Programming and Reprogramming the Viscoelasticity and Magnetic Response of Magnetoactive Thermoplastic Elastomers

Abstract

1. Introduction

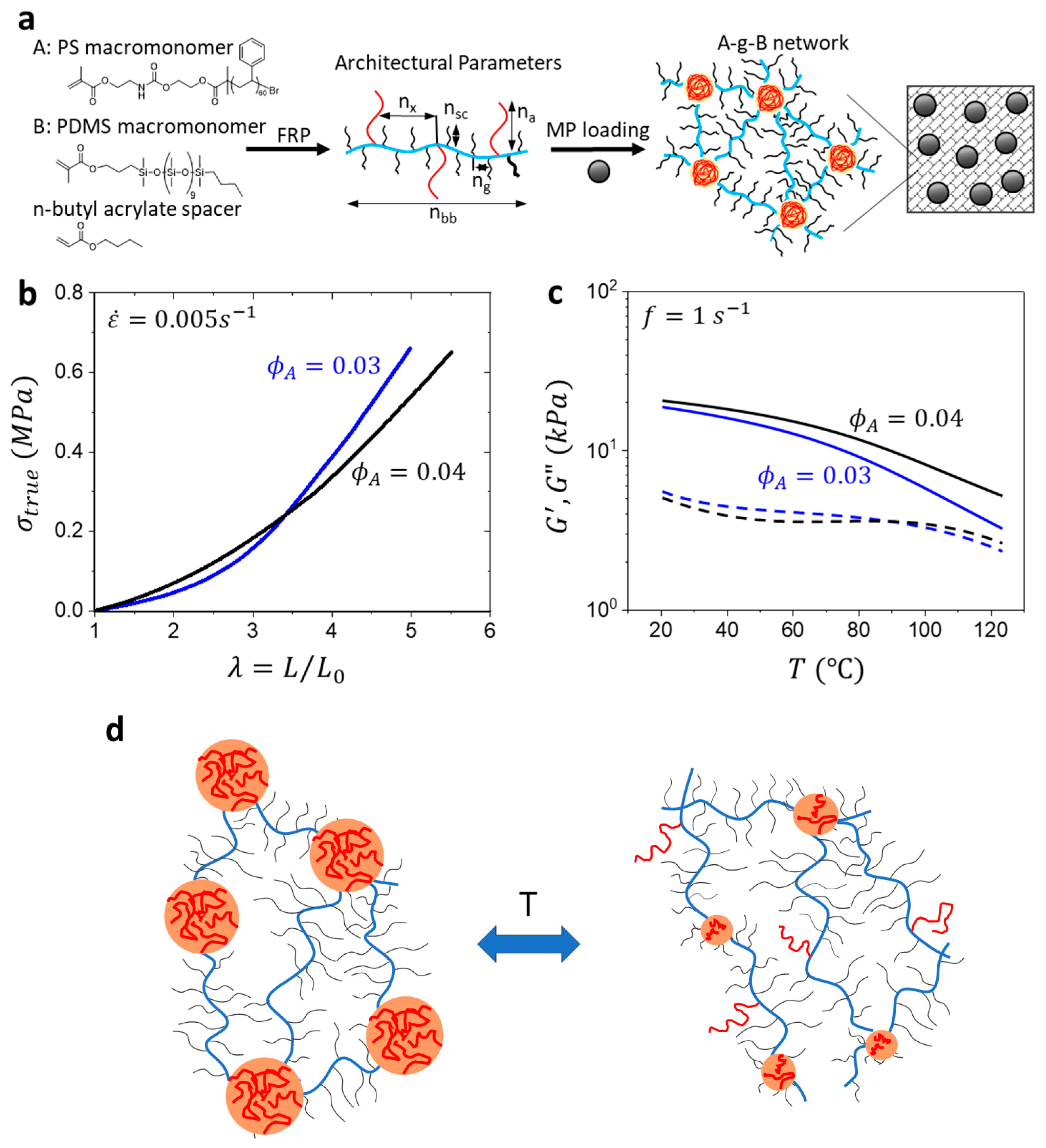

2. Materials and Methods

2.1. Preparation of Magnetic Composites

