Optimization of Laminated Bio-Polymer Fabrication for Food Packaging Application: A Sustainable Plasma-Activated Approach

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

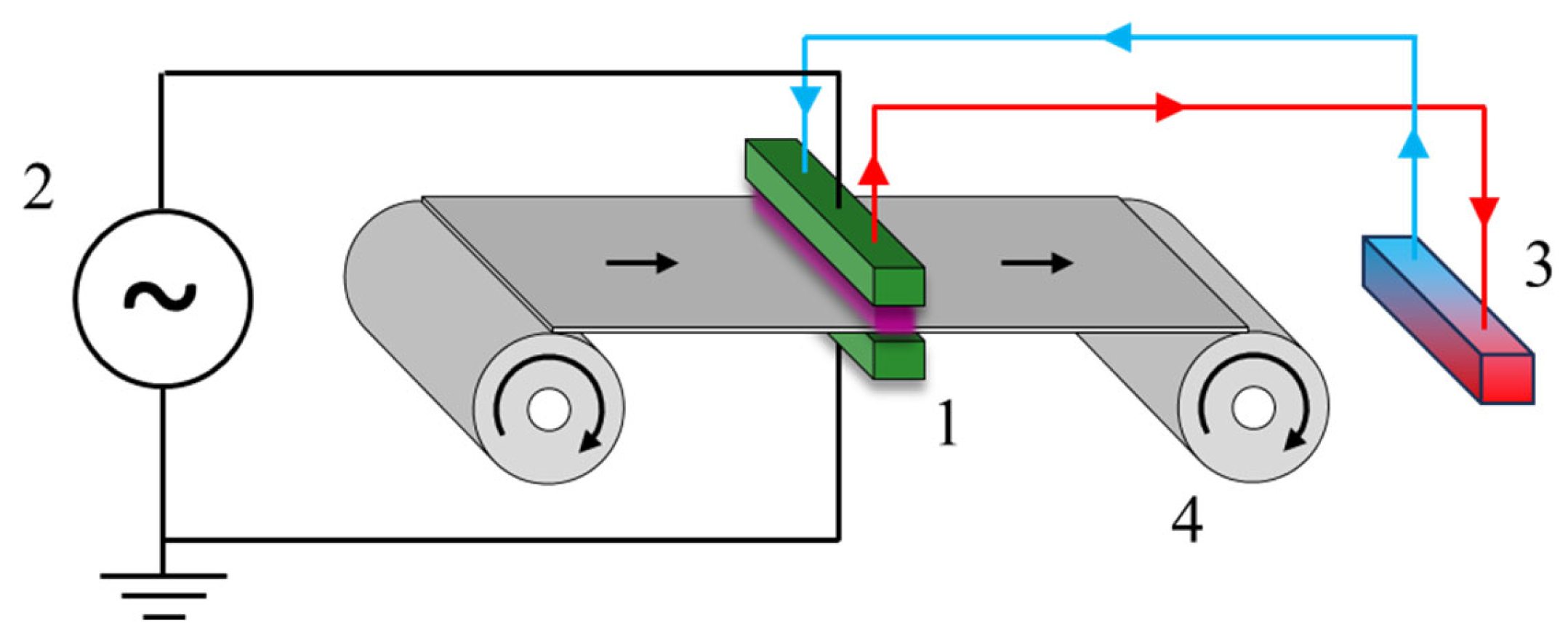

2.2. Procedure of Plasma Activation

2.3. Characterizations

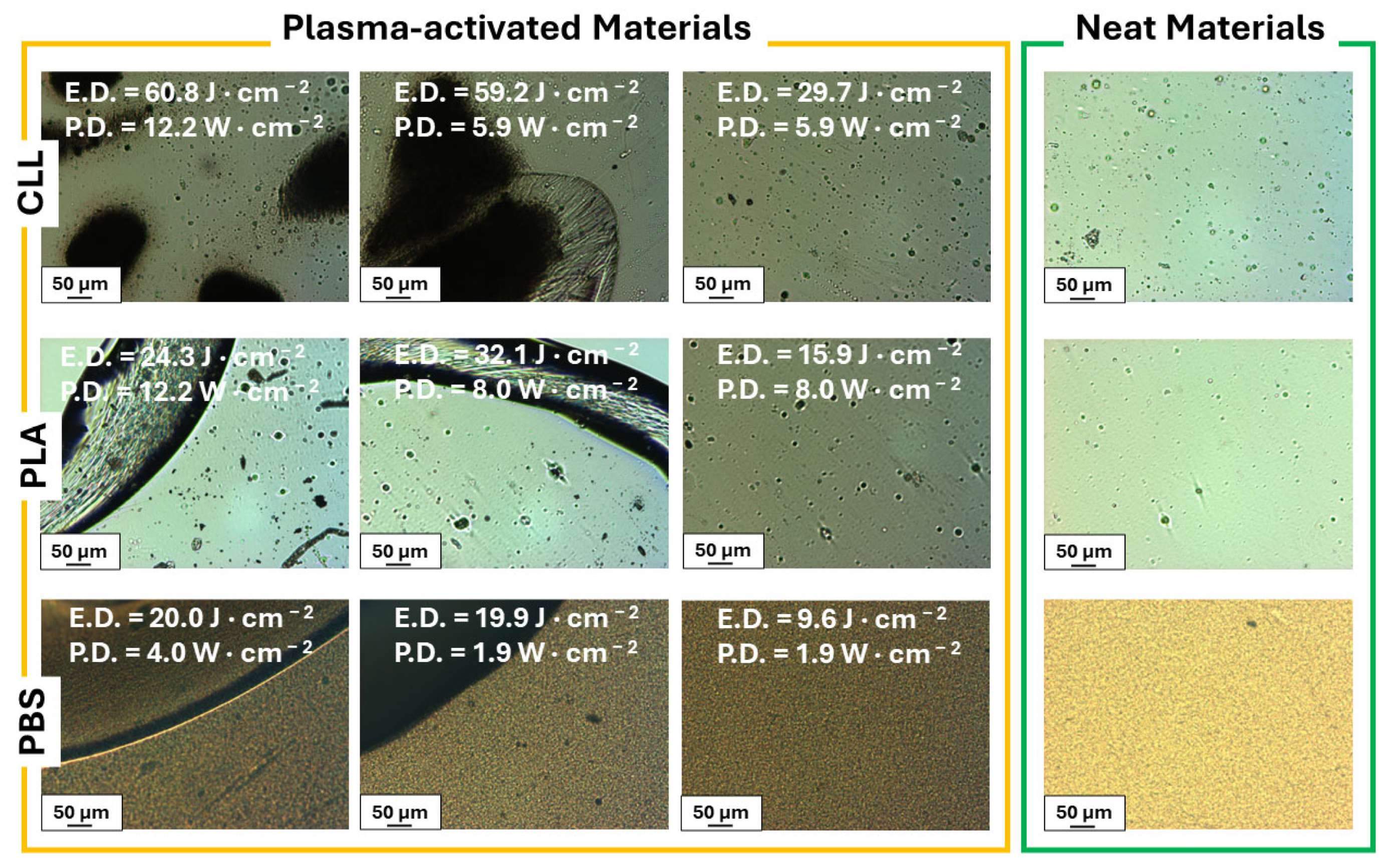

2.3.1. Optical Microscopy (OM) Analyses

2.3.2. Water Contact Angle (WCA) Analyses

2.3.3. Adhesion Tests (T-Peel Test)

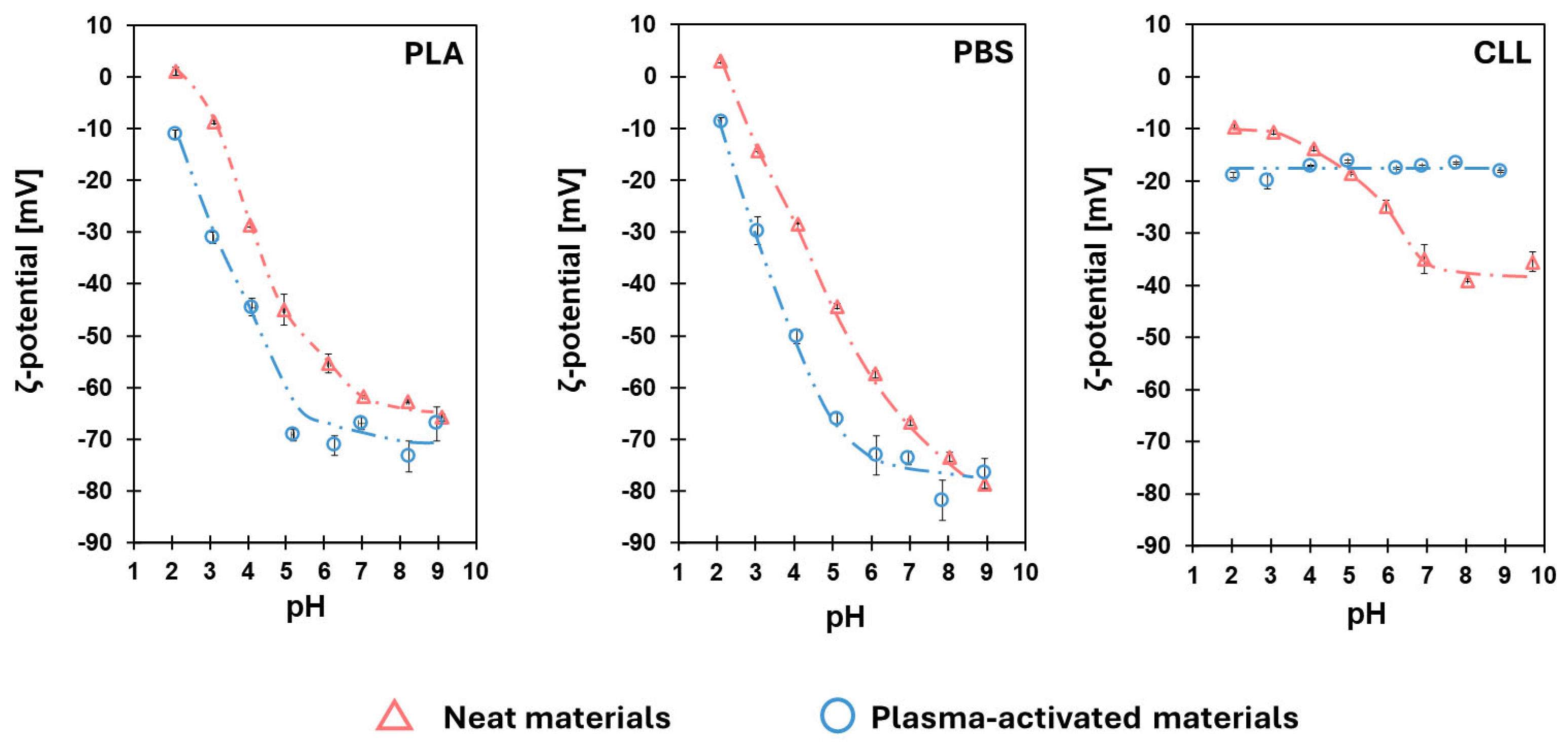

2.3.4. Determination of the Surface Zeta-Potential (ζ-Potential)

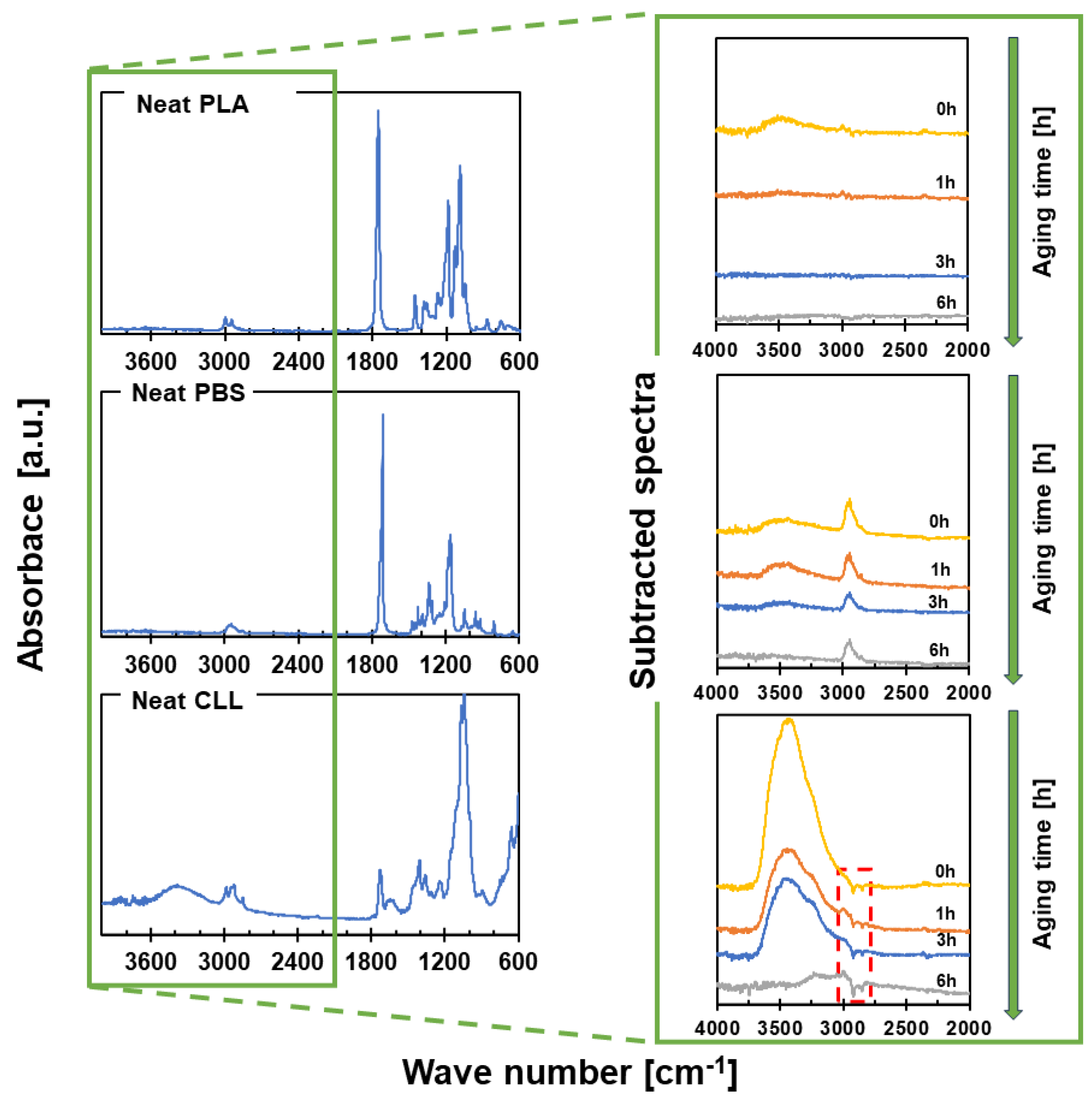

