Selection and Optimization of Carbon-Reinforced Polyether Ether Ketone Process Parameters in 3D Printing—A Rotating Component Application

Abstract

1. Introduction

Thermoplastic Polymers in Rotating Component Application

Mathematical Programming Technique

2. Materials and Methods

2.1. Assumptions of the Research

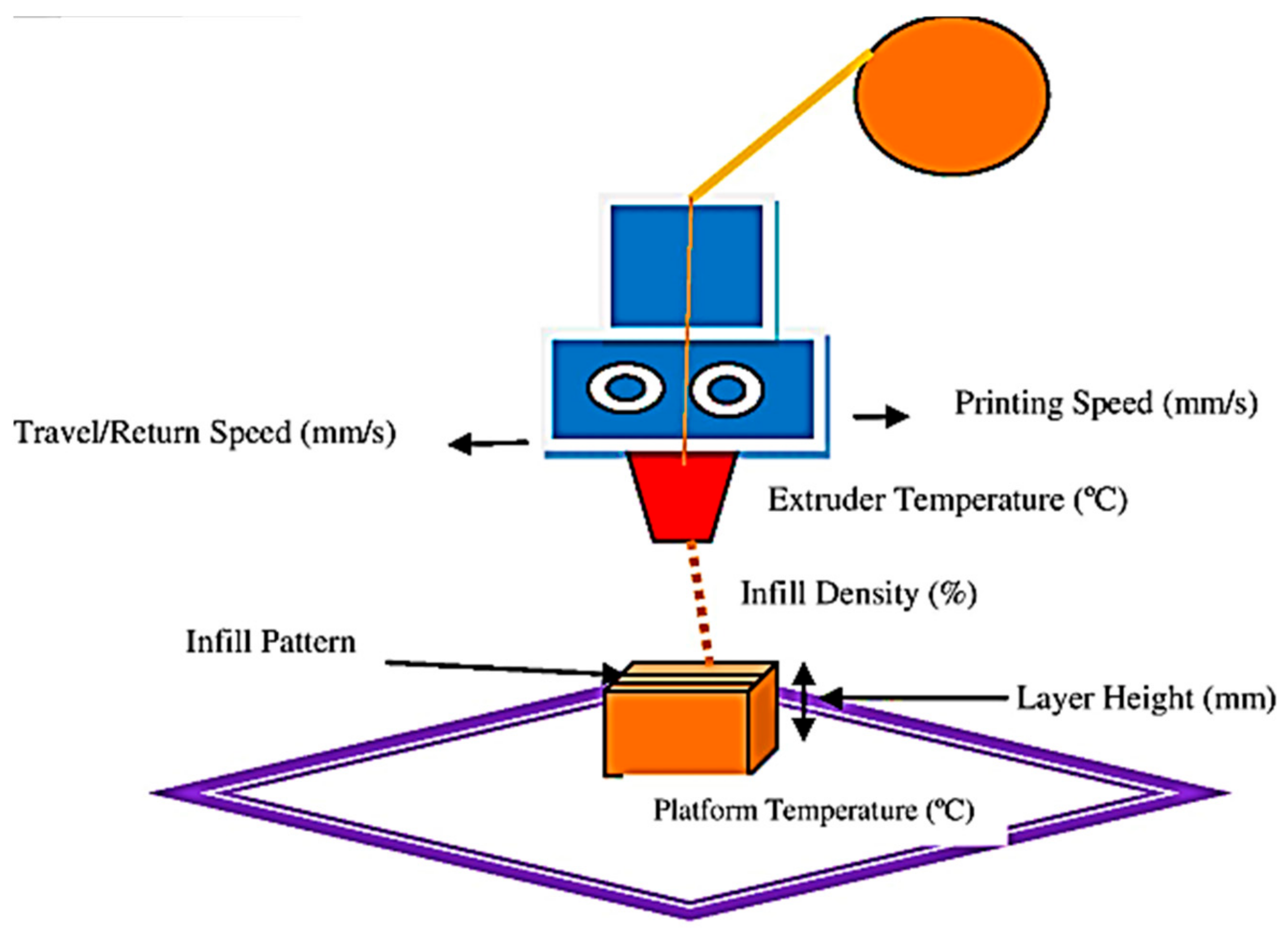

- This study considers multiple process parameters that can affect the mechanical properties of the final product. For instance, if the extrusion temperature decreases while the printing speed is high during the fabrication of a product, the final result may be compromised if the raw material does not solidify as expected. Similarly, variations in mechanical characteristics can occur if the printing speed is high, the extruder travel speed is slow, and the infill amount fluctuates.

