Heat Transfer Efficiency and pMDI Curing Behavior during Hot-Pressing Process of Tea Oil Camellia (Camellia Oleifera Abel.) Shell Particleboard

Abstract

1. Introduction

2. Materials and Methods

2.1. Raw Materials

2.2. Particle Preparation

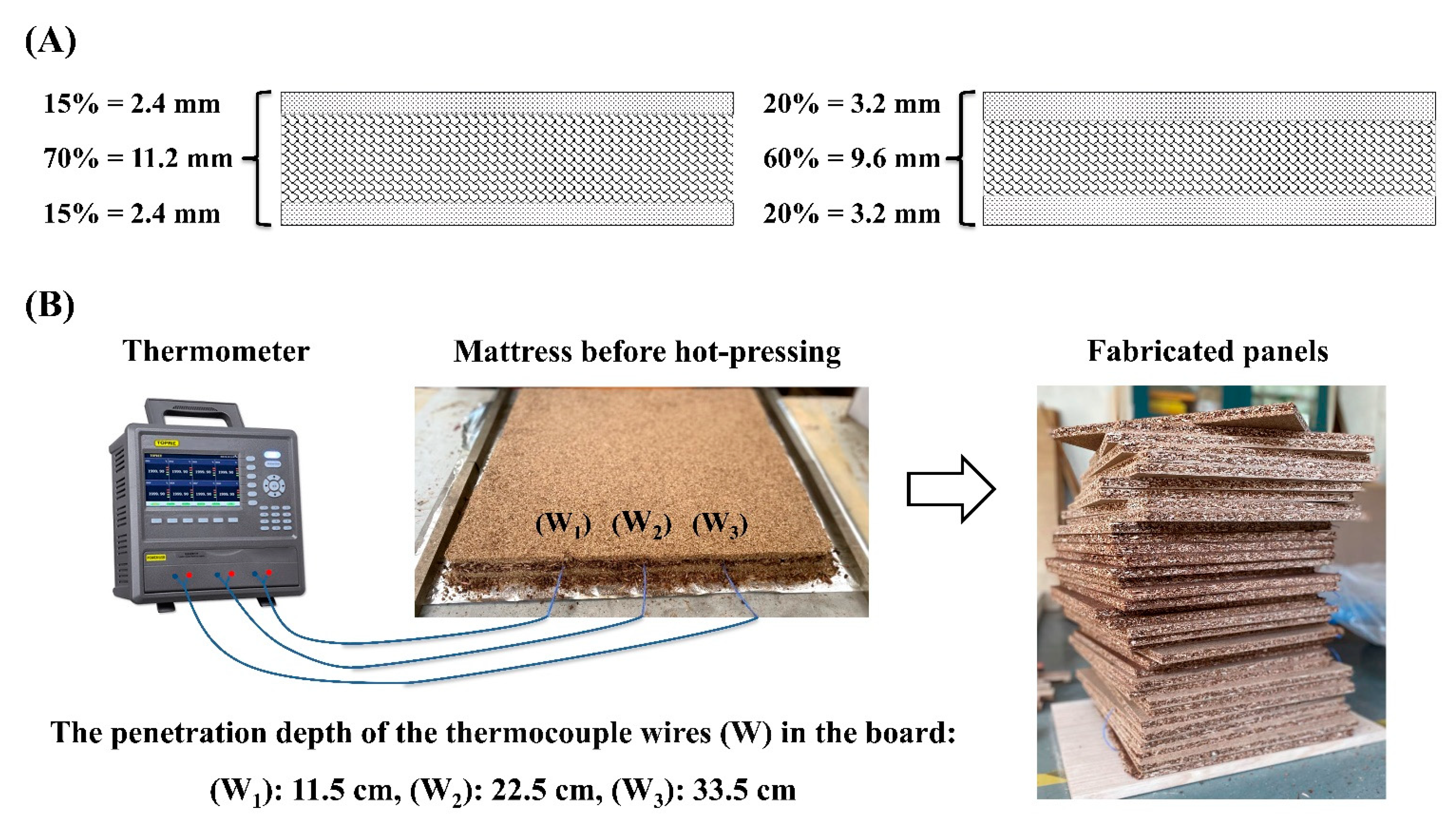

2.3. TOCS-Based Particleboard Production

2.4. Characterization of Particleboards

2.4.1. Mechanical Properties

2.4.2. Physical Properties

2.5. Statistical Analysis

3. Results and Discussion

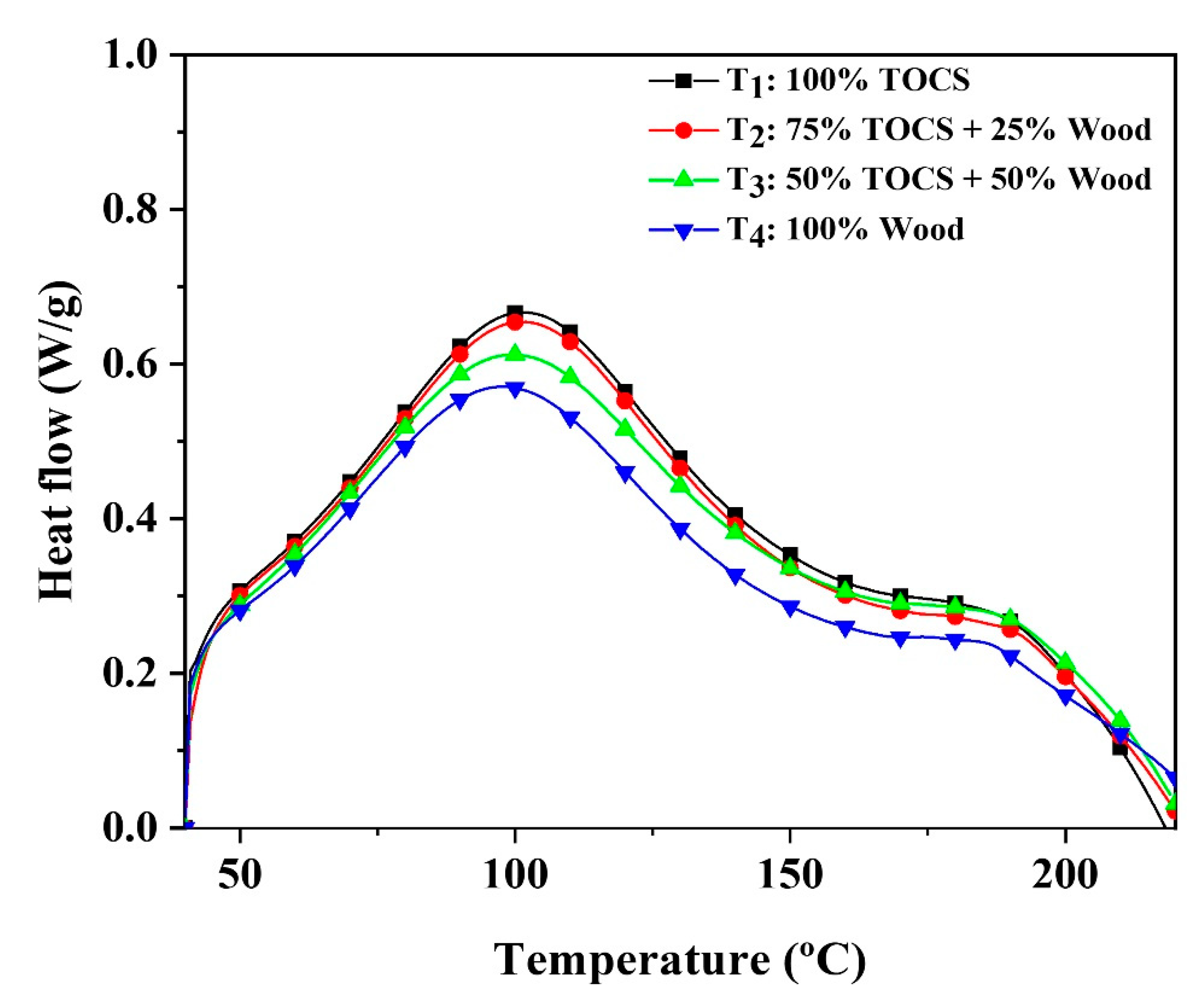

3.1. Curing Behavior of pMDI

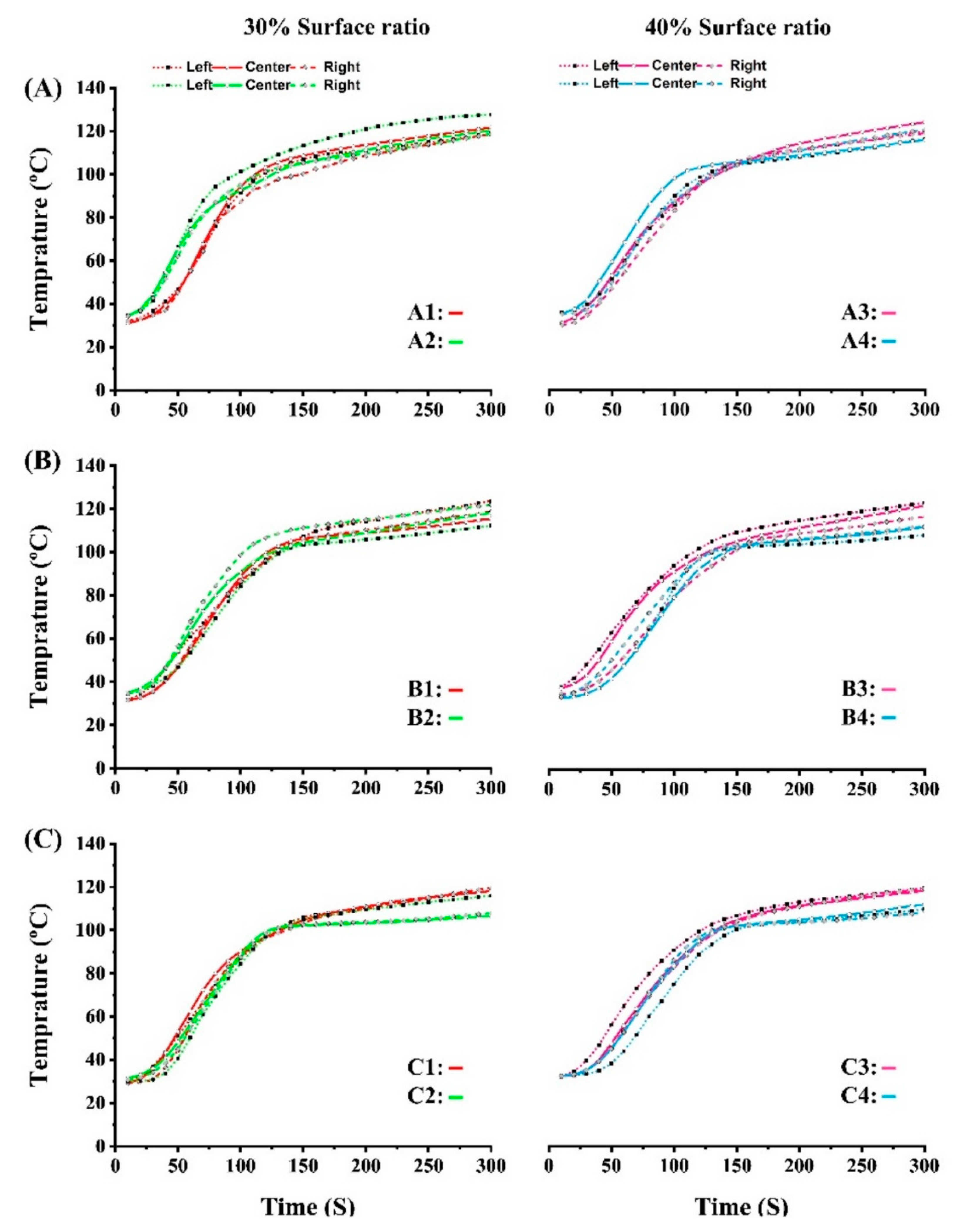

3.2. Heat Transfer during Hot-Pressing Process

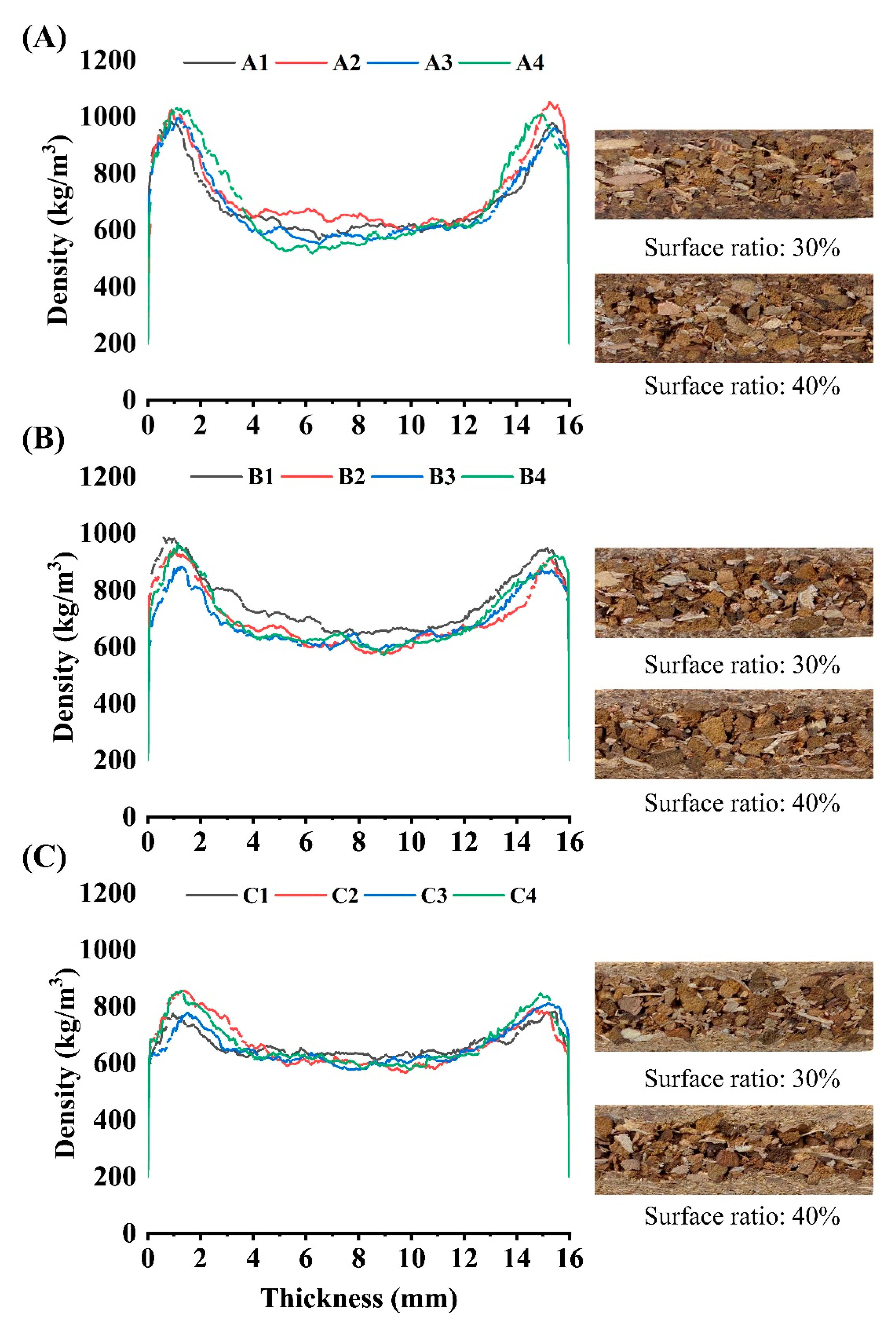

3.3. Density, Compaction Ratio, and Moisture Content

3.4. Mechanical Properties

3.4.1. Flexural Properties

3.4.2. Internal Bonding Strength

3.4.3. Screw Holding Resistance

3.5. Physical Properties

3.5.1. Dimensional Stability

