Does a Compatibilizer Enhance the Properties of Carbon Fiber-Reinforced Composites?

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

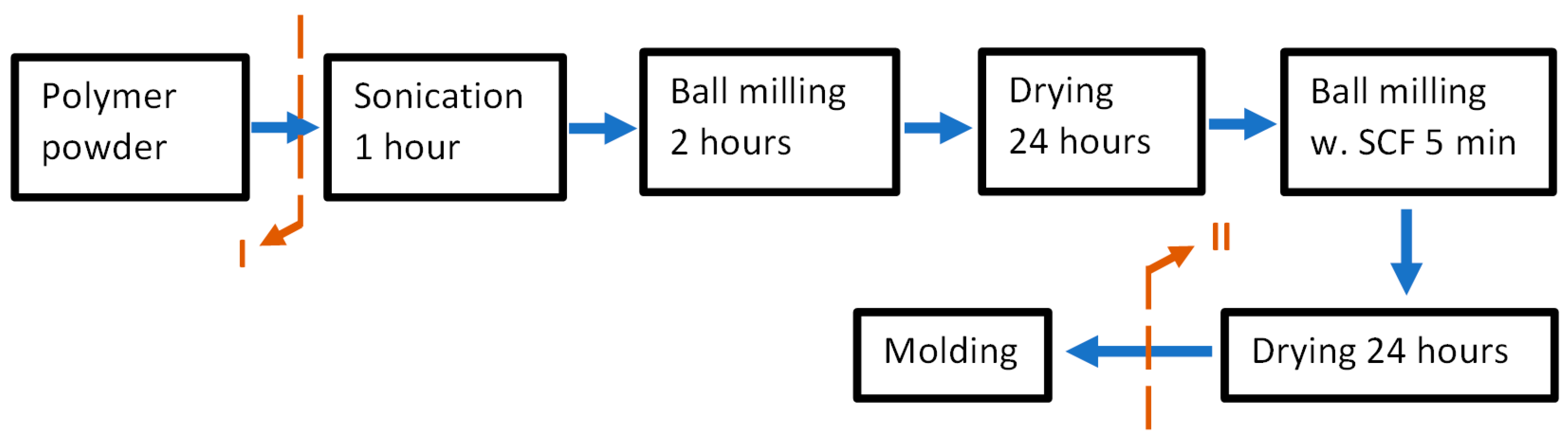

2.2. Manufacturing

2.3. Compositions

2.4. Experimental

- is the enthalpy of fusion determined by measuring the area under the melting peak.

- 100 is the enthalpy of fusion of 100% crystalline polymer.

- is the fraction of polymer (in wt. %) whose crystallinity is measured in the composition.

