The Behavior of Glass Fiber Composites under Low Velocity Impacts

Abstract

:1. Introduction

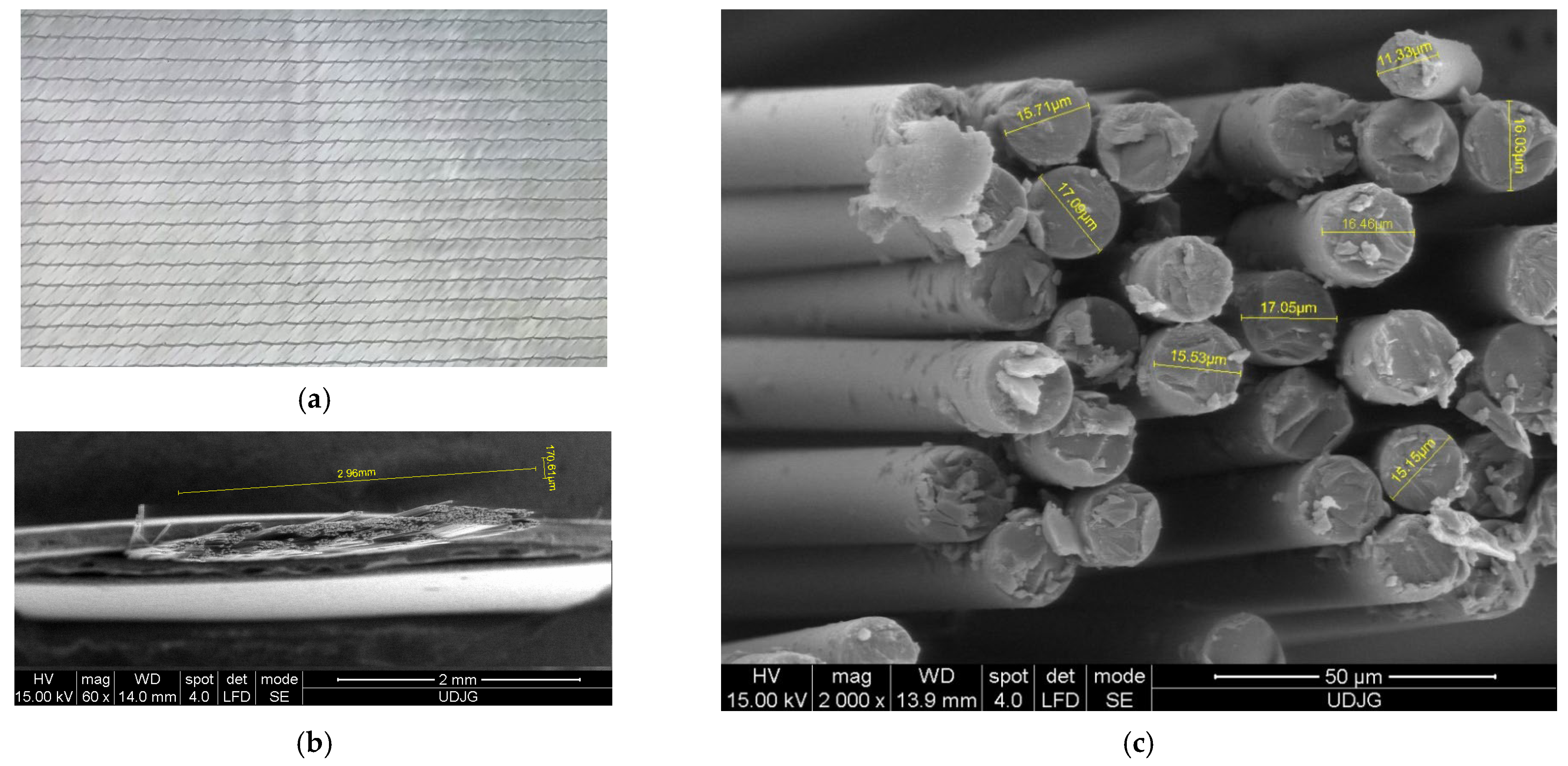

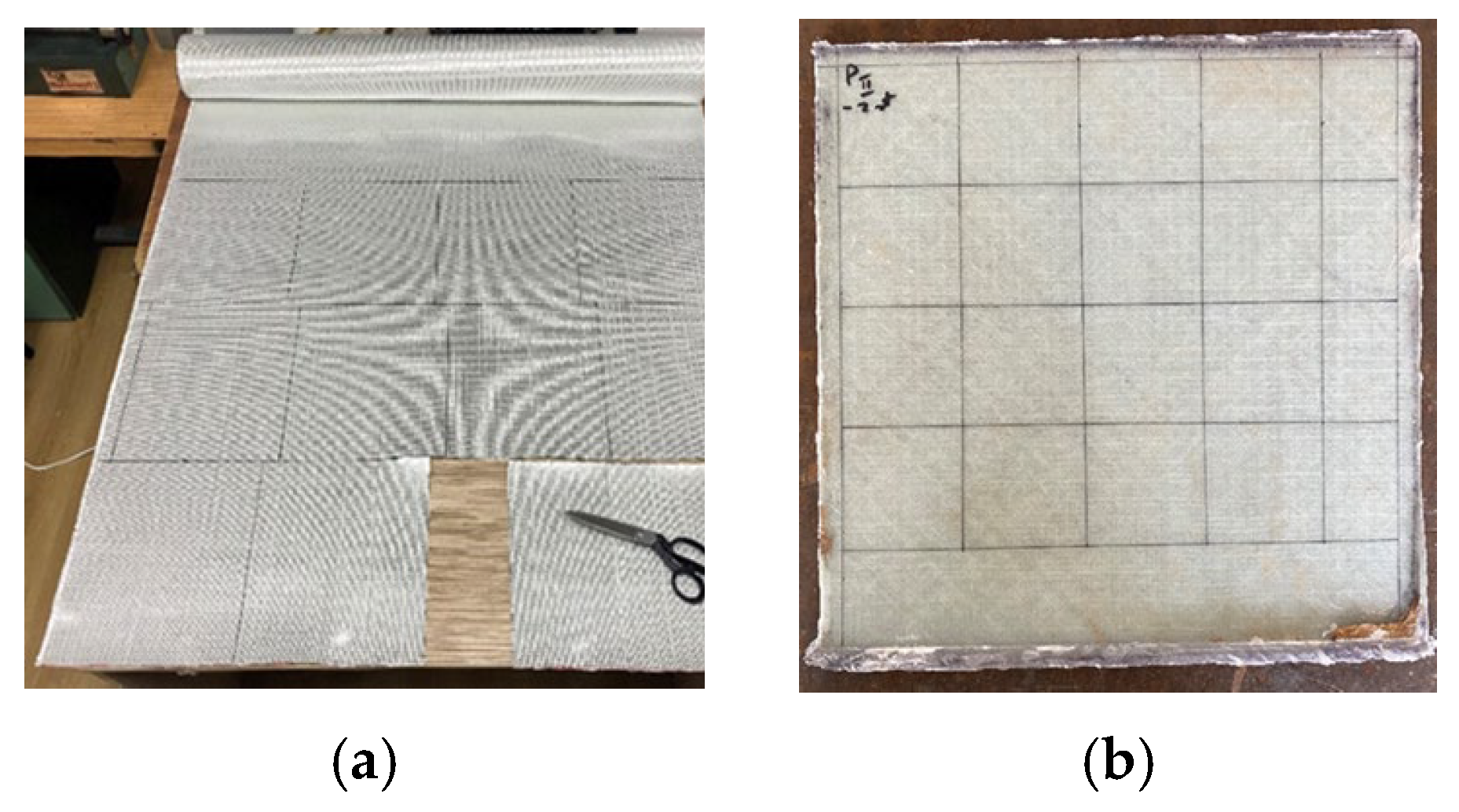

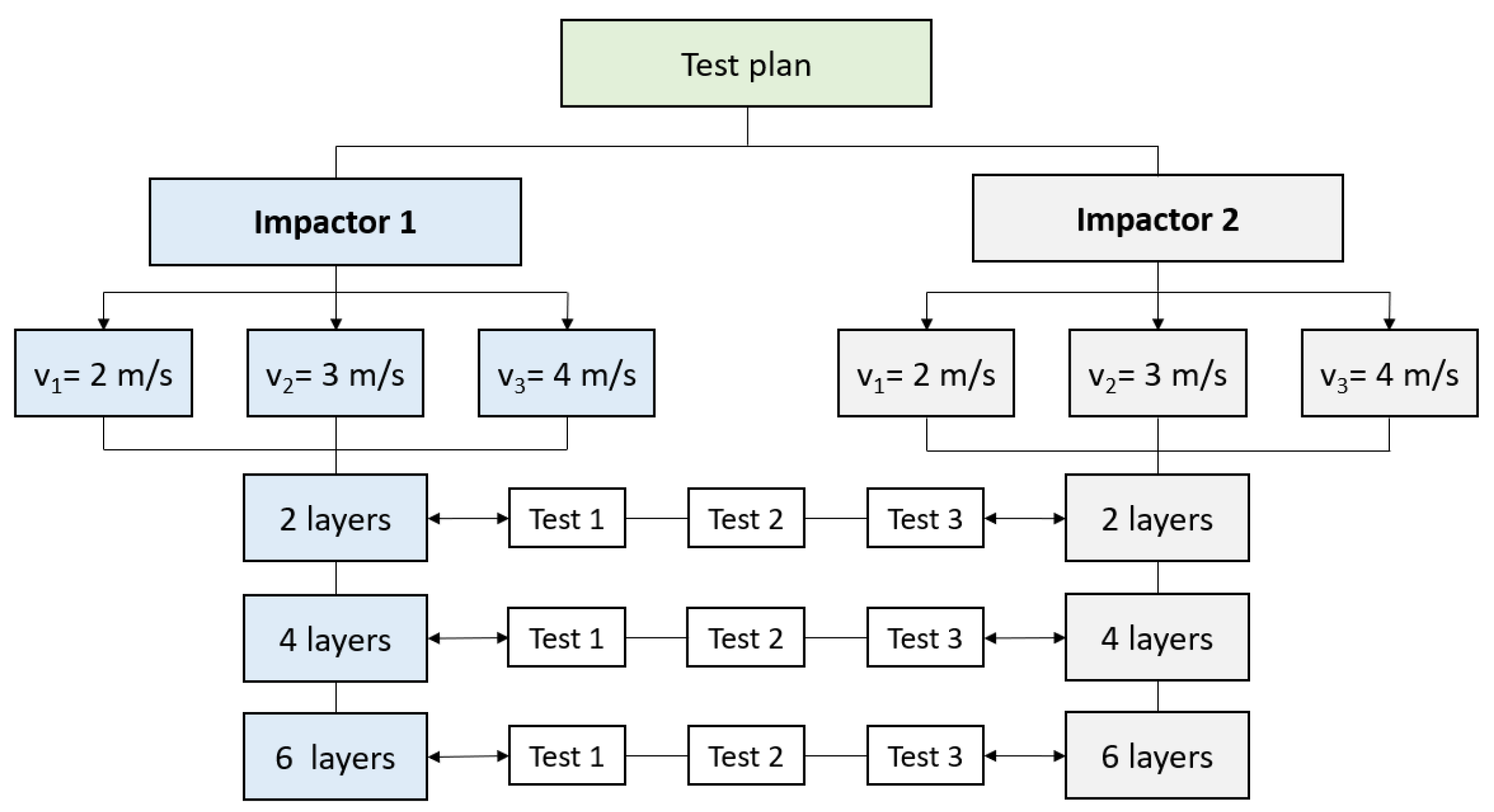

2. Materials and Methods

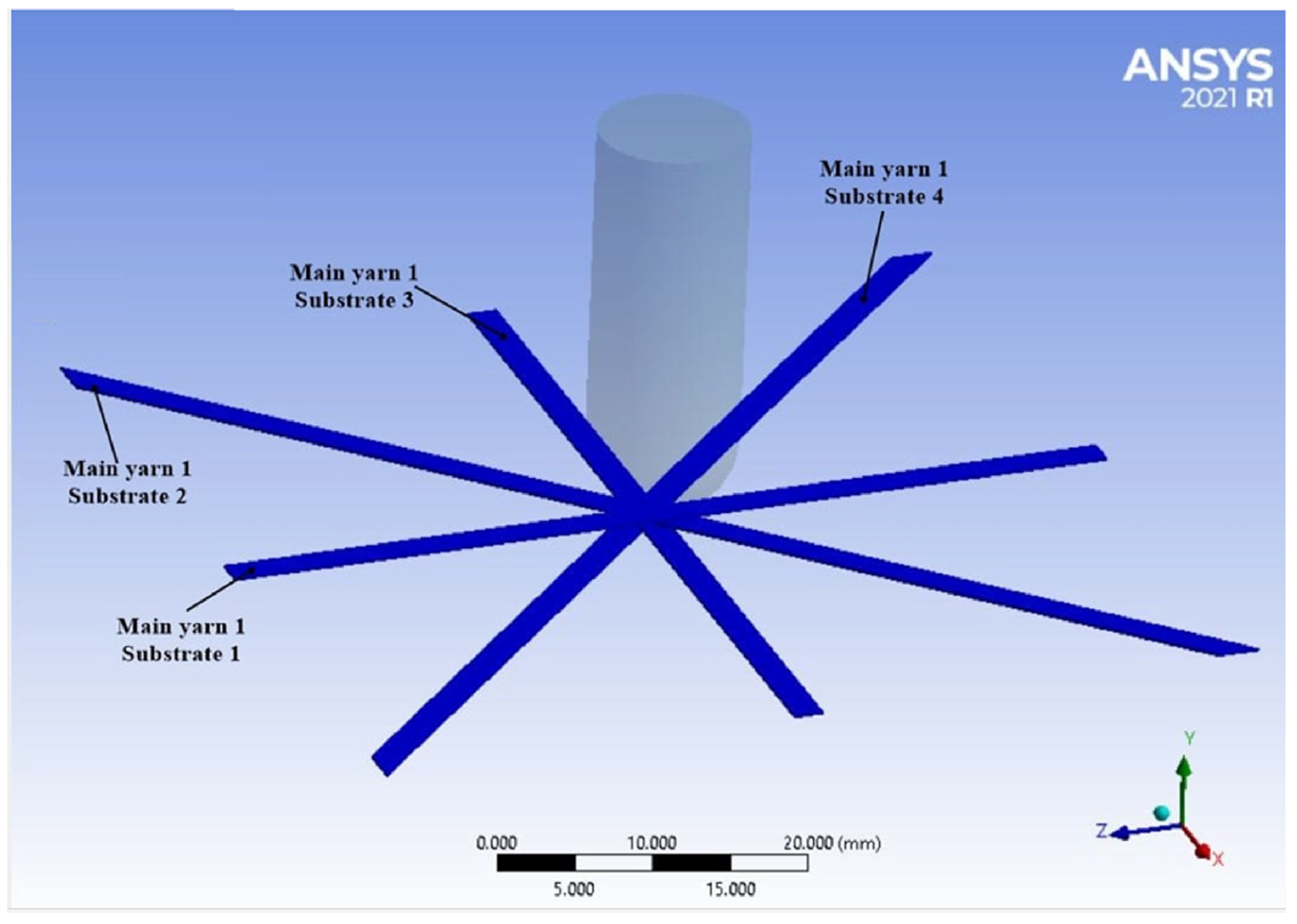

3. Finite Element Model and Results of the Simulation

- -

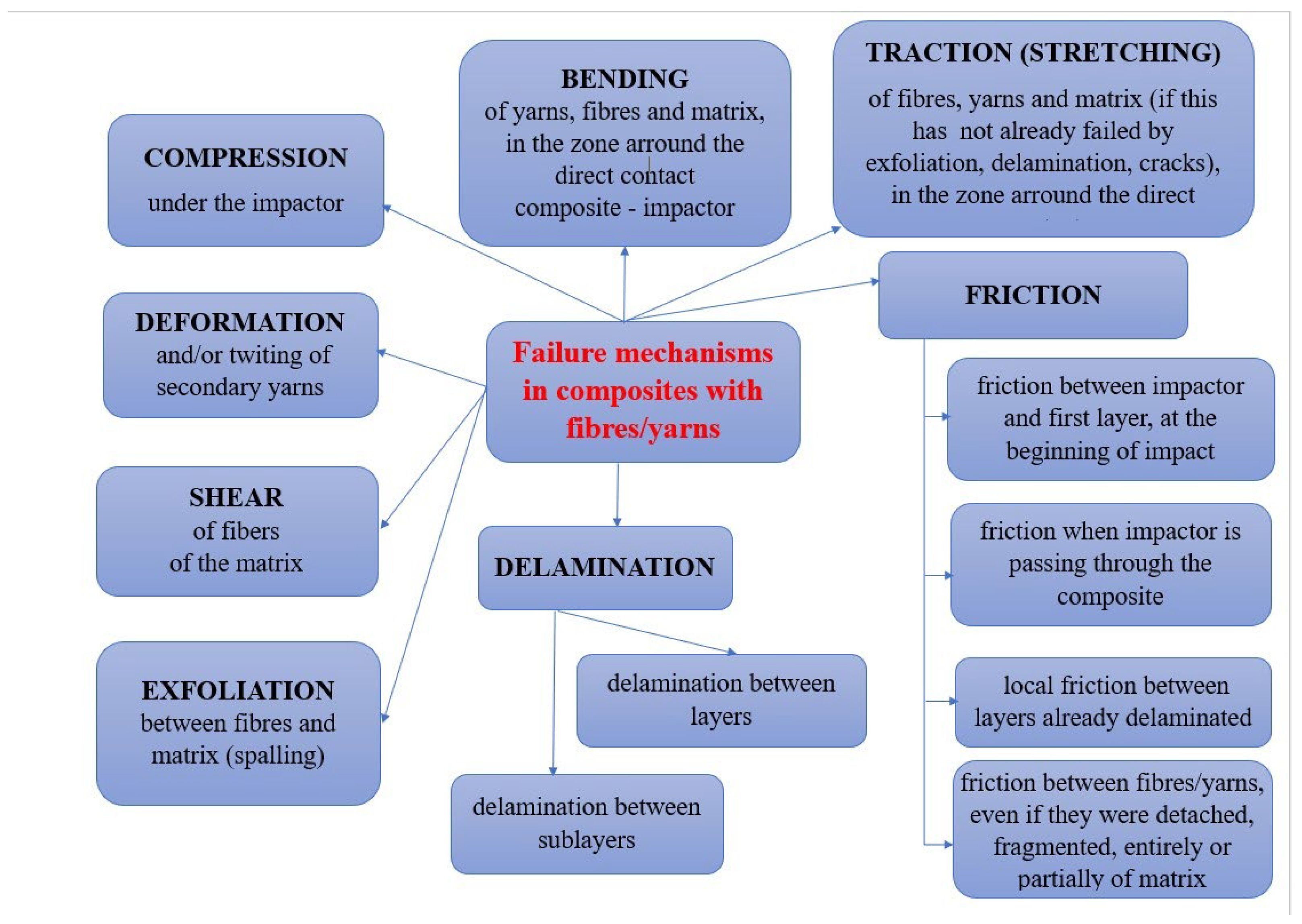

- the failure criterion, which describes the breaking, detachment and cracking when the critical value of a material characteristic (for instance, for stress or strain) is exceeded;

- -

- the stress/strain evolution model for each material used for the solid bodies, which could include a particular behavior (elastic, plastic, viscous or combined) of the materials.