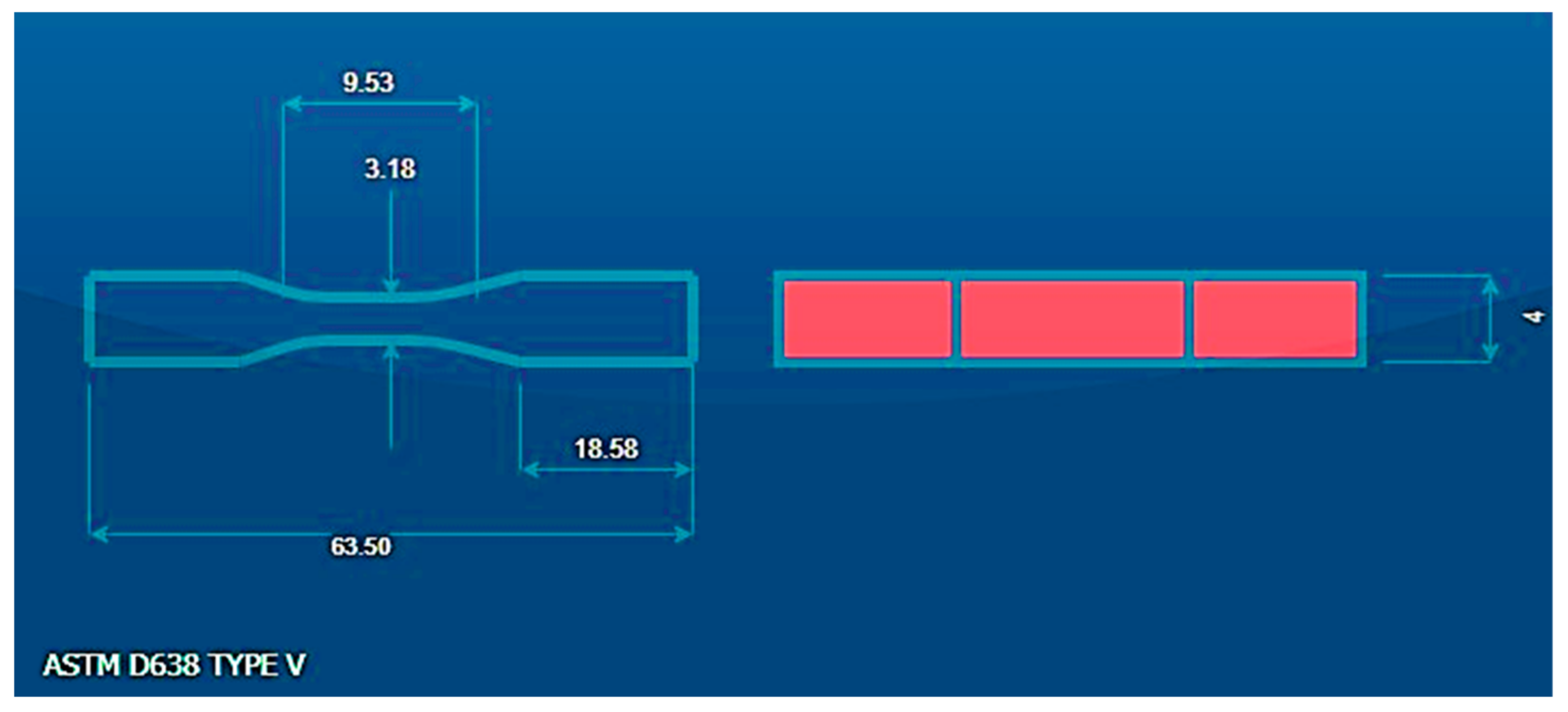

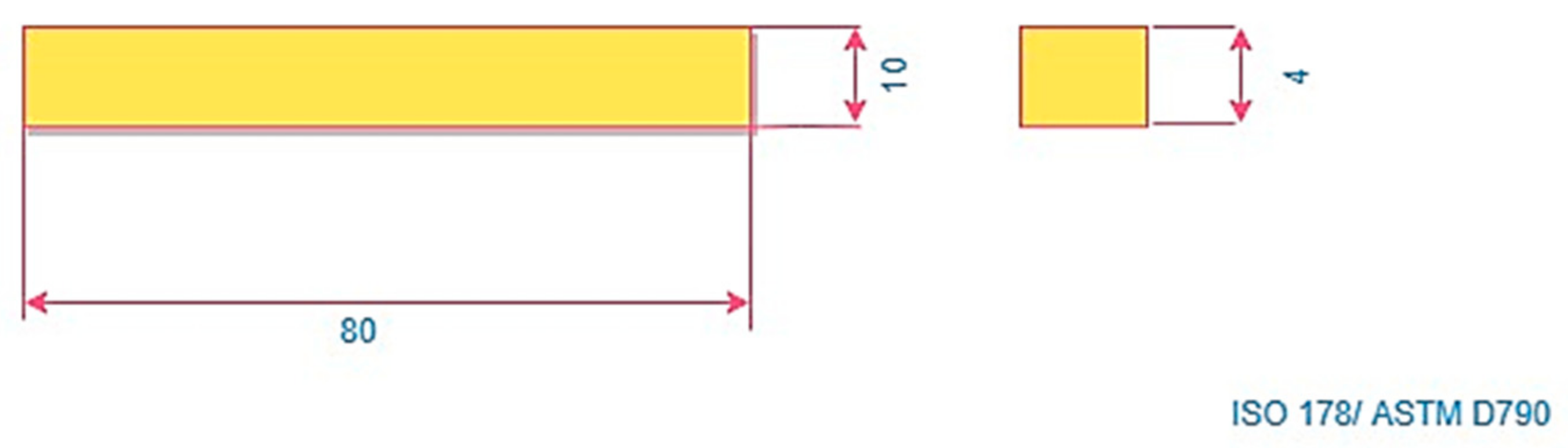

- The evaluation framework is based on the results of the available data. Criteria 1 (C1) corresponds to the observation of ultimate tensile strength (UTS), Criteria 2 (C2) corresponds to the observation of Young’s modulus, Criteria 3 (C3) corresponds to the observation of ultimate flexural test, and Criteria 4 (C4) corresponds to the observation of surface defects. Notably, the options mentioned are labelled explicitly as Sample 1 to Sample 5, rather than Alternative (A1, A2, A3, A4, and A5).

- As reported in previous literature, printing parameter values range from the minimum to maximum values for both PEEK and carbon-reinforced PEEK, refer Table 1.

- Furthermore, the infill printing parameter was set to a normal “line” as per standard practice, although it can be adjusted to accommodate other infill designs such as hexagonal or triangular patterns. Each of the alternatives mentioned represents a distinct set of parameters (referred to as a cluster of process parameters), as outlined in Table 1.

2.2. Material Extrusion Printing

Material Extrusion Process Parameter

| Process Parameter | Infill Pattern | Layer Height (mm) | Print Speed (mm/s) | Platform Temperature (°C) | Extruder Temperature (°C) | Travel Speed (mm/s) | Infill Density (%) |

