The Use of Additive Manufacturing Techniques in the Development of Polymeric Molds: A Review

Abstract

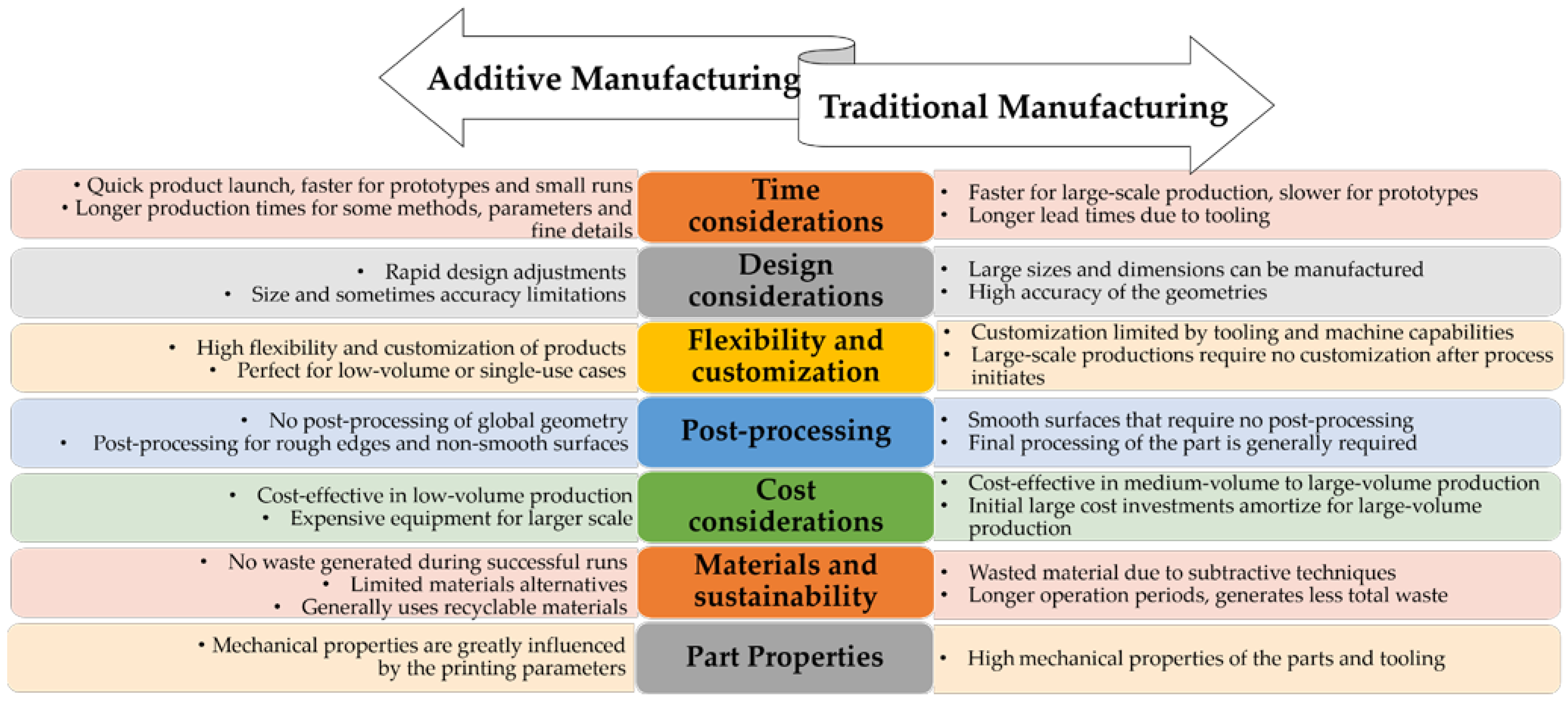

1. Additive Manufacturing Introduction

| AM Class | Materials Used | Principle | Techniques | Advantages | Disadvantages |

|---|---|---|---|---|---|

| Vat Photo Polymerization | Polymers (UV-curable photopolymer resins) | A liquid photopolymer in a vat is exposed to light source to be selectively cured into solid form | Stereolithography (SLA); Digital Light Processing (DLP); Continuous Liquid Interface Production (CLIP); Daylight Polymer Printing (DPP) | Rapid processing High quality finish of the part | High costs Extracting the 3D object from the mold generates issues |

| Material Jetting | Polymers (PP, HDPE, PS, PMMA), Waxes | Droplets of material are selectively deposited (jetted) on a substrate to build a 3D object | Material Jetting (MJ); Multi-jet Modeling (MJM); Nanoparticles Jetting (NPJ); Drop on Demand (DOD) | Less to zero waste | Difficult to apply in structural parts Post-processing required |

| Binder Jetting | Polymers (PA, ABS), Metals (stainless steel), Ceramics (Sand Glass) | Liquid bonding agent that acts as adhesive is selectively deposited to join materials in powder form | Powder Bed and Inkjet Head (PBIH); Plaster-based 3D Printing (PP) | Rapid processing No melting | Lower mechanical performance Post-processing required |

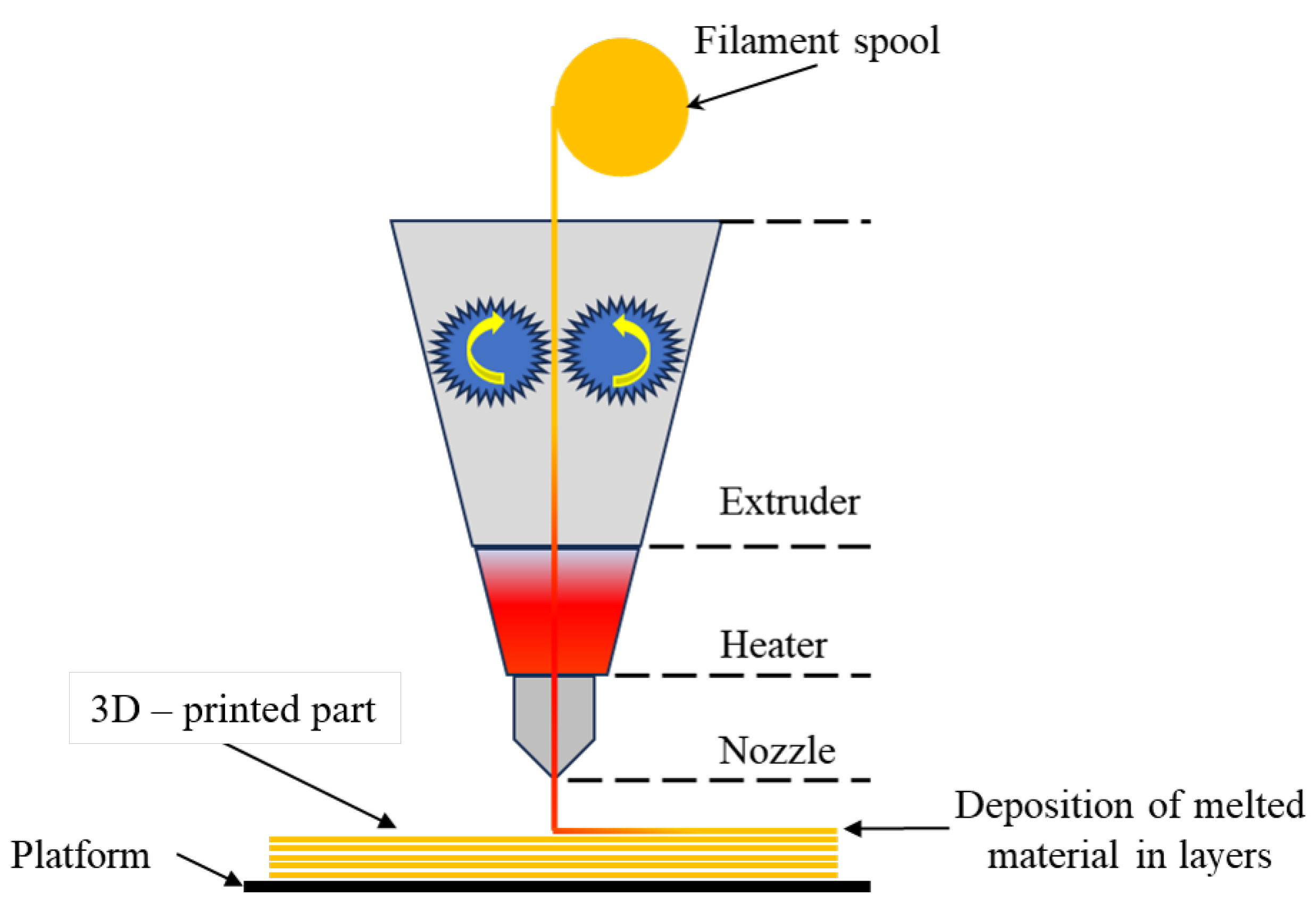

| Material Extrusion | Polymers (ABS, Polyamides, PC, PEI, PLA) | Thermoplastic polymer filament is extruded through a nozzle to build a 3D object | Fused Deposition Modeling (FDM); Fused Filament Fabrication (FFF) | Lower costs Good mechanical and structural properties High availability materials | Lower precision— many factors influence final model quality Accuracy and speed Nozzle requires technical attention |

| Sheet Lamination | Paper, Sheet Metals | Layers of material are joined together using an adhesive and printed one after the other (layer by layer) to build a 3D object | Laminated Object Manufacturing (LOM) | Low costs Acceptable accuracy | Limited material alternatives Post-processing required |

| Power Bed Fusion (PBF) | Metals (Stainless Steel, Aluminum, Titanium), Polymers (Polyamides) | Laser or electron beam melts or sinters the material in powder to build a 3D object | Selective Laser Sintering (SLS); Selective Laser Melting (SLM); Electron Beam Melting (EBM); Multi-Jet Fusion (MJF) | Suitable for prototyping Complex geometries | High costs Difficult to apply in structural parts Size limitations |

| Powder-fed Directed Energy Deposition (DED) | Metals (Stainless Steel, Aluminum, Titanium, etc.), Ceramics, Polymers | An electron beam, laser or arc energy source is directed toward a substrate material where it impinges with wire or powder feedstock material and melts, depositing the material on the substrate and building the part layer by layer | Wire Arc Additive Manufacturing (WAAM); Laser Metal Deposition (LMD); Laser Engineered Net Shaping (LENS); Laser Solid Forming (LSF); Directed Light Fabrication (DLF); 3D laser cladding | Suitable for repair/coat existing parts Machine large parts with high mechanical properties | Not suitable for small parts Lower detail accuracy and simple geometries |

