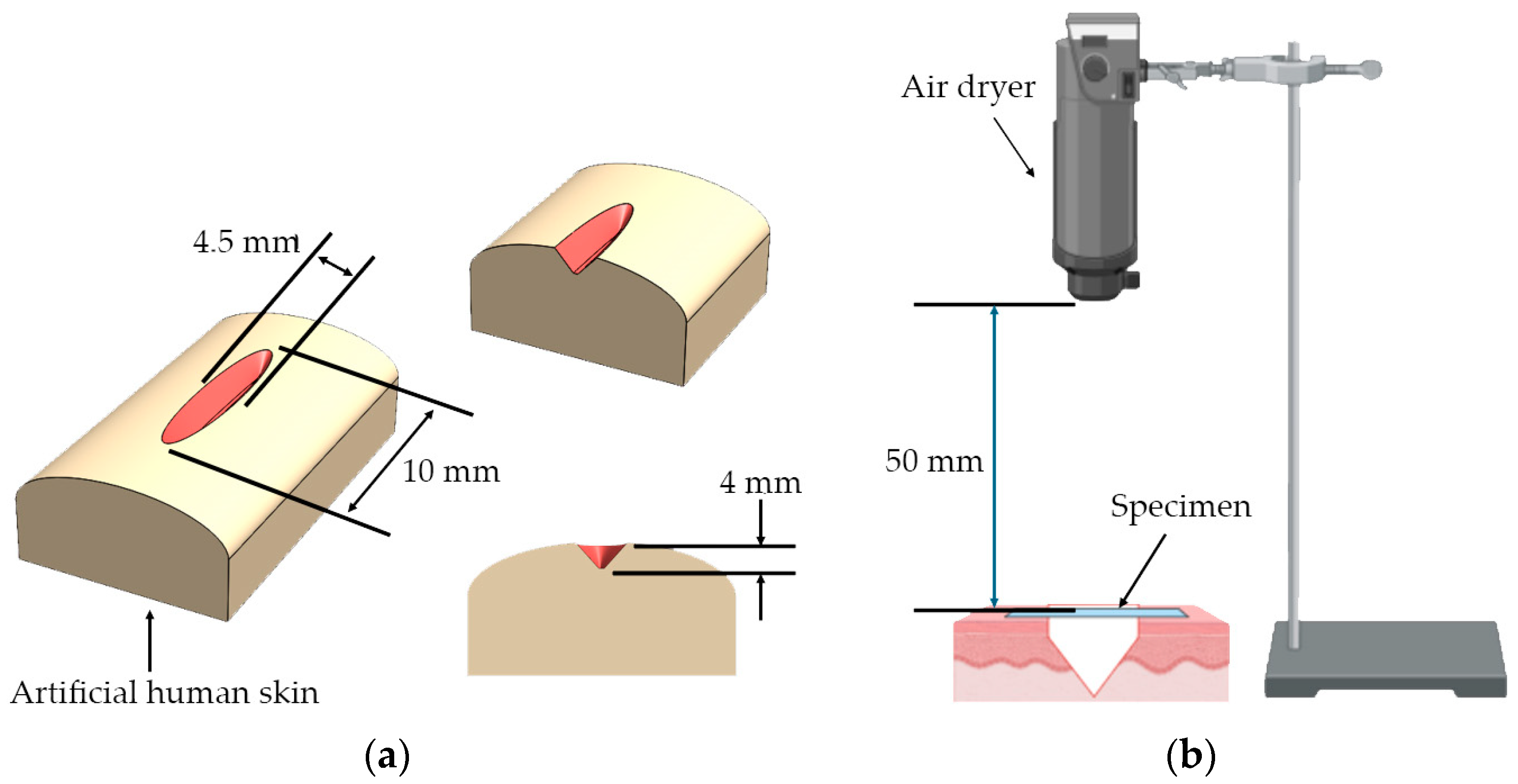

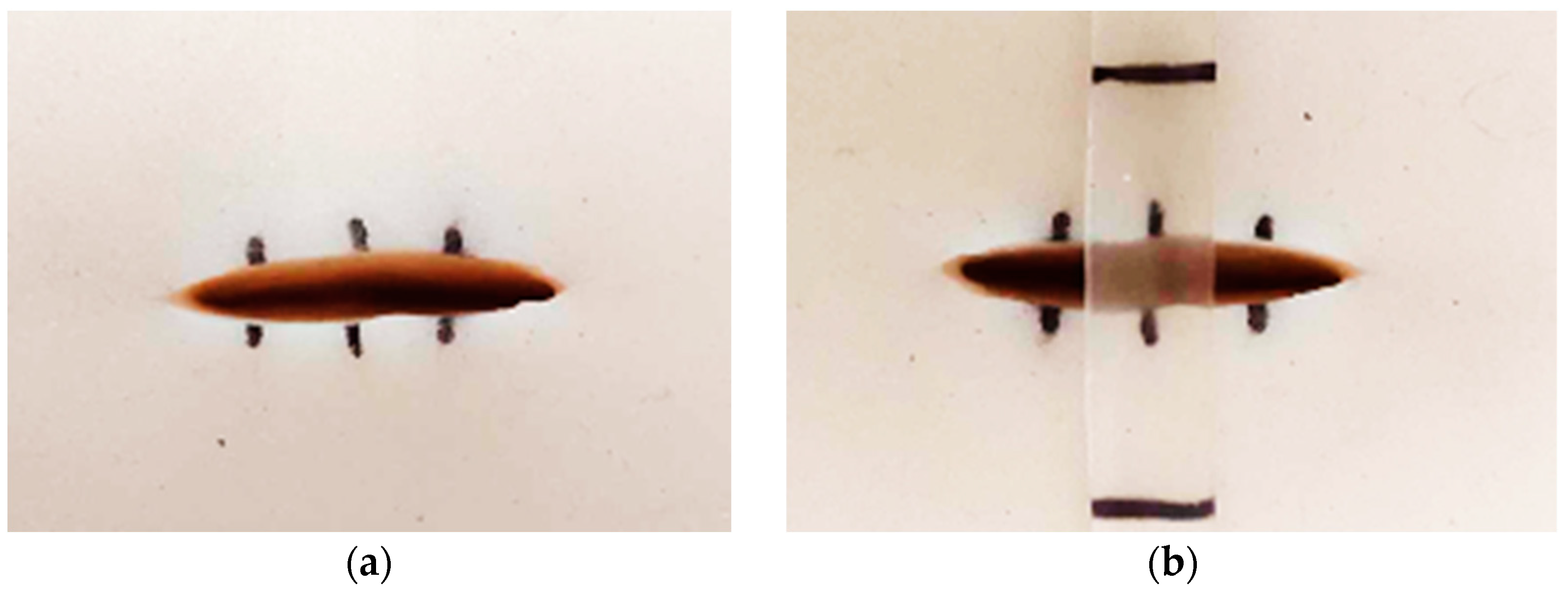

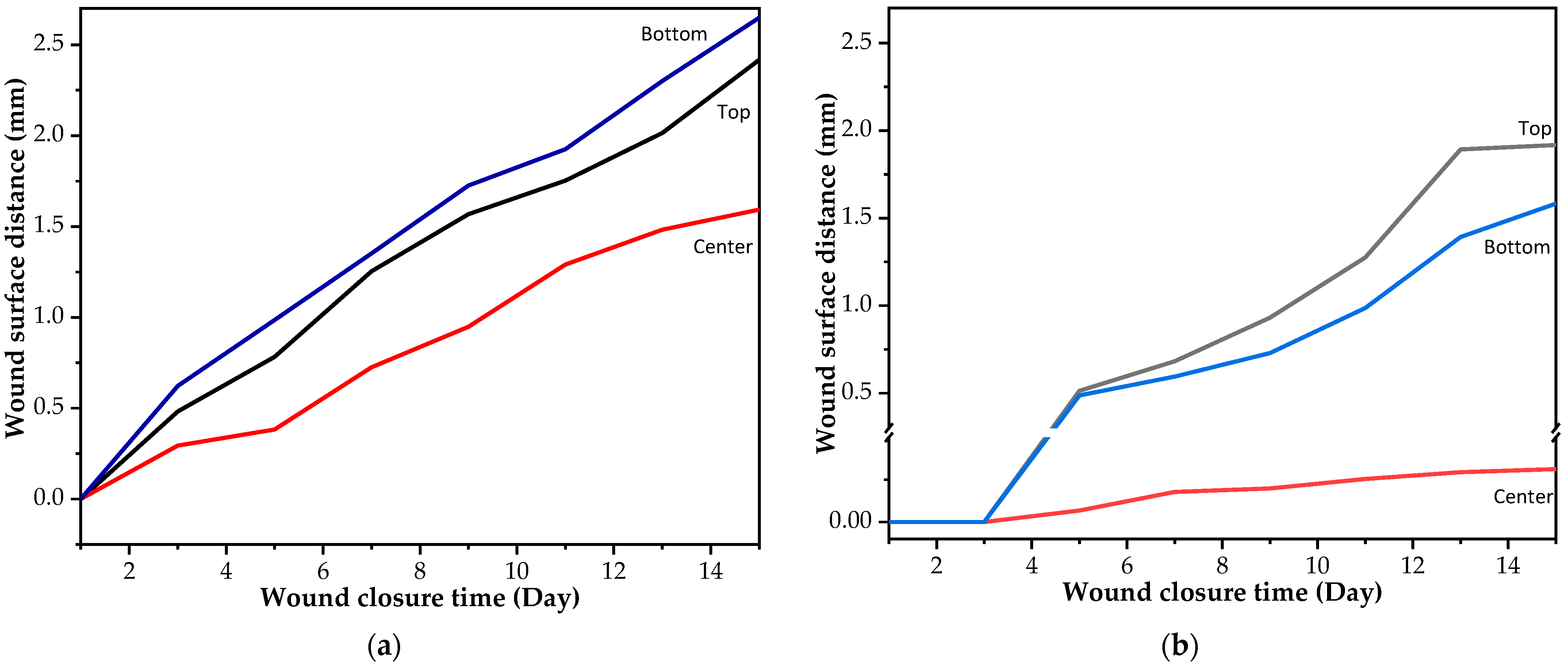

3.6. Proof-of-Concept of Thermo-Responsive Wound Closure Strip Application

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Peterson, G.I.; Dobrynin, A.V.; Becker, M.L. α-Amino Acid-Based Poly(Ester urea)s as Multishape Memory Polymers for Biomedical Applications. ACS Macro Lett. 2016, 5, 1176–1179. [Google Scholar] [CrossRef] [PubMed]

- Wei, Z.G.; Sandstroröm, R.; Miyazaki, S. Shape-memory materials and hybrid composites for smart systems: Part I Shape-memory materials. J. Mater. Sci. 1998, 33, 3743–3762. [Google Scholar] [CrossRef]