3.5.2. Sound Absorption

3.5.3. Thermal Conductivity

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Brito, F.M.S.; Bortoletto, J.G.; Paes, J.B.; Belini, U.L.; Tomazello-Filho, M. Technological characterization of particleboards made with sugarcane bagasse and bamboo culm particles. Constr. Build. Mater. 2020, 262, 120501. [Google Scholar] [CrossRef]

- Hou, J.; Jin, Y.; Che, W.; Yu, Y. Value-added utilization of wood processing residues into cement-bonded particleboards with admirable integrated performance. Constr. Build. Mater. 2022, 344, 128144. [Google Scholar] [CrossRef]

- Sutiawan, J.; Hadi, Y.S.; Nawawi, D.S.; Abdillah, I.B.; Zulfiana, D.; Lubis, M.A.R.; Nugroho, S.; Astuti, D.; Zhao, Z.; Handayani, M.; et al. The properties of particleboard composites made from three sorghum (Sorghum bicolor) accessions using maleic acid adhesive. Chemosphere 2021, 290, 133163. [Google Scholar] [CrossRef] [PubMed]

- Lee, S.H.; Lum, W.C.; Boon, J.G.; Kristak, L.; Antov, P.; Pędzik, M.; Rogoziński, T.; Taghiyari, H.R.; Lubis, M.A.R.; Fatriasari, W.; et al. Particleboard from agricultural biomass and recycled wood waste: A review. J. Mater. Res. Technol. 2022, 20, 4630–4658. [Google Scholar] [CrossRef]

- Silva, V.U.; Nascimento, M.F.; Oliveira, P.R.; Panzera, T.H.; Rezende, M.O.; Silva, D.A.L.; Aquino, V.B.D.M.; Lahr, F.A.R.; Christoforo, A.L. Circular vs. linear economy of building materials: A case study for particleboards made of recycled wood and biopolymer vs. conventional particleboards. Constr. Build. Mater. 2021, 285, 122906. [Google Scholar] [CrossRef]

- Pędzik, M.; Janiszewska, D.; Rogoziński, T. Alternative lignocellulosic raw materials in particleboard production: A review. Ind. Crops Prod. 2021, 174, 114162. [Google Scholar] [CrossRef]

- Hua, L.S.; Chen, L.W.; Antov, P.; Kristak, L.; Tahir, P.M. Engineering Wood Products from Eucalyptus spp. Adv. Mater. Sci. Eng. 2022, 2022, 1–14. [Google Scholar] [CrossRef]

- Chen, P.; Hu, C.; Gu, J.; Lin, X.; Yang, C.; Leu, S.-Y.; Guan, L. Pyrolysis characteristics of tea oil camellia (Camellia oleifera Abel.) shells and their chemically pre-treated residues: Kinetics, mechanisms, product evaluation and joint optimization. J. Anal. Appl. Pyrolysis 2022, 164, 105526. [Google Scholar] [CrossRef]

- Liang, D.; Hu, C.; Chaydarreh, K.C.; Liu, X.; Ye, Y.; Wei, Y.; Zhang, W.; Guan, L.; Gu, J.; Lin, X. Volatile components analysis of Camellia oleifera shells and related products based on HS-SPME-GC-MS. Microchem. J. 2022, 181, 107842. [Google Scholar] [CrossRef]

- Chaydarreh, K.C.; Lin, X.; Guan, L.; Yun, H.; Gu, J.; Hu, C. Utilization of tea oil camellia (Camellia oleifera Abel.) shells as alternative raw materials for manufacturing particleboard. Ind. Crop. Prod. 2021, 161, 113221. [Google Scholar] [CrossRef]