2. Additive Manufacturing Technologies That Use Polymers

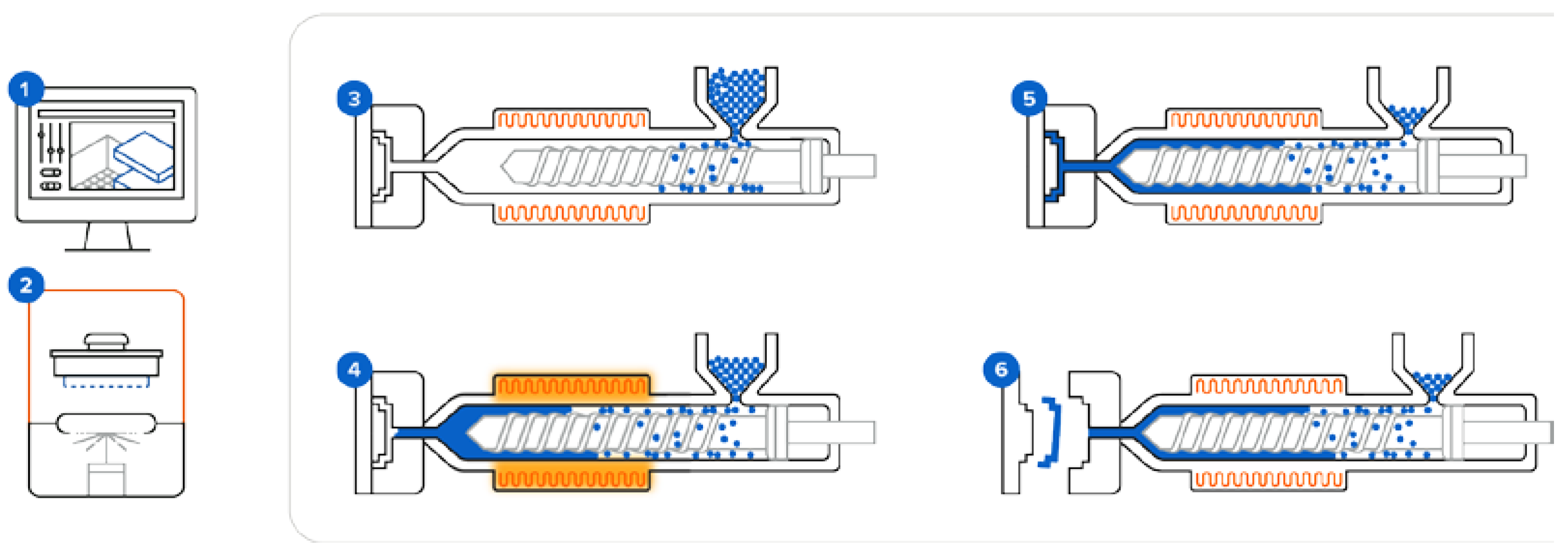

2.1. Fused Deposition Modeling

2.2. Stereolithography

2.3. Selective Laser Sintering

3. Technologies That Use Molds

- Casting—it is the simplest molding process, as it requires simple tooling and low costs, and can be performed at low pressures. The thermoplastic is heated until it reaches a molten state, poured into the mold, and allowed to cool before extraction from the mold. Although it allows the production of complex shapes, it can be used for parts with a thickness higher than 12–13 mm.

- Injection molding—it is one of the most extensively used techniques for molding plastics or metals as it allows the production of three-dimensional parts which can be easily reproduced. The material brought in liquid form is inserted/injected at a high pressure into a closed, cooled mold, filling it and taking its shape. The molded material is extracted after complete cooling and solidification. It is a process suitable for large quantity production (i.e., more than 30,000 parts per year). Despite the use of expensive tooling (i.e., expensive metallic molds), the large volume production ensures its cost-effectiveness; however, recent trends promote its use for smaller production volumes with the tooling adaption.

- Extrusion molding—it is similar to injection molding, but with the difference that the molten material is inserted/injected through a die and the obtained structure is linear and rod-like (not necessarily cylindrical). After cooling, the rod structure can be cut at different lengths depending on necessities.

- Compression molding—it is the most complicated molding process, in terms of labor, being used only for large-scale production (such as a higher number of small parts in boats, the automotive industry, etc.), and not for mass production. The liquid molten material is poured into a lower mold and compressed with an upper mold into the desired shape and extracted after complete cooling and solidification. The high temperatures used ensure material strength.

- Blow molding—it is a process mainly used for pipes and milk bottle production, allowing the production of up to 1400 parts in a 12 h shift, with uniform wall thickness achievement. Although it uses the standard concept, it requires several different mold parts. The plastic in a melted state is injected into a cold mold, concomitant with air blowing into an attached tube, pressing the plastic against the walls of the mold so that it takes the shape of the mold. After complete cooling, the part is extracted.

- Rotational molding—it is an environmentally compatible process, as raw material does not go to waste. The process involves high-speed rotating using two mechanical arms, the mold that contains the hot liquid material, which uniformly coats the mold surface, and the final part has a uniform wall thickness and hollow shape. It is widely used for toys, tanks, and different other consumer goods.

- Suitable mechanical properties, especially in terms of high stiffness—for example, injection molds must exhibit suitable mechanical performance to withstand the high pressure used during injection while maintaining a good dimensional stability (no deformation) and accuracy over multiple-use cycles.

- Suitable thermo-mechanical properties, in terms of resistance to high temperatures without showing deformation, meaning that the polymer used needs to exhibit a high value of heat deflection temperature in order to ensure a precise control of the process and the required dimensional stability.

- Dimensional accuracy is crucial for the production of parts with a high level of details.

- When fast turnaround times are needed (1–2 weeks for 3D-printed molds as opposed to 5–7 weeks for traditional ones);

- Low-volume production (applications where a maximum number of 50–100 parts are needed);

- Small-size parts are to be produced (up to a maximum of 150 mm);

- Applications where design changes or iterations are foreseen.

- Selection of optimum material—the used materials need to withstand the parameters required to be implemented during the molding process (i.e., temperature, pressure) without melting, warping or deforming.

- Design considerations—the design of the mold needs to be optimized to build molds for any molding processes, especially injection molding, as design items (i.e., number of walls, wall thickness, draft angles, infill patterns, etc.) generate significant modifications to the quality and durability of the mold and consequently to the quality of the part and cost investments in the technology for the product.

- Testing trials and validation stages—as with any product or other processes, molds printed via 3D need to be tested in terms of resistance to the conditions required by the parameters used (thermal resistance, mechanical resistance and dimensional stability at the processing temperatures, pressures generating mechanical loads and during a required number of cycles), in order to establish the molds’ limitations and perform adjustments if needed, before production starts.

- Production volume considerations—especially for injection molding that generally is suitable for thousands of cycles, 3D-printed molds cannot surpass traditional metallic tooling and can only be used when low-volume production (50–100) is possible due to the modification of their properties after a number of cycles; therefore, they can only be used in rapid prototyping, low-volume production, and other molding techniques that require single use or constant tailoring of the design.

- Size and shape of the molds—the selection of the mold type needs to take into consideration that it has to handle the size of the part to be manufactured, as generally mold machines by CNC are larger, and molds produced by 3D printing exhibit some size limitations compared to them.

- Surface finish—considering the high degree of surface finish offered by metallic molds (aluminum or steel), 3D-printed molds tend to exhibit generally rougher surfaces, decreasing the surface finish quality, without taking into consideration the degradation scenarios during injection molding, for example, rendering them the less suitable candidate in some applications.

- Draft angle—this factor needs to be considered especially for injection molding and composite fabrication, as its correct selection can contribute significantly to the facile extraction/demolding of the part at the end of the process.

4. Applications That Use 3D-Printed Polymeric Molds

4.1. 3D Printing of Molds for Injection Techniques

- soft (temporary) tool/molds (i.e., silicone molds)—as expected, they can be used for a very limited number of cycles before they reach their usage period.

- bridge tool/molds (i.e., plastic molds)—can be used for small-batch production (i.e., hundreds to thousands) and they generally require shorter manufacturing periods, their durability being strongly influenced by the material used for production within them.

- hard tool/molds (i.e., metallic molds)—can be used for large-batch production (i.e., hundred thousand), similar to the molds manufactured by conventional methods, but they require longer processing time and costs, compared to the other two categories.

4.2. 3D Printing of Molds for Casting Techniques

4.3. 3D Printing of Molds for Thermoforming

4.4. 3D Printing of Molds for Composites Fabrication

- one-part mold—used in vacuum bagging methods (i.e., for hand lay-up, resin infusion, prepregs, etc.) and generally for parts that need a glossy finish for one of the sides;

- two-parts mold—used in compression molding for parts that need both sides with a glossy finish;

- bladder mold—used in pressure molding where one side is the mold, the other is the bladder surface, for complex geometry that cannot be achieved via vacuum bagging or compression molding due to the impossibility of demolding the composite;

- mold pattern for negative mold—used when multiple molds are needed for production increase, a single pattern can be used to manufacture several molds.

4.5. 3D Printing of Molds for Tissue Engineering Scaffolds and Medical Applications

4.6. 3D Printing f Molds for Soft Lithography

4.7. 3D Printing of Sacrificial Molds

- when small size features complex geometries like the ones provided with microchannels or overhangs, seamless or hollow areas are needed;

- when removing/debonding the part from a fix mold is technologically challenging or generates significant damage to the formed part;

- when complex geometry requires the use of multipart or articulated molds and demolding becomes challenging;

- when the volume of production allows the use of molds that become waste once a part is produced.

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Balasubramanian, K.R.; Senthilkumar, V. (Eds.) Additive Manufacturing Applications for Metals and Composites; Advances in Civil and Industrial Engineering; IGI Global: Hershey, PA, USA, 2020; ISBN 978-1-79984-054-1. [Google Scholar]

- Gardan, J. Additive manufacturing technologies: State of the art and trends. Int. J. Prod. Res. 2016, 54, 3118–3132. [Google Scholar] [CrossRef]

- Gardan, J. Additive manufacturing technologies for polymer composites: State-of-the-art and future trends. In Structure and Properties of Additive Manufactured Polymer Components; Woodhead Publishing: Cambridge, UK, 2020. [Google Scholar]

- Rane, K.; Strano, M. A comprehensive review of extrusion-based additive manufacturing processes for rapid production of metallic and ceramic parts. Adv. Manuf. 2019, 7, 155–173. [Google Scholar] [CrossRef]

- Al Rashid, A.; Khan, S.A.; Al-Ghamdi, S.G.; Koç, M. Additive manufacturing: Technology, applications, markets, and opportunities for the built environment. Autom. Constr. 2020, 118, 103268. [Google Scholar] [CrossRef]

- Živanović, S.; Popović, M.; Vorkapić, N.; Pjević, M.; Slavković, N. An overview of rapid prototyping technologies using subtractive, additive and formative processes. FME Trans. 2020, 48, 246–253. [Google Scholar] [CrossRef]

- Chua, C.K.; Leong, K.F.; Lim, C.S. Rapid Prototyping: Principles and Applications, 3rd ed.; World Scientific: River Edge, NJ, USA, 2010; ISBN 978-981-277-897-0. [Google Scholar]

- Sztorch, B.; Brząkalski, D.; Jałbrzykowski, M.; Przekop, R.E. Processing Technologies for Crisis Response on the Example of COVID-19 Pandemic—Injection Molding and FFF Case Study. Processes 2021, 9, 791. [Google Scholar] [CrossRef]

- Picariello, P. Committee F42 on Additive Manufacturing Technologies, ASTM F42-Additive Manufacturing Technologies; ASTM International: West Conshohocken, PA, USA, 2017. [Google Scholar]

- Collins, S. What’s New with ASTM F42 On Additive Manufacturing—ASTM Center of Excellence—Research to Standards—Additive Manufacturing. 2022. Available online: https://gain.inl.gov/AMMQualificationWorkshopPresentations/08-Collins-ASTM_AMMQualWkshp.Rev1_2021.08.24.pdf (accessed on 12 February 2024).