3. Results

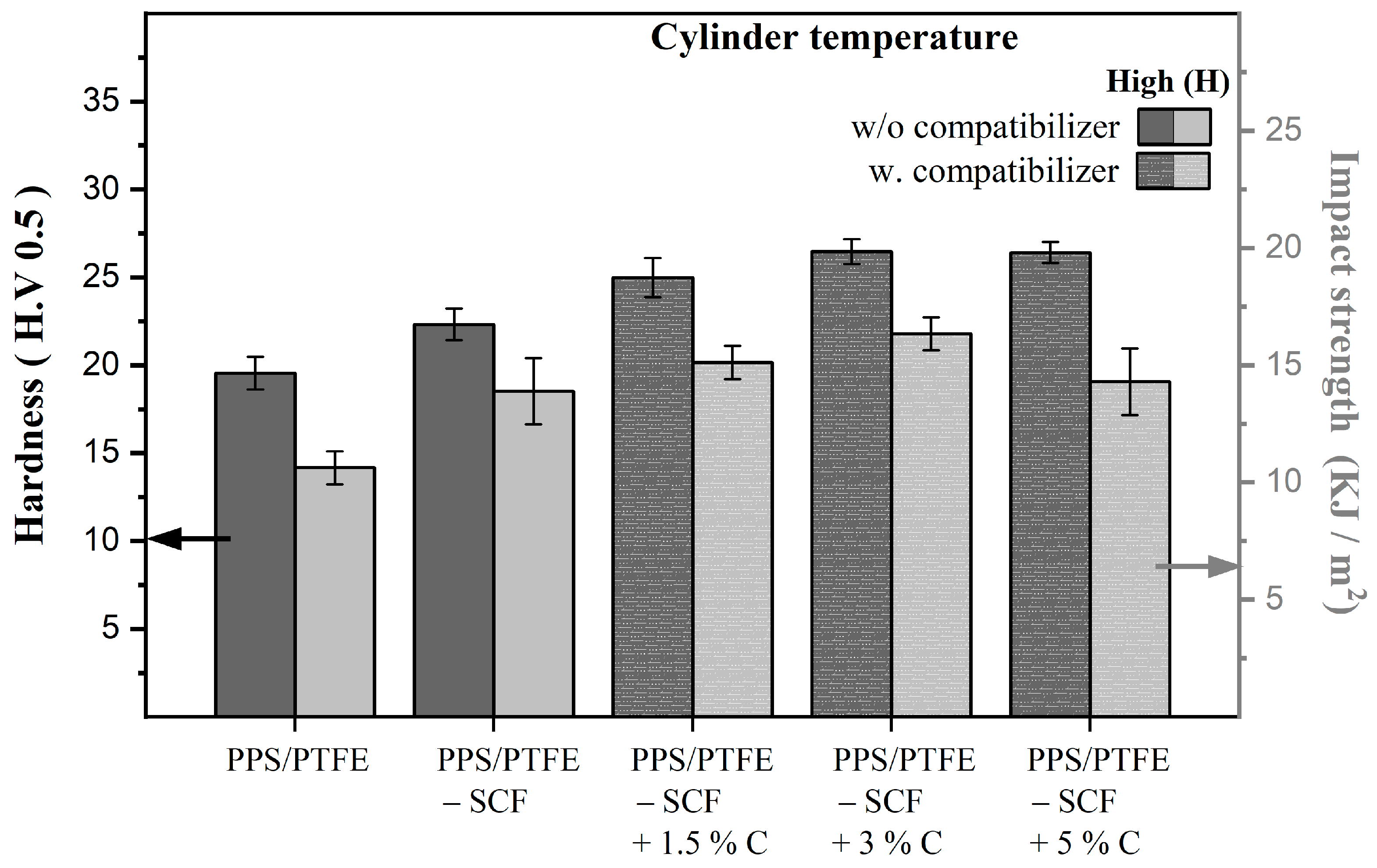

3.1. Mechanical Testing

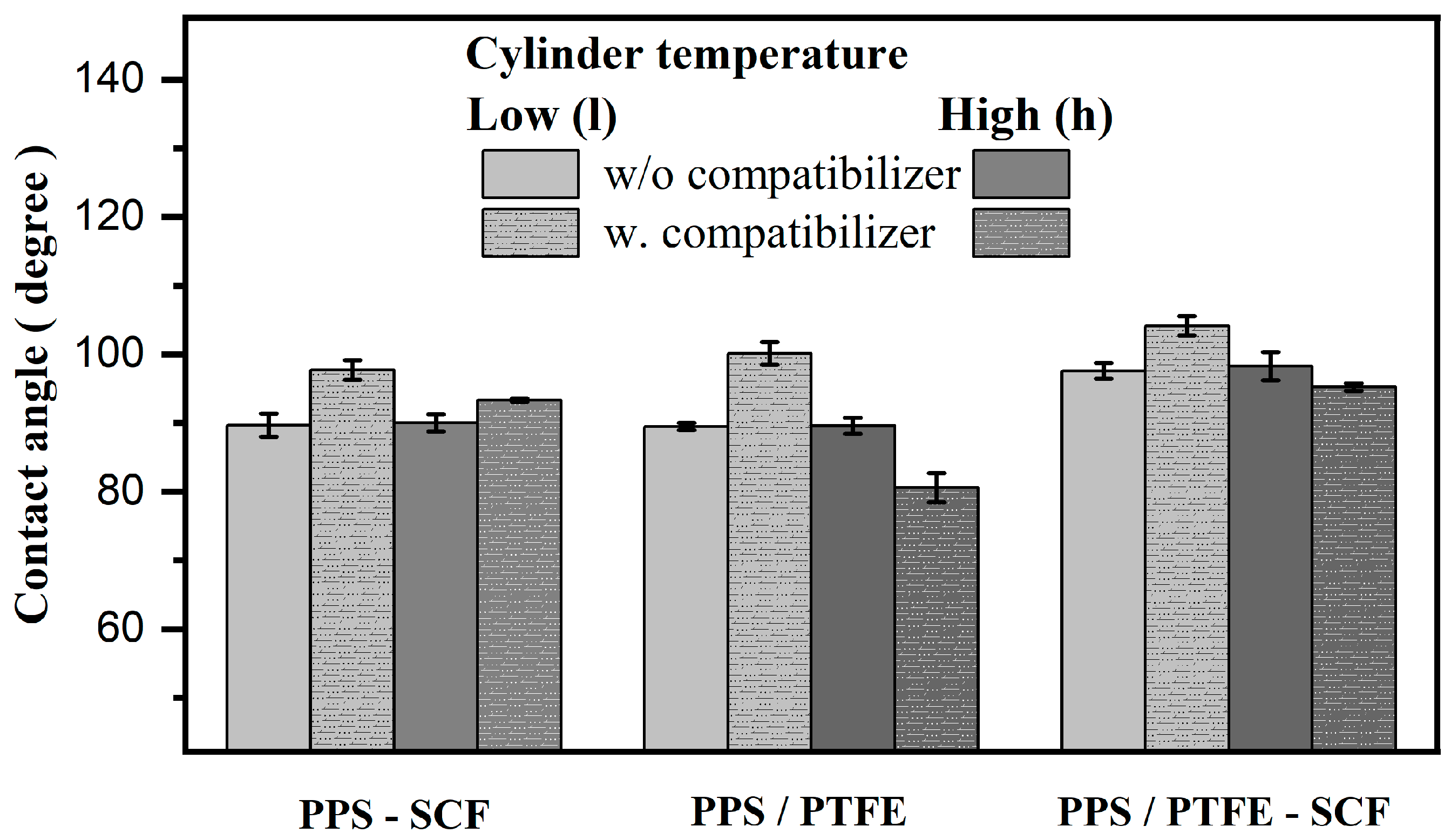

3.2. Wettability

3.3. Thermal Characterization

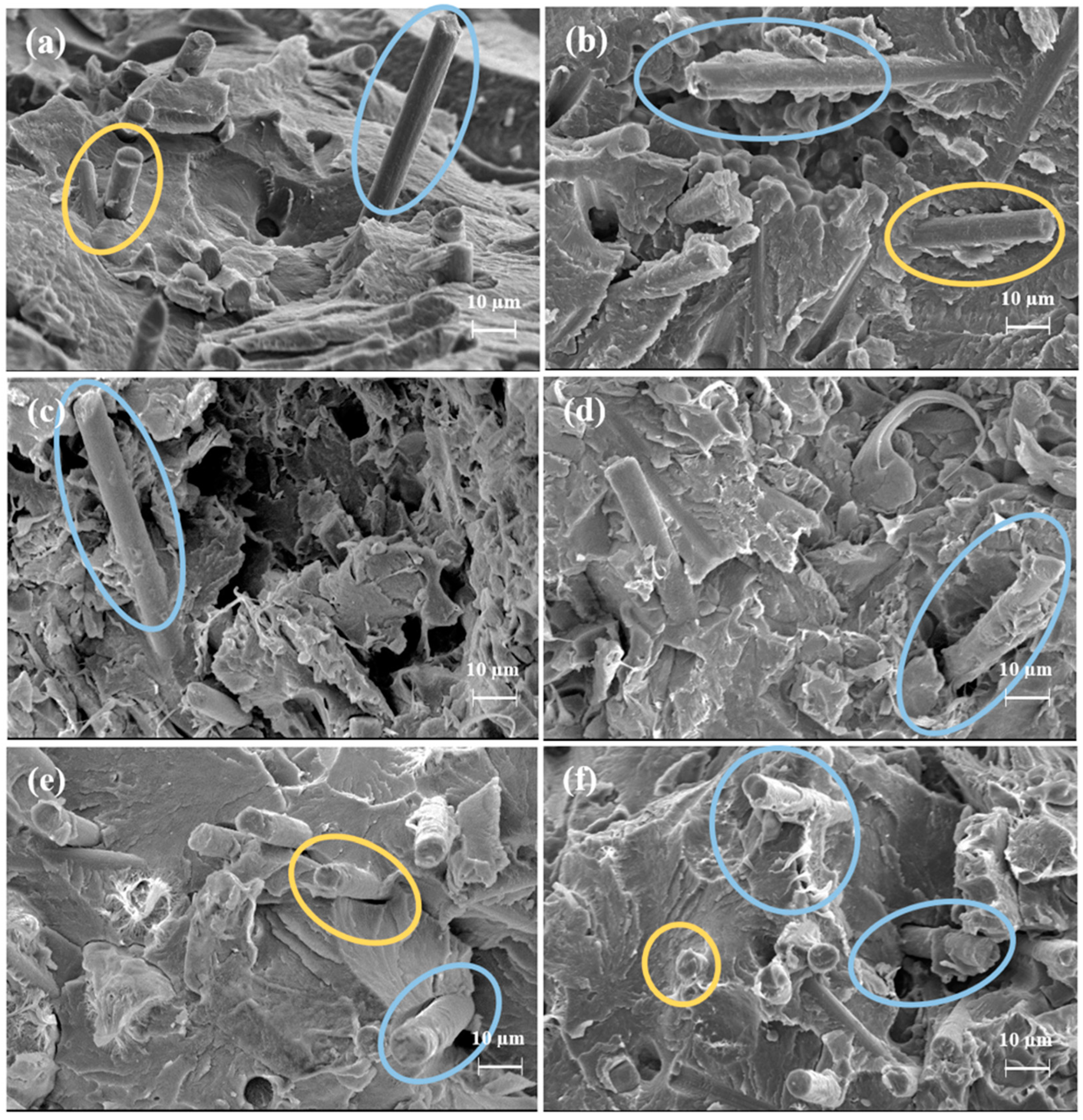

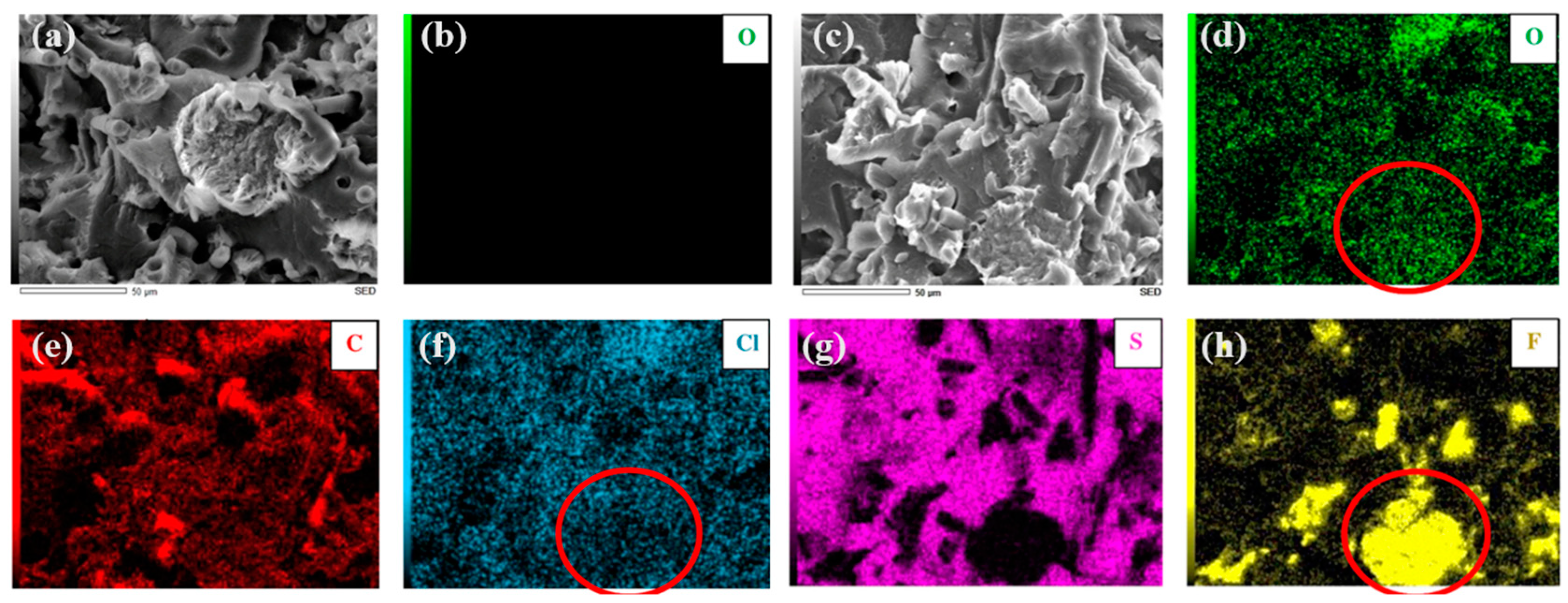

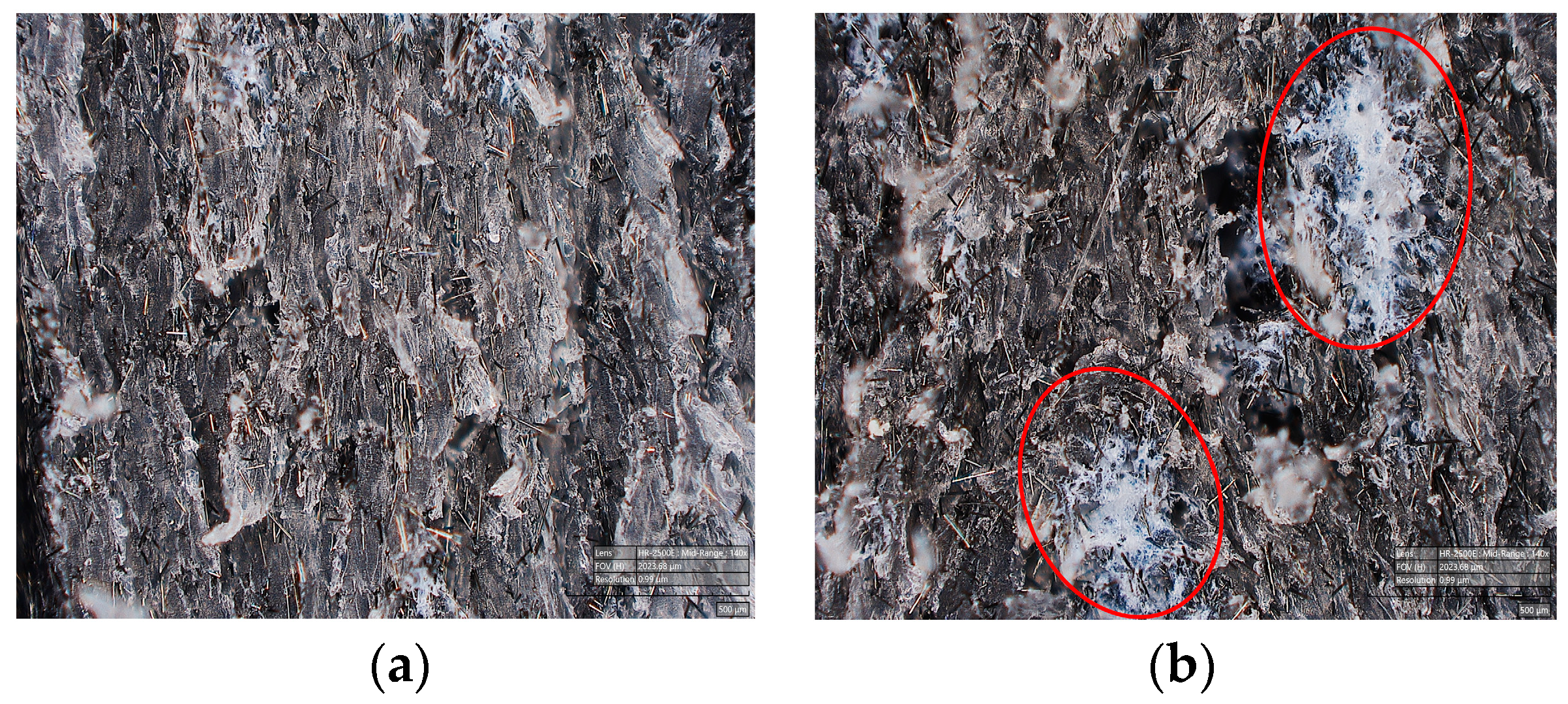

3.4. Scanning Electron Microscopy

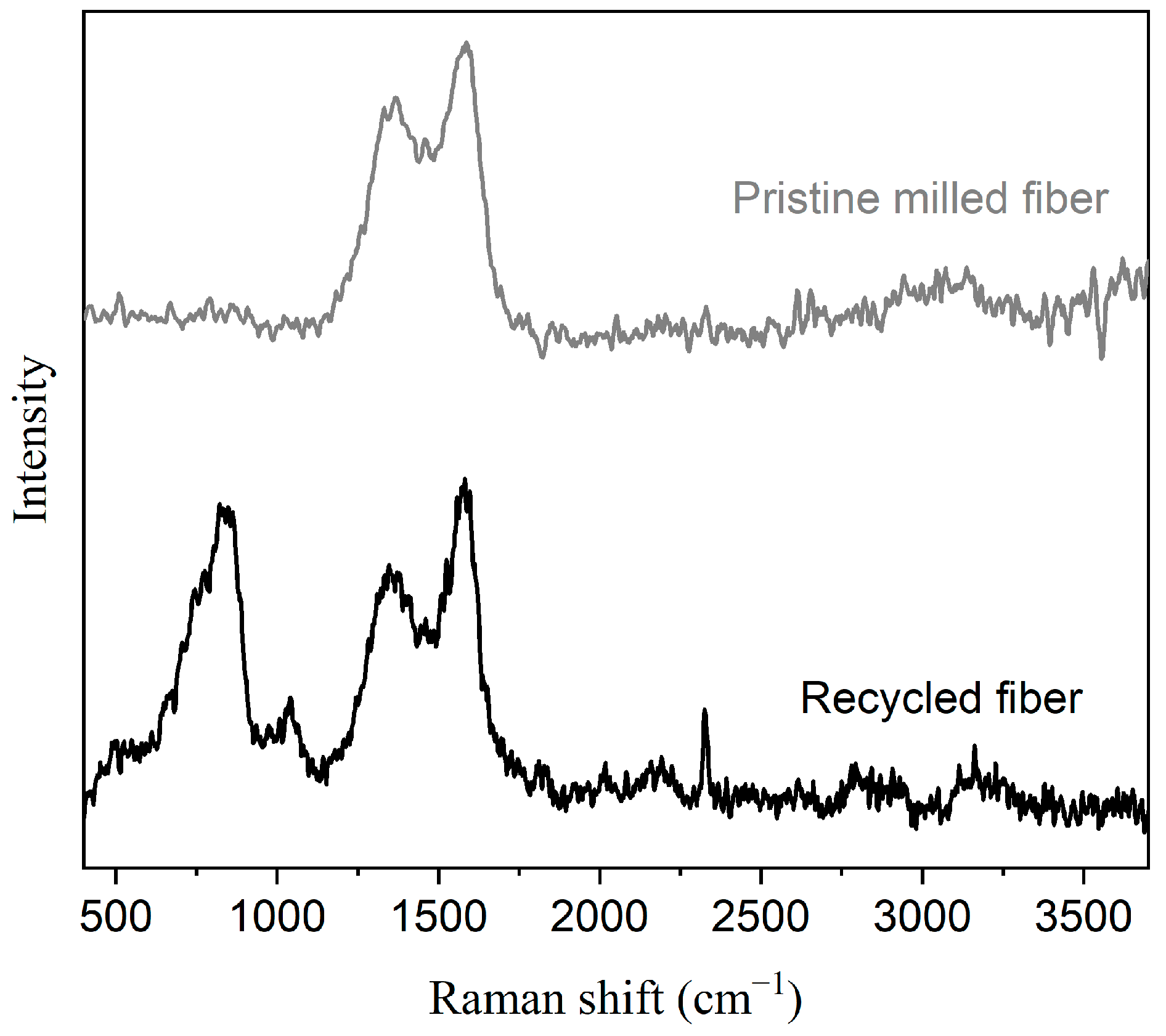

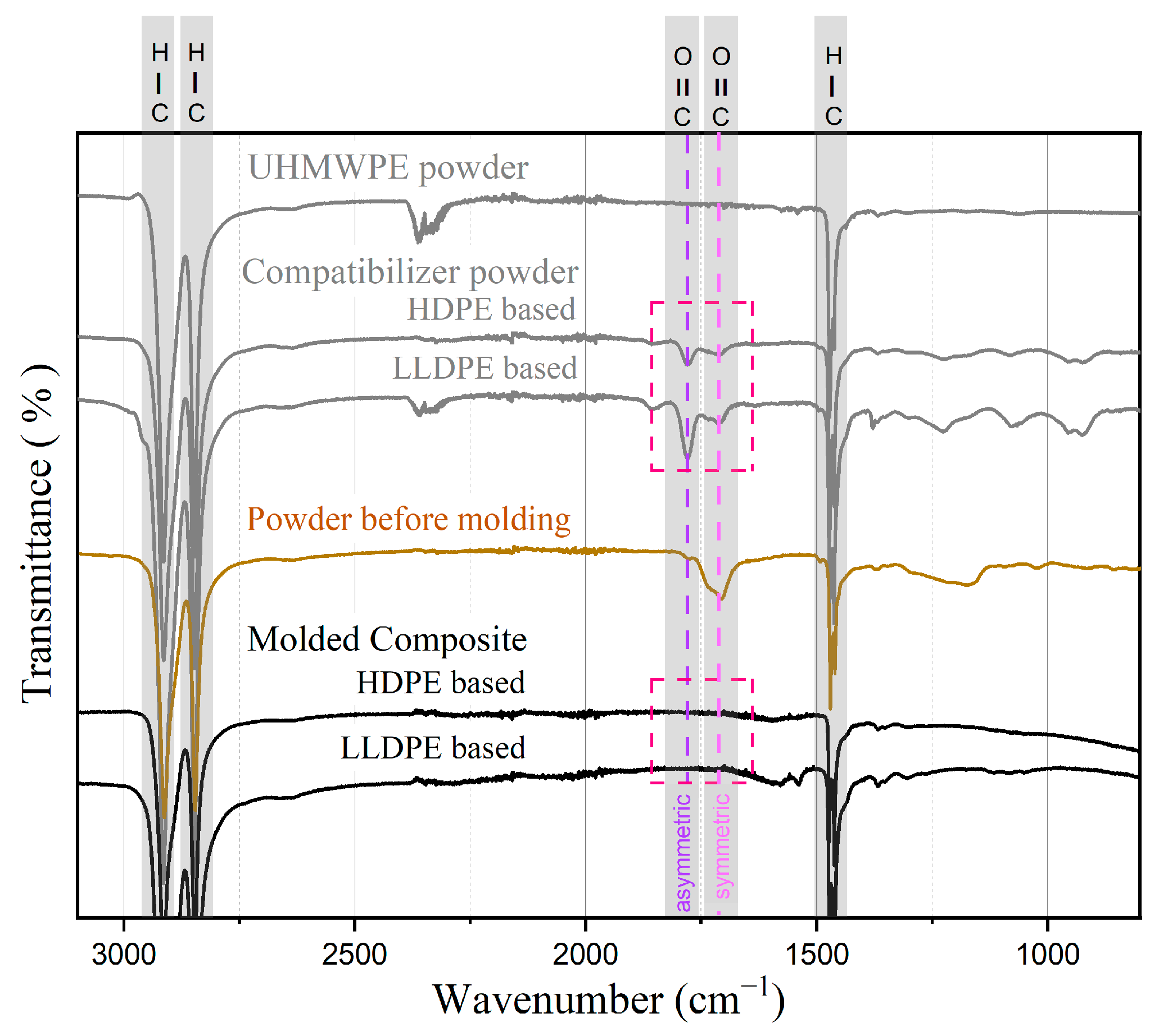

3.5. Fourier-Transform Infrared Spectroscopy

4. Discussion

5. Conclusions

- In the case of PPS-based compositions, compatibilizers proved to be effective primarily in less-complex compositions, like the PPS-PTFE polymer blend or short-carbon-fiber-reinforced PPS, with compatibilizers delivering 10% higher hardness and 20% greater impact strength. For more intricate compositions, such as the short-carbon-fiber-reinforced PPS-PTFE, the improvements were only marginal and failed to justify the use of compatibilizers. Interestingly, neither the high manufacturing temperature nor the concentration