Mechanical Characterization, Water Absorption, and Thickness Swelling of Lightweight Pineapple Leaf/Ramie Fabric-Reinforced Polypropylene Hybrid Composites

Abstract

1. Introduction

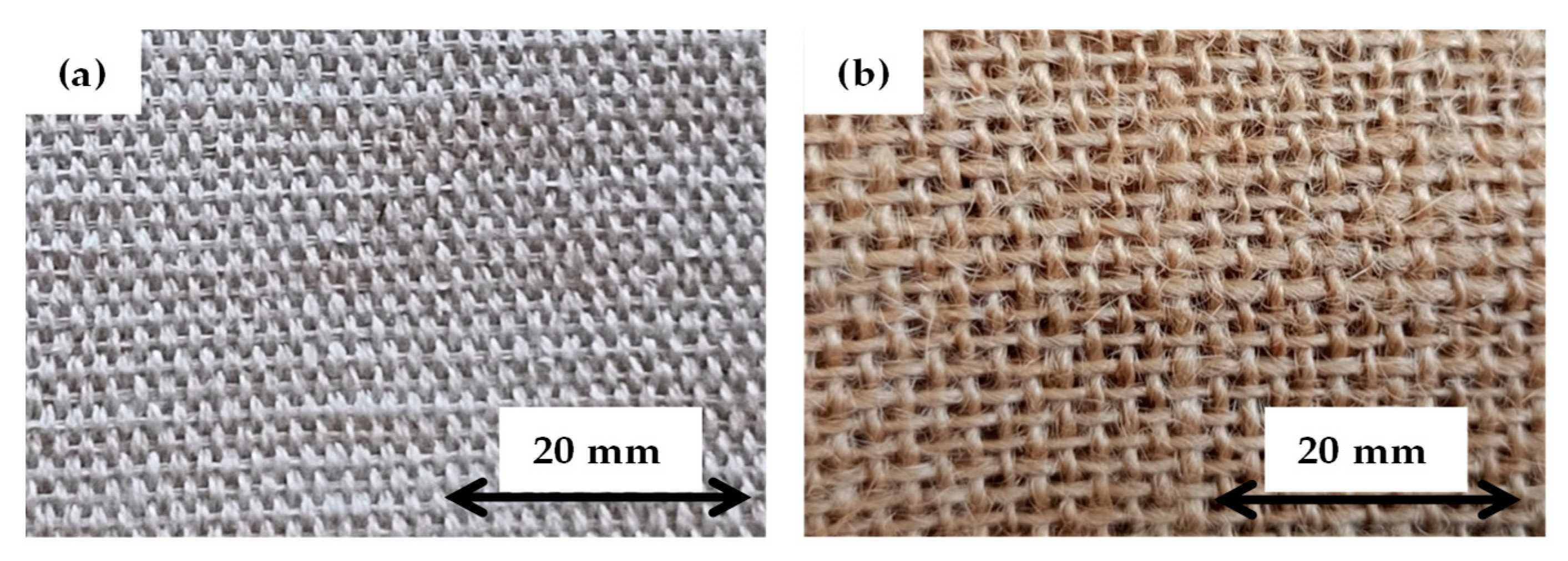

2. Materials and Methods

2.1. Materials

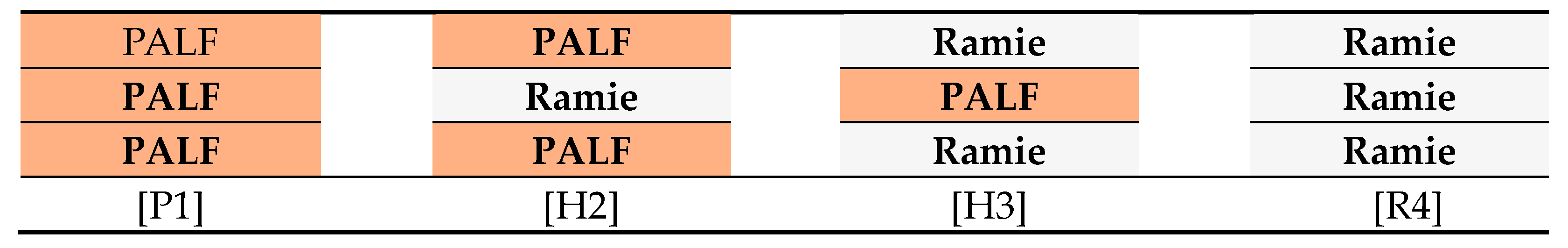

2.2. Sample Preparation

