Pyroresistive Properties of Composites Based on HDPE and Carbon Fillers

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

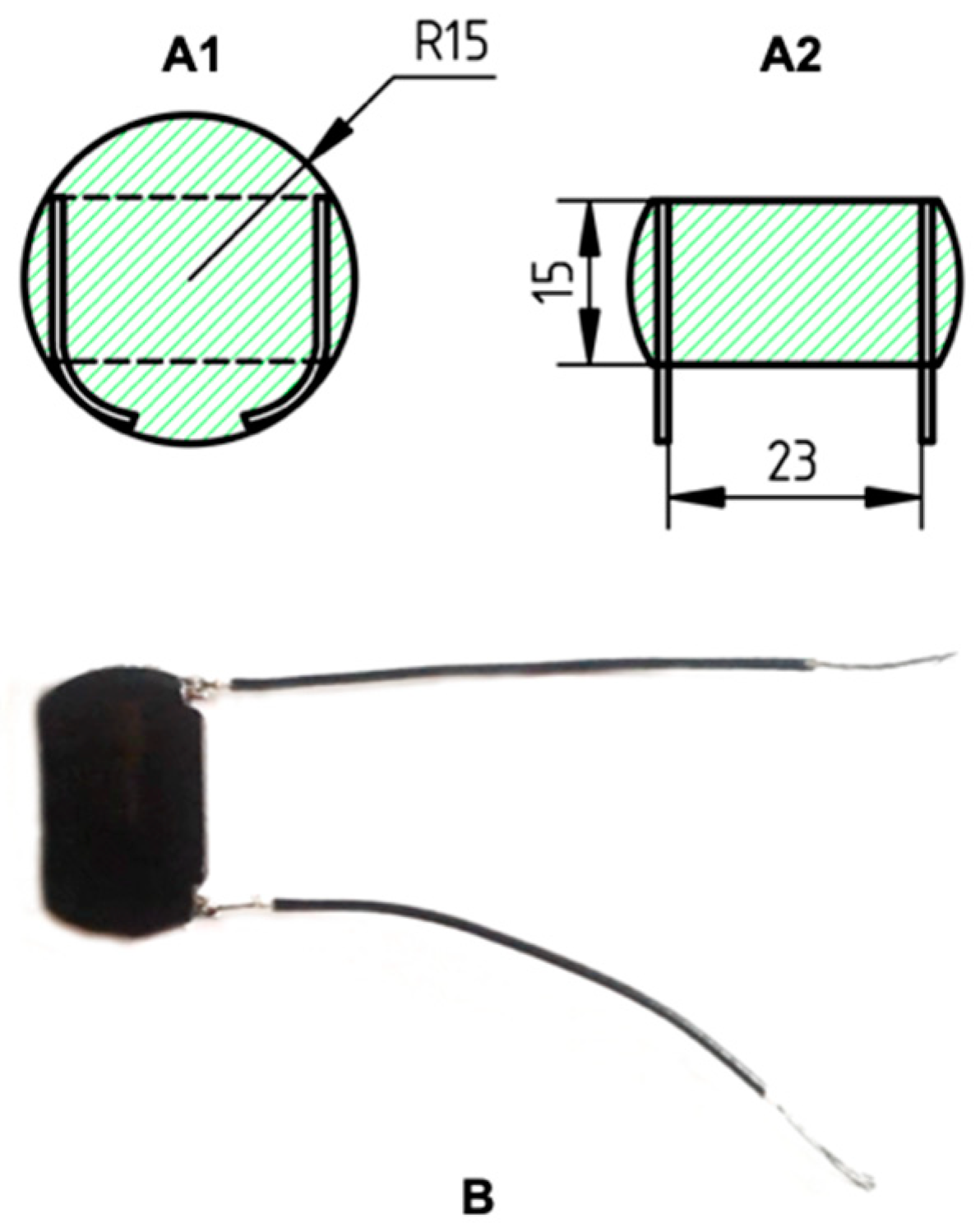

2.2. Sample Preparation

2.3. Measurement of Electrical and Thermal Characteristics

3. Results and Discussion

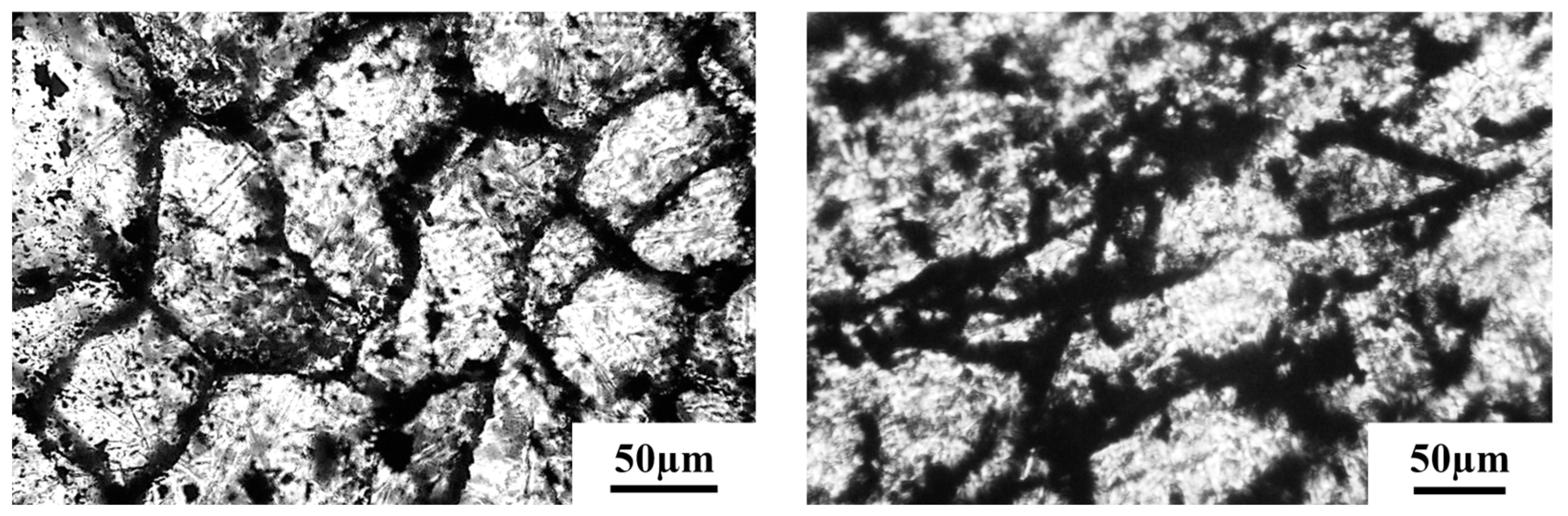

3.1. Structure of Composites

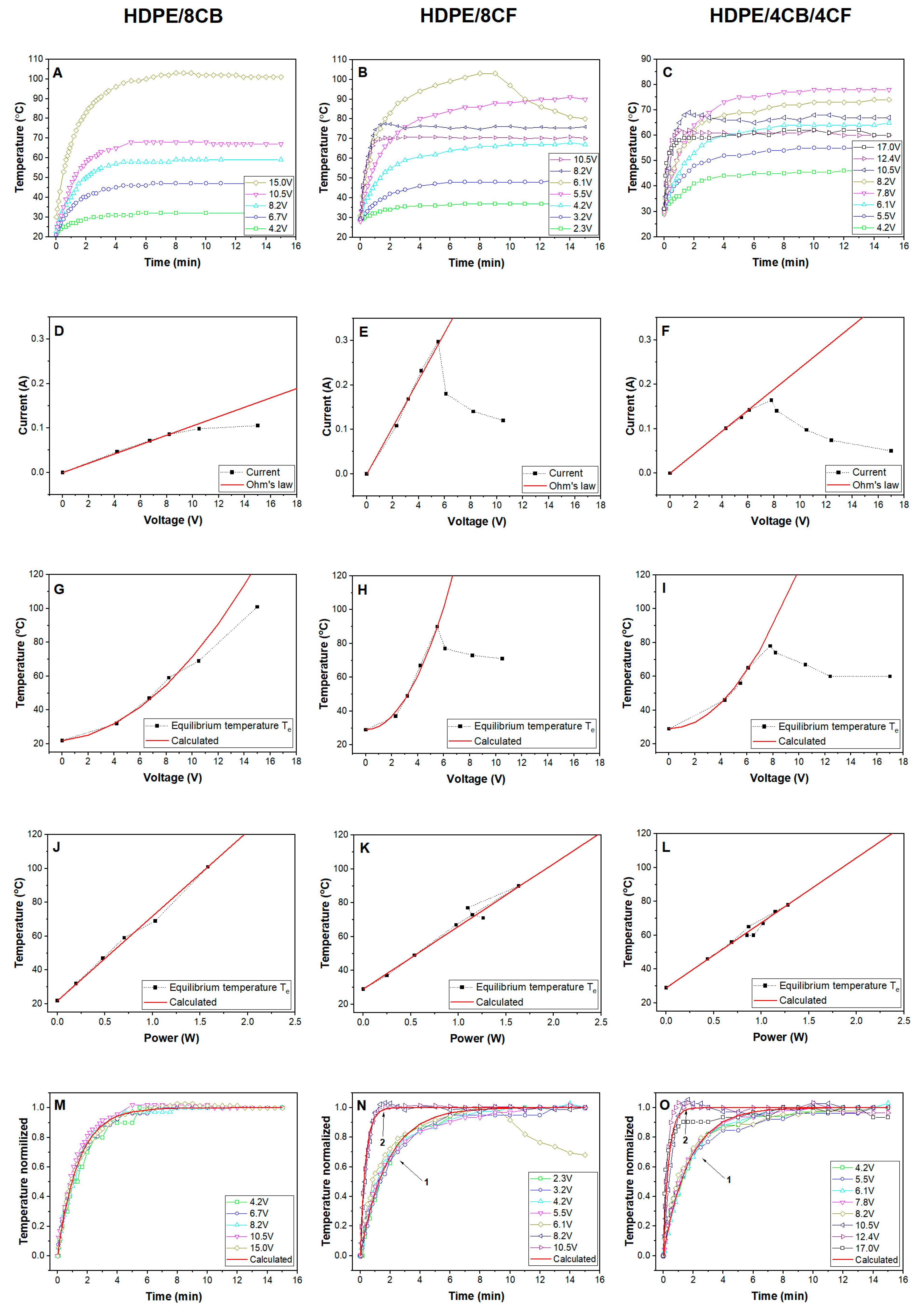

3.2. Kinetic Temperature Dependence of Composites

3.3. Electrical Properties of Composites

3.4. Influence of the PTC Effect on the Pyroresistive Properties of Composites

