Mechanical and Thermal Properties of Wood-Fiber-Based All-Cellulose Composites and Cellulose-Polypropylene Biocomposites

Abstract

:1. Introduction

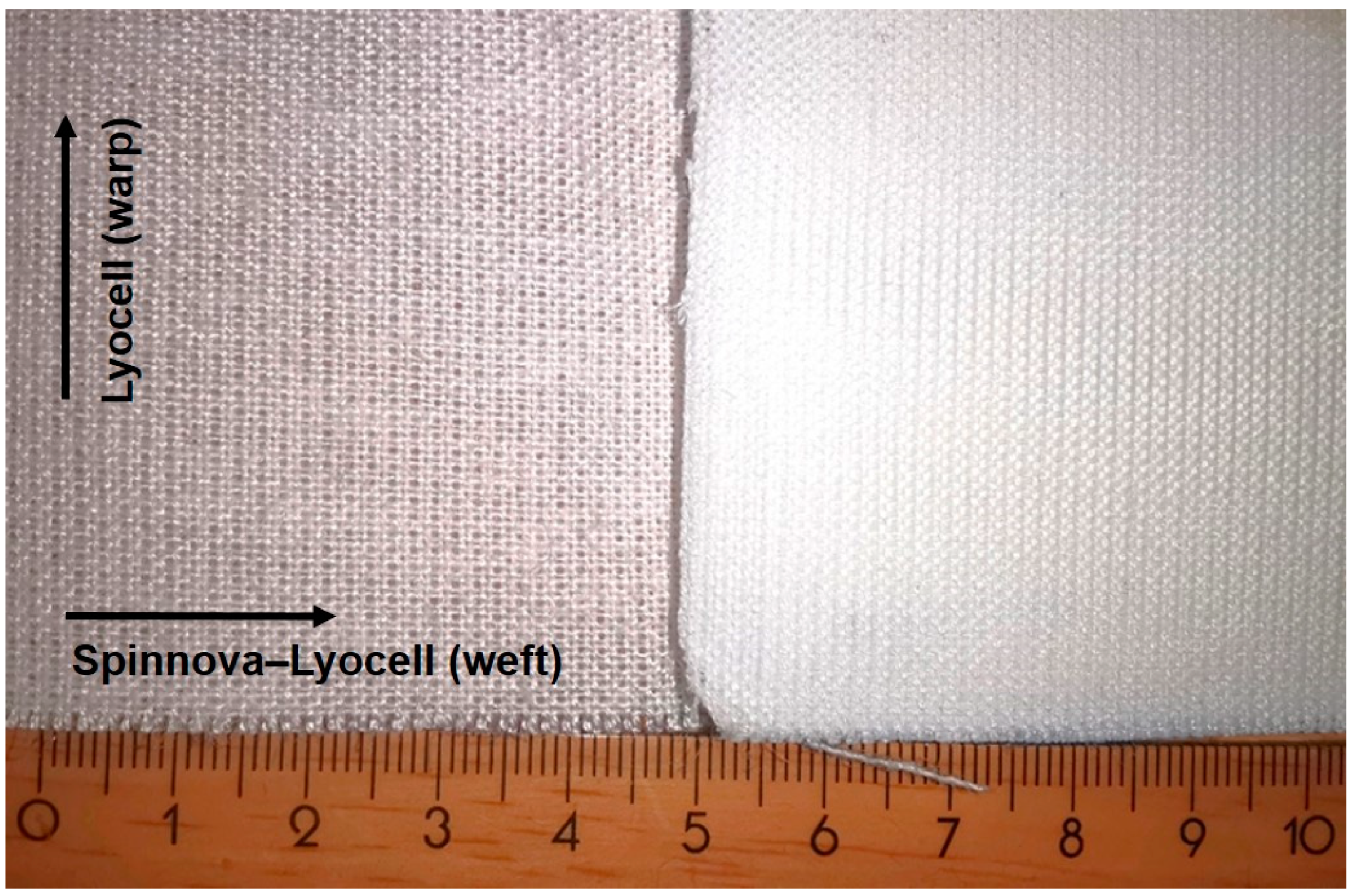

2. Materials and Methods