- Sokolowski, W.; Metcalfe, A.; Hayashi, S.; Yahia, L.H.; Raymond, J. Medical applications of shape memory polymers. Biomed. Mater. 2007, 2, S23. [Google Scholar] [CrossRef] [PubMed]

- Peterson, G.I.; Dobrynin, A.V.; Becker, M.L. Biodegradable Shape Memory Polymers in Medicine. Adv. Healthc. Mater. 2017, 6, 1700694. [Google Scholar] [CrossRef]

- Meng, H.; Hu, J. A Brief Review of Stimulus-active Polymers Responsive to Thermal, Light, Magnetic, Electric, and Water/Solvent Stimuli. J. Intell. Mater. Syst. Struct. 2010, 21, 859–885. [Google Scholar] [CrossRef]

- Kim, B.K.; Shin, Y.J.; Cho, S.M.; Jeong, H.M. Shape-memory behavior of segmented polyurethanes with an amorphous reversible phase: The effect of block length and content. J. Polym. Sci. Part B Polym. Phys. 2000, 38, 2652–2657. [Google Scholar] [CrossRef]

- Elshazly, T.M.; Keilig, L.; Alkabani, Y.; Ghoneima, A.; Abuzayda, M.; Talaat, S.; Bourauel, C.P. Primary Evaluation of Shape Recovery of Orthodontic Aligners Fabricated from Shape Memory Polymer (A Typodont Study). Dent. J. 2021, 9, 31. [Google Scholar] [CrossRef] [PubMed]

