Preparation of Gradient Polyurethane and Its Performance for Flexible Sensors

Abstract

1. Introduction

2. Materials and Methods

2.1. Chemicals and Reagents

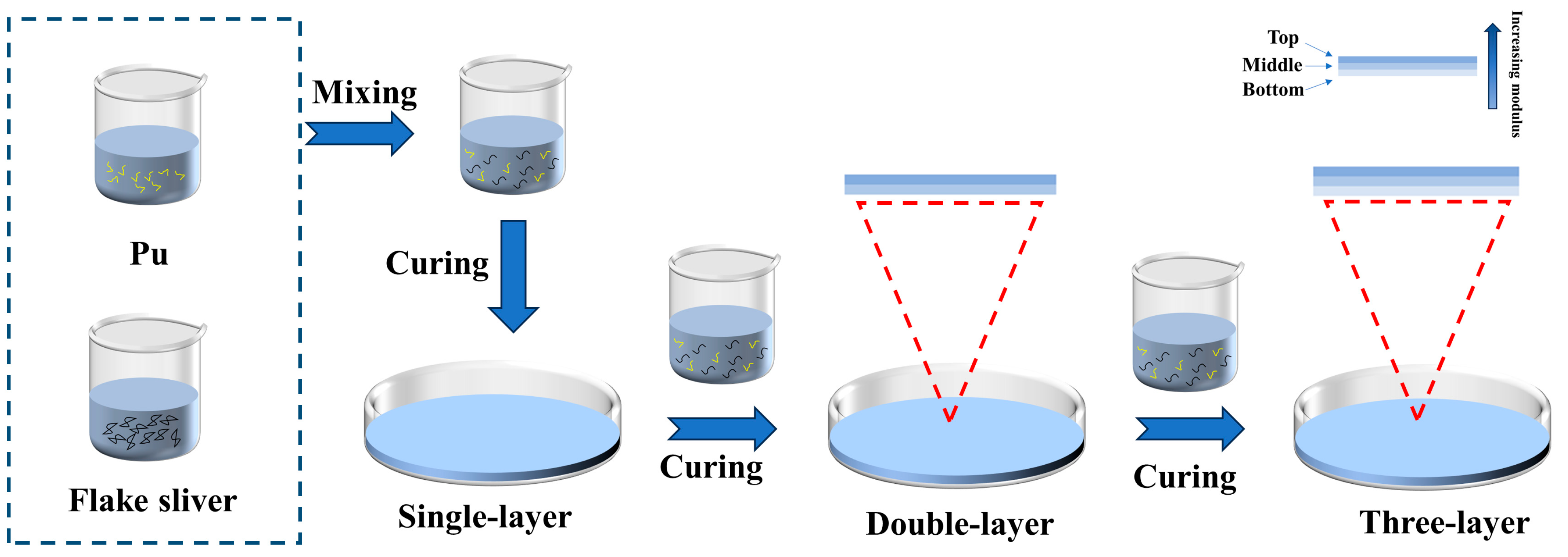

2.2. Preparation of Gradient Polyurethane and Gradient Polyurethane Composites

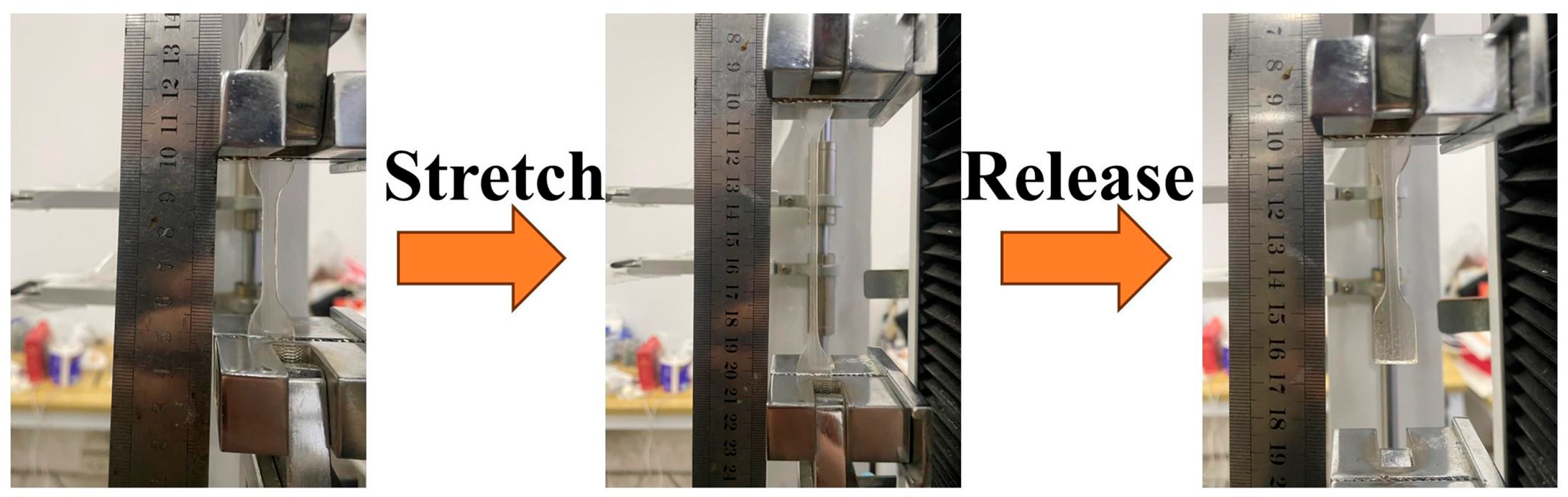

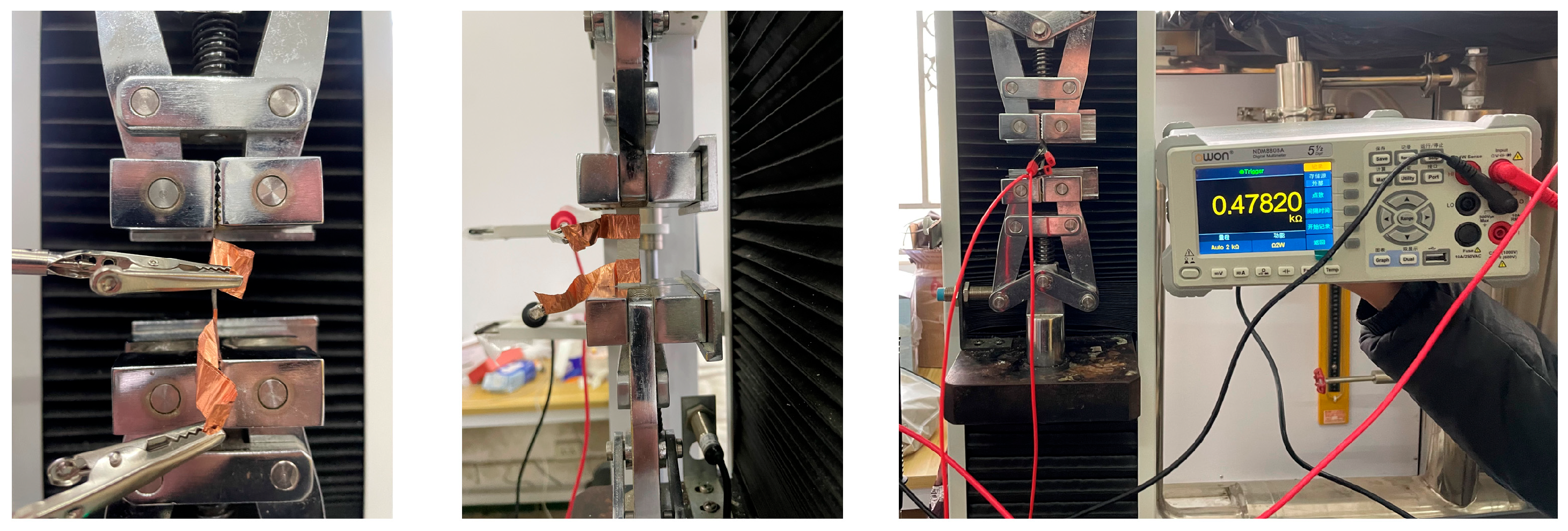