- Reddy, K.S.; Dufera, S. Additive manufacturing technologies. BEST Int. J. Manag. Inf. Technol. Eng. 2016, 4, 89–112. [Google Scholar]

- Srivastava, M.; Rathee, S.; Patel, V.; Kumar, A.; Koppad, P.G. A review of various materials for additive manufacturing: Recent trends and processing issues. J. Mater. Res. Technol. 2022, 21, 2612–2641. [Google Scholar] [CrossRef]

- Sefene, E.M. State-of-the-art of selective laser melting process: A comprehensive review. J. Manuf. Syst. 2022, 63, 250–274. [Google Scholar] [CrossRef]

- Vartanian, K.; Brewer, L.; Manley, K.; Cobbs, T. Powder Bed Fusion vs. Directed Energy Deposition Benchmark Study; Optomec Corporation: Albuquerque, NM, USA, 2016. [Google Scholar]

- 3Dnatives. PBF vs. DED: Which Metal 3D Printing Process Should You Choose? Available online: https://www.3dnatives.com/en/pbf-vs-ded-which-metal-3d-printing-process-should-you-choose-140320234/ (accessed on 26 February 2024).

- EREA Future Sky Circular Aviation White Paper—A Research Programme of the Future Sky Joint Research Initiative 2019. Available online: https://futuresky.eu/themes/circular-aviation/ (accessed on 13 January 2024).

- Guo, N.; Leu, M.C. Additive manufacturing: Technology, applications and research needs. Front. Mech. Eng. 2013, 8, 215–243. [Google Scholar] [CrossRef]

- 3DEXPERIENCE Make Dasault Systems—FDM—Fused Deposition Modeling. Available online: https://www.3ds.com/make/service/3d-printing-service/fdm-fused-deposition-modeling (accessed on 14 February 2024).

- Registered Trademark: Stratasys Inc FDM—Trademark Details—Serial Number 74133656, Registration Number 1663961 1991. Available online: https://trademarks.justia.com/741/33/fdm-74133656.html (accessed on 23 February 2024).

- Formlabs. Guide to 3D Printing Materials: Types, Applications, and Properties. Available online: https://formlabs.com/blog/3d-printing-materials/ (accessed on 28 January 2024).

- Mwema, F.M.; Akinlabi, E.T. Basics of Fused Deposition Modelling (FDM). In Fused Deposition Modeling; Springer Briefs in Applied Sciences and Technology; Springer International Publishing: Cham, Switzerland, 2020; pp. 1–15. ISBN 978-3-030-48258-9. [Google Scholar]

- Głowacki, M.; Mazurkiewicz, A.; Słomion, M.; Skórczewska, K. Resistance of 3D-Printed Components, Test Specimens and Products to Work under Environmental Conditions—Review. Materials 2022, 15, 6162. [Google Scholar] [CrossRef]

- Zaldivar, R.J.; Mclouth, T.D.; Ferrelli, G.L.; Patel, D.N.; Hopkins, A.R.; Witkin, D. Effect of initial filament moisture content on the microstructure and mechanical performance of ULTEM® 9085 3D printed parts. Addit. Manuf. 2018, 24, 457–466. [Google Scholar] [CrossRef]

- Stratasys. ULTEMTM 9085 Resin—High-Performance FDM PEI Thermoplastic—Stratasys Catalog. Available online: https://www.stratasys.com/en/materials/materials-catalog/fdm-materials/ultem-9085/ (accessed on 28 February 2024).

- Intamsys Technology Co., Ltd. 3D Printing in Aerospace. Available online: https://www.intamsys.com/aerospace/ (accessed on 29 February 2024).

- Iftekar, S.F.; Aabid, A.; Amir, A.; Baig, M. Advancements and Limitations in 3D Printing Materials and Technologies: A Critical Review. Polymers 2023, 15, 2519. [Google Scholar] [CrossRef] [PubMed]

- Liu, Z.; Wang, Y.; Wu, B.; Cui, C.; Guo, Y.; Yan, C. A critical review of fused deposition modeling 3D printing technology in manufacturing polylactic acid parts. Int. J. Adv. Manuf. Technol. 2019, 102, 2877–2889. [Google Scholar] [CrossRef]

- Moradi, M.; Beygi, R.; Yusof, N.M.; Amiri, A.; Da Silva, L.F.M.; Sharif, S. 3D Printing of Acrylonitrile Butadiene Styrene by Fused Deposition Modeling: Artificial Neural Network and Response Surface Method Analyses. J. Mater. Eng. Perform. 2023, 32, 2016–2028. [Google Scholar] [CrossRef]

- Kotomin, S.V.; Kramarev, D.V.; Obidin, I.M.; Polunin, S.V. Influence of 3D Printing Conditions of Polyethylene Terephthalate Glycol on the Mechanical Properties of Products Based on It. Polym. Sci. Ser. A 2022, 64, 617–623. [Google Scholar] [CrossRef]

- León-Calero, M.; Reyburn Valés, S.C.; Marcos-Fernández, Á.; Rodríguez-Hernandez, J. 3D Printing of Thermoplastic Elastomers: Role of the Chemical Composition and Printing Parameters in the Production of Parts with Controlled Energy Absorption and Damping Capacity. Polymers 2021, 13, 3551. [Google Scholar] [CrossRef] [PubMed]

- Mohd Radzuan, N.A.; Khalid, N.N.; Foudzi, F.M.; Rajendran Royan, N.R.; Sulong, A.B. Mechanical Analysis of 3D Printed Polyamide Composites under Different Filler Loadings. Polymers 2023, 15, 1846. [Google Scholar] [CrossRef] [PubMed]

- Hanitio, E.W.; Lutfhyansyah, N.R.; Efendi, B.M.; Mardiyati, Y.; Steven, S. From Electronic Waste to 3D-Printed Product, How Multiple Recycling Affects High-Impact Polystyrene (HIPS) Filament Performances. Materials 2023, 16, 3412. [Google Scholar] [CrossRef]

- Mallakpour, S.; Tabesh, F.; Hussain, C.M. A new trend of using poly(vinyl alcohol) in 3D and 4D printing technologies: Process and applications. Adv. Colloid Interface Sci. 2022, 301, 102605. [Google Scholar] [CrossRef] [PubMed]

- Geng, P.; Zhao, J.; Gao, Z.; Wu, W.; Ye, W.; Li, G.; Qu, H. Effects of Printing Parameters on the Mechanical Properties of High-Performance Polyphenylene Sulfide Three-Dimensional Printing. 3D Print. Addit. Manuf. 2021, 8, 33–41. [Google Scholar] [CrossRef]

- Geng, P.; Zhao, J.; Wu, W.; Wang, Y.; Wang, B.; Wang, S.; Li, G. Effect of Thermal Processing and Heat Treatment Condition on 3D Printing PPS Properties. Polymers 2018, 10, 875. [Google Scholar] [CrossRef] [PubMed]

- Jiang, S.; Liao, G.; Xu, D.; Liu, F.; Li, W.; Cheng, Y.; Li, Z.; Xu, G. Mechanical properties analysis of polyetherimide parts fabricated by fused deposition modeling. High Perform. Polym. 2019, 31, 97–106. [Google Scholar] [CrossRef]

- SyBridge Technologies. 5 of the Highest-Performing Industrial FDM Plastics. Available online: https://sybridge.com/highest-performing-industrial-fdm-plastics/ (accessed on 20 January 2024).

- McLouth, T.; Severino, J.; Adams, P.; Patel, P.; Zaldivar, D. The impact of print orientation and raster pattern on fracture toughness in additively manufactured ABS. Addit. Manuf. 2017, 18, 103–109. [Google Scholar] [CrossRef]

- Ahn, S.H.; Baek, C.; Lee, S.; Ahn, I.S. Anisotropic Tensile Failure Model of Rapid Prototyping Parts—Fused Deposition Modeling (FDM). Int. J. Mod. Phys. B 2003, 17, 1510–1516. [Google Scholar] [CrossRef]

- Bellehumeur, C.; Li, L.; Sun, Q.; Gu, P. Modeling of Bond Formation Between Polymer Filaments in the Fused Deposition Modeling Process. J. Manuf. Process. 2004, 6, 170–178. [Google Scholar] [CrossRef]

- Zaldivar, R.J.; Witkin, D.B.; McLouth, T.; Patel, D.N.; Schmitt, K.; Nokes, J.P. Influence of processing and orientation print effects on the mechanical and thermal behavior of 3D-Printed ULTEM® 9085 Material. Addit. Manuf. 2017, 13, 71–80. [Google Scholar] [CrossRef]

- Parandoush, P.; Lin, D. A review on additive manufacturing of polymer-fiber composites. Compos. Struct. 2017, 182, 36–53. [Google Scholar] [CrossRef]

- Stratasys Inc. FDM Nylon 12CF—FDM Thermoplastic Filament—Datasheet. Available online: https://www.stratasys.com/en/stratasysdirect/materials/thermoplastics/nylon/nylon-12-carbon-fiber/ (accessed on 21 January 2024).

- Protolabs Network. What’s the Right Resin for SLA? 3D Printing Materials Compared. Available online: https://www.hubs.com/knowledge-base/sla-3d-printing-materials-compared/ (accessed on 1 April 2024).

- Protolabs. Selecting a Material for Stereolithography (SLA) 3D Printing. Available online: https://www.protolabs.com/resources/design-tips/a-guide-to-stereolithography-3d-printing-materials/ (accessed on 1 April 2024).

- Morano, C.; Pagnotta, L. Additive Manufactured Parts Produced Using Selective Laser Sintering Technology: Comparison between Porosity of Pure and Blended Polymers. Polymers 2023, 15, 4446. [Google Scholar] [CrossRef] [PubMed]

- Formlabs. Guide to Selective Laser Sintering (SLS) 3D Printing. Available online: https://formlabs.com/eu/blog/what-is-selective-laser-sintering/ (accessed on 1 April 2024).

