On-Chip 3D Printing of Polymer Waveguide-Coupled Single-Photon Emitter Based on Colloidal Quantum Dots

Abstract

1. Introduction

2. Methods

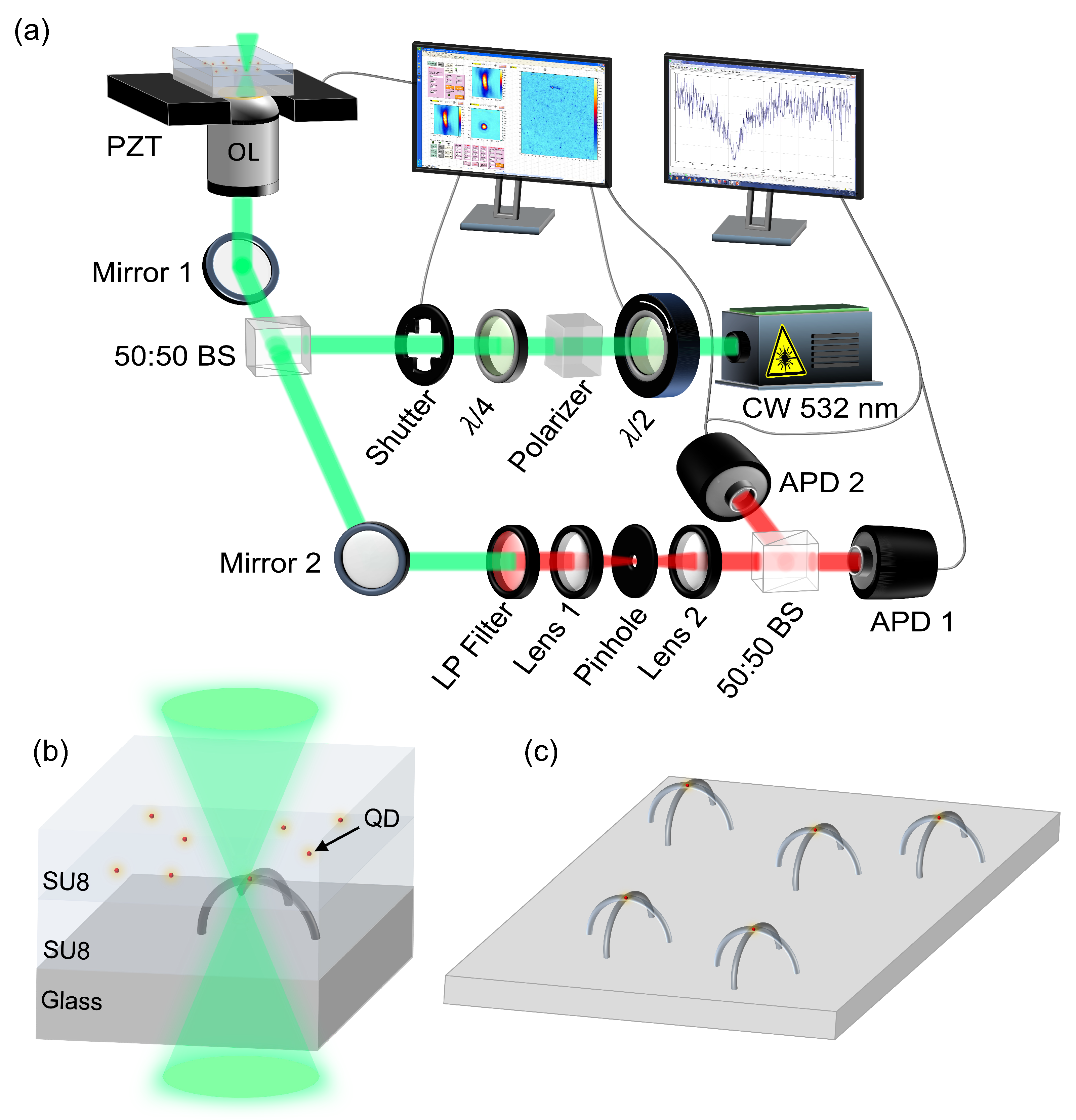

2.1. Experiment Setup