of the compatibilizer posed severe problems. Instead, the limitation appeared to be the availability of the polymer to react, which hindered the effectiveness of the compatibilizers.

- In the UHMWPE compositions, the compatibilizers either had no effect or, in some cases, had a detrimental impact on the properties. This was attributed to their incompatibility with certain elements of the manufacturing method and their inability to consistently integrate into the material.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gopanna, A.; Rajan, K.P.; Thomas, S.P.; Chavali, M. Polyethylene and polypropylene matrix composites for biomedical applications. In Materials for Biomedical Engineering: Thermoset and Thermoplastic Polymers; Elsevier: Amsterdam, The Netherlands, 2019; pp. 175–216. [Google Scholar] [CrossRef]

- Sahoo, B.P.; Tripathy, D.K. Properties and Applications of Polymer Nanocomposites: Clay and Carbon Based Polymer Nanocomposites; Springer: Berlin/Heidelberg, Germany, 2017; pp. 1–222. Available online: https://link.springer.com/book/10.1007/978-3-662-53517-2 (accessed on 15 October 2023).

- Njuguna, J.; Pielichowski, K.; Fan, J. Polymer nanocomposites for aerospace applications. In Advances in Polymer Nanocomposites: Types and Applications; Elsevier: Amsterdam, The Netherlands, 2012; pp. 472–539. [Google Scholar] [CrossRef]

- Friedrich, K. Polymer composites for tribological applications. Adv. Ind. Eng. Polym. Res. 2018, 1, 3–39. [Google Scholar] [CrossRef]

- Wypych, G. Fillers in Commercial Polymers. In Handbook of Fillers; Elsevier: Amsterdam, The Netherlands, 2021; pp. 787–932. [Google Scholar] [CrossRef]

- Jain, A.; Somberg, J.; Emami, N. Development and characterization of multi-scale carbon reinforced PPS composites for tribological applications. Lubricants 2019, 7, 34. [Google Scholar] [CrossRef]

- Somberg, J.; Saravanan, P.; Vadivel, H.S.; Berglund, K.; Shi, Y.; Ukonsaari, J.; Emami, N. Tribological characterisation of polymer composites for hydropower bearings: Experimentally developed versus commercial materials. Tribol. Int. 2021, 162, 107101. [Google Scholar] [CrossRef]

