Composite materials are extensively utilized in aerospace, marine, civil, automotive, and sporting applications [

1] owing to their exceptional physical, mechanical, and thermal characteristics, especially their high stiffness and strength-to-weight ratios, superior fatigue strength, great corrosion resistance, and dimensional stabilities. The landing gear system is one of the most important systems in an aircraft’s as it withstand significant structural stresses that are encountered during landing. The landing process is the most critical phase in the flight operation as it involves a massive amount of energy transfer due to the landing impact, and the system of the aircraft is required to be stable enough so that it can operate successfully under these conditions [

2]. Structural rigidity is one of the important design requirements for landing gear because it absorbs kinetic energy of the vertical load and it causes a reduction in the impact energy that causes vibrations at touchdown [

3]. Most of the composite-based landing gear struts are non-retractable; however, designers of landing gear systems are now working on the development of retractable landing gear systems as well to improve the aircraft performance, payload capacity, and fuel efficiency [

4]. A review of the literature suggests that new areas of research including numerical simulations, curing processes, and experimental testing of composite materials have been introduced and are also addressed in this research domain. Liviu Dragus et al. [

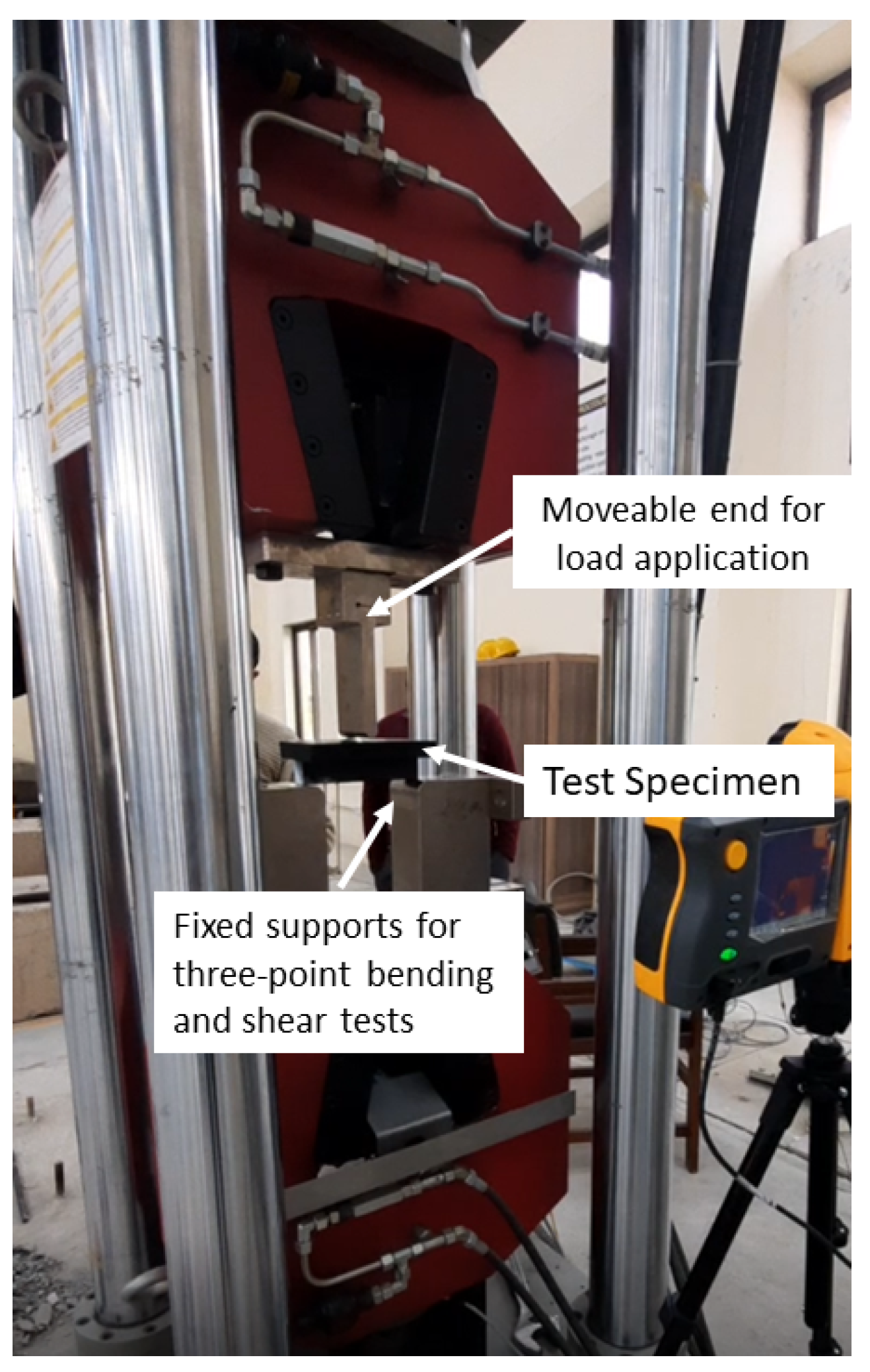

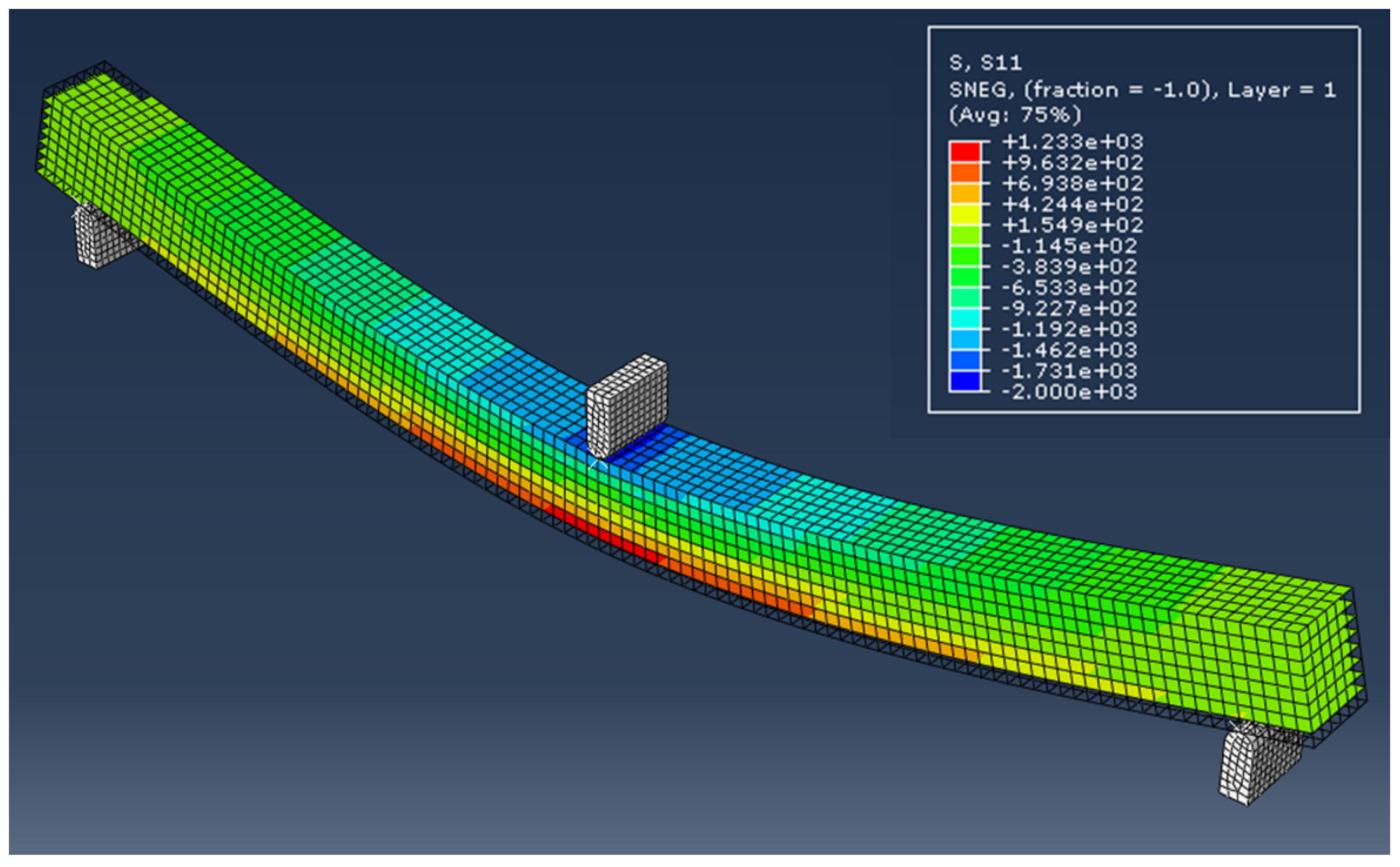

5] designed a low-cost, low-mass landing gear system for an aerial target by performing the design calculation and analysis using a finite element approach. Using lamina macro mechanics and composite sheet resistance theories, simulations of the stresses in laminate composite materials are performed. After performing the computational analysis, experimental tests are conducted to validate the designed model.

Patunkar et al. [

6] presented a comparison of a suspension system composed of glass fiber and steel leaf spring after carrying out their complete design and analysis using Pro-E

® and ANSYS 10.0

®. The results presented in their research work showed that the deflection of the steel leaf spring was better than the composite leaf spring but at the cost of weight. A significant weight reduction of 84.4% was achieved by using a composite leaf spring suspension system. Xue et al. [

7] also used a flexible leaf spring and presented a flexible multi-body dynamics model for the aircraft suspension system. Similarly, carbon-fiber-based landing gear struts were also presented by Liang et al. [

8] with complete computational design and analysis and experimental validation. A comprehensive selection methodology for fiber-reinforced composite materials for retractable main landing gear struts of a lightweight aircraft up to 1600 kg mass is proposed by the authors in one of their recent studies [

