Solid-State Surface Patterning on Polymer Using the Microcellular Foaming Process

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.1.1. Specimen

2.1.2. Blowing Agents

2.2. Experiment Setup

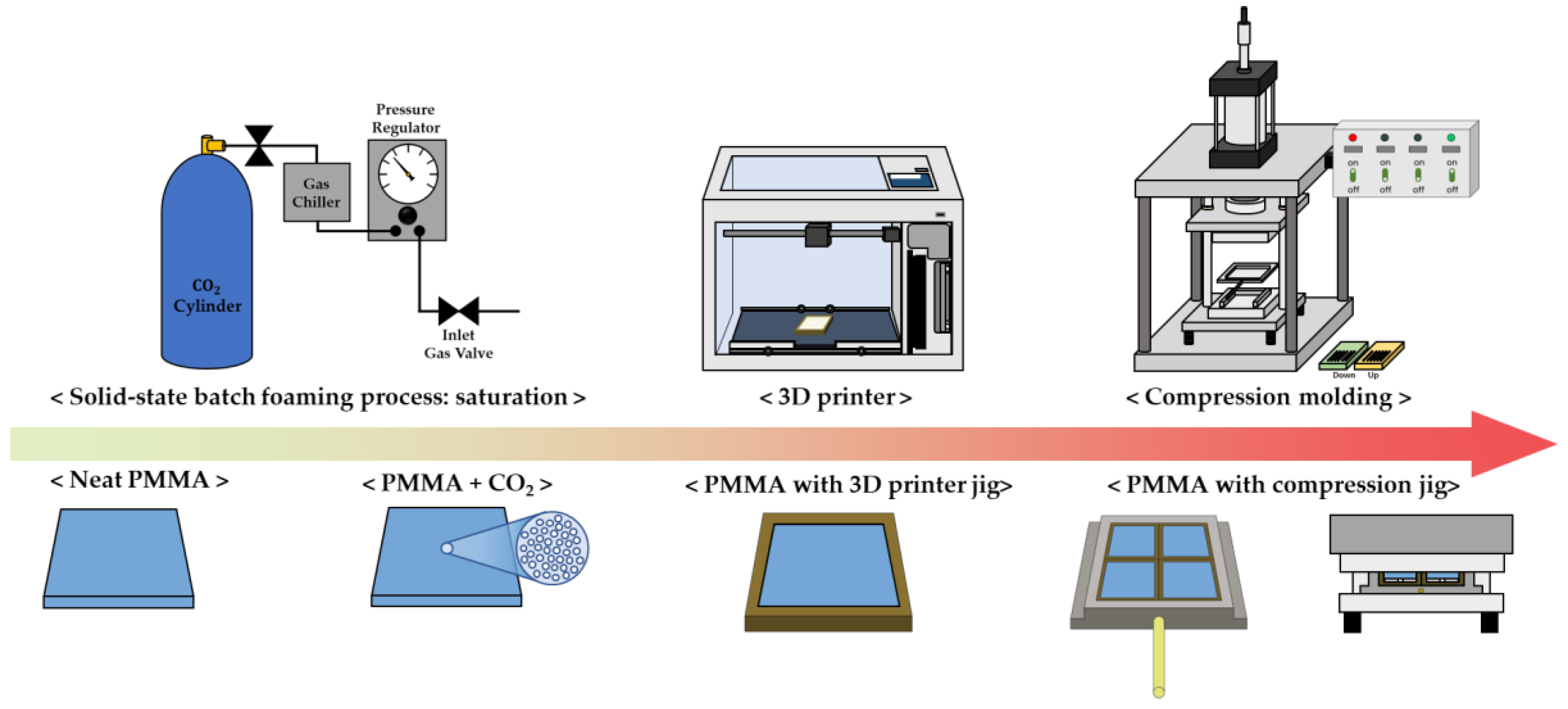

2.2.1. Solid-State Batch-Foaming Process

2.2.2. Compression Molding

2.2.3. Specimen Jig Using 3D Printer

2.2.4. Overall Process

3. Results

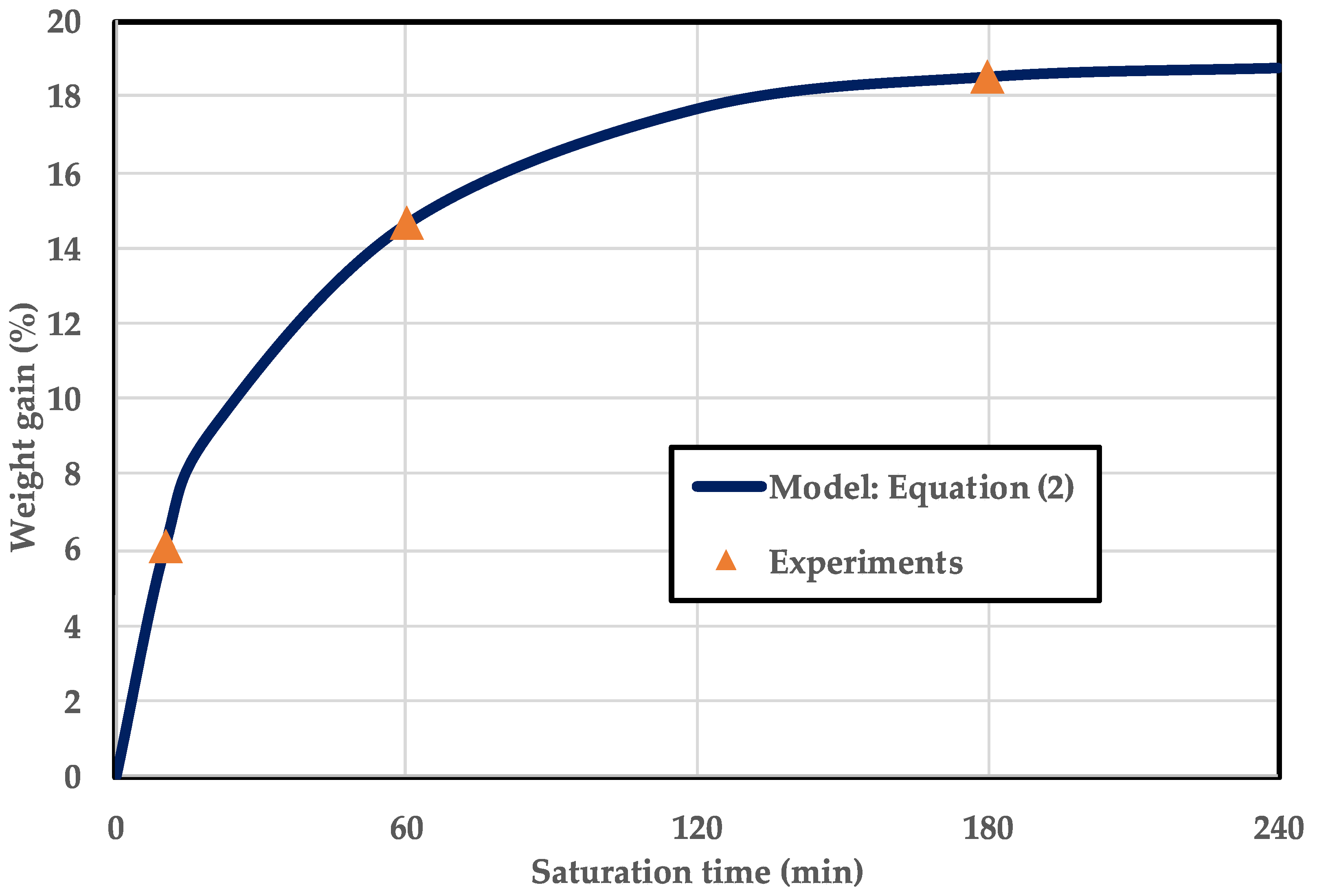

3.1. Gas Adsorption

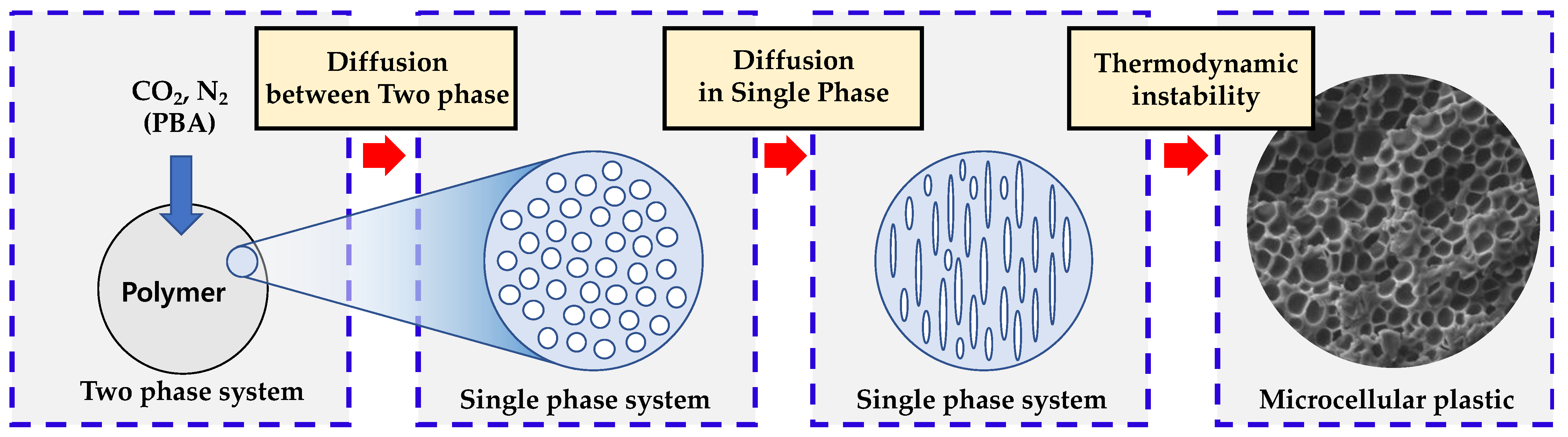

3.2. Theoretical Mechanism

3.3. Cell Morphology

3.4. Surface Topology

4. Discussion

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Suh, N.P. Challenges in Designing and Implementing Large Systems (Overcoming Cost Overruns and Missed Project