- -

- quantitative: here, the number of broken layers, size of the indentation or orifice for total penetration, impactor displacement over time and size of the delamination (or detachment of layers and sublayers), observable on the simulation by virtually sectioning the model,

- -

- qualitative: including the geometric shape of the indentation or orifice produced by the impactor, and the shape of the delamination.

- -

- sublayers 0° and 90° have 30 yarns on each layer;

- -

- sublayers +45° and −45° have 36 yarns on each layer.

- -

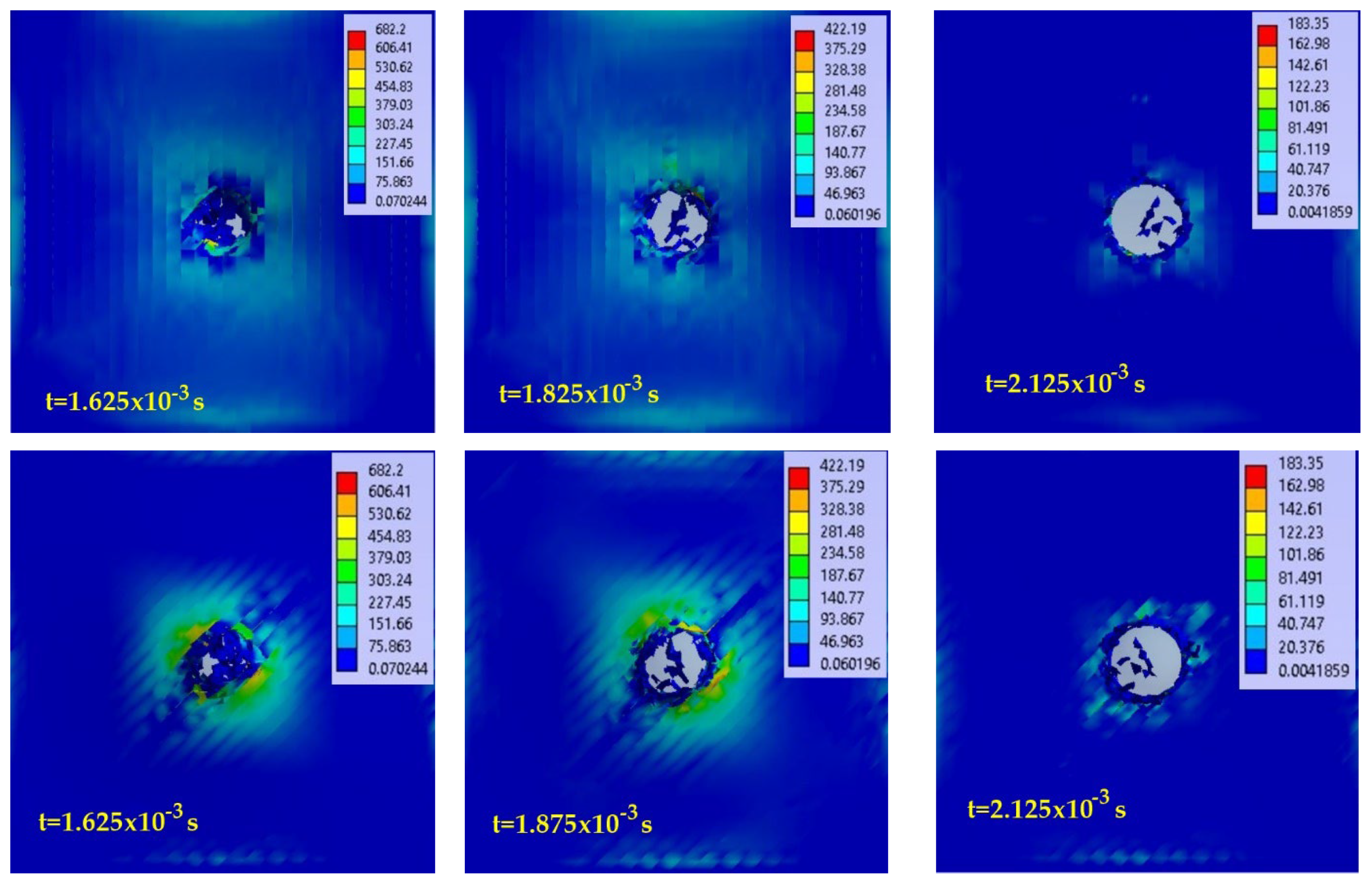

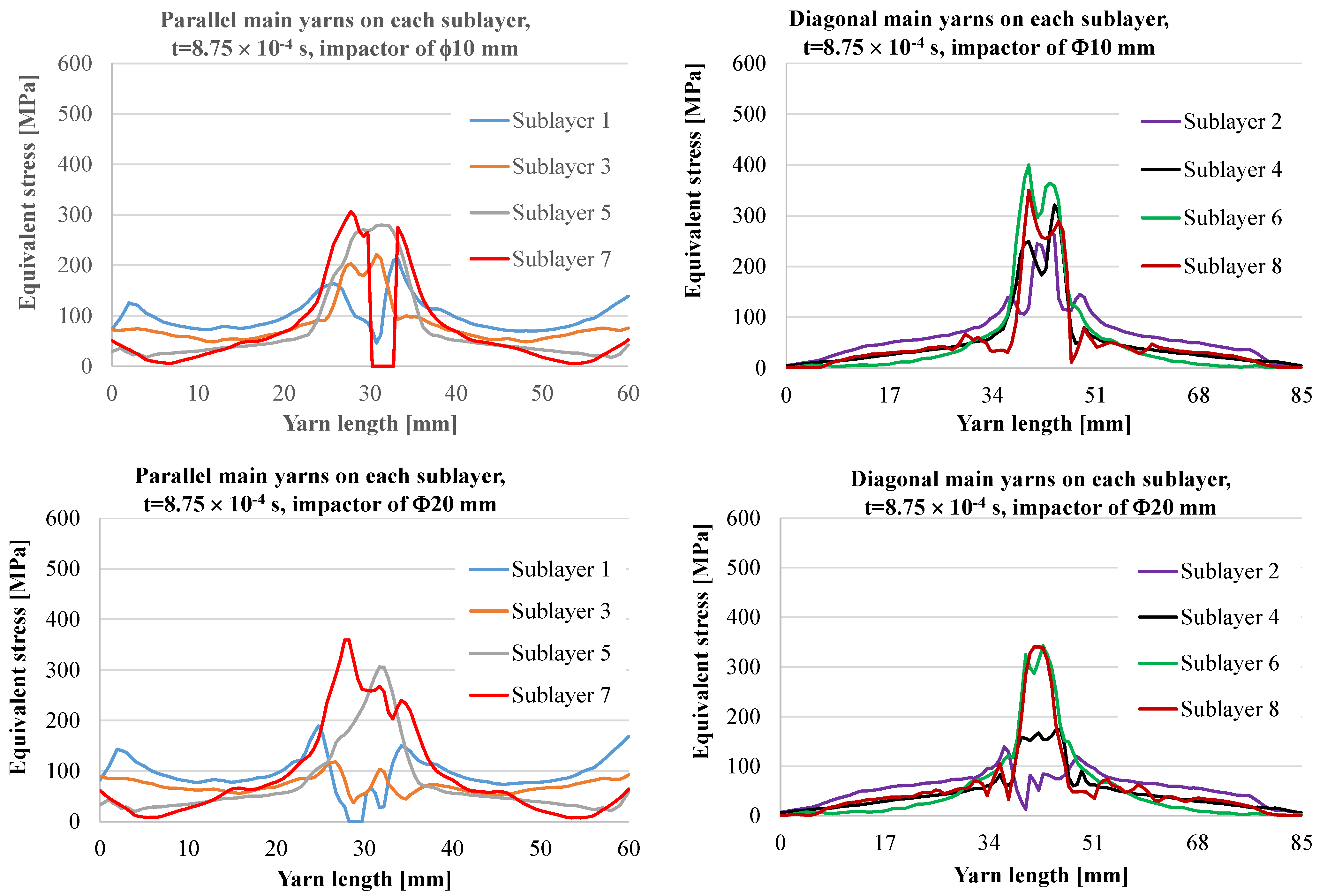

- the stressing of sublayers without breaking yarns is a very short stage, lasting 10−4 to 10−3 s, longer than in a ballistic impact, which is of the order of 10−5–10−6 s [20], but the equivalent stress values reach high values, close to the breaking limit, and the fiber strain approaches the failure criterion value, which is, here, the equivalent plastic deformation at break;

- -

- the initiation of yarn breakage and delamination between substrates from the moment when the value set for the yarn failure criterion is reached (here equivalent plastic strain at break—EPS); higher delamination is observed between the last substrates due to their higher strains;

- -

- the stage with successive breakage of all yarns (the breakage of one or more yarns can be achieved in the simulation between the selected moments, and therefore, the equivalent stress graphs on the yarns can have values lower than the breakage limit);

- -

- the stage with equivalent stresses on the main yarns being lower than the stress limit of the yarns but with values that can detach adjacent yarns in the same sublayer and yarns situated on adjacent sublayers; this is because the stress exceeded the failure criterion for the composite matrix given in Relationship (1), simulated by the detachment of nodes at certain values of tensile or shear stress between yarns (in this study, the matrix has zero thickness, but it manifests its mechanical properties);

- -

- the stage with equivalent stress below the values that cause the matrix to fail; no more yarn detachment occurs and the impact process can be considered complete.