2.2. Mechanical Characterization of A-g-B: Tensile and T-Sweep

3. Results

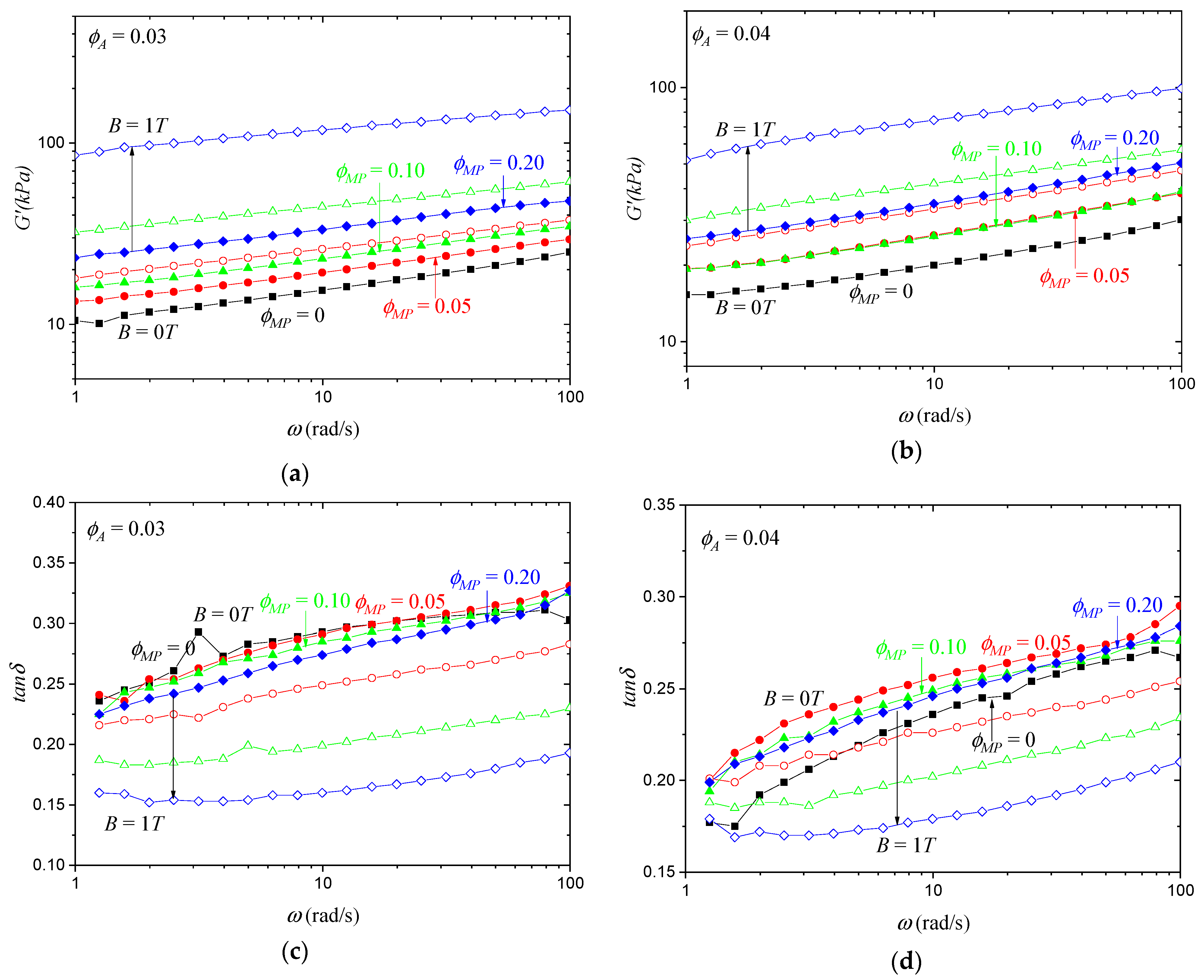

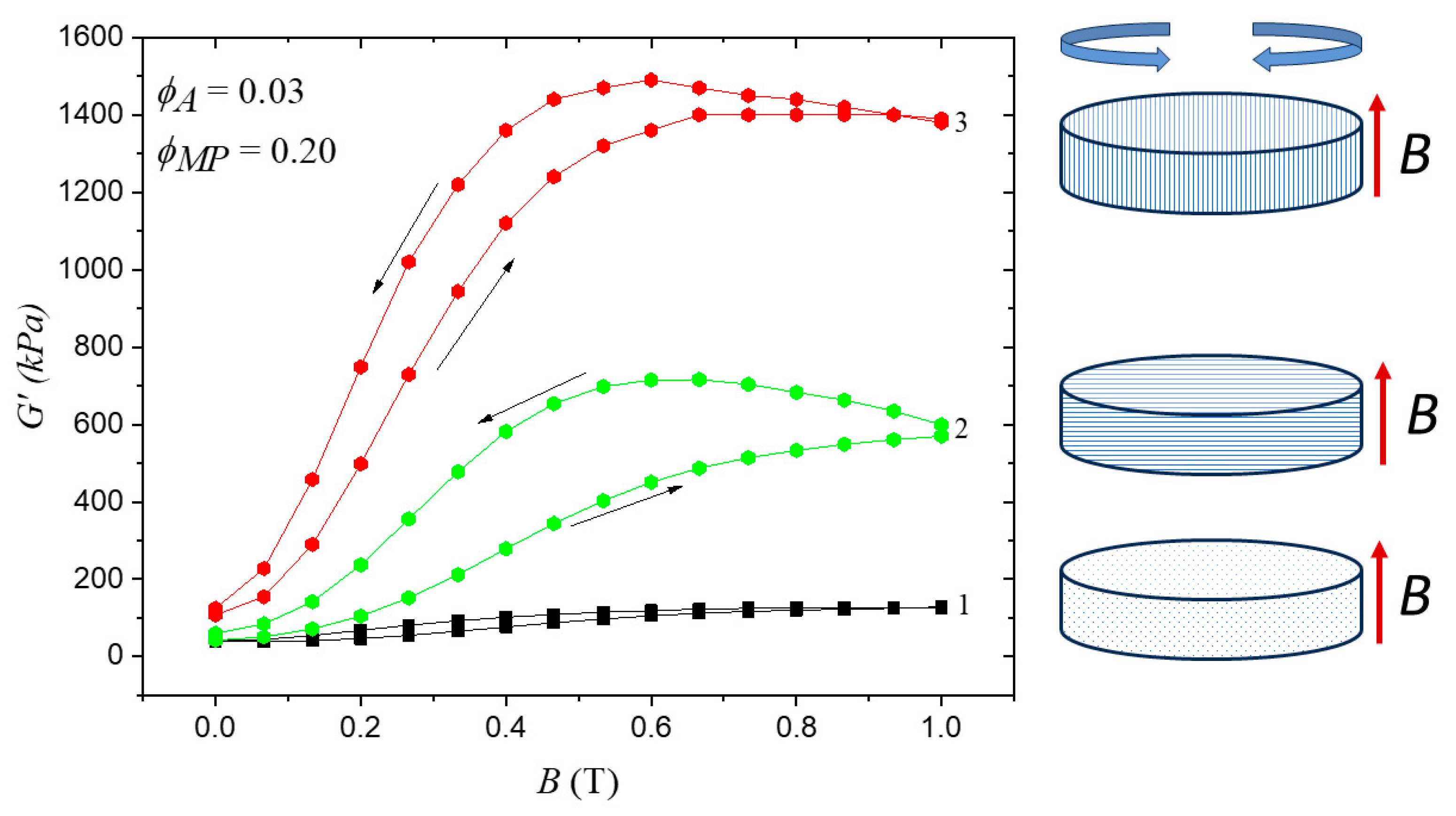

3.1. Magnetic Response at Room Temperature

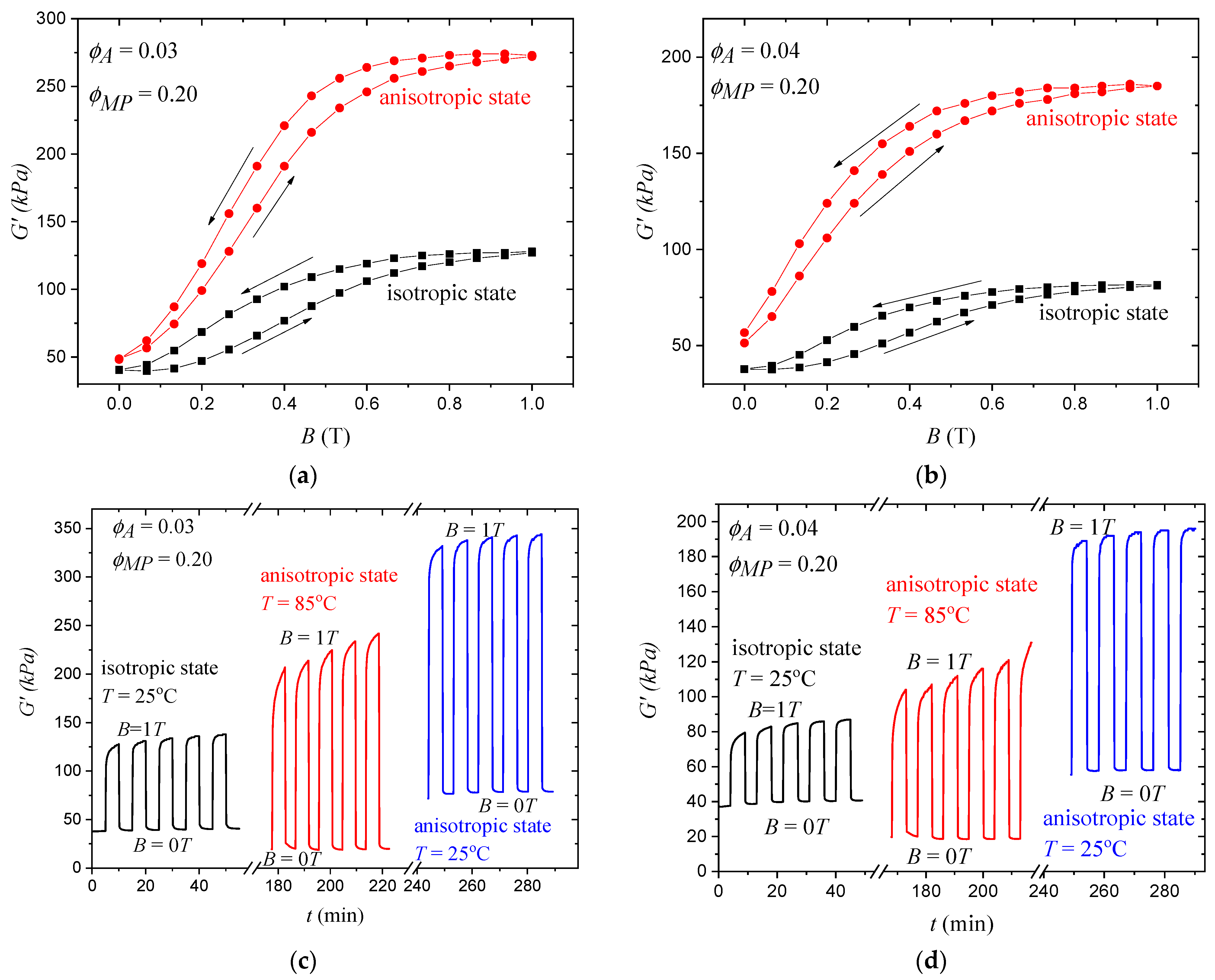

3.2. Orientation of MPs Inside MATEs