- Aurum3D. SLS 3D Printing Materials. Available online: https://www.aurum3d.com/blog/sls-3d-printing-materials/ (accessed on 1 April 2024).

- 3DSPRO. Selective Laser Sintering (SLS) Materials Guide. Available online: https://3dspro.com/resources/blog/selective-laser-sintering-materials-guide (accessed on 3 April 2024).

- Bobby, S.; Singamneni, S. Conformal cooling through thin shell moulds produced by 3D printing. Aust. J. Multi-Discip. Eng. 2013, 9, 155–163. [Google Scholar] [CrossRef]

- Masato, D.; Kim, S.K. Global Workforce Challenges for the Mold Making and Engineering Industry. Sustainability 2023, 16, 346. [Google Scholar] [CrossRef]

- Epictool. The Mold and Die Tooling Industry. Available online: https://epictool.ca/the-mold-and-die-tooling-industry/ (accessed on 1 April 2024).

- Prototool. The Complete Introduction of Mold Parts. Available online: https://prototool.com/mold-parts/ (accessed on 30 March 2024).

- Protolabs Network. 3D Printed Injection Molds: Materials Compared. Available online: https://www.hubs.com/knowledge-base/3d-printed-injection-molds-materials-compared/#requirements (accessed on 28 February 2024).

- Xometry. How to Create 3D-Printed Molds for Injection Molding. Available online: https://www.xometry.com/resources/3d-printing/3d-printed-molds-for-injection-molding/ (accessed on 27 February 2024).

- Engineering.com. Friends or Foes: Additive and Traditional Manufacturing. Available online: https://www.engineering.com/story/friends-or-foes-additive-and-traditional-manufacturing (accessed on 21 January 2024).

- The CASTOR Team. Additive Manufacturing Tooling—Why 3D Printing Technology Is Ideal for Jigs, Tools & Fixtures? Available online: https://www.3dcastor.com/post/why-3d-printing-is-the-best-solution-for-tooling (accessed on 23 January 2024).

- Ebnesajjad, S. Injection Molding. In Fluoroplastics; Elsevier: Amsterdam, The Netherlands, 2015; pp. 236–281. ISBN 978-1-4557-3197-8. [Google Scholar]

- Rosato, D.V.; Rosato, M.G. 4—INJECTION MOLDING. In Plastic Product Material and Process Selection Handbook; Elsevier Science: Amsterdam, The Netherlands, 2004. [Google Scholar] [CrossRef]

- Khan, R.M.; Acharya, G. Plastic Injection Molding Process and Its Aspects for Quality: A Review. Eur. J. Adv. Eng. Technol. 2016, 3, 66–70. [Google Scholar]

- Kausalyah, V.; Nik Maisara, E.N.M.; Shasthri, S. Experimental analysis on the effects of pigmentation in the defects formation of the polypropylene plastic injection moulding. IOP Conf. Ser. Mater. Sci. Eng. 2020, 834, 012038. [Google Scholar] [CrossRef]

- Formlabs. How to Estimate Injection Molding Cost? Available online: https://formlabs.com/blog/injection-molding-cost/ (accessed on 19 January 2024).

- DesignWorld. Mold Design and Tooling for Injection Molding. 2013. Available online: https://www.designworldonline.com/mold-design-tooling-for-injection-molding/ (accessed on 20 January 2024).

- Dizon, J.R.C.; Valino, A.D.; Souza, L.R.; Espera, A.H.; Chen, Q.; Advincula, R.C. Three-dimensional-printed molds and materials for injection molding and rapid tooling applications. MRS Commun. 2019, 9, 1267–1283. [Google Scholar] [CrossRef]

- Wang, H.S.; Wang, Y.N.; Wang, Y.C. Cost estimation of plastic injection molding parts through integration of PSO and BP neural network. Expert Syst. Appl. 2013, 40, 418–428. [Google Scholar] [CrossRef]

- Kerkstra, R. How to Select the Right Tool Steel for Mold Cavities. Available online: https://www.ptonline.com/articles/tooling-how-to-select-the-right-tool-steel-for-mold-cavities (accessed on 20 January 2024).

- Dizon, J.R.C.; Valino, A.D.; Souza, L.R.; Espera, A.H.; Chen, Q.; Advincula, R.C. 3D Printed Injection Molds Using Various 3D Printing Technologies. Mater. Sci. Forum 2020, 1005, 150–156. [Google Scholar] [CrossRef]

- Whlean, C.; Sheahan, C. Using Additive Manufacturing to Produce Injection Moulds Suitable for Short Series Production. Procedia Manuf. 2019, 38, 60–68. [Google Scholar] [CrossRef]

- Afonso, D.; Pires, L.; De Sousa, R.A.; Torcato, R. Direct rapid tooling for polymer processing using sheet metal tools. Procedia Manuf. 2017, 13, 102–108. [Google Scholar] [CrossRef]

- Stratasys. Precision Prototyping: The Role of 3D Printed Molds in the Injection Molding Industry, White Paper—Stratasys. 2014. Available online: https://www.stratasys.com/en/resources/whitepapers/precision-prototyping/ (accessed on 20 January 2024).

- Schwaar, C. 3D Printing Injection Molds—The Ultimate Guide (All3DPro). Available online: https://all3dp.com/1/3d-printing-injection-molds-the-ultimate-guide/ (accessed on 3 February 2024).

- Protolabs. 3D Printing Low-Run Injection Molds. Available online: https://www.hubs.com/knowledge-base/3d-printing-low-run-injection-molds/ (accessed on 3 February 2024).

- Formlabs. Formlabs White Paper—Low-Volume Rapid Injection Molding with 3D Printed Molds; Formlabs: Somerville, MA, USA, 2020. [Google Scholar]

- Stratasys. Whie Paper—White PaperTop Five Reasons to Integrate PolyJet Technology into your Product Development Lifecycle. 2020. Available online: https://www.stratasys.com/en/guide-to-3d-printing/technologies-and-materials/polyjet-technology/ (accessed on 8 March 2024).

- Javelin. 3D Print Production Molds. Available online: https://www.javelin-tech.com/3d/manufacture/molds/ (accessed on 8 March 2024).

- Chung, P.; Heller, J.A.; Etemadi, M.; Ottoson, P.E.; Liu, J.A.; Rand, L.; Roy, S. Rapid and Low-cost Prototyping of Medical Devices Using 3D Printed Molds for Liquid Injection Molding. J. Vis. Exp. 2014, 88, e51745. [Google Scholar] [CrossRef]

- Altaf, K.; Qayyum, J.; Rani, A.; Ahmad, F.; Megat-Yusoff, P.; Baharom, M.; Aziz, A.; Jahanzaib, M.; German, R. Performance Analysis of Enhanced 3D Printed Polymer Molds for Metal Injection Molding Process. Metals 2018, 8, 433. [Google Scholar] [CrossRef]

- Godec, D.; Breški, T.; Katalenić, M. Additive Manufacturing of Polymer Moulds for Small-Batch Injection Moulding. Teh. Glas. 2020, 14, 218–223. [Google Scholar] [CrossRef]

- Godec, D.; Gabrić, I.; PilipoviC, A.; Smoljkić, A.; Surma, R. Tensile properties of multi-material 3D-printed parts. In Proceedings of the MOTSP 2018/10th International scientific conference on Management of Technology Step to Sustainable Production, Primošten, Croatia, 6–8 June 2018. [Google Scholar]

- León-Cabezas, M.A.; Martínez-García, A.; Varela-Gandía, F.J. Innovative advances in additive manufactured moulds for short plastic injection series. Procedia Manuf. 2017, 13, 732–737. [Google Scholar] [CrossRef]

- Noble, J.; Walczak, K.; Dornfeld, D. Rapid Tooling Injection Molded Prototypes: A Case Study in Artificial Photosynthesis Technology. Procedia CIRP 2014, 14, 251–256. [Google Scholar] [CrossRef]

- Ma, S.; Gibson, I.; Balaji, G.; Hu, Q.J. Development of epoxy matrix composites for rapid tooling applications. J. Mater. Process. Technol. 2007, 192–193, 75–82. [Google Scholar] [CrossRef]

- Rahmati, S.; Dickens, P. Rapid tooling analysis of Stereolithography injection mould tooling. Int. J. Mach. Tools Manuf. 2007, 47, 740–747. [Google Scholar] [CrossRef]

- RPM Industrial Rubber Parts. 3 Types of Rubber Injection Molding|RPM Rubber Parts. Available online: https://www.rpmrubberparts.com/blog/3-types-of-rubber-injection-molding (accessed on 2 March 2024).

- Langnau, L.; 3D Print Molds for Custom Manufacture of Rubber Parts. MakePartsFast 21 February 2018. Available online: https://www.makepartsfast.com/3d-print-molds-for-custom-manufacture-of-rubber-parts/ (accessed on 3 February 2024).

- Dimla, D.E.; Camilotto, M.; Miani, F. Design and optimisation of conformal cooling channels in injection moulding tools. J. Mater. Process. Technol. 2005, 164, 1294–1300. [Google Scholar] [CrossRef]

- Spina, R.; Spekowius, M.; Hopmann, C. Multiphysics simulation of thermoplastic polymer crystallization. Mater. Des. 2016, 95, 455–469. [Google Scholar] [CrossRef]

- Sachs, E.; Wylonis, E.; Allen, S.; Cima, M.; Guo, H. Production of injection molding tooling with conformal cooling channels using the three dimensional printing process. Polym. Eng. Sci. 2000, 40, 1232–1247. [Google Scholar] [CrossRef]

- Xu, X.; Sachs, E.; Allen, S. The design of conformal cooling channels in injection molding tooling. Polym. Eng. Sci. 2001, 41, 1265–1279. [Google Scholar] [CrossRef]

- Hsu, F.H.; Wang, K.; Huang, C.T.; Chang, R.Y. Investigation on conformal cooling system design in injection molding. Adv. Prod. Eng. Manag. 2013, 8, 107–115. [Google Scholar] [CrossRef]

- Khan, M.; Afaq, S.K.; Khan, N.U.; Ahmad, S. Cycle Time Reduction in Injection Molding Process by Selection of Robust Cooling Channel Design. ISRN Mech. Eng. 2014, 2014, 1–8. [Google Scholar] [CrossRef]

- Saifullah, A.B.M.; Masood, S.H.; Sbarski, I. New Cooling Channel Design for Injection Moulding. In Proceedings of the World Congress on Engineering, London, UK, 1–3 July 2009. [Google Scholar]

- Feng, S.; Kamat, A.M.; Pei, Y. Design and fabrication of conformal cooling channels in molds: Review and progress updates. Int. J. Heat Mass Transf. 2021, 171, 121082. [Google Scholar] [CrossRef]

- Jahan, S.; El-Mounayri, H. A Thermomechanical Analysis of Conformal Cooling Channels in 3D Printed Plastic Injection Molds. Appl. Sci. 2018, 8, 2567. [Google Scholar] [CrossRef]

- Chen, Q.; Mangadlao, J.D.; Wallat, J.; De Leon, A.; Pokorski, J.K.; Advincula, R.C. 3D Printing Biocompatible Polyurethane/Poly(lactic acid)/Graphene Oxide Nanocomposites: Anisotropic Properties. ACS Appl. Mater. Interfaces 2017, 9, 4015–4023. [Google Scholar] [CrossRef]

- De Leon, A.C.; Chen, Q.; Palaganas, N.B.; Palaganas, J.O.; Manapat, J.; Advincula, R.C. High performance polymer nanocomposites for additive manufacturing applications. React. Funct. Polym. 2016, 103, 141–155. [Google Scholar] [CrossRef]

- Wick-Joliat, R.; Tschamper, M.; Kontic, R.; Penner, D. Water-soluble sacrificial 3D printed molds for fast prototyping in ceramic injection molding. Addit. Manuf. 2021, 48, 102408. [Google Scholar] [CrossRef]

- An Introduction to Injection Molding, Casting, and Thermoforming. Available online: https://formlabs.com/eu/blog/low-volume-production-injection-molding-casting-thermoforming/ (accessed on 2 March 2024).

