Sunflower and Watermelon Seeds and Their Hybrids with Pineapple Leaf Fibers as New Novel Thermal Insulation and Sound-Absorbing Materials

Abstract

:1. Introduction

2. Materials and Methods

2.1. Obtaining and Preparing the Raw Materials

2.2. Preparing the Samples for Testing

3. Laboratory Tests

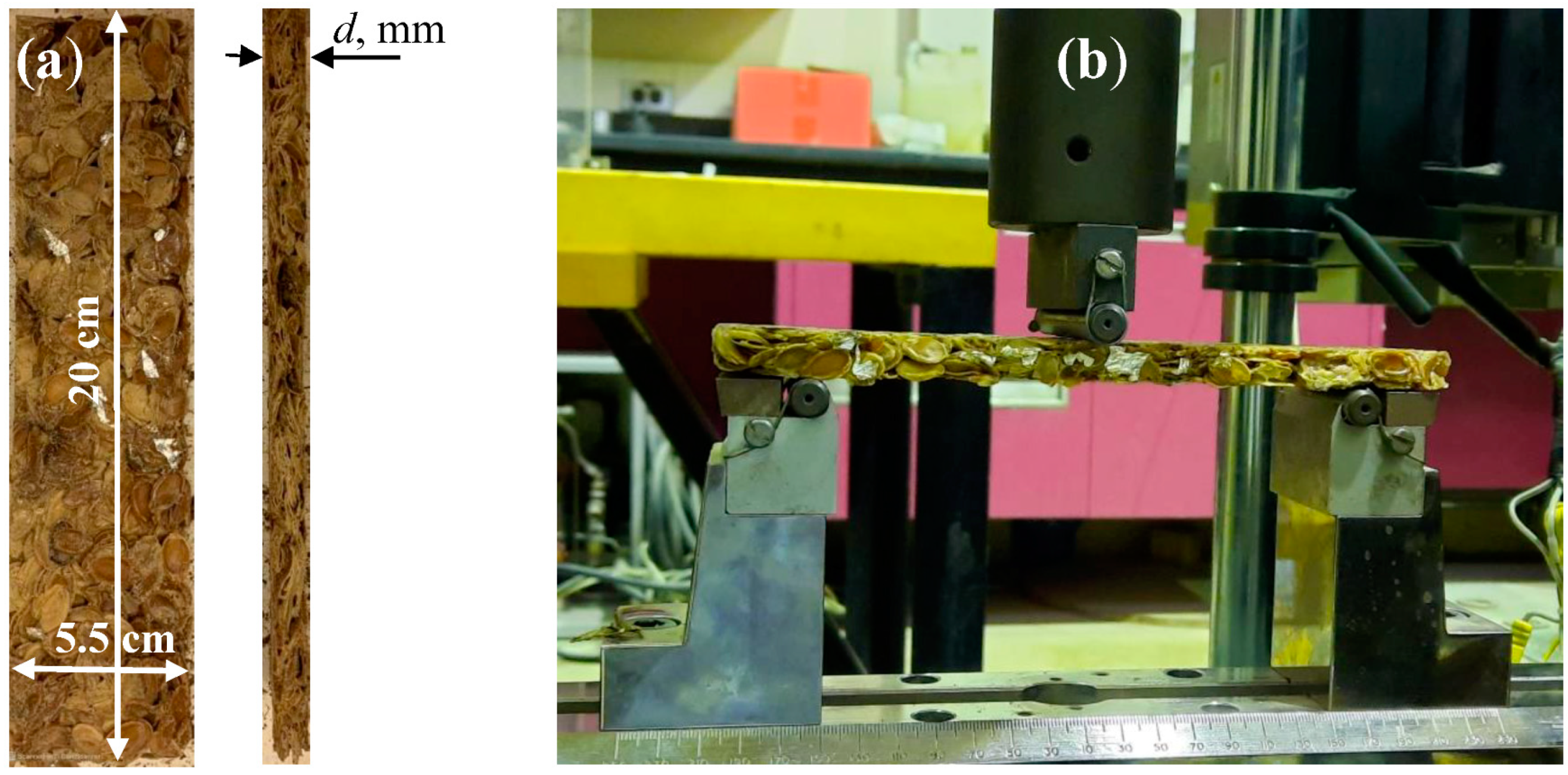

3.1. Three-Point Bending Moment Test

3.2. Thermal Stability Test