3.3. Magnetic Responses of Isotropic and Anisotropic Samples

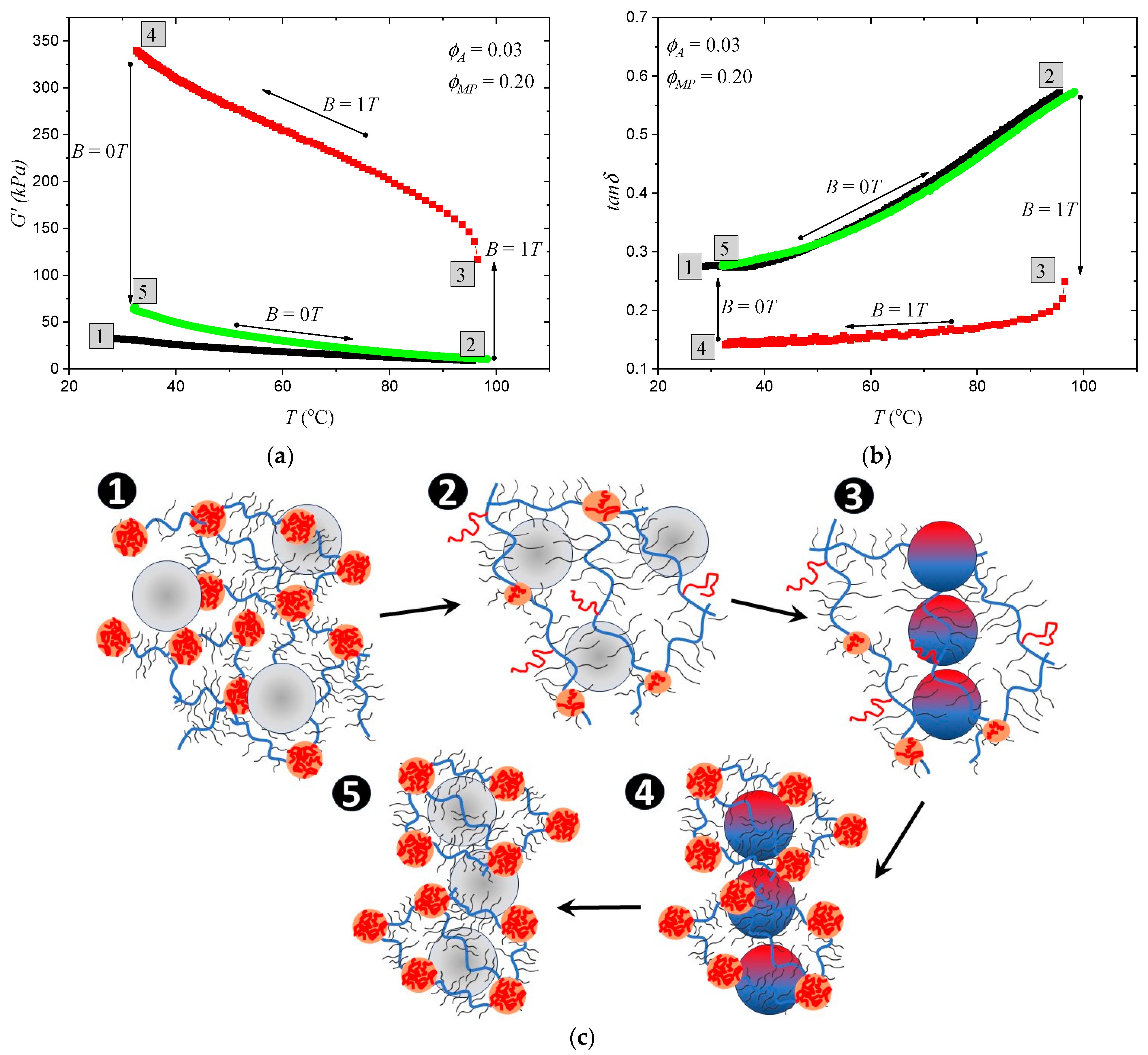

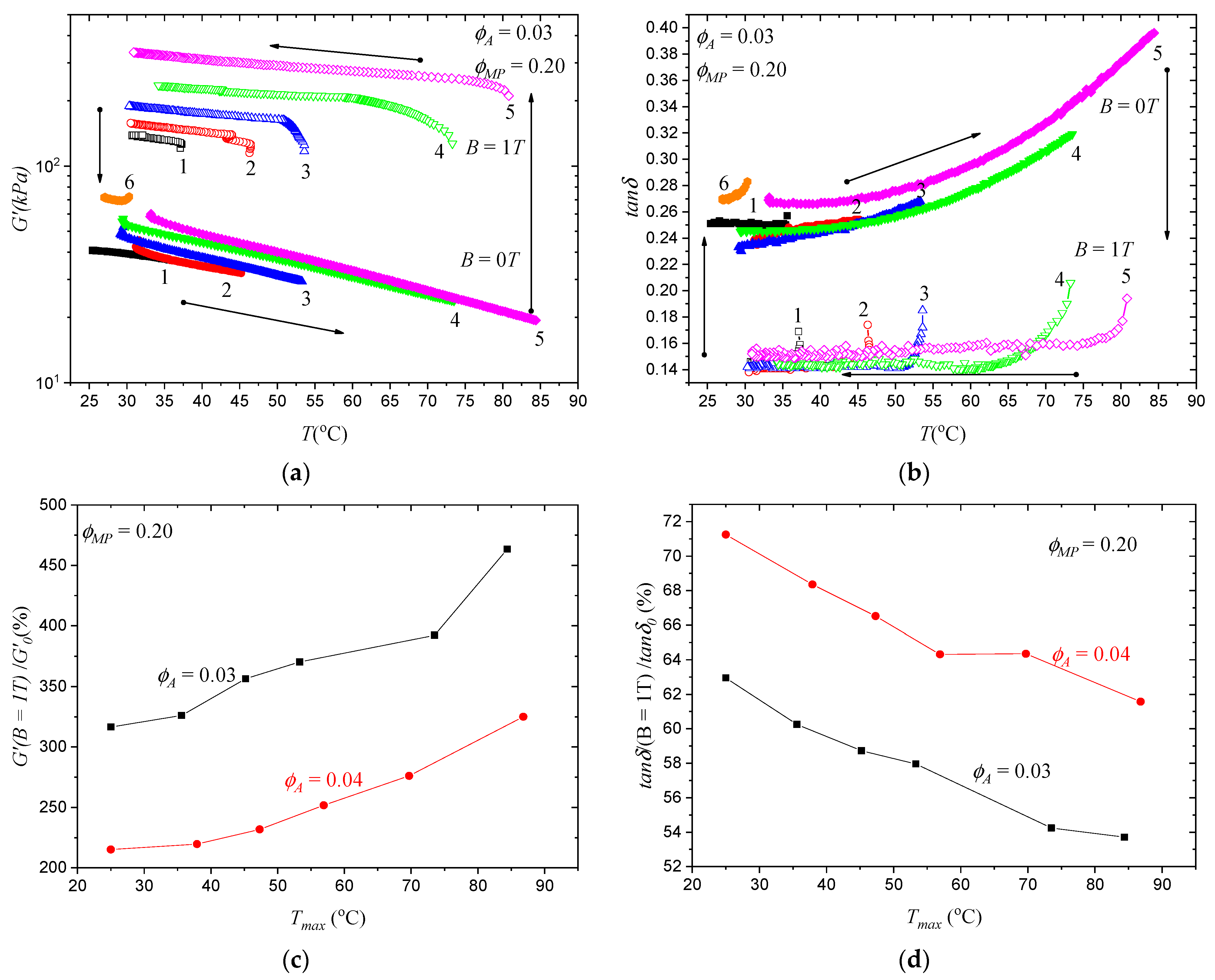

3.4. Programming of the MATEs’ Properties

3.5. Reorientation of MP Structures and Reprogramming the MATEs’ Properties

4. Discussion

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ubaidillah; Sutrisno, J.; Purwanto, A.; Mazlan, S.A. Recent Progress on Magnetorheological Solids: Materials, Fabrication, Testing, and Applications. Adv. Eng. Mater. 2015, 17, 563–597. [Google Scholar] [CrossRef]

