Study of the Viscoelastic and Rheological Properties of Rubber-Bitumen Binders Obtained from Rubber Waste

Abstract

:1. Introduction

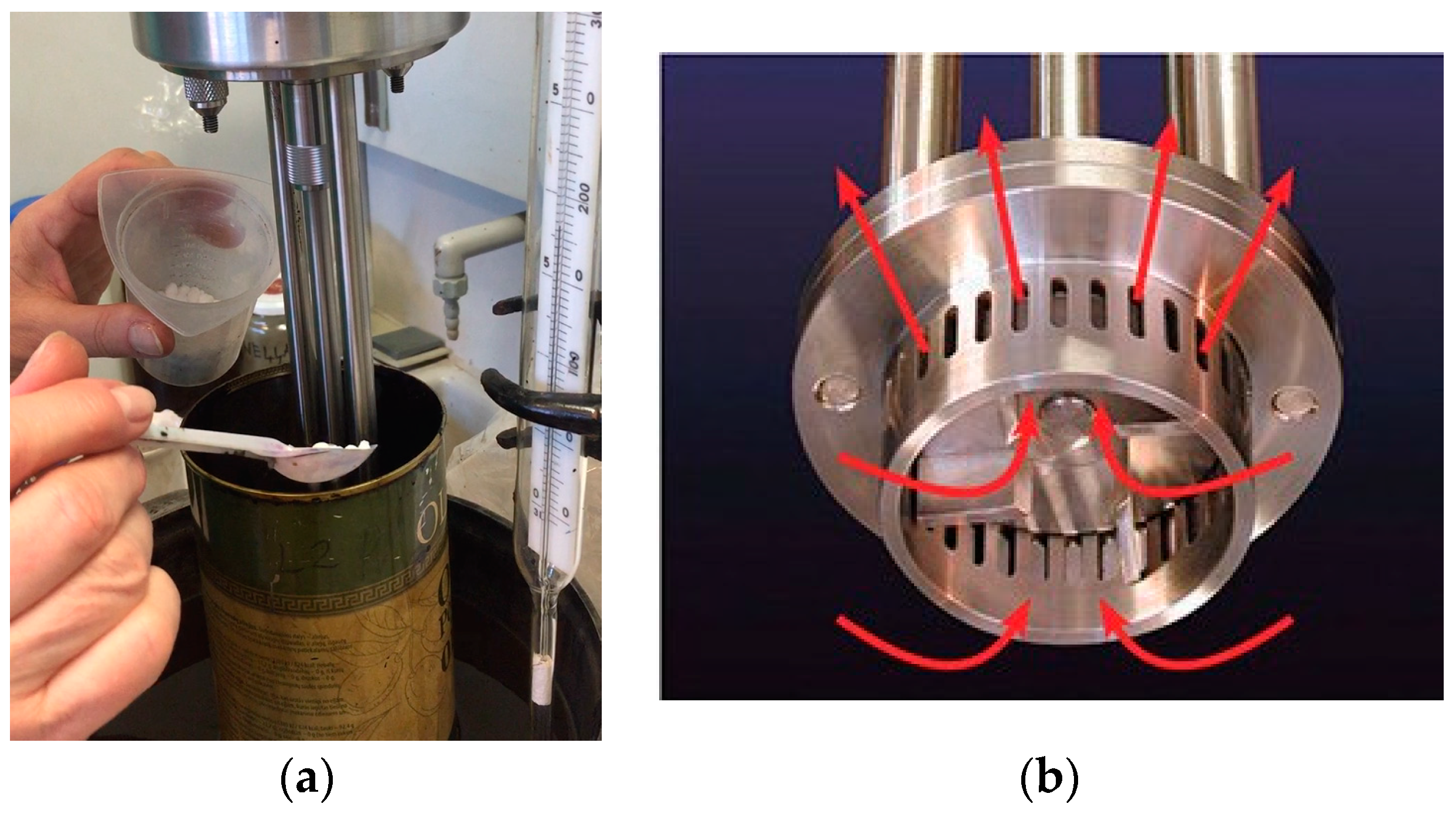

2. Materials and Methods

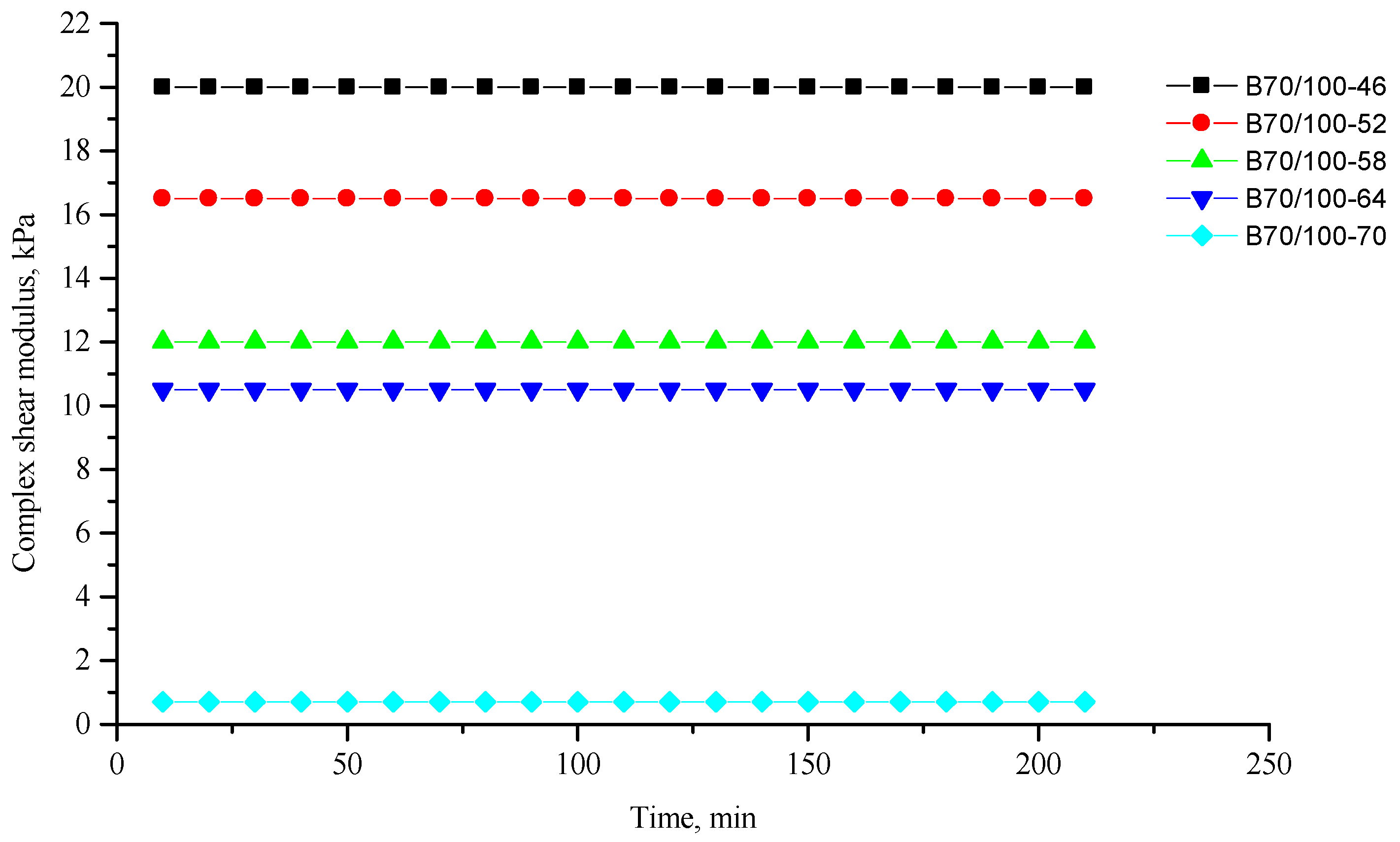

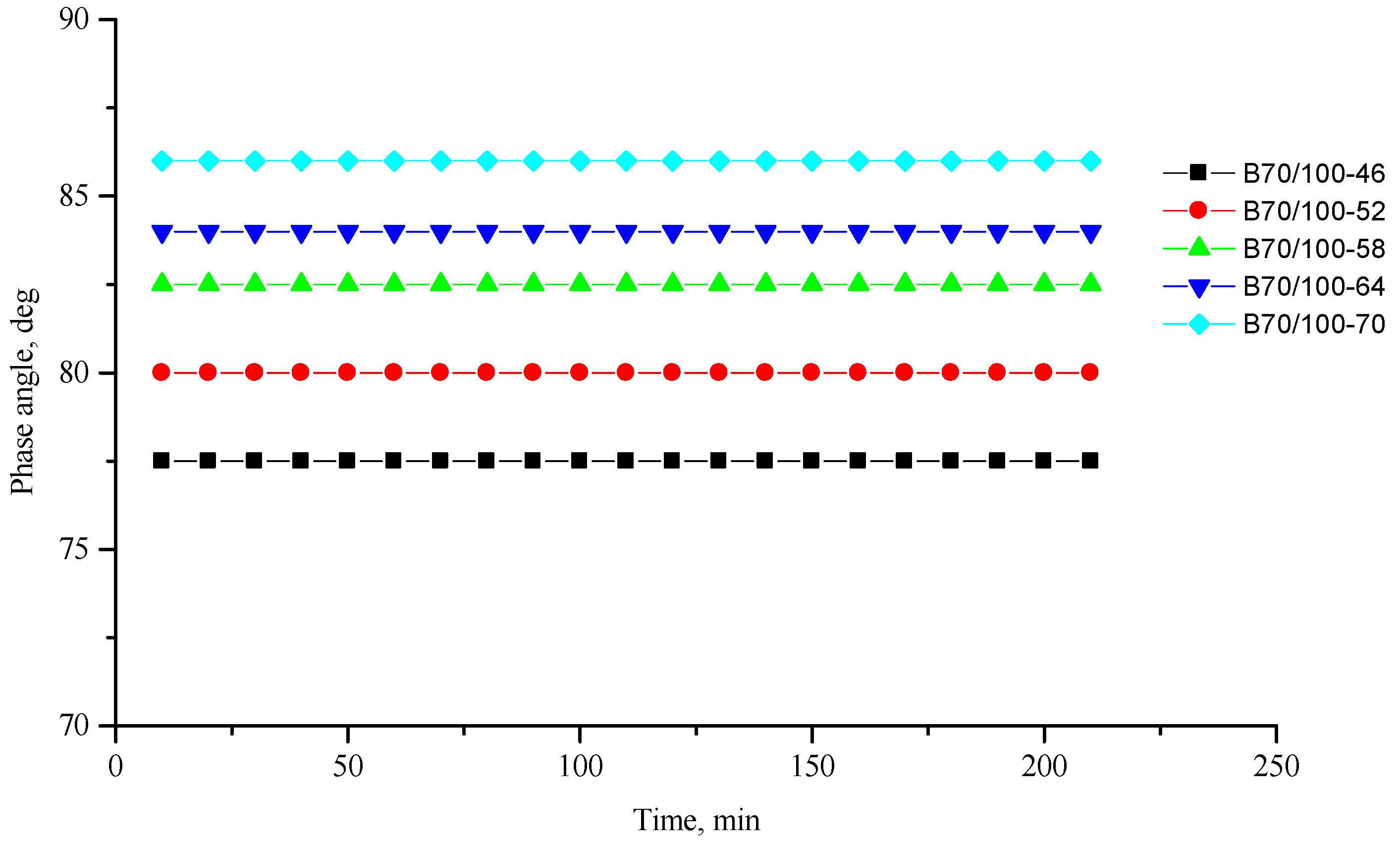

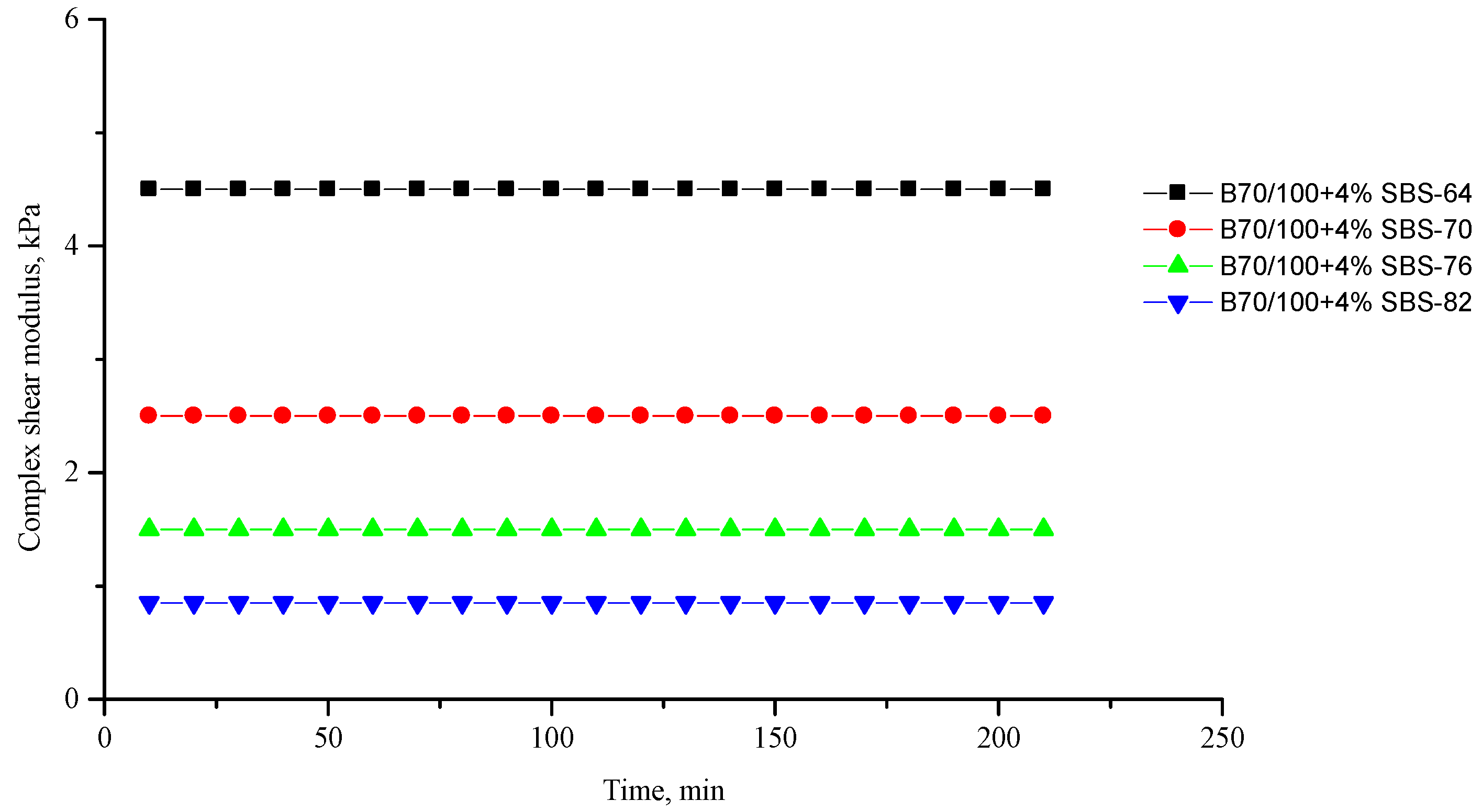

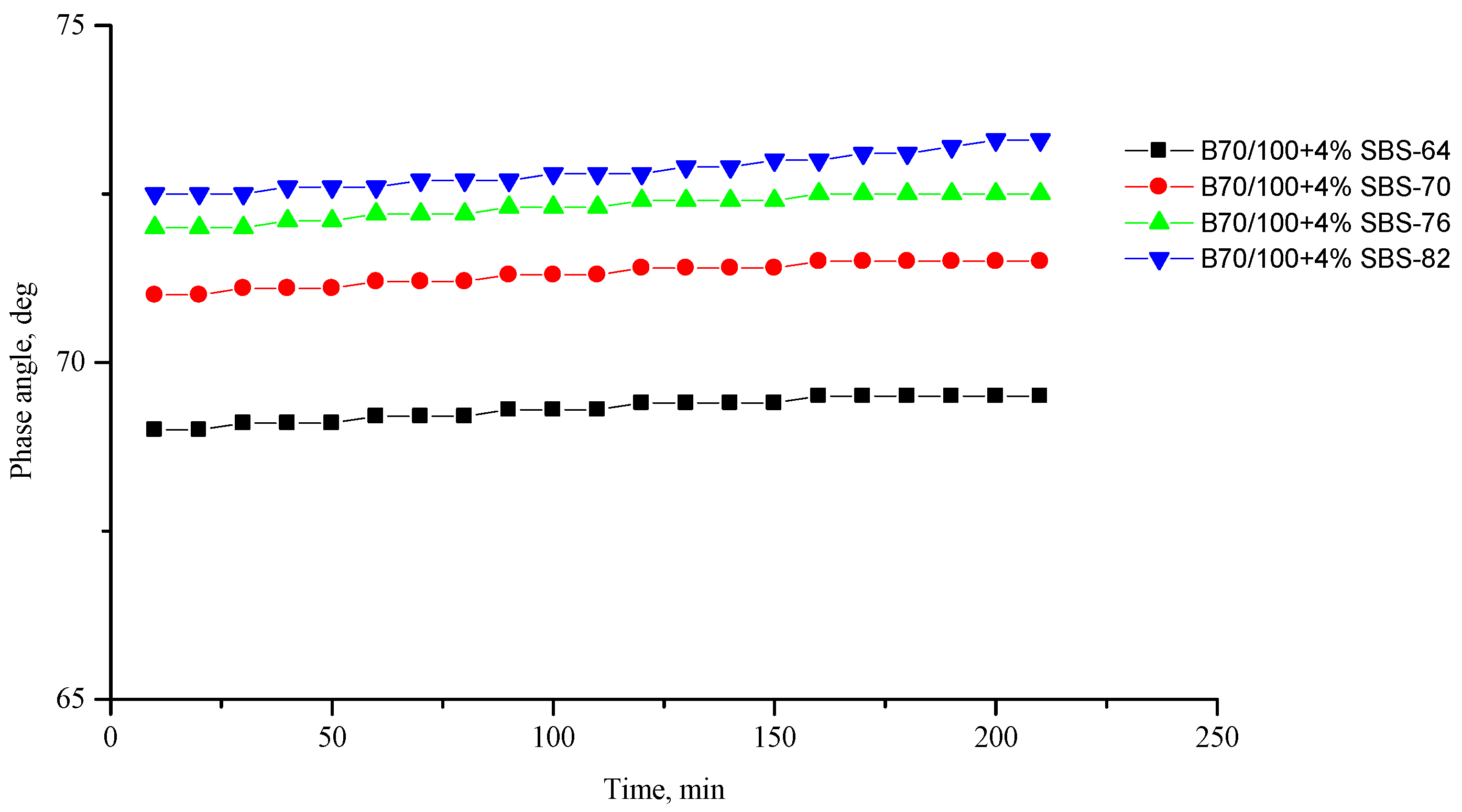

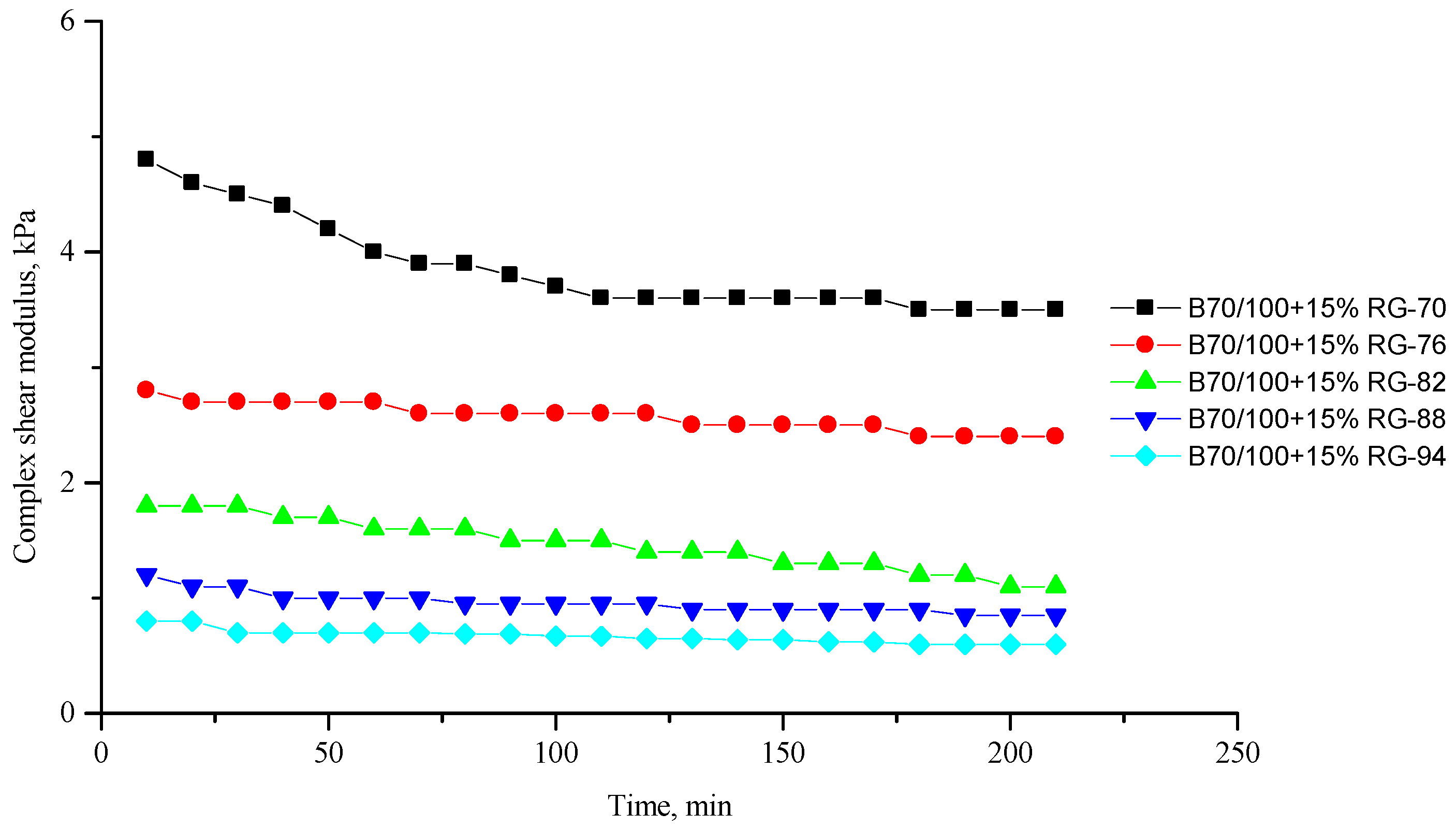

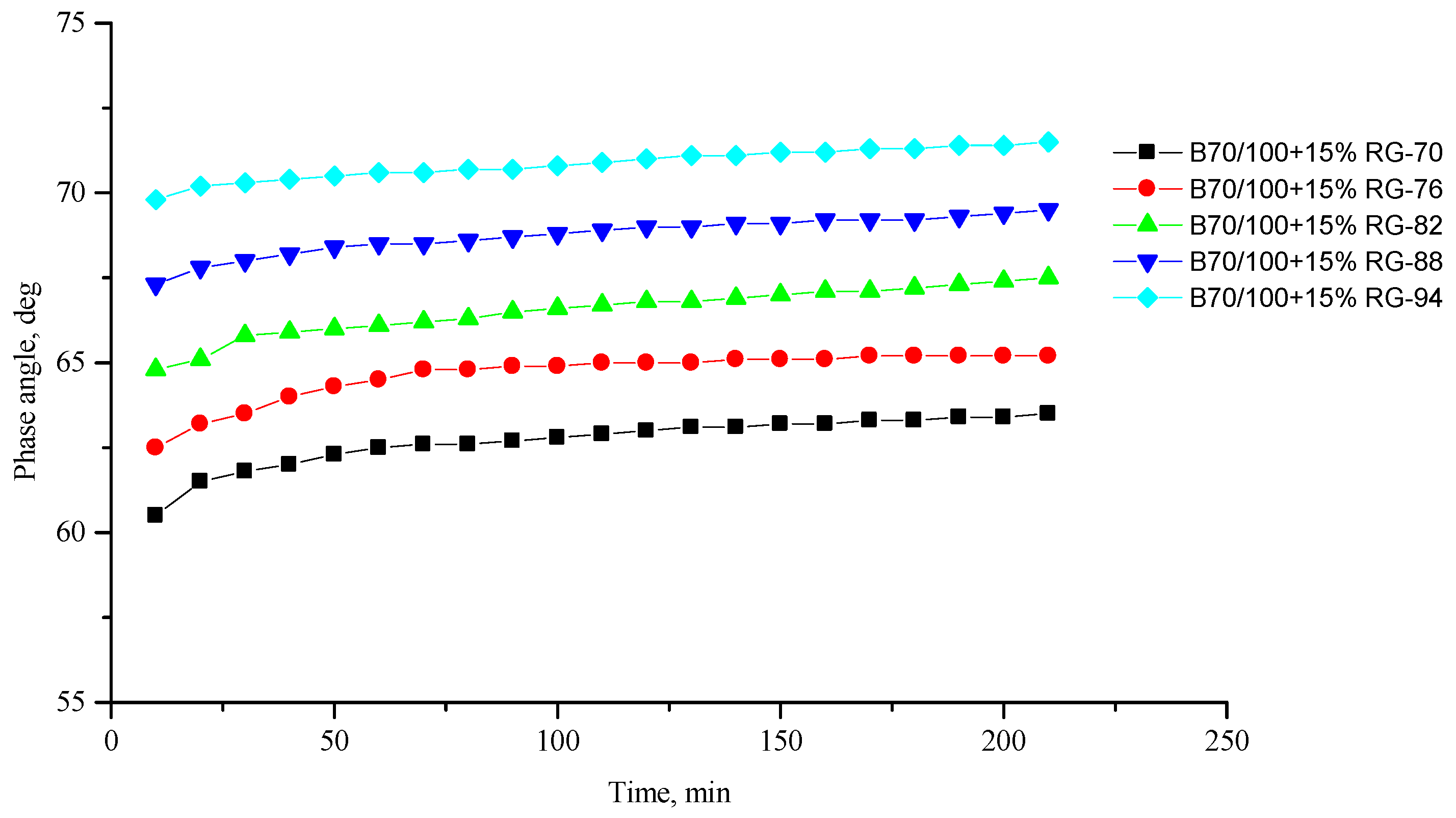

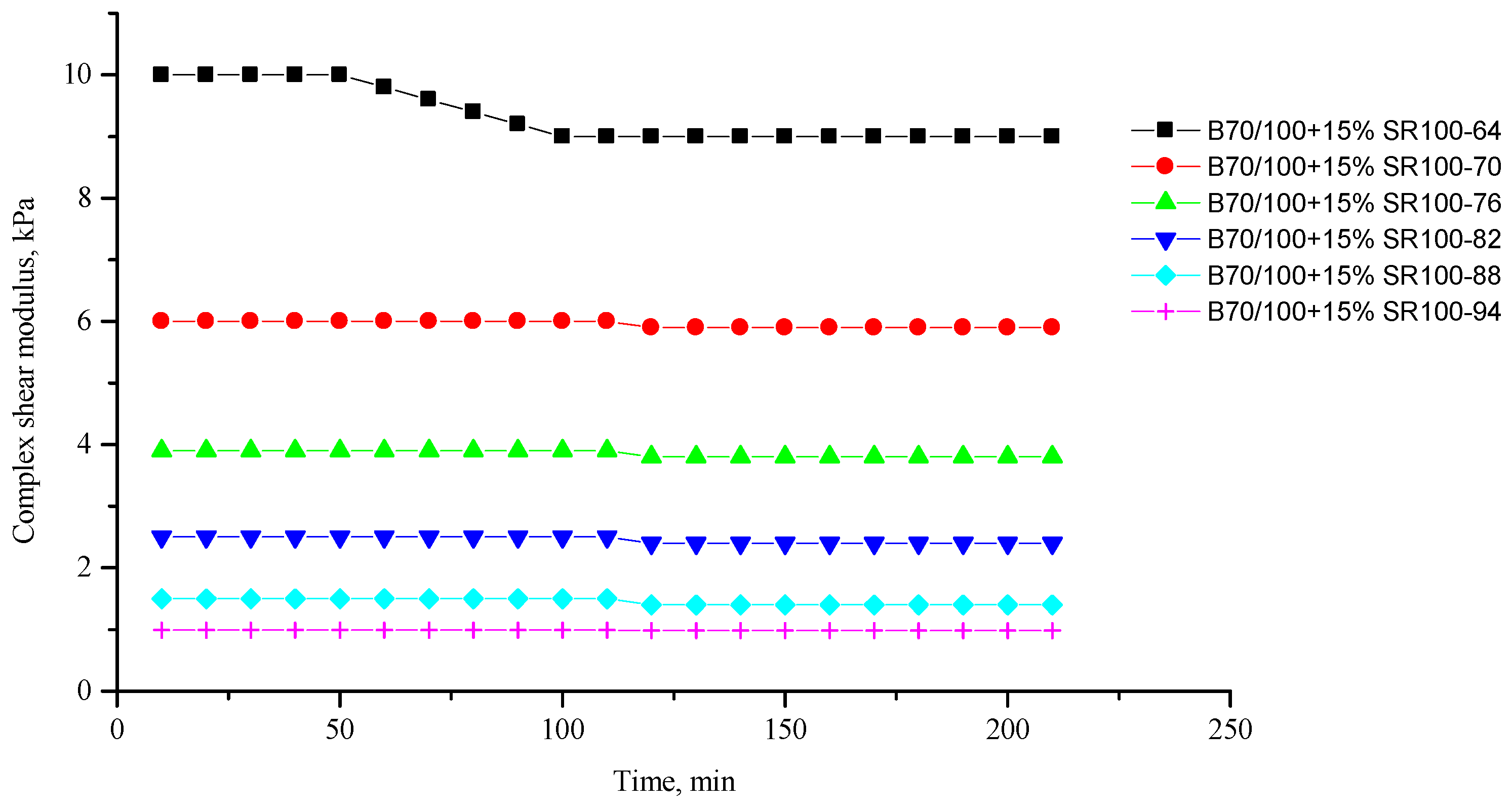

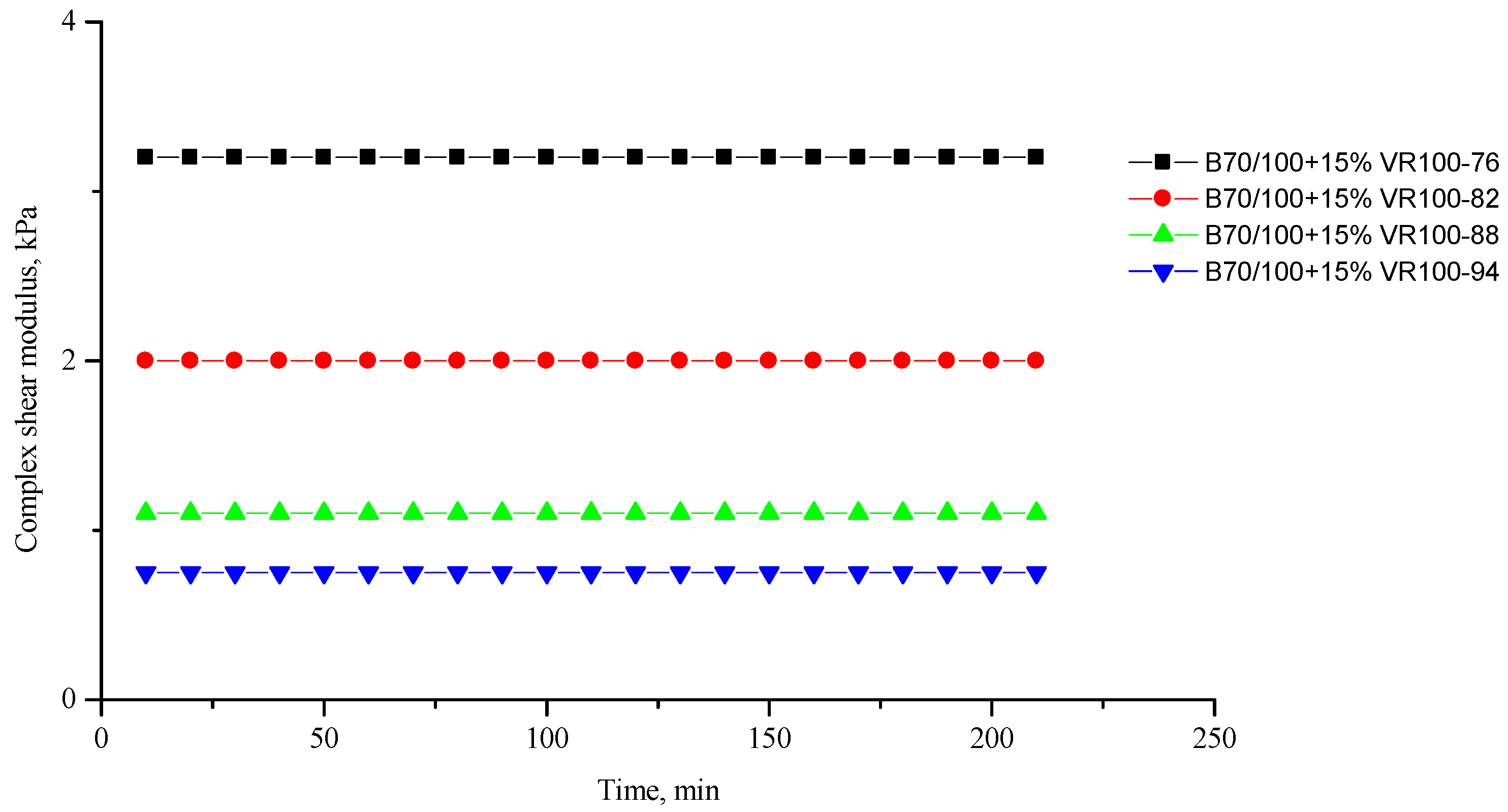