- Peng, Q.; Li, Y.; He, X.; Lv, H.; Hu, P.; Shang, Y.; Wang, C.; Wang, R.; Sritharan, T.; Du, S. Interfacial enhancement of carbon fiber composites by poly(amido amine) functionalization. Compos. Sci. Technol. 2013, 74, 37–42. [Google Scholar] [CrossRef]

- Anagreh, N.; Dorn, L.; Bilke-Krause, C. Low-pressure plasma pretreatment of polyphenylene sulfide (PPS) surfaces for adhesive bonding. Int. J. Adhes. Adhes. 2008, 28, 16–22. [Google Scholar] [CrossRef]

- Yang, X.; Wang, H.; Chen, J.; Fu, Z.; Zhao, X.; Li, Y. Copolymers containing two types of reactive groups: New compatibilizer for immiscible PLLA/PA11 polymer blends. Polymer 2019, 177, 139–148. [Google Scholar] [CrossRef]

- Karsli, N.G.; Aytac, A. Effects of maleated polypropylene on the morphology, thermal and mechanical properties of short carbon fiber reinforced polypropylene composites. Mater. Des. 2011, 32, 4069–4073. [Google Scholar] [CrossRef]

- Durmaz, B.U.; Aytac, A. Characterization of carbon fiber-reinforced poly(phenylene sulfide) composites prepared with various compatibilizers. J. Compos. Mater. 2020, 54, 89–100. [Google Scholar] [CrossRef]

- Hu, L.; Vuillaume, P.Y. Reactive compatibilization of polymer blends by coupling agents and interchange catalysts. In Compatibilization of Polymer Blends: Micro and Nano Scale Phase Morphologies, Interphase Characterization and Properties; Elsevier: Amsterdam, The Netherlands, 2020; pp. 205–248. [Google Scholar] [CrossRef]

- Thomas, S.; Ajitha, A.R. Compatibilization of Polymer Blends: Micro and Nano Scale Phase Morphologies, Interphase Characterization, and Properties; Elsevier: Amsterdam, The Netherlands, 2019. [Google Scholar]

- Srithep, Y.; Pholharn, D.; Dassakorn, A.; Morris, J. Effect of chain extenders on mechanical and thermal properties of recycled poly (ethylene terephthalate) and polycarbonate blends. IOP Conf. Ser. Mater. Sci. Eng. 2017, 213, 012008. [Google Scholar] [CrossRef]