2.3. Experimental Methods

3. Results and Discussion

3.1. Tensile Properties

3.2. Flexural Properties

3.3. Impact Properties

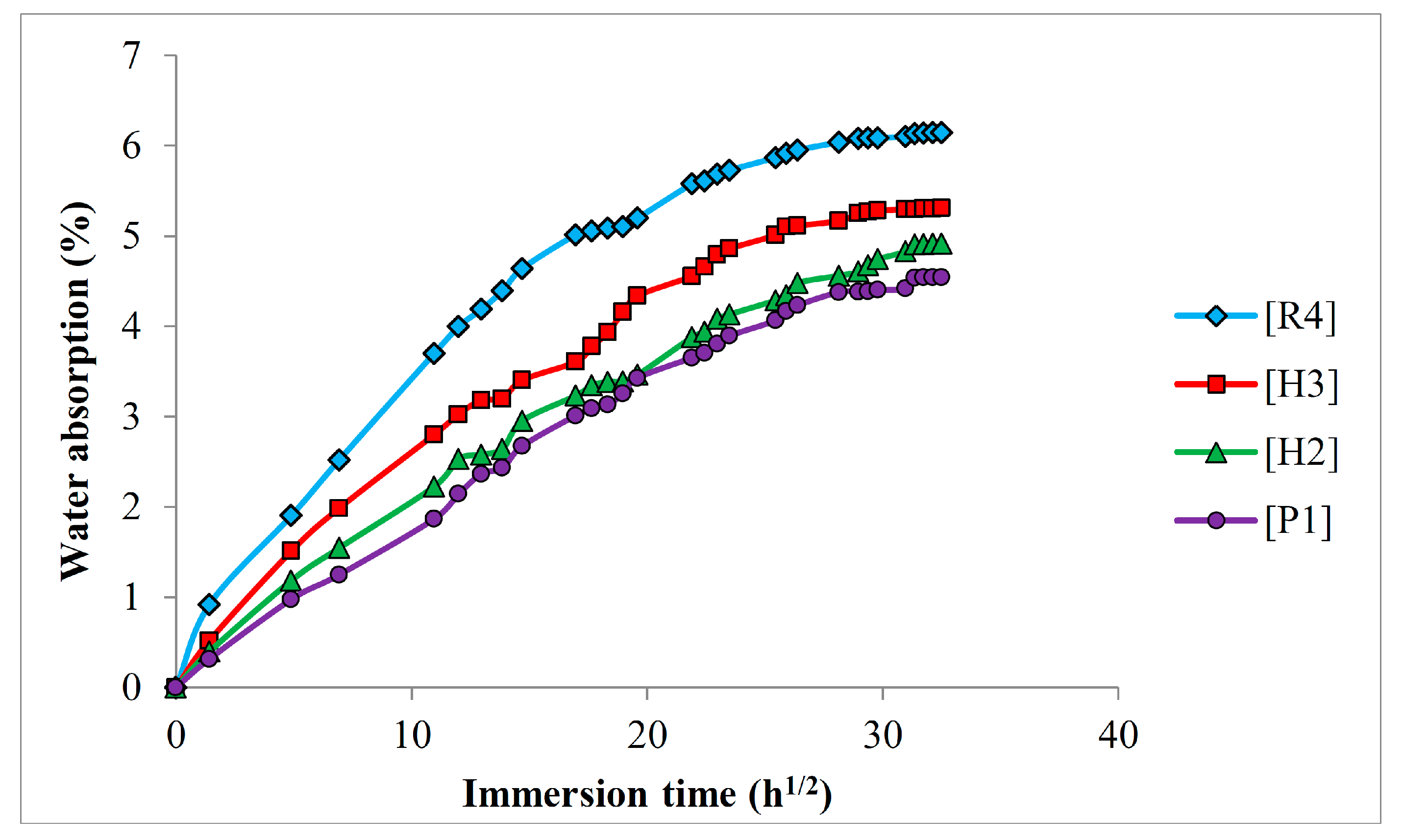

3.4. Water Absorption Behavior

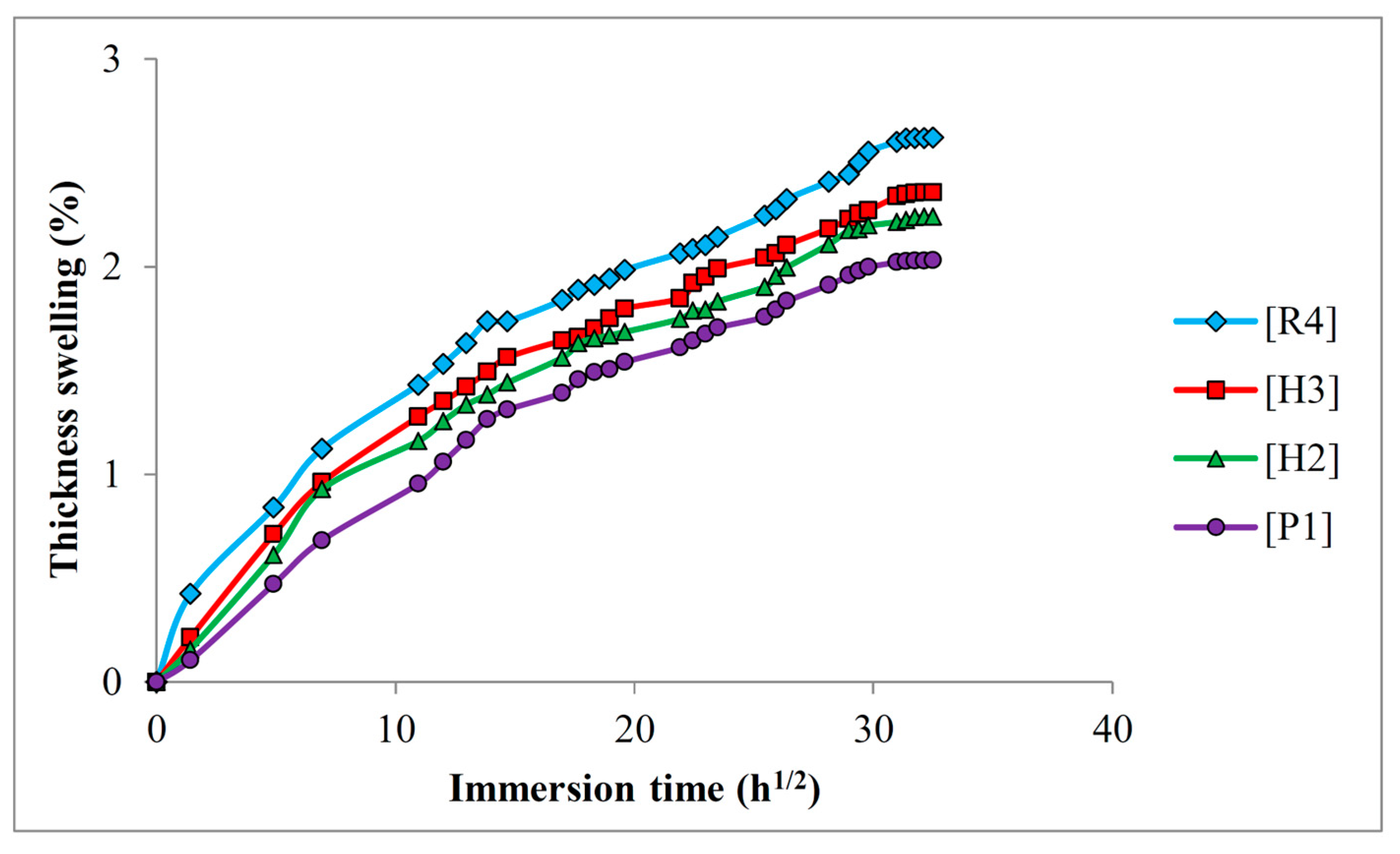

3.5. Thickness Swelling

3.6. Morphological Behavior

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Marichelvam, M.K.; Kumar, C.L.; Kandakodeeswaran, K.; Thangagiri, B.; Saxena, K.K.; Kishore, K.; Wagri, N.K.; Kumar, S. Investigation on Mechanical Properties of Novel Natural Fiber-Epoxy Resin Hybrid Composites for Engineering Structural Applications. Case Stud. Constr. Mater. 2023, 19, e02356. [Google Scholar] [CrossRef]