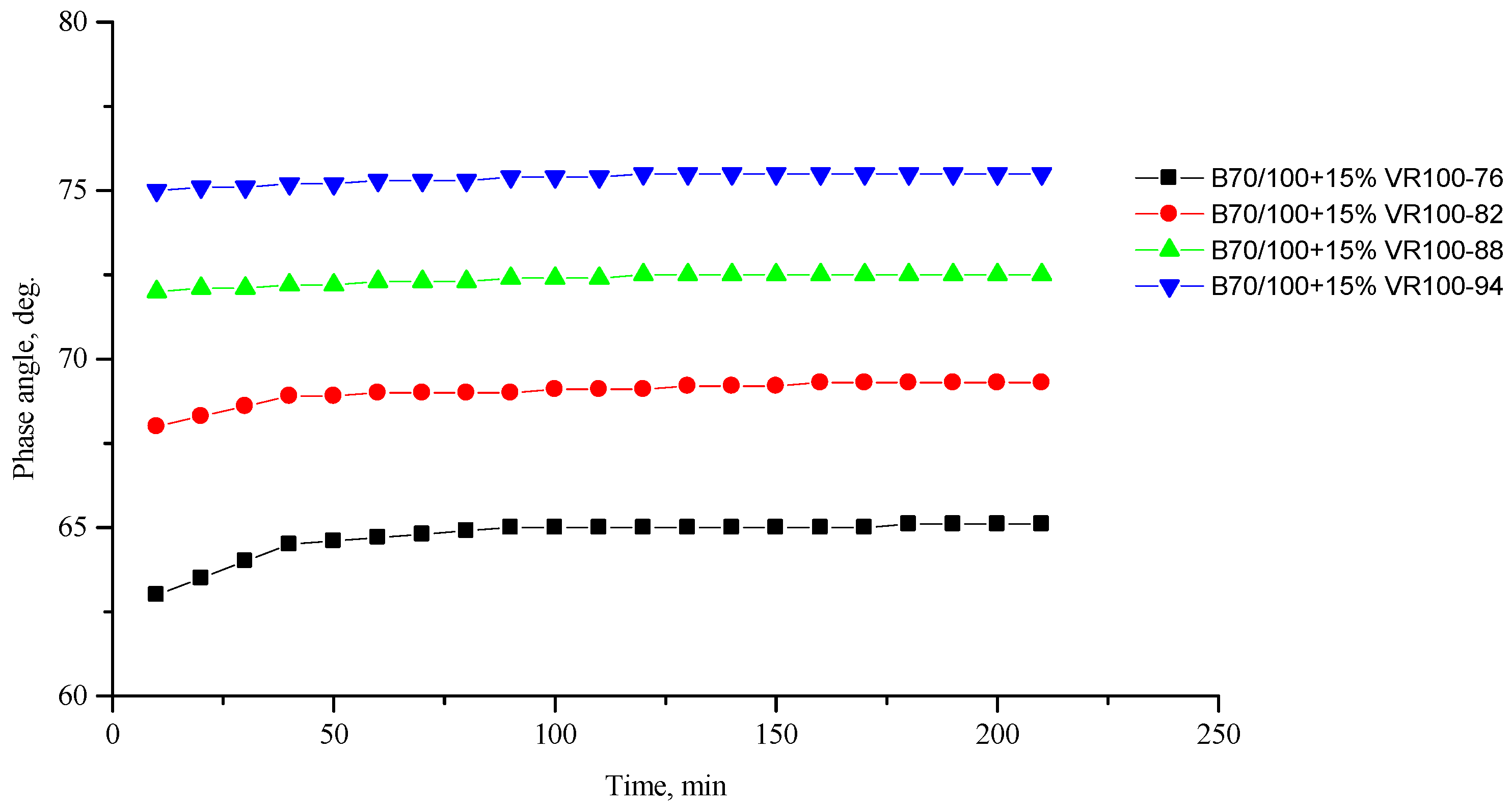

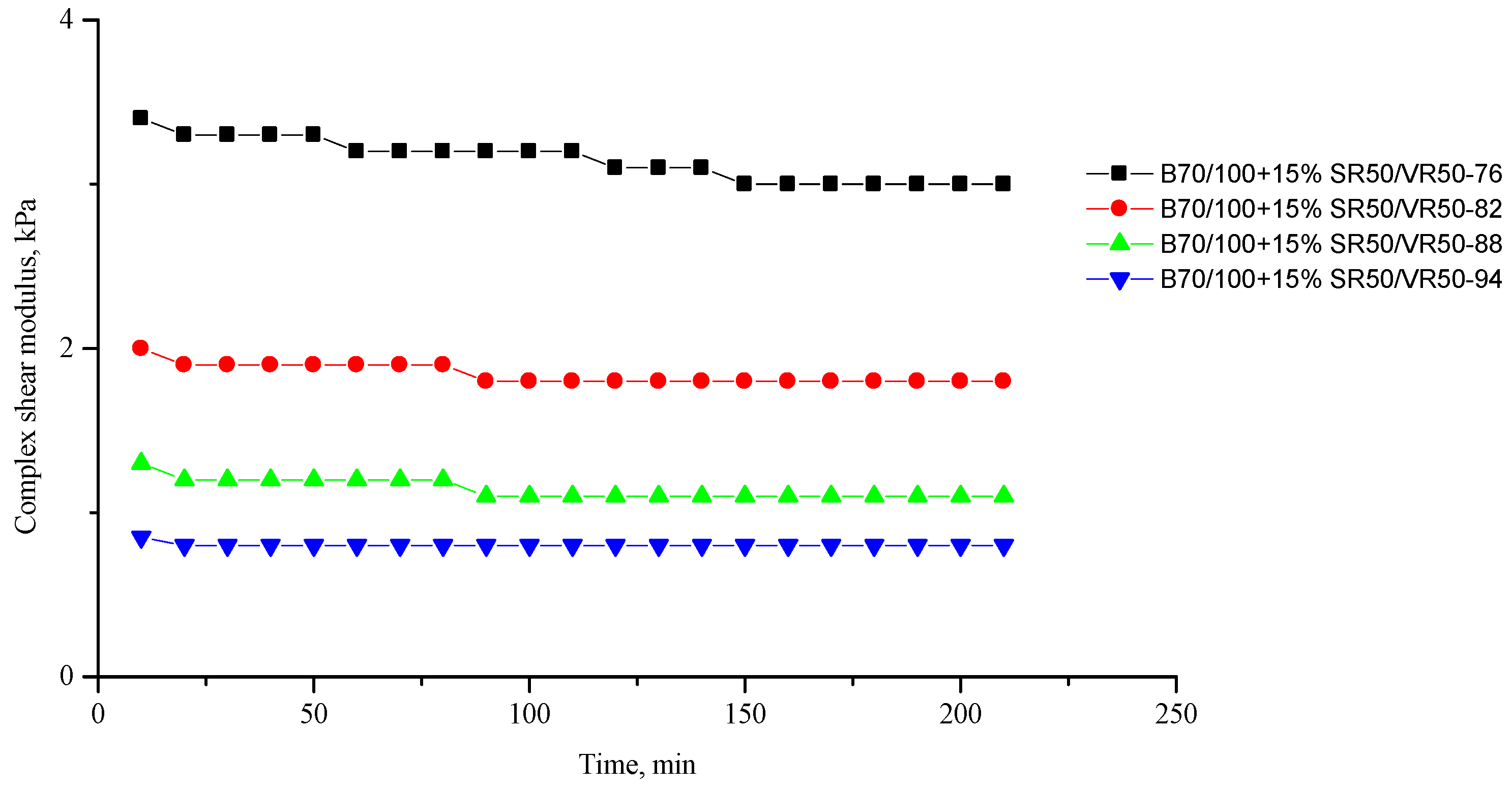

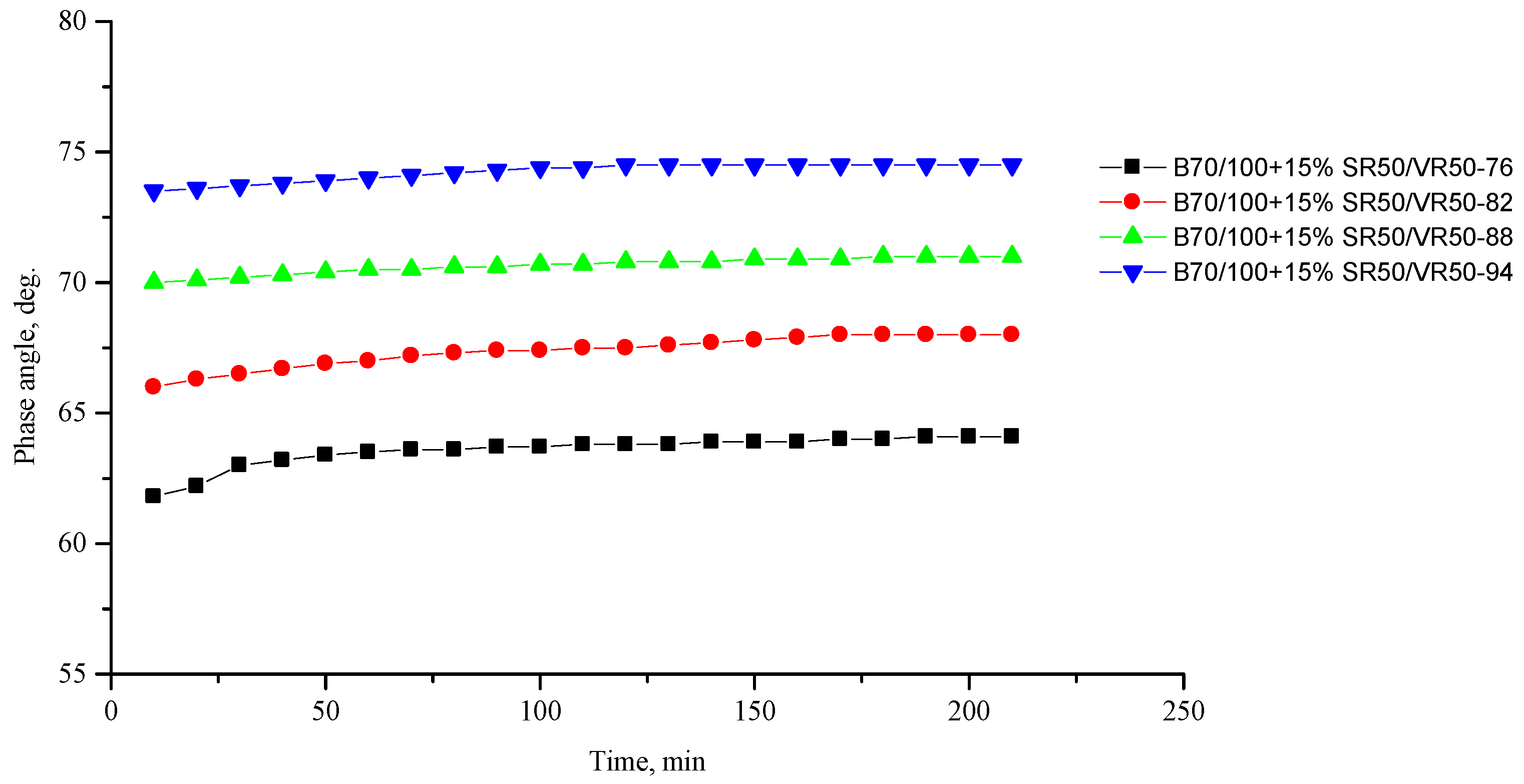

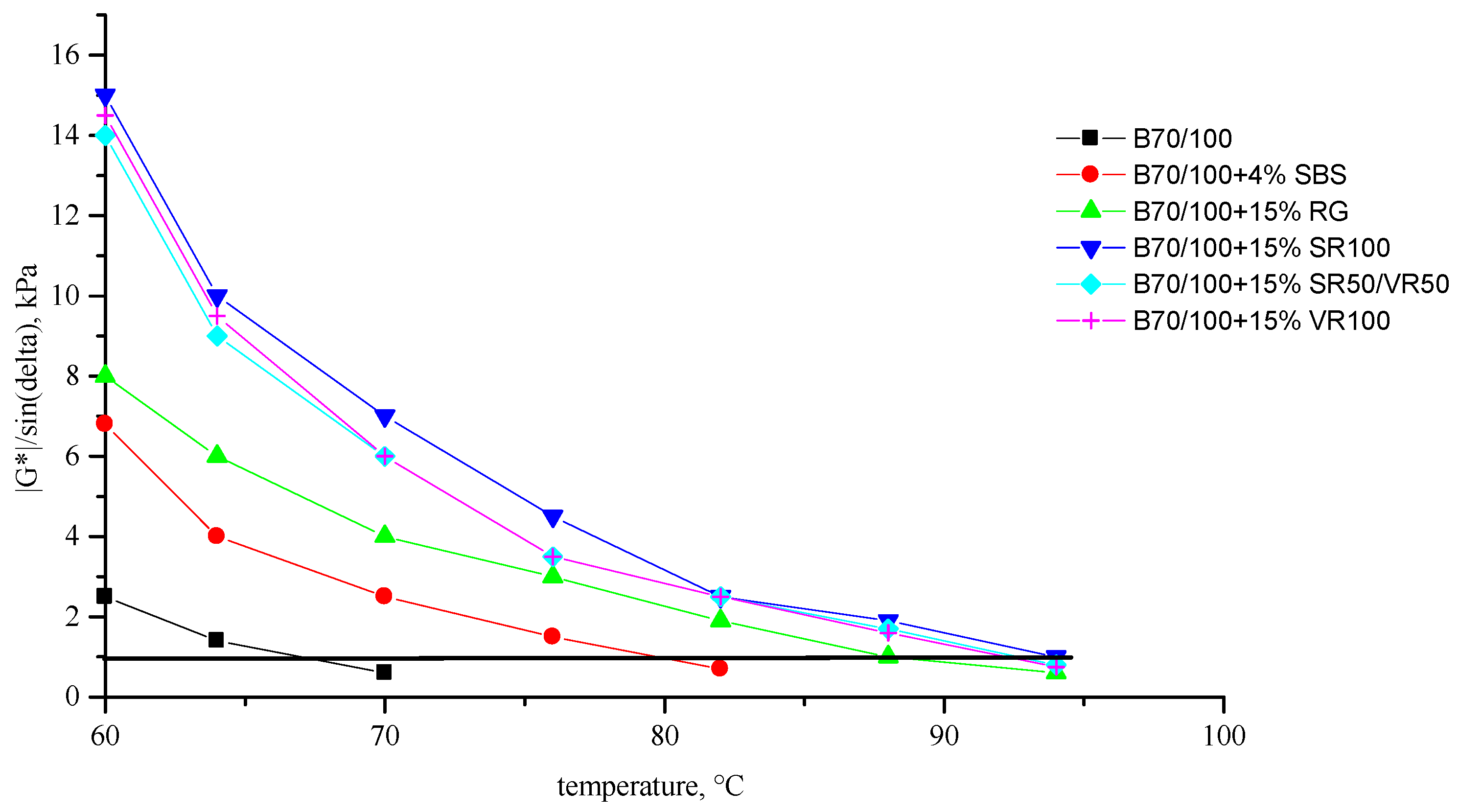

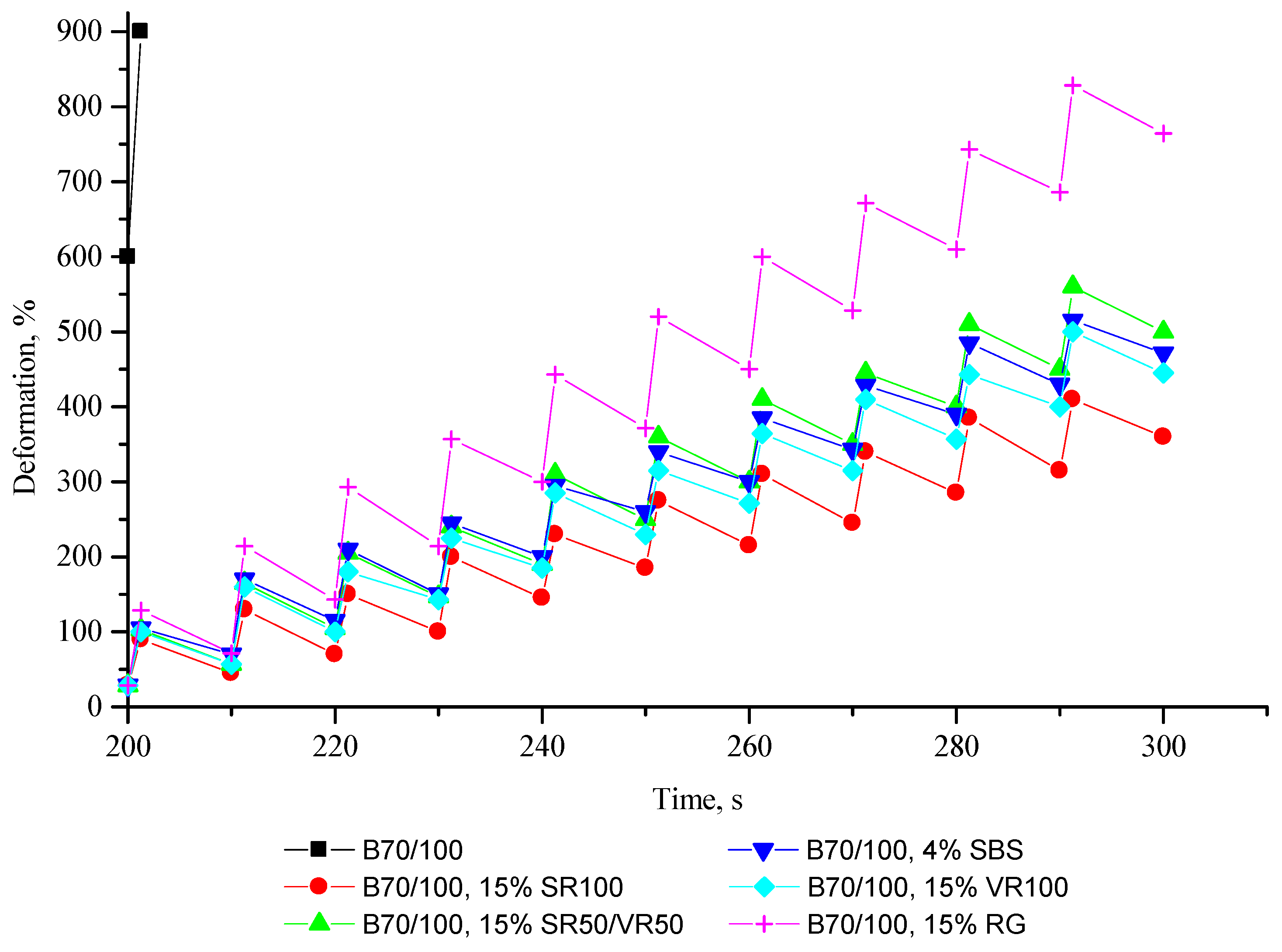

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- European Tyre & Rubber Manufacturers Association. Press Release. Europe—92% of All End of Life Tyres Collected and Treated in 2017. 2019; pp.1–3. Available online: https://www.etrma.org/wp-content/uploads/2019/11/20191119-Europe-92-of-all-End-of-Life-Tyres-collected-and-treated-in-2017.pdf (accessed on 27 November 2023).