2.2. Sample Preparation

2.3. Numerical Calculation Method

3. Results and Discussion

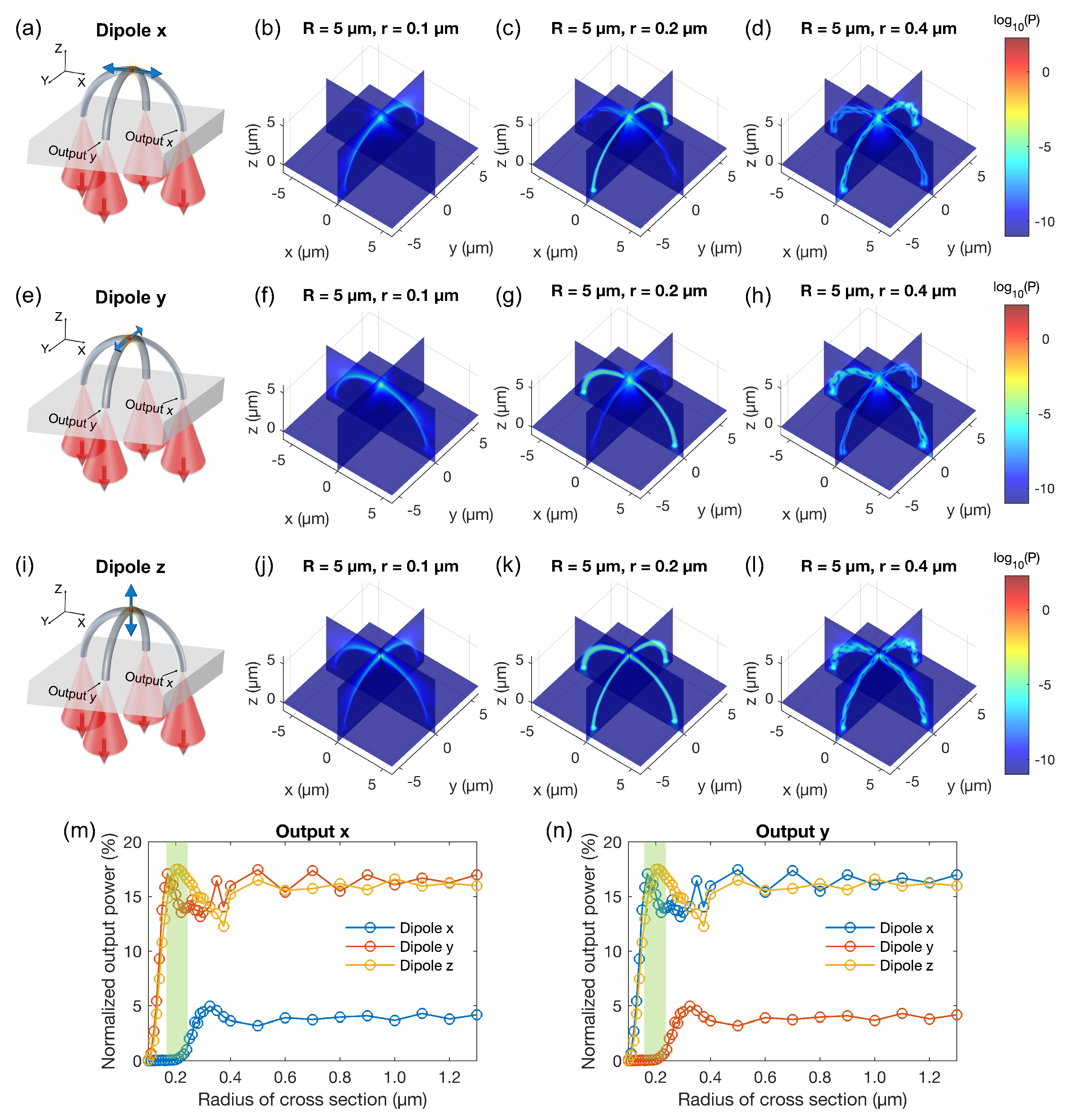

3.1. Numerical Results

3.1.1. Guiding the Emission of a Single Dipole