- Barik, S.K.; Rao, P.S.; Mohanty, R. A review on initiation, structure and advance utilization of shape memory polymer. J. Adv. Sci. Res. 2019, 10, 131–138. [Google Scholar]

- Jung, Y.C.; Cho, J.W. Application of shape memory polyurethane in orthodontic. J. Mater. Sci. Mater. Med. 2010, 21, 2881–2886. [Google Scholar] [CrossRef]

- Jeewantha, J.; Jayalath, S.; Emmanuel, C.; Herath, M.; Forster, E.; Islam, M.; Leng, J.; Epaarachchi, J. Shape memory polymer smart plaster for orthopaedic treatments. Smart Mater. Struct. 2022, 31, 115016. [Google Scholar] [CrossRef]

- Valerie, E.-J. Essential Microbiology for Wound Care; OUP Oxford: Oxford, UK, 2016. [Google Scholar]

- CHAPTER 14–Tissue Adhesives and Alternative Wound Closure. In Wounds and Lacerations, 3rd ed.; Trott, A.T., Ed.; Mosby: Philadelphia, Pennsylvania, 2005; pp. 209–222. [Google Scholar]

- Simcock, J.W.; Armitage, J.; Dixon, L.; MacFarlane, K.; Robertson, G.M.; Frizelle, F.A. Skin closure after laparotomy with staples or sutures: A study of the mature scar. ANZ J. Surg. 2014, 84, 656–659. [Google Scholar] [CrossRef] [PubMed]

- Shagan, A.; Zhang, W.; Mehta, M.; Levi, S.; Kohane, D.; Mizrahi, B. Hot Glue Gun Releasing Biocompatible Tissue Adhesive. Adv. Funct. Mater. 2019, 30, 1900998. [Google Scholar] [CrossRef]

- van de Gevel, D.F.D.; Hamad, M.A.S.; Elenbaas, T.W.O.; Ostertag, J.U.; Schönberger, J.P.A.M. Is the use of Steri-Strip™ S for wound closure after coronary artery bypass grafting better than intracuticular suture? Interact. CardioVascular Thorac. Surg. 2010, 10, 561–564. [Google Scholar] [CrossRef]

- Taira, B.R.; Singer, A.J.; Rooney, J.; Steinhauff, N.T.; Zimmerman, T. An In-Vivo Study of the Wound-Bursting Strengths of Octyl-Cyanoacrylate, Butyl-Cyanoacrylate, and Surgical Tape in Rats. J. Emerg. Med. 2010, 38, 546–551. [Google Scholar] [CrossRef] [PubMed]

- Kwon, J.Y.; Yun, H.G.; Park, I.Y. n-Butyl-2-cyanoacrylate tissue adhesive (Histoacryl) vs. subcuticular sutures for skin closure of Pfannenstiel incisions following cesarean delivery. PLoS ONE 2018, 13, e0202074. [Google Scholar] [CrossRef] [PubMed]

- Greenwald, D.; Shumway, S.; Albear, P.; Gottlieb, L. Mechanical comparison of 10 suture materials before and after in vivo incubation. J. Surg. Res. 1994, 56, 372–377. [Google Scholar] [CrossRef] [PubMed]

- Goldstein, L.S.; Dewhirst, M.W.; Repacholi, M.; Kheifets, L. Summary, conclusions and recommendations: Adverse temperature levels in the human body. Int. J. Hyperth. 2003, 19, 373–384. [Google Scholar] [CrossRef]

- Saad, N.M.; Zubir, S.A. Palm Kernel Oil Polyol-based Polyurethane as Shape Memory Material: Effect of Polyol Molar Ratio. J. Phys. Sci. 2019, 30, 77–89. [Google Scholar] [CrossRef]

- Xia, Y.; Larock, R.C. Vegetable oil-based polymeric materials: Synthesis, properties, and applications. Green Chem. 2010, 12, 1893–1909. [Google Scholar] [CrossRef]