4. Experimental Results

- -

- the maximum force, Fmax,

- -

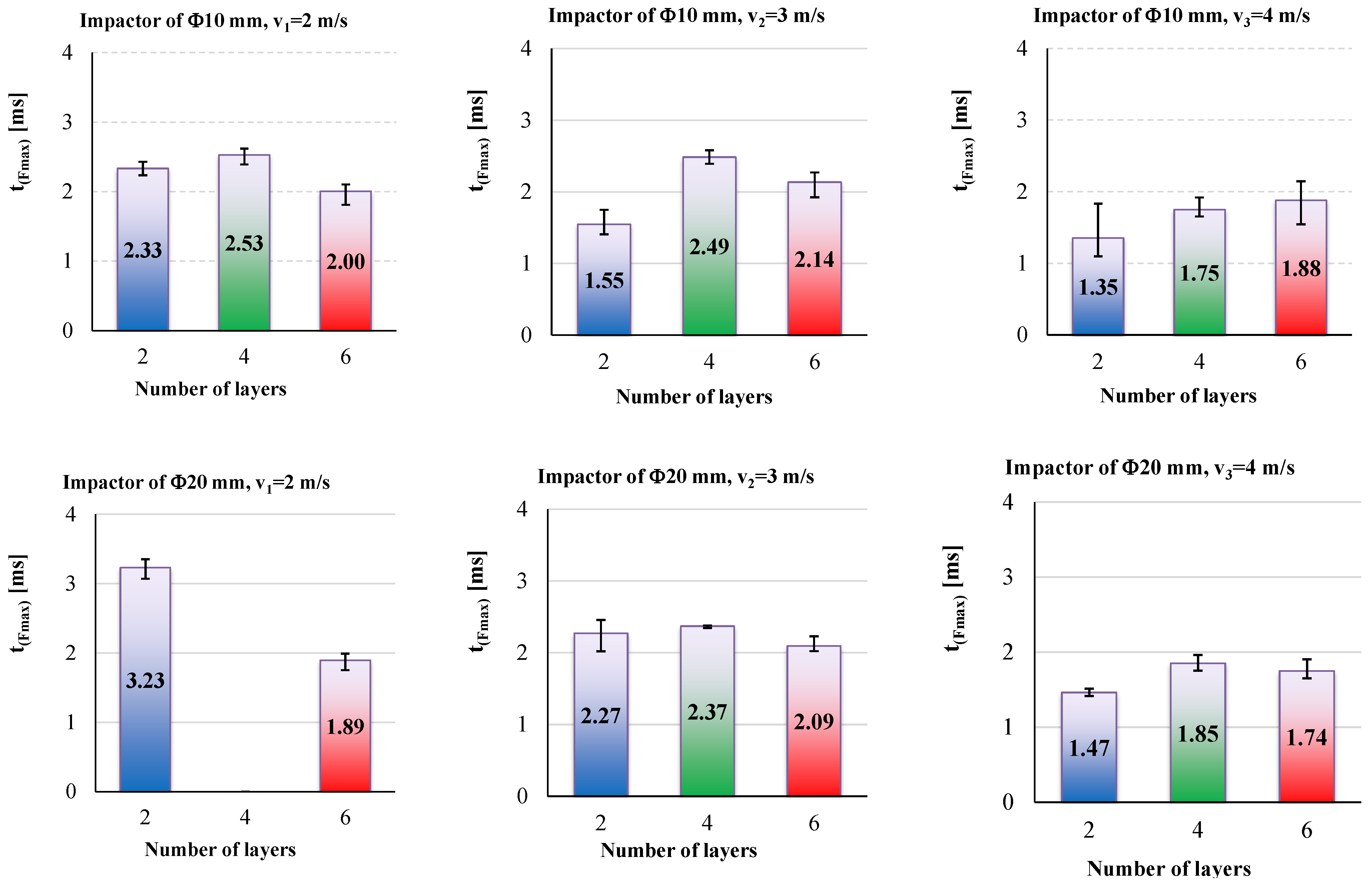

- the duration till Fmax, t(Fmax),

- -

- the duration of the impact, considered from the last recorded values F = 0, from which the force increases, marking the moment, t0, till the moment when force, after its evolution through Fmax, is again 0; this happens at moment tf.

- -

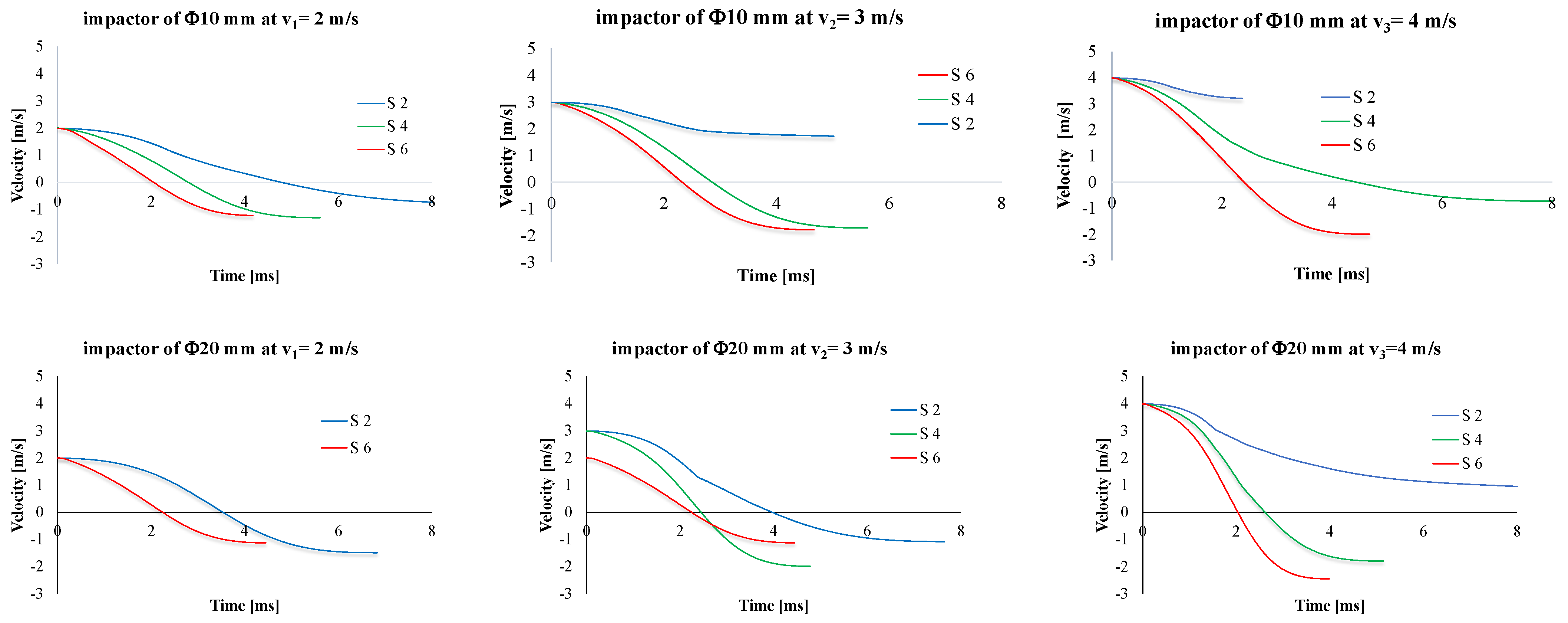

- Fmax increases with the increase in the number of quadriaxial layers: for the two-layer panels, Fmax increases by 14.6% for v3 = 4 m/s as compared to the value for v1 = 2 m/s; for the same values of the impact velocities, a larger difference is obtained for the six-layer panel, as Fmax(v3=4 m/s) is greater by 89.4% than Fmax(v1=2 m/s);

- -

- the moments when the force reaches its maximum values are larger for the lower impact velocity and shorter for higher velocities, but the difference is small, about 0.3–1.0 ms;

- -

- tf has a clear tendency to be reduced both with the increase in panel thickness and impact velocity;