|---|---|---|---|---|---|---|---|

| Alternative 1 | Line | 0.30 | 30 | 180 | 430 | 80 | 55 |

| Alternative 2 | 0.25 | 40 | 185 | 435 | 85 | 60 | |

| Alternative 3 | 0.20 | 50 | 190 | 440 | 90 | 65 | |

| Alternative 4 | 0.15 | 60 | 195 | 445 | 95 | 70 | |

| Alternative 5 | 0.10 | 70 | 200 | 450 | 100 | 75 |

2.3. Fuzzy AHP-TOPSIS

2.4. Mechanical Testing

2.5. Morphology Analysis

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Marino, S.G.; Košťáková, E.K.; Czél, G. Development of pseudo-ductile interlayer hybrid composites of standard thickness plies by interleaving polyamide 6 nanofibrous layers. Compos. Sci. Technol. 2023, 234, 109924. [Google Scholar] [CrossRef]

- Adapa, S.K. Jagadish Prospects of Natural Fiber-Reinforced Polymer Composites for Additive Manufacturing Applications: A Review. JOM 2023, 75, 920–940. [Google Scholar] [CrossRef]

- Subramani, R.; Kaliappan, S.; Sekar, S.; Patil, P.P.; Usha, R.; Manasa, N.; Esakkiraj, E.S. Polymer Filament Process Parameter Optimization with Mechanical Test and Morphology Analysis. Adv. Mater. Sci. Eng. 2022, 2022, 8259804. [Google Scholar] [CrossRef]

- Raja, S.; Rajan, A.J. A Decision-Making Model for Selection of the Suitable FDM Machine Using Fuzzy TOPSIS. Math. Probl. Eng. 2022, 2022, 7653292. [Google Scholar] [CrossRef]