- Tobushi, H.; Hayashi, S.; Kojima, S. Mechanical Properties of Shape Memory Polymer of Polyurethane Series: Basic Characteristics of Stress-Strain-Temperature Relationship. JSME Int. J. Ser. 1 Solid Mech. Strength Mater. 1992, 35, 296–302. [Google Scholar] [CrossRef]

- Tantisuwanno, C.; Jain, T.; Tseng, Y.-M.; Joy, A. Pendant Amines in the Hard or Soft Segments of PCL-Polyurethanes Have Contrasting Effects on the Mechanical and Surface Properties. Macromolecules 2024, 57, 4448–4459. [Google Scholar] [CrossRef]

- Ahmad, M.; Luo, J.; Xu, B.; Purnawali, H.; King, P.J.; Chalker, P.R.; Fu, Y.; Huang, W.; Miraftab, M. Synthesis and Characterization of Polyurethane-Based Shape-Memory Polymers for Tailored Tg around Body Temperature for Medical Applications. Macromol. Chem. Phys. 2011, 212, 592–602. [Google Scholar] [CrossRef]

- Kalita, H. Shape Memory Polymers: Theory and Application; Walter de Gruyter GmbH & Co KG: Berlin, Germany, 2018. [Google Scholar]

- Lee, B.S.; Chun, B.C.; Chung, Y.-C.; Sul, K.I.; Cho, J.W. Structure and Thermomechanical Properties of Polyurethane Block Copolymers with Shape Memory Effect. Macromolecules 2001, 34, 6431–6437. [Google Scholar] [CrossRef]

- Wang, H.; Domingos, M.; Scenini, F. Advanced mechanical and thermal characterization of 3D bioextruded poly(e-caprolactone)-based composites. Rapid Prototyp. J. 2018, 24, 731–738. [Google Scholar] [CrossRef]

- Eyvazzadeh Kalajahi, A.; Rezaei, M.; Abbasi, F. Preparation, characterization, and thermo-mechanical properties of poly (ε-caprolactone)-piperazine-based polyurethane-urea shape memory polymers. J. Mater. Sci. 2016, 51, 4379–4389. [Google Scholar] [CrossRef]

- Ping, P.; Wang, W.; Chen, X.; Jing, X. Poly(ε-caprolactone) Polyurethane and Its Shape-Memory Property. Biomacromolecules 2005, 6, 587–592. [Google Scholar] [CrossRef] [PubMed]

- Mahmud, S.N.S.; Jusoh, M.A.; Jasim, S.E.; Gambang, P. A Review: Method of Preparing Palm Oil Based Polyurethane. In Proceedings of the National Conference for Postgraduate University Malaysia Pahang, Pekan, Malaysia, 24–25 September 2016; pp. 655–662. [Google Scholar]

- Stavila, E.; Yuliati, F.; Adharis, A.; Laksmono, J.A.; Iqbal, M. Recent advances in synthesis of polymers based on palm oil and its fatty acids. RSC Adv. 2023, 13, 14747–14775. [Google Scholar] [CrossRef] [PubMed]

- Pawlik, H.; Prociak, A. Influence of Palm Oil-Based Polyol on the Properties of Flexible Polyurethane Foams. J. Polym. Environ. 2012, 20, 438–445. [Google Scholar] [CrossRef]

- Tanaka, R.; Hirose, S.; Hatakeyama, H. Preparation and characterization of polyurethane foams using a palm oil-based polyol. Bioresour. Technol. 2008, 99, 3810–3816. [Google Scholar] [CrossRef]

- Zhang, C. Plant Oil-based Polyurethanes. In Green Chemistry and Green Materials from Plant Oils and Natural Acids; Liu, Z., Kraus, G., Eds.; Royal Society of Chemistry: London, UK, 2023; Volume 83. [Google Scholar]

- Kaikade, D.S.; Sabnis, A.S. Recent Advances in Polyurethane Coatings and Adhesives Derived from Vegetable Oil-Based Polyols. J. Polym. Environ. 2023, 31, 4583–4605. [Google Scholar] [CrossRef]