- -

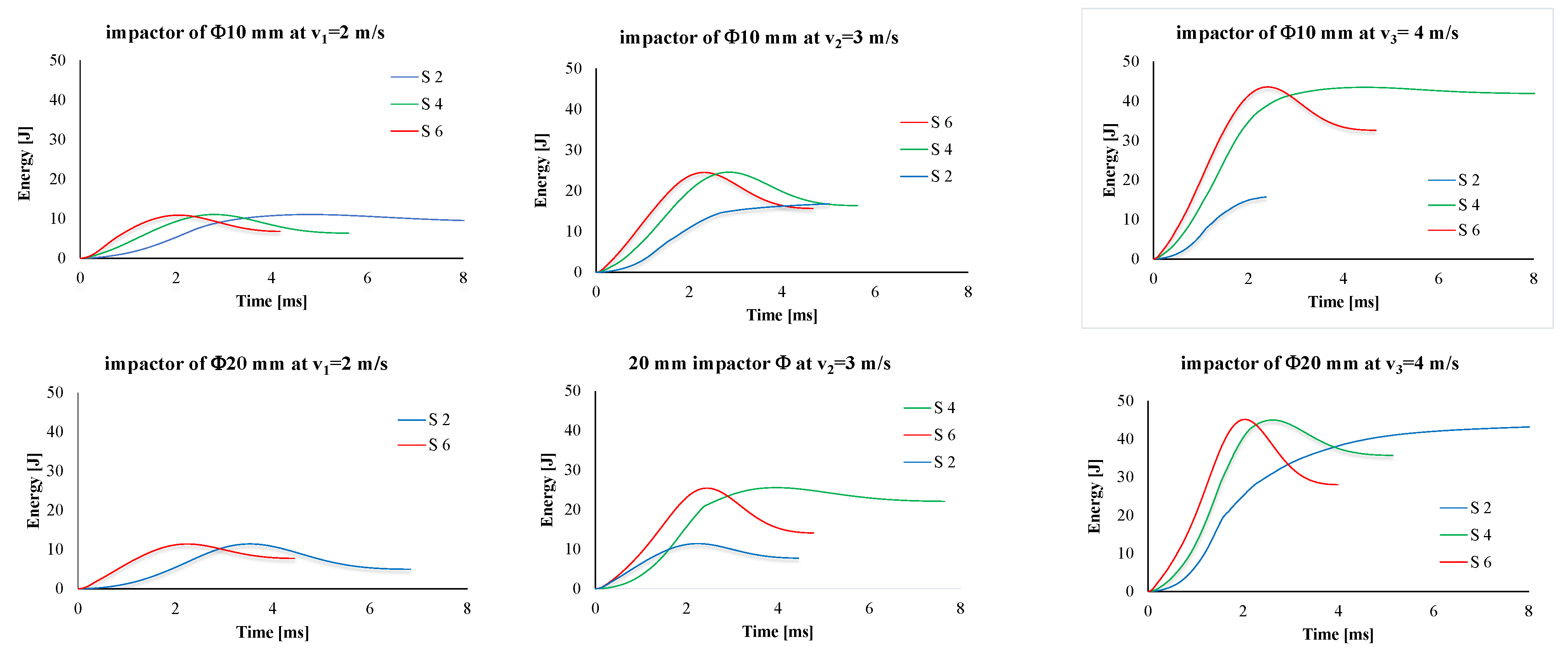

- t(v=0) represents the moment when the entire kinetic energy is transferred to the panel; always t(v=0) < tf as during the rebounding of the impactor, the impactor has to face the force produced by friction and supplementary delamination could occur by gripping the perforated layers during the rebound;

- -

- when total perforation occurs (as for the two-layer panels impacted with v2 = 3 m/s and v3 = 4 m/s), Emax is lower than the nominal energy of the impact, EN, (here, EN has the values 11 J, 25 J and 44 J, respectively).