3.5. The Influence of Voltage on the Kinetic Heating

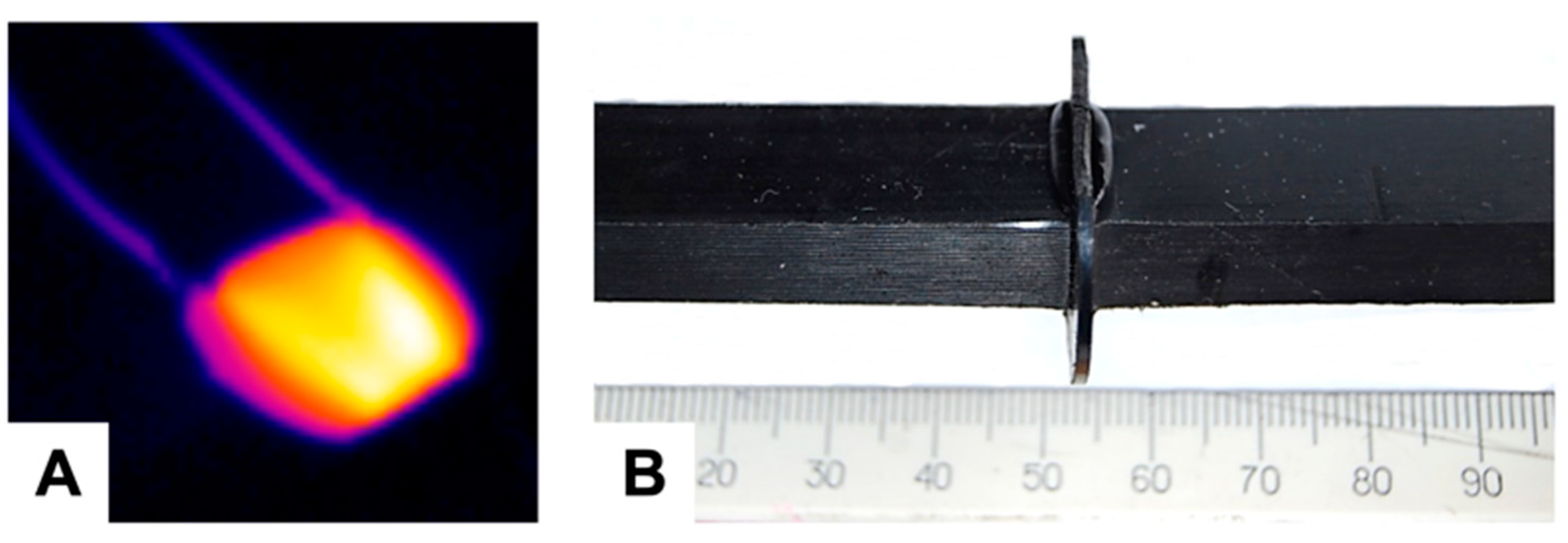

3.6. Application

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Liu, Y.; Zhang, H.; Porwal, H.; Busfield, J.J.; Peijs, T.; Bilotti, E. Pyroresistivity in conductive polymer composites: A perspective on recent advances and new applications. Polym. Int. 2019, 68, 299–305. [Google Scholar] [CrossRef]

- Chen, X.; Zheng, Y.; Han, X.; Jing, Y.; Du, M.; Lu, C.; Zhang, K. Low-dimensional Thermoelectric