- Choi, S.B.; Li, W.; Yu, M.; Du, H.; Fu, J.; Do, P.X. State of the Art of Control Schemes for Smart Systems Featuring Magneto-Rheological Materials. Smart Mater. Struct. 2016, 25, 043001. [Google Scholar] [CrossRef]

- Filipcsei, G.; Csetneki, I.; Szilágyi, A.; Zrínyi, M. Magnetic Field-Responsive Smart Polymer Composites. In Oligomers-Polymer Composites-Molecular Imprinting; Gong, B., Sanford, A.R., Ferguson, J.S., Eds.; Advances in Polymer Science; Springer: Berlin/Heidelberg, Germany, 2007; pp. 137–189. ISBN 978-3-540-46830-1. [Google Scholar]

- Shamonin, M.; Kramarenko, E.Y. Chapter 7—Highly Responsive Magnetoactive Elastomers. In Novel Magnetic Nanostructures; Domracheva, N., Caporali, M., Rentschler, E., Eds.; Advanced Nanomaterials; Elsevier: Amsterdam, The Netherlands, 2018; pp. 221–245. ISBN 978-0-12-813594-5. [Google Scholar]

- Nguyen, V.Q.; Ahmed, A.S.; Ramanujan, R.V. Morphing Soft Magnetic Composites. Adv. Mater. 2012, 24, 4041–4054. [Google Scholar] [CrossRef] [PubMed]

- Bastola, A.K.; Paudel, M.; Li, L.; Li, W. Recent Progress of Magnetorheological Elastomers: A Review. Smart Mater. Struct. 2020, 29, 123002. [Google Scholar] [CrossRef]

- Cantera, M.A.; Behrooz, M.; Gibson, R.F.; Gordaninejad, F. Modeling of Magneto-Mechanical Response of Magnetorheo-logical Elastomers (MRE) and MRE-Based Systems: A Review. Smart Mater. Struct. 2017, 26, 023001. [Google Scholar] [CrossRef]

- Lopez-Lopez, M.T.; Durán, J.D.G.; Iskakova, L.Y.; Zubarev, A.Y. Mechanics of Magnetopolymer Composites: A Review. J. Nanofluids 2016, 5, 479–495. [Google Scholar] [CrossRef]

- Odenbach, S. Microstructure and Rheology of Magnetic Hybrid Materials. Arch. Appl. Mech. 2016, 86, 269–279. [Google Scholar] [CrossRef]

- Menzel, A.M. Tuned, Driven, and Active Soft Matter. Phys. Rep. 2015, 554, 1–45. [Google Scholar] [CrossRef]

- Galipeau, E.; Ponte Castañeda, P. Giant Field-Induced Strains in Magnetoactive Elastomer Composites. Proc. R. Soc. A Math. Phys. Eng. Sci. 2013, 469, 20130385. [Google Scholar] [CrossRef]

- Saveliev, D.V.; Belyaeva, I.A.; Chashin, D.V.; Fetisov, L.Y.; Romeis, D.; Kettl, W.; Kramarenko, E.Y.; Saphiannikova, M.; Stepanov, G.V.; Shamonin, M. Giant Extensional Strain of Magnetoactive Elastomeric Cylinders in Uniform Magnetic Fields. Materials 2020, 13, 3297. [Google Scholar] [CrossRef]

- Glavan, G.; Belyaeva, I.A.; Drevenšek-Olenik, I.; Shamonin, M. Experimental Study of Longitudinal, Transverse and Volume Strains of Magnetoactive Elastomeric Cylinders in Uniform Magnetic Fields. J. Magn. Magn. Mater. 2023, 579, 170826. [Google Scholar] [CrossRef]

- Sánchez, P.A.; Stolbov, O.V.; Kantorovich, S.S.; Raikher, Y.L. Modeling the Magnetostriction Effect in Elastomers with Magnetically Soft and Hard Particles. Soft Matter 2019, 15, 7145–7158. [Google Scholar] [CrossRef]

- Ginder, J.M.; Clark, S.M.; Schlotter, W.F.; Nichols, M.E. Magnetostrictive Phenomena in Magnetorheological Elastomers. Int. J. Mod. Phys. B 2002, 16, 2412–2418. [Google Scholar] [CrossRef]

- Bednarek, S. The Giant Magnetostriction in Ferromagnetic Composites within an Elastomer Matrix. Appl. Phys. A 1999, 68, 63–67. [Google Scholar] [CrossRef]

- Kostrov, S.A.; Shamonin, M.; Stepanov, G.V.; Kramarenko, E.Y. Magnetodielectric Response of Soft Magnetoactive Elastomers: Effects of Filler Concentration and Measurement Frequency. Int. J. Mol. Sci. 2019, 20, 2230. [Google Scholar] [CrossRef]

- Moucka, R.; Sedlacik, M.; Cvek, M. Dielectric Properties of Magnetorheological Elastomers with Different Microstructure. Appl. Phys. Lett. 2018, 112, 122901. [Google Scholar] [CrossRef]

- Bica, I.; Liu, Y.D.; Choi, H.J. Magnetic Field Intensity Effect on Plane Electric Capacitor Characteristics and Viscoelasticity of Magnetorheological Elastomer. Colloid Polym. Sci. 2012, 290, 1115–1122. [Google Scholar] [CrossRef]