- Kang, J.; Shangguan, H.; Deng, C.; Hu, Y.; Yi, J.; Wang, X.; Zhang, X.; Huang, T. Additive manufacturing-driven mold design for castings. Addit. Manuf. 2018, 22, 472–478. [Google Scholar] [CrossRef]

- O’Neill, B. Anniwa—Guide to 3D Printing Molds for Metal Casting. Available online: https://www.aniwaa.com/guide/3d-printers/guide-3d-printing-molds-for-metal-casting/ (accessed on 2 March 2024).

- Martinez, D.; Bate, C.; Manogharan, G. Towards Functionally Graded Sand Molds for Metal Casting: Engineering Thermo-mechanical Properties Using 3D Sand Printing. JOM 2020, 72, 1340–1354. [Google Scholar] [CrossRef]

- Mitra, S.; Rodríguez De Castro, A.; El Mansori, M. The effect of ageing process on three-point bending strength and permeability of 3D printed sand molds. Int. J. Adv. Manuf. Technol. 2018, 97, 1241–1251. [Google Scholar] [CrossRef]

- Sivarupan, T.; El Mansori, M.; Coniglio, N.; Dargusch, M. Effect of process parameters on flexure strength and gas permeability of 3D printed sand molds. J. Manuf. Process. 2020, 54, 420–437. [Google Scholar] [CrossRef]

- Sivarupan, T.; Upadhyay, M.; Ali, Y.; El Mansori, M.; Dargusch, M.S. Reduced consumption of materials and hazardous chemicals for energy efficient production of metal parts through 3D printing of sand molds. J. Clean. Prod. 2019, 224, 411–420. [Google Scholar] [CrossRef]

- Snelling, D.; Li, Q.; Meisel, N.; Williams, C.B.; Batra, R.C.; Druschitz, A.P. Lightweight Metal Cellular Structures Fabricated via 3D Printing of Sand Cast Molds. Adv. Eng. Mater. 2015, 17, 923–932. [Google Scholar] [CrossRef]

- Formlabs. Formlabs White Paper—Introduction to Casting for 3D Printed Jewelry Patterns. 2021. Available online: https://3d.formlabs.com/white-paper-introduction-casting-3d-printed-jewelry-patterns/ (accessed on 2 April 2024).

- Formlabs. FormLabs White Paper—Vulcanized Rubber Molding with 3D Printed Masters. 2020. Available online: https://3d.formlabs.com/white-paper-vulcanized-rubber-molding-3d-printed-masters/ (accessed on 2 April 2024).

- Formlabs. Injection Molding, Casting, and Thermoforming with 3D Printed Molds. Available online: https://formlabs.com/blog/low-volume-production-injection-molding-casting-thermoforming/ (accessed on 2 April 2024).

- Fraunhofer Institute for Production Engineering and Automation IPA. Combined Advantages of 3D Printing and Injection Molding. 14 March 2018. Available online: https://www.ipa.fraunhofer.de/de/presse/presseinformationen/vorzuege-von-3d-druck-und-spritzguss-kombiniert.html (accessed on 2 March 2024).

- Watkin, H. Fraunhofer IPA Combine 3D Printing and Injection Molding Advantages. 15 March 2018. Available online: https://all3dp.com/fraunhofer-ipa-combine-3d-printing-injection-molding-advantages/ (accessed on 2 March 2024).

- Koivikko, A.; Sariola, V. Fabrication of Soft Devices with Buried Fluid Channels by Using Sacrificial 3D Printed Molds. In Proceedings of the 2019 2nd IEEE International Conference on Soft Robotics (RoboSoft), Seoul, Republic of Korea, 14–18 April 2019; IEEE: Seoul, Republic of Korea, 2019; pp. 509–513. [Google Scholar]

- Traczyk, M. Zmorph3D—How to Create 3D Printed PVA Molds Ready for Metal Fluid Casting. Available online: https://zmorph3d.com/blog/3d-printed-pva-molds-metal-fluid/ (accessed on 2 March 2024).

- Tan, E.T.W.; Ling, J.M.; Dinesh, S.K. The feasibility of producing patient-specific acrylic cranioplasty implants with a low-cost 3D printer. J. Neurosurg. 2016, 124, 1531–1537. [Google Scholar] [CrossRef] [PubMed]

- Abdel Hay, J.; Smayra, T.; Moussa, R. Customized Polymethylmethacrylate Cranioplasty Implants Using 3-Dimensional Printed Polylactic Acid Molds: Technical Note with 2 Illustrative Cases. World Neurosurg. 2017, 105, 971–979. [Google Scholar] [CrossRef]

- Ajmal, A.; Meskarzadeh, A.; Genina, N.; Hirschberg, C.; Boetker, J.P.; Rantanen, J. The Use of 3D Printed Molds to Cast Tablets with a Designed Disintegration Profile. AAPS PharmSciTech 2019, 20, 127. [Google Scholar] [CrossRef]

- Lv, S.; Nie, J.; Gao, Q.; Xie, C.; Zhou, L.; Qiu, J.; Fu, J.; Zhao, X.; He, Y. Micro/nanofabrication of brittle hydrogels using 3D printed soft ultrafine fiber molds for damage-free demolding. Biofabrication 2020, 12, 025015. [Google Scholar] [CrossRef] [PubMed]

- Formlabs. FormLabs White Paper—Low-Volume Rapid Thermoforming with 3D Printed Molds. 2022. Available online: https://3d.formlabs.com/thermoforming/#form (accessed on 2 March 2024).

- Chimento, J.; Jason Highsmith, M.; Crane, N. 3D printed tooling for thermoforming of medical devices. Rapid Prototyp. J. 2011, 17, 387–392. [Google Scholar] [CrossRef]

- Z Corp. ZP—Material Safety Data Sheet zp130 Powder 2007. Available online: http://ytec3d.com/wp-content/uploads/2014/08/zp130.pdf (accessed on 2 February 2024).

- Junk, S.; Sämann-Sun, J.; Niederhofer, M. Application of 3D Printing for the Rapid Tooling of Thermoforming Moulds. In Proceedings of the 36th International MATADOR Conference; Hinduja, S., Li, L., Eds.; Springer: London, UK, 2010; pp. 369–372. ISBN 978-1-84996-431-9. [Google Scholar]

- Serrano-Mira, J.; Gual-Ortí, J.; Bruscas-Bellido, G.; Abellán-Nebot, J.V. Use of additive manufacturing to obtain moulds to thermoform tactile graphics for people with visual impairment. Procedia Manuf. 2017, 13, 810–817. [Google Scholar] [CrossRef]

- Stratasys. Stratasys White Paper—Additively Manufactured Composite Tooling. 2020. Available online: https://www.stratasys.com/en/resources/whitepapers/additively-manufactured-composite-tooling/ (accessed on 2 March 2024).

- Formlabs. WHITE PAPER Carbon Fiber Parts Manufacturing with 3D Printed Molds; Formlabs: Somerville, MA, USA, 2021. [Google Scholar]

- Stratasys. ULTEMTM 1010 Resin Data Sheet. 2024. Available online: https://www.stratasys.com/siteassets/materials/materials-catalog/fdm-materials/ultem1010/mds_fdm_ultem-1010-resin_0224a.pdf?v=49221c (accessed on 2 March 2024).

- Dynamism. How to 3D Print Molds for Carbon Fiber Parts. Available online: https://www.dynamism.com/learn/automotive/how-to-3d-print-carbon-fiber-molds.html (accessed on 2 March 2024).

- Manufacturing—3D-Printed Tools. 2016. Available online: https://www.ornl.gov/news/manufacturing-3d-printed-tools (accessed on 2 March 2024).

- ORNL and Boeing Perform First Successful Autoclave Testing of 100% 3D Printed Tools. Available online: https://www.3ders.org/articles/20160506-ornl-and-boeing-perform-first-successful-autoclave-testing-of-3d-printed-tools.html (accessed on 1 March 2024).

- Kunc, V.; Lindahl, J.; Dinwiddie, R.; Post, B.; Love, L.; Matlack, M.; Fahey, R.L., Jr.; Hassen, A.A. Investigation of In-Autoclave Additive Manufacturing Composite Tooling; CAMX: Anaheim, CA, USA, 2016. [Google Scholar]

- Gardiner, G. 3D-Printed CFRP Tools for Serial Production of Composite Landing Flaps. 28 June 2023. Available online: https://www.compositesworld.com/articles/3d-printed-cfrp-tools-for-serial-production-of-composite-landing-flaps (accessed on 1 March 2024).