- Chalapud, M.C.; Herdt, M.; Nicolao, E.S.; Ruseckaite, R.A.; Ciannamea, E.M.; Stefani, P.M. Biobased particleboards based on rice husk and soy proteins: Effect of the impregnation with tung oil on the physical and mechanical behavior. Constr. Build. Mater. 2020, 230, 116996. [Google Scholar] [CrossRef]

- Laksono, A.D.; Susanto, T.F.; Dikman, R.; Awali, J.; Sasria, N.; Wardhani, I.Y. Mechanical properties of particleboards produced from wasted mixed sengon (Paraserianthes falcataria (L.) Nielsen) and bagasse particles. Mater. Today Proc. 2022, 65, 2927–2933. [Google Scholar] [CrossRef]

- Zeleniuc, O.; Brenci, L.M.; Cosereanu, C.; Fotin, A. Influence of adhesive type and content on the properties of particleboard made from sunflower husks. BioResources 2019, 14, 7316–7331. [Google Scholar] [CrossRef]

- Kramár, S.; Mayer, A.K.; Schöpper, C.; Mai, C. Use of basalt scrim to enhance mechanical properties of particleboards. Constr. Build. Mater. 2019, 238, 117769. [Google Scholar] [CrossRef]

- Narciso, C.R.P.; Reis, A.H.S.; Mendes, J.F.; Nogueira, N.D. Potential for the Use of Coconut Husk in the Production of Medium Density Particleboard. Waste Biomass Valorization 2020, 12, 1647–1658. [Google Scholar] [CrossRef]

- Rofii, M.N.; Yamamoto, N.; Ueda, S.; Kojima, Y.; Suzuki, S. The temperature behaviour inside the mat of wood-based panel during hot pressing under various manufacturing conditions. J. Wood Sci. 2014, 60, 414–420. [Google Scholar] [CrossRef]

- Silva, L.C.L.; Lima, F.O.; Chahud, E.; Christoforo, A.L.; Lahr, F.A.R.; Favarim, H.R.; de Campos, C.I. Heat transfer and physical-mechanical properties analysis of particleboard produced with ZnO nanoparticles addition. Bioresources 2019, 14, 9904–9915. [Google Scholar] [CrossRef]

- Hrčka, R.; Babiak, M. Wood Thermal Properties; Wood in Civil Engineering; IntechOpen: Rijeka, Croatia, 2017; pp. 25–43. [Google Scholar] [CrossRef]

- Chaydarreh, K.C.; Lin, X.; Dandan, L.; Zhang, W.; Guan, L.; Hu, C. Developing 3-layer tea oil camellia (Camellia oleifera Abel.) shells-based particleboard with systematic study on particle geometry and distribution. Ind. Crops Prod. 2022, 179, 114682. [Google Scholar] [CrossRef]

- CEN/TS 16368; Lightweight Particleboards. Specifications. European Committee for Standardisation: Brussels, Belgium, 2014.

- EN 310; Wood-Based Pnels. Determination of Modulud of Elasticity in Bending and Bending Strength. European Committee for Standardisation: Brussels, Belgium, 1994.

- EN 319; Particleboards and Fiberboards. Determination of Tensile Strength Perpendicular to the Plane of Board. European Committee for Standardisation: Brussels, Belgium, 1999.

- EN 13446; Wood-Based Pnels. Determination of Withdrawal Capacity of Fasteners. European Committee for Standardisation: Brussels, Belgium, 1999.

- EN 317; Particleboards and Fiberboards. Determination of of Swelling after Immersion in Water. BEuropean Committee for Standardisation: Brussels, Belgium, 1999.

- EN 322; Wood-Based Pnels. Determination of Moisture Content. European Committee for Standardisation: Brussels, Belgium, 1993.

- EN 323; Wood-Based Pnels. Determination of Density. European Committee for Standardisation: Brussels, Belgium, 1999.

- Alade, A.A.; Naghizadeh, Z.; Wessels, C.B.; Tyhoda, L. A review of the effects of wood preservative impregnation on adhesive bonding and joint performance. J. Adhes. Sci. Technol. 2021, 36, 1593–1617. [Google Scholar] [CrossRef]

- Sam-Brew, S.; Smith, G.D. Flax Shive and Hemp Hurd Residues as Alternative Raw Material for Particleboard Production. Bioresources 2017, 12, 5715–5735. [Google Scholar] [CrossRef]

- Chen, H.; Yan, N. Application of Western red cedar (Thuja plicata) tree bark as a functional filler in pMDI wood adhesives. Ind. Crops Prod. 2018, 113, 1–9. [Google Scholar] [CrossRef]

- Das, S.; Malmberg, M.J.; Frazier, C.E. Cure chemistry of wood/polymeric isocyanate (PMDI) bonds: Effect of wood species. Int. J. Adhes. Adhes. 2007, 27, 250–257. [Google Scholar] [CrossRef]

- Solt, P.; Konnerth, J.; Gindl-Altmutter, W.; Kantner, W.; Moser, J.; Mitter, R.; van Herwijnen, H.W. Technological performance of formaldehyde-free adhesive alternatives for particleboard industry. Int. J. Adhes. Adhes. 2019, 94, 99–131. [Google Scholar] [CrossRef]