3.1.2. Guiding the Emission of Two Orthogonal Dipoles

3.1.3. Laser Excitation Configuration

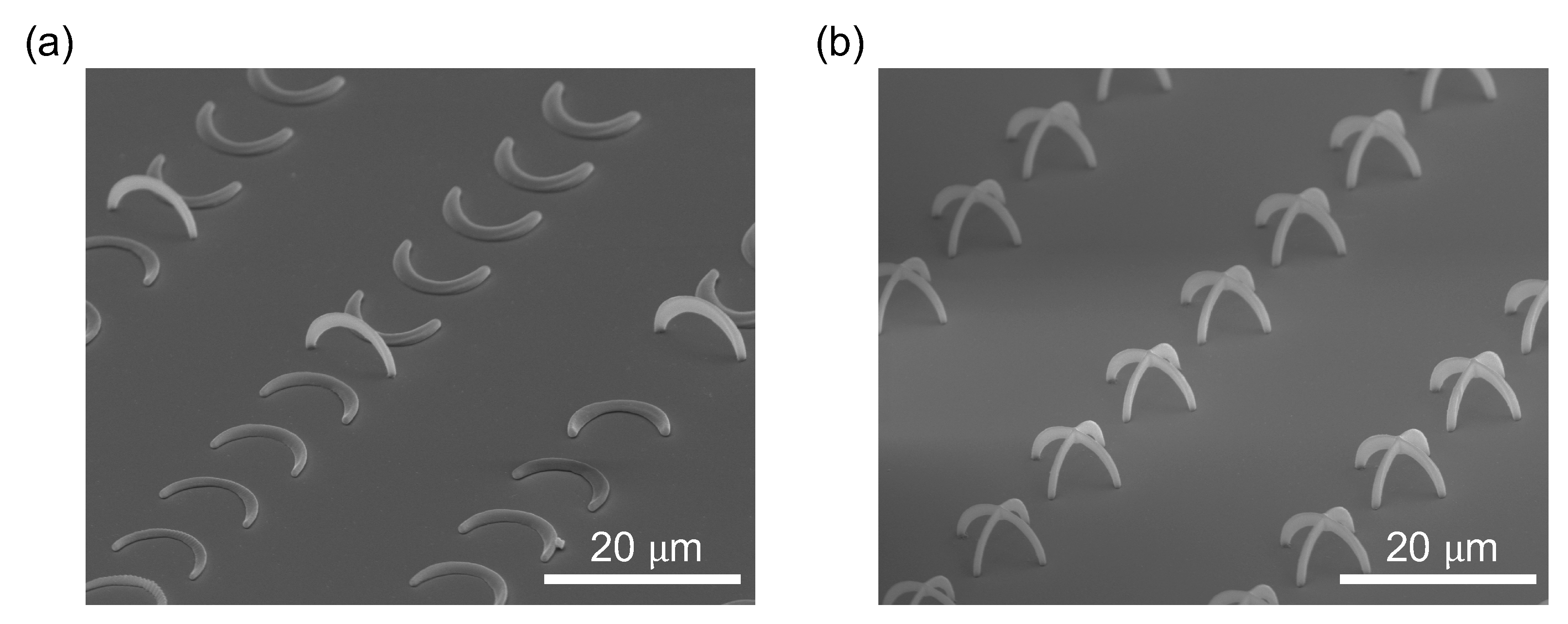

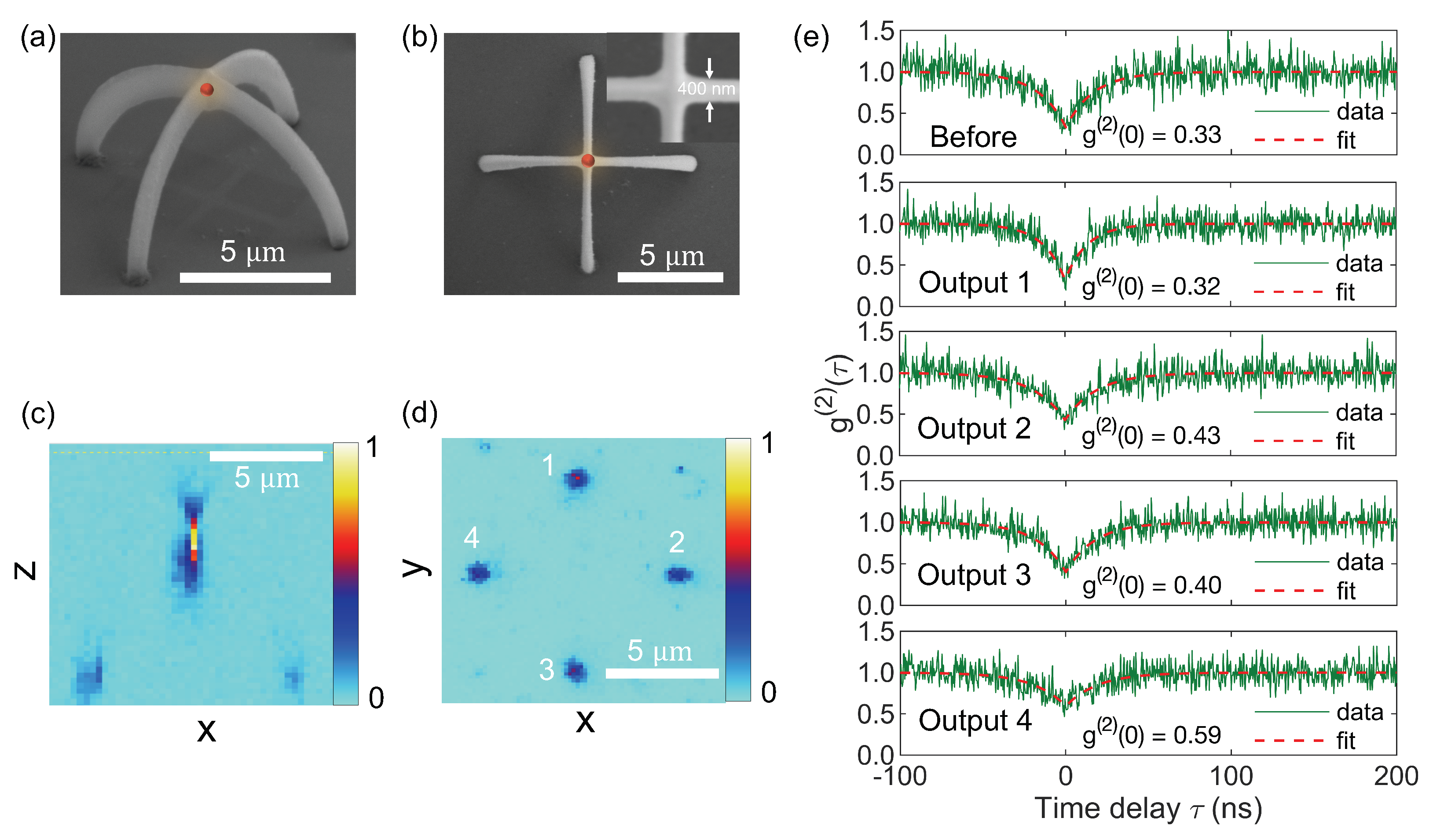

3.2. Experimental Results

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Arakawa, Y.; Holmes, M.J. Progress in quantum-dot single photon sources for quantum information technologies: A broad spectrum overview. Appl. Phys. Rev. 2020, 7, 021309. [Google Scholar] [CrossRef]