2.3.5. Attenuated Total Reflectance–Fourier Transform Infrared (ATR-FTIR) Characterizations

2.3.6. Gas Transport Analysis

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kim, M.S.; Chang, H.; Zheng, L.; Yan, Q.; Pfleger, B.F.; Klier, J.; Nelson, K.; Majumder, E.L.W.; Huber, G.W. A Review of Biodegradable Plastics: Chemistry, Applications, Properties, and Future Research Needs. Chem. Rev. 2022, 123, 9915–9939. [Google Scholar] [CrossRef] [PubMed]

- Jubinville, D.; Esmizadeh, E.; Saikrishnan, S.; Tzoganakis, C.; Mekonnen, T. A Comprehensive Review of Global Production and Recycling Methods of Polyolefin (PO) Based Products and Their Post-Recycling Applications. Sustain. Mater. Technol. 2020, 25, e00188. [Google Scholar] [CrossRef]

- Muñoz Meneses, R.A.; Cabrera-Papamija, G.; Machuca-Martínez, F.; Rodríguez, L.A.; Diosa, J.E.; Mosquera-Vargas, E. Plastic Recycling and Their Use as Raw Material for the Synthesis of Carbonaceous Materials. Heliyon 2022, 8, e09028. [Google Scholar] [CrossRef] [PubMed]

- Directive (EU) 2019/904 of the European Parliament and of the Council of 5 June 2019 on the Reduction of the Impact of Certain Products on the Environment. Off. J. Eur. Union 2019, L155, 1–15.