- Raja, S.; Rajan, A.J.; Kumar, V.P.; Rajeswari, N.; Girija, M.; Modak, S.; Kumar, R.V.; Mammo, W.D. Selection of Additive Manufacturing Machine Using Analytical Hierarchy Process. Sci. Program. 2022, 2022, 1596590. [Google Scholar] [CrossRef]

- Subramani, R.; Kaliappan, S.; Arul, P.V.; Sekar, S.; Poures, M.V.; De Patil, P.P.; Esakki, E.S. A Recent Trend on Additive Manufacturing Sustainability with Supply Chain Management Concept, Multicriteria Decision Making Techniques. Adv. Mater. Sci. Eng. 2022, 2022, 9151839. [Google Scholar] [CrossRef]

- Lu, S.; Zhang, B.; Niu, J.; Yang, C.; Sun, C.; Wang, L.; Li, D. Effect of fiber content on mechanical properties of carbon fiber-reinforced polyether-ether-ketone composites prepared using screw extrusion-based online mixing 3D printing. Addit. Manuf. 2024, 80, 103976. [Google Scholar] [CrossRef]

- Chithambaram, K.; Senthilnathan, N. Effects of printing parameters on hardness and wear characteristics of 3D printed polyetheretherketone (PEEK) polymer. Mater. Lett. 2024, 356, 135588. [Google Scholar] [CrossRef]

- Sivakumar, N.K.; Palaniyappan, S.; Bodaghi, M.; Azeem, P.; Nandhakumar, G.; Basavarajappa, S.; Pandiaraj, S.; Hashem, M.I. Predictive modeling of compressive strength for additively manufactured PEEK spinal fusion cages using machine learning techniques. Mater. Today Commun. 2024, 38, 108307. [Google Scholar] [CrossRef]

- Kechagias, J.; Zaoutsos, S. Effects of 3D-printing processing parameters on FFF parts’ porosity: Outlook and trends. Mater. Manuf. Process. 2024, 39, 804–814. [Google Scholar] [CrossRef]

- Jiang, C.-P.; Cheng, Y.-C.; Lin, H.-W.; Chang, Y.-L.; Pasang, T.; Lee, S.-Y. Optimization of FDM 3D printing parameters for high strength PEEK using the Taguchi method and experimental validation. Rapid Prototyp. J. 2022, 28, 1260–1271. [Google Scholar] [CrossRef]

- Liu, H.; Cheng, X.; Yang, X.H.; Zheng, G.M.; Guo, Q.J. Experimental study on parameters of 3D printing process for PEEK materials. In Proceedings of the IOP Conference Series: Materials Science and Engineering, the 2nd International Workshop on Materials Science and Mechanical Engineering (IWMSME2018), Qingdao, China, 26–28 October 2018; IOP Publishing: Bristol, UK, 2018; Volume 504, p. 012001. [Google Scholar] [CrossRef]

- Olaiya, N.G.; Maraveas, C.; Salem, M.A.; Raja, S.; Rashedi, A.; Alzahrani, A.Y.; El-Bahy, Z.M.; Olaiya, F.G. Viscoelastic and Properties of Amphiphilic Chitin in Plasticised Polylactic Acid/Starch Biocomposite. Polymers 2022, 14, 2268. [Google Scholar] [CrossRef] [PubMed]

- Raja, S.; Logeshwaran, J.; Venkatasubramanian, S.; Jayalakshmi, M.; Rajeswari, N.; Olaiya, N.G.; Mammo, W.D. OCHSA: Designing Energy-Efficient Lifetime-Aware Leisure Degree Adaptive Routing Protocol with Optimal Cluster Head Selection for 5G Communication Network Disaster Management. Sci. Program. 2022, 2022, 5424356. [Google Scholar] [CrossRef]

- Praveenkumar, V.; Raja, S.; Jamadon, N.H.; Yishak, S. Role of laser power and scan speed combination on the surface quality of additive manufactured nickel-based superalloy. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2023, in press. [Google Scholar] [CrossRef]

- Raja, S.; Rajan, J. Selection of Polymer Extrusion Parameters By Factorial Experimental Design—A Decision Making Model. Sci. Iran. 2023, in press. [Google Scholar]

- Subramani, R.; Kalidass, A.K.; Muneeswaran, M.D.; Lakshmipathi, B.G. Effect of fused deposition modeling process parameter in influence of mechanical property of acrylonitrile butadiene styrene polymer. Appl. Chem. Eng. 2024, 7, 3576. [Google Scholar] [CrossRef]