- Feng, N.L.; Malingam, S.D.; Subramaniam, K.; Selamat, M.Z.; Ali, M.B.; Bapokutty, O. The Influence of Fibre Stacking Configurations on the Indentation Behaviour of Pineapple Leaf/Glass Fibre Reinforced Hybrid Composites. Def. S T Tech. Bull. 2019, 12, 113–123. [Google Scholar]

- Indran, S.; Divya, D.; Raja, S.; Sanjay, M.R.; Siengchin, S. Physico-Chemical, Mechanical and Morphological Characterization of Furcraea selloa K.Koch Plant Leaf Fibers-An Exploratory Investigation. J. Nat. Fibers 2023, 20, 2146829. [Google Scholar] [CrossRef]

- Aruchamy, K.; Mylsamy, B.; Palaniappan, S.K.; Subramani, S.P.; Velayutham, T.; Rangappa, S.M.; Siengchin, S. Influence of Weave Arrangements on Mechanical Characteristics of Cotton and Bamboo Woven Fabric Reinforced Composite Laminates. J. Reinf. Plast. Compos. 2023, 42, 776–789. [Google Scholar] [CrossRef]

- Chandramohan, P.; Kalimuthu, M.; Subramanian, K.; Nagarajan, R.; Muhammed, F.; Al-Lohedan, H.; Krishnan, K. Mechanical and Thermo-Mechanical Behaviors of Snake Grass Fiber-Reinforced Epoxy Composite. BioResources 2024, 19, 1119–1135. [Google Scholar] [CrossRef]

- Feng, N.L.; Malingam, S.D.; Ping, C.W.; Selamat, M.Z. Mechanical Characterization of Metal-Composite Laminates Based on Cellulosic Kenaf and Pineapple Leaf Fiber. J. Nat. Fibers 2022, 19, 2163–2175. [Google Scholar] [CrossRef]

- Gedik, G. Extraction of New Natural Cellulosic Fiber from Trachelospermum Jasminoides (Star Jasmine) and Its Characterization for Textile and Composite Uses. Cellulose 2021, 28, 6899–6915. [Google Scholar] [CrossRef]

- Yaisun, S.; Trongsatitkul, T. PLA-Based Hybrid Biocomposites: Effects of Fiber Type, Fiber Content, and Annealing on Thermal and Mechanical Properties. Polymers 2023, 15, 4106. [Google Scholar] [CrossRef]

- Montreuil, A.; Mertz, G.; Bardon, J.; Guillot, J.; Grysan, P.; Addiego, F. Flax Fiber Treatment by an Alkali Solution and Poly(Dopamine) Coating: Effects on the Fiber Physico-Chemistry and Flax/Elium® Composite Interfacial Properties. Compos. Part A Appl. Sci. Manuf. 2024, 177, 107963. [Google Scholar] [CrossRef]

- Shibly, M.A.H.; Islam, M.I.; Rahat, M.N.H.; Billah, M.M.; Rahman, M.M.; Bashar, M.S.; Abdul, B.; Alorfi, H.S. Extraction and Characterization of a Novel Cellulosic Fiber Derived from the Bark of Rosa Hybrida Plant. Int. J. Biol. Macromol. 2024, 257, 128446. [Google Scholar] [CrossRef]

- Dahal, R.K.; Acharya, B.; Dutta, A. Mechanical, Thermal, and Acoustic Properties of Hemp and Biocomposite Materials: A Review. J. Compos. Sci. 2022, 6, 373. [Google Scholar] [CrossRef]

- Ganesan, K.; Kailasanathan, C.; Sanjay, M.R.; Senthamaraikannan, P.; Saravanakumar, S.S. A New Assessment on Mechanical Properties of Jute Fiber Mat with Egg Shell Powder/Nanoclay-Reinforced Polyester Matrix Composites. J. Nat. Fibers 2020, 17, 482–490. [Google Scholar] [CrossRef]

- Ng, L.F.; Yahya, M.Y.; Leong, H.Y.; Parameswaranpillai, J.; Dzulkifli, M.H. Evaluation of Physical and Mechanical Properties of Pineapple Leaf and Kenaf Fabrics as Potential Reinforcement in Bio-Composites. Biomass Convers. Biorefinery 2023, 1–10. [Google Scholar] [CrossRef]

- Vigneshwaran, S.; Sundarakannan, R.; John, K.M.; Joel Johnson, R.D.; Prasath, K.A.; Ajith, S.; Arumugaprabu, V.; Uthayakumar, M. Recent Advancement in the Natural Fiber Polymer Composites: A Comprehensive Review. J. Clean. Prod. 2020, 277, 124109. [Google Scholar] [CrossRef]