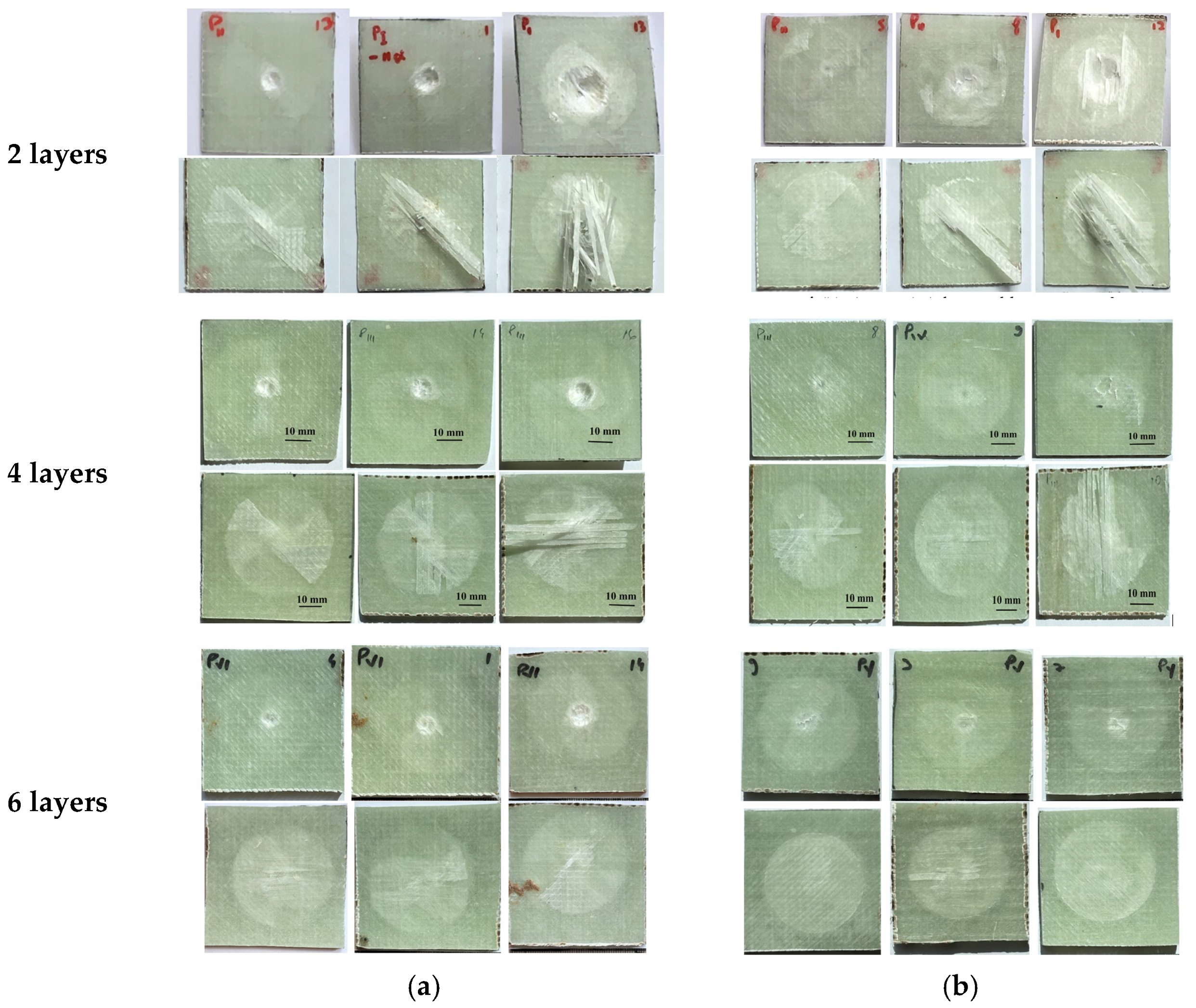

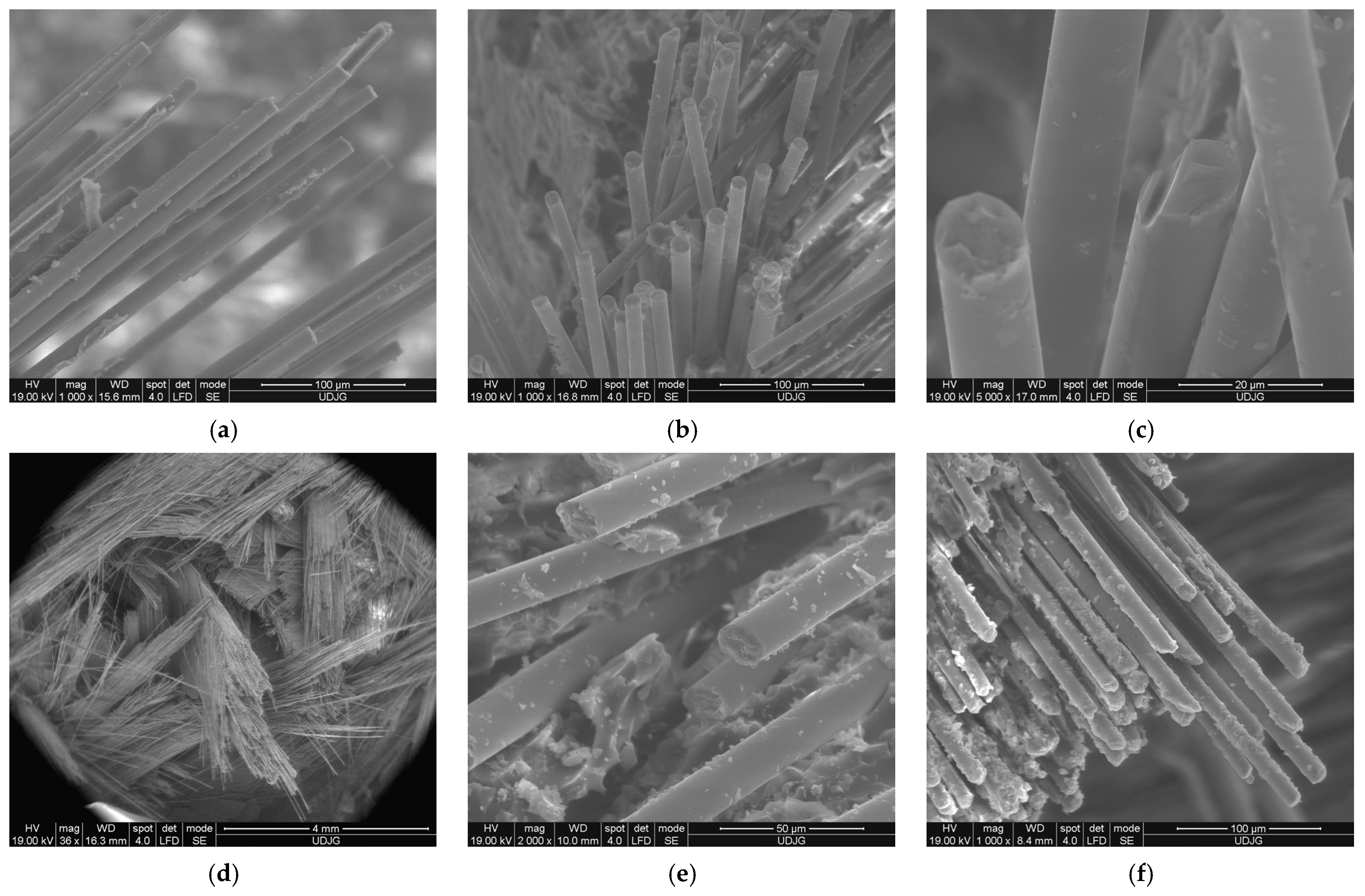

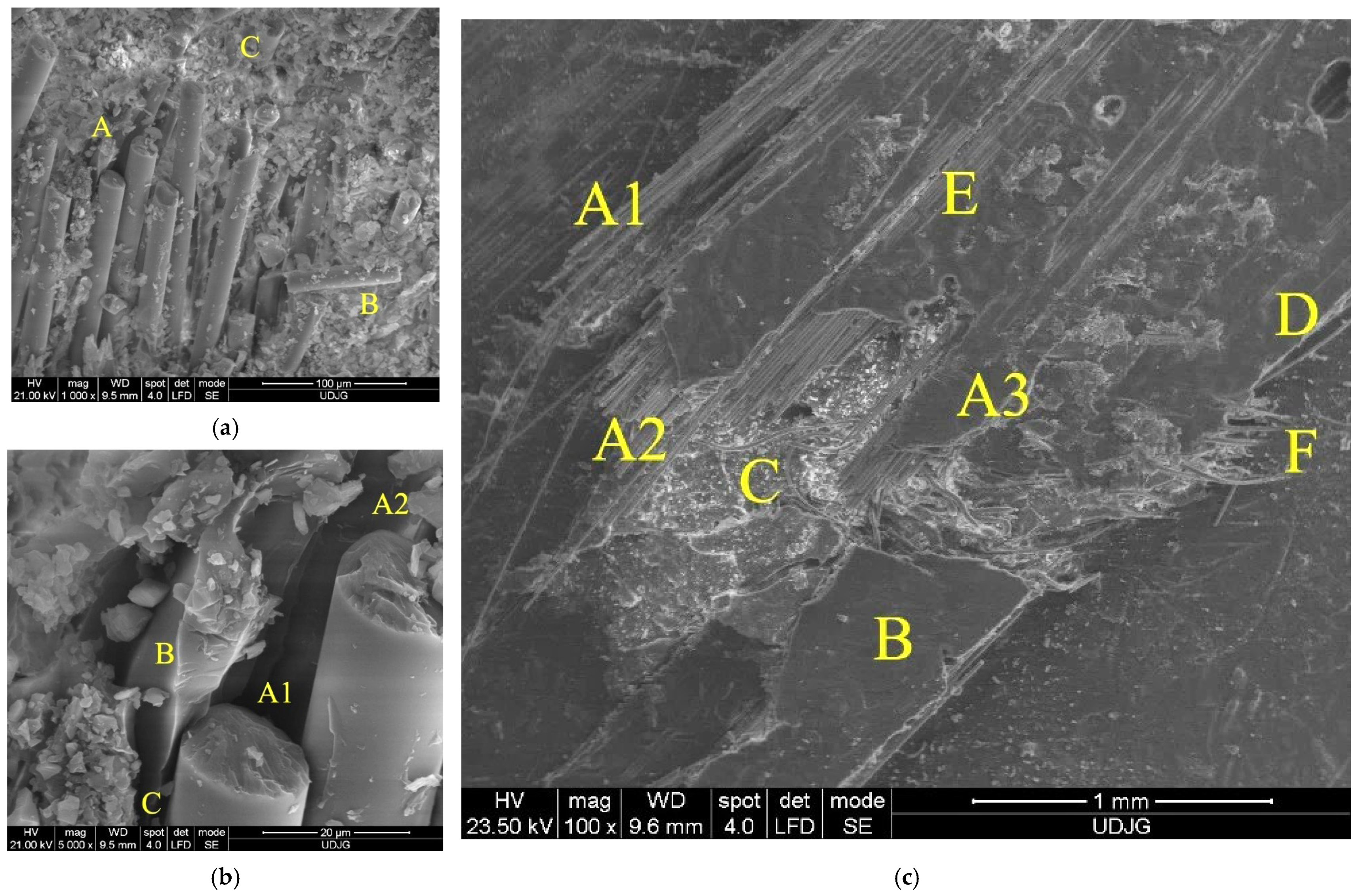

5. Failure Mechanisms

- (a)

- fibres broken by shearing at different lengths: the matrix was already detached from the fibers as its mechanical characteristics are much lower; breakage occurred at different positions on the fibers (not like a straight cut resulting from a knife impact) by shear, which is more visible in image b); the fibers are stressed above the limit of the matrix, and thus, the matrix was already detached from the fibers, weakening the zone; the image is from the face of layer 1;

- (b)

- an image of broken fibers near the edge of the imprint; two different orientations of fibers are visible, with sections of the shear breakage being almost perpendicular to the fiber length;

- (c)

- detail with shear-cut fibers, one having a chippy edge;

- (d)

- a low magnification (×30) that points out the different orientations of the yarns in the quadriaxial architecture; the impactor has penetrated the entire panel and broken the yarns and fibers that subsequently are bent and forced by the impactor trajectory through the orifice;

- (e)

- detail with shear-cut fibers, with small spots of the matrix still bonded to the fibers; bellow the ”naked” fibers, the fragmented matrix is visible;

- (f)

- the cut fibers in a yarn at different lengths suggest a statistical process of being broken; it is visible that the matrix was already detached on the end of cut fibers.

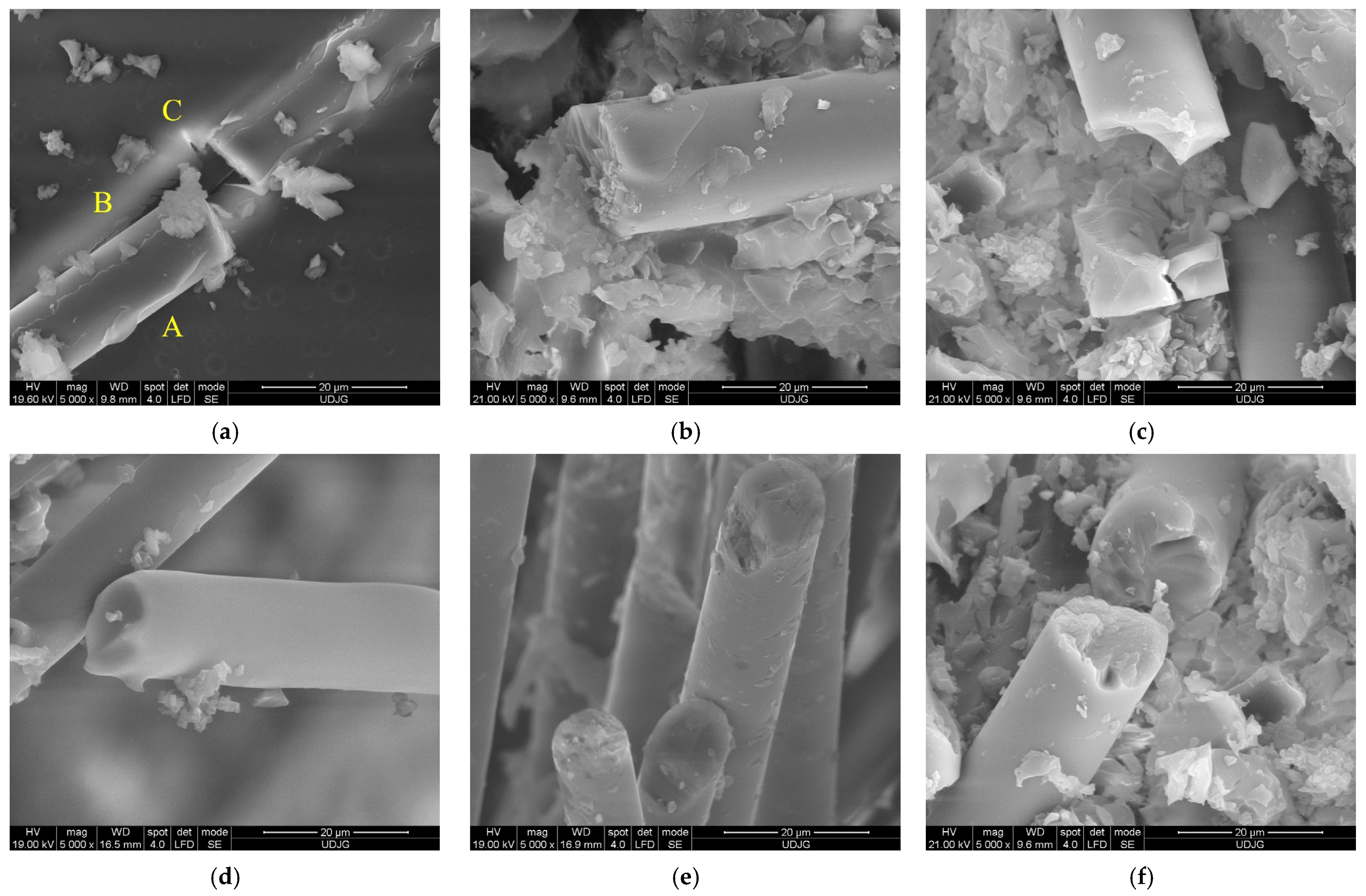

- (a)

- A—a detail from the panel face on the imprint contour, evidencing several fibers from the same yarn cut by shear loading and with their ends detached from the matrix; B—a fragment of glass fiber proving that the fibers could be broken in two points along their length, as reflected in Figure 9, by zero-stress segment for the main yarn in sublayer 7, at moment t = 8.75 × 10−4 s and also several moments later in the simulation for the other main yarns; C—a cut fiber that obviously has other orientations than those in point A;

- (b)

- a detail of the same zone on the panel face: A1 and A2—the broken fibers by shear, B—the matrix that kept the shape of the broken and detached fiber and C—the crack that detached the matrix from a broken fiber;

- (c)

- the back view of the panel, at smaller magnification (×100): A—partially broken yarns, A1—the fibers are broken at different lengths and the matrix is detached from these fibers, A2 and A3—the zones with broken fibers of the same yarn that kept the matrix attached to them, B—spalling of the matrix, C—the zone with a crushed matrix, D—visible local delamination, E—a small area with matrix exfoliations and F—cut fibers that were laterally underdriven by the local relative movement between the impactor and composite under load, as compared to the initial direction of the yarn; the last layer was locally damaged, but then, there was only a partial penetration.

6. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References and Note

- Broutman, L.J.; Rotem, A. Impact Strength and Toughness of Fiber Composite Materials; ASTM International: West Conshohocken, PA, USA, 1975; pp. 114–133. [Google Scholar]

- Khan, Z.; Naik, M.K.; Al-Sulaiman, F.; Merah, N. Low velocity impact of filament-wound glass-fiber reinforced composite pipes. J. Mater. Sci. Eng. 2016, 5, 2169-0022. [Google Scholar] [CrossRef]

- Giasin, K.; Dhakal, H.N.; Featheroson, C.A.; Pimenov, D.Y.; Lupton, C.; Jiang, C.; Barouni, A.; Koklu, U. Effect of Fibre Orientation on Impact Damage Resistance of S2/FM94 Glass Fibre Composites for Aerospace Applications: An Experimental Evaluation and Numerical Validation. Polymers 2022, 14, 95. [Google Scholar] [CrossRef] [PubMed]

- Chandekar, G.S.; Thatte, B.S.; Kelkar, A.D. On the behavior of fiberglass epoxy composites under low velocity impact loading. Adv. Mech. Eng. 2010, 2, 621406. [Google Scholar] [CrossRef]

- Bilisik, K.; Sahbaz Karaduman, S.N.; Bilisikiber, N.E. Architectures for Composite Applications. In Fibrous and Textile Materials for Composite Applications, Textile Science and Clothing Technology; Rana, S., Fangueiro, R., Eds.; Springer Science+Business Media: Singapore, 2016. [Google Scholar] [CrossRef]

- What Are Nonwovens? Available online: https://www.edana.org/nw-related-industry/what-are-nonwovens (accessed on 22 February 2022).

- Wang, Y.; Chen, X.; Young, R.; Kinloch, I.; Wells, G. A numerical study of ply orientation on ballistic impact resistance of multi-ply fabric panels. Compos. Part B 2015, 68, 259–265. [Google Scholar] [CrossRef]

- Balasubramaniam, K.; Ziaja, D.; Jurek, M.; Fiborek, P.; Malinowski, P. Experimental and numerical analysis of multiple low-velocity impact damages in a glass fibered composite structure. Materials 2021, 14, 7268. [Google Scholar] [CrossRef] [PubMed]

- Carlsson, L.A.; Adams, D.F.; Pipes, R.B. Experimental Characterization of Advanced Composite Materials; CRC Press: Boca Raton, FL, USA, 2014. [Google Scholar]

- Clyne, T.W.; Hull, D. An Introduction to Composite Materials; Cambridge University Press: Cambridge, UK, 2019. [Google Scholar]

- Cormos, R.; Petrescu, H.; Hadar, A.; Adir, G.M.; Gheorghiu, H. Finite Element Analysis of the Multilayered Honeycomb Composite Material Subjected to Impact Loading. Mater. Plast. 2017, 54, 180–185. [Google Scholar] [CrossRef]

- Uses of Fiberglass. 2017. Available online: https://www.thoughtco.com/uses-offiberglass-820412 (accessed on 22 February 2022).

- Wu, W.; Li, W. Parametric modeling based on the real geometry of glass fiber unidirectional non-crimp fabric. Text. Res. J. 2019, 89, 3949–3959. [Google Scholar] [CrossRef]

- Md Shah, A.U.; Hameed Sultan, M.T.; Safri, S.N.A. Experimental Evaluation of Low Velocity Impact Properties and Damage Progression on Bamboo/Glass Hybrid Composites Subjected to Different Impact Energy Levels. Polymers 2020, 12, 1288. [Google Scholar] [CrossRef]

- Rezasefat, M.; Ma, D.; da Silva, A.A.X.; Colombo, C.; Amico, S.C.; Giglio, M.; Manes, A. Multi-criteria decision-making analysis and numerical simulation of the low-velocity impact response of inter-ply S2-glass/aramid woven fabric hybrid laminates. Compos. Struct. 2023, 312, 116867. [Google Scholar] [CrossRef]

- Donough, M.J.; Prusty, B.G.; Van Donselaar, M.J.; Morozov, E.V.; Wang, H.; Hazell, P.J.; St John, N.A. In-plane and oblique edge-on impact on thick glass-fibre/epoxy composite laminates. Int. J. Impact Eng. 2023, 171, 104373. [Google Scholar] [CrossRef]

- High Strength Glass Fibers. 2017. Available online: https://www.agy.com/wp-content/uploads/2022/03/AGY_HighStBro_HR.pdf AGY; http://www.agy.com/wp-content/uploads/2014/03/High_Strength_Glass_Fibers-Technical.pdf (accessed on 12 March 2022).

- Technical Design Guide for FRP Composite Products and Parts. 2022. Available online: https://moldedfiberglass.com/wp-content/uploads/2020/01/pdf_Technical_Design_Guide_for_FRP_Composite_Products_and_Parts_2018.pdf (accessed on 20 March 2022).

- 1200 g/m2 Quadriaxial Stitched Glass Fabric (0°/+45°/90°/−45°), 127 cm Wide. Available online: https://www.castrocompositesshop.com/en/fibre-reinforcements/1204-1200-gm2-quadriaxial-stitched-glass-fabric-0%C2%BA45%C2%BA90%C2%BA-45%C2%BA-127-cm-wide.html (accessed on 1 January 2022).

- Ojoc, G.G. A Theoretical and Experimental Study of Ballistic Protection Packages Made of Glass Fibers. Ph.D. Thesis, “Dunarea de Jos” University of Galati, Galati, Romania, 2022. [Google Scholar]

- Sika Group. About Us. Available online: https://www.sika.com/en/home.html (accessed on 3 October 2021).

- Biresin®CR82. Composite Resin System. Available online: https://industry.sika.com/dms/getdocument.get/93a3a9b1-7291-47ce-8ca7-18ae3f458043/Biresin-CR82-New.pdf (accessed on 4 October 2021) and https://industry.sika.com/en/home/advanced-resins/sports-and-leisure/composite-resin-systems/composite-systemsforwetlay-up/sikabiresin-cr82.html (accessed on 7 June 2023).

- WB1268C, CEAST 9300 Series. Droptower Impact Systems. Illinois Tool Works Inc.: Glenview, IL, USA, 2009.

- Cangiani, A.; Manzini, G.; Russo, A.; Sukumar, N. Hourglass stabilization and the virtual element method. Int. J. Numer. Methods Eng. 2015, 102, 404–436. [Google Scholar] [CrossRef]

- de Souza Neto, E.A.; Peric, D.; Owen, D.R. Computational Methods for Plasticity: Theory and Applications; John Wiley & Sons: New York, NY, USA, 2011. [Google Scholar]

- Bao, H.; Liu, G. Progressive failure analysis on scaled open-hole tensile composite laminates. Compos. Struct. 2016, 150, 173–180. [Google Scholar] [CrossRef]

- Titire, L.C.; Rusu, V.T.; Sandu, S. Influence of material characteristics on impact response for fabrics made of glass and aramid fibers. IOP Conf. Ser. Mater. Sci. Eng. 2022, 1262, 012045. [Google Scholar] [CrossRef]

- Endruweit, A.; Zeng, X.; Matveev, M.; Long, A.C. Effect of yarn cross-sectional shape on resin flow through inter-yarn gaps in textile reinforcements. Compos. Part A Appl. Sci. Manuf. 2018, 104, 139–150. [Google Scholar] [CrossRef]

- Jinescu, V.V. Application in Mechanical Engineering of Principle of Critical Energy; Lambert Academic Publishing: Saarbrücken, Germany, 2015. [Google Scholar]

- Năstăsescu, V.; Ştefan, A.; Lupoiu, C. Analiza Neliniară Prin Metoda Elementelor Finite; Fundamente Teoretice şi Aplicaţii; Academia Tehnică Militară: Bucharest, Romania, 2001. [Google Scholar]

- Chib, A. Parametric Study of Low Velocity Impact Analysis on Composite Tubes. Ph.D. Dissertation, University of Pune, Maharashtra, India, 2006. [Google Scholar]

- Williams, K.V.; Vaziri, R. Parameters influencing the impact response of fiber-reinforced polymer matrix composite materials: A critical review. Comput. Struct. 2001, 79, 997–1011. [Google Scholar] [CrossRef]

- Kim, E.H.; Rim, M.S.; Lee, I.; Hwang, T.K. Composite damage model based on continuum damage mechanics and low velocity impact analysis of composite plates. Comput. Struct. 2013, 95, 123–134. [Google Scholar] [CrossRef]

- Sathishkumar, T.P.; Satheeshkumar, S.; Naveen, J. Glass fiber-reinforced polymer composites—A review. J. Reinf. Plast. Compos. 2014, 33, 1258–1275. [Google Scholar] [CrossRef]

- Lopresto, V.; Langella, A.; Pagliarulo, V.; Papa, I. On low-velocity impact behaviour of composite laminates: Damage investigation and influence of matrix and temperature. Prog. Aerosp. Sci. 2022, 129, 100786. [Google Scholar] [CrossRef]

- Meyer, C.S.; Haque, B.Z.G.; O’Brien, D.J.; Getinet, N.; Jian, H.Y.; Bonyi, E.; Gillespie, J.W., Jr. Mesoscale ballistic damage mechanisms of a single-layer woven glass/epoxy composite. Int. J. Impact Eng. 2018, 113, 118–131. [Google Scholar] [CrossRef]