Schedules) in Axiomatic Design in Large Systems; Farid, A.M., Suh, N.P., Eds.; Springer: Cham, Switzerland, 2016; pp. 273–309. [Google Scholar] [CrossRef]

- Wang, G.; Zhao, J.; Mark, L.H.; Wang, G.; Yu, K.; Wang, C.; Park, C.B.; Zhao, G. Ultra-Tough and Super Thermal-Insulation Nanocellular PMMA/TPU. Chem. Eng. J. 2017, 325, 632–646. [Google Scholar] [CrossRef]

- Zhang, Y.; Dong, K.; Wang, F.; Wang, H.; Wang, J.; Jiang, Z.; Diao, S. Three Dimensional Macroporous Hydroxyapatite/Chitosan Foam-Supported Polymer Micelles for Enhanced Oral Delivery of Poorly Soluble Drugs. Colloids Surf. B Biointerfaces 2018, 170, 497–504. [Google Scholar] [CrossRef]

- Hasanzadeh, R.; Azdast, T.; Mojaver, M.; Darvishi, M.M.; Park, C.B. Cost-Effective and Reproducible Technologies for Fabrication of Tissue Engineered Scaffolds: The State-of-the-Art and Future Perspectives. Polymer 2022, 244, 124681. [Google Scholar] [CrossRef]

- Ferreira, F.V.; Otoni, C.G.; De France, K.J.; Barud, H.S.; Lona, L.M.; Cranston, E.D.; Rojas, O.J. Porous nanocellulose gels and foams: Breakthrough status in the development of scaffolds for tissue engineering. Mater. Today 2020, 37, 126–141. [Google Scholar] [CrossRef]

- Yang, J.; Liao, X.; Wang, G.; Chen, J.; Tang, W.; Wang, T.; Li, G. Fabrication of Lightweight and Flexible Silicon Rubber Foams with Ultra-Efficient Electromagnetic Interference Shielding and Adjustable Low Reflectivity. J. Mater. Chem. C Mater. 2019, 8, 147–157. [Google Scholar] [CrossRef]