- Jayanth, D.; Kumar, P.S.; Nayak, G.C.; Kumar, J.S.; Pal, S.K.; Rajasekar, R. A Review on Biodegradable Polymeric Materials Striving Towards the Attainment of Green Environment. J. Polym. Environ. 2018, 26, 838–865. [Google Scholar] [CrossRef]

- Ong, H.C.; Mahlia, T.M.I.; Masjuki, H.H. A Review on Emissions and Mitigation Strategies for Road Transport in Malaysia. Renew. Sustain. Energy Rev. 2011, 15, 3516–3522. [Google Scholar] [CrossRef]

- Subramanian, G.K.M.; Balasubramanian, M.; Jeya Kumar, A.A. A Review on the Mechanical Properties of Natural Fiber Reinforced Compressed Earth Blocks. J. Nat. Fibers 2022, 19, 7687–7701. [Google Scholar] [CrossRef]

- Thapliyal, D.; Verma, S.; Sen, P.; Kumar, R.; Thakur, A.; Tiwari, A.K.; Singh, D.; Verros, G.D.; Arya, R.K. Natural Fibers Composites: Origin, Importance, Consumption Pattern, and Challenges. J. Compos. Sci. 2023, 7, 506. [Google Scholar] [CrossRef]

- Sathishkumar, G.K.; Ibrahim, M.; Mohamed Akheel, M.; Rajkumar, G.; Gopinath, B.; Karpagam, R.; Karthik, P.; Martin Charles, M.; Gautham, G.; Gowri Shankar, G. Synthesis and Mechanical Properties of Natural Fiber Reinforced Epoxy/Polyester/Polypropylene Composites: A Review. J. Nat. Fibers 2022, 19, 3718–3741. [Google Scholar] [CrossRef]

- Dang, C.Y.; Shen, X.J.; Nie, H.J.; Yang, S.; Shen, J.X.; Yang, X.H.; Fu, S.Y. Enhanced Interlaminar Shear Strength of Ramie Fiber/Polypropylene Composites by Optimal Combination of Graphene Oxide Size and Content. Compos. Part B Eng. 2019, 168, 488–495. [Google Scholar] [CrossRef]

- Ke, J.; Liu, L.; Wu, Z.; Le, Z.; Bao, L.; Luo, D. Torsional Mechanical Properties and Damage Mechanism of Glass Fiber-Ramie Hybrid Circular Tube. Compos. Struct. 2024, 327, 117680. [Google Scholar] [CrossRef]

- Zhang, X.; Yang, J.; Wang, Y.; Duan, C.; Liu, Y.; Lu, M. Study on the Ramie Fabric Treated with Copper Ammonia to Slenderize Fiber for Eliminating Prickle. J. Nat. Fibers 2023, 20, 2120150. [Google Scholar] [CrossRef]

- Gadzama, S.W.; Sunmonu, O.K.; Isiaku, U.S.; Danladi, A. Effects of Surface Modifications on the Mechanical Properties of Reinforced Pineapple Leaf Fibre Polypropylene Composites. Adv. Chem. Eng. Sci. 2020, 10, 24–39. [Google Scholar] [CrossRef]

- Gaba, E.W.; Asimeng, B.O.; Kaufmann, E.E.; Katu, S.K.; Foster, E.J.; Tiburu, E.K. Mechanical and Structural Characterization of Pineapple Leaf Fiber. Fibers 2021, 9, 51. [Google Scholar] [CrossRef]

- Tanpichai, S.; Witayakran, S. All-Cellulose Composites from Pineapple Leaf Microfibers: Structural, Thermal, and Mechanical Properties. Polym. Compos. 2018, 39, 895–903. [Google Scholar] [CrossRef]

- Ng, L.F.; Yahya, M.Y.; Muthukumar, C. Mechanical Characterization and Water Absorption Behaviors of Pineapple Leaf/Glass Fiber-Reinforced Polypropylene Hybrid Composites. Polym. Compos. 2022, 43, 203–214. [Google Scholar] [CrossRef]

- Feng, N.L.; Malingam, S.D.; Subramaniam, K.; Selamat, M.Z.; Juan, W.X. The Investigation of the Tensile and Quasi-Static Indentation Properties of Pineapple Leaf / Kevlar Fibre Reinforced Hybrid Composites. Def. S T Tech. Bull. 2020, 13, 117–129. [Google Scholar]