- Choi, H.; Zhu, D.; Yoon, Y.; Englund, D. Cascaded cavities boost the indistinguishability of imperfect quantum emitters. Phys. Rev. Lett. 2019, 122, 183602. [Google Scholar] [CrossRef] [PubMed]

- Lodahl, P.; Ludwig, A.; Warburton, R.J. A deterministic source of single photons. Phys. Today 2022, 75, 3–44. [Google Scholar] [CrossRef]

- Loredo, J.C.; Zakaria, N.A.; Somaschi, N.; Anton, C.; De Santis, L.; Giesz, V.; Grange, T.; Broome, M.A.; Gazzano, O.; Coppola, G.; et al. Scalable performance in solid-state single-photon sources. Optica 2016, 3, 433–440. [Google Scholar] [CrossRef]

- Loredo, J.; Broome, M.; Hilaire, P.; Gazzano, O.; Sagnes, I.; Lemaitre, A.; Almeida, M.; Senellart, P.; White, A. Boson sampling with single-photon fock states from a bright solid-state source. Phys. Rev. Lett. 2017, 118, 130503. [Google Scholar] [CrossRef]

- Moody, G.; Sorger, V.J.; Blumenthal, D.J.; Juodawlkis, P.W.; Loh, W.; Sorace-Agaskar, C.; Jones, A.E.; Balram, K.C.; Matthews, J.C.; Laing, A.; et al. 2022 Roadmap on integrated quantum photonics. J. Phys. Photonics 2022, 4, 012501. [Google Scholar] [CrossRef]

- Somaschi, N.; Giesz, V.; De Santis, L.; Loredo, J.; Almeida, M.P.; Hornecker, G.; Portalupi, S.L.; Grange, T.; Anton, C.; Demory, J.; et al. Near-optimal single-photon sources in the solid state. Nat. Photonics 2016, 10, 340–345. [Google Scholar] [CrossRef]

- Reimer, M.E.; Bulgarini, G.; Akopian, N.; Hocevar, M.; Bavinck, M.B.; Verheijen, M.A.; Bakkers, E.P.; Kouwenhoven, L.P.; Zwiller, V. Bright single-photon sources in bottom-up tailored nanowires. Nat. Commun. 2012, 3, 737. [Google Scholar] [CrossRef] [PubMed]

- Chanana, A.; Larocque, H.; Moreira, R.; Carolan, J.; Guha, B.; Melo, E.G.; Anant, V.; Song, J.; Englund, D.; Blumenthal, D.J.; et al. Ultra-low loss quantum photonic circuits integrated with single quantum emitters. Nat. Commun. 2022, 13, 7693. [Google Scholar] [CrossRef]

- Prtljaga, N.; Coles, R.; O’Hara, J.; Royall, B.; Clarke, E.; Fox, A.; Skolnick, M. Monolithic integration of a quantum emitter with a compact on-chip beam-splitter. Appl. Phys. Lett. 2014, 104, 231107. [Google Scholar] [CrossRef]

- Prtljaga, N.; Bentham, C.; O’Hara, J.; Royall, B.; Clarke, E.; Wilson, L.R.; Skolnick, M.S.; Fox, A.M. On-chip interference of single photons from an embedded quantum dot and an external laser. Appl. Phys. Lett. 2016, 108, 251101. [Google Scholar] [CrossRef]

- Jiang, P.; Ma, N.; Liu, P.; Wu, W.; Zhang, K. An Easy-Implemented On-Chip Waveguide Coupled Single Photon Source Based on Self-Assembled Quantum Dots Membrane. Appl. Sci. 2021, 11, 695. [Google Scholar] [CrossRef]

- Schnauber, P.; Schall, J.; Bounouar, S.; Hohne, T.; Park, S.I.; Ryu, G.H.; Heindel, T.; Burger, S.; Song, J.D.; Rodt, S.; et al. Deterministic integration of quantum dots into on-chip multimode interference beamsplitters using in situ electron beam lithography. Nano Lett. 2018, 18, 2336–2342. [Google Scholar] [CrossRef] [PubMed]