- Torretta, V.; Cristina, E.; Ragazzi, M.; Trulli, E.; Aura, I.; Ionel, L. Treatment and disposal of tyres: Two EU approaches. A review. Waste Manag. 2015, 45, 152–160. [Google Scholar] [CrossRef]

- Danon, B.; Van Der Gryp, P.; Schwarz, C.E.; Gorgens, J.F. A review of dipentene (dl-limonene) production from waste tire pyrolysis. J. Anal. Appl. Pyrolysis 2015, 112, 1–13. [Google Scholar] [CrossRef]

- Fiksel, J.; Bakshi, B.R.; Baral, A.; Guerra, E.; DeQuervain, B. Comparative life cycle assessment of beneficial applications for scrap tires. Clean. Technol. Environ. Policy 2011, 13, 19–35. [Google Scholar] [CrossRef]

- Fazli, A.; Rodrigue, D. Recycling waste tires into ground tire rubber (GTR)/rubber compounds: A review. J. Compos. Sci. 2020, 4, 103. [Google Scholar] [CrossRef]

- Alkadi, F.; Lee, J.; Yeo, J.S.; Hwang, S.H.; Choi, J.W. 3D printing of ground tire rubber composites. Int. J. Precis. Eng. Manuf. 2019, 6, 211–222. [Google Scholar] [CrossRef]

- Toncheva, A.; Brison, L.; Dubois, P.; Laoutid, F. Recycled tire rubber in additive manufacturing: Selective