3.3. Thermal Conductivity Test

3.4. Sound Absorption Test

3.5. Moisture Content Test

4. Results and Discussion

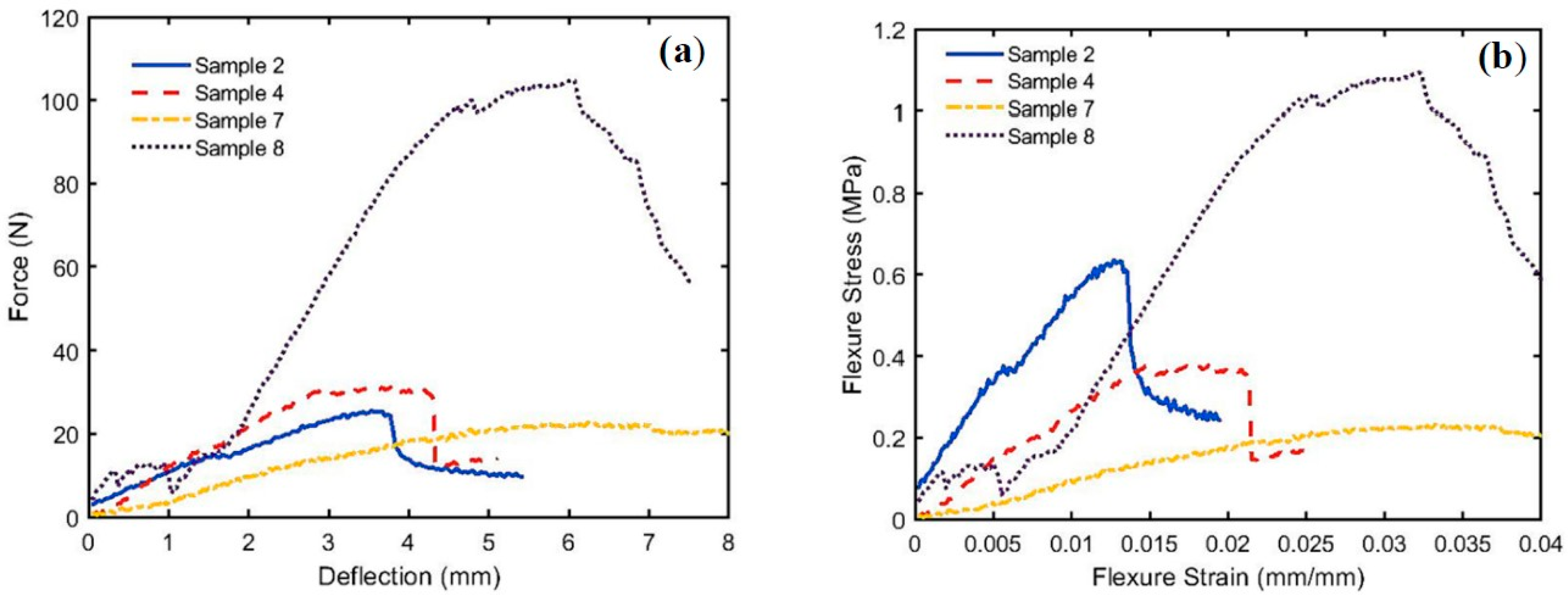

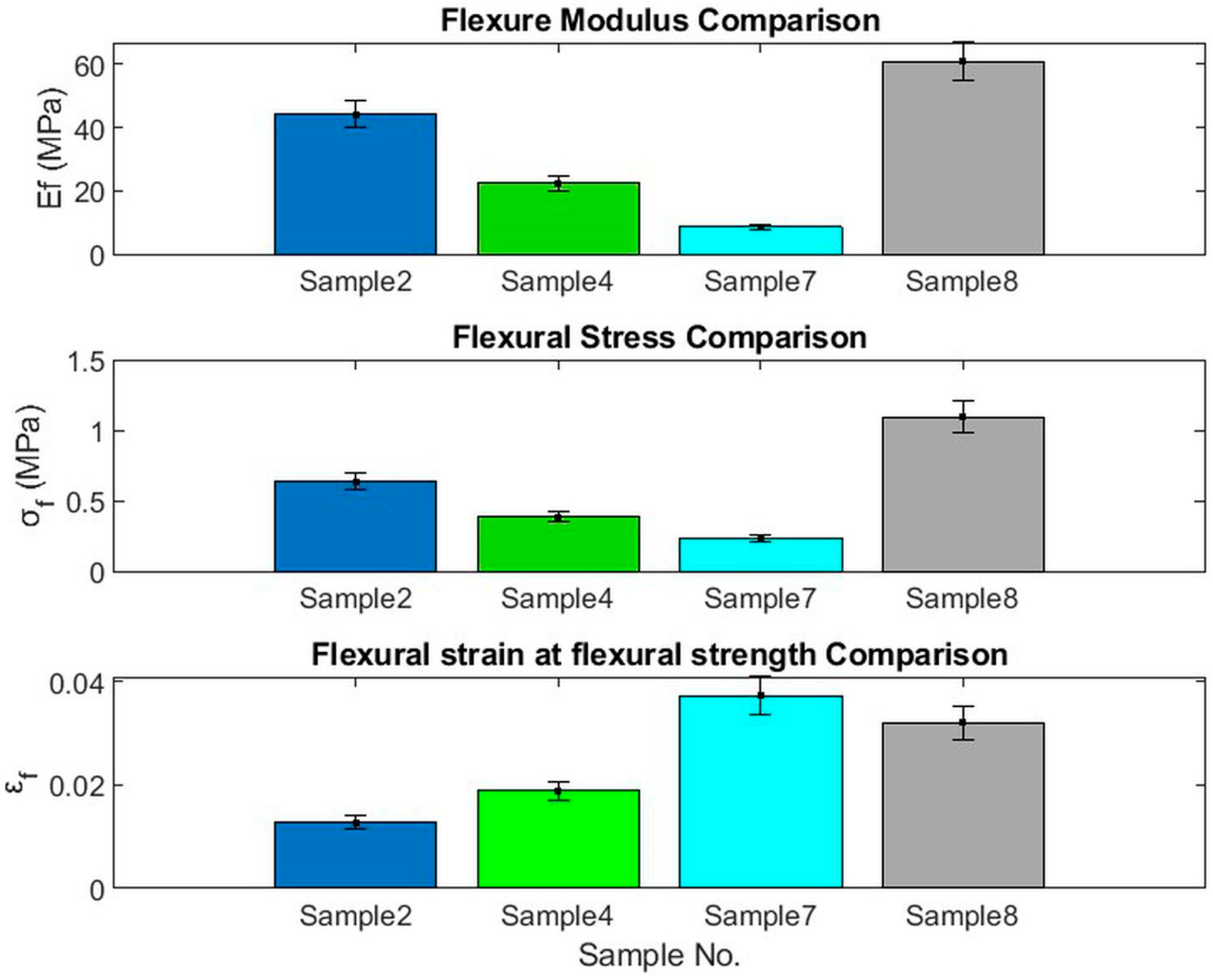

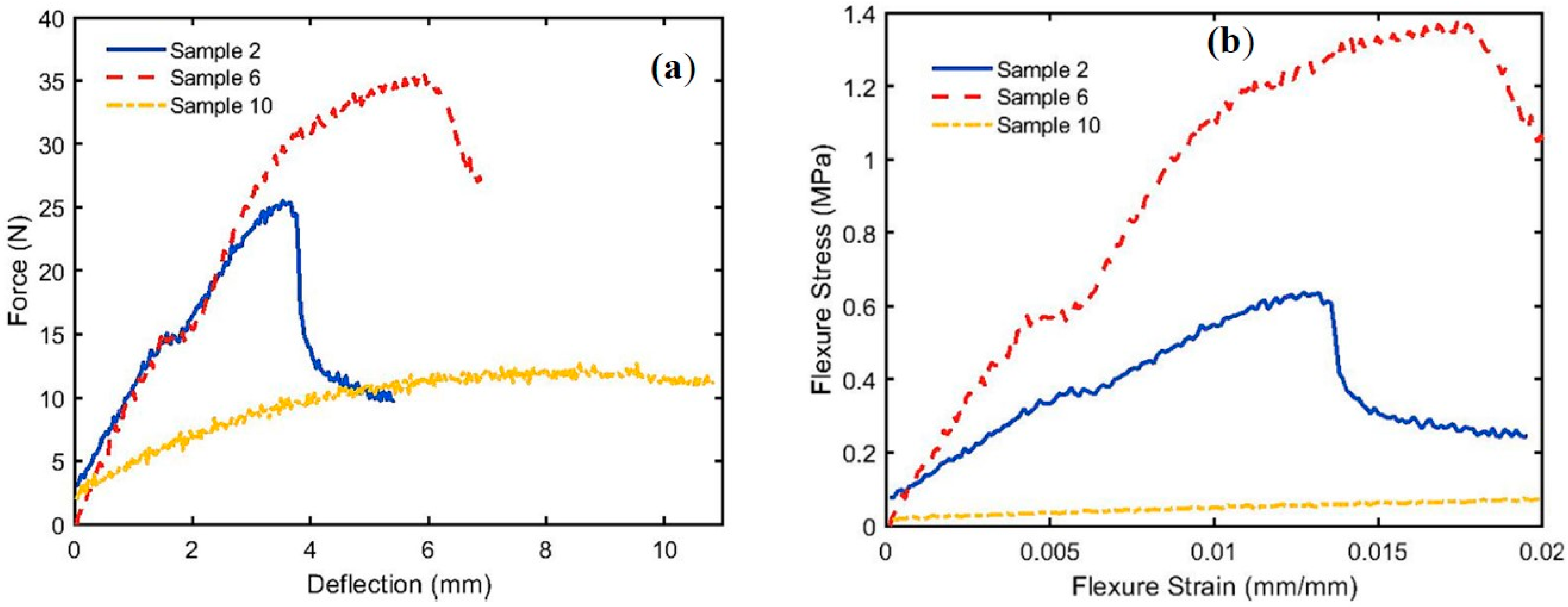