- Aversa, C.; Barletta, M.; Koca, N. Processing PLA/P(3HB)(4HB) Blends for the Manufacture of Highly Transparent, Gas Barrier and Fully Bio-Based Films for Compostable Packaging Applications. J. Appl. Polym. Sci. 2023, 140, e53669. [Google Scholar] [CrossRef]

- Di Lorenzo, M.L. Poly(l-Lactic Acid)/Poly(Butylene Succinate) Biobased Biodegradable Blends. Polym. Rev. 2021, 61, 457–492. [Google Scholar] [CrossRef]

- Scarfato, P.; Graziano, M.L.; Pietrosanto, A.; Di Maio, L.; Incarnato, L. Use of Hazelnut Perisperm as an Antioxidant for Production of Sustainable Biodegradable Active Films. Polymers 2022, 14, 4156. [Google Scholar] [CrossRef] [PubMed]

- Costa, P.; Basaglia, M.; Casella, S.; Favaro, L. Polyhydroxyalkanoate Production from Fruit and Vegetable Waste Processing. Polymers 2022, 14, 5529. [Google Scholar] [CrossRef] [PubMed]

- McNeill, D.C.; Pal, A.K.; Mohanty, A.K.; Misra, M. High Biomass Filled Biodegradable Plastic in Engineering Sustainable Composites. Compos. Part C Open Access 2023, 12, 100388. [Google Scholar] [CrossRef]

- Castro-Aguirre, E.; Iñiguez-Franco, F.; Samsudin, H.; Fang, X.; Auras, R. Poly(Lactic Acid)—Mass Production, Processing, Industrial Applications, and End of Life. Adv. Drug Deliv. Rev. 2016, 107, 333–366. [Google Scholar] [CrossRef]

- Aliotta, L.; Seggiani, M.; Lazzeri, A.; Gigante, V.; Cinelli, P. A Brief Review of Poly (Butylene Succinate) (PBS) and Its Main Copolymers: Synthesis, Blends, Composites, Biodegradability, and Applications. Polymers 2022, 14, 844. [Google Scholar] [CrossRef] [PubMed]

- Thakur, S.; Chaudhary, J.; Singh, P.; Alsanie, W.F.; Grammatikos, S.A.; Thakur, V.K. Synthesis of Bio-Based Monomers and Polymers Using Microbes for a Sustainable Bioeconomy. Bioresour. Technol. 2022, 344, 126156. [Google Scholar] [CrossRef] [PubMed]

- Zhong, C. Industrial-Scale Production and Applications of Bacterial Cellulose. Front. Bioeng. Biotechnol. 2020, 8, 605374. [Google Scholar] [CrossRef] [PubMed]

- Hussain, Z.; Sajjad, W.; Khan, T.; Wahid, F. Production of Bacterial Cellulose from Industrial Wastes: A Review. Cellulose 2019, 26, 2895–2911. [Google Scholar] [CrossRef]

- Avcioglu, N.H. Bacterial Cellulose: Recent Progress in Production and Industrial Applications. World J. Microbiol. Biotechnol. 2022, 38, 86. [Google Scholar] [CrossRef] [PubMed]

- Lambré, C.; Barat Baviera, J.M.; Bolognesi, C.; Chesson, A.; Cocconcelli, P.S.; Crebelli, R.; Gott, D.M.; Grob, K.; Lampi, E.; Mengelers, M.; et al. Safety Assessment of Bleached Cellulose Pulp for Use in Plastic Food Contact Materials. EFSA J. 2022, 20, 7171. [Google Scholar] [CrossRef]

- Ullah, H.; Santos, H.A.; Khan, T. Applications of Bacterial Cellulose in Food, Cosmetics and Drug Delivery. Cellulose 2016, 23, 2291–2314. [Google Scholar] [CrossRef]

- Al-Gharrawi, M.Z.; Wang, J.; Bousfield, D.W. Improving Water Vapor Barrier of Cellulose Based Food Packaging Using Double Layer Coatings and Cellulose Nanofibers. Food Packag. Shelf Life 2022, 33, 100895. [Google Scholar] [CrossRef]

- Kim, J.M.; Lee, M.H.; Ko, J.A.; Kang, D.H.; Bae, H.; Park, H.J. Influence of Food with High Moisture Content on Oxygen Barrier Property of Polyvinyl Alcohol (PVA)/Vermiculite Nanocomposite Coated Multilayer Packaging Film. J. Food Sci. 2018, 83, 349–357. [Google Scholar] [CrossRef]

- Li, H.; He, Y.; Yang, J.; Wang, X.; Lan, T.; Peng, L. Fabrication of Food-Safe Superhydrophobic Cellulose Paper with Improved Moisture and Air Barrier Properties. Carbohydr. Polym. 2019, 211, 22–30. [Google Scholar] [CrossRef]