laser sintering for polymer-ground rubber composites. Appl. Sci. 2021, 11, 8778. [Google Scholar] [CrossRef]

- Nguyen, H.T.; Crittenden, K.; Weiss, L.; Bardaweel, H. Recycle of waste tire rubber in a 3D printed composite with enhanced damping properties. J. Clean. Prod. 2022, 368, 33085. [Google Scholar] [CrossRef]

- Martinez, J.D.; Puy, N.; Murillo, R.; Garcia, T.; Navarro, M.V.; Mastral, A.M. Waste tyre pyrolysis–a review. Renew. Sustain. Energy Rev. 2013, 23, 179–213. [Google Scholar] [CrossRef]

- Sienkiewicz, M.; Kucinska-Lipka, J.; Janik, H.; Balas, A. Progress in used tyres management in the European Union: A review. Waste Manag. 2012, 32, 1742–1751. [Google Scholar] [CrossRef]

- Mistry, M.K.; Shukla, S.J.; Solanki, C.H. Reuse of waste tyre products as a soil reinforcing material: A critical review. Environ. Sci. Pollut. Res. 2021, 28, 24940–24971. [Google Scholar] [CrossRef]

- Przydatek, G.; Budzik, G.; Janik, M. Effectiveness of selected issues related to used tyre management in Poland. Environ. Sci. Pollut. Res. 2022, 29, 31467–31475. [Google Scholar] [CrossRef] [PubMed]