2.1. Materials and Treatments

2.2. Composite Laminate Preparation

2.3. Composite Characterisation

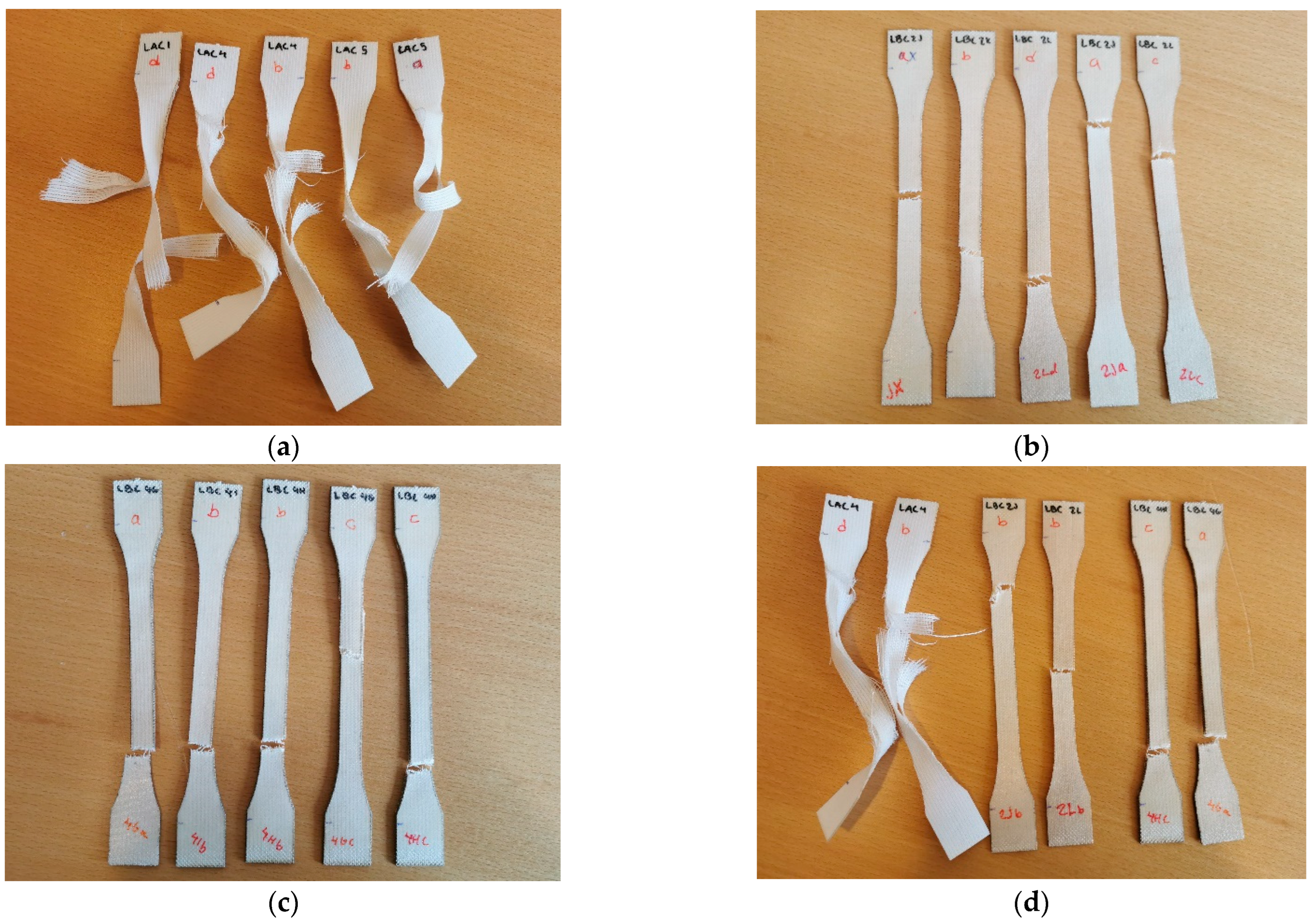

2.3.1. Tensile Test

2.3.2. Thermogravimetric Analysis