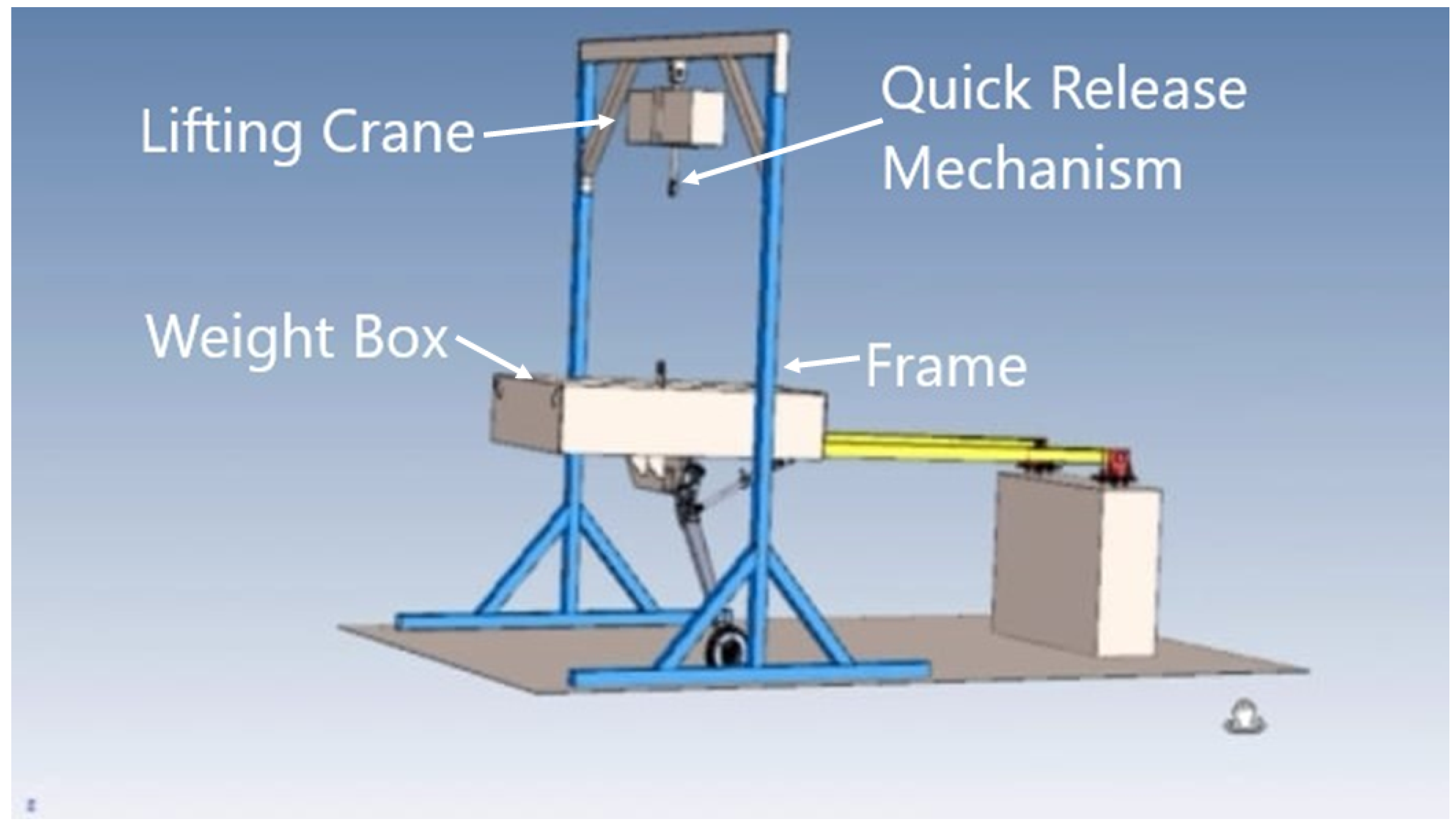

9]. In our previous work, four different fiber-reinforced composite materials were used for the design of the main landing gear struts of the aircraft under one-point landing condition. Finally, a material having a maximum strength-to-weight ratio and qualifying Tsai-Wu failure criterion was recommended for manufacturing the struts. Once the landing gear strut is manufactured based on the qualified design and using the selected material, a full-scale prototype is qualified for further installation on an aircraft subject to the clearance of a drop test as per the standard defined in the UAV Systems Airworthiness Requirements (USAR) [