2.3. Tensile Testing (Stress–Strain Curves)

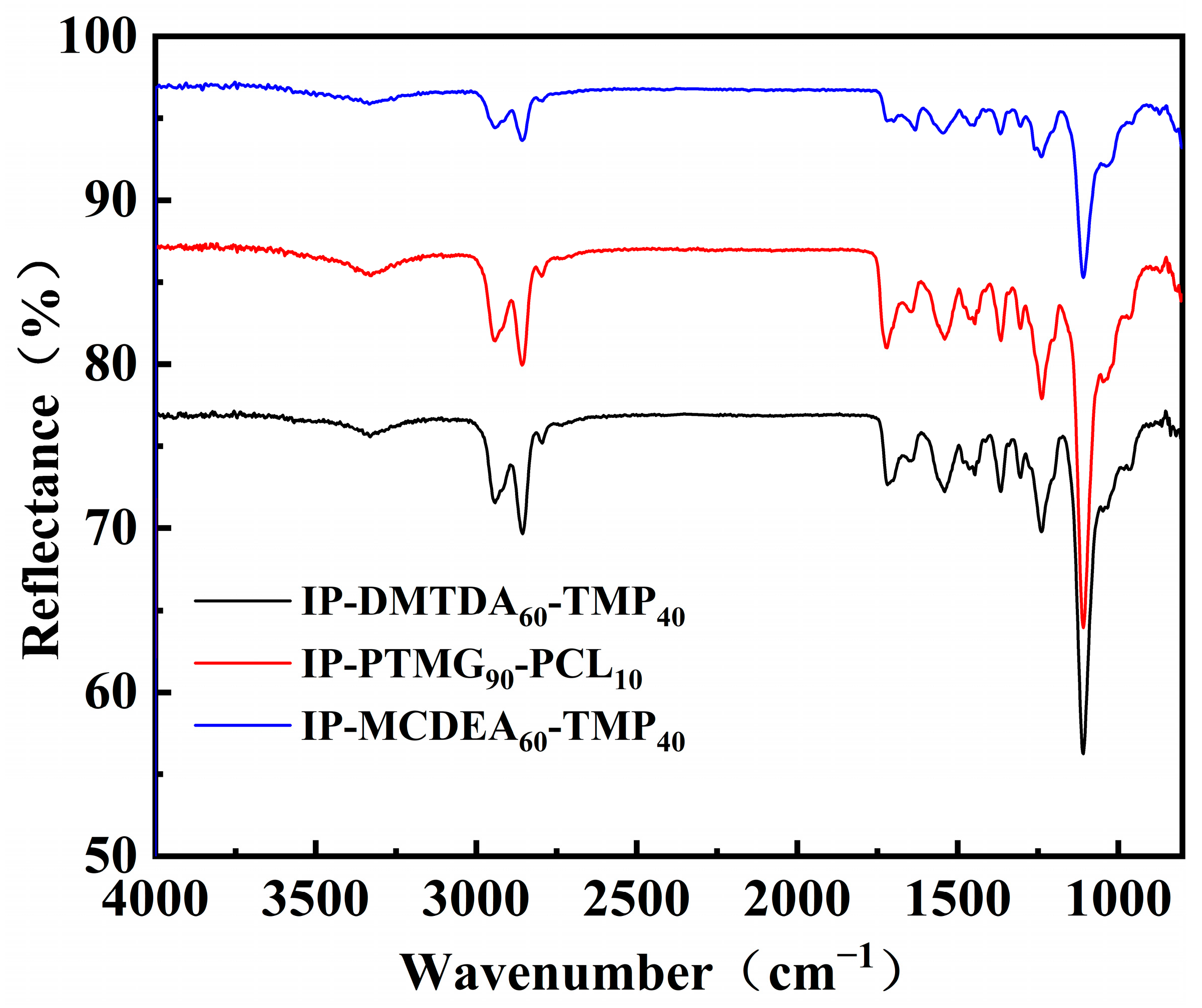

2.4. Attenuated Total Reflection Fourier Transform Infrared Spectroscopy (ATR-FTIR)

2.5. Recovery Time and Residual Strain Testing

2.6. Sensing Performance

3. Results

3.1. Preparation of Gradient Polyurethanes and Polyurethane Layers with Properties of Tensile Strength and Modulus of Elasticity