- Andrés, M.S.; Chércoles, R.; Navarro, E.; de la Roja, J.M.; Gorostiza, J.; Higueras, M.; Blanch, E. Use of 3D printing PLA and ABS materials for fine art. Analysis of composition and long-term behaviour of raw filament and printed parts. J. Cult. Herit. 2023, 59, 181–189. [Google Scholar] [CrossRef]

- Raja, S.; Agrawal, A.P.; Patil, P.P.; Thimothy, P.; Capangpangan, R.Y.; Singhal, P.; Wotango, M.T. Optimization of 3D Printing Process Parameters of Polylactic Acid Filament Based on the Mechanical Test. Int. J. Chem. Eng. 2022, 2022, 5830869. [Google Scholar] [CrossRef]

- Joseph, T.M.; Kallingal, A.; Suresh, A.M.; Mahapatra, D.K.; Hasanin, M.S.; Haponiuk, J.; Thomas, S. 3D printing of polylactic acid: Recent advances and opportunities. Int. J. Adv. Manuf. Technol. 2023, 125, 1015–1035. [Google Scholar] [CrossRef]

- Pulipaka, A.; Gide, K.M.; Beheshti, A.; Bagheri, Z.S. Effect of 3D printing process parameters on surface and mechanical properties of FFF-printed PEEK. J. Manuf. Process. 2023, 85, 368–386. [Google Scholar] [CrossRef]

- French, A.; Anguiano, S.; Bliss, M.; Christ, J.; di Vacri, M.; Erikson, R.; Harouaka, K.; Hoppe, E.; Grate, J.; Arnquist, I. Mass spectrometric investigations into 3D printed parts to assess radiopurity as ultralow background materials for rare event physics detectors. Nucl. Instrum. Methods Phys. Res. Sect. A Accel. Spectrometers Detect. Assoc. Equip. 2023, 1047, 167830. [Google Scholar] [CrossRef]

- Hernandez-Carrillo, I.; Wood, C.J.; Liu, H. Advanced materials for the impeller in an ORC radial microturbine. Energy Procedia 2017, 129, 1047–1054. [Google Scholar] [CrossRef]

- Pavlović, A.; Šljivić, M.; Kraisnik, M.; Ilić, J.; Anić, J. Polymers in additive manufacturing: The case of a water pump impeller. FME Trans. 2017; 45, 354–359. [Google Scholar]

- Polák, M. Behaviour of 3D printed impellers in performance tests of hydrodynamic pump. In Proceedings of the 7th International Conference on Trends in Agricultural Engineering, Prague, Czech Republic, 17–20 September 2019; pp. 17–20. [Google Scholar]

- Kyzyrov, U.; Turgali, D. Performance Enhancement of a Centrifugal Pump by Impeller Retrofitting; Nazarbayev University School of Engineering and Digital Sciences: 2019. Available online: https://nur.nu.edu.kz/bitstream/handle/123456789/4476/Performance%20Enhancement%20of%20a%20Centrifugal%20Pump%20by%20Impeller%20Retrofitting.pdf;jsessionid=3A3B30B32BD593170B53A63F8FFC63C9?sequence=5 (accessed on 3 December 2023).

- Kopparapu, R.; Mathew, S.; Siciliano, E.; Stasick, G.; Dias, M. Designing a Centrifugal Pump System for High Altitude Water Crises. 2017. Available online: https://engineering.rutgers.edu/sites/default/files/imce/gov2017/Designing%20a%20Centrifugal%20Pump%20System%20for%20High%20Altitude%20Water%20Crises.pdf.pdfing.rutgers.edu (accessed on 10 December 2023).

- Warner, J.; Celli, D.; Scott-Emuakpor, O.; George, T.; Tomlin, T. Fused Deposition Modeling Fabrication Evaluation of a Ti-6Al-4V Centrifugal Compressor. J. Eng. Gas Turbines Power 2022, 145, 031008. [Google Scholar] [CrossRef]

- Matos, T.; Pinto, V.; Sousa, P.; Martins, M.; Fernández, E.; Henriques, R.; Gonçalves, L.M. Design and In Situ Validation of Low-Cost and Easy to Apply Anti-Biofouling Techniques for Oceanographic Continuous Monitoring with Optical Instruments. Sensors 2023, 23, 605. [Google Scholar] [CrossRef] [PubMed]

- Mishra, V.; Negi, S.; Kar, S. FDM-based additive manufacturing of recycled thermoplastics and associated composites. J. Mater. Cycles Waste Manag. 2023, 25, 758–784. [Google Scholar] [CrossRef] [PubMed]