Materials. In Flexible Thermoelectric Polymers and Systems; Ouyang, J., Ed.; Wiley: New York, NY, USA, 2022; pp. 209–238. [Google Scholar]

- Liu, Y.; Zhang, H.; Bilotti, E. Polymer nanocomposites for temperature sensing and self-regulating heating devices. In Polymer Nanocomposite Materials; Zhou, Y., Ding, G., Eds.; Wiley: New York, NY, USA, 2021; pp. 247–266. [Google Scholar]

- Hu, Y.; Shenderova, O.A.; Hu, Z.; Padgett, C.W.; Brenner, D.W. Carbon nanostructures for advanced composites. Rep. Prog. Phys. 2006, 69, 1847–1895. [Google Scholar] [CrossRef]

- Tian, K.; Hu, D.; Wei, Q.; Fu, Q.; Deng, H. Recent progress on multifunctional electromagnetic interference shielding polymer composites. J. Mater. Sci. Technol. 2023, 134, 106–131. [Google Scholar] [CrossRef]

- Lee, Y.; Park, J.; Choe, A.; Shin, Y.E.; Kim, J.; Myoung, J.; Lee, S.; Lee, Y.; Kim, Y.; Yi, K.; et al. Flexible Pyroresistive Graphene Composites for Artificial Thermosensation Differentiating Materials and Solvent Types. ACS Nano 2022, 16, 1208–1219. [Google Scholar] [CrossRef] [PubMed]