3.2. Recovery Time and Residual Strain of Gradient Polyurethane with Layers of Polyurethane

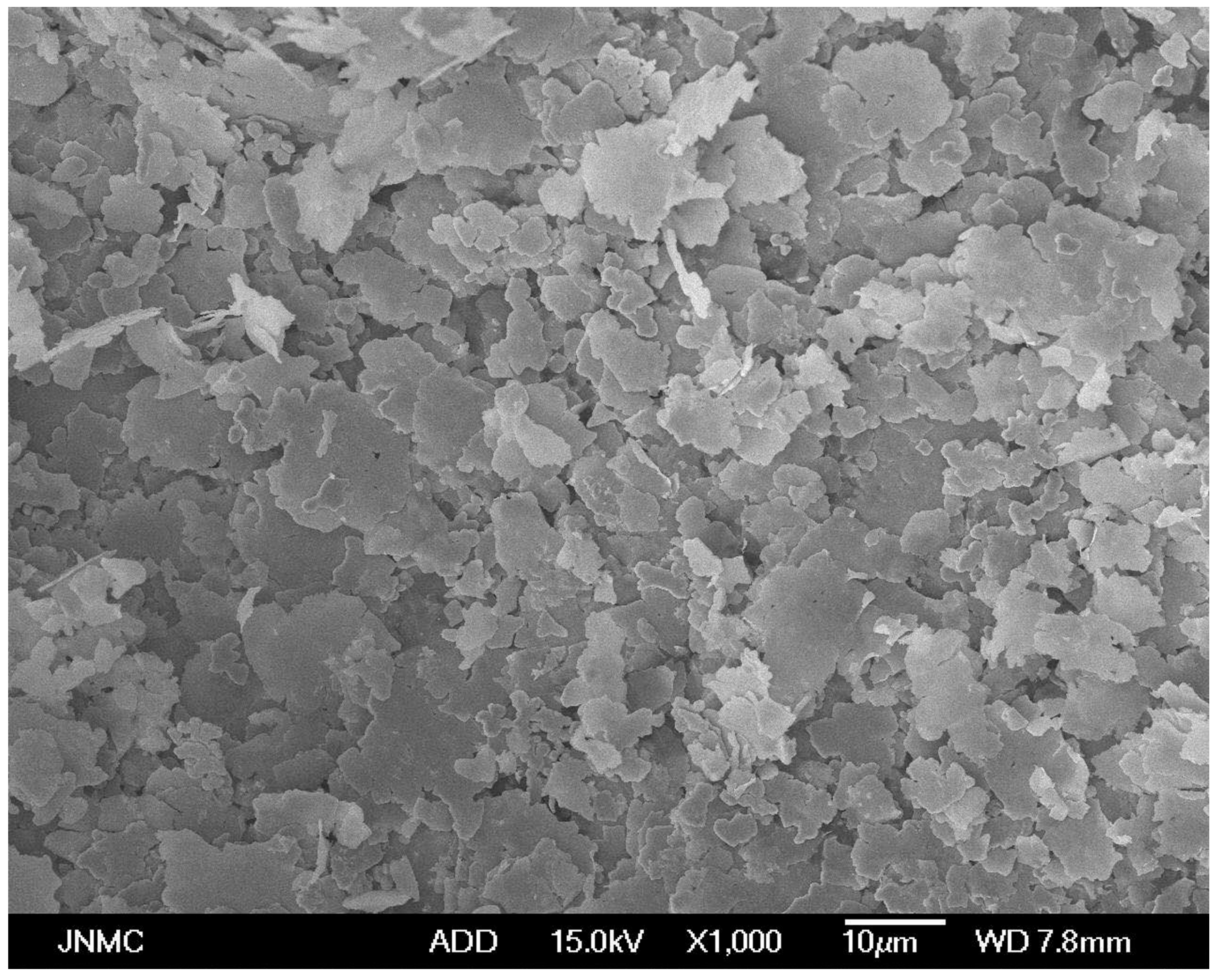

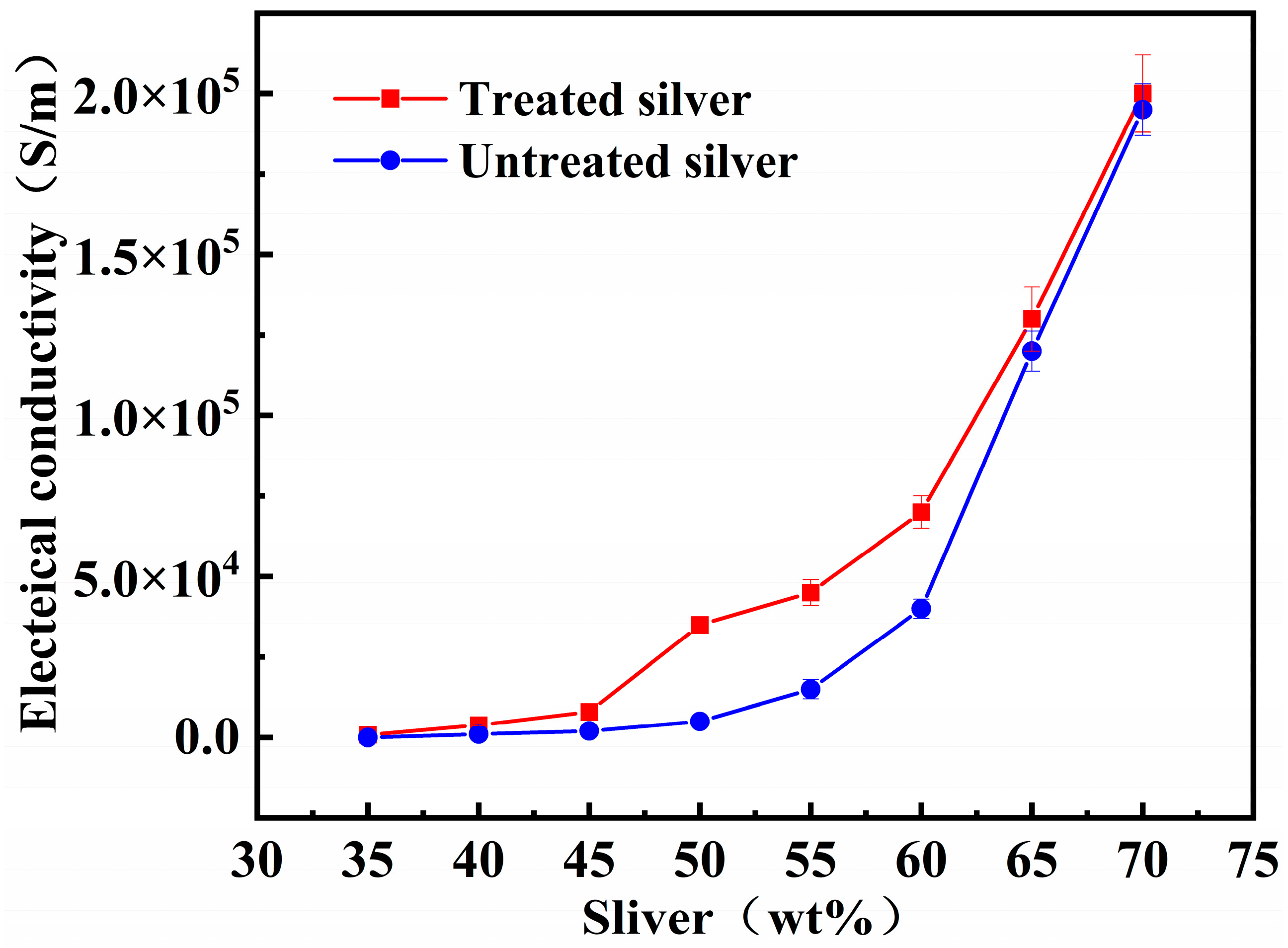

3.3. Conductivity of the Bottom Polyurethane as a Function of the Mass Fraction of Silver Flake Powder

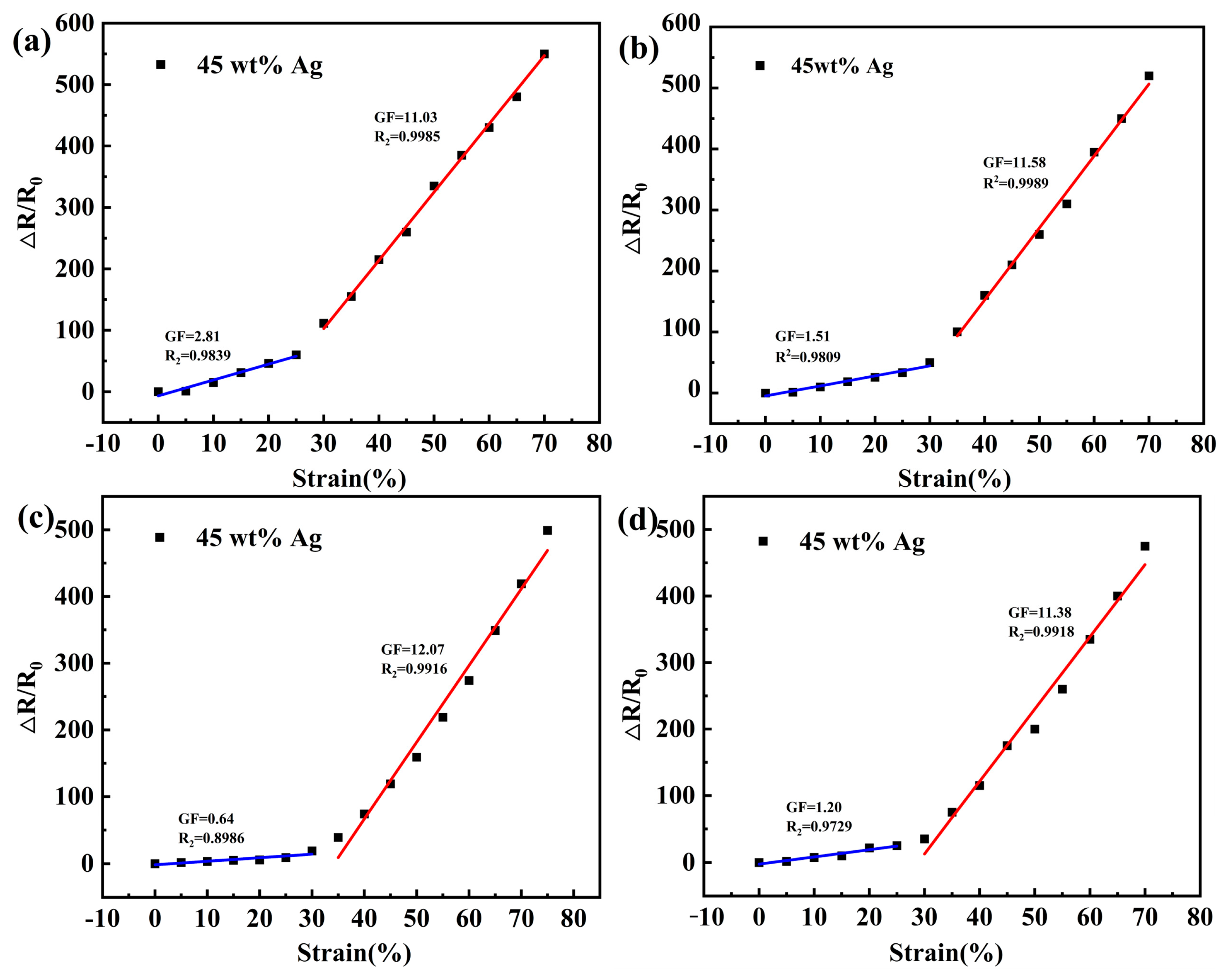

3.4. Mechanical Properties of and Ag/Gradient Polyurethane Composites

3.5. Strain Sensing Performance

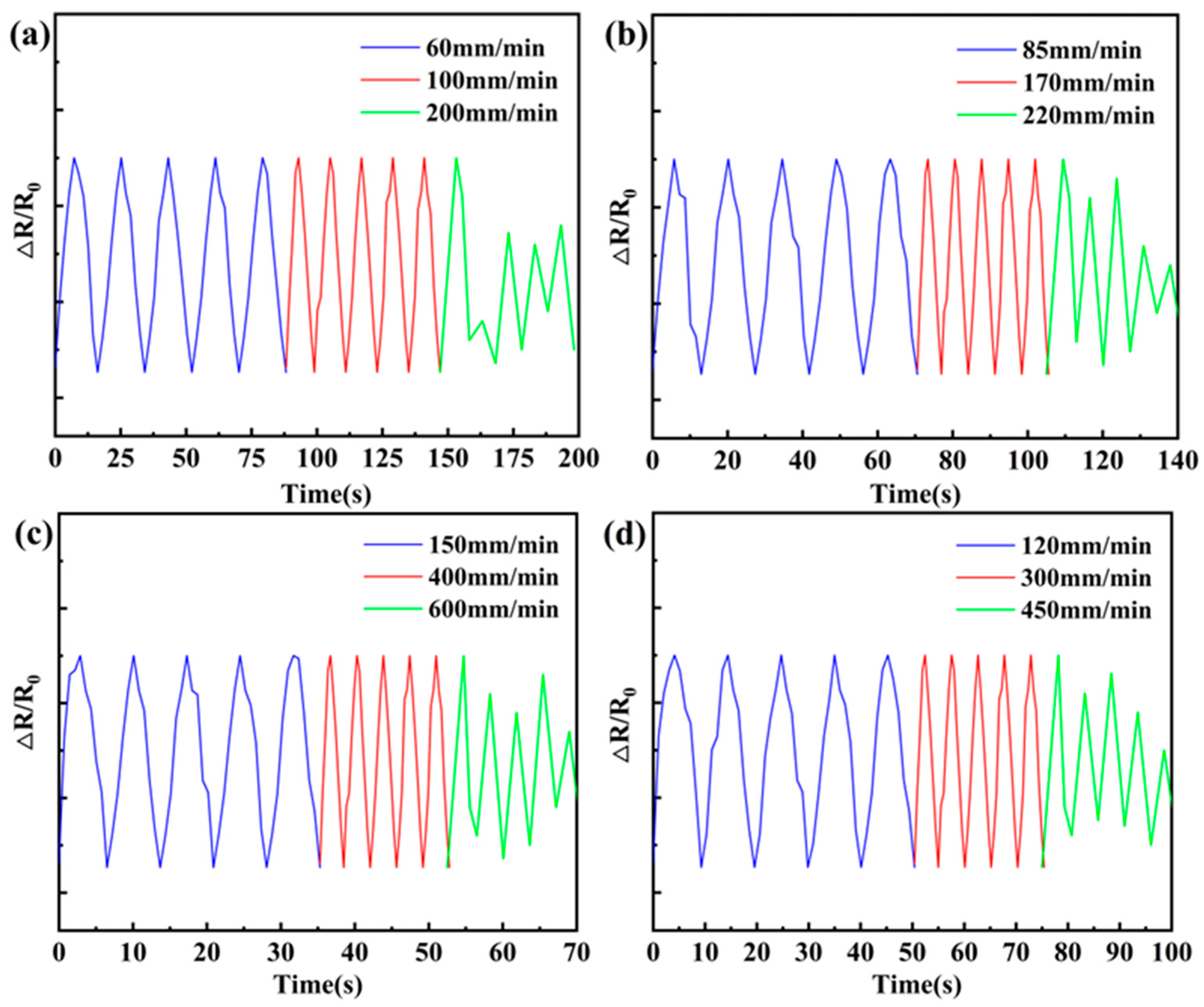

3.6. Different Cyclic Strain Frequencies

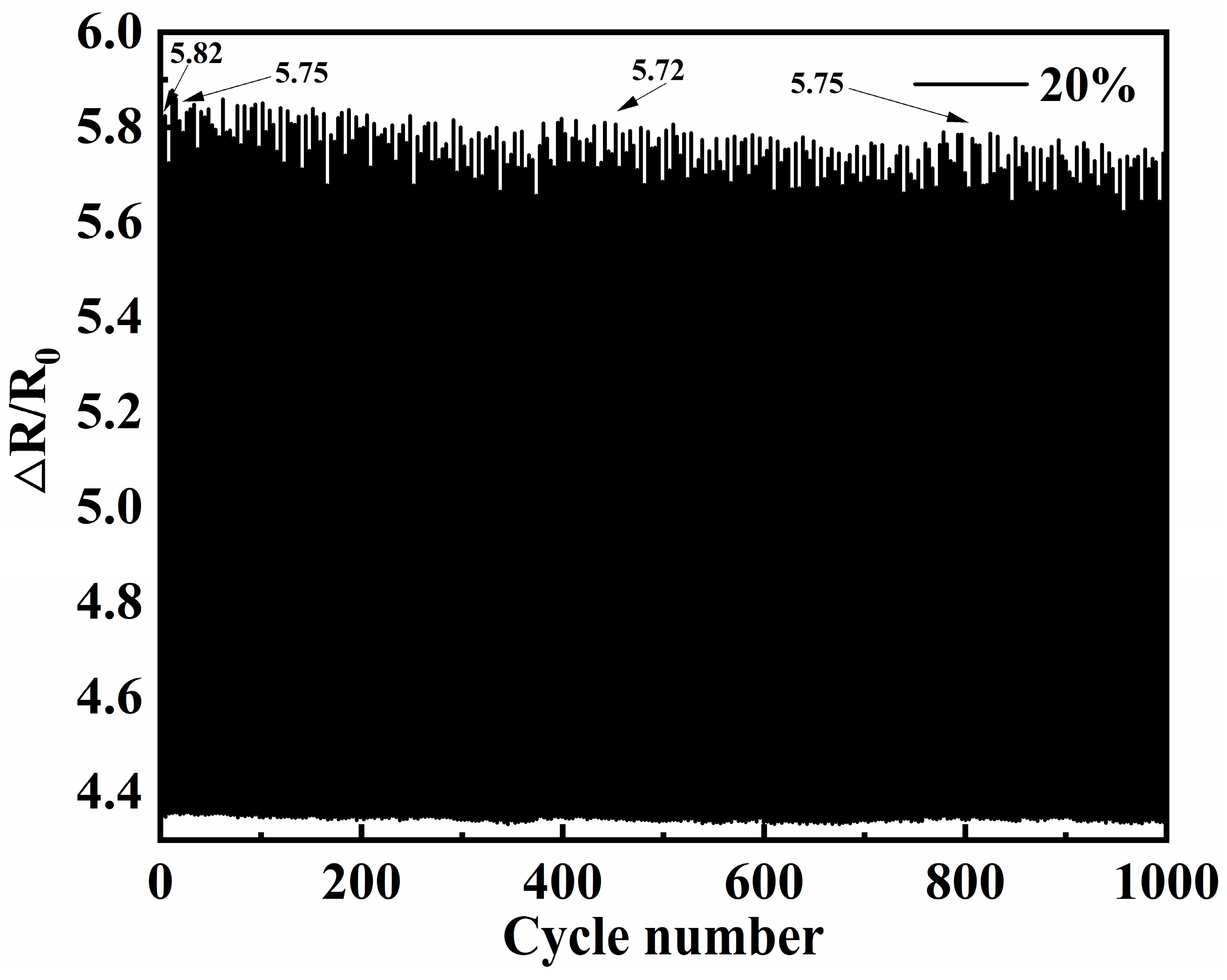

3.7. Fatigue Resistance

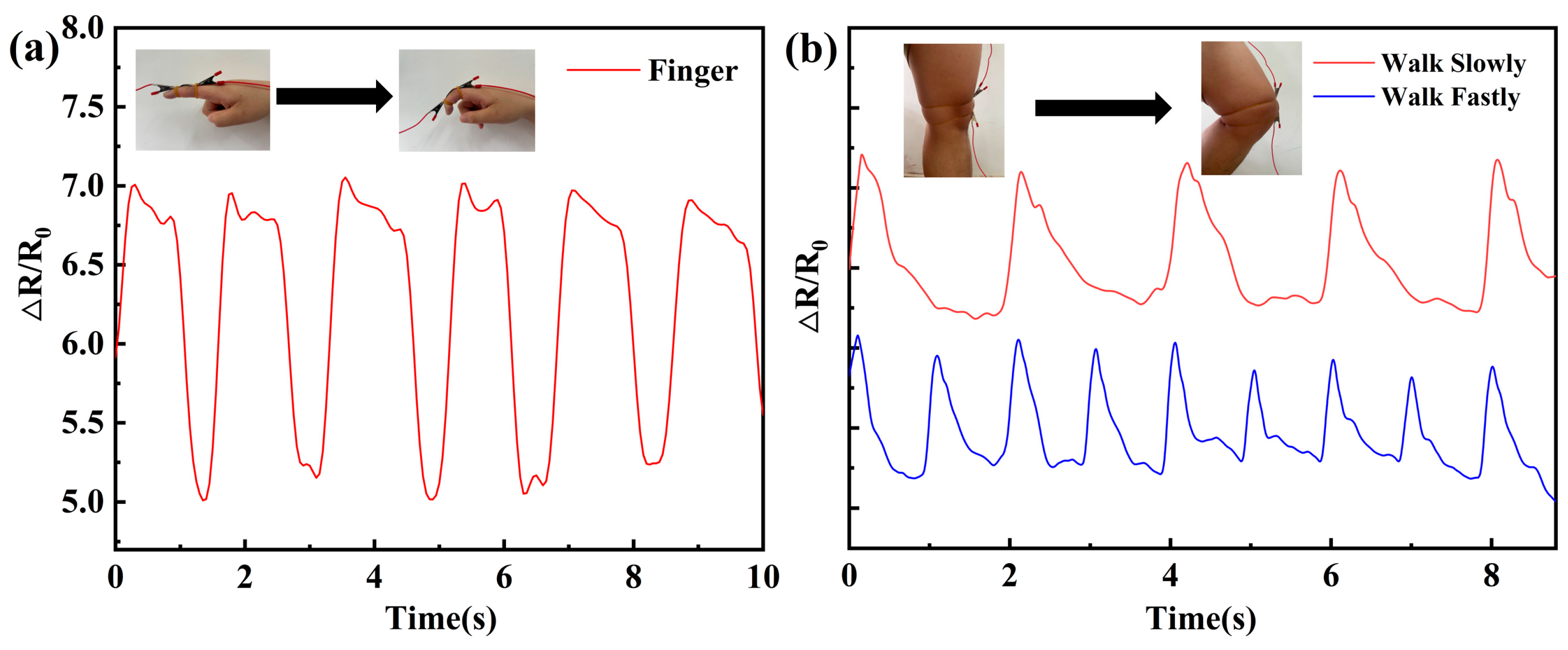

3.8. Human Motion Detection