- Birosz, M.T.; Andó, M.; Jeganmohan, S. Finite Element Method modeling of Additive Manufactured Compressor Wheel. J. Inst. Eng. Ser. D 2021, 102, 79–85. [Google Scholar] [CrossRef]

- Odetti, A.; Altosole, M.; Bruzzone, G.; Caccia, M.; Viviani, M. Design and construction of a modular pump-jet thruster for autonomous surface vehicle operations in extremely shallow water. J. Mar. Sci. Eng. 2019, 7, 222. [Google Scholar] [CrossRef]

- Zywica, G.; Kaczmarczyk, T.Z.; Ihnatowicz, E.; Baginski, P.; Andrearczyk, A. Application Of a heat resistant plastic IN a high-speed microturbine designed for the domestic ORC system. In Proceedings of the 5th International Seminar on ORC Power Systems, Athens, Greece, 9–11 September 2019; pp. 1–8. [Google Scholar]

- Malaga, A.; Vinodh, S. Technology Selection for Additive Manufacturing in Industry 4.0 Scenario Using Hybrid MCDM Approach. In Industry 4.0 and Advanced Manufacturing; Springer: Singapore, 2023; pp. 207–217. [Google Scholar]

- Ghuge, S.; Parhi, S. Additive Manufacturing Service Provider Selection Using a Neutrosophic Best Worst Method. Procedia Comput. Sci. 2023, 217, 1550–1559. [Google Scholar] [CrossRef]

- Chandra, M.; Shahab, F.; Kek, V.; Rajak, S. Selection for additive manufacturing using hybrid MCDM technique considering sustainable concepts. Rapid Prototyp. J. 2022, 28, 1297–1311. [Google Scholar] [CrossRef]

- Rinaldi, M.; Ghidini, T.; Cecchini, F.; Brandao, A.; Nanni, F. Additive layer manufacturing of poly (ether ether ketone) via FDM. Compos. Part B Eng. 2018, 145, 162–172. [Google Scholar] [CrossRef]

- Algarni, M.; Ghazali, S. Comparative Study of the Sensitivity of PLA, ABS, PEEK, and PETG’s mechanical properties to FDM printing process parameters. Crystals 2021, 11, 995. [Google Scholar] [CrossRef]

- Fountasa, N.; Kechagiasb, J.; Vaxevanidisa, N. Statistical Modeling and Optimization of Surface Roughness for PLA and PLA/Wood FDM Fabricated Items. J. Mater. Eng. 2023, 1, 38–44. [Google Scholar] [CrossRef]

- Mustafa, M.A.; Raja, S.; Asadi, L.A.A.L.; Jamadon, N.H.; Rajeswari, N.; Kumar, A.P. A Decision-Making Carbon Reinforced Material Selection Model for Composite Polymers in Pipeline Applications. Adv. Polym. Technol. 2023, 2023, 6344193. [Google Scholar] [CrossRef]

- Shekar, A.C.; Djilani, A.H.; Zitoune, R.; Toubal, L.; Hof, L.A. Effect of input variables on the mechanical properties of additively manufactured PEEK thermoplastics. Mater. Today Proc. 2023, in press. [Google Scholar] [CrossRef]

- Raja, S.; Al-Tmimi, H.M.; Ghadir, G.K.; Mustafa, M.A.; Alani, Z.K.; Rusho, M.A.; Rajeswari, N. An analysis of polymer material selection and design optimization to improve Structural Integrity in 3D printed aerospace components. Appl. Chem. Eng. 2024, 7, 1875. [Google Scholar] [CrossRef]

- Patel, A.; Taufik, M. Extrusion-Based Technology in Additive Manufacturing: A Comprehensive Review. Arab. J. Sci. Eng. 2024, 49, 1309–1342. [Google Scholar] [CrossRef]

- ASTM D638-14; Standard Practice for Preparation of Metallographic Specimens. ASTM International: West Conshohocken, PA, USA, 2016; pp. 1–15.

- ASTM D790; Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials. ASTM International: West Conshohocken, PA, USA, 2002; pp. 1–12.