2.3.3. Differential Scanning Calorimetry

2.3.4. Dynamic Mechanical Analysis

2.3.5. Water Absorption Test

2.3.6. Scanning Electron Microscopy

3. Results and Discussion

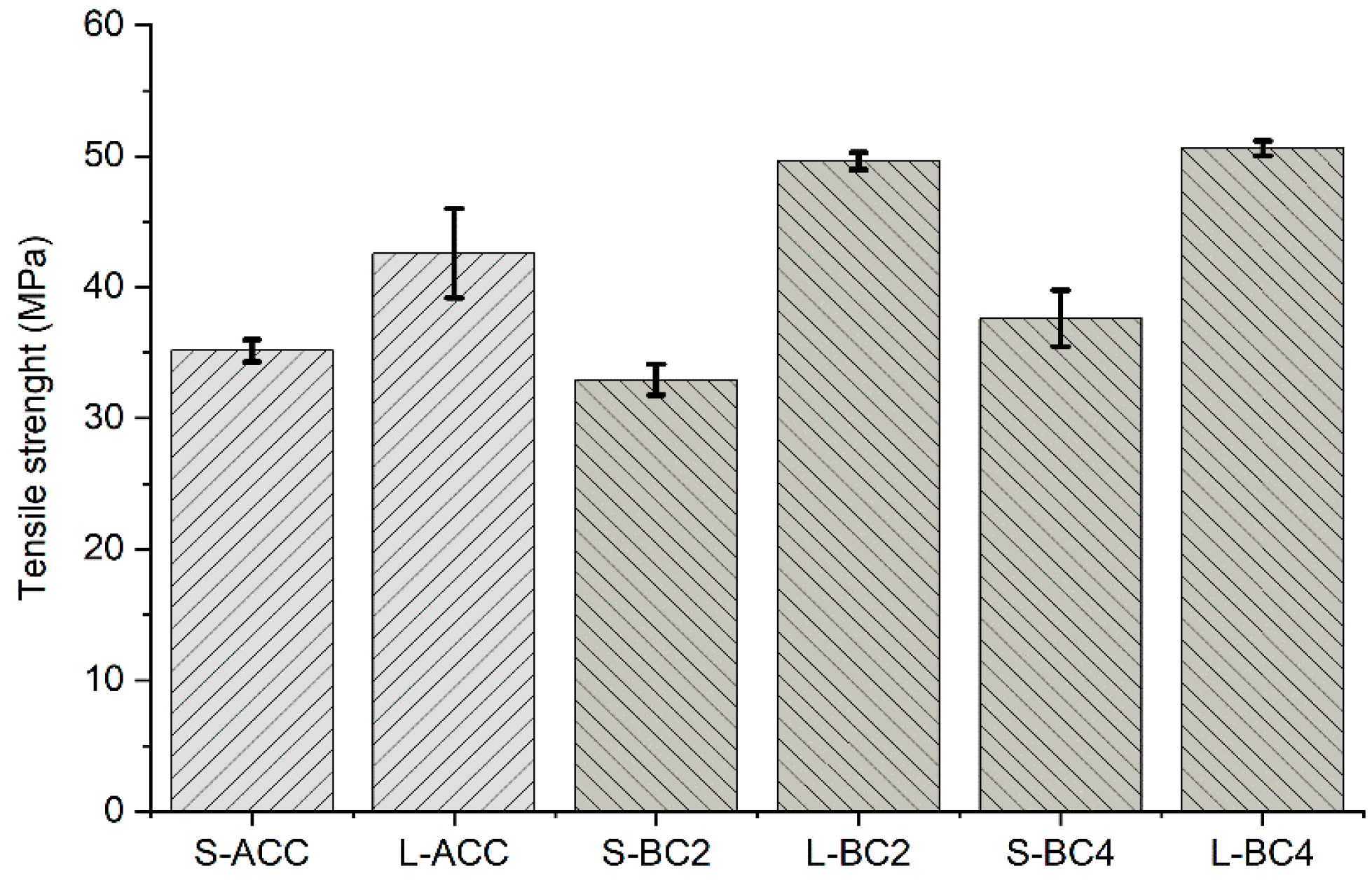