- Prasad, L.; Kapri, P.; Patel, R.V.; Yadav, A.; Winczek, J. Physical and Mechanical Behavior of Ramie and Glass Fiber Reinforced Epoxy Resin-Based Hybrid Composites. J. Nat. Fibers 2023, 20, 2234080. [Google Scholar] [CrossRef]

- Thiyagu, C.; Narendrakumar, U. Vibrational Analysis of Glass/Ramie Fiber Reinforced Hybrid Polymer Composite. Polym. Compos. 2022, 43, 1395–1406. [Google Scholar] [CrossRef]

- Bakhori, S.N.M.; Hassan, M.Z.; Bakhori, N.M.; Rashedi, A.; Mohammad, R.; Md Daud, M.Y.; Aziz, S.A.; Ramlie, F.; Kumar, A.; Naveen, J. Mechanical Properties of PALF/Kevlar-Reinforced Unsaturated Polyester Hybrid Composite Laminates. Polymers 2022, 14, 2468. [Google Scholar] [CrossRef] [PubMed]

- Velmurugan, G. Experimental Investigations of Physical and Mechanical Properties of Pineapple Leaf/Carbon Fiber–Reinforced Unsaturated Polyester Composites at Liquid Nitrogen Environment. Biomass Convers. Biorefin. 2023. [Google Scholar] [CrossRef]

- Ramasubbu, R.; Madasamy, S. Fabrication of Automobile Component Using Hybrid Natural Fiber Reinforced Polymer Composite. J. Nat. Fibers 2022, 19, 736–746. [Google Scholar] [CrossRef]

- Bekele, A.E.; Lemu, H.G.; Jiru, M.G. Exploration of Mechanical Properties of Enset–Sisal Hybrid Polymer Composite. Fibers 2022, 10, 14. [Google Scholar] [CrossRef]

- Tezara, C.; Hadi, A.E.; Siregar, J.P.; Muhamad, Z.; Hamdan, M.H.M.; Oumer, A.N.; Jaafar, J.; Irawan, A.P.; Rihayat, T.; Fitriyana, D.F. The Effect of Hybridisation on Mechanical Properties and Water Absorption Behaviour of Woven Jute/Ramie Reinforced Epoxy Composites. Polymers 2021, 13, 2964. [Google Scholar] [CrossRef] [PubMed]

- Feng, N.L.; Malingam, S.D.; Ping, C.W.; Razali, N. Mechanical Properties and Water Absorption of Kenaf/Pineapple Leaf Fiber-Reinforced Polypropylene Hybrid Composites. Polym. Compos. 2020, 41, 1255–1264. [Google Scholar] [CrossRef]

- Ismail, A.S.; Jawaid, M.; Sultan, M.T.H.; Hassan, A. Physical and Mechanical Properties of Woven Kenaf/Bamboo Fiber Mat Reinforced Epoxy Hybrid Composites. BioResources 2019, 14, 1390–1404. [Google Scholar] [CrossRef]

- Dittenber, D.B.; Gangarao, H.V.S. Critical Review of Recent Publications on Use of Natural Composites in Infrastructure. Compos. Part A Appl. Sci. Manuf. 2012, 43, 1419–1429. [Google Scholar] [CrossRef]

- Cherian, B.M.; Leão, A.L.; de Souza, S.F.; Thomas, S.; Pothan, L.A.; Kottaisamy, M. Isolation of Nanocellulose from Pineapple Leaf Fibres by Steam Explosion. Carbohydr. Polym. 2010, 81, 720–725. [Google Scholar] [CrossRef]

- Maslinda, A.B.; Abdul Majid, M.S.; Ridzuan, M.J.M.; Afendi, M.; Gibson, A.G. Effect of Water Absorption on the Mechanical Properties of Hybrid Interwoven Cellulosic-Cellulosic Fibre Reinforced Epoxy Composites. Compos. Struct. 2017, 167, 227–237. [Google Scholar] [CrossRef]

- Sahu, P.; Gupta, M.K. Water Absorption Behavior of Cellulosic Fibres Polymer Composites: A Review on Its Effects and Remedies. J. Ind. Text. 2022, 51, 7480S–7512S. [Google Scholar] [CrossRef]