- Raja, S.; Rajan, A.J. Challenges and Opportunities in Additive Manufacturing Polymer Technology: A Review Based on Optimization Perspective. Adv. Polym. Technol. 2023, 2023, 8639185. [Google Scholar] [CrossRef]

- Maniya, K.; Bhatt, M. An alternative multiple attribute decision making methodology for solving optimal facility layout design selection problems. Comput. Ind. Eng. 2011, 61, 542–549. [Google Scholar] [CrossRef]

| Saaty Parameters | Saaty Scale | Fuzzified Using Triangle Membership Function | |

|---|---|---|---|

| Equal consideration | 1 | 1,1,1 | |

| Moderate consideration | 3 | 2,3,4 | |

| Strong consideration | 5 | 4,5,6 | |

| Very strong consideration | 7 | 6,7,8 | |

| Extremely strong consideration | 9 | 9,9,9 | |

| Intermediate consideration | 2 | 1,2,3 | |

| 4 | 3,4,5 | ||

| 6 | 5,6,7 | ||

| 8 | 7,8,9 | ||

| Linguistics Terms | Fuzzy Numbers Based on Triangular Membership Function | Linguistics Scales |

|---|---|---|

| Very Low (VL) | 1,1,3 | 1 |

| Low (L) | 1,3,5 | 2 |

| Average (A) | 3,5,7 | 3 |

| High (H) | 5,7,9 | 4 |

| Very High (VH) | 7,9,9 | 5 |

| A1 | A2 | A3 | A4 | A5 | |

| A | 3.61 | 3.25 | 3.71 | 3.05 | 3.17 |

| B | 3.54 | 3.21 | 3.64 | 2.99 | 3.08 |

| C | 3.49 | 3.11 | 3.69 | 3.01 | 3.01 |

| Average | 3.54 | 3.19 | 3.68 | 3.01 | 3.08 |

| Importance | H | A | VH | VL | L |

| A1 | A2 | A3 | A 4 | A5 | |

| A | 82.1 | 83.7 | 80.2 | 80.3 | 79.8 |

| B | 82.6 | 84.2 | 80.6 | 79.6 | 78.6 |

| C | 83.4 | 84.1 | 79.8 | 79.2 | 78.2 |

| Average | 82.7 | 84 | 80.2 | 79.7 | 78.8 |

| Importance | H | VH | A | L | VL |

| A1 | A2 | A3 | A4 | A5 | |

| A | 148 | 149.6 | 144.5 | 140.3 | 138.6 |

| B | 147.3 | 148.2 | 143.6 | 141.2 | 137.9 |

| C | 146.9 | 148.9 | 144.1 | 139.7 | 138.1 |

| Average | 147.4 | 148.9 | 144.06 | 140.4 | 138.2 |

| Importance | H | VH | A | L | VL |

| C1 | C2 | C3 | C4 | |

|---|---|---|---|---|

| Alternative 1 | H | H | H | VL |

| Alternative 2 | VH | A | VH | A |

| Alternative 3 | A | VH | A | H |

| Alternative 4 | L | VL | L | L |

| Alternative 5 | VL | L | VL | VH |

| C1 | C2 | C3 | C4 | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Alternative 1 | 5 | 7 | 9 | 5 | 7 | 9 | 5 | 7 | 9 | 1 | 1 | 3 |

| Alternative 2 | 7 | 9 | 9 | 3 | 5 | 7 | 7 | 9 | 9 | 3 | 5 | 7 |

| Alternative 3 | 3 | 5 | 7 | 7 | 9 | 9 | 3 | 5 | 7 | 5 | 7 | 9 |

| Alternative 4 | 1 | 3 | 5 | 1 | 1 | 3 | 1 | 3 | 5 | 1 | 3 | 5 |

| Alternative 5 | 1 | 1 | 3 | 1 | 3 | 5 | 1 | 1 | 3 | 7 | 9 | 9 |

| C1 | C2 | C3 | C4 | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A1 | 0.555 | 0.777 | 0.555 | 0.777 | 0.555 | 0.777 | 0.111 | 0.111 | 0.333 | |||