10] and Air Worthiness Standards FAA FAR Part 23 [

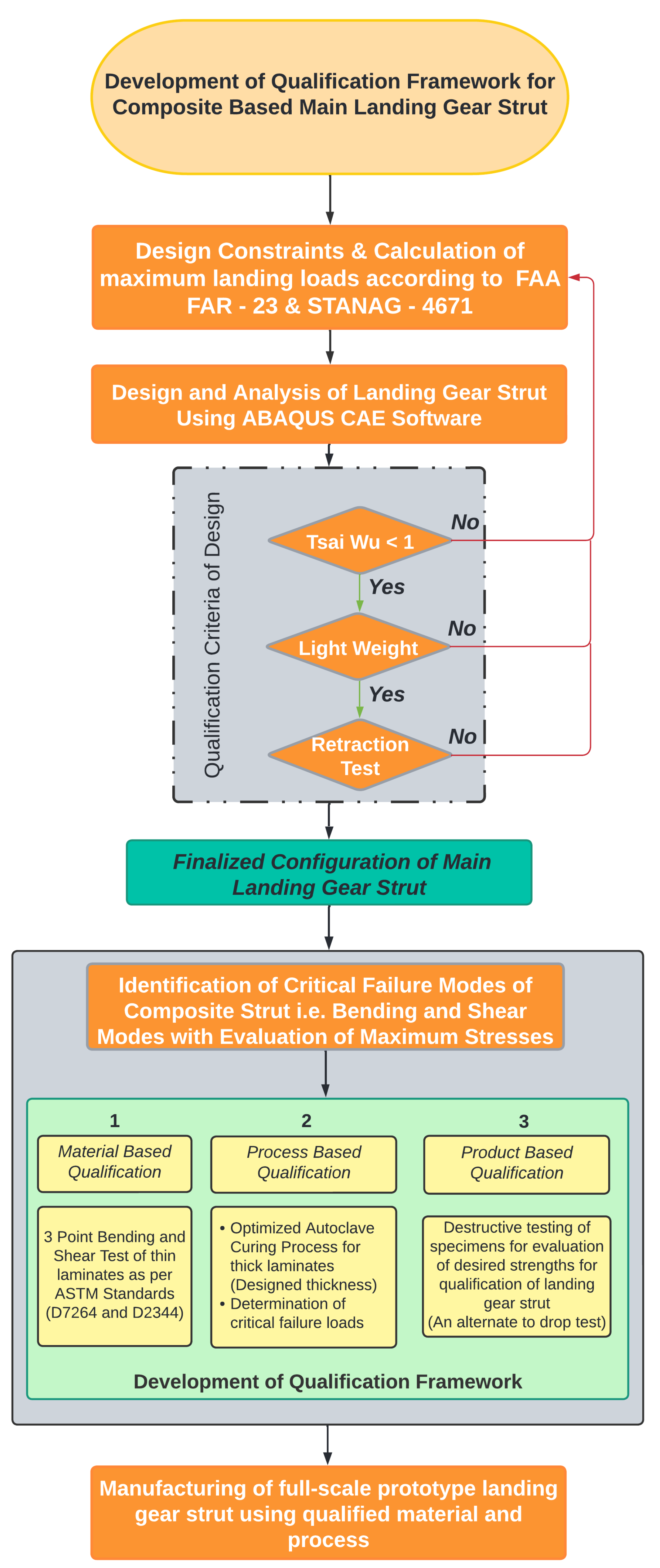

11]. In compliance with the drop test, either a complete aircraft or a landing gear unit is used for the drop test to validate the strength of the landing gear system. For this purpose, the limits for drop test heights are between 9.2 inches and 18.7 inches as per the standards mentioned above. However, no qualification framework is available during mass production for conventional as well as composite-based landing gear struts. In the same context, the research aimed to propose the qualification criteria which would not only be required to be fulfilled before undertaking the full-scale manufacturing task of main landing gear struts but would also be used as the qualification criteria of the main landing gear struts of the given aircraft during mass production. As no studies are available in the literature that are relevant to qualification criteria of composite main landing gear struts during mass production, the methodologies proposed in this research are therefore considered to be novel, and are shown in

Figure 1. This aim is achieved through developing a qualification criterion for the mass production by using available ASTM testing standards for the evaluation of mechanical properties of specimens. As bending and shear stresses are the most critical and prominent stresses encountered by the landing gear struts, bending and shear strength of the composite material can therefore be evaluated as per ASTM standards D 7264 [

12] and D 2344 [

13], respectively. Subsequently, the evaluation of these strengths can then be compared with the respective stresses and a logical framework can be developed for a qualification.

There are five sections in this research article.

Section 2, which follows the Introduction, covers the design and analysis of a retractable landing gear strut for a given aircraft.

Section 3 proposes a three-step qualification framework based on experimental techniques for material, process, and product. Required future work as a continuation of this research work is discussed in

Section 4 followed by Conclusions in

Section 5.