- Martínez-Sanz, M.; Lopez-Rubio, A.; Lagaron, J.M. High-Barrier Coated Bacterial Cellulose Nanowhiskers Films with Reduced Moisture Sensitivity. Carbohydr. Polym. 2013, 98, 1072–1082. [Google Scholar] [CrossRef]

- Minelli, M.; Baschetti, M.G.; Doghieri, F.; Ankerfors, M.; Lindström, T.; Siró, I.; Plackett, D. Investigation of Mass Transport Properties of Microfibrillated Cellulose (MFC) Films. J. Memb. Sci. 2010, 358, 67–75. [Google Scholar] [CrossRef]

- Fotie, G.; Rampazzo, R.; Ortenzi, M.A.; Checchia, S.; Fessas, D.; Piergiovanni, L. The Effect of Moisture on Cellulose Nanocrystals Intended as a High Gas Barrier Coating on Flexible Packaging Materials. Polymers 2017, 9, 415. [Google Scholar] [CrossRef] [PubMed]

- NatureFlexTM Packaging Solutions. Available online: https://www.natureflex.com/packaging-solutions/ (accessed on 7 November 2023).

- Patanè, C.; Malvuccio, A.; Saita, A.; Rizzarelli, P.; Siracusa, L.; Rizzo, V.; Muratore, G. Nutritional Changes during Storage in Fresh-Cut Long Storage Tomato as Affected by Biocompostable Polylactide and Cellulose Based Packaging. LWT 2019, 101, 618–624. [Google Scholar] [CrossRef]

- Reinas, I.; Oliveira, J.; Pereira, J.; Mahajan, P.; Poças, F. A Quantitative Approach to Assess the Contribution of Seals to the Permeability of Water Vapour and Oxygen in Thermosealed Packages. Food Packag. Shelf Life 2016, 7, 34–40. [Google Scholar] [CrossRef]

- Li, C.; Wu, J.; Shi, H.; Xia, Z.; Sahoo, J.K.; Yeo, J.; Kaplan, D.L. Fiber-Based Biopolymer Processing as a Route toward Sustainability. Adv. Mater. 2022, 34, 2105196. [Google Scholar] [CrossRef] [PubMed]

- Collins, S.; Yoda, K.; Anazawa, N.; Birkinshaw, C. The Thermal Stability of Some Vinylidene Chloride Copolymers. Polym. Degrad. Stab. 1999, 66, 87–94. [Google Scholar] [CrossRef]

- Hosseinzadeh, S.; Mohebby, B.; Elyasi, M. Bending Performances and Rolling Shear Strength of Nail-Cross-Laminated Timber. Wood Mater. Sci. Eng. 2022, 17, 113–120. [Google Scholar] [CrossRef]

- Takechi, K.; Yamaguchi, S.; Tanabe, H.; Kaneko, S. Development of Rollable Silicon Thin-Film-Transistor Backplanes Utilizing a Roll-to-Roll Continuous Lamination Process. J. Soc. Inf. Disp. 2010, 18, 391–398. [Google Scholar] [CrossRef]

- Howard, G.T. Biodegradation of Polyurethane: A Review. Int. Biodeterior. Biodegrad. 2002, 49, 245–252. [Google Scholar] [CrossRef]

- Patel, A.; Rajput, B.S.; Hai, T.A.P.; Zhen, D.; Gunawan, N.R.; Tessman, M.; Reindel, J.; Shepherd, J.; Simkovsky, R.; Pomeroy, R.S.; et al. Biodegradable Waterborne Polyurethane-Urea Dispersion Adhesives with High Biocontent. J. Appl. Polym. Sci. 2023, 140, e54307. [Google Scholar] [CrossRef]

- Gunawan, N.R.; Tessman, M.; Zhen, D.; Johnson, L.; Evans, P.; Clements, S.M.; Pomeroy, R.S.; Burkart, M.D.; Simkovsky, R.; Mayfield, S.P. Biodegradation of Renewable Polyurethane Foams in Marine Environments Occurs through Depolymerization by Marine Microorganisms. Sci. Total Environ. 2022, 850, 158761. [Google Scholar] [CrossRef] [PubMed]

- Hieda, J.; Niinomi, M.; Nakai, M.; Kamura, H.; Tsutsumi, H.; Hanawa, T. Improvement of Adhesive Strength of Segmented Polyurethane on Ti-29Nb-13Ta-4.6Zr Alloy through H2O2 Treatment for Biomedical Applications. J. Biomed. Mater. Res. B Appl. Biomater. 2013, 101B, 776–783. [Google Scholar] [CrossRef] [PubMed]

- Zimmermann, S.; Specht, U.; Spieß, L.; Romanus, H.; Krischok, S.; Himmerlich, M.; Ihde, J. Improved Adhesion at Titanium Surfaces via Laser-Induced Surface Oxidation and Roughening. Mater. Sci. Eng. A 2012, 558, 755–760. [Google Scholar] [CrossRef]

- Hetemi, D.; Pinson, J. Surface Functionalisation of Polymers. Chem. Soc. Rev. 2017, 46, 5701–5713. [Google Scholar] [CrossRef] [PubMed]

- Puthirath, A.B.; Oliveira, E.F.; Gao, G.; Chakingal, N.; Kannan, H.; Li, C.; Zhang, X.; Biswas, A.; Neupane, M.R.; Pate, B.B.; et al. Oxygenation of Diamond Surfaces via Hummer’s Method. Chem. Mater. 2021, 33, 4977–4987. [Google Scholar] [CrossRef]