- Reddy, T.S.; Reddy, P.R.S.; Madhu, V. Low velocity impact studies of E-glass/epoxy composite laminates at different thicknesses and temperatures. Def. Technol. 2019, 15, 897–904. [Google Scholar] [CrossRef]

- Rogani, A.; Navarro, P.; Marguet, S.; Ferrero, J.F.; Lanouette, C. Study of post-impact behaviour of thin hybrid carbon/epoxy and glass/epoxy woven composite laminates under fatigue tensile loading—Part II: Numerical study. Compos. Struct. 2021, 260, 113451. [Google Scholar] [CrossRef]

- Rabbi, M.F.; Meninno, C.M.; Chalivendra, V. Damage monitoring of conductive glass fiber/epoxy laminated composites under dynamic mixed-mode fracture loading. Mater. Lett. 2021, 283, 128766. [Google Scholar] [CrossRef]

| Wt% | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| B | C | O | Na | Mg | Al | Si | S | Cl | K | Ca | Ti | Fe | Zn |

| Fiber cross-section | |||||||||||||

| 29.39 | 24.75 | 9.03 | 0.38 | 0.42 | 3.55 | 14.21 | 1.75 | 0.20 | 0.22 | 8.88 | 0.50 | 2.19 | 4.43 |

| Glass fiber jacket | |||||||||||||

| 30.81 | 24.11 | 10.34 | 0.48 | 0.74 | 3.61 | 13.21 | 1.61 | 0.22 | 0.48 | 9.07 | 0.88 | 2.82 | 6.69 |

| Properties | Resin Component (A) | Hardener Component (B) | |

|---|---|---|---|

| Components of the epoxy resin | Biresin® CR82 | Biresin® CH80-2 | |

| Mixture ratio (parts) | Mass | 100 | 27 |

| Color | Transparent | In color till yellow or blue | |

| Viscosity, 25 °C | mPa·s | ~1600 | |

| Density, 25 °C | g/mL | 1.11 | 0.99 |

| Mixture | |||

| Pot life, 100 g/RT, approximative value | min | 80 | |

| Viscosity of the mixture, 25 °C | mPa·s | 600 | |

| Mechanical Properties of the Resin (after Ageing and Thermal Treatment) | ||||||

|---|---|---|---|---|---|---|

| Resin Biresin® CR82 (A) | With Hardener Biresin® (B) | CH80-1 | CH80-2 | CH80-6 | CH80-10 | |

| Tensile strength at breakage | ISO 527 | MPa | 94 | 90 | 84 | 82 |

| Elastic modulus for traction | ISO 527 | MPa | 3000 | 3000 | 2900 | 2900 |

| Strain at breakage | ISO 527 | % | 4.9 | 5.6 | 6.4 | 6.2 |

| Flexural strength at breakage | ISO 178 | MPa | 140 | 130 | 127 | 118 |

| Flexural modulus | ISO 178 | MPa | 3300 | 3200 | 2900 | 2800 |

| Strength limit under compression | ISO 604 | MPa | 120 | 105 | 110 | 110 |

| Density | ISO 1183 | g/cm3 | 1.14 | 1.14 | 1.14 | 1.14 |

| Shore hardness | ISO 868 | - | D 85 | D 85 | D 85 | D 85 |

| Impact resistance | ISO 179 | kJ/m2 | 38 | 66 | 55 | 56 |

| Thermal properties of the resin (after ageing and thermal treatment) | ||||||

| Temperature of deflection under load | ISO 75-1 | °C | 93 | 83 | 71 | 71 |

| Glass transition temperature | ISO 11357 | °C | 97 | 90 | 83 | 85 |

| No. | Fabric Mass | Panel Mass | Resin Mass * | Mass Ratio Fabric/Panel ** | Surface Density *** | Thickness in 4 Points | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | Average | ||||||

| [g] | [g] | [g] | - | [kg/m2] | [mm] | |||||

| Panel with 2 layers of quadriaxial fabric | ||||||||||

| Panel 1/2 | 221.5 | 316 | 94.5 | 0.70 | 3.51 | 1.65 | 1.61 | 1.65 | 1.70 | 1.65 |

| Panel 2/2 | 218.3 | 302.6 | 92.8 | 0.67 | 3.36 | 1.68 | 1.70 | 1.60 | 1.62 | 1.63 |

| Average | 219.9 | 309.3 | 93.65 | 0.68 | 3.43 | 1.66 | 1.65 | 1.62 | 1.66 | 1.64 |

| Panel with 4 layers of quadriaxial fabric | ||||||||||

| Panel 1/4 | 439.5 | 608.5 | 169 | 0.72 | 6.761 | 3.35 | 3.34 | 3.4 | 3.45 | 3.38 |

| Placa 2/4 | 440 | 603.5 | 163.5 | 0.72 | 6.7 | 3.4 | 3.45 | 3.6 | 3.5 | 3.48 |

| Average | 439.75 | 606.0 | 166.25 | 0.72 | 6.73 | 3.37 | 3.39 | 3.50 | 3.47 | 3.43 |

| Panel with 6 layers of quadriaxial fabric | ||||||||||

| Panel 1/6 | 664 | 897 | 233 | 0.74 | 9.96 | 5.00 | 4.50 | 5.5 | 5.00 | 5.00 |

| Panel 2/6 | 662 | 883.5 | 221.5 | 0.75 | 9.81 | 5.60 | 5.70 | 5.80 | 5.70 | 5.70 |

| Average | 663 | 890.25 | 227.25 | 0.74 | 9.89 | 5.3 | 5.1 | 5.65 | 5.35 | 5.35 |

| Panel | Thickness | Fmax | t(Fmax) | tf | t(v=0) | Emax |

|---|---|---|---|---|---|---|

| [mm] | [N] | [ms] | [ms] | [ms] | [J] | |

| v1 = 2 m/s | ||||||

| 2-layer | 1.67 | 4075.0 | 2.34 | 9.37 | 4.66 | 11.09 |

| 4-layer | 3.37 | 5832.1 | 2.53 | 5.67 | 2.82 | 11.01 |

| 6-layer | 5.27 | 6396.7 | 2.00 | 4.51 | 2.21 | 10.89 |

| v2 = 3 m/s | ||||||

| 2-layer | 1.66 | 3962.6 | 1.54 | 5.96 | 4.49 | 16.44 |

| 4-layer | 3.73 | 8625.8 | 2.48 | 5.57 | 2.84 | 24.57 |

| 6-layer | 5.27 | 9785.3 | 2.13 | 4.70 | 2.36 | 24.51 |

| v3 = 4 m/s | ||||||

| 2-layer | 1.66 | 4673.6 | 1.35 | - * | - * | 14.3 * |

| 4-layer | 3.38 | 9529.4 | 1.75 | 4.92 | 2.52 | 43.54 |

| 6-layer | 5.26 | 12,119.3 | 1.87 | 4.00 | 2.04 | 43.5 |

| Panel | Thickness | Fmax | t(Fmax) | tf | t(v=0) | Emax |

|---|---|---|---|---|---|---|

| [mm] | [N] | [ms] | [ms] | [ms] | [J] | |

| v1 = 2 m/s | ||||||

| 2-layer | 1.63 | 6143.6 | 3.22 | 6.80 | 3.56 | 11.42 |

| 6-layer | 5.20 | 6618.6 | 1.89 | 4.66 | 2.20 | 11.40 |

| v2 = 3 m/s | ||||||

| 2-layer | 1.70 | 9185.7 | 2.27 | 7.93 | 4.11 | 25.38 |

| 4-layer | 3.37 | 11,711.4 | 2.37 | 4.84 | 2.40 | 25.44 |

| 6-layer | 5.26 | 11,883.2 | 2.09 | 4.11 | 2.22 | 25.40 |

| v3 = 4 m/s | ||||||

| 2-layer | 1.65 | 8868.5 | 1.46 | - * | - * | 44.7 |

| 4-layer | 3.36 | 15,051.8 | 1.85 | 4.92 | 2.52 | 44.9 |

| 6-layer | 5.27 | 18,250.2 | 1.74 | 4.00 | 2.04 | 45.1 |

| Number of Layers | v1 = 2 m/s | v2 = 3 m/s | v3 = 4 m/s |

|---|---|---|---|

| 10 mm | |||

| S2 | PP | PP ⁕ | PT |

| S4 | PP | PP ⁕ | PP ⁕ |

| S6 | PP | PP | PP |

| 20 mm | |||

| S2 | PP | PP ⁕ | PT |

| S4 | PP | PP | PP ⁕ |

| S6 | PP | PP | PP |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Păduraru, I.; Ojoc, G.G.; Petrescu, H.; Graur, I.; Pîrvu, C.; Deleanu, L. The Behavior of Glass Fiber Composites under Low Velocity Impacts. Polymers 2023, 15, 4549. https://doi.org/10.3390/polym15234549

Păduraru I, Ojoc GG, Petrescu H, Graur I, Pîrvu C, Deleanu L. The Behavior of Glass Fiber Composites under Low Velocity Impacts. Polymers. 2023; 15(23):4549. https://doi.org/10.3390/polym15234549

Chicago/Turabian StylePăduraru, Iulian, George Ghiocel Ojoc, Horia Petrescu, Iulia Graur, Cătălin Pîrvu, and Lorena Deleanu. 2023. "The Behavior of Glass Fiber Composites under Low Velocity Impacts" Polymers 15, no. 23: 4549. https://doi.org/10.3390/polym15234549

APA StylePăduraru, I., Ojoc, G. G., Petrescu, H., Graur, I., Pîrvu, C., & Deleanu, L. (2023). The Behavior of Glass Fiber Composites under Low Velocity Impacts. Polymers, 15(23), 4549. https://doi.org/10.3390/polym15234549