- Chen, R.S.; Ab Ghani, M.H.; Salleh, M.N.; Ahmad, S.; Gan, S. Influence of Blend Composition and Compatibilizer on Mechanical and Morphological Properties of Recycled HDPE/PET Blends. Mater. Sci. Appl. 2014, 5, 943–952. [Google Scholar] [CrossRef]

- Savas, L.A.; Tayfun, U.; Dogan, M. The use of polyethylene copolymers as compatibilizers in carbon fiber reinforced high density polyethylene composites. Compos. Part B Eng. 2016, 99, 188–195. [Google Scholar] [CrossRef]

- Zhang, K.; Zhang, G.; Liu, B.; Wang, X.; Long, S.; Yang, J. Effect of aminated polyphenylene sulfide on the mechanical properties of short carbon fiber reinforced polyphenylene sulfide composites. Compos. Sci. Technol. 2014, 98, 57–63. [Google Scholar] [CrossRef]

- Anjali, S.; Aishwaryalakshmi, S.; Ashwin, V.; Neeraja, S.; Rasana, N.; Jayanarayanan, K. Effect of Compatibilizer and Carbon Nanotubes on Blends of Polypropylene and Nylon 6. Mater. Today Proc. 2018, 5, 25524–25533. [Google Scholar] [CrossRef]

- Seo, H.Y.; Cho, K.Y.; Im, D.; Kwon, Y.J.; Shon, M.; Baek, K.Y.; Yoon, H.G. High mechanical properties of covalently functionalized carbon fiber and polypropylene composites by enhanced interfacial adhesion derived from rationally designed polymer compatibilizers. Compos. Part B Eng. 2022, 228, 109439. [Google Scholar] [CrossRef]

- Hari, B.S.; Mahesh Kumar, M.K.; Krishnamurthy, K.; Gobinath, V.K.; Sachinbala, R.; Rajasekar, R. Influence of graphene oxide on the morphological and mechanical behaviour of compatibilized low density polyethylene nanocomposites. Mater. Today Proc. 2021, 39, 1487–1493. [Google Scholar]

- Ventura, A.M.; Kneissl, L.M.; Nunes, S.; Emami, N. Recycled carbon fibers as an alternative reinforcement in UHMWPE composite. Circular economy within polymer tribology. Sustain. Mater. Technol. 2022, 34, e00510. [Google Scholar] [CrossRef]

- Somberg, J.; Jain, A.; Lagrama, K.R.; Emami, N. High Performance PPS Composites for Tribological Applications. In Proceedings of the International Tribological Conference, Sendai, Japan, 17–21 September 2019. [Google Scholar]

- Golchin, A.; Friedrich, K.; Noll, A.; Prakash, B. Tribological behavior of carbon-filled PPS composites in water lubricated contacts. Wear 2015, 328–329, 456–463. [Google Scholar] [CrossRef]

- Enqvist, E.; Emami, N. Nanodiamond reinforced ultra high molecular weight polyethylene for orthopaedic applications: Dry versus wet ball milling manufacturing methods. Tribol.-Mater. Surf. Interfaces 2014, 8, 7–13. [Google Scholar] [CrossRef]

- Enqvist, E.; Ramanenka, D.; Marques, P.A.A.P.; Gracio, J.; Emami, N. The effect of ball milling time and rotational speed on ultra high molecular weight polyethylene reinforced with multiwalled carbon nanotubes. Polym. Compos. 2016, 37, 1128–1136. [Google Scholar] [CrossRef]

- Cheng, B.; Duan, H.; Chen, S.; Shang, H.; Li, J.; Shao, T. Effects of thermal aging on the blend phase morphology and tribological performance of PI/UHMWPE blend composites. Wear 2021, 477, 203840. [Google Scholar] [CrossRef]

- EN ISO 179-1; Plastics—Determination of Charpy Impact Properties—Part 1: Non-Instrumented Impact Test. International Organization for Standardization: Geneva, Switzerland, 2010.

- Luo, W.; Liu, Q.; Li, Y.; Zhou, S.; Zou, H.; Liang, M. Enhanced mechanical and tribological properties in polyphenylene sulfide/polytetrafluoroethylene composites reinforced by short carbon fiber. Compos. Part B Eng. 2016, 91, 579–588. [Google Scholar] [CrossRef]

- Zuo, P.; Tcharkhtchi, A.; Shirinbayan, M.; Fitoussi, J.; Bakir, F. Overall Investigation of Poly (Phenylene Sulfide) from Synthesis and Process to Applications—A Review. Macromol. Mater. Eng. 2019, 304, 1800686. [Google Scholar] [CrossRef]

- Casimero, C.; Hegarty, C.; McGlynn, R.J.; Davis, J. Ultrasonic exfoliation of carbon fiber: Electroanalytical perspectives. J. Appl. Electrochem. 2020, 50, 383–394. [Google Scholar] [CrossRef]

- Wypych, G. Handbook of Polymers, 2nd ed.; Elsevier Inc.: Amsterdam, The Netherlands, 2016. [Google Scholar] [CrossRef]

- Gui, H.; Zhou, T.; Li, L.; Zhou, T.; Liu, F.; Zhan, Y.; Zhang, A. Structure, properties, and mechanism of reactive compatibilization of epoxy to polyphenylene sulfide/polyamide elastomer. J. Appl. Polym. Sci. 2013, 130, 3411–3420. [Google Scholar] [CrossRef]

- Standau, T.; Nofar, M.; Dörr, D.; Ruckdäschel, H.; Altstädt, V. A Review on Multifunctional Epoxy-Based Joncryl® ADR Chain Extended Thermoplastics. Polym. Rev. 2021, 62, 296–350. [Google Scholar] [CrossRef]