- Stefanov, S.B.; Biočanin, R.R.; Vojinović-Miloradov, M.; Sokolovic, S.; Ivanković, D. Ecological Modeling of Pollutants in Accidental Fire At The Landfill Waste. Therm. Sci. Year 2013, 17, 903–913. [Google Scholar] [CrossRef]

- Horner, J.M. Environmental Health Implications of Heavy Metal Pollution from Car Tires. Rev. Environ. Health 1996, 11, 175–178. [Google Scholar] [CrossRef] [PubMed]

- Nuzaimah, M.; Sapuan, S.M.; Nadlene, R.; Jawaid, M. Recycling ofwaste rubber as fillers: A review. IOP Conf. Ser. Mater. Sci. Eng. 2018, 368, 012016. [Google Scholar] [CrossRef]

- Bockstal, L.; Berchem, T.; Schmetz, Q.; Richel, A. Devulcanisation and reclaiming of tires and rubber by physical and chemical processes: A review. J. Clean. Prod. 2019, 236, 117574. [Google Scholar] [CrossRef]

- Tladi, M.; Mashifana, T.; Sithole, N.T. Utilization of Plastic Waste and Waste Rubber Tyres to Modify Bitumen Binder in Road Construction. Key Eng. Mater. 2023, 947, 131–138. [Google Scholar] [CrossRef]

- Magagula, S.I.; Lebelo, K.; Motloung, T.M.; Mokhena, T.C.; Mochane, M.J. Recent advances on waste tires: Bibliometric analysis, processes, and waste management approaches. Environ. Sci. Pollut. Res. 2023, 30, 118213–118245. [Google Scholar] [CrossRef] [PubMed]

- Rogachuk, B.E.; Okolie, J.A. Waste tires based biorefinery for biofuels and value-added materials production. Chem. Eng. J. Adv. 2023, 14, 100476. [Google Scholar] [CrossRef]

- Riekstins, A.; Baumanis, J.; Barbars, J. Laboratory investigation of crumb rubber in dense graded asphalt by wet and dry processes. Constr. Build. Mater. 2021, 292, 123459. [Google Scholar] [CrossRef]

- Latvian Tire Management Association. Industry Data. 2020. Available online: www.lraa.lv (accessed on 12 June 2023).

- Bressi, S.; Fiorentini, N.; Huang, J.; Losa, M. Crumb rubber modifier in road asphalt pavements: State of the art and statistics. Coatings 2019, 9, 384. [Google Scholar] [CrossRef]

- Kaloush, K.E.; Biligiri, K.P. Asphalt Rubber Standard Practice Guide. 2011. Available online: https://www.rubberpavements.org/Library_Information/AR_Std_Practice_Guide_20111221.pdf (accessed on 28 November 2023).

- Presti, D.L. Recycled Tyre Rubber Modified Bitumens for road asphalt mixtures: A literature review Constr. Build. Mater. 2013, 49, 863–881. [Google Scholar] [CrossRef]

- Mohajerani, A.; Burnett, L.; Smith, J.V.; Markovski, S.; Rodwell, G.; Rahman, M.T.; Kurmus, H.; Mirzababaei, M.; Arulrajah, A.; Horpibulsuk, S.; et al. Recycling waste rubber tyres in construction materials and associated environmental considerations: A review. Resour. Conserv. Recycl. 2020, 155, 104679. [Google Scholar] [CrossRef]

- Barišić, I.; Zvonarić, M.; Grubeša, I.N.; Šurdonja, S. Recycling waste rubber tyres in road construction. Pol. Acad. Sci. 2021, 67, 499–512. [Google Scholar]

- Airey, G.D.; Collop, A.C.; Mujibur, M.M. Mechanical properties of crumb rubber modified asphalt mixtures. In Proceedings of the 3rd Eurasphalt & Eurobitume Congress, Vienna, Austria, 12–14 May 2004; pp. 800–812. [Google Scholar]

- Amirkhanian, S.N. Utilization of Crumb Rubber in Asphaltic Concrete Mixtures—South Carolina Experience; Department of Civil Engineering, Clemson University: Clemson, SC, USA, 2001. [Google Scholar]

- Bahia, H.U.; Davis, R. Effect of Crumb Rubber Modifiers (CRM) on performance related properties of asphalt binders. J. Assoc. Asph. Paving Technol. 1994, 63, 414–449. [Google Scholar]

- Picado-Santos, L.G.; Capitão, S.D.; Neves, J.M.C. Crumb rubber asphalt mixtures: A literature review. Constr. Build. Mater. 2020, 247, 118577. [Google Scholar] [CrossRef]

- Picado-Santos, L.G.; Capitão, S.D.; Dias, J.L.F. Crumb rubber asphalt mixtures by dry process: Assessment after eight years of use on a low/medium trafficked pavement. Constr. Build. Mater. 2019, 215, 9–21. [Google Scholar] [CrossRef]

- Chavez, F.; Marcobal, J.; Gallego, J. Laboratory evaluation of the mechanical properties of asphalt mixtures with rubber incorporated by the wet, dry, and semi-wet process. Constr. Build. Mater. 2019, 205, 164–174. [Google Scholar] [CrossRef]

- Król, J.B.; Radziszewski, P.; Kowalski, K.J.; Sarnowski, M.; Czajkowski, P. Laboratory and Field Investigations of Polymer and Crumb Rubber Modified Bitumen. J. Civ. Eng. Archit. 2014, 8, 1327–1334. [Google Scholar] [CrossRef]

- Ilyin, S.O.; Arinina, M.P.; Mamulat, Y.S.; Malkin, A.Y.; Kulichikhi, V.G. Rheological Properties of Road Bitumens Modified with Polymer and Solid Nanosized Additives. Colloid J. 2014, 76, 425–434. [Google Scholar] [CrossRef]

- Yang, X.; You, Z.; Perram, D.; Hand, D.; Ahmed, Z.; Wei, W.; Luo, S. Emission analysis of recycled tire rubber modified asphalt in hot and warm mix conditions. J. Hazard. Mater. 2019, 365, 942–951. [Google Scholar] [CrossRef]

- Huang, B.; Mohammad, L.N.; Graves, P.S.; Abadie, C. Louisiana experience with crumb rubber-modified hot-mix asphalt pavement. Transp. Res. Rec. 2002, 1789, 1–13. [Google Scholar] [CrossRef]

- Denneman, E.; Lee, J.; Raymond, C.; Choi, Y.; Khoo, K.Y.; Dias, M. P31 and P32 Optimising the Use of Crumb Rubber Modified Bitumen in Seals and Asphalt. 2015. Available online: https://nacoe.com.au/wp-content/uploads/2017/10/P31-P32-Optimising-the-use-of-crumb-rubber_Yr1-2014-15-Final.pdf (accessed on 28 November 2023).

- Li, B.; Huang, W.; Tang, N.; Hu, J.; Lin, P.; Guan, W.; Xiao, F.; Shan, Z. Evolution of components distribution and its effect on low temperature properties of terminal blend rubberized asphalt binder. Constr. Build. Mater. 2017, 136, 598–608. [Google Scholar] [CrossRef]

- Zanzotto, L.; Kennepohl, G.J. Development of rubber and asphalt binders by depolymerization and devulcanization of scrap tires in asphalt. Transp. Res. Rec. 1996, 1530, 51–58. [Google Scholar] [CrossRef]

- Pavlovich, R.D.; Shuler, T.S.; Rosner, J.C. Chemical & Physical Properties of Asphalt Rubber Mixtures—Phase II: Product Specifications and Test Procedures; FHWA/AZ-79/121; Arizona Department of Transportation: Pheonix, AZ, USA, 1979. [Google Scholar]

- Chehovits, J.D.; Dunning, R.L.; Morris, G.E. Characteristics of asphalt–rubber by the sliding plate microviscometer. J. Assoc. Asph. Paving Technol. 1982, 51, 240–261. [Google Scholar]

- Billiter, T.C.; Chun, J.S.; Davison, R.R.; Glover, C.J.; Bullin, J.A. Investigation of the curing variables of asphalt–rubber binder. Petrol. Sci. Technol. 1997, 15, 445–469. [Google Scholar] [CrossRef]

- Navarro, F.J.; Partal, P.; Martínez-Boza, F.J.; Gallegos, C. Influence of processing conditions on the rheological behavior of crumb tire rubber-modified bitumen. Appl. Polym. Sci. 2007, 104, 1683–1691. [Google Scholar] [CrossRef]

- Takallou, H.B.; Sainton, A. Advances in technology of asphalt paving materials containing used tire rubber. Transp. Res. Rec. 1992, 1339, 23–29. [Google Scholar]

- Luksha, O.V.; Opanasenko, O.N.; Krut’ko, N.P.; Loboda, Y.V. Modification of oxidized bitumen with styrene-butadiene-styrene copolymers of various structures. Russ. J. Appl. Chem. 2006, 79, 1021. [Google Scholar] [CrossRef]

- Rozental, D.A.; Kutsenko, V.I.; Miroshnikov, E.P. Modification of bitumen with polymer materials. Constr. Mater. 1995, 9, 23–25. (In Russian) [Google Scholar]

- Gokhman, L.M.; Gurarii, E.M.; Davydova, A.R.; Davydova, K.I. Polimernobitumnye Vyazhushchie Materialy na Osnove SBS Dlya Dorozhnogo Stroitel’stva. Vyp. 4 (SBBased Polymer Bitumen Binders for Road Building); Inforavtodor: Moscow, Russia, 2002; no. 4. [Google Scholar]

- Pechenyi, B.G. Bitumy i Bitumnye Kompozitsii (Bitu Men and Bituminous Compositions); Khimiya: Moscow, Russia, 1990. [Google Scholar]

- Rudenskii, A.V.; Nikonova, O.N.; Kaziev, M.G. Increasing the durability of asphalt concrete by introducing an active complex modifier. Mater. Road Constr. 2011, 10. (In Russian) [Google Scholar]

- Ivan’ski, M.; Uriev, N.B. Asfal’tobeton kak Kompozitsionnyi Material (s Nanodispersnym i Polimernym Komponentami) (Asphalt Concrete as Com posite Material (with Nanodisperse and Polymer Components)); Tekhpoligraftsentr: Moscow, Russia, 2007. [Google Scholar]

- Yousefi, A.A. Phase-Destabilization Mechanism of Polymer-Modified Bitumens in Quiescent Annealing. Prog. Color Color. Coat. 2009, 2, 53–59. [Google Scholar]

- EN 1426:2015; Bitumen and Bituminous Binders—Determination of Needle Penetration. CEN-CENELEC Management Centre: Brussels, Belgium, 2015.