- An, J.E.; Jeong, Y.G. Structure and electric heating performance of graphene/epoxy composite films. Eur. Polym. J. 2013, 49, 1322–1330. [Google Scholar] [CrossRef]

- Chen, L.; Zhang, J. Designs of conductive polymer composites with exceptional reproducibility of positive temperature coefficient effect: A review. J. Appl. Polym. Sci. 2020, 138, e49677. [Google Scholar] [CrossRef]

- Chu, K.; Yun, D.; Kim, D.; Park, H.; Park, S. Study of electric heating effects on carbon nanotube polymer composites. Org. Electron. 2014, 15, 2734–2741. [Google Scholar] [CrossRef]

- Bauhofer, W.; Kovacs, J.Z. A review and analysis of electrical percolation in carbon nanotube polymer composites. Compos. Sci. Technol. 2009, 69, 1486–1498. [Google Scholar] [CrossRef]

- Spitalsky, Z.; Tasis, D.; Papagelis, K.; Galiotis, C. Carbon nanotube-polymer composites: Chemistry, processing, mechanical and electrical properties. Prog. Polym. Sci. 2010, 35, 357–401. [Google Scholar] [CrossRef]

- Szeluga, U.; Kumanek, B.; Trzebicka, B. Synergy in hybrid polymer/nanocarbon composites. A review. Compos. Part A Appl. Sci. Manuf. 2015, 73, 204–231. [Google Scholar] [CrossRef]

- Pang, H.; Xu, L.; Yan, D.X.; Li, Z.M. Conductive polymer composites with segregated structures. Prog. Polym. Sci. 2014, 39, 1908–1933. [Google Scholar] [CrossRef]

- Grunlan, J.C.; Gerberich, W.W.; Francis, L.F. Lowering the percolation threshold of conductive composites using particulate polymer microstructure. J. Appl. Polym. Sci. 2001, 80, 692–705. [Google Scholar] [CrossRef]

- Grunlan, J.C.; Gerberich, W.W.; Francis, L.F. Electrical and mechanical behavior of carbon black-filled poly(vinyl acetate) latex-based composites. Polym. Eng. Sci. 2001, 41, 1947–1962. [Google Scholar] [CrossRef]

- Pang, H.; Chen, C.; Bao, Y.; Chen, J.; Ji, X.; Lei, J.; Li, Z.M. Electrically conductive carbon nanotube/ultrahigh molecular weight polyethylene composites with segregated and double percolated structure. Mater. Lett. 2012, 79, 96–99. [Google Scholar] [CrossRef]

- Al-Saleh, M.H.; Sundararaj, U. An innovative method to reduce percolation threshold of carbon black filled immiscible polymer blends. Compos. Part A Appl. Sci. Manuf. 2008, 39, 284–293. [Google Scholar] [CrossRef]

- Kusy, R.P.; Turner, D.T. Electrical conductivity of a polyurethane elastomer containing segregated particles of nickel. J. Appl. Polym. Sci. 1973, 17, 1631–1633. [Google Scholar] [CrossRef]

- Wang, B.J.; Li, H.Y.; Li, L.Z.; Chen, P.; Wang, Z.B.; Gu, Q. Electrostatic adsorption method for preparing electrically conducting ultrahigh molecular weight polyethylene/graphene nanosheets composites with a segregated network. Compos. Sci. Technol. 2013, 89, 180–185. [Google Scholar] [CrossRef]

- Lisunova, M.O.; Mamunya, Y.P.; Lebovka, N.I.; Melezhyk, A.V. Percolation behaviour of ultrahigh molecular weight polyethylene/multi-walled carbon nanotubes composites. Eur. Polym. J. 2007, 43, 949–958. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, H.; Porwal, H.; Tu, W.; Evans, J.; Newton, M.; Busfield, J.; Peijs, T.; Bilotti, E. Universal control on pyroresistive behavior of flexible self-regulating heating devices. Adv. Funct. Mater. 2017, 27, 1702253. [Google Scholar] [CrossRef]