- Chandio, A.D.; Shaikh, A.A.; Channa, I.A.; Bacha, M.S.; Bhatti, J.; Khan, M.Y.; Bhutto, S. Synthesis of Graphene Oxide (GO) by Modified Hummer’s Method with Improved Oxidation through Ozone Treatment. J. Chem. Soc. Pak. 2023, 45, 1–7. [Google Scholar] [CrossRef]

- Yu, J.; Niedenthal, W.; Smarsly, B.M.; Natile, M.M.; Huang, Y.; Carraro, M. Au Nanoparticles Supported on Piranha Etched Halloysite Nanotubes for Highly Efficient Heterogeneous Catalysis. Appl. Surf. Sci. 2021, 546, 149100. [Google Scholar] [CrossRef]

- Strobel, M.; Branch, M.C.; Ulsh, M.; Kapaun, R.S.; Kirk, S.; Lyons, C.S. Flame Surface Modification of Polypropylene Film. J. Adhes. Sci. Technol. 1996, 10, 515–539. [Google Scholar] [CrossRef]

- Song, J.; Gunst, U.; Arlinghaus, H.F.; Vancso, G.J. Flame Treatment of Low-Density Polyethylene: Surface Chemistry across the Length Scales. Appl. Surf. Sci. 2007, 253, 9489–9499. [Google Scholar] [CrossRef]

- Stroud, C.; Branch, M.C. Modeling of the Surface Oxidation of Flame-Treated Polypropylene Film. Combust. Sci. Technol. 2007, 179, 2091–2105. [Google Scholar] [CrossRef]

- Yulenets, Y.P.; Markov, A.V.; Grachev, S.Y. Effect of Conditions for Modification in a High-Frequency Discharge Plasma on the Reversibility of the Surface Properties of Polyethylene Films. Surf. Eng. Appl. Electrochem. 2021, 57, 185–189. [Google Scholar] [CrossRef]

- Markov, A.V.; Yulenets, Y.P. Heating of a Gas and a Polymeric Material in Low-Temperature Plasma of a High-Frequency Discharge. High Temp. 2015, 53, 167–170. [Google Scholar] [CrossRef]

- Yang, R.H.; Gao, W.D.; Xue, Y. Airflow Characteristics of Different Groove Type during Rotor Spinning Process. Ind. Textila 2017, 68, 165–169. [Google Scholar] [CrossRef]

- Sanchis, M.R.; Calvo, O.; Fenollar, O.; Garcia, D.; Balart, R. Surface Modification of a Polyurethane Film by Low Pressure Glow Discharge Oxygen Plasma Treatment. J. Appl. Polym. Sci. 2007, 105, 1077–1085. [Google Scholar] [CrossRef]

- Zhang, S.; Li, X.S.; Zhu, B.; Liu, J.L.; Zhu, X.; Zhu, A.M.; Jang, B.W.L. Atmospheric-Pressure O2 Plasma Treatment of Au/TiO2 Catalysts for CO Oxidation. Catal. Today 2015, 256, 142–147. [Google Scholar] [CrossRef]

- Borisov, I.; Ovcharova, A.; Bakhtin, D.; Bazhenov, S.; Volkov, A.; Ibragimov, R.; Gallyamov, R.; Bondarenko, G.; Mozhchil, R.; Bildyukevich, A.; et al. Development of Polysulfone Hollow Fiber Porous Supports for High Flux Composite Membranes: Air Plasma and Piranha Etching. Fibers 2017, 5, 6. [Google Scholar] [CrossRef]

- Matveev, I.B.; Serbin, S.I.; Washchilenko, N.V. Plasma-Assisted Treatment of Sewage Sludge. IEEE Trans. Plasma Sci. 2016, 44, 3023–3027. [Google Scholar] [CrossRef]

- Fateh-Alavi, K.; Gedde, U.W. Effect of Stabilizers on Surface Oxidation of Silicone Rubber by Corona Discharge. Polym. Degrad. Stab. 2004, 84, 469–474. [Google Scholar] [CrossRef]

- Borcia, G.; Anderson, C.A.; Brown, N.M.D. The Surface Oxidation of Selected Polymers Using an Atmospheric Pressure Air Dielectric Barrier Discharge. Part I. Appl. Surf. Sci. 2004, 221, 203–214. [Google Scholar] [CrossRef]

- Borcia, G.; Anderson, C.A.; Brown, N.M.D. The Surface Oxidation of Selected Polymers Using an Atmospheric Pressure Air Dielectric Barrier Discharge. Part II. Appl. Surf. Sci. 2004, 225, 186–197. [Google Scholar] [CrossRef]

- Booth, J.P.; Mozetič, M.; Nikiforov, A.; Oehr, C. Foundations of Plasma Surface Functionalization of Polymers for Industrial and Biological Applications. Plasma Sources Sci. Technol. 2022, 31, 103001. [Google Scholar] [CrossRef]

- Şaşmazel, H.T.; Manolache, S.; Gümüderelioǧlu, M. Functionalization of Nonwoven Pet Fabrics by Water/O2 Plasma for Biomolecule Mediated Cell Cultivation. Plasma Process. Polym. 2010, 7, 588–600. [Google Scholar] [CrossRef]