- Bavaneghi, F.; Ghorbani, M. Mechanical behavior and springback of acetylated particleboard made in different press times. Wood Mater. Sci. Eng. 2016, 11, 57–61. [Google Scholar] [CrossRef]

- Iswanto, A.H.; Ompusunggu, P.L. Sandwich Particleboard (SPb): Effect of particle length on the quality of board. IOP Conf. Ser. Earth Environ. Sci. 2019, 374, 11–15. [Google Scholar] [CrossRef]

- Si, S.; Zheng, X.; Li, X. Effect of carbonization treatment on the physicochemical properties of bamboo particleboard. Constr. Build. Mater. 2022, 344, 128204. [Google Scholar] [CrossRef]

- Wong, M.C.; Hendrikse, S.I.; Sherrell, P.C.; Ellis, A.V. Grapevine waste in sustainable hybrid particleboard production. Waste Manag. 2020, 118, 501–509. [Google Scholar] [CrossRef]

- Nicolao, E.; Leiva, P.; Chalapud, M.; Ruseckaite, R.; Ciannamea, E.; Stefani, P. Flexural and tensile properties of biobased rice husk-jute-soybean protein particleboards. J. Build. Eng. 2020, 30, 101261. [Google Scholar] [CrossRef]

- Chaydarreh, K.C.; Lin, X.; Guan, L.; Hu, C. Interaction between particle size and mixing ratio on porosity and properties of tea oil camellia (Camellia oleifera Abel.) shells-based particleboard. J. Wood Sci. 2022, 68, 43. [Google Scholar] [CrossRef]

- Iswanto, A.H.; Febrianto, F.; Hadi, Y.S.; Ruhendi, S.; Hermawan, D. The Effect of Pressing Temperature and Time on the Quality of Particle Board Made from Jatropha Fruit Hulls Treated in Acidic Condition. Makara J. Technol. 2014, 17, 145–151. [Google Scholar] [CrossRef]

- Pramana, A.; Zalfiatri, Y.; Sari, E.O. Effect of Temperature on Lignin Isolation by Using Organosolv Method from Oil Palm Empty Fruit Bunch. J. Phys. Conf. Ser. 2021, 2049, 012037. [Google Scholar] [CrossRef]

- Yorur, H.; Birinci, E.; Gunay, M.N.; Tor, O. Effects of factors on direct screw withdrawal resistance in medium density fiberboard and particleboard. Maderas Cienc. Tecnol. 2020, 22, 375–384. [Google Scholar] [CrossRef]

- Shalbafan, A.; Chaydarreh, K.C.; Welling, J. Development of a One-Step Process for Production of Foam Core Particleboards using Rigid Polyurethane Foam. Bioresources 2016, 11, 9480–9495. [Google Scholar] [CrossRef]

- Borysiuk, P.; Jenczyk-Tolloczko, I.; Auriga, R.; Kordzikowski, M. Sugar beet pulp as raw material for particleboard production. Ind. Crops Prod. 2019, 141, 111829. [Google Scholar] [CrossRef]

- Jimenez, J.P.; Acda, M.N.; Razal, R.A.; Abasolo, W.P.; Hernandez, H.P.; Elepaño, A.R. Influence of mixing waste tobacco stalks and paper mulberry wood chips on the physico-mechanical properties, formaldehyde emission, and termite resistance of particleboard. Ind. Crops Prod. 2022, 187, 115483. [Google Scholar] [CrossRef]

- Karlinasari, L.; Hermawan, D.; Maddu, A.; Bagus, M.; Lucky, I.K.; Nugroho, N.; Hadi, Y.S. Acoustical properties of particleboards made from betung bamboo (Dendrocalamus asper) as building construction material. Bioresources 2012, 7, 5700–5709. [Google Scholar] [CrossRef]

- Barbu, M.; Sepperer, T.; Tudor, E.; Petutschnigg, A. Walnut and Hazelnut Shells: Untapped Industrial Resources and Their Suitability in Lignocellulosic Composites. Appl. Sci. 2020, 10, 6340. [Google Scholar] [CrossRef]

- Ong, T.K.; Choo, H.L.; Lee, S.M.; Kong, K.Y. Oil Palm Wastes as Sustainable Sound Absorbing Particleboard. IOP Conf. Ser. Mater. Sci. Eng. 2020, 815, 012010. [Google Scholar] [CrossRef]

- ISO 11654; Acoustics. Sound Absorbers for Use in Buildings. Rating of Sound Absorption. The International Organization for Standardization: Geneva, Switzerland, 1997.