- Marischal, L.; Cayla, A.; Lemort, G.; Campagne, C.; Devaux, É. Selection of immiscible polymer blends filled with carbon nanotubes for heating applications. Polymers 2019, 11, 1827. [Google Scholar] [CrossRef]

- Isaji, S.; Bin, Y.; Matsuo, M. Electrical conductivity and self-temperature-control heating properties of carbon nanotubes filled polyethylene films. Polymer 2009, 50, 1046–1053. [Google Scholar] [CrossRef]

- Chu, K.; Park, S. Electrical heating behavior of flexible carbon nanotube composites with different aspect ratios. J. Ind. Eng. Chem. 2016, 35, 195–198. [Google Scholar] [CrossRef]

- Lee, Y.S.; Yu, J.; Shim, S.E.; Yang, C.M. Synergistic effects of hybrid carbonaceous fillers of carbon fibers and reduced graphene oxides on enhanced heat-dissipation capability of polymer composites. Polymers 2020, 12, 909. [Google Scholar] [CrossRef]

- Jeong, Y.G.; An, J. Effects of mixed carbon filler composition on electric heating behavior of thermally-cured epoxy-based composite films. Compos. Part A Appl. Sci. Manuf. 2014, 56, 1–7. [Google Scholar] [CrossRef]

- Yan, J.; Jeong, Y.G. Synergistic effect of hybrid carbon fillers on electric heating behavior of flexible polydimethylsiloxane-based composite films. Compos. Sci. Technol. 2015, 106, 134–140. [Google Scholar] [CrossRef]

- Lee, T.; Jeong, Y.G. Regenerated cellulose/multiwalled carbon nanotube composite films with efficient electric heating performance. Carbohydr. Polym. 2015, 133, 456–463. [Google Scholar] [CrossRef]

- Lee, T.; Lee, S.; Jeong, Y.G. Carbon nanotube/cellulose papers with high performance in electric heating and electromagnetic interference shielding. Compos. Sci. Technol. 2016, 131, 77–87. [Google Scholar] [CrossRef]

- Yan, J.; Jeong, Y.G. Highly elastic and transparent multiwalled carbon nanotube/polydimethylsiloxane bilayer films as electric heating materials. Mater. Des. 2015, 86, 72–79. [Google Scholar] [CrossRef]

- Cheng, Y.; Zhang, H.; Wang, R.; Wang, X.; Zhai, H.; Wang, T.; Jin, Q.; Sun, J. Highly Stretchable and Conductive Copper Nanowire Based Fibers with Hierarchical Structure for Wearable Heaters. ACS Appl. Mater. Interfaces 2016, 8, 32925–32933. [Google Scholar] [CrossRef]

- Vertuccio, L.; De Santis, F.; Pantani, R.; Lafdi, K.K.; Guadagno, L. Effective de-icing skin using graphene-based flexible heater. Compos. Part B Eng. 2019, 162, 600–610. [Google Scholar] [CrossRef]

- Luo, J.; Lu, H.; Zhang, Q.; Yao, Y.; Chen, M.; Li, Q. Flexible carbon nanotube/polyurethane electrothermal films. Carbon 2016, 110, 343–349. [Google Scholar] [CrossRef]

- Noel, H.; Glouannec, P.; Ploteau, J.; Chauvelon, P.; Feller, J.F. Design and study of an electrical liquid heater using conductive polymer composite tubes. Appl. Therm. Eng. 2013, 54, 507–515. [Google Scholar] [CrossRef]

- Park, J.; Jeong, Y.G. Investigation of microstructure and electric heating behavior of hybrid polymer composite films based on thermally stable polybenzimidazole and multiwalled carbon nanotube. Polymer 2015, 59, 102–109. [Google Scholar] [CrossRef]

- Rybak, A.; Boiteux, G.; Melis, F.; Seytre, G. Conductive polymer composites based on metallic nanofiller as smart materials for current limiting devices. Compos. Sci. Technol. 2010, 70, 410–416. [Google Scholar] [CrossRef]