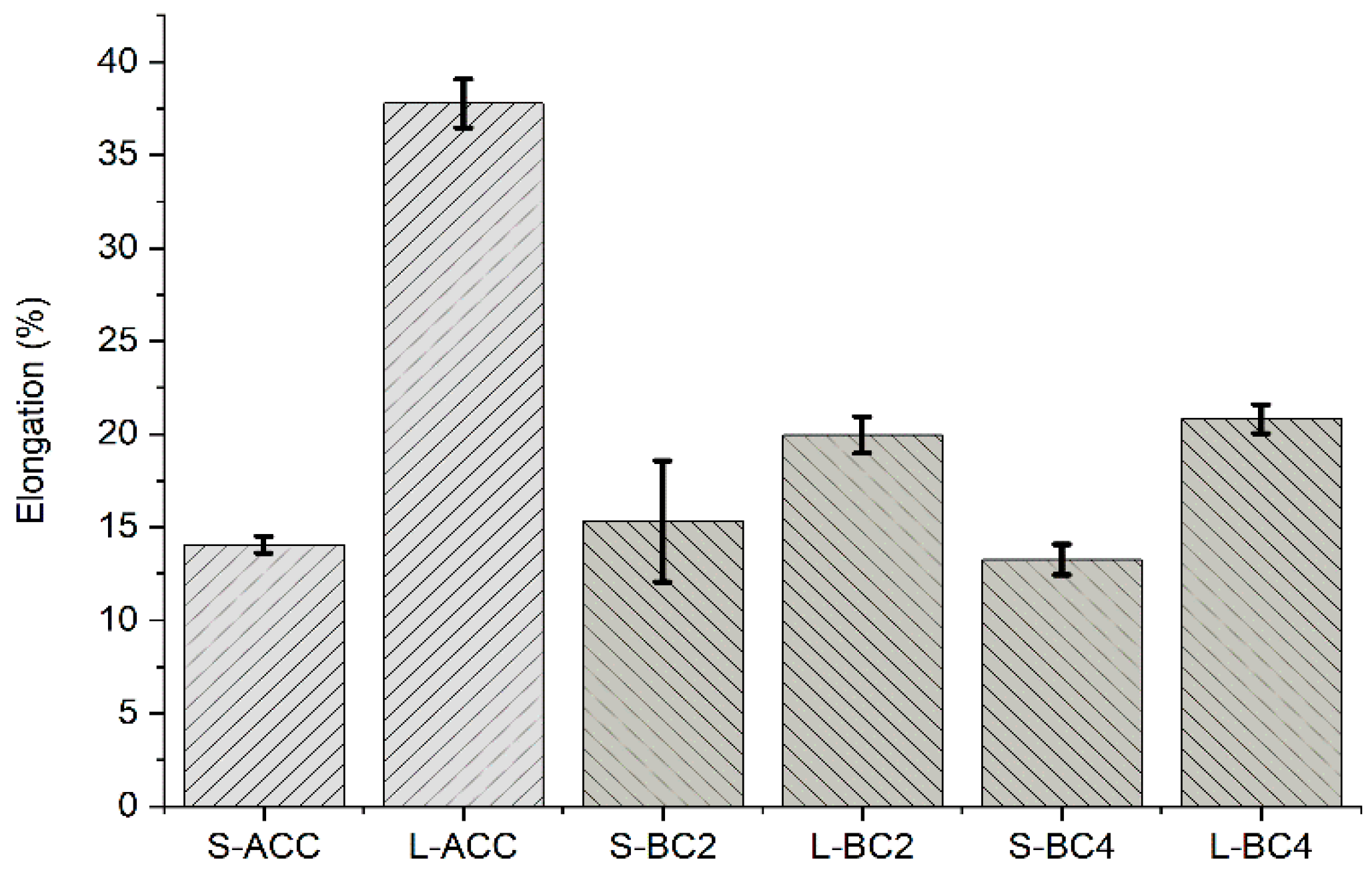

3.1. Tensile Test

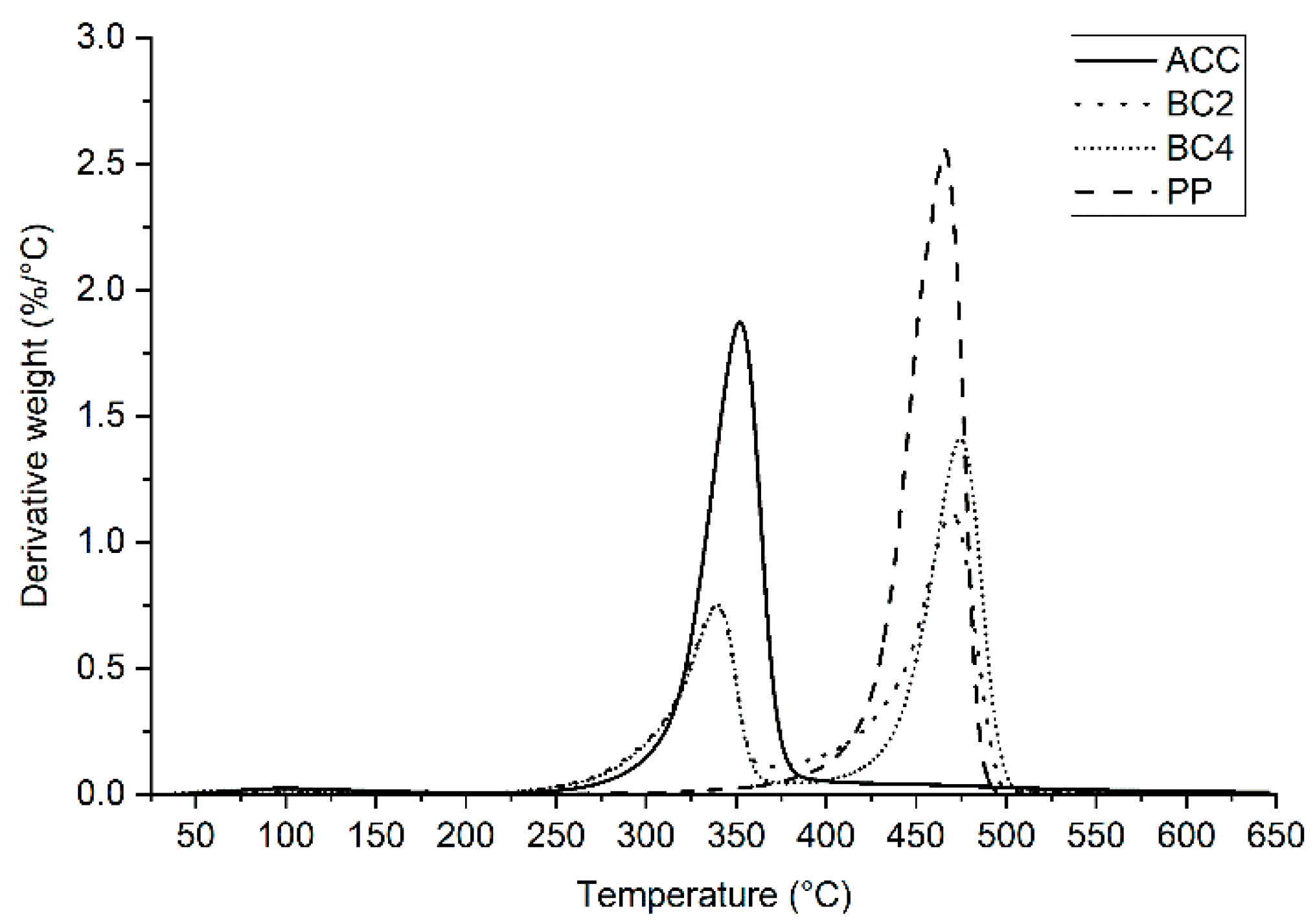

3.2. Thermogravimetric Analysis

3.3. Differential Scanning Calorimetry

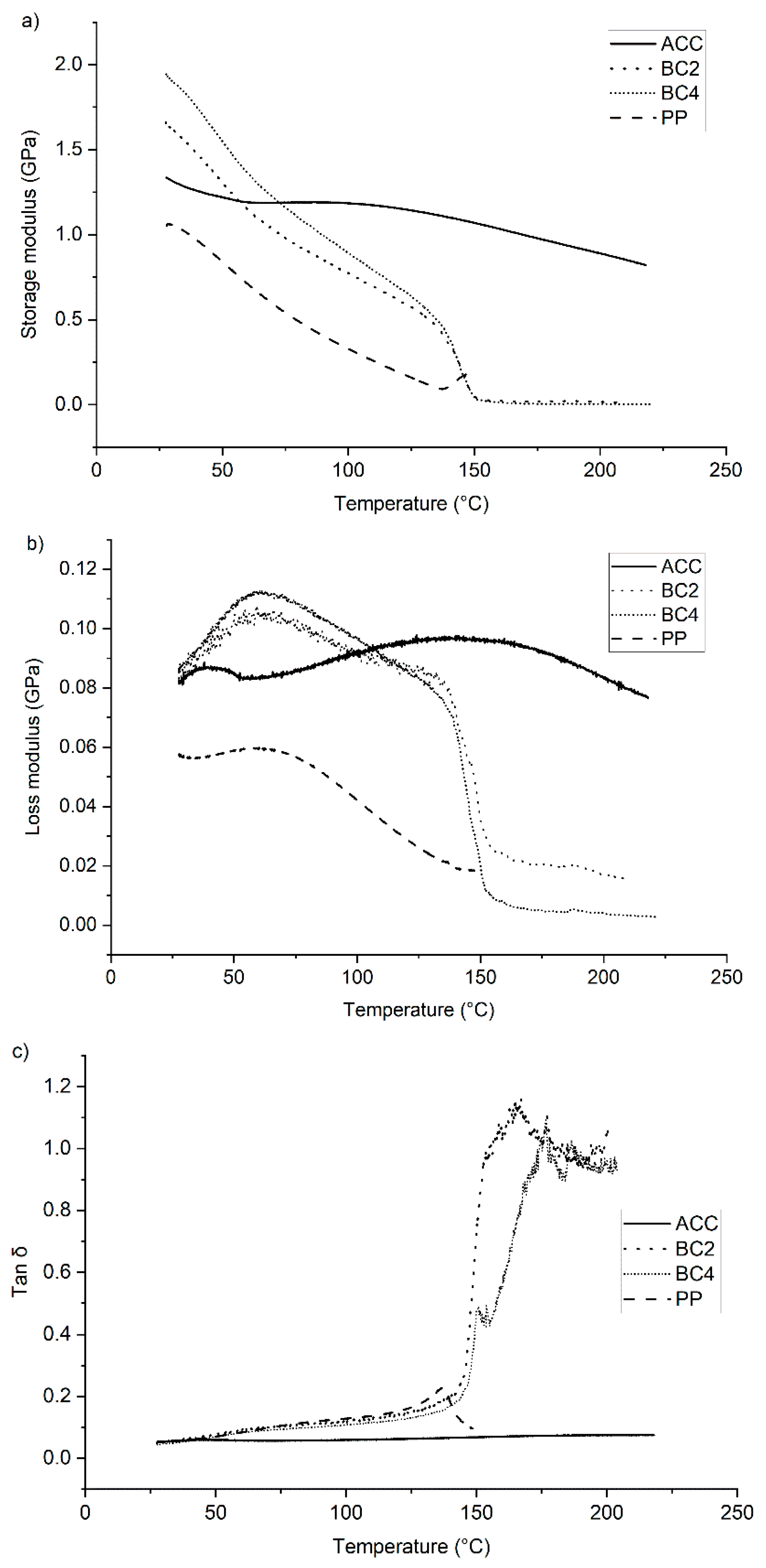