- Ferrandez-Villena, M.; Ferrandez-Garcia, A.; Garcia-Ortuño, T.; Ferrandez-Garcia, M.T. Acoustic and Thermal Properties of Particleboards Made from Mulberry Wood (Morus alba L.) Pruning Residues. Agronomy 2022, 12, 1803. [Google Scholar] [CrossRef]

- Nguyen, D.M.; Grillet, A.-C.; Bui, Q.-B.; Diep, T.M.H.; Woloszyn, M. Building bio-insulation materials based on bamboo powder and bio-binders. Constr. Build. Mater. 2018, 186, 686–698. [Google Scholar] [CrossRef]

- Essid, S.; Hegde, V.J.; Mahieu, A.; Bizet, L.; Leblanc, N.; Saouab, A. Comparison of the properties of flax shives based particleboards prepared using binders of bio-based lignin and partially bio-based epoxy resin. Int. J. Adhes. Adhes. 2021, 109, 102915. [Google Scholar] [CrossRef]

| Group | Treatment | Surface Ratio | Surface Layers Combination | Core Layer Combination (TOCS to Wood) |

|---|---|---|---|---|

| A | A1 | 30% | 100% TOCS fine particles | 75:25 |

| A2 | 30% | 50:50 | ||

| A3 | 40% | 75:25 | ||

| A4 | 40% | 50:50 | ||

| B | B1 | 30% | 50% TOCS + 50% wood fine particles | 75:25 |

| B2 | 30% | 50:50 | ||

| B3 | 40% | 75:25 | ||

| B4 | 40% | 50:50 | ||

| C | C1 | 30% | 100% Wood fine particles | 75:25 |

| C2 | 30% | 50:50 | ||

| C3 | 40% | 75:25 | ||

| C4 | 40% | 50:50 |

| Group | Treatment | MC (%) | Density (kg/m3) | Compaction Ratio |

|---|---|---|---|---|

| A | A1 | 9.11 (0.57) a | 700 (10) ab | 0.88 (0.013) a |

| A2 | 8.91 (0.51) a | 711 (10) a | 0.95 (0.013) bc | |

| A3 | 8.84 (0.49) a | 695 (10) abc | 0.90 (0.013) ad | |

| A4 | 9.36 (0.56) a | 712 (10) b | 0.95 (0.014) bc | |

| B | B1 | 9.38 (0.92) a | 694 (14) abc | 0.94 (0.017) bd |

| B2 | 8.61 (0.45) a | 690 (14) abc | 0.99 (0.020) ce | |

| B3 | 8.39 (0.94) a | 687(10) abc | 0.93 (0.014) bd | |

| B4 | 9.09 (0.75) a | 696 (12) abc | 0.99 (0.017) e | |

| C | C1 | 8.97 (0.89) a | 672 (13) c | 0.95 (0.018) bc |

| C2 | 9.05 (0.78) a | 679 (11) ac | 1.04 (0.017) f | |

| C3 | 9.21 (0.66) a | 676 (12) ac | 0.99 (0.017) ce | |

| C4 | 8.98 (0.43) a | 683 (11) ac | 1.07 (0.018) f |

| Group | Treatment | MOR (N/mm2) | MOE (N/mm2) | IB (N/mm2) | FSW (N/mm2) | ESW (N/mm2) |

|---|---|---|---|---|---|---|

| A | A1 | 4.50 (1.18) a | 771 (102) a | 0.84 (0.12) ab | 667 (143) a | 501 (78) a |

| A2 | 5.47 (0.91) ab | 1001 (63) b | 0.81 (0.11) ab | 699 (67) abc | 602 (105) ab | |

| A3 | 4.99 (0.76) ab | 731 (154) a | 0.73 (0.16) a | 718 (162) abc | 590 (83) abc | |

| A4 | 6.48 (0.79) bc | 1098 (124) bc | 0.71 (0.07) a | 738 (155) bc | 653 (86) abc | |

| B | B1 | 8.30 (1.59) de | 1117 (163) bc | 0.92 (0.17) b | 698 (80) ab | 516 (64) abc |

| B2 | 8.74 (1.68) de | 1170 (123) bc | 0.86 (0.10) ab | 715 (99) c | 674 (84) abc | |

| B3 | 8.02 (0.55) cd | 1002 (66) b | 0.78 (0.08) ab | 749 (74) abc | 603 (89) abc | |

| B4 | 8.97 (1.53) def | 1086 (86) bc | 0.74 (0.11) ab | 797 (145) abc | 600 (61) abc | |

| C | C1 | 9.71 (1.06) defg | 1196 (171) bcd | 0.81 (0.14) ab | 816 (161) abc | 559 (113) abc |

| C2 | 10.51 (0.90) fg | 1396 (154) de | 0.72 (0.12) b | 885 (181) abc | 606 (101) bc | |

| C3 | 10.01 (1.32) efg | 1241 (187) cde | 0.75 (0.07) ab | 866 (105) abc | 609 (123) abc | |

| C4 | 11.29 (0.97) g | 1415 (91) e | 0.78 (0.08) ab | 926 (186) c | 684 (54) c |

| Group | Treatment | WA 2 (%) | WA 24 h (%) | TS 2 h (%) | TS 24 h (%) |

|---|---|---|---|---|---|

| A | A1 | 32.0 (10.84) ab | 67.83 (7.39) ab | 6.87 (0.98 ab | 12.87 (0.66) ab |

| A2 | 29.24 (9.45) abc | 56.72 (9.08) acd | 7.27 (1.04) ab | 12.76 (0.93) ac | |