- Liu, Y.; Zhang, H.; Porwal, H.; Tu, W.; Wan, K.; Evans, J.; Newton, M.; Busfield, J.J.C.; Peijs, T.; Bilotti, E. Tailored pyroresistive performance and flexibility by introducing a secondary thermoplastic elastomeric phase into graphene nanoplatelet (GNP) filled polymer composites for self-regulating heating devices. J. Mater. Chem. C 2018, 6, 2760–2768. [Google Scholar] [CrossRef]

- Kolisnyk, R.; Korab, M.; Iurzhenko, M.; Masiuchok, O.; Mamunya, Y. Development of heating elements based on conductive polymer composites for electrofusion welding of plastics. J. Appl. Polym. Sci. 2020, 138, e50418. [Google Scholar] [CrossRef]

- Maruzhenko, O.; Mamunya, Y.; Boiteux, G.; Pusz, S.; Szeluga, U.; Pruvost, S. Improving the thermal and electrical properties of polymer composites by ordered distribution of carbon micro- and nanofillers. Int. J. Heat Mass Transf. 2019, 138, 75–84. [Google Scholar] [CrossRef]

- Mamunya, Y.P.; Davydenko, V.V.; Pissis, P.; Lebedev, E.V. Electrical and thermal conductivity of polymers filled with metal powders. Eur. Polym. J. 2002, 38, 1887–1897. [Google Scholar] [CrossRef]

- Lebovka, N.; Lisunova, M.; Mamunya, Y.; Vygornitskii, N. Scaling in percolation behaviour in conductive-insulating composites with particles of different size. J. Phys. D Appl. Phys. 2006, 39, 2264. [Google Scholar] [CrossRef]

- Deng, F.; Zheng, Q.S. An analytical model of effective electrical conductivity of carbon nanotube composites. Appl. Phys. Lett. 2008, 92, 071902. [Google Scholar] [CrossRef]

- Wang, F.X.; Liang, W.Y.; Wang, Z.Q.; Yang, B.; He, L.; Zhang, K. Preparation and property investigation of multi-walled carbon nanotube (MWCNT)/epoxy composite films as high-performance electric heating (resistive heating) element. Express Polym. Lett. 2018, 12, 285–295. [Google Scholar] [CrossRef]

- Smith, W.R.; Thornhill, F.S.; Bray, R.I. Surface area and properties of carbon black. Rubber Chem. Technol. 1942, 15, 206–215. [Google Scholar] [CrossRef]

- Al-juothry, S. The influence surface area and structure of particles carbon black on cure characteristics and mechanical properties of natural rubber. Int. J. Adv. Res. Sci. Eng. Technol. 2014, 5, 149–159. [Google Scholar]

- Al-Hartomy, O.A.; Al-Solamy, F.; Al-Ghamdi, A.; Dishovsky, N.; Ivanov, M.; Mihaylov, M.; El-Tantawy, F. Influence of carbon black structure and specific surface area on the mechanical and dielectric properties of filled rubber composites. Int. J. Polym. Sci. 2011, 2011, 521985. [Google Scholar] [CrossRef]

- Feng, J.; Chan, C.M. Carbon black-filled immiscible blends of poly(viny1idene fluoride) and high density polyethylene: The relationship between morphology and positive and negative temperature coefficient effects. Pol. Eng. Sci. 1999, 39, 1207–1215. [Google Scholar] [CrossRef]

- Zhao, Z.; Yu, W.; He, X.; Chen, X. The conduction mechanism of carbon black-filled poly(vinylidene fluoride) composite. Mater. Lett. 2003, 57, 3082–3088. [Google Scholar] [CrossRef]

- Mamunya, Y.P.; Muzychenko, Y.V.; Lebedev, E.V.; Boiteux, G.; Seytre, G.; Boullanger, C.; Pissis, P. PTC effect and structure of polymer composites based on polyethylene/polyoxymethylene blend filled with dispersed iron. Pol. Eng. Sci. 2007, 47, 34–42. [Google Scholar] [CrossRef]