- Garrison, T.F.; Kessler, M.R. 3-Plant Oil-Based Polyurethanes. In Bio-Based Plant Oil Polymers and Composites; Madbouly, S.A., Zhang, C., Kessler, M.R., Eds.; William Andrew Publishing: Norwich, NY, USA, 2016; pp. 37–54. [Google Scholar]

- Lumcharoen, D.; Saravari, O. Preparation and characterization of flexible polyurethane foams from palm oil-based polyol. Adv. Mater. Res. 2014, 911, 352–356. [Google Scholar] [CrossRef]

- Lee, C.S.; Ooi, T.L.; Chuah, C.H.; Ahmad, S. Rigid Polyurethane Foam Production from Palm Oil-Based Epoxidized Diethanolamides. J. Am. Oil Chem. Soc. 2007, 84, 1161–1167. [Google Scholar] [CrossRef]

- Badri, K.; Othman, Z.; Ahmad, S. Rigid polyurethane foams from oil palm resources. J. Mater. Sci. 2004, 39, 5541–5542. [Google Scholar] [CrossRef]

- Brito, Y.C.; Ferreira, D.A.C.; Fragoso, D.M.d.A.; Mendes, P.R.; Oliveira, C.M.J.d.; Meneghetti, M.R.; Meneghetti, S.M.P. Simultaneous conversion of triacylglycerides and fatty acids into fatty acid methyl esters using organometallic tin(IV) compounds as catalysts. Appl. Catal. A Gen. 2012, 443–444, 202–206. [Google Scholar] [CrossRef]

- Chanda, A.; Unnikrishnan, V. A Realistic 3D Computational Model of the Closure of Skin Wound with Interrupted Sutures. J. Mech. Med. Biol. 2017, 17, 1750025. [Google Scholar] [CrossRef]

- Khan, F.; Valere, S.; Fuhrmann, S.; Arrighi, V.; Bradley, M. Synthesis and cellular compatibility of multi-block biodegradable poly(ε-caprolactone)-based polyurethanes. J. Mater. Chem. B 2013, 1, 2590–2600. [Google Scholar] [CrossRef]

- Eftekhari, B.S.; Karkhaneh, A.; Alizadeh, A. Physically targeted intravenous polyurethane nanoparticles for controlled release of atorvastatin calcium. Iran. Biomed. J. 2017, 21, 369. [Google Scholar]

- Rubino, L.; Torrisi, G.; Brambilla, L.; Rubino, L.; Ortenzi, M.A.; Galimberti, M.; Barbera, V. Polyhydroxylated Nanosized Graphite as Multifunctional Building Block for Polyurethanes. Polymers 2022, 14, 1159. [Google Scholar] [CrossRef]

- Binti, K.; Haji Badri, K.; Maisara, S.; Binti, S.; Shahrom, R.; Hao, L.; Baderuliksan, N.; Norzali, A.; Sien, W. FTIR spectroscopy analysis of the prepolymerization of palm-based polyurethane. Solid State Sci. Technol. 2010, 18, 1–8. [Google Scholar]

- Yeoh, F.H.; Lee, C.S.; Kang, Y.B.; Wong, S.F.; Cheng, S.F.; Ng, W.S. Production of Biodegradable Palm Oil-Based Polyurethane as Potential Biomaterial for Biomedical Applications. Polymers 2020, 12, 1842. [Google Scholar] [CrossRef]

- International, A. ASTM D638-14; Standard Test Method for Tensile Properties of Plastics. ASTM International: West Conshohocken, PA, YSA, 2015.

- Sabahi, N.; Roohani, I.; Wang, C.H.; Farajzadeh, E.; Li, X. Thermoplastic polyurethane-based shape memory polymers with potential biomedical application: The effect of TPU soft-segment on shape memory effect and cytocompatibility. Polymer 2023, 283, 126189. [Google Scholar] [CrossRef]

- Crescenzi, V.; Manzini, G.; Calzolari, G.; Borri, C. Thermodynamics of fusion of poly-β-propiolactone and poly-ϵ-caprolactone. comparative analysis of the melting of aliphatic polylactone and polyester chains. Eur. Polym. J. 1972, 8, 449–463. [Google Scholar] [CrossRef]