- Wang, G.; Wang, L.; Mark, L.H.; Shaayegan, V.; Wang, G.; Li, H.; Zhao, G.; Park, C.B. Ultralow-Threshold and Lightweight Biodegradable Porous PLA/MWCNT with Segregated Conductive Networks for High-Performance Thermal Insulation and Electromagnetic Interference Shielding Applications. ACS Appl. Mater. Interfaces 2018, 10, 1195–1203. [Google Scholar] [CrossRef] [PubMed]

- Huang, P.; Su, Y.; Wu, F.; Lee, P.C.; Luo, H.; Lan, X.; Zhang, L.; Shen, B.; Wang, L.; Zheng, W. Extruded Polypropylene Foams with Radially Gradient Porous Structures and Selective Filtration Property via Supercritical CO2 foaming. J. CO2 Util. 2022, 60, 101995. [Google Scholar] [CrossRef]

- Chu, R.K.M.; Mark, L.H.; Park, C.B. Scalable Fabrication of Microcellular Open-Cell Polymer Foams. Adv. Eng. Mater. 2022, 24, 2100985. [Google Scholar] [CrossRef]

- Colton, J.S.; Suh, N.P. The Nucleation of Microcellular Thermoplastic Foam with Additives: Part I: Theoretical Considerations. Polym. Eng. Sci. 1987, 27, 485–492. [Google Scholar] [CrossRef]

- Kim, S.W.; Sohn, J.S.; Kim, H.K.; Ryu, Y.; Cha, S.W. Effects of Gas Adsorption on the Mechanical Properties of Amorphous Polymer. Polymers 2019, 11, 817. [Google Scholar] [CrossRef] [Green Version]

- Nofar, M.; Park, C.B. Poly (Lactic Acid) Foaming. Prog. Polym. Sci. 2014, 39, 1721–1741. [Google Scholar] [CrossRef]

- Wang, C.; Shaayegan, V.; Ataei, M.; Costa, F.; Han, S.; Bussmann, M.; Park, C.B. Accurate Theoretical Modeling of Cell Growth by Comparing with Visualized Data in High-Pressure Foam Injection Molding. Eur. Polym. J. 2019, 119, 189–199. [Google Scholar] [CrossRef]

- Guo, Q.-P.; Wang, J.; Park, C.B. A Comparison of CO2 and N2 Foaming Behaviors of PP in a Visualization System. Int. Polym. Process. 2020, 35, 503–517. [Google Scholar] [CrossRef]

- di Maio, E.; Kiran, E. Foaming of Polymers with Supercritical Fluids and Perspectives on the Current Knowledge Gaps and Challenges. J. Supercrit. Fluids. 2018, 134, 157–166. [Google Scholar] [CrossRef]

- Cho, S.h.; Kim, H.K.; Sohn, J.S.; Ryu, Y.; Cha, S.W. Effect of Foaming Processes on the Reduction of Warpage in Glass Fiber Reinforced Plastic Composites. J. Mech. Sci. Technol. 2019, 33, 4227–4232. [Google Scholar] [CrossRef]

- Guo, W.; He, B.; Mao, H.; Zhang, M.; Hua, L.; Meng, Z. Mechanism of Bubble Formation in a Combined In-Mold Decoration and Microcellular Foaming Injection Molding Process. Fibers Polym. 2019, 20, 1526–1537. [Google Scholar] [CrossRef]

- Ronkay, F.; Molnar, B.; Dogossy, G. The Effect of Mold Temperature on Chemical Foaming of Injection Molded Recycled Polyethylene-Terephthalate. Thermochim. Acta 2017, 651, 65–72. [Google Scholar] [CrossRef] [Green Version]

- Lee, J.W.S.; Lee, R.E.; Wang, J.; Jung, P.U.; Park, C.B. Study of the Foaming Mechanisms Associated with Gas Counter Pressure and Mold Opening Using the Pressure Profiles. Chem. Eng. Sci. 2017, 167, 105–119. [Google Scholar] [CrossRef]

- Wang, C.; Shaayegan, V.; Costa, F.; Han, S.; Park, C.B. The Critical Requirement for High-Pressure Foam Injection Molding with Supercritical Fluid. Polymer 2022, 238, 124388. [Google Scholar] [CrossRef]