- Murmu, U.K.; Adhikari, J.; Naskar, A.; Dey, D.; Roy, A.; Ghosh, A.; Ghosh, M. Mechanical Properties of Crystalline and Semicrystalline Polymer Systems. In Encyclopedia of Materials: Plastics and Polymers; Elsevier: Amsterdam, The Netherlands, 2022; pp. 917–927. [Google Scholar] [CrossRef]

- Chen, X.; Hou, G.; Chen, Y.; Yang, K.; Dong, Y.; Zhou, H. Effect of molecular weight on crystallization, melting behavior and morphology of poly(trimethylene terephalate). Polym. Test. 2007, 26, 144–153. [Google Scholar] [CrossRef]

- Saleh, T.A. Polymer science and polymerization methods toward hybrid materials. In Polymer Hybrid Materials and Nano-Composites; Elsevier: Amsterdam, The Netherlands, 2021; pp. 59–103. [Google Scholar] [CrossRef]

- Mandelkern, L. The crystallization of flexible polymer molecules. Chem. Rev. 1956, 56, 903–958. [Google Scholar] [CrossRef]

- Greene, J.P. Microstructures of Polymers. In Automotive Plastics and Composites; Elsevier: Amsterdam, The Netherlands, 2021; pp. 27–37. [Google Scholar] [CrossRef]

- Bessell, T.J.; Hull, D.; Shortall, J.B. The effect of polymerization conditions and crystallinity on the mechanical properties and fracture of spherulitic nylon 6. J. Mater. Sci. 1975, 10, 1127–1136. [Google Scholar] [CrossRef]

- Odrobina, M.; Deák, T.; Székely, L.; Mankovits, T.; Keresztes, R.Z.; Kalácska, G. The Effect of Crystallinity on the Toughness of Cast Polyamide 6 Rods with Different Diameters. Polymers 2020, 12, 293. [Google Scholar] [CrossRef]

- Socrates, G. Infrared and Raman Characteristic Group Frequencies. Tables and Charts; John Wiley & Sons: Hoboken, NJ, USA, 2001; p. 347. [Google Scholar] [CrossRef]

- Baker, B.B.; Kasprzak, D.J. Thermal degradation of commercial fluoropolymers in air. Polym. Degrad. Stab. 1993, 42, 181–188. [Google Scholar] [CrossRef]

- Conesa, J.A.; Font, R. Polytetrafluoroethylene decomposition in air and nitrogen. Polym. Eng. Sci. 2001, 41, 2137–2147. [Google Scholar] [CrossRef]

- Kim, H.-I.; Han, W.; Choi, W.-K.; Park, S.-J.; An, K.-H.; Kim, B.-J. Effects of maleic anhydride content on mechanical properties of carbon fibers-reinforced maleic anhydride-grafted-poly-propylene matrix composites. Carbon Lett. 2016, 20, 39–46. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| Pressure | |

| Pressing | 500 bar |

| Post pressing | 300 bar |

| Temperature | |

| Cylinder | 315 or 375 °C |

| Mold | 200 °C |

| Time | |

| Injection | 45 s |

| Hold | 15 s |

| Matrix | Additives |

|---|---|

| PPS-SCF | - |

| +1.5% Epoxy comp. | |

| PPS/PTFE | - |

| +1.5% Epoxy comp. | |

| PPS/PTFE-SCF | - |

| +1.5% Epoxy comp. | |

| +3% Epoxy comp. | |

| +5% Epoxy comp. | |

| UHMWPE | - |

| +3% HDPE or LLDPE comp. | |

| UHMWPE-SCF | - |

| +3% HDPE or LLDPE comp. |

| Property | PPS/PTFE-SCF at 315 °C | PPS/PTFE-SCF at 375 °C | ||

|---|---|---|---|---|

| No Comp. | 1.5 wt.% Comp. | No Comp. | 1.5 wt.% Comp. | |

| PPS | ||||

| 1st heating | ||||

| Tm (°C) | 283 | 282 | 285 | 282 |

| Crystallinity (%) | 61.8 | 51.8 | 59.5 | 53.2 |

| 2nd heating | ||||

| Tm (°C) | 280 | 277 | 279 | 277 |

| Crystallinity (%) | 54.8 | 48.1 | 53.4 | 47.5 |

| PTFE | ||||

| 1st heating | ||||

| Tm (°C) | 327 | 327 | 326 | 326 |

| Crystallinity (%) | 75.2 | 79.1 | 70.3 | 72.9 |

| 2nd heating | ||||

| Tm (°C) | 328 | 327 | 328 | 327 |

| Crystallinity (%) | 71.1 | 75.2 | 72.0 | 76.9 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gangwani, P.; Kalin, M.; Emami, N. Does a Compatibilizer Enhance the Properties of Carbon Fiber-Reinforced Composites? Polymers 2023, 15, 4608. https://doi.org/10.3390/polym15234608

Gangwani P, Kalin M, Emami N. Does a Compatibilizer Enhance the Properties of Carbon Fiber-Reinforced Composites? Polymers. 2023; 15(23):4608. https://doi.org/10.3390/polym15234608

Chicago/Turabian StyleGangwani, Prashant, Mitjan Kalin, and Nazanin Emami. 2023. "Does a Compatibilizer Enhance the Properties of Carbon Fiber-Reinforced Composites?" Polymers 15, no. 23: 4608. https://doi.org/10.3390/polym15234608

APA StyleGangwani, P., Kalin, M., & Emami, N. (2023). Does a Compatibilizer Enhance the Properties of Carbon Fiber-Reinforced Composites? Polymers, 15(23), 4608. https://doi.org/10.3390/polym15234608