3.4. Dynamic Mechanical Analysis

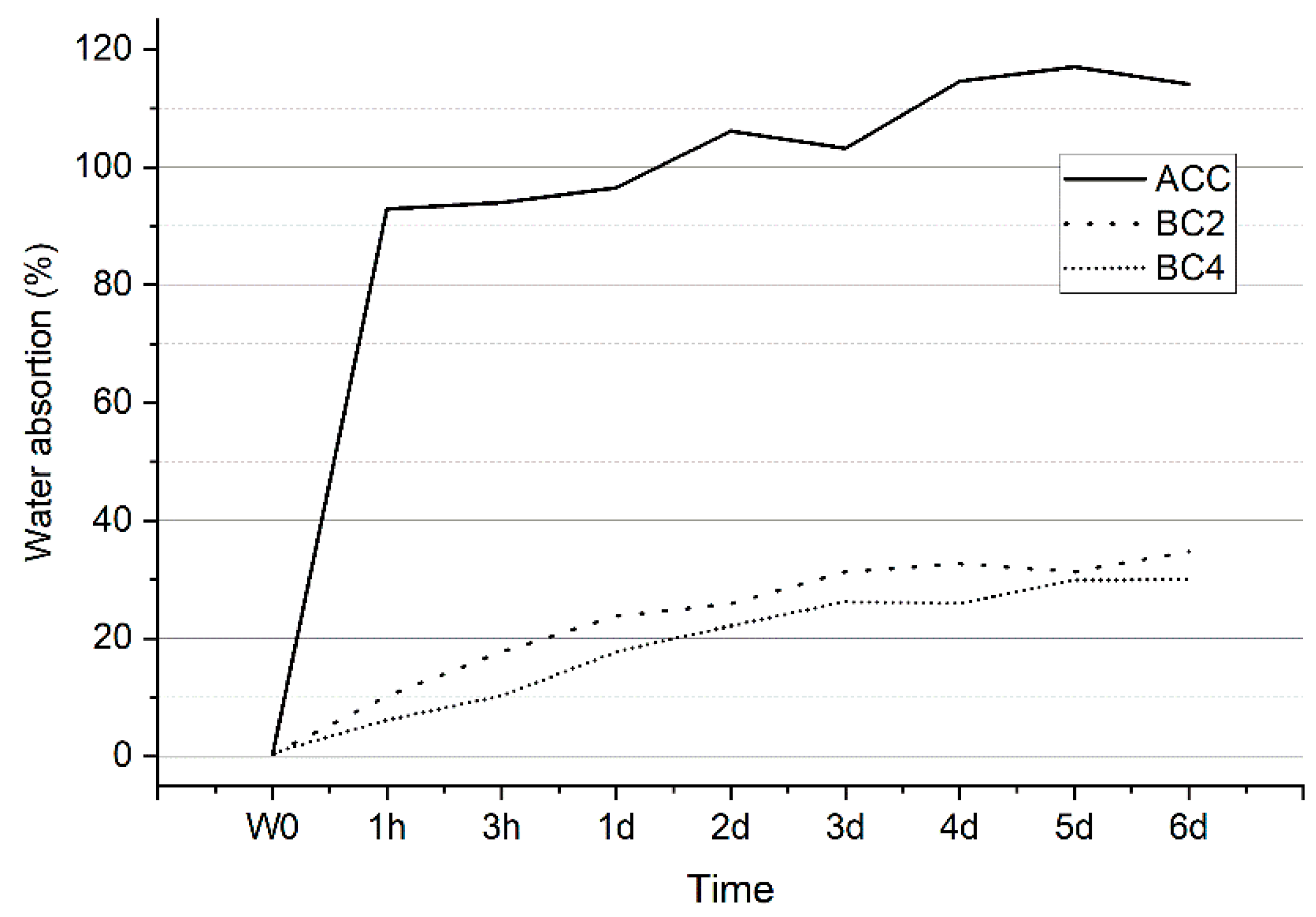

3.5. Water Absorption Test

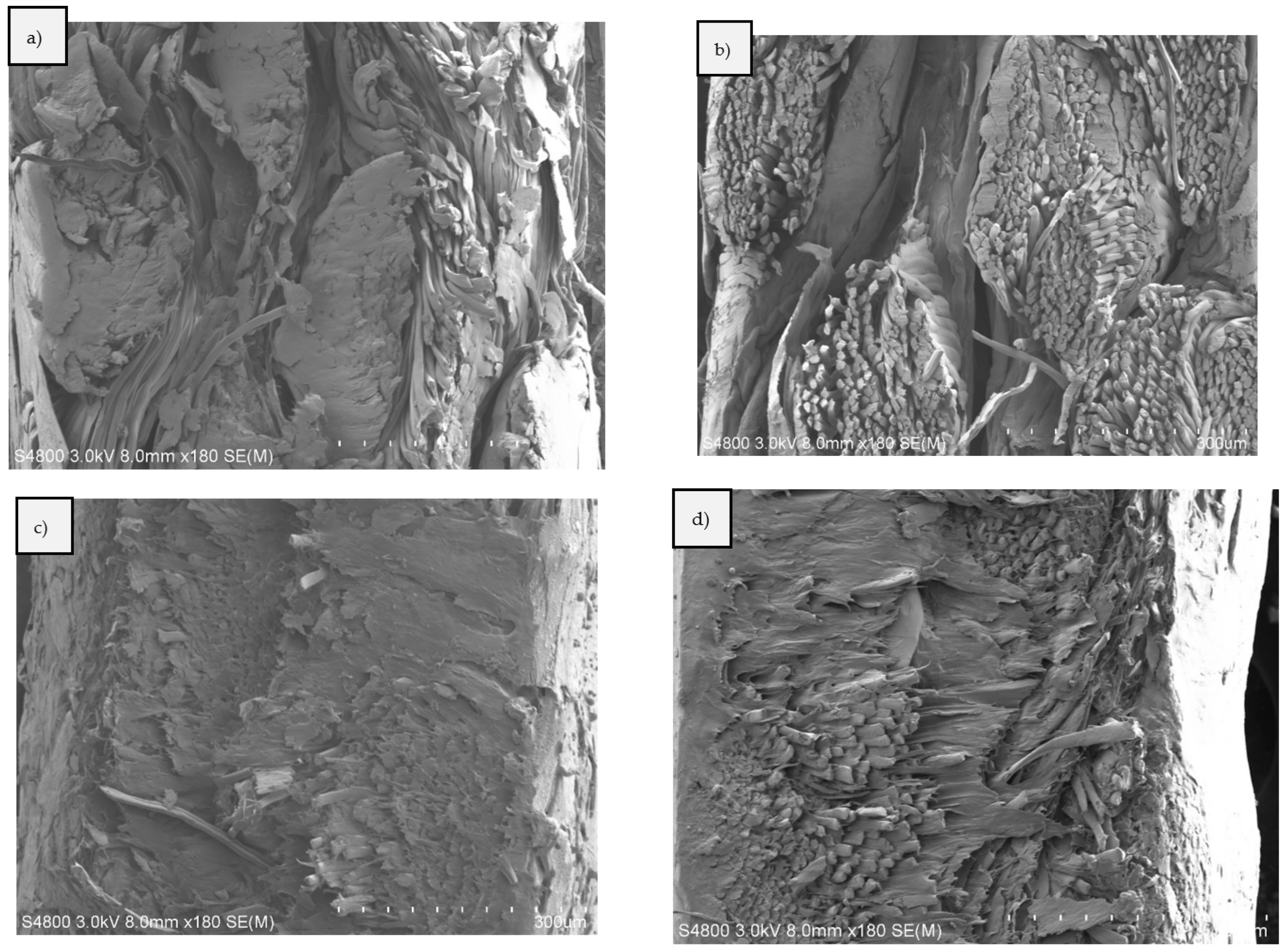

3.6. Scanning Electron Microscopy

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Mohanty, A.K.; Misra, M.; Hinrichsen, G. Biofibres, biodegradable polymers and biocomposites: An overview. Macromol. Mater. Eng. 2000, 276, 1–24. [Google Scholar] [CrossRef]