- Ameli, A.; Nofar, M.; Jahani, D.; Rizvi, G.; Park, C.B. Development of High Void Fraction Polylactide Composite Foams Using Injection Molding: Crystallization and Foaming Behaviors. Chem. Eng. J. 2015, 262, 78–87. [Google Scholar] [CrossRef]

- Youngjae, R. Continuous Foam Additive Manufacturing Using Dynamically Sealed Pressure Vessel. Ph.D. Thesis, Yonsei University, Seoul, Republic of Korea, 28 February 2022. [Google Scholar]

- Hyun Keun, K. Bubble Cluster Patterning Process and Sound Scattering Effect. Ph.D. Thesis, Yonsei University, Seoul, Republic of Korea, 31 January 2023. [Google Scholar]

- Ock, J.; Li, W. Fabrication of a Three-Dimensional Tissue Model Microarray Using Laser Foaming of a Gas-Impregnated Biodegradable Polymer. Biofabrication 2014, 6, 024110. [Google Scholar] [CrossRef]

- Kirka, M.M.; Nandwana, P.; Lee, Y.; Dehoff, R.R. Solidification and Solid-State Transformation Sciences in Metals Additive Manufacturing. Scr. Mater. 2017, 135, 130–134. [Google Scholar] [CrossRef]

- Cha, S.W.; Cho, S.H.; Sohn, J.S.; Ryu, Y.; Ahn, J. Reflectance According to Cell Size, Foaming Ratio and Refractive Index of Microcellular Foamed Amorphous Polymer. Int. J. Mol. Sci. 2019, 20, 6068. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kweon, B.C.; Sohn, J.S.; Ryu, Y.; Cha, S.W. Energy Harvesting of Ionic Polymer-Metal Composites Based on Microcellular Foamed Nafion in Aqueous Environment. Actuators 2020, 9, 71. [Google Scholar] [CrossRef]

- Kim, J.; Kim, K.H.; Ryu, Y.; Cha, S.W. Modeling and Experiment for the Diffusion Coefficient of Subcritical Carbon Dioxide in Poly(Methyl Methacrylate) to Predict Gas Sorption and Desorption. Polymers 2022, 14, 596. [Google Scholar] [CrossRef] [PubMed]

- Shieh, Y.-T.; Liu, K.-H. The Effect of Carbonyl Group on Sorption of CO2 in Glassy Polymers. J. Supercrit. Fluids 2003, 25, 261–268. [Google Scholar] [CrossRef]

- Li, R.; Lee, J.H.; Wang, C.; Howe Mark, L.; Park, C.B. Solubility and Diffusivity of CO2 and N2 in TPU and Their Effects on Cell Nucleation in Batch Foaming. J. Supercrit. Fluids 2019, 154, 104623. [Google Scholar] [CrossRef]

- Wang, Z.; Zhao, J.; Wang, G.; Xu, Z.; Zhang, A.; Dong, G.; Zhao, G. Lightweight, Low-Shrinkage and High Elastic Poly(Butylene Adipate-Co-Terephthalate) Foams Achieved by Microcellular Foaming Using N2 & CO2 as Co-Blowing Agents. J. CO2 Util. 2022, 64, 102149. [Google Scholar] [CrossRef]

- Dugad, R.; Radhakrishna, G.; Gandhi, A. Recent Advancements in Manufacturing Technologies of Microcellular Polymers: A Review. J. Polym. Res. 2020, 27, 182. [Google Scholar] [CrossRef]

- Shirvan, M.M.; Famili, M.H.N.; Golbang, A. A Review on the Application of Nucleation Theories in Thermoplastic Foams. Plast. Polym. Technol. 2016, 4, 11. [Google Scholar] [CrossRef]

- Azdast, T.; Hasanzadeh, R. Increasing cell density/decreasing cell size to produce microcellular and nanocellular thermoplastic foams: A review. J. Cell. Plast. 2021, 57, 769–797. [Google Scholar] [CrossRef]

- Martín-de León, J.; Bernardo, V.; Rodríguez-Pérez, M.Á. Key Production Parameters to Obtain Transparent Nanocellular PMMA. Macromol. Mater. Eng. 2017, 302, 1700343. [Google Scholar] [CrossRef]