- LVS EN 1427:2015; Bitumen and Bituminous Binders—Determination of the Softening Point—Ring and Ball Method. CEN-CENELEC Management Centre: Brussels, Belgium, 2015.

- EN 12593:2015; Bitumen and Bituminous Binders—Determination of the Fraass Breaking Point. CEN-CENELEC Management Centre: Brussels, Belgium, 2015.

- EN 12592:2015; Bitumen and Bituminous Binders—Determination of Solubility. CEN-CENELEC Management Centre: Brussels, Belgium, 2015.

- EN ISO 2592:2017; Petroleum and Related Products Determination of Flash and Fire Points Cleveland Open Cup Method. ISO: Geneva, Switzerland, 2017.

- EN 12607-1:2015; Bitumen and Bituminous Binders—Determination of the Resistance to Hardening under Influence of Heat and Air—Part 1: RTFOT Method. CEN-CENELEC Management Centre: Brussels, Belgium, 2015.

- EN 13398; Bitumen and Bituminous Binders—Determination of the Elastic Recovery of Modified Bitumen. CEN-CENELEC Management Centre: Brussels, Belgium, 2017.

- EN 14770; Bitumen and Bituminous Binders—Determination of Complex Shear Modulus and Phase Angle—Dynamic Shear Rheometer (DSR). CEN-CENELEC Management Centre: Brussels, Belgium, 2012.

- EN 13398; Standard Method of Test for Multiple Stress Creep Recovery (MSCR) Test of Asphalt Binder Using a Dynamic Shear Rheometer (DSR). CEN-CENELEC Management Centre: Brussels, Belgium, 2017.

- ASTM D 7404; Standard Test Method for Determination of Emulsified Asphalt Residue by Moisture Balance Analyzer. ASTM: West Conshehoken, PA, USA, 2007.

- EN 14023; Bitumen and Bituminous Binders—Specification Framework for Polymer Modified Bitumens. CEN-CENELEC Management Centre: Brussels, Belgium, 2010.

- Ibrahim, M.R.; Katman, H.Y.; Karim, M.R.; Koting, S.; Mashaa, N.S. A Review on the Effect of Crumb Rubber Addition to the Rheology of Crumb Rubber Modified Bitumen. Adv. Mater. Sci. Eng. 2013, 2013, 415246. [Google Scholar] [CrossRef]

- Sun, D.Q.; Li, L.H. Factors affecting the viscosity of crumb rubber-modified asphalt. Pet. Sci. Technol. 2010, 28, 1555–1566. [Google Scholar] [CrossRef]

- Billiter, T.C.; Davison, R.R.; Glover, C.J.; Bullin, J.A. Physical properties of asphalt-rubber binder. Pet. Sci. Technol. 1997, 15, 205–236. [Google Scholar] [CrossRef]

- Putman, B.J.; Amirkhanian, S.N. Crumb rubber modification of binders: Interaction and particle effects. Road Mater. Pavement Des. 2006, 10, 128716. [Google Scholar]

- Navarro, F.J.; Partal, P.; Mart, F.; Valencia, C.; Gallegos, C. Rheological characteristics of ground tire rubber modified bitumens. Chem. Eng. J. 2002, 89, 53–61. [Google Scholar] [CrossRef]

- Wong, C.C.; Wong, W.-G. Effect of crumb rubber modifiers on high temperature susceptibility of wearing course mixtures. Constr. Build. 2007, 21, 1741–1745. [Google Scholar] [CrossRef]

- Cao, R.; Bai, Q. Laboratory evaluation of performances of asphalt rubber and gap graded mixtures. In Proceedings of the 7th International Conference of Chinese Transportation Professionals Congress: Plan, Build, and Manage Transportation Infrastructures in China (ISSTP ’07), Shanghai, China, 21–22 May 2007; pp. 786–798. [Google Scholar]

| Bitumen Properties | Normative Indicators of the Road Bitumen B 70/100 | Actual Value | Test Method |

|---|---|---|---|

| Penetration at 25 °C, 0.1 mm, not lower | 87 ± 5 | 87.2 | EN 1426:2015 [54] |

| Softening point °C, not below | 45.8 ± 1.6 | 45.85 | EN 1427:2015 [55] |

| Brittleness temperature on Fraas °C, not higher | −21 ± 3 | −21 | EN 12593:2015 [56] |

| Solubility %, not less | 99.75 ± 0.1 | 99.75 | EN 12592:2015 [57] |

| Flashpoint °C, not below | 334 ± 4 | 335 | EN ISO 2592:2006 [58] |

| Rolling Thin Film Oven Test (RTFOT) | |||

| Change of Mass, % | −0.021 ± 0.01 | −0.0212 | EN 12607-1:2015 [59] |

| Increasing in Softening Point °C | 7.0 ± 3.6 | 7.0 | EN 1427:2015 [55] |

| Decreasing in Softening Point °C | 52.8 ± 1.6 | 53.25 | EN 1427:2015 [55] |

| Retained Penetration, % | 52 ± 3 | 51.9 | EN 1426:2015 [54] |

| Polymer Properties | SBS-01-10 |

|---|---|

| Structure | Linear |

| Molecular weight, g/mol | 150,000 |

| Bound styrene, % | 30 |

| Shore A hardness | 80 |

| Volatile matter, % | 0.8 |

| Ash content, % | 0.3 |

| Specific gravity | 0.95 |

| Tensile strength, MPa | 21 |

| Melt flow index, 200 °C/5 kgf | 1 |

| Bitumen | Penetration at 25 °C, mm−1 | Brittleness Temperature on Fraas, °C | Softening Point, °C | Elasticity, % | DSR Test, G*/sinδ at 60 °C, kPa | DSR Test, Tcrit. at G*/sinδ = 1 kPa, °C |

|---|---|---|---|---|---|---|

| B70/100 | 87.0 | −21 | 45.8 | - | 2.4 | 66 |

| B70/100 + SBS 2.5% | 62.0 | −20 | 60.0 | 60 | - | - |

| B70/100 + SBS 4% | 50.4 | −17 | 66.3 | 88 | 6.8 | 80 |

| B70/100 + 15% RC | 54.6 | −22 | 66.8 | >70 | 8 | 89 |

| B70/100 + 15% SR100 | 49.4 | −23 | 70.0 | >70 | 14.4 | 94 |

| B70/100 + 15% SR50/VR50 | 47.6 | −22 | 69.2 | >70 | 12 | 91 |

| B70/100 + 15% VR100 | 52.3 | −21 | 65.9 | >70 | 13.2 | 90 |

| Target value | 45–80 | ≤−15 | ≥55 | ≥50 | ≥1 | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Akkenzheyeva, A.; Haritonovs, V.; Bussurmanova, A.; Merijs-Meri, R.; Imanbayev, Y.; Riekstins, A.; Serikbayeva, A.; Sydykov, S.; Aimova, M.; Mustapayeva, G. Study of the Viscoelastic and Rheological Properties of Rubber-Bitumen Binders Obtained from Rubber Waste. Polymers 2024, 16, 114. https://doi.org/10.3390/polym16010114

Akkenzheyeva A, Haritonovs V, Bussurmanova A, Merijs-Meri R, Imanbayev Y, Riekstins A, Serikbayeva A, Sydykov S, Aimova M, Mustapayeva G. Study of the Viscoelastic and Rheological Properties of Rubber-Bitumen Binders Obtained from Rubber Waste. Polymers. 2024; 16(1):114. https://doi.org/10.3390/polym16010114

Chicago/Turabian StyleAkkenzheyeva, Anar, Viktors Haritonovs, Akkenzhe Bussurmanova, Remo Merijs-Meri, Yerzhan Imanbayev, Arturs Riekstins, Akmaral Serikbayeva, Serik Sydykov, Murshida Aimova, and Gulnara Mustapayeva. 2024. "Study of the Viscoelastic and Rheological Properties of Rubber-Bitumen Binders Obtained from Rubber Waste" Polymers 16, no. 1: 114. https://doi.org/10.3390/polym16010114

APA StyleAkkenzheyeva, A., Haritonovs, V., Bussurmanova, A., Merijs-Meri, R., Imanbayev, Y., Riekstins, A., Serikbayeva, A., Sydykov, S., Aimova, M., & Mustapayeva, G. (2024). Study of the Viscoelastic and Rheological Properties of Rubber-Bitumen Binders Obtained from Rubber Waste. Polymers, 16(1), 114. https://doi.org/10.3390/polym16010114