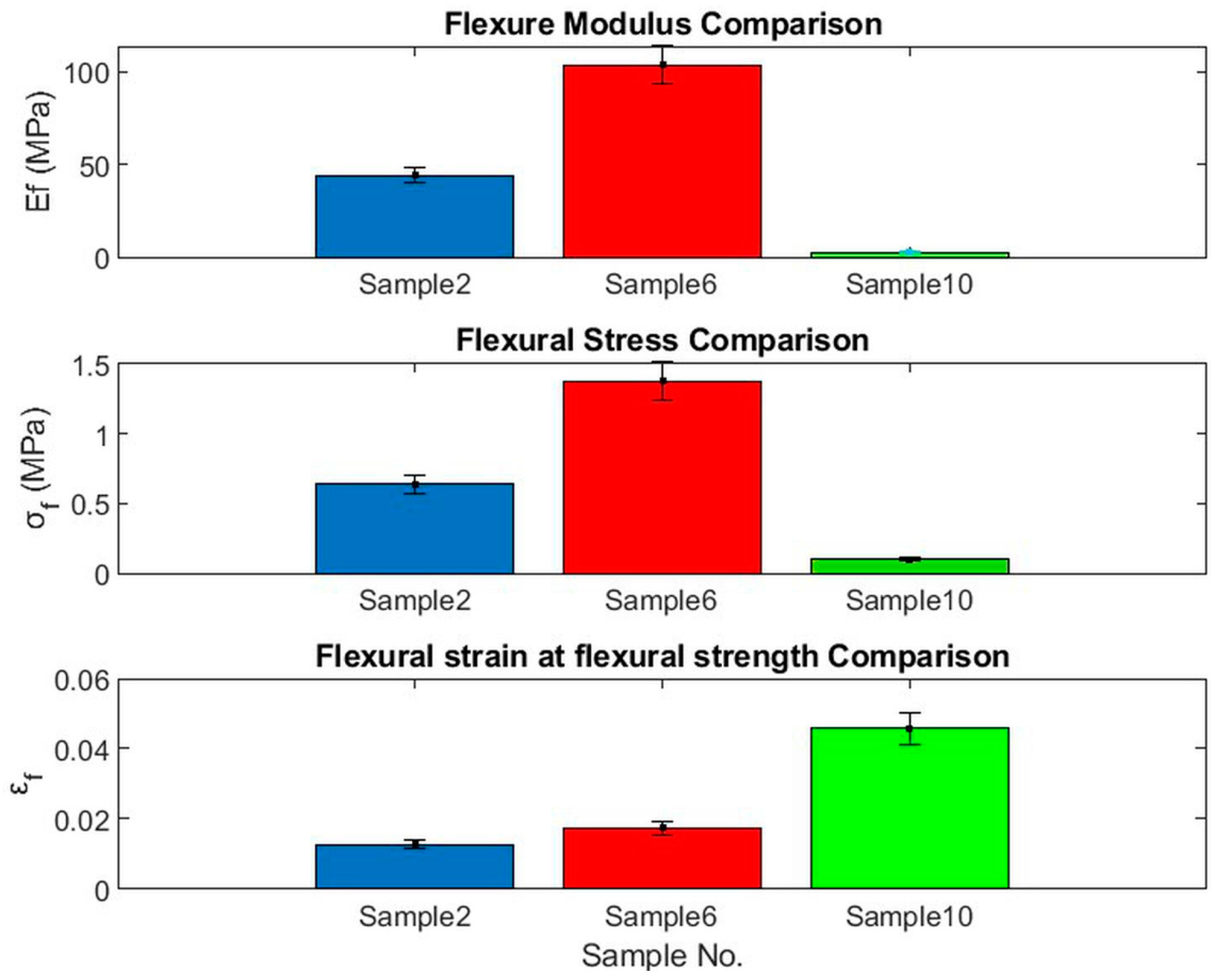

4.1. Bending Moment Test

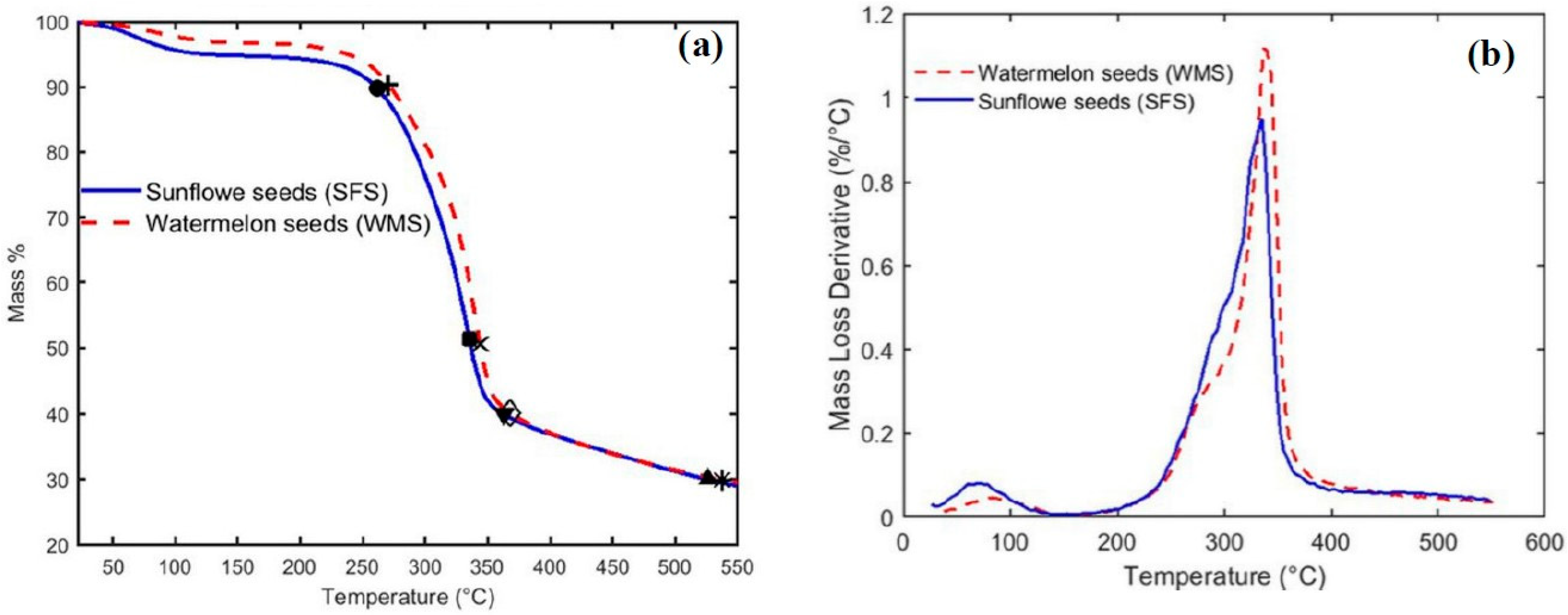

4.2. Thermal Stability Test Analyses