- Capek, L.; Jacquet, E.; Dzan, L.; Simunek, A. The analysis of forces needed for the suturing of elliptical skin wounds. Med. Biol. Eng. Comput. 2012, 50, 193–198. [Google Scholar] [CrossRef] [PubMed]

- Larrabee, W.F., Jr. A finite element model of skin deformation. I. Biomechanics of skin and soft tissue: A review. Laryngoscope 1986, 96, 399–405. [Google Scholar] [CrossRef] [PubMed]

- Larrabee, W.F., Jr.; Sutton, D. A finite element model of skin deformation. II. An experimental model of skin deformation. Laryngoscope 1986, 96, 406–412. [Google Scholar] [CrossRef] [PubMed]

- Larrabee, W.F.; Galt, J.A. A finite element model of skin deformation. III. The finite element model. Laryngoscope 2009, 96, 413–419. [Google Scholar] [CrossRef]

- Kandi, R.; Pandey, P.M.; Majood, M.; Mohanty, S. Fabrication and characterization of customized tubular scaffolds for tracheal tissue engineering by using solvent based 3D printing on predefined template. Rapid Prototyp. J. 2021, 27, 421–428. [Google Scholar] [CrossRef]

- Han, J.; Chen, B.; Ye, L.; Zhang, A.-y.; Zhang, J.; Feng, Z.-g. Synthesis and characterization of biodegradable polyurethane based on poly(ε-caprolactone) and L-lysine ethyl ester diisocyanate. Front. Mater. Sci. China 2009, 3, 25–32. [Google Scholar] [CrossRef]

- Tan, C.; Tirri, T.; Wilen, C.-E. Investigation on the Influence of Chain Extenders on the Performance of One-Component Moisture-Curable Polyurethane Adhesives. Polymers 2017, 9, 184. [Google Scholar] [CrossRef] [PubMed]

- Berger, K.G.; Siew, W.L.; Oh, F.C.H. Factors affecting slip melting point of palm oil products. J. Am. Oil Chem. Soc. 1982, 59, 244–249. [Google Scholar] [CrossRef]

- Tan, C.P.; Che Man, Y.B. Differential scanning calorimetric analysis of palm oil, palm oil based products and coconut oil: Effects of scanning rate variation. Food Chem. 2002, 76, 89–102. [Google Scholar] [CrossRef]

- Li, X.; Liu, H.; Wang, J.; Li, C. Preparation and characterization of poly(ɛ-caprolactone) nonwoven mats via melt electrospinning. Polymer 2012, 53, 248–253. [Google Scholar] [CrossRef]

- Zhang, H.; Zhang, F.; Wu, Y. Robust Stretchable Thermoplastic Polyurethanes with Long Soft Segments and Steric Semisymmetric Hard Segments. Ind. Eng. Chem. Res. 2020, 59, 4483–4492. [Google Scholar] [CrossRef]

- Staszczak, M.; Nabavian Kalat, M.; Golasiński, K.M.; Urbański, L.; Takeda, K.; Matsui, R.; Pieczyska, E.A. Characterization of Polyurethane Shape Memory Polymer and Determination of Shape Fixity and Shape Recovery in Subsequent Thermomechanical Cycles. Polymers 2022, 14, 4775. [Google Scholar] [CrossRef] [PubMed]

- Tobushi, H.; Shimada, D.; Hayashi, S.; Endo, M. Shape fixity and shape recovery of polyurethane shape-memory polymer foams. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2003, 217, 135–143. [Google Scholar] [CrossRef]

- Pringpromsuk, S.; Xia, H.; Ni, Q.-Q. Multifunctional stimuli-responsive shape memory polyurethane gels for soft actuators. Sens. Actuators A Phys. 2020, 313, 112207. [Google Scholar] [CrossRef]

- Tobushi, H.; Hashimoto, T.; Ito, N.; Hayashi, S.; Yamada, E. Shape Fixity and Shape Recovery in a Film of Shape Memory Polymer of Polyurethane Series. J. Intell. Mater. Syst. Struct. 1998, 9, 127–136. [Google Scholar] [CrossRef]