- De Wilde, J.; Lorant, C.; Descamps, P. 2D Modeling and Simulation of the Flow Dynamics, Electric Field and Reactions in a Low-Temperature, Atmospheric-Pressure Nitrogen Plasma Sharp-End Plate-to-Plane Configuration and CVD Reactor. J. Phys. D Appl. Phys. 2017, 50, 135202. [Google Scholar] [CrossRef]

- Fang, Z.; Ruan, C.; Shao, T.; Zhang, C. Two Discharge Modes in an Atmospheric Pressure Plasma Jet Array in Argon. Plasma Sources Sci. Technol. 2016, 25, 01LT01. [Google Scholar] [CrossRef]

- Ono, T.; Akagi, T.; Ichiki, T. Hydrophilization of Amorphous Perfluoropolymer Using Low-Pressure Argon Plasma. J. Photopolym. Sci. Technol. 2009, 22, 683–689. [Google Scholar] [CrossRef]

- Lianos, L.; Parrat, D.; Hoc, T.Q.; Duc, T.M. Secondary Ion Mass Spectrometry Time of Flight and in Situ X-Ray Photoelectron Spectroscopy Studies of Polymer Surface Modifications by a Remote Oxygen Plasma Treatment. J. Vac. Sci. Technol. A Vac. Surf. Film. 1994, 12, 2491–2498. [Google Scholar] [CrossRef]

- Nikiforov, A.; Li, L.; Britun, N.; Snyders, R.; Vanraes, P.; Leys, C. Influence of Air Diffusion on the OH Radicals and Atomic O Distribution in an Atmospheric Ar (Bio)Plasma Jet. Plasma Sources Sci. Technol. 2014, 23, 015015. [Google Scholar] [CrossRef][Green Version]

- Abenojar, J.; Martínez, M.A.; Encinas, N.; Velasco, F. Modification of Glass Surfaces Adhesion Properties by Atmospheric Pressure Plasma Torch. Int. J. Adhes. Adhes. 2013, 44, 1–8. [Google Scholar] [CrossRef]

- Novák, I.; Sedliačik, J.; Gajtanska, M.; Schmidtová, J.; Popelka, A.; Bekhta, P.; Krystofiak, T.; Proszyk, S.; Žigo, O. Effect of Barrier Plasma Pre-Treatment on Polyester Films and Their Adhesive Properties on Oak Wood. Bioresources 2016, 11, 6335–6345. [Google Scholar] [CrossRef][Green Version]

- Shu, Z.; Qiao, J.; Wang, C.; Xiong, Q. Simultaneous Quantification of Atomic Oxygen and Ozone by Full Photo-Fragmentation Two-Photon Absorption Laser-Induced Fluorescence Spectroscopy. Plasma Sources Sci. Technol. 2021, 30, 055001. [Google Scholar] [CrossRef]

- Wayakron Phetphaisit, C.; Bumee, R.; Namahoot, J.; Ruamcharoen, J.; Ruamcharoen, P. Polyurethane Polyester Elastomer: Innovative Environmental Friendly Wood Adhesive from Modified PETs and Hydroxyl Liquid Natural Rubber Polyols. Int. J. Adhes. Adhes. 2013, 41, 127–131. [Google Scholar] [CrossRef]

- ASTM D-1876; Standard Test Method for Peel Resistance of Adhesives (T-Peel Test). ASTM: West Conshohocken, PA, USA, 2015.

- ASTM D-1434; Standard Test Method for Determining Gas Permeability Characteristics of Plastic Film and Sheeting. ASTM: West Conshohocken, PA, USA, 2015. [CrossRef]

- de Medeiros Neto, J.F.; de Souza, I.A.; Feitor, M.C.; Targino, T.G.; Diniz, G.F.; Libório, M.S.; Sousa, R.R.M.; de Carvalho Costa, T.H. Study of High-Density Polyethylene (HDPE) Kinetics Modification Treated by Dielectric Barrier Discharge (DBD) Plasma. Polymers 2020, 12, 2422. [Google Scholar] [CrossRef] [PubMed]

- Xing, W.; Hao, J.; Sikora, K.S. Shear Performance of Adhesive Bonding of Cross-Laminated Bamboo. J. Mater. Civ. Eng. 2019, 31, 04019201. [Google Scholar] [CrossRef]

- Thompson, R.; Austin, D.; Wang, C.; Neville, A.; Lin, L. Low-Frequency Plasma Activation of Nylon 6. Appl. Surf. Sci. 2021, 544, 148929. [Google Scholar] [CrossRef]

- Izdebska-Podsiadły, J.; Trokowska, P.; Dörsam, E. Aging of Polylactide Films Exposed to Plasma—Hydrophobic Recovery and Selected Application Properties. Appl. Sci. 2023, 13, 2751. [Google Scholar] [CrossRef]

- Bismarck, A.; Springer, J.; Mohanty, A.K.; Hinrichsen, G.; Khan, M.A. Characterization of Several Modified Jute Fibers Using Zeta-Potential Measurements. Colloid Polym. Sci. 2000, 278, 229–235. [Google Scholar] [CrossRef]

- Matter, F.; Luna, A.L.; Niederberger, M. From Colloidal Dispersions to Aerogels: How to Master Nanoparticle Gelation. Nano Today 2020, 30, 100827. [Google Scholar] [CrossRef]

- Brotherton, E.E.; Johnson, E.C.; Smallridge, M.J.; Hammond, D.B.; Leggett, G.J.; Armes, S.P. Hydrophilic Aldehyde-Functional Polymer Brushes: Synthesis, Characterization, and Potential Bioapplications. Macromolecules 2023, 56, 2070–2080. [Google Scholar] [CrossRef]