- Munoz-Guijosa, J.M.; Zapata Martínez, R.; Martínez Cendrero, A.; Díaz Lantada, A. Rapid Prototyping of Personalized Articular Orthoses by Lamination of Composite Fibers upon 3D-Printed Molds. Materials 2020, 13, 939. [Google Scholar] [CrossRef]

- De La Lastra, A.; Hixon, K.; Aryan, L.; Banks, A.; Lin, A.; Hall, A.; Sell, S. Tissue Engineering Scaffolds Fabricated in Dissolvable 3D-Printed Molds for Patient-Specific Craniofacial Bone Regeneration. J. Funct. Biomater. 2018, 9, 46. [Google Scholar] [CrossRef]

- Jacobs, C.; Lin, A. A New Classification of Three-Dimensional Printing Technologies: Systematic Review of Three-Dimensional Printing for Patient-Specific Craniomaxillofacial Surgery. Plast. Reconstr. Surg. 2017, 139, 1211–1220. [Google Scholar] [CrossRef] [PubMed]

- Mani, M.; Sadia, M.; Jaganathan, S.; Khudzari, A.; Supriyanto, E.; Saidin, S.; Ramakrishna, S.; Ismail, A.; Mohd Faudzi, A.A. A review on 3D printing in tissue engineering applications. J. Polym. Eng. 2022, 42, 243–265. [Google Scholar] [CrossRef]

- Hixon, K.; Melvin, A.; Lin, A.; Hall, A.; Sell, S. Cryogel scaffolds from patient-specific 3D-printed molds for personalized tissue-engineered bone regeneration in pediatric cleft-craniofacial defects. J. Biomater. Appl. 2017, 32, 088532821773482. [Google Scholar] [CrossRef]

- Duran, C.; Subbian, V.; Giovanetti, M.; Simkins, J.; Beyette, F. Experimental desktop 3D printing using dual extrusion and water-soluble polyvinyl alcohol. Rapid Prototyp. J. 2015, 21, 528–534. [Google Scholar] [CrossRef]

- Paradossi, G.; Cavalieri, F.; Chiessi, E.; Spagnoli, C.; Cowman, M.K. Poly(vinyl alcohol) as versatile biomaterial for potential biomedical applications. J. Mater. Sci. Mater. Med. 2003, 14, 687–691. [Google Scholar] [CrossRef]

- Baker, M.; Walsh, S.; Schwartz, Z.; Boyan, B. A review of polyvinyl alcohol and its uses in cartilage and orthopedic applications. J. Biomed. Mater. Res. B Appl. Biomater. 2012, 100, 1451–1457. [Google Scholar] [CrossRef]

- Mohanty, S.; Larsen, L.B.; Trifol, J.; Szabo, P.; Burri, H.V.R.; Canali, C.; Dufva, M.; Emnéus, J.; Wolff, A. Fabrication of scalable and structured tissue engineering scaffolds using water dissolvable sacrificial 3D printed moulds. Mater. Sci. Eng. C 2015, 55, 569–578. [Google Scholar] [CrossRef]

- Saggiomo, V.; Velders, A.H. Simple 3D Printed Scaffold-Removal Method for the Fabrication of Intricate Microfluidic Devices. Adv. Sci. 2015, 2, 1500125. [Google Scholar] [CrossRef]

- Brooks-Richards, T.L.; Paxton, N.C.; Allenby, M.C.; Woodruff, M.A. Dissolvable 3D printed PVA moulds for melt electrowriting tubular scaffolds with patient-specific geometry. Mater. Des. 2022, 215, 110466. [Google Scholar] [CrossRef]

- Rankin, T.; Mailey, B.; Cucher, D.; Giovinco, N.; Armstrong, D.; Gosman, A. Use of 3D Printing for Auricular Template Molds in First Stage Microtia. Plast. Reconstr. Surg. 2014, 134, 16–17. [Google Scholar] [CrossRef][Green Version]

- Yang, Y.; Li, H.; Xu, Y.; Dong, Y.; Shan, W.; Shen, J. Fabrication and evaluation of dental fillers using customized molds via 3D printing technology. Int. J. Pharm. 2019, 562, 66–75. [Google Scholar] [CrossRef] [PubMed]

- Miller, M.; Hutchins, G. Development of anatomically realistic PET and PET/CT phantoms with rapid prototyping technology. In Proceedings of the 2007 IEEE Nuclear Science Symposium Conference Record, Honolulu, HI, USA, 26 October–3 November 2007; IEEE: Piscataway, NJ, USA, 2007; Volume 2007, p. 4257, ISBN 978-1-4244-0922-8. [Google Scholar]

- Heron, W.; dos Santos, J.; Fontes, R.; Daltro, P.; Gasparetto, E.; Marchiori, E.; Campbell, S. Additive manufacturing models of fetuses built from three-dimensional ultrasound, magnetic resonance imaging and computed tomography scan data. Ultrasound Obstet. Gynecol. Off. J. Int. Soc. Ultrasound Obstet. Gynecol. 2010, 36, 355–361. [Google Scholar] [CrossRef]

- Samuel, B.; Pinto, C.; Pietila, T.; Vettukattil, J. Ultrasound-derived three-dimensional printing in congenital heart disease. J. Digit. Imaging 2015, 28, 459–461. [Google Scholar] [CrossRef] [PubMed]

- Pokorny, T.; Tesarik, J. 3D Printed Multi-layer Molds of Human Head Tissue Phantoms for Microwave Stroke Detection. In Proceedings of the 2019 PhotonIcs & Electromagnetics Research Symposium—Spring (PIERS-Spring), Rome, Italy, 17–20 June 2019; IEEE: Rome, Italy, 2019; pp. 1424–1427. [Google Scholar]

- Costa, D.N.; Chatzinoff, Y.; Passoni, N.M.; Kapur, P.; Roehrborn, C.G.; Xi, Y.; Rofsky, N.M.; Torrealba, J.; Francis, F.; Futch, C.; et al. Improved Magnetic Resonance Imaging-Pathology Correlation with Imaging-Derived, 3D-Printed, Patient-Specific Whole-Mount Molds of the Prostate. Investig. Radiol. 2017, 52, 507–513. [Google Scholar] [CrossRef]

- Priester, A.; Wu, H.; Khoshnoodi, P.; Schneider, D.; Zhang, Z.; Asvadi, N.H.; Sisk, A.; Raman, S.; Reiter, R.; Grundfest, W.; et al. Registration Accuracy of Patient-Specific, Three-Dimensional-Printed Prostate Molds for Correlating Pathology with Magnetic Resonance Imaging. IEEE Trans. Biomed. Eng. 2019, 66, 14–22. [Google Scholar] [CrossRef]

- Lasserve, J.; Lim, S.A.; Wisse, L.; Ittyerah, R.; Ravikumar, S.; Lavery, M.; Robinson, J.L.; Schuck, T.; Grossman, M.; Lee, E.B.; et al. Optimized extraction of the medial temporal lobe for postmortem MRI based on custom 3D printed molds: Neuroimaging/New imaging methods. Alzheimers Dement. 2020, 16, e043254. [Google Scholar] [CrossRef]

- Weadock, W.J.; Heisel, C.J.; Kahana, A.; Kim, J. Use of 3D Printed Models to Create Molds for Shaping Implants for Surgical Repair of Orbital Fractures. Acad. Radiol. 2020, 27, 536–542. [Google Scholar] [CrossRef]

- Winkel, A.; Honart, A.; Robinson, A.; Jones, A.-A.; Squires, A.; Royce, C.; McKeon, B.A.; Bookman, L.; Vicari, L.; Dalrymple, J.; et al. Validation of a Simulation Model for Laparoscopic Myomectomy Developed with 3D-Printed Molds. Obstet. Gynecol. 2018, 132, 33S. [Google Scholar] [CrossRef]

- Hummelink, S.; Verhulst, A.C.; Maal, T.J.J.; Ulrich, D.J.O. Applications and limitations of using patient-specific 3D printed molds in autologous breast reconstruction. Eur. J. Plast. Surg. 2018, 41, 571–576. [Google Scholar] [CrossRef] [PubMed]

- Moreira, F.T.C.; Guerreiro, J.R.L.; Brandão, L.; Sales, M.G.F. 1—Synthesis of molecular biomimetics. In Biomimetic Technologies; Ngo, T.D., Ed.; Woodhead Publishing: Sawston, UK, 2015; pp. 3–31. ISBN 978-0-08-100249-0. [Google Scholar]

- Chow, W.W.Y.; Lei, K.F.; Shi, G.; Li, W.J.; Huang, Q. Microfluidic channel fabrication by PDMS-interface bonding. Smart Mater. Struct. 2006, 15, S112–S116. [Google Scholar] [CrossRef]

- Miranda, I.; Souza, A.; Sousa, P.; Ribeiro, J.; Castanheira, E.M.S.; Lima, R.; Minas, G. Properties and Applications of PDMS for Biomedical Engineering: A Review. J. Funct. Biomater. 2021, 13, 2. [Google Scholar] [CrossRef]

- Razavi Bazaz, S.; Kashaninejad, N.; Azadi, S.; Patel, K.; Asadnia, M.; Jin, D.-Y.; Ebrahimi Warkiani, M. Rapid Softlithography Using 3D-Printed Molds. Adv. Mater. 2019, 4, 1900425. [Google Scholar] [CrossRef]

- Mi, S.; Du, Z.; Xu, Y.; Sun, W. The crossing and integration between microfluidic technology and 3D printing for organ-on-chips. J. Mater. Chem. B 2018, 6, 6191–6206. [Google Scholar] [CrossRef]

- Hwang, Y.; Paydar, O.H.; Candler, R.N. 3D printed molds for non-planar PDMS microfluidic channels. Sens. Actuators Phys. 2015, 226, 137–142. [Google Scholar] [CrossRef]

- Dinh, T.; Phan, H.-P.; Kashaninejad, N.; Nguyen, T.-K.; Dao, D.V.; Nguyen, N.-T. An On-Chip SiC MEMS Device with Integrated Heating, Sensing, and Microfluidic Cooling Systems. Adv. Mater. Interfaces 2018, 5, 1800764. [Google Scholar] [CrossRef]

- Chan, H.N.; Chen, Y.; Shu, Y.; Chen, Y.; Tian, Q.; Wu, H. Direct, one-step molding of 3D-printed structures for convenient fabrication of truly 3D PDMS microfluidic chips. Microfluid. Nanofluidics 2015, 19, 9–18. [Google Scholar] [CrossRef]

- Villegas, M.; Cetinic, Z.; Shakeri, A.; Didar, T.F. Fabricating smooth PDMS microfluidic channels from low-resolution 3D printed molds using an omniphobic lubricant-infused coating. Anal. Chim. Acta 2018, 1000, 248–255. [Google Scholar] [CrossRef]

- Comina, G.; Suska, A.; Filippini, D. Low cost lab-on-a-chip prototyping with a consumer grade 3D printer. Lab. Chip 2014, 14, 2978–2982. [Google Scholar] [CrossRef] [PubMed]

- Waheed, S.; Cabot, J.M.; Macdonald, N.P.; Kalsoom, U.; Farajikhah, S.; Innis, P.C.; Nesterenko, P.N.; Lewis, T.W.; Breadmore, M.C.; Paull, B. Enhanced physicochemical properties of polydimethylsiloxane based microfluidic devices and thin films by incorporating synthetic micro-diamond. Sci. Rep. 2017, 7, 15109. [Google Scholar] [CrossRef]

- Shrestha, J.; Ghadiri, M.; Shanmugavel, M.; Razavi Bazaz, S.; Vasilescu, S.; Ding, L.; Ebrahimi Warkiani, M. A rapidly prototyped lung-on-a-chip model using 3D-printed molds. Organs-on-a-Chip 2019, 1, 100001. [Google Scholar] [CrossRef]