- Rodríguez, D.C.; Carrascal, D.; Solórzano, E.; Pérez, M.A.R.; Pinto, J. Analysis of the Retrograde Behavior in PMMA-CO2 Systems by Measuring the (Effective) Glass Transition Temperature Using Refractive Index Variations. J. Supercrit. Fluids 2021, 170, 105159. [Google Scholar] [CrossRef]

- Tsioptsias, C.; Panayiotou, C. Simultaneous Determination of Sorption, Heat of Sorption, Diffusion Coefficient and Glass Transition Depression in Polymer-CO2 Systems. Thermochim. Acta 2011, 521, 98–106. [Google Scholar] [CrossRef]

- Ghadi, R.; Muntimadugu, E.; Domb, A.; Khan, W.; Zhang, X. 5—Synthetic Biodegradable Medical Polymer: PolyanhydridesZhang, X., Ed.; Science and Principles of Biodegradable and Bioresorbable Medical PolymersWoodhead Publishing: London, UK, 2017; pp. 153–188. [CrossRef]

| Property | Value |

|---|---|

| Width height (mm) | 25 25 (±0.5) |

| Density (g/cm3) | 1.19 |

| Thickness (mm) | 1.25–1.28 |

| Purity (%) | 99.98 |

| Glass transition temperature (°C) | 110 |

| Melting temperature (°C) | 158 |

| Coefficient of thermal expansion (/°C) | 6 10−5 |

| Property | Value |

|---|---|

| Saturation pressure (MPa) | 5.5 (0.05) |

| Saturation temperature (°C) | 20 (0.5) |

| Saturation time (min) | 10/60/180 |

| Depressurization ratio (MPa/s) | 5.5 |

| Foaming temperature (°C) | - |

| Foaming time (min) | - |

| Parameters | 10 min | 60 min | 180 min |

|---|---|---|---|

| H0 | 25 | 0 | 0 |

| H1 | 45 | 125 | 150 |

| H2 | 65 | 250 | 300 |

| Parameter | 10 min | 60 min | 180 min | |||

|---|---|---|---|---|---|---|

| All Regions (μm) | Line (μm) | All Regions (μm) | Line (μm) | All Regions (μm) | Line (μm) | |

| Ra | 4 | 2 | 29 | 9 | 42 | 22 |

| Rq | 6 | 5 | 40 | 23 | 57 | 37 |

| Rp | 14 | 3 | 65 | 24 | 98 | 39 |

| Saturation Time | Weight Gain | Maximum Depth | Pattern Gap | Roughness (All Regions) | ||||

|---|---|---|---|---|---|---|---|---|

| Mold | Sample | Mold | Sample | Ra (μm) | Rq (μm) | Rp (μm) | ||

| 10 min | 6.13% | 200 μm | 335 μm | 0.4 mm | - | 4 | 6 | 14 |

| 60 min | 14.65% | 129 μm | 0.8 mm | 29 | 40 | 65 | ||

| 180 min | 18.51% | 208 μm | 0.4 mm | 42 | 57 | 98 | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, J.; Kim, S.W.; Kweon, B.C.; Kim, K.H.; Cha, S.W. Solid-State Surface Patterning on Polymer Using the Microcellular Foaming Process. Polymers 2023, 15, 1153. https://doi.org/10.3390/polym15051153

Kim J, Kim SW, Kweon BC, Kim KH, Cha SW. Solid-State Surface Patterning on Polymer Using the Microcellular Foaming Process. Polymers. 2023; 15(5):1153. https://doi.org/10.3390/polym15051153

Chicago/Turabian StyleKim, Jaehoo, Shin Won Kim, Byung Chul Kweon, Kwan Hoon Kim, and Sung Woon Cha. 2023. "Solid-State Surface Patterning on Polymer Using the Microcellular Foaming Process" Polymers 15, no. 5: 1153. https://doi.org/10.3390/polym15051153

APA StyleKim, J., Kim, S. W., Kweon, B. C., Kim, K. H., & Cha, S. W. (2023). Solid-State Surface Patterning on Polymer Using the Microcellular Foaming Process. Polymers, 15(5), 1153. https://doi.org/10.3390/polym15051153