- Píchal, J.; Klenko, Y. ADBD Plasma Surface Treatment of PES Fabric Sheets. Eur. Phys. J. D 2009, 54, 271–279. [Google Scholar] [CrossRef]

- Keshk, S.M.A.S. Homogenous Reactions of Cellulose from Different Natural Sources. Carbohydr. Polym. 2008, 74, 942–945. [Google Scholar] [CrossRef]

- Cataldo, F.; Ursini, O.; Ragni, P.; Lilla, V.; Angelini, G. Radiation-Induced Polymerization of Vinylidene Chloride in Bulk and Included in Thiourea Crystals. J. Macromol. Sci. Part A Pure Appl. Chem. 2009, 46, 16–24. [Google Scholar] [CrossRef]

- Simončič, B.; Černe, L.; Tomšič, B.; Orel, B. Surface Properties of Cellulose Modified by Imidazolidinone. Cellulose 2008, 15, 47–58. [Google Scholar] [CrossRef]

- Melendez-Rodriguez, B.; Torres-Giner, S.; Angulo, I.; Pardo-Figuerez, M.; Hilliou, L.; Escuin, J.M.; Cabedo, L.; Nevo, Y.; Prieto, C.; Lagaron, J.M. High-Oxygen-Barrier Multilayer Films Based on Polyhydroxyalkanoates and Cellulose Nanocrystals. Nanomaterials 2021, 11, 1443. [Google Scholar] [CrossRef] [PubMed]

- Foli, G.; Degli Esposti, M.; Morselli, D.; Fabbri, P. Two-Step Solvent-Free Synthesis of Poly(Hydroxybutyrate)-Based Photocurable Resin with Potential Application in Stereolithography. Macromol. Rapid Commun. 2020, 41, 1900660. [Google Scholar] [CrossRef] [PubMed]

- Choi, S.W.; Seo, D.W.; Lim, Y.D.; Jeong, Y.G.; Islam Mollah, M.S.; Park, H.; Hong, T.W.; Kim, W.G. Synthesis and Properties of Multihydroxy Soybean Oil from Soybean Oil and Polymeric Methylene-Diphenyl- 4,4′-Diisocyanate/Multihydroxy Soybean Oil Polyurethane Adhesive to Wood. J. Appl. Polym. Sci. 2011, 121, 764–769. [Google Scholar] [CrossRef]

- Hooper, A.E.; Tompkins, H.G. Convenient Calibration of FTIR Peak “size” for Thin Organic/Polymer Films. Surf. Interface Anal. 2001, 31, 805–808. [Google Scholar] [CrossRef]

- Wei, X.; Lu, Q.; Sui, X.; Wang, Z.; Zhang, Y. Characterization of the Water-Insoluble Pyrolytic Cellulose from Cellulose Pyrolysis Oil. J. Anal. Appl. Pyrolysis 2012, 97, 49–54. [Google Scholar] [CrossRef]

| Material | Voltage [kV] | Frequency [kHz] | Time [s] | Energy Density [J · cm−2] | Power Density [W · cm−2] | WCA [deg] | |

|---|---|---|---|---|---|---|---|

| Pre- Plasma | Post- Plasma | ||||||

| CLL | 12 | 20 | 5 | 29.7 | 5.9 | 85.9 ± 2.8 | 54.2 ± 4.8 |

| PLA | 14 | 20 | 2 | 15.9 | 8.0 | 79.7 ± 1.6 | 47.4 ± 3.6 |

| PBS | 14 | 5 | 5 | 9.6 | 1.9 | 63.4 ± 3.8 | 49.9 ± 1.3 |

| Material | Tension [kV] | Frequency [kHz] | Energy Density [J · cm−2] | Power Density [W · cm−2] |

|---|---|---|---|---|

| PLA | 10 | 2 | 27.2 | 152.3 |

| PBS | 12 | 10 | 9.9 | 55 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Foli, G.; Capelli, F.; Grande, M.; Tagliabue, S.; Gherardi, M.; Minelli, M. Optimization of Laminated Bio-Polymer Fabrication for Food Packaging Application: A Sustainable Plasma-Activated Approach. Polymers 2024, 16, 1851. https://doi.org/10.3390/polym16131851

Foli G, Capelli F, Grande M, Tagliabue S, Gherardi M, Minelli M. Optimization of Laminated Bio-Polymer Fabrication for Food Packaging Application: A Sustainable Plasma-Activated Approach. Polymers. 2024; 16(13):1851. https://doi.org/10.3390/polym16131851

Chicago/Turabian StyleFoli, Giacomo, Filippo Capelli, Mariachiara Grande, Stefano Tagliabue, Matteo Gherardi, and Matteo Minelli. 2024. "Optimization of Laminated Bio-Polymer Fabrication for Food Packaging Application: A Sustainable Plasma-Activated Approach" Polymers 16, no. 13: 1851. https://doi.org/10.3390/polym16131851

APA StyleFoli, G., Capelli, F., Grande, M., Tagliabue, S., Gherardi, M., & Minelli, M. (2024). Optimization of Laminated Bio-Polymer Fabrication for Food Packaging Application: A Sustainable Plasma-Activated Approach. Polymers, 16(13), 1851. https://doi.org/10.3390/polym16131851