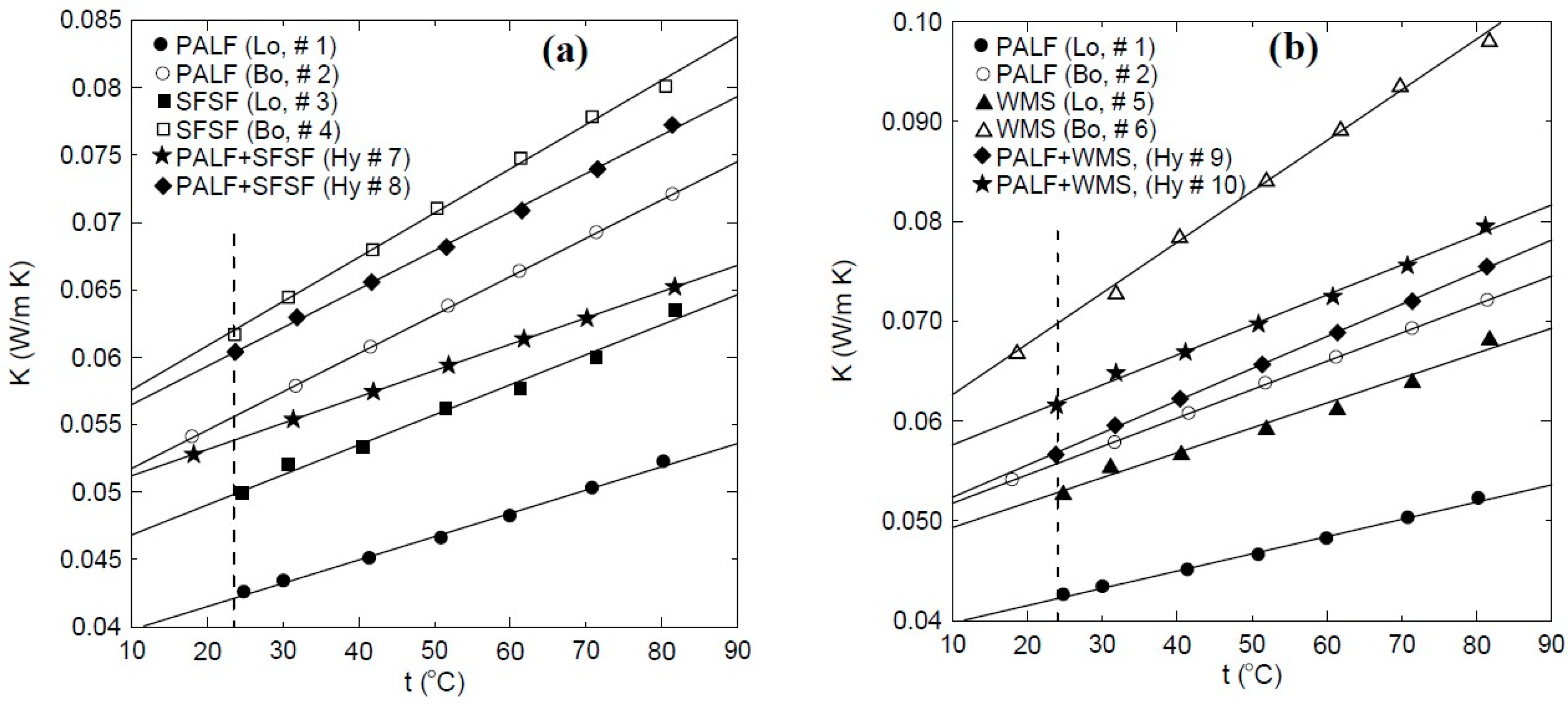

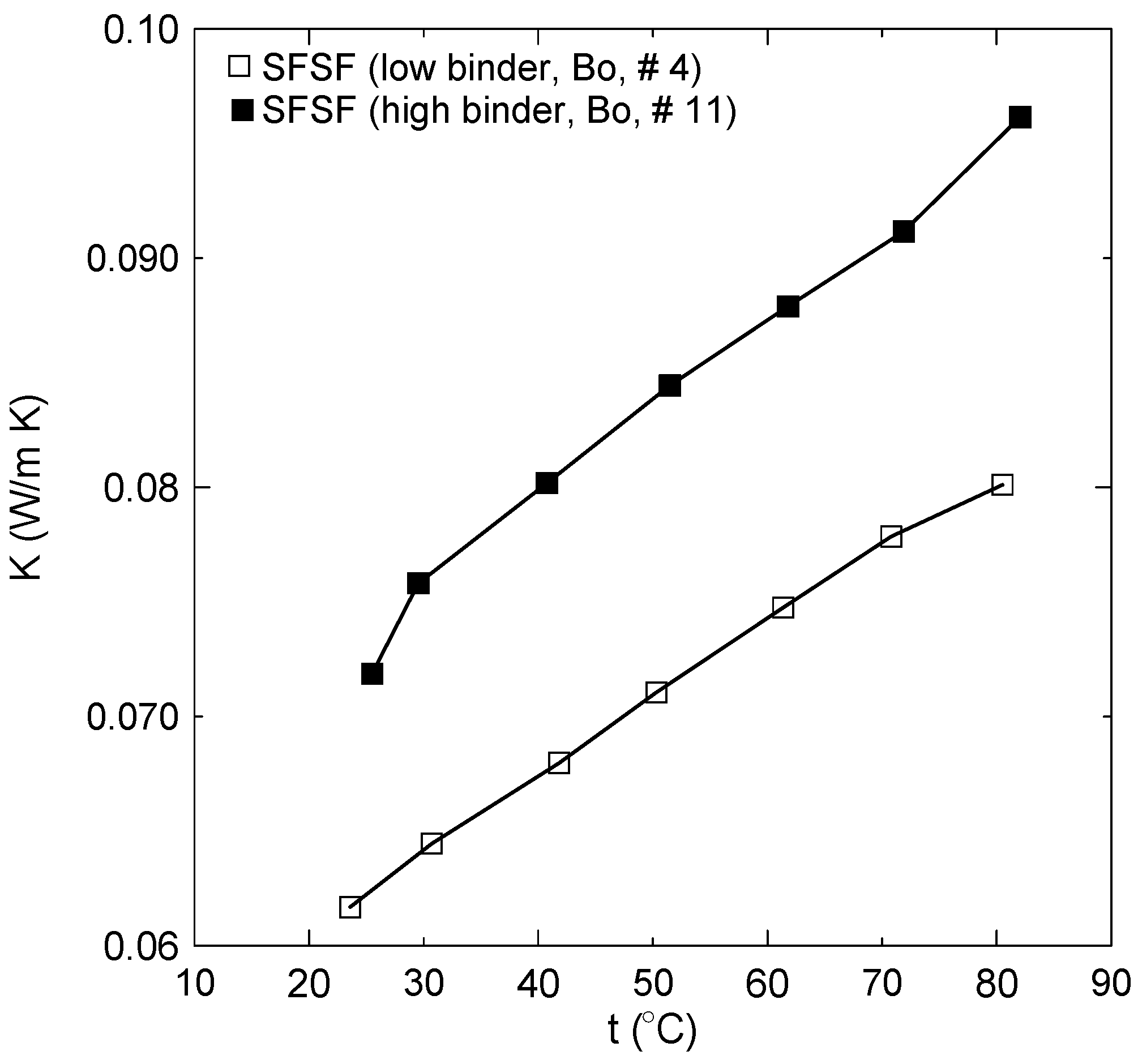

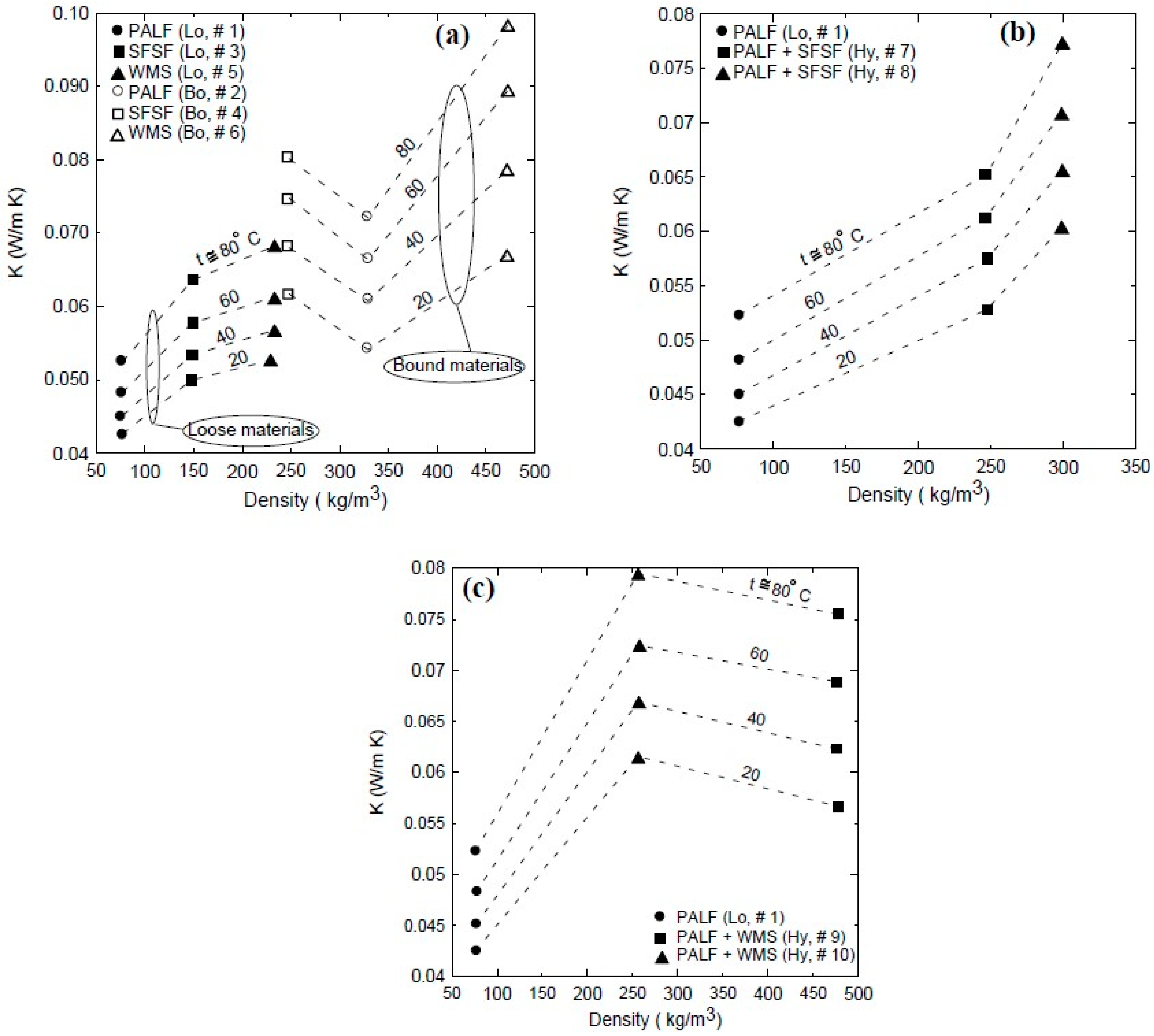