| A3 | 34.21 (5.63) b | 68.95 (4.73) b | 7.88 (0.75) b | 13.10 (0.76) ab | |

| A4 | 30.75 (6.81) abc | 60.06 (4.44) abd | 7.54 (0.89) ab | 13.38 (0.74) b | |

| B | B1 | 22.97 (5.42) ac | 58.36 (3.55) ad | 6.86 (0.55) ab | 12.18 (0.78) abcde |

| B2 | 23.09 (5.70) ac | 60.41 (8.43) abd | 6.60 (0.55) ab | 12.38 (0.48) acde | |

| B3 | 26.16 (4.94) ac | 60.47 (8.53) abd | 6.82 (1.03) ab | 11.64 (0.99) cde | |

| B4 | 27.31 (8.97) ac | 58.25 (8.71) ad | 6.58 (1.19) ab | 11.25 (0.43) cde | |

| C | C1 | 24.70 (12.76) ac | 52.69 (8.67) dc | 6.31 (0.57) ab | 11.92 (0.92) abcde |

| C2 | 20.13 (6.22) ac | 50.96 (6.33) dc | 6.87 (1.18) ab | 10.93 (0.99) de | |

| C3 | 14.22 (4.90) c | 42.55 (6.59) c | 6.35 (0.37) ab | 10.98 (0.98) de | |

| C4 | 18.63 (5.47) ac | 43.24 (6.30) c | 6.14 (0.69) a | 10.72 (0.65) e |

| Group | Treatment | Thermal Conductivity (W/mK) | Sound Absorption Coefficients α | |||||

|---|---|---|---|---|---|---|---|---|

| 100 Hz | 200 Hz | 500 Hz | 1000 Hz | 1500 Hz | 2000 Hz | |||

| A | A1 | 0.1706 (0.007) ab | 0.032 | 0.057 | 0.191 | 0.307 | 0.324 | 0.396 |

| A2 | 0.1742 (0.008) b | 0.032 | 0.054 | 0.198 | 0.296 | 0.347 | 0.374 | |

| A3 | 0.1507 (0.004) cd | 0.031 | 0.056 | 0.184 | 0.253 | 0.322 | 0.374 | |

| A4 | 0.1549 (0.007) cd | 0.031 | 0.055 | 0.202 | 0.291 | 0.334 | 0.355 | |

| B | B1 | 0.1603 (0.016) da | 0.037 | 0.071 | 0.196 | 0.273 | 0.295 | 0.289 |

| B2 | 0.1606 (0.005) da | 0.032 | 0.059 | 0.211 | 0.323 | 0.349 | 0.322 | |

| B3 | 0.1512 (0.004) cd | 0.036 | 0.070 | 0.210 | 0.265 | 0.308 | 0.337 | |

| B4 | 0.1533 (0.008) cd | 0.035 | 0.063 | 0.241 | 0.299 | 0.323 | 0.324 | |

| C | C1 | 0.1440 (0.009) c | 0.035 | 0.064 | 0.221 | 0.295 | 0.327 | 0.328 |

| C2 | 0.1505 (0.005) cd | 0.035 | 0.066 | 0.224 | 0.286 | 0.319 | 0.329 | |

| C3 | 0.1323 (0.004) e | 0.035 | 0.064 | 0.228 | 0.293 | 0.323 | 0.327 | |

| C4 | 0.1441 (0.009) c | 0.035 | 0.065 | 0.224 | 0.292 | 0.323 | 0.328 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Choupani Chaydarreh, K.; Li, Y.; Lin, X.; Zhang, W.; Hu, C. Heat Transfer Efficiency and pMDI Curing Behavior during Hot-Pressing Process of Tea Oil Camellia (Camellia Oleifera Abel.) Shell Particleboard. Polymers 2023, 15, 959. https://doi.org/10.3390/polym15040959

Choupani Chaydarreh K, Li Y, Lin X, Zhang W, Hu C. Heat Transfer Efficiency and pMDI Curing Behavior during Hot-Pressing Process of Tea Oil Camellia (Camellia Oleifera Abel.) Shell Particleboard. Polymers. 2023; 15(4):959. https://doi.org/10.3390/polym15040959

Chicago/Turabian StyleChoupani Chaydarreh, Kamran, Yongtao Li, Xiuyi Lin, Weiwei Zhang, and Chuanshuang Hu. 2023. "Heat Transfer Efficiency and pMDI Curing Behavior during Hot-Pressing Process of Tea Oil Camellia (Camellia Oleifera Abel.) Shell Particleboard" Polymers 15, no. 4: 959. https://doi.org/10.3390/polym15040959

APA StyleChoupani Chaydarreh, K., Li, Y., Lin, X., Zhang, W., & Hu, C. (2023). Heat Transfer Efficiency and pMDI Curing Behavior during Hot-Pressing Process of Tea Oil Camellia (Camellia Oleifera Abel.) Shell Particleboard. Polymers, 15(4), 959. https://doi.org/10.3390/polym15040959