- Stepanov, G.V.; Semerenko, D.A.; Bakhtiiarov, A.V.; Storozhenko, P.A. Magnetoresistive Effect in Magnetoactive Elastomers. J. Supercond. Nov. Magn. 2013, 26, 1055–1059. [Google Scholar] [CrossRef]

- Winger, J.; Schümann, M.; Kupka, A.; Odenbach, S. Influence of the Particle Size on the Magnetorheological Effect of Magnetorheological Elastomers. J. Magn. Magn. Mater. 2019, 481, 176–182. [Google Scholar] [CrossRef]

- Nam, T.H.; Petríková, I.; Marvalová, B. Experimental Characterization and Viscoelastic Modeling of Isotropic and Anisotropic Magnetorheological Elastomers. Polym. Test. 2020, 81, 106272. [Google Scholar] [CrossRef]

- Sorokin, V.V.; Ecker, E.; Stepanov, G.V.; Shamonin, M.; Monkman, G.J.; Kramarenko, E.Y.; Khokhlov, A.R. Experimental Study of the Magnetic Field Enhanced Payne Effect in Magnetorheological Elastomers. Soft Matter 2014, 10, 8765–8776. [Google Scholar] [CrossRef]

- Kostrov, S.A.; Gorodov, V.V.; Muzafarov, A.M.; Kramarenko, E.Y. Comparative Analysis of Magnetorheological Effect in Soft Isotropic and Anisotropic Magnetoactive Elastomers. Polym. Sci. Ser. B 2022, 64, 888–896. [Google Scholar] [CrossRef]

- Shen, Y.; Golnaraghi, M.F.; Heppler, G.R. Experimental Research and Modeling of Magnetorheological Elastomers. J. Intell. Mater. Syst. Struct. 2004, 15, 27–35. [Google Scholar] [CrossRef]

- Bellan, C.; Bossis, G. Field Dependence of Viscoelastic Properties of MR Elastomers. Int. J. Mod. Phys. B 2002, 16, 2447–2453. [Google Scholar] [CrossRef]

- Lokander, M.; Stenberg, B. Performance of Isotropic Magnetorheological Rubber Materials. Polym. Test. 2003, 22, 245–251. [Google Scholar] [CrossRef]

- Li, W.H.; Zhou, Y.; Tian, T.F. Viscoelastic Properties of MR Elastomers under Harmonic Loading. Rheol. Acta 2010, 49, 733–740. [Google Scholar] [CrossRef]

- Chiba, N.; Yamamoto, K.; Hojo, T.; Kawai, M.; Mitsumata, T. Wide-Range Modulation of Dynamic Modulus and Loss Tangent for Magnetic Elastomers Containing Submilimeter Magnetic Particles. Chem. Lett. 2013, 42, 253–254. [Google Scholar] [CrossRef]

- Bira, N.; Dhagat, P.; Davidson, J.R. A Review of Magnetic Elastomers and Their Role in Soft Robotics. Front. Robot. AI 2020, 7, 588391. [Google Scholar] [CrossRef]

- Hu, W.; Lum, G.Z.; Mastrangeli, M.; Sitti, M. Small-Scale Soft-Bodied Robot with Multimodal Locomotion. Nature 2018, 554, 81–85. [Google Scholar] [CrossRef]

- Makarova, L.A.; Alekhina, Y.A.; Rusakova, T.S.; Perov, N.S. Tunable Properties of Magnetoactive Elastomers for Biomedical Applications. Phys. Procedia 2016, 82, 38–45. [Google Scholar] [CrossRef]

- Hooshiar, A.; Payami, A.; Dargahi, J.; Najarian, S. Magnetostriction-Based Force Feedback for Robot-Assisted Cardiovascular Surgery Using Smart Magnetorheological Elastomers. Mech. Syst. Signal Process. 2021, 161, 107918. [Google Scholar] [CrossRef]

- Makarova, L.A.; Alekhina, Y.A.; Isaev, D.A.; Khairullin, M.F.; Perov, N.S. Tunable Layered Composites Based on Magnetoactive Elastomers and Piezopolymer for Sensors and Energy Harvesting Devices. J. Phys. D Appl. Phys. 2021, 54, 015003. [Google Scholar] [CrossRef]

- Xu, T.; Zhang, J.; Salehizadeh, M.; Onaizah, O.; Diller, E. Millimeter-Scale Flexible Robots with Programmable Three-Dimensional Magnetization and Motions. Sci. Robot. 2019, 4, eaav4494. [Google Scholar] [CrossRef] [PubMed]

- Shinoda, H.; Azukizawa, S.; Maeda, K.; Tsumori, F. Bio-Mimic Motion of 3D-Printed Gel Structures Dispersed with Magnetic Particles. J. Electrochem. Soc. 2019, 166, B3235–B3239. [Google Scholar] [CrossRef]

- Ren, Z.; Hu, W.; Dong, X.; Sitti, M. Multi-Functional Soft-Bodied Jellyfish-like Swimming. Nat. Commun. 2019, 10, 2703. [Google Scholar] [CrossRef] [PubMed]

- Liao, Z.; Zoumhani, O.; Boutry, C.M. Recent Advances in Magnetic Polymer Composites for BioMEMS: A Review. Materials 2023, 16, 3802. [Google Scholar] [CrossRef]

- Li, Y.; Li, J.; Li, W.; Du, H. A State-of-the-Art Review on Magnetorheological Elastomer Devices. Smart Mater. Struct. 2014, 23, 123001. [Google Scholar] [CrossRef]

- Stoll, A.; Mayer, M.; Monkman, G.J.; Shamonin, M. Evaluation of Highly Compliant Magneto-Active Elastomers with Colossal Magnetorheological Response. J. Appl. Polym. Sci. 2014, 131, 39793. [Google Scholar] [CrossRef]