- Yasuda, Y.; Zhang, K.; Sasaki, O.; Tomita, M.; Rival, D.; Galipon, J. Manufacturing of Biomimetic Silicone Rubber Films for Experimental Fluid Mechanics: 3D Printed Shark Skin Molds. J. Electrochem. Soc. 2019, 166, B3302–B3308. [Google Scholar] [CrossRef]

- Van Der Borg, G.; Warner, H.; Ioannidis, M.; Van Den Bogaart, G.; Roos, W.H. PLA 3D Printing as a Straightforward and Versatile Fabrication Method for PDMS Molds. Polymers 2023, 15, 1498. [Google Scholar] [CrossRef]

- Hernández Vera, R.; O’Callaghan, P.; Fatsis-Kavalopoulos, N.; Kreuger, J. Modular microfluidic systems cast from 3D-printed molds for imaging leukocyte adherence to differentially treated endothelial cultures. Sci. Rep. 2019, 9, 11321. [Google Scholar] [CrossRef] [PubMed]

- Dhaliwal, S.; Gupta, S.K.; Huang, J.; Kumar, M. A Feature-Based Approach to Automated Design of Multi-Piece Sacrificial Molds. J. Comput. Inf. Sci. Eng. 2001, 1, 225–234. [Google Scholar] [CrossRef][Green Version]

- Spielman, S. MachineDesign: Dissolving Molds: A New Way to Think About Injection Molding. Available online: https://www.machinedesign.com/3d-printing-cad/video/21271382/nexa3d-dissolving-molds-a-new-way-to-think-about-injection-molding (accessed on 1 March 2024).

- Erickson, A. The Value and Benefits of FDM Sacrificial Tooling. Available online: https://www.cati.com/blog/value-benefits-fdm-sacrificial-tooling/ (accessed on 1 March 2024).

- Goh, W.; Hashimoto, M. Fabrication of 3D Microfluidic Channels and In-Channel Features Using 3D Printed, Water-Soluble Sacrificial Mold. Macromol. Mater. Eng. 2018, 303, 1700484. [Google Scholar] [CrossRef]

- Lu, R.; Chandrasekaran, S.; Du Frane, W.L.; Landingham, R.L.; Worsley, M.A.; Kuntz, J.D. Complex shaped boron carbides from negative additive manufacturing. Mater. Des. 2018, 148, 8–16. [Google Scholar] [CrossRef]

- Xiao, S.; Zhao, T.; Wang, J.; Wang, C.; Du, J.; Ying, L.; Lin, J.; Zhang, C.; Hu, W.; Wang, L.; et al. Gelatin Methacrylate (GelMA)-Based Hydrogels for Cell Transplantation: An Effective Strategy for Tissue Engineering. Stem Cell Rev. Rep. 2019, 15, 664–679. [Google Scholar] [CrossRef] [PubMed]

- Mohanty, S.; Sanger, K.; Heiskanen, A.; Trifol, J.; Szabo, P.; Dufva, M.; Emnéus, J.; Wolff, A. Fabrication of scalable tissue engineering scaffolds with dual-pore microarchitecture by combining 3D printing and particle leaching. Mater. Sci. Eng. C 2016, 61, 180–189. [Google Scholar] [CrossRef]

- Li, S.; Li, H.; Shang, X.; He, J.; Hu, Y. Recent advances in 3D printing sacrificial templates for fabricating engineered vasculature. MedComm—Biomater. Appl. 2023, 2, e46. [Google Scholar] [CrossRef]

- Nagarajan, S.; Belaid, H.; Radhakrishnan, S.; Teyssier, C.; Balme, S.; Miele, P.; Cornu, D.; Subbaraya, N.K.; Cavaillès, V.; Bechelany, M. Sacrificial mold-assisted 3D printing of stable biocompatible gelatin scaffolds. Bioprinting 2021, 22, e00140. [Google Scholar] [CrossRef]

- Zou, Q.; Tian, X.; Luo, S.; Yuan, D.; Xu, S.; Yang, L.; Ma, M.; Ye, C. Agarose composite hydrogel and PVA sacrificial materials for bioprinting large-scale, personalized face-like with nutrient networks. Carbohydr. Polym. 2021, 269, 118222. [Google Scholar] [CrossRef]

- Park, S.-H.; Kang, B.-K.; Lee, J.E.; Chun, S.W.; Jang, K.; Kim, Y.H.; Jeong, M.A.; Kim, Y.; Kang, K.; Lee, N.K.; et al. Design and Fabrication of a Thin-Walled Free-Form Scaffold on the Basis of Medical Image Data and a 3D Printed Template: Its Potential Use in Bile Duct Regeneration. ACS Appl. Mater. Interfaces 2017, 9, 12290–12298. [Google Scholar] [CrossRef]

- Lee, J.E.; Park, S.J.; Yoon, Y.; Son, Y.; Park, S.-H. Fabrication of 3D freeform porous tubular constructs with mechanical flexibility mimicking that of soft vascular tissue. J. Mech. Behav. Biomed. Mater. 2018, 91, 193–201. [Google Scholar] [CrossRef]

- Hu, M.; Dailamy, A.; Lei, X.; Parekh, U.; McDonald, D.; Kumar, A.; Mali, P. Facile Engineering of Long-Term Culturable Ex Vivo Vascularized Tissues Using Biologically Derived Matrices. Adv. Healthc. Mater. 2018, 7, 1800845. [Google Scholar] [CrossRef]

- Davoodi, E.; Montazerian, H.; Zhianmanesh, M.; Abbasgholizadeh, R.; Haghniaz, R.; Baidya, A.; Pourmohammadali, H.; Annabi, N.; Weiss, P.; Toyserkani, E.; et al. Template-Enabled Biofabrication of Thick 3D Tissues with Patterned Perfusable Macrochannels (Adv. Healthcare Mater. 7/2022). Adv. Healthc. Mater. 2022, 11, 2270038. [Google Scholar] [CrossRef]

- Montazerian, H.; Mohamed, M.G.A.; Montazeri, M.M.; Kheiri, S.; Milani, A.S.; Kim, K.; Hoorfar, M. Permeability and mechanical properties of gradient porous PDMS scaffolds fabricated by 3D-printed sacrificial templates designed with minimal surfaces. Acta Biomater. 2019, 96, 149–160. [Google Scholar] [CrossRef]

- Haq, M.A.; Su, Y.; Wang, D. Mechanical properties of PNIPAM based hydrogels: A review. Mater. Sci. Eng. C 2016, 70, 842–855. [Google Scholar] [CrossRef] [PubMed]

- Lee, J.; Wang, X.; Faley, S.; Baer, B.; Balikov, D.; Sung, H.-J.; Bellan, L. Development of 3D Microvascular Networks within Gelatin Hydrogels Using Thermoresponsive Sacrificial Microfibers. Adv. Healthc. Mater. 2016, 5, 781. [Google Scholar] [CrossRef]

- Lee, J.; Kim, D.-H.; Yoon, J.-K.; Park, D.; Kim, H.-S.; Shin, Y.M.; Baek, W.; Kang, M.-L.; Sung, H.-J. Microchannel network hydrogel induced ischemic blood perfusion connection. Nat. Commun. 2020, 11, 615. [Google Scholar] [CrossRef] [PubMed]

- Giuliano, E.; Paolino, D.; Fresta, M.; Cosco, D. Mucosal Applications of Poloxamer 407-Based Hydrogels: An Overview. Pharmaceutics 2018, 10, 159. [Google Scholar] [CrossRef] [PubMed]

- Kolesky, D.B.; Homan, K.A.; Skylar-Scott, M.A.; Lewis, J.A. Three-dimensional bioprinting of thick vascularized tissues. Proc. Natl. Acad. Sci. USA 2016, 113, 3179–3184. [Google Scholar] [CrossRef] [PubMed]

- Nothdurfter, D.; Ploner, C.; Coraça-Huber, D.; Wilflingseder, D.; Müller, T.; Hermann, M.; Hagenbuchner, J.; Ausserlechner, M. 3D bioprinted, vascularized neuroblastoma tumor environment in fluidic chip devices for precision medicine drug testing. Biofabrication 2022, 14, 035002. [Google Scholar] [CrossRef]

- Neufeld, L.; Yeini, E.; Reisman, N.; Shtilerman, Y.; Ben-Shushan, D.; Pozzi, S.; Madi, A.; Tiram, G.; Eldar-Boock, A.; Ferber, S.; et al. Microengineered perfusable 3D-bioprinted glioblastoma model for in vivo mimicry of tumor microenvironment. Sci. Adv. 2021, 7, eabi9119. [Google Scholar] [CrossRef]

- Hynes, W.; Pepona, M.; Robertson, C.; Alvarado, J.; Dubbin, K.; Triplett, M.; Adorno, J.; Randles, A.; Moya, M. Examining metastatic behavior within 3D bioprinted vasculature for the validation of a 3D computational flow model. Sci. Adv. 2020, 6, eabb3308. [Google Scholar] [CrossRef]

- Ji, S.; Almeida, E.; Guvendiren, M. 3D Bioprinting of Complex Channels within Cell-Laden Hydrogels. Acta Biomater. 2019, 95, 214–224. [Google Scholar] [CrossRef]

- Zhou, K.; Dey, M.; Ayan, B.; Zhang, Z.; Ozbolat, V.; Kim, M.H.; Khristov, V.; Ozbolat, I. Fabrication of PDMS microfluidic devices using nanoclay-reinforced Pluronic F-127 as a sacrificial ink. Biomed. Mater. 2021, 16, 045005. [Google Scholar] [CrossRef]

- Wang, A.; Dong, L.; Guo, Z.; Sun, W.; Mi, S. A methacrylated hyaluronic acid network reinforced Pluronic F-127 gel for treatment of bacterial keratitis. Biomed. Mater. 2022, 17, 045017. [Google Scholar] [CrossRef]

- Ludueña, L.; Alvarez, V.; Vázquez, A. Processing and microstructure of PCL/clay nanocomposites. Mater. Sci. Eng. A 2007, 460, 121–129. [Google Scholar] [CrossRef]

- Yuan, X.; Duan, X.; Enhejirigala; Li, Z.; Yao, B.; Song, W.; Wang, Y.; Kong, Y.; Zhu, S.; Zhang, F.; et al. Reciprocal interaction between vascular niche and sweat gland promotes sweat gland regeneration. Bioact. Mater. 2023, 21, 340–357. [Google Scholar] [CrossRef]