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhang, J.; Sun, T.; Chen, Y.; Liu, L.; Zhao, H.; Zhang, C.; Meng, X.; Wang, D.; Hu, Z.; Zhang, H.; et al. Nanowires in Flexible Sensors: Structure Is Becoming a Key in Controlling the Sensing Performance. Adv. Mater. Technol. 2022, 7, 2200163. [Google Scholar] [CrossRef]

- Huang, Y.; Peng, C.; Li, Y.; Yang, Y.; Feng, W. Elastomeric Polymers for Conductive Layers of Flexible Sensors: Materials, Fabrication, Performance, and Applications. Aggregate 2023, 4, e319. [Google Scholar] [CrossRef]

- Lin, J.X.; Hu, H.W.; Luo, J.; Miao, L.; Yang, Z.H.; Chen, M.; Zhang, M.; Ou, J.Z. Micro/Nanoarrays and Their Applications in Flexible Sensors: A Review. Mater. Today Nano 2022, 19, 100224. [Google Scholar] [CrossRef]

- Wu, F.; Li, Y.; Zhang, H.; Jiang, H.; Wei, W.; Deng, C. Self-Powered Ultra-Flexible Infrared Sensor Based on PVA-PEDOT: PSS/Ti3C2Tx Composite Film. Appl. Surf. Sci. 2023, 639, 158212. [Google Scholar] [CrossRef]

- Wang, S.; Fang, Y.; He, H.; Zhang, L.; Li, C.; Ouyang, J. Wearable Stretchable Dry and Self-Adhesive Strain Sensors with Conformal Contact to Skin for High-Quality Motion Monitoring. Adv. Funct. Mater. 2021, 31, 2007495. [Google Scholar] [CrossRef]

- Xiao, X.; Zheng, Z.; Zhong, X.; Gao, R.; Piao, Z.; Jiao, M.; Zhou, G. Rational Design of Flexible Zn-Based Batteries for Wearable Electronic Devices. ACS Nano 2023, 17, 1764–1802. [Google Scholar] [CrossRef]

- Zhang, Y.; Lin, H.; Zhang, L.; Peng, S.; Weng, Z.; Wang, J.; Wu, L.; Zheng, L. Mechanical Exfoliation Assisted with Carbon Nanospheres to Prepare a Few-Layer Graphene for Flexible Strain Sensor. Appl. Surf. Sci. 2023, 611, 155649. [Google Scholar] [CrossRef]

- Lu, M.; Huang, C.; Xu, Z.; Yuan, Y.; Wang, M.; Xiao, M.; Zhang, L.; Wan, P. A Skin-Bioinspired Urchin-Like Microstructure-Contained Photothermal-Therapy Flexible Electronics for Ultrasensitive Human-Interactive Sensing. Adv. Funct. Mater. 2023, 33, 2306591. [Google Scholar] [CrossRef]

- Kong, H.; Lu, L.; Yu, J.; Chen, Y.; Tang, F. Continuous Authentication Through Finger Gesture Interaction for Smart Homes Using WiFi. IEEE Trans. Mob. Comput. 2021, 20, 3148–3162. [Google Scholar] [CrossRef]