- Lendlein, A.; Kelch, S. Shape-Memory Polymers. Angew. Chem. Int. Ed. 2002, 41, 2034–2057. [Google Scholar] [CrossRef]

- Ohki, T.; Ni, Q.-Q.; Ohsako, N.; Iwamoto, M. Mechanical and shape memory behavior of composites with shape memory polymer. Compos. Part A Appl. Sci. Manuf. 2004, 35, 1065–1073. [Google Scholar] [CrossRef]

| Code Name | Molar Ratio | HSC (%) | |||

|---|---|---|---|---|---|

| PCL | PO | HMDI | BDO | ||

| PU0 | 1 | 0 | 6 | 5 | 50.31 |

| PU10 | 0.9 | 0.1 | 6 | 5 | 53.47 |

| PU20 | 0.8 | 0.2 | 6 | 5 | 56.89 |

| PU30 | 0.7 | 0.3 | 6 | 5 | 60.62 |

| PU40 | 0.6 | 0.4 | 6 | 5 | 64.69 |

| Sample | Tg (°C) | Tm,PO (°C) | ,PO (J/g) | Tm,PCL (°C) | ,PCL (J/g) | Xc,PCL (%) | Tm,BD (°C) | ,BD (J/g) |

|---|---|---|---|---|---|---|---|---|

| PU0 | −55.50 | - | - | 51.33 | 0.64 | 0.91 | 76.92 | 5.99 |

| PU10 | −53.98 | - | - | 52.25 | 0.34 | 0.51 | 78.75 | 5.28 |

| PU20 | −57.21 | - | - | 53.67 | 0.84 | 1.28 | 80.25 | 6.53 |

| PU30 | −62.54 | 14.33 | 1.25 | 44.25 | 0.24 | 0.37 | 74.50 | 5.50 |

| PU40 | −54.00 | 12.17 | 0.75 | 50.92 | 0.43 | 0.43 | 77.83 | 6.66 |

| Sample | Young’s Modulus (MPa) | Tensile Strength (MPa) | Elongation at Break (%) |

|---|---|---|---|

| PU0 | 88.60 ± 3.20 × 10−2 | 10.15 ± 2.09 | 113.64 ± 15.37 |

| PU10 | 81.40 ± 6.26 × 10−2 | 15.70 ± 1.22 | 118.82 ± 10.18 |

| PU20 | 155.60 ± 6.22 × 10−2 | 13.01 ± 2.15 | 191.67 ± 22.16 |

| PU30 | 327.60 ± 2.80 × 10−2 | 22.64 ± 5.54 | 184.13 ± 12.43 |

| PU40 | 235.60 ± 0.82 × 10−2 | 20.75 ± 7.02 | 145.43 ± 22.52 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kampangsat, S.; Kajornprai, T.; Tangjatuporn, W.; Suppakarn, N.; Trongsatitkul, T. Enhancing Tensile Modulus of Polyurethane-Based Shape Memory Polymers for Wound Closure Applications through the Addition of Palm Oil. Polymers 2024, 16, 1941. https://doi.org/10.3390/polym16131941

Kampangsat S, Kajornprai T, Tangjatuporn W, Suppakarn N, Trongsatitkul T. Enhancing Tensile Modulus of Polyurethane-Based Shape Memory Polymers for Wound Closure Applications through the Addition of Palm Oil. Polymers. 2024; 16(13):1941. https://doi.org/10.3390/polym16131941

Chicago/Turabian StyleKampangsat, Sirasit, Todsapol Kajornprai, Warakarn Tangjatuporn, Nitinat Suppakarn, and Tatiya Trongsatitkul. 2024. "Enhancing Tensile Modulus of Polyurethane-Based Shape Memory Polymers for Wound Closure Applications through the Addition of Palm Oil" Polymers 16, no. 13: 1941. https://doi.org/10.3390/polym16131941

APA StyleKampangsat, S., Kajornprai, T., Tangjatuporn, W., Suppakarn, N., & Trongsatitkul, T. (2024). Enhancing Tensile Modulus of Polyurethane-Based Shape Memory Polymers for Wound Closure Applications through the Addition of Palm Oil. Polymers, 16(13), 1941. https://doi.org/10.3390/polym16131941