- Ryma, M.; Genç, H.; Nadernezhad, A.; Paulus, I.; Schneidereit, D.; Friedrich, O.; Andelovic, K.; Lyer, S.; Alexiou, C.; Cicha, I.; et al. A Print-and-Fuse Strategy for Sacrificial Filaments Enables Biomimetically Structured Perfusable Microvascular Networks with Functional Endothelium Inside 3D Hydrogels. Adv. Mater. 2022, 34, 2200653. [Google Scholar] [CrossRef] [PubMed]

- Wang, H.; Zhou, X.; Wang, J.; Zhang, X.; Zhu, M.; Wang, H. Fabrication of channeled scaffolds through polyelectrolyte complex (PEC) printed sacrificial templates for tissue formation. Bioact. Mater. 2022, 17, 261–275. [Google Scholar] [CrossRef]

- Szklanny, A.; Machour, M.; Redenski, I.; Chochola, V.; Goldfracht, I.; Kaplan, B.; Epshtein, M.; Yameen, H.; Merdler, U.; Feinberg, A.; et al. 3D Bioprinting of Engineered Tissue Flaps with Hierarchical Vessel Networks (VesselNet) for Direct Host-To-Implant Perfusion. Adv. Mater. 2021, 33, 2102661. [Google Scholar] [CrossRef] [PubMed]

- Shakeri, A.; Khan, S.; Didar, T. Conventional and emerging strategies for the fabrication and functionalization of PDMS-based microfluidic devices. Lab Chip 2021, 21, 3053–3075. [Google Scholar] [CrossRef] [PubMed]

- Cheng, F.; Cao, X.; Li, H.; Liu, T.; Xie, X.; Huang, D.; Maharjan, S.; Bei, H.P.; Gomez Espinosa, A.; Li, J.; et al. Generation of Cost-Effective Paper-Based Tissue Models through Matrix-Assisted Sacrificial 3D Printing. Nano Lett. 2019, 19, 3603–3611. [Google Scholar] [CrossRef] [PubMed]

- Celikkin, N.; Simó Padial, J.; Costantini, M.; Hendrikse, H.; Cohn, R.; Wilson, C.; Rowan, A.; Święszkowski, W. 3D Printing of Thermoresponsive Polyisocyanide (PIC) Hydrogels as Bioink and Fugitive Material for Tissue Engineering. Polymers 2018, 10, 555. [Google Scholar] [CrossRef]

- Therriault, D.; White, S.R.; Lewis, J.A. Chaotic mixing in three-dimensional microvascular networks fabricated by direct-write assembly. Nat. Mater. 2003, 2, 265–271. [Google Scholar] [CrossRef] [PubMed]

| FFF Thermoplastics | Advantages | Disadvantages | Applications |

|---|---|---|---|

| PLA | Biodegradable, easy to print, cost-effective | Low strength, low durability, brittle | Consumer goods, toys, DYI, packaging, biomedical |

| ABS | More durable than PLA, impact-, heat-, chemical-, abrasion-resistant | More challenging to print, prone to warping | Consumer goods, tools, automotive, electrical enclosures |

| Polyamides | Durable, high strength, flexible | Water uptake, delamination, and poor adhesion when filled | Prosthetics, tools, encapsulations, working prototypes, mechanical components |

| PET-G | Versatile, flexible, mechanical strength, easy to print | Prone to dampness, easily scratched | Packaging, mechanical parts, printer parts, protective components |

| TPU | Rubber-like, flexible, durable | Challenging to print | Seals, gaskets, automotive, medical supplies |

| HIPS | Strength, flexible | Only compatible with ABS, easy to recycle, good support material | Protective packaging, containers |

| PVA | Biodegradable, cost-effective | Moisture uptake | Support in overhanging parts, sacrificial molds |

| PPS | Mechanical strength, thermally stable, chemically resistant | Low Tg, brittleness, low impact strength, prone to warping without fillers | Mechanical parts |

| PEI | High Tg, flame retardant, mechanical strength | Expensive, susceptible to cracking | Automotive, aircraft parts |

| PEI/PC | High Tg, thermally stable, mechanical strength, chemically resistant | Water uptake | Transport, automotive, space applications |

| Carbon, glass, aramid fibers composites | Rigid, strong, tough | Compatibility limited to expensive industrial FDM 3D printers | Functional prototypes, jigs, fixtures, tooling |

| SLA Resins | Advantages | Disadvantages | Applications |

|---|---|---|---|

| Standard | High tensile strength, high resolution, smooth surface finish | Very brittle (low elongation at break) | Visual prototypes, art models, concept models, looks-like prototypes |

| Tough (ABS-like) | High stiffness, excellent resistance to cyclic loads, compromise between properties of durable and standard resin | Not for parts with thin walls (minimum 1 mm), low HDT, brittle (low elongation at break) | Functional prototypes, mechanical assemblies, rigid parts that require high stiffness, housings and enclosures, jigs and fixtures, connectors, wear-and-tear prototypes |

| Durable (PP-like) | Highest impact strength and elongation at break, wear-resistant, flexible | Not for parts with thin walls (minimum 1 mm), low HDT, low tensile strength (lower than tough resin) | Prototyping parts with moving elements and snap-fits, consumer products, and low-friction and low-wear mechanical parts, housings and enclosures, jigs and fixtures, connectors, wear-and-tear prototypes |

| Heat-resistant | HDT between 200–300 °C, smooth surface finish | Poor impact strength, brittle, not for parts with thin walls (minimum 1 mm), temperature resistance increase decreases elongation | Heat-resistant fixtures, mold prototypes, hot air, gas and fluid flow equipment, and casting and thermoforming tooling, heat-resistant mounts, housings, and fixtures, molds and inserts |

| Ceramic-filled | Very stiff and rigid (high modulus and low creep), very smooth surface finish, good thermal stability and heat resistance) | More brittle than the tough and durable resins, brittle (low elongation at break), low impact strength | Molds and tooling, jigs, manifolds, fixtures, electrical application housings, and automotive parts |

| Flexible and elastic resin (rubber, TPU, silicone-like) | High flexibility (high elongation at break), low hardness (simulates an 80A durometer rubber), high impact resistance, flexibility of rubber, TPU, or silicone, bending, flexing, and compression resistance, repeated cycles without tearing | Lack the properties of true rubber, require extensive support structures, UV radiation sensibility, not for parts with thin walls (minimum 1 mm) | Objects that will be bent or compressed, wearables prototyping, multi-material assemblies, handles, grips, and overmolding, consumer goods prototyping, compliant features for robotics, medical devices, and anatomical models, special effects props and models |

| Clear resin | Polishes to near optical transparency, moisture-resistant, durable, large format available, stiff | Requires secondary operations for functional part clarity | Parts requiring optical transparency, millifluidics |

| SLS Resins | Advantages | Disadvantages | Applications |

|---|---|---|---|

| PA12 | Strong, stiff, durable, impact-resistant and can endure repeated wear and tear; Resistant to UV, light, heat, moisture, solvents, temperature, and water | High porosity and low molecular weight deteriorate its mechanical properties, especially ductility and toughness | Functional and high-performance prototyping, end-use parts, medical devices, permanent jigs, fixtures, and tooling |

| PA11 | Similar to PA12, but higher elasticity, elongation at break, and impact resistance | Lower stiffness than PA12 | Functional prototyping, structural end-use parts, jigs, and fixtures, snaps, clips, and hinges, orthotics and prosthetics |

| Glass-filled PA12 | Enhanced stiffness and thermal stability | More brittle, reduced impact resistance and flexibility | Robust jigs, fixtures, replacement parts, parts subjected to sustained loadings and high temperature, threads, and sockets |

| Carbon fiber-filled PA11 | Highly stable, lightweight, high-performance material | More brittle, reduced impact resistance | Replacement for metal parts, tooling, jigs, fixtures, high-impact equipment, functional composite prototypes |

| Mineral-filled PA | Enhanced thermal properties, dimensional stability, rigidity, high HDT | Reduced impact resistance and flexibility, rougher surface than unfilled PA | Parts to withstand high temperatures or mechanical loads |

| Aluminum-filled PA | Dense, thermal, and conductive properties | Reduced impact resistance and flexibility | Parts with a metallic appearance, mechanical parts that do not experience high stress |

| Polypropylene | Ductile, durable, chemically resistant, watertight, weldable | Not as strong or rigid as other 3D-printed materials | Functional prototyping, end-use parts, watertight housings, cases, packaging prototypes, medical devices (orthotics and prosthetics), automotive interior components, strong and chemically resistant fixtures, tools, jigs |

| TPU | Flexible, elastic, rubbery, resilient to deformation, high UV stability, great shock absorption | Limited heat resistance, moisture sensitivity | Functional prototyping, flexible, rubber-like end-use parts, wearables and soft-touch elements, padding, dampers, cushions, grippers, gaskets, seals, masks, belts, plugs, tubes, medical devices (soles, splints, orthotics, prosthetics) |

| TPE | Elasticity, resistance to abrasion and good UV and ozone resistance | Temperature-sensitive, prone to shrinking | Seals, gaskets, plugs, grips, handles, over-molds, tubes, masks, and gloves |

| PEEK, PEKK | Excellent mechanical strength, stiffness, chemical resistance, wear resistance, thermal resistance | Low resistance to UV light, low flexibility, expensive | Components subject to friction or wear, surgical tools and implant, applications that require superior thermal resistance |

| Prototype Production Methods | Mold Durability | Average Mold Cost | Average Cost/Part | Production Average Cost | Lead Time | Design Flexibility |

|---|---|---|---|---|---|---|

| FDM direct 3D printing | N/A | N/A | Low to high | Low to high | Short to medium | High |

| Conventional Molds and Tooling | High (>10,000 parts) | High (2000 USD) | Low | High | Long | Low |

| 3D-Printed Polymer Molds and Tooling | Low (1–10 parts) | Low (50–80 USD) | Low to medium | Low | Short | High |

| 3D-Printed Metal Molds and Tooling | High (>10,000 parts) | High | Medium to high | Low to High | Short to long | Low |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pelin, G.; Sonmez, M.; Pelin, C.-E. The Use of Additive Manufacturing Techniques in the Development of Polymeric Molds: A Review. Polymers 2024, 16, 1055. https://doi.org/10.3390/polym16081055

Pelin G, Sonmez M, Pelin C-E. The Use of Additive Manufacturing Techniques in the Development of Polymeric Molds: A Review. Polymers. 2024; 16(8):1055. https://doi.org/10.3390/polym16081055

Chicago/Turabian StylePelin, George, Maria Sonmez, and Cristina-Elisabeta Pelin. 2024. "The Use of Additive Manufacturing Techniques in the Development of Polymeric Molds: A Review" Polymers 16, no. 8: 1055. https://doi.org/10.3390/polym16081055

APA StylePelin, G., Sonmez, M., & Pelin, C.-E. (2024). The Use of Additive Manufacturing Techniques in the Development of Polymeric Molds: A Review. Polymers, 16(8), 1055. https://doi.org/10.3390/polym16081055