- Yahaya, R.; Sapuan, S.M.; Jawaid, M.; Leman, Z.; Zainudin, E.S. Effect of Fibre Orientations on the Mechanical Properties of Kenaf–Aramid Hybrid Composites for Spall-Liner Application. Def. Technol. 2016, 12, 52–58. [Google Scholar] [CrossRef]

- Ghani, M.U.; Siddique, A.; Abraha, K.G.; Yao, L.; Li, W.; Khan, M.Q.; Kim, I.S. Performance Evaluation of Jute/Glass-Fiber-Reinforced Polybutylene Succinate (PBS) Hybrid Composites with Different Layering Configurations. Materials 2022, 15, 1055. [Google Scholar] [CrossRef]

- Azlin, M.N.M.; Sapuan, S.M.; Zuhri, M.Y.M.; Zainudin, E.S. Effect of Stacking Sequence and Fiber Content on Mechanical and Morphological Properties of Woven Kenaf/Polyester Fiber Reinforced Polylactic Acid (PLA) Hybrid Laminated Composites. J. Mater. Res. Technol. 2022, 16, 1190–1201. [Google Scholar] [CrossRef]

- Patti, A.; Acierno, D. Materials, Weaving Parameters, and Tensile Responses of Woven Textiles. Macromol 2023, 3, 665–680. [Google Scholar] [CrossRef]

- Asgarinia, S.; Viriyasuthee, C.; Phillips, S.; Dube, M.; Baets, J.; Van Vuure, a.; Verpoest, I.; Lessard, L. Tension-Tension Fatigue Behaviour of Woven Flax/Epoxy Composites. J. Reinf. Plast. Compos. 2015, 34, 857–867. [Google Scholar] [CrossRef]

- Kusmono; Hestiawan, H. Jamasri The Water Absorption, Mechanical and Thermal Properties of Chemically Treated Woven Fan Palm Reinforced Polyester Composites. J. Mater. Res. Technol. 2020, 9, 4410–4420. [Google Scholar] [CrossRef]

- Yorseng, K.; Rangappa, S.M.; Parameswaranpillai, J.; Siengchin, S. Influence of Accelerated Weathering on the Mechanical, Fracture Morphology, Thermal Stability, Contact Angle, and Water Absorption Properties of Natural Fiber Fabric-Based Epoxy Hybrid Composites. Polymers 2020, 12, 2254. [Google Scholar] [CrossRef]

- Mohammed, M.; Jawad, A.J.A.M.; Mohammed, A.M.; Oleiwi, J.K.; Adam, T.; Osman, A.F.; Dahham, O.S.; Betar, B.O.; Gopinath, S.C.B.; Jaafar, M. Challenges and Advancement in Water Absorption of Natural Fiber-Reinforced Polymer Composites. Polym. Test. 2023, 124, 108083. [Google Scholar] [CrossRef]

- Espert, A.; Vilaplana, F.; Karlsson, S. Comparison of Water Absorption in Natural Cellulosic Fibres from Wood and One-Year Crops in Polypropylene Composites and Its Influence on Their Mechanical Properties. Compos. Part A Appl. Sci. Manuf. 2004, 35, 1267–1276. [Google Scholar] [CrossRef]

- Almeida-Naranjo, C.E.; Valle, V.; Aguilar, A.; Cadena, F.; Kreiker, J.; Raggiotti, B. Water Absorption Behavior of Oil Palm Empty Fruit Bunch (OPEFB) and Oil Palm Kernel Shell (OPKS) as Fillers in Acrylic Thermoplastic Composites. Materials 2022, 15, 5015. [Google Scholar] [CrossRef]

- Nosbi, N.; Akil, H.M.; Mohd Ishak, Z.A.; Abu Bakar, A. Behavior of Kenaf Fibers after Immersion in Several Water Conditions. BioResources 2011, 6, 950–960. [Google Scholar] [CrossRef]