- Laucht, A.; Pütz, S.; Günthner, T.; Hauke, N.; Saive, R.; Frédérick, S.; Bichler, M.; Amann, M.C.; Holleitner, A.; Kaniber, M.; et al. A waveguide-coupled on-chip single-photon source. Phys. Rev. X 2012, 2, 011014. [Google Scholar] [CrossRef]

- Uppu, R.; Eriksen, H.T.; Thyrrestrup, H.; Uğurlu, A.D.; Wang, Y.; Scholz, S.; Wieck, A.D.; Ludwig, A.; Löbl, M.C.; Warburton, R.J.; et al. On-chip deterministic operation of quantum dots in dual-mode waveguides for a plug-and-play single-photon source. Nat. Commun. 2020, 11, 3782. [Google Scholar] [CrossRef]

- Eich, A.; Spiekermann, T.C.; Gehring, H.; Sommer, L.; Bankwitz, J.R.; Schrinner, P.P.; Preuß, J.A.; Michaelis de Vasconcellos, S.; Bratschitsch, R.; Pernice, W.H.; et al. Single-photon emission from individual nanophotonic-integrated colloidal quantum dots. ACS Photonics 2022, 9, 551–558. [Google Scholar] [CrossRef]

- Tonndorf, P.; Del Pozo-Zamudio, O.; Gruhler, N.; Kern, J.; Schmidt, R.; Dmitriev, A.I.; Bakhtinov, A.P.; Tartakovskii, A.I.; Pernice, W.; Michaelis de Vasconcellos, S.; et al. On-chip waveguide coupling of a layered semiconductor single-photon source. Nano Lett. 2017, 17, 5446–5451. [Google Scholar] [CrossRef]

- Shi, Q.; Sontheimer, B.; Nikolay, N.; Schell, A.; Fischer, J.; Naber, A.; Benson, O.; Wegener, M. Wiring up pre-characterized single-photon emitters by laser lithography. Sci. Rep. 2016, 6, 31135. [Google Scholar] [CrossRef]

- Schell, A.W.; Kaschke, J.; Fischer, J.; Henze, R.; Wolters, J.; Wegener, M.; Benson, O. Three-dimensional quantum photonic elements based on single nitrogen vacancy-centres in laser-written microstructures. Sci. Rep. 2013, 3, 1577. [Google Scholar] [CrossRef]

- Ngo, G.L.; Hermier, J.P.; Lai, N.D. Single-photon splitting by polymeric submicropillars structures. AVS Quantum Sci. 2023, 5, 011403. [Google Scholar] [CrossRef]

- Ngo, G.L.; Hermier, J.P.; Lai, N.D. Combining single-photon signals by deterministic coupling of CdSe/CdS quantum dots into submicropillars structures. In Proceedings of the Quantum Sensing and Nano Electronics and Photonics XIX, SPIE, San Francisco, CA, USA, 5 April 2023; Volume 12430, pp. 242–248. [Google Scholar]

- Do, M.T.; Nguyen, T.T.N.; Li, Q.; Benisty, H.; Ledoux-Rak, I.; Lai, N.D. Submicrometer 3D structures fabrication enabled by one-photon absorption direct laser writing. Opt. Express 2013, 21, 20964–20973. [Google Scholar] [CrossRef]

- Au, T.H.; Buil, S.; Quélin, X.; Hermier, J.P.; Lai, N.D. Suppression of grey state and optimization of the single photon emission of a colloidal semiconductor at room temperature. Appl. Phys. Lett. 2018, 113, 111105. [Google Scholar] [CrossRef]

- Au, T.H.; Buil, S.; Quélin, X.; Hermier, J.P.; Lai, N.D. Photostability and long-term preservation of a colloidal semiconductor-based single photon emitter in polymeric photonic structures. Nanoscale Adv. 2019, 1, 3225–3231. [Google Scholar] [CrossRef] [PubMed]