- Hu, F.; Wang, M.; Wang, N.; Hu, Y.; Gan, M.; Liu, D.; Xie, Y.; Feng, Q. All-cellulose composites prepared by partially dissolving cellulose using NaOH/thiourea aqueous solution. J. Appl. Polym. Sci. 2021, 138, 51298. [Google Scholar] [CrossRef]

- Carrillo, F.; Colom, X.; Cañavate, X. Properties of Regenerated Cellulose Lyocell Fiber-Reinforced Composites. J. Reinf. Plast. Compos. 2010, 29, 359–371. [Google Scholar] [CrossRef]

- Fujisawa, S.; Saito, T.; Isogai, A. All-cellulose (cellulose-cellulose) green composites. In Advanced Green Composites; John and Wiley and Sons: Hoboken, NJ, USA, 2018; pp. 111–133. [Google Scholar] [CrossRef]

- Sharma, A.; Nagarkar, S.; Thakre, S.; Kumaraswamy, G. Structure–property relations in regenerated cellulose fibers: Comparison of fibers manufactured using viscose and lyocell processes. Cellulose 2019, 26, 3655–3669. [Google Scholar] [CrossRef]

- Lenz, J.; Shurz, J.; Eichinger, D. Properties and Structure of Lyocell and Viscose-Type Fibers in the Swollen State. Lezinger Ber. 1994, 9, 19–25. [Google Scholar]

- Mathur, K. New Developments in Fibers, Yarns & Fabrics. Text. World 2020, 170, 32–35. [Google Scholar]

- Uusi-Tarkka, E.-K.; Skrifvars, M.; Haapala, A. Fabricating sustainable all-cellulose composites. Appl. Sci. 2021, 11, 10069. [Google Scholar] [CrossRef]

- Trejo-O’Reilly, J.A.; Cavaillé, J.Y.; Paillet, M.; Gandini, A.; Herrera-Franco, P.; Cauich, J. Interfacial properties of regenerated cellulose fiber/polystyrene composite materials. Effect of the coupling agent’s structure on the micromechanical behavior. Polym. Compos. 2000, 21, 65–71. [Google Scholar] [CrossRef]

- Jayamol, G.; Sreekala, M.S.; Sabu, T. A review on interface modification and characterization of natural fiber reinforced plastic composites. Polym. Eng. Sci. 2001, 41, 1471–1485. [Google Scholar] [CrossRef]

- Zafeiropoulos, N.E. Interface Engineering of Natural Fibre Composites for Maximum Performance; Woodhead Publishing: Sawston, UK, 2011. [Google Scholar]

- Arévalo, R.; Peijs, T. Binderless all-cellulose fibreboard from microfibrillated lignocellulosic natural fibres. Compos. Part A Appl. Sci. Manuf. 2016, 83, 38–46. [Google Scholar] [CrossRef]

- Alcock, B.; Cabrera, N.O.; Barkoula, N.-M.; Loos, J.; Peijs, T. The mechanical properties of unidirectional all-polypropylene composites. Compos. Part A Appl. Sci. Manuf. 2006, 37, 716–726. [Google Scholar] [CrossRef]

- Capiati, N.J.; Porter, R.S. The concept of one polymer composites modelled with high density polyethylene. J. Mater. Sci. 1975, 10, 1671–1677. [Google Scholar] [CrossRef]

- Baghaei, B.; Skrifvars, M. All-Cellulose Composites: A Review of Recent Studies on Structure, Properties and Applications. Molecules 2020, 25, 2836. [Google Scholar] [CrossRef] [PubMed]

- Ramamoorthy, S.K.; Skrifvars, M.; Persson, A. A Review of Natural Fibers Used in Biocomposites: Plant, Animal and Regenerated Cellulose Fibers. Polym. Rev. 2015, 55, 107–162. [Google Scholar] [CrossRef]

- Gindl-Altmutter, W.; Keckes, J.; Plackner, J.; Liebner, F.; Englund, K.; Laborie, M.-P. All-cellulose composites prepared from flax and lyocell fibres compared to epoxy–matrix composites. Compos. Sci. Technol. 2012, 72, 1304–1309. [Google Scholar] [CrossRef]

- Adak, B.; Mukhopadhyay, S. Effect of the dissolution time on the structure and properties of lyocell-fabric-based all-cellulose composite laminates. J. Appl. Polym. Sci. 2016, 133, 43398. [Google Scholar] [CrossRef]

- Fink, H.P.; Weigel, P.; Purz, H.; Ganster, J. Structure formation of regenerated cellulose materials from NMMO-solutions. Prog. Polym. Sci. 2001, 26, 1473–1524. [Google Scholar] [CrossRef]

- Adusumali, R.-B.; Reifferscheid, M.; Weber, H.; Roeder, T.; Sixta, H.; Gindl, W. Mechanical Properties of Regenerated Cellulose Fibres for Composites. Macromol. Symp. 2006, 244, 119–125. [Google Scholar] [CrossRef]

- Tanpichai, S.; Witayakran, S. All-cellulose composites from pineapple leaf microfibers: Structural, thermal, and mechanical properties. Polym. Compos. 2018, 39, 895–903. [Google Scholar] [CrossRef]

- Yang, Q.; Lue, A.; Zhang, L. Reinforcement of ramie fibers on regenerated cellulose films. Compos. Sci. Technol. 2010, 70, 2319–2324. [Google Scholar] [CrossRef]