- Fournier, J.; Boiteux, G.; Seytre, G.; Marichy, G. Study of the PTC effect in conducting epoxy polymer composites. J. Chim. Phys. 1998, 95, 1510–1513. [Google Scholar] [CrossRef]

- Stavrov, D.; Bersee, H.E.N. Resistance welding of thermoplastic composites-an overview. Compos. Part A Appl. Sci. Manuf. 2005, 36, 39–54. [Google Scholar] [CrossRef]

- Dube, M.; Hubert, P.; Yousefpour, A.; Denault, J. Resistance welding of thermoplastic composites skin/stringer joints. Compos. Part A Appl. Sci. Manuf. 2007, 38, 2541–2552. [Google Scholar] [CrossRef]

- de Souza, S.D.B.; Abrahão, A.B.R.M.; Costa, M.L.; Marlet, J.M.F.; Hein, L.R.O.; Botelho, E.C. Experimental Investigation of Processing Welding Parameters For PPS/Carbon Fiber Laminates for Aeronautical Applications. Adv. Mat. Res. 2016, 1135, 62–74. [Google Scholar] [CrossRef]

- Brassard, D.; Dubé, M.; Tavares, J.R. Resistance welding of thermoplastic composites with a nanocomposite heating element. Compos. Part B Eng. 2019, 165, 779–784. [Google Scholar] [CrossRef]

| 8CB | 8CF | 4CB/4CF | ||

|---|---|---|---|---|

| 1/R | [S] | 10 × 10−3 | 53 × 10−3 | 24 × 10−3 |

| R | [Ohm] | 100 | 18.9 | 41.7 |

| a | [°C/V2] | 0.46 | 2.0 | 0.94 |

| b | [°C/W] | 50.0 | 37.0 | 38.5 |

| hrc = 1/b | [mW/°C] | 20 | 27 | 26 |

| tc | [s] | 73.8 | 21.6/109.2 | 21.0/101.4 |

| k = 1/tc | [s−1] | 136 × 10−3 | 46.3/9.2 × 10−3 | 47.6/9.9 × 10−3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mamunya, Y.; Maruzhenko, O.; Kolisnyk, R.; Iurzhenko, M.; Pylypenko, A.; Masiuchok, O.; Godzierz, M.; Krivtsun, I.; Trzebicka, B.; Pruvost, S. Pyroresistive Properties of Composites Based on HDPE and Carbon Fillers. Polymers 2023, 15, 2105. https://doi.org/10.3390/polym15092105

Mamunya Y, Maruzhenko O, Kolisnyk R, Iurzhenko M, Pylypenko A, Masiuchok O, Godzierz M, Krivtsun I, Trzebicka B, Pruvost S. Pyroresistive Properties of Composites Based on HDPE and Carbon Fillers. Polymers. 2023; 15(9):2105. https://doi.org/10.3390/polym15092105

Chicago/Turabian StyleMamunya, Yevgen, Oleksii Maruzhenko, Roman Kolisnyk, Maksym Iurzhenko, Andrii Pylypenko, Olha Masiuchok, Marcin Godzierz, Igor Krivtsun, Barbara Trzebicka, and Sébastien Pruvost. 2023. "Pyroresistive Properties of Composites Based on HDPE and Carbon Fillers" Polymers 15, no. 9: 2105. https://doi.org/10.3390/polym15092105

APA StyleMamunya, Y., Maruzhenko, O., Kolisnyk, R., Iurzhenko, M., Pylypenko, A., Masiuchok, O., Godzierz, M., Krivtsun, I., Trzebicka, B., & Pruvost, S. (2023). Pyroresistive Properties of Composites Based on HDPE and Carbon Fillers. Polymers, 15(9), 2105. https://doi.org/10.3390/polym15092105