- Mahler, B.; Spinicelli, P.; Buil, S.; Quelin, X.; Hermier, J.P.; Dubertret, B. Towards non-blinking colloidal quantum dots. Nat. Mater. 2008, 7, 659–664. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.C.; Salter, P.S.; Knauer, S.; Weng, L.; Frangeskou, A.C.; Stephen, C.J.; Ishmael, S.N.; Dolan, P.R.; Johnson, S.; Green, B.L.; et al. Laser writing of coherent colour centres in diamond. Nat. Photonics 2017, 11, 77–80. [Google Scholar] [CrossRef]

- Zhang, Q.; Dang, C.; Urabe, H.; Wang, J.; Sun, S.; Nurmikko, A. Large ordered arrays of single photon sources based on II–VI semiconductor colloidal quantum dot. Opt. Express 2008, 16, 19592–19599. [Google Scholar] [CrossRef]

- Palacios-Berraquero, C.; Kara, D.M.; Montblanch, A.R.P.; Barbone, M.; Latawiec, P.; Yoon, D.; Ott, A.K.; Loncar, M.; Ferrari, A.C.; Atatüre, M. Large-scale quantum-emitter arrays in atomically thin semiconductors. Nat. Commun. 2017, 8, 15093. [Google Scholar] [CrossRef]

- Wu, W.; Dass, C.K.; Hendrickson, J.R.; Montaño, R.D.; Fischer, R.E.; Zhang, X.; Choudhury, T.H.; Redwing, J.M.; Wang, Y.; Pettes, M.T. Locally defined quantum emission from epitaxial few-layer tungsten diselenide. Appl. Phys. Lett. 2019, 114, 213102. [Google Scholar] [CrossRef]

- Li, C.; Mendelson, N.; Ritika, R.; Chen, Y.; Xu, Z.Q.; Toth, M.; Aharonovich, I. Scalable and deterministic fabrication of quantum emitter arrays from hexagonal boron nitride. Nano Lett. 2021, 21, 3626–3632. [Google Scholar] [CrossRef]

- Parto, K.; Azzam, S.I.; Banerjee, K.; Moody, G. Defect and strain engineering of monolayer WSe2 enables site-controlled single-photon emission up to 150 K. Nat. Commun. 2021, 12, 3585. [Google Scholar] [CrossRef]

- Fournier, C.; Plaud, A.; Roux, S.; Pierret, A.; Rosticher, M.; Watanabe, K.; Taniguchi, T.; Buil, S.; Quélin, X.; Barjon, J.; et al. Position-controlled quantum emitters with reproducible emission wavelength in hexagonal boron nitride. Nat. Commun. 2021, 12, 3779. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ngo, G.L.; Nguyen, L.; Hermier, J.-P.; Lai, N.D. On-Chip 3D Printing of Polymer Waveguide-Coupled Single-Photon Emitter Based on Colloidal Quantum Dots. Polymers 2023, 15, 2201. https://doi.org/10.3390/polym15092201

Ngo GL, Nguyen L, Hermier J-P, Lai ND. On-Chip 3D Printing of Polymer Waveguide-Coupled Single-Photon Emitter Based on Colloidal Quantum Dots. Polymers. 2023; 15(9):2201. https://doi.org/10.3390/polym15092201

Chicago/Turabian StyleNgo, Gia Long, Long Nguyen, Jean-Pierre Hermier, and Ngoc Diep Lai. 2023. "On-Chip 3D Printing of Polymer Waveguide-Coupled Single-Photon Emitter Based on Colloidal Quantum Dots" Polymers 15, no. 9: 2201. https://doi.org/10.3390/polym15092201

APA StyleNgo, G. L., Nguyen, L., Hermier, J.-P., & Lai, N. D. (2023). On-Chip 3D Printing of Polymer Waveguide-Coupled Single-Photon Emitter Based on Colloidal Quantum Dots. Polymers, 15(9), 2201. https://doi.org/10.3390/polym15092201