- Uusi-Tarkka, E.-K.; Levanic, J.; Herajarvi, H.; Kadi, N.; Skrifvars, M.; Haapala, A. All-Cellulose Composite Laminates Made from Wood-Based Textiles: Effects of Process Conditions and the Addition of TEMPO-Oxidized Nanocellulose. Polymers 2022, 14, 3959. [Google Scholar] [CrossRef] [PubMed]

- Navarro, R.; Torre, L.; Kenny, J.M.; Jiménez, A. Thermal degradation of recycled polypropylene toughened with elastomers. Polym. Degrad. Stab. 2003, 82, 279–290. [Google Scholar] [CrossRef]

- Esmizadeh, E.; Tzoganakis, C.; Mekonnen, T.H. Degradation behavior of polypropylene during reprocessing and its biocomposites: Thermal and oxidative degradation kinetics. Polymers 2020, 12, 1627. [Google Scholar] [CrossRef] [PubMed]

- Bhasney, S.M.; Kumar, A.; Katiyar, V. Microcrystalline cellulose, polylactic acid and polypropylene biocomposites and its morphological, mechanical, thermal and rheological properties. Compos. Part B Eng. 2020, 184, 107717. [Google Scholar] [CrossRef]

- Belgacem, M.N.; Gandini, A. Production, chemistry and properties of cellulose-based materials. In Biopolymers—New Materials for Sustainable Films and Coatings; Plackett, D., Ed.; Wiley: West Sussex, UK, 2011; pp. 151–178. [Google Scholar]

- Nishino, T.; Matsuda, I.; Hirao, K. All-Cellulose Composite. Macromolecules 2004, 37, 7683–7687. [Google Scholar] [CrossRef]

- Soykeabkaew, N.; Nishino, T.; Peijs, T. All-cellulose composites of regenerated cellulose fibres by surface selective dissolution. Compos. Part A Appl. Sci. Manuf. 2009, 40, 321–328. [Google Scholar] [CrossRef]

- Franck, A. Viscoelasticity and Dynamic Mechanical Testing, TA Instruments. Germany. 2022. Available online: https://www.tainstruments.com/pdf/literature/AAN004_Viscoelasticity_and_DMA.pdf (accessed on 11 November 2022).

- Greene, J.O. 3—Microstructures of Polymers. In Plastics Design Library, Automotive Plastics and Composites; Greene, J.P., Ed.; William Andrew Publishing: Norwich, NY, USA, 2021; pp. 27–37. ISBN 9780128180082. [Google Scholar] [CrossRef]

- Woicke, N.; Keuerleber, M.; Hegemann, B.; Eyerer, P. Three-dimensional thermorheological behavior of isotactic polypropylene across glass transition temperature. J. Appl. Polym. Sci. 2004, 94, 877–880. [Google Scholar] [CrossRef]

- Gómez-del Río, T.; Rodríguez, J. Compression yielding of polypropylenes above glass transition temperature. Eur. Polym. J. 2010, 46, 1244–1250. [Google Scholar] [CrossRef]

- Salmén, N.L.; Back, E.L. The influence of water on the glass phase transition temperature of cellulose. TAPPI 1977, 60, 137–140. [Google Scholar]

- Wunderlich, B. Thermal Analysis of Polymeric Materials; Springer: Berlin/Heidelberg, Germany, 2005. [Google Scholar]

- Vittadini, E.; Dickinson, L.; Chinachoti, P. H-1 and H-2 NMR mobility in cellulose. Carbohydr. Polym. 2001, 46, 49–57. [Google Scholar] [CrossRef]

| Cycle Order | Pressure Time | Release Time | Number of Cycles | Pressure | Temperature |

|---|---|---|---|---|---|

| 1 | 5 s | 10 s | 4 | 60 bar | 100 °C |

| 2 | 1 min | 10 s | 3 | 60 bar | 100 °C |

| 3 | 3 min | 20 s | 1 | 60 bar | 100 °C |

| 4 | 5 min | 20 s | 2 | 60 bar | 100 °C |

| 5 | 20 min | 20 s | 1 | 60 bar | 100 °C |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Uusi-Tarkka, E.-K.; Skrifvars, M.; Khalili, P.; Heräjärvi, H.; Kadi, N.; Haapala, A. Mechanical and Thermal Properties of Wood-Fiber-Based All-Cellulose Composites and Cellulose-Polypropylene Biocomposites. Polymers 2023, 15, 475. https://doi.org/10.3390/polym15030475

Uusi-Tarkka E-K, Skrifvars M, Khalili P, Heräjärvi H, Kadi N, Haapala A. Mechanical and Thermal Properties of Wood-Fiber-Based All-Cellulose Composites and Cellulose-Polypropylene Biocomposites. Polymers. 2023; 15(3):475. https://doi.org/10.3390/polym15030475

Chicago/Turabian StyleUusi-Tarkka, Eija-Katriina, Mikael Skrifvars, Pooria Khalili, Henrik Heräjärvi, Nawar Kadi, and Antti Haapala. 2023. "Mechanical and Thermal Properties of Wood-Fiber-Based All-Cellulose Composites and Cellulose-Polypropylene Biocomposites" Polymers 15, no. 3: 475. https://doi.org/10.3390/polym15030475

APA StyleUusi-Tarkka, E.-K., Skrifvars, M., Khalili, P., Heräjärvi, H., Kadi, N., & Haapala, A. (2023). Mechanical and Thermal Properties of Wood-Fiber-Based All-Cellulose Composites and Cellulose-Polypropylene Biocomposites. Polymers, 15(3), 475. https://doi.org/10.3390/polym15030475