- Grosberg, A.Y.; Khokhlov, A.R. Statistical Physics of Macromolecules; Nauka: Moscow, Russia, 1989. [Google Scholar]

- Stepanov, G.V.; Borin, D.Y.; Kramarenko, E.Y.; Bogdanov, V.V.; Semerenko, D.A.; Storozhenko, P.A. Magnetoactive Elastomer Based on Magnetically Hard Filler: Synthesis and Study of Viscoelastic and Damping Properties. Polym. Sci. Ser. A 2014, 56, 603–6136. [Google Scholar] [CrossRef]

- Kostrov, S.A.; Dashtimoghadam, E.; Keith, A.N.; Sheiko, S.S.; Kramarenko, E.Y. Regulating Tissue-Mimetic Mechanical Properties of Bottlebrush Elastomers by Magnetic Field. ACS Appl. Mater. Interfaces 2021, 13, 38783–38791. [Google Scholar] [CrossRef]

- Tian, T.; Nakano, M. Fabrication and Characterisation of Anisotropic Magnetorheological Elastomer with 45° Iron Particle Alignment at Various Silicone Oil Concentrations. J. Intell. Mater. Syst. Struct. 2018, 29, 151–159. [Google Scholar] [CrossRef]

- Li, W.H.; Zhang, X.Z. A Study of the Magnetorheological Effect of Bimodal Particle Based Magnetorheological Elastomers. Smart Mater. Struct. 2010, 19, 035002. [Google Scholar] [CrossRef]

- Schmauch, M.M.; Mishra, S.R.; Evans, B.A.; Velev, O.D.; Tracy, J.B. Chained Iron Microparticles for Directionally Controlled Actuation of Soft Robots. ACS Appl. Mater. Interfaces 2017, 9, 11895–11901. [Google Scholar] [CrossRef] [PubMed]

- Ding, L.; Zhang, J.; Shu, Q.; Liu, S.; Xuan, S.; Gong, X.; Zhang, D. Magnetism-Responsive Anisotropic Film with Self-Sensing and Multifunctional Shape Manipulation. ACS Appl. Mater. Interfaces 2021, 13, 13724–13734. [Google Scholar] [CrossRef] [PubMed]

- Lin, D.; Yang, F.; Gong, D.; Lin, Z.; Li, R.; Qian, W.; Li, C.; Jia, S.; Chen, H. Magnetoactive Soft Drivers with Radial-Chain Iron Microparticles. ACS Appl. Mater. Interfaces 2021, 13, 34935–34941. [Google Scholar] [CrossRef] [PubMed]

- Lu, H.; Zhang, M.; Yang, Y.; Huang, Q.; Fukuda, T.; Wang, Z.; Shen, Y. A Bioinspired Multilegged Soft Millirobot That Functions in Both Dry and Wet Conditions. Nat. Commun. 2018, 9, 3944. [Google Scholar] [CrossRef] [PubMed]

- Farshad, M.; Benine, A. Magnetoactive Elastomer Composites. Polym. Test. 2004, 23, 347–353. [Google Scholar] [CrossRef]

- Puente-Córdova, J.G.; Reyes-Melo, M.E.; Palacios-Pineda, L.M.; Martínez-Perales, I.A.; Martínez-Romero, O.; Elías-Zúñiga, A. Fabrication and Characterization of Isotropic and Anisotropic Magnetorheological Elastomers, Based on Silicone Rubber and Carbonyl Iron Microparticles. Polymers 2018, 10, 1343. [Google Scholar] [CrossRef]

- Sohoni, G.B.; Mark, J.E. Anisotropic Reinforcement in Elastomers Containing Magnetic Filler Particles. J. Appl. Polym. Sci. 1987, 34, 2853–2859. [Google Scholar] [CrossRef]

- Sun, T.L.; Gong, X.L.; Jiang, W.Q.; Li, J.F.; Xu, Z.B.; Li, W.H. Study on the Damping Properties of Magnetorheological Elastomers Based on Cis-Polybutadiene Rubber. Polym. Test. 2008, 27, 520–526. [Google Scholar] [CrossRef]

- Wu, J.; Gong, X.; Fan, Y.; Xia, H. Anisotropic Polyurethane Magnetorheological Elastomer Prepared through in Situ Polycondensation under a Magnetic Field. Smart Mater. Struct. 2010, 19, 105007. [Google Scholar] [CrossRef]

- Kaleta, J.; Królewicz, M.; Lewandowski, D. Magnetomechanical Properties of Anisotropic and Isotropic Magnetorheological Composites with Thermoplastic Elastomer Matrices. Smart Mater. Struct. 2011, 20, 085006. [Google Scholar] [CrossRef]

- Varga, Z.; Filipcsei, G.; Zrínyi, M. Smart Composites with Controlled Anisotropy. Polymer 2005, 46, 7779–7787. [Google Scholar] [CrossRef]

- Hajsz, T.; Csetneki, I.; Filipcsei, G.; Zrinyi, M. Swelling Kinetics of Anisotropic Filler Loaded PDMS Networks. Phys. Chem. Chem. Phys. 2006, 8, 977–984. [Google Scholar] [CrossRef]

- Varga, Z.; Filipcsei, G.; Szilágyi, A.; Zrínyi, M. Electric and Magnetic Field-Structured Smart Composites. Macromol. Symp. 2005, 227, 123–134. [Google Scholar] [CrossRef]

- Ouchi, S.; Mitsumata, T. Magnetorheological Effect of Magnetic Gels Containing Fe2O3. Trans. Mater. Res. Soc. Jpn. 2009, 34, 459–460. [Google Scholar] [CrossRef][Green Version]

- Boczkowska, A.; Awietjan, S.F.; Wroblewski, R. Microstructure-Property Relationships of Urethane Magnetorheological Elastomers. Smart Mater. Struct. 2007, 16, 1924–1930. [Google Scholar] [CrossRef]