- Liang, J.; Sheng, H.; Ma, H.; Wang, P.; Wang, Q.; Yuan, J.; Zhang, X.; Shao, M.; Li, W.; Xie, E.; et al. Transparent Electronic Skin from the Integration of Strain Sensors and Supercapacitors. Adv. Mater. Technol. 2023, 8, 2201234. [Google Scholar] [CrossRef]

- He, Y.; Xu, X.; Xiao, S.; Wu, J.; Zhou, P.; Chen, L.; Liu, H. Research Progress and Application of Multimodal Flexible Sensors for Electronic Skin. ACS Sens. 2024, 9, 2275–2293. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Zhang, Y.; Li, Y.; Wang, P. Textile-Based Flexible Pressure Sensors: A Review. Polym. Rev. 2022, 62, 65–94. [Google Scholar] [CrossRef]

- Shu, Q. Flexible Resistive Tactile Pressure Sensors. J. Mater. Chem. A 2024, 12, 9296–9321. [Google Scholar] [CrossRef]

- Song, Y.; Chen, L.; Yang, Q.; Liu, G.; Yu, Q.; Xie, X.; Chen, C.; Liu, J.; Chao, G.; Chen, X.; et al. Graphene-Based Flexible Sensors for Respiratory and Airflow Monitoring. ACS Appl. Nano Mater. 2023, 6, 8937–8944. [Google Scholar] [CrossRef]

- Wang, Z.; Zhou, Z.; Tian, Y.; Lei, D.; Liu, Y.; Huang, T.; Tang, Q.; Zhang, Y.; Wang, D. Semi-Solid Stretchable Carbon Nanotubes Inkpad for Hand-Based Haptic Interaction. Adv. Mater. Technol. 2024, 9, 2301877. [Google Scholar] [CrossRef]

- Feng, Y.; Liu, H.; Zhu, W.; Guan, L.; Yang, X.; Zvyagin, A.V.; Zhao, Y.; Shen, C.; Yang, B.; Lin, Q. Muscle-Inspired MXene Conductive Hydrogels with Anisotropy and Low-Temperature Tolerance for Wearable Flexible Sensors and Arrays. Adv. Funct. Mater. 2021, 31, 2105264. [Google Scholar] [CrossRef]

- Bai, S.; Zhang, S.; Zhou, W.; Ma, D.; Ma, Y.; Joshi, P.; Hu, A. Laser-Assisted Reduction of Highly Conductive Circuits Based on Copper Nitrate for Flexible Printed Sensors. Nano-Micro Lett. 2017, 9, 42. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; He, P.; Luo, M.; Xu, X.; Dai, G.; Yang, J. Highly Stretchable Polymer/Silver Nanowires Composite Sensor for Human Health Monitoring. Nano Res. 2020, 13, 919–926. [Google Scholar] [CrossRef]

- Jiang, Y.; He, Q.; Cai, J.; Shen, D.; Hu, X.; Zhang, D. Flexible Strain Sensor with Tunable Sensitivity via Microscale Electrical Breakdown in Graphene/Polyimide Thin Films. ACS Appl. Mater. Interfaces 2020, 12, 58317–58325. [Google Scholar] [CrossRef]

- Li, M.; Chen, X.; Li, X.; Dong, J.; Zhao, X.; Zhang, Q. Wearable and Robust Polyimide Hydrogel Fiber Textiles for Strain Sensors. ACS Appl. Mater. Interfaces 2021, 13, 43323–43332. [Google Scholar] [CrossRef]

- Shi, J.; Wang, Z.; Zheng, T.; Liu, X.; Guo, B.; Xu, J. Thermal and UV Light Adaptive Polyurethane Elastomers for Photolithography-Transfer Printing of Flexible Circuits. Mater. Horiz. 2022, 9, 3070–3077. [Google Scholar] [CrossRef]

- Pan, X.; Li, J.; Ma, N.; Ma, X.; Gao, M. Bacterial Cellulose Hydrogel for Sensors. Chem. Eng. J. 2023, 461, 142062. [Google Scholar] [CrossRef]

- Li, X.-P.; Li, Y.; Li, X.; Song, D.; Min, P.; Hu, C.; Zhang, H.-B.; Koratkar, N.; Yu, Z.-Z. Highly Sensitive, Reliable and Flexible Piezoresistive Pressure Sensors Featuring Polyurethane Sponge Coated with MXene Sheets. J. Colloid Interface Sci. 2019, 542, 54–62. [Google Scholar] [CrossRef]

- Mitsuzuka, M.; Takarada, J.; Kawahara, I.; Morimoto, R.; Wang, Z.; Kawamura, S.; Tajitsu, Y. Application of High-Photoelasticity Polyurethane to Tactile Sensor for Robot Hands. Polymers 2022, 14, 5057. [Google Scholar] [CrossRef] [PubMed]

- Zhang, F.; Hu, H.; Hu, S.; Yue, J. Significant Strain-Rate Dependence of Sensing Behavior in TiO2@carbon Fibre/PDMS Composites for Flexible Strain Sensors. J. Adv. Ceram. 2021, 10, 1350–1359. [Google Scholar] [CrossRef]

- Gao, K.; Song, J.; Niu, Q.; Tang, Q.; Sun, X.; Wang, L. Wood-Based Aligned Carbon Microtubule Array Flexible Strain Sensor with High Sensitivity. J. Mater. Sci. 2023, 58, 13009–13018. [Google Scholar] [CrossRef]

- Xia, S.; Zhang, Q.; Song, S.; Duan, L.; Gao, G. Bioinspired Dynamic Cross-Linking Hydrogel Sensors with Skin-like Strain and Pressure Sensing Behaviors. Chem. Mater. 2019, 31, 9522–9531. [Google Scholar] [CrossRef]

- Wang, H.; Zhou, R.; Li, D.; Zhang, L.; Ren, G.; Wang, L.; Liu, J.; Wang, D.; Tang, Z.; Lu, G.; et al. High-Performance Foam-Shaped Strain Sensor Based on Carbon Nanotubes and Ti3C2Tx MXene for the Monitoring of Human Activities. ACS Nano 2021, 15, 9690–9700. [Google Scholar] [CrossRef] [PubMed]

- Fang, Y.; Xu, J.; Gao, F.; Du, X.; Du, Z.; Cheng, X.; Wang, H. Self-Healable and Recyclable Polyurethane-Polyaniline Hydrogel toward Flexible Strain Sensor. Compos. Part B Eng. 2021, 219, 108965. [Google Scholar] [CrossRef]