- Kamaruddin, Z.H.; Jumaidin, R.; Ilyas, R.A.; Selamat, M.Z.; Alamjuri, R.H.; Md Yusof, F.A. Influence of Alkali Treatment on the Mechanical, Thermal, Water Absorption, and Biodegradation Properties of Cymbopogan Citratus Fiber-Reinforced, Thermoplastic Cassava Starch–Palm Wax Composites. Polymers 2022, 14, 2769. [Google Scholar] [CrossRef]

| Properties | Ramie | PALF |

|---|---|---|

| Density (g/cm3) | 1.0–1.55 | 0.8–1.6 |

| TS (MPa) | 400–1000 | 180–1627 |

| Elastic modulus (GPa) | 24.5–128 | 1.44–82.5 |

| Cellulose (%) | 68.6–85.0 | 81.27 |

| Hemicellulose (%) | 13.0–16.7 | 12.31 |

| Lignin (%) | 0.5–0.7 | 3.46 |

| Fiber Layup | Fiber Weight Fraction (%) | Fiber Volume Fraction (%) | ||

|---|---|---|---|---|

| PALF | Ramie | Total | ||

| [P1] | 28.91 ± 0.76 | 24.30 ± 0.63 | – | 24.30 ± 0.63 |

| [H2] | 29.60 ± 0.75 | 23.45 ± 0.48 | 8.68 ± 0.28 | 32.13 ± 0.76 |

| [H3] | 32.36 ± 1.35 | 8.04 ± 0.01 | 18.73 ±0.03 | 26.77 ± 0.04 |

| [R4] | 34.56 ± 0.90 | – | 28.77 ± 0.38 | 28.77 ± 0.38 |

| Fabric Stacking Configuration | Tensile Properties | Flexural Properties | ||

|---|---|---|---|---|

| TS (MPa) | TM (GPa) | FS (MPa) | TM (GPa) | |

| [R4] | 84.82 ± 1.72 | 1.29 ± 0.25 | 88.30 ± 1.39 | 3.73 ± 0.32 |

| [H3] | 63.35 ± 1.19 | 1.60 ± 0.16 | 75.13 ± 1.44 | 3.25 ± 0.24 |

| [H2] | 44.39 ± 1.94 | 1.78 ± 0.15 | 66.76 ± 0.31 | 2.91 ± 0.17 |

| [P1] | 41.65 ± 2.27 | 1.94 ± 0.18 | 63.25 ± 2.74 | 2.87 ± 0.34 |

| Fabric Stacking Configuration | Water Uptake Percentage at Saturation Point (%) | Diffusion Coefficient, D × 10−8 (m2/s) | Sorption Coefficient | Permeability Coefficient, P × 10−8 (m2/s) |

|---|---|---|---|---|

| [R4] | 6.14 | 1.97 | 3.21 | 6.32 |

| [H3] | 5.31 | 0.84 | 3.52 | 2.96 |

| [H2] | 4.92 | 0.57 | 4.13 | 2.35 |

| [P1] | 4.54 | 0.43 | 4.63 | 1.99 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ng, L.F.; Yahya, M.Y.; Muthukumar, C.; Parameswaranpillai, J.; Ma, Q.; Muhammad Asyraf, M.R.; Abdul Majid, R. Mechanical Characterization, Water Absorption, and Thickness Swelling of Lightweight Pineapple Leaf/Ramie Fabric-Reinforced Polypropylene Hybrid Composites. Polymers 2024, 16, 1847. https://doi.org/10.3390/polym16131847

Ng LF, Yahya MY, Muthukumar C, Parameswaranpillai J, Ma Q, Muhammad Asyraf MR, Abdul Majid R. Mechanical Characterization, Water Absorption, and Thickness Swelling of Lightweight Pineapple Leaf/Ramie Fabric-Reinforced Polypropylene Hybrid Composites. Polymers. 2024; 16(13):1847. https://doi.org/10.3390/polym16131847

Chicago/Turabian StyleNg, Lin Feng, Mohd Yazid Yahya, Chandrasekar Muthukumar, Jyotishkumar Parameswaranpillai, Quanjin Ma, Muhammad Rizal Muhammad Asyraf, and Rohah Abdul Majid. 2024. "Mechanical Characterization, Water Absorption, and Thickness Swelling of Lightweight Pineapple Leaf/Ramie Fabric-Reinforced Polypropylene Hybrid Composites" Polymers 16, no. 13: 1847. https://doi.org/10.3390/polym16131847

APA StyleNg, L. F., Yahya, M. Y., Muthukumar, C., Parameswaranpillai, J., Ma, Q., Muhammad Asyraf, M. R., & Abdul Majid, R. (2024). Mechanical Characterization, Water Absorption, and Thickness Swelling of Lightweight Pineapple Leaf/Ramie Fabric-Reinforced Polypropylene Hybrid Composites. Polymers, 16(13), 1847. https://doi.org/10.3390/polym16131847