- Berasategi, J.; Salazar, D.; Gomez, A.; Gutierrez, J.; Sebastián, M.S.; Bou-Ali, M.; Barandiaran, J.M. Anisotropic Behaviour Analysis of Silicone/Carbonyl Iron Particles Magnetorheological Elastomers. Rheol. Acta 2020, 59, 469–476. [Google Scholar] [CrossRef]

- Chokkalingam, R.; Pandi, R.S.; Mahendran, M. Magnetomechanical Behavior of Fe/PU Magnetorheological Elastomers. J. Compos. Mater. 2011, 45, 1545–1552. [Google Scholar] [CrossRef]

- Coquelle, E.; Bossis, G.; Szabo, D.; Giulieri, F. Micromechanical Analysis of an Elastomer Filled with Particles Organized in Chain-like Structure. J. Mater. Sci. 2006, 41, 5941–5953. [Google Scholar] [CrossRef]

- Mitsumata, T.; Nagata, A.; Sakai, K.; Taniguchi, T. Anisotropy in Storage Modulus of Magnetic Gels Induced by Magnetization. Jpn. J. Appl. Phys. 2004, 43, 8203–8207. [Google Scholar] [CrossRef]

- Komarov, P.V.; Khalatur, P.G.; Khokhlov, A.R. Magnetoresponsive Smart Nanocomposites with Highly Cross-Linked Polymer Matrix. Polym. Adv. Technol. 2021, 32, 3922–3933. [Google Scholar] [CrossRef]

- Romeis, D.; Toshchevikov, V.; Saphiannikova, M. Elongated Micro-Structures in Magneto-Sensitive Elastomers: A Dipolar Mean Field Model. Soft Matter 2016, 12, 9364–9376. [Google Scholar] [CrossRef] [PubMed]

- Kostrov, S.A.; Maw, M.R.; Sheiko, S.S.; Kramarenko, E.Y. Magnetoactive Thermoplastic Elastomers with Bottlebrush Strands: Switching and Programming of Mechanical Properties by a Magnetic Field. ACS Appl. Polym. Mater. 2023, 5, 7458–7466. [Google Scholar] [CrossRef]

- Dashtimoghadam, E.; Maw, M.; Keith, A.N.; Vashahi, F.; Kempkes, V.; Gordievskaya, Y.D.; Kramarenko, E.Y.; Bersenev, E.A.; Nikitina, E.A.; Ivanov, D.A.; et al. Super-Soft, Firm, and Strong Elastomers toward Replication of Tissue Viscoelastic Response. Mater. Horiz. 2022, 9, 3022–3030. [Google Scholar] [CrossRef]

- Chen, L.; Gong, X.L.; Li, W.H. Microstructures and Viscoelastic Properties of Anisotropic Magnetorheological Elastomers. Smart Mater. Struct. 2007, 16, 2645–2650. [Google Scholar] [CrossRef]

- Ivaneyko, D.; Toshchevikov, V.; Saphiannikova, M. Dynamic-Mechanical Behaviour of Anisotropic Magneto-Sensitive Elastomers. Polymer 2018, 147, 95–107. [Google Scholar] [CrossRef]

- Asadi Khanouki, M.; Sedaghati, R.; Hemmatian, M. Experimental Characterization and Microscale Modeling of Isotropic and Anisotropic Magnetorheological Elastomers. Compos. Part B Eng. 2019, 176, 107311. [Google Scholar] [CrossRef]

- Chougale, S.; Romeis, D.; Saphiannikova, M. Magneto-Mechanical Enhancement of Elastic Moduli in Magnetoactive Elastomers with Anisotropic Microstructures. Materials 2022, 15, 645. [Google Scholar] [CrossRef]

- Abramchuk, S.; Kramarenko, E.; Stepanov, G.; Nikitin, L.V.; Filipcsei, G.; Khokhlov, A.R.; Zrínyi, M. Novel Highly Elastic Magnetic Materials for Dampers and Seals: Part I. Preparation and Characterization of the Elastic Materials. Polym. Adv. Technol. 2007, 18, 883–890. [Google Scholar] [CrossRef]

- Dashtimoghadam, E.; Fahimipour, F.; Keith, A.N.; Vashahi, F.; Popryadukhin, P.; Vatankhah-Varnosfaderani, M.; Sheiko, S.S. Injectable Non-Leaching Tissue-Mimetic Bottlebrush Elastomers as an Advanced Platform for Reconstructive Surgery. Nat. Commun. 2021, 12, 3961. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kostrov, S.A.; Marshall, J.H.; Maw, M.; Sheiko, S.S.; Kramarenko, E.Y. Programming and Reprogramming the Viscoelasticity and Magnetic Response of Magnetoactive Thermoplastic Elastomers. Polymers 2023, 15, 4607. https://doi.org/10.3390/polym15234607

Kostrov SA, Marshall JH, Maw M, Sheiko SS, Kramarenko EY. Programming and Reprogramming the Viscoelasticity and Magnetic Response of Magnetoactive Thermoplastic Elastomers. Polymers. 2023; 15(23):4607. https://doi.org/10.3390/polym15234607

Chicago/Turabian StyleKostrov, Sergei A., Josiah H. Marshall, Mitchell Maw, Sergei S. Sheiko, and Elena Yu. Kramarenko. 2023. "Programming and Reprogramming the Viscoelasticity and Magnetic Response of Magnetoactive Thermoplastic Elastomers" Polymers 15, no. 23: 4607. https://doi.org/10.3390/polym15234607

APA StyleKostrov, S. A., Marshall, J. H., Maw, M., Sheiko, S. S., & Kramarenko, E. Y. (2023). Programming and Reprogramming the Viscoelasticity and Magnetic Response of Magnetoactive Thermoplastic Elastomers. Polymers, 15(23), 4607. https://doi.org/10.3390/polym15234607