- Amjadi, M.; Pichitpajongkit, A.; Lee, S.; Ryu, S.; Park, I. Highly Stretchable and Sensitive Strain Sensor Based on Silver Nanowire–Elastomer Nanocomposite. ACS Nano 2014, 8, 5154–5163. [Google Scholar] [CrossRef]

- Zhou, B.; Liu, Z.; Li, C.; Liu, M.; Jiang, L.; Zhou, Y.; Zhou, F.; Chen, S.; Jerrams, S.; Yu, J. A Highly Stretchable and Sensitive Strain Sensor Based on Dopamine Modified Electrospun SEBS Fibers and MWCNTs with Carboxylation. Adv. Electron. Mater. 2021, 7, 2100233. [Google Scholar] [CrossRef]

- Yang, J.; Ye, Y.; Li, X.; Lü, X.; Chen, R. Flexible, Conductive, and Highly Pressure-Sensitive Graphene-Polyimide Foam for Pressure Sensor Application. Compos. Sci. Technol. 2018, 164, 187–194. [Google Scholar] [CrossRef]

- Luo, C.; Tian, B.; Liu, Q.; Feng, Y.; Wu, W. One-Step-Printed, Highly Sensitive, Textile-Based, Tunable Performance Strain Sensors for Human Motion Detection. Adv. Mater. Technol. 2020, 5, 1900925. [Google Scholar] [CrossRef]

- Wang, R.; Xu, W.; Shen, W.; Shi, X.; Huang, J.; Song, W. A Highly Stretchable and Transparent Silver Nanowire/Thermoplastic Polyurethane Film Strain Sensor for Human Motion Monitoring. Inorg. Chem. Front. 2019, 6, 3119–3124. [Google Scholar] [CrossRef]

- Liu, L.; Niu, S.; Zhang, J.; Mu, Z.; Li, J.; Li, B.; Meng, X.; Zhang, C.; Wang, Y.; Hou, T.; et al. Bioinspired, Omnidirectional, and Hypersensitive Flexible Strain Sensors. Adv. Mater. 2022, 34, 2200823. [Google Scholar] [CrossRef]

- Webber, S.C.; Hahn, F.; Lix, L.M.; Tittlemier, B.J.; Salbach, N.M.; Barclay, R. Accuracy of Thresholds Based on Cadence and Lifestyle Counts per Minute to Detect Outdoor Walking in Older Adults with Mobility Limitations. J. Aging Phys. Act. 2020, 28, 782–786. [Google Scholar] [CrossRef]

| Sample | IPDI | PTMG | DMTDA | TMP |

|---|---|---|---|---|

| IP-DMTDA100-TMP0 | 75 | 25 | 47.5 | 0 |

| IP-DMTDA90-TMP10 | 75 | 25 | 42.75 | 3.17 |

| IP-DMTDA80-TMP20 | 75 | 25 | 38 | 6.33 |

| IP-DMTDA70-TMP30 | 75 | 25 | 33.25 | 9.5 |

| IP-DMTDA60-TMP40 | 75 | 25 | 28.5 | 12.67 |

| Sample | IPDI | PTMG | PCL | DMTDA | TMP |

|---|---|---|---|---|---|

| IP-PTMG100-PCL0 | 75 | 25 | 0 | 28.5 | 12.67 |

| IP-PTMG90-PCL10 | 75 | 22.5 | 2.5 | 28.5 | 12.67 |

| IP-PTMG80-PCL20 | 75 | 20 | 5 | 28.5 | 12.67 |

| IP-PTMG70-PCL30 | 75 | 17.5 | 7.5 | 28.5 | 12.67 |

| IP-PTMG60-PCL40 | 75 | 15 | 10 | 28.5 | 12.67 |

| Sample | IPDI | PTMG | DMTDA | TMP |

|---|---|---|---|---|

| IP-DMTDA100-TMP0 | 75 | 25 | 47.5 | 0 |

| IP-DMTDA90-TMP10 | 75 | 25 | 42.75 | 3.17 |

| IP-DMTDA80-TMP20 | 75 | 25 | 38 | 6.33 |

| IP-DMTDA70-TMP30 | 75 | 25 | 33.25 | 9.5 |

| IP-DMTDA60-TMP40 | 75 | 25 | 28.5 | 12.67 |

| Mass of Polyurethane (g) | Mass of Flaky Silver Powder (g) | Acetone (mL) | Acetic Acid (mL) |

|---|---|---|---|

| 2 | 0.6 | 15 | 3 |

| 2 | 0.7 | 15 | 3 |

| 2 | 0.8 | 15 | 3 |

| 2 | 0.9 | 15 | 3 |

| 2 | 1.0 | 15 | 3 |

| 2 | 1.1 | 15 | 3 |

| 2 | 1.2 | 15 | 3 |

| 2 | 1.3 | 15 | 3 |

| 2 | 1.4 | 15 | 3 |

| Sample | Tensile Strength (MPa) | Elongation at Break (%) | Modulus of Elasticity (MPa) |

|---|---|---|---|

| Bottom | 7.9 ± 0.92 MPa | 590 ± 46.32% | 0.74 ± 0.12 MPa |

| Middle | 9.93 ± 1.38 MPa | 629 ± 33.09% | 1.90 ± 0.15 MPa |

| Top | 26.04 ± 0.69 MPa | 597 ± 26.88% | 3.63 ± 1.01 MPa |

| Gradient | 13.08 ± 2.06 MPa | 416 ± 39.84% | 2.58 ± 0.85 MPa |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ning, C.; Gong, D.; Wu, L.; Chen, W.; Zhang, C. Preparation of Gradient Polyurethane and Its Performance for Flexible Sensors. Polymers 2024, 16, 1617. https://doi.org/10.3390/polym16121617

Ning C, Gong D, Wu L, Chen W, Zhang C. Preparation of Gradient Polyurethane and Its Performance for Flexible Sensors. Polymers. 2024; 16(12):1617. https://doi.org/10.3390/polym16121617

Chicago/Turabian StyleNing, Chuanqi, Depeng Gong, Lili Wu, Wanyu Chen, and Chaocan Zhang. 2024. "Preparation of Gradient Polyurethane and Its Performance for Flexible Sensors" Polymers 16, no. 12: 1617. https://doi.org/10.3390/polym16121617

APA StyleNing, C., Gong, D., Wu, L., Chen, W., & Zhang, C. (2024). Preparation of Gradient Polyurethane and Its Performance for Flexible Sensors. Polymers, 16(12), 1617. https://doi.org/10.3390/polym16121617