| 1 | 1 | 1 | ||||||||||

| A2 | 0.777 | 0.333 | 0.555 | 0.777 | 0.777 | 0.333 | 0.555 | 0.777 | ||||

| 1 | 1 | 1 | 1 | |||||||||

| A3 | 0.333 | 0.555 | 0.777 | 0.777 | 0.333 | 0.555 | 0.777 | 0.555 | 0.777 | |||

| 1 | 1 | 1 | ||||||||||

| A 4 | 0.111 | 0.333 | 0.555 | 0.111 | 0.111 | 0.333 | 0.111 | 0.333 | 0.555 | 0.111 | 0.333 | 0.555 |

| A 5 | 0.111 | 0.111 | 0.333 | 0.111 | 0.333 | 0.555 | 0.111 | 0.111 | 0.333 | 0.777 | ||

| 1 | 1 | |||||||||||

| A+ | 0.777 | 0.777 | ||||||||||

| 0.777 | 1 | 1 | 0.777 | 1 | 1 | 1 | 1 | 1 | 1 | |||

| A− | 0.111 | 0.111 | 0.333 | 0.111 | 0.111 | 0.333 | 0.111 | 0.111 | 0.333 | |||

| 0.111 | 0.333 | 0.111 | ||||||||||

| C1 | C2 | C3 | C4 | di+ | |

|---|---|---|---|---|---|

| Alternative 1 | 0 | 0.181 | 0 | 0.748 | 0.929 |

| Alternative 2 | 0 | 0.384 | 0 | 0.384 | 0.769 |

| Alternative 3 | 0.384 | 0 | 0.384 | 0.181 | 0.951 |

| Alternative 4 | 0.379 | 0.748 | 0.601 | 0.601 | 2.331 |

| Alternative 5 | 0.748 | 0 | 0.748 | 0 | 1.496 |

| C1 | C2 | C3 | C4 | |

|---|---|---|---|---|

| Alternative 1 | 0.601 | 0 | 0.601 | 0 |

| Alternative 2 | 0 | 0.384 | 0.748 | 0.384 |

| Alternative 3 | 0.384 | 0.748 | 0.384 | 0.601 |

| Alternative 4 | 0.181 | 0 | 0 | 0 |

| Alternative 5 | 0 | 0.181 | 0 | 0.748 |

| Closeness Co-Efficient (Cci) | Rank | |

|---|---|---|

| Alternative 1 | 0.564 | III |

| Alternative 2 | 0.663 | II |

| Alternative 3 | 0.060 | V |

| Alternative 4 | 0.722 | I |

| Alternative 5 | 0.383 | IV |

| Set 1—High Weightage to C1, C2 | Set 2—High Weightage to C1, C2, C3 | Set 3—High Weightage to C1, C2, C4 | Set 4 (Original)—Equal Weightage to All Criteria | Rank | |

|---|---|---|---|---|---|

| Alternative 1 | 0.589 | 0.498 | 0.509 | 0.564 | III |

| Alternative 2 | 0.699 | 0.572 | 0.589 | 0.663 | II |

| Alternative 3 | 0.092 | 0.049 | 0.054 | 0.060 | V |

| Alternative 4 | 0.813 | 0.633 | 0.676 | 0.722 | I |

| Alternative 5 | 0.412 | 0.282 | 0.302 | 0.383 | IV |

| Preference Selection Index (PSI) Method | Fuzzy-AHP TOPSIS (This Method) | Rank | |

|---|---|---|---|

| Alternative 1 | 0.522 | 0.564 | III |

| Alternative 2 | 0.654 | 0.663 | II |

| Alternative 3 | 0.085 | 0.060 | V |

| Alternative 4 | 0.746 | 0.722 | I |

| Alternative 5 | 0.392 | 0.383 | IV |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Subramani, R.; Vijayakumar, P.; Rusho, M.A.; Kumar, A.; Shankar, K.V.; Thirugnanasambandam, A.K. Selection and Optimization of Carbon-Reinforced Polyether Ether Ketone Process Parameters in 3D Printing—A Rotating Component Application. Polymers 2024, 16, 1443. https://doi.org/10.3390/polym16101443

Subramani R, Vijayakumar P, Rusho MA, Kumar A, Shankar KV, Thirugnanasambandam AK. Selection and Optimization of Carbon-Reinforced Polyether Ether Ketone Process Parameters in 3D Printing—A Rotating Component Application. Polymers. 2024; 16(10):1443. https://doi.org/10.3390/polym16101443

Chicago/Turabian StyleSubramani, Raja, Praveenkumar Vijayakumar, Maher Ali Rusho, Anil Kumar, Karthik Venkitaraman Shankar, and Arun Kumar Thirugnanasambandam. 2024. "Selection and Optimization of Carbon-Reinforced Polyether Ether Ketone Process Parameters in 3D Printing—A Rotating Component Application" Polymers 16, no. 10: 1443. https://doi.org/10.3390/polym16101443

APA StyleSubramani, R., Vijayakumar, P., Rusho, M. A., Kumar, A., Shankar, K. V., & Thirugnanasambandam, A. K. (2024). Selection and Optimization of Carbon-Reinforced Polyether Ether Ketone Process Parameters in 3D Printing—A Rotating Component Application. Polymers, 16(10), 1443. https://doi.org/10.3390/polym16101443