4.3. Thermal Conductivity Coefficient Analyses

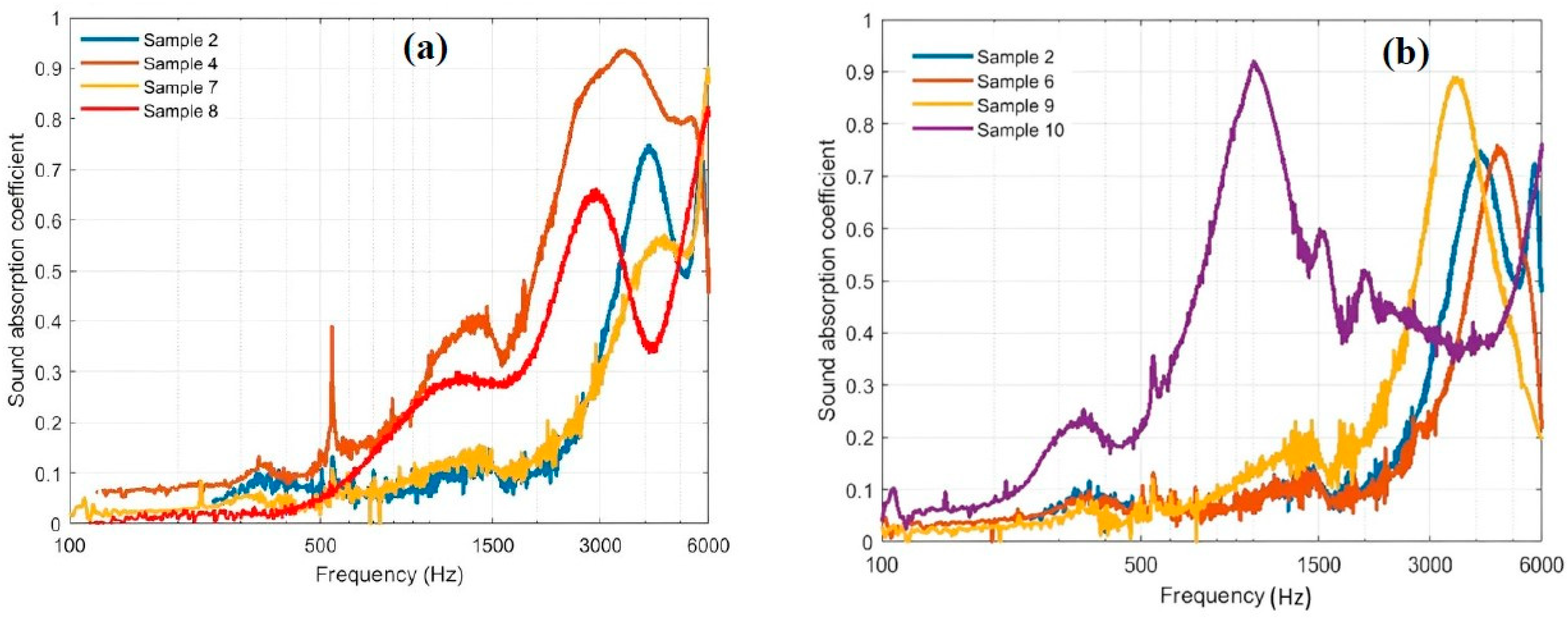

4.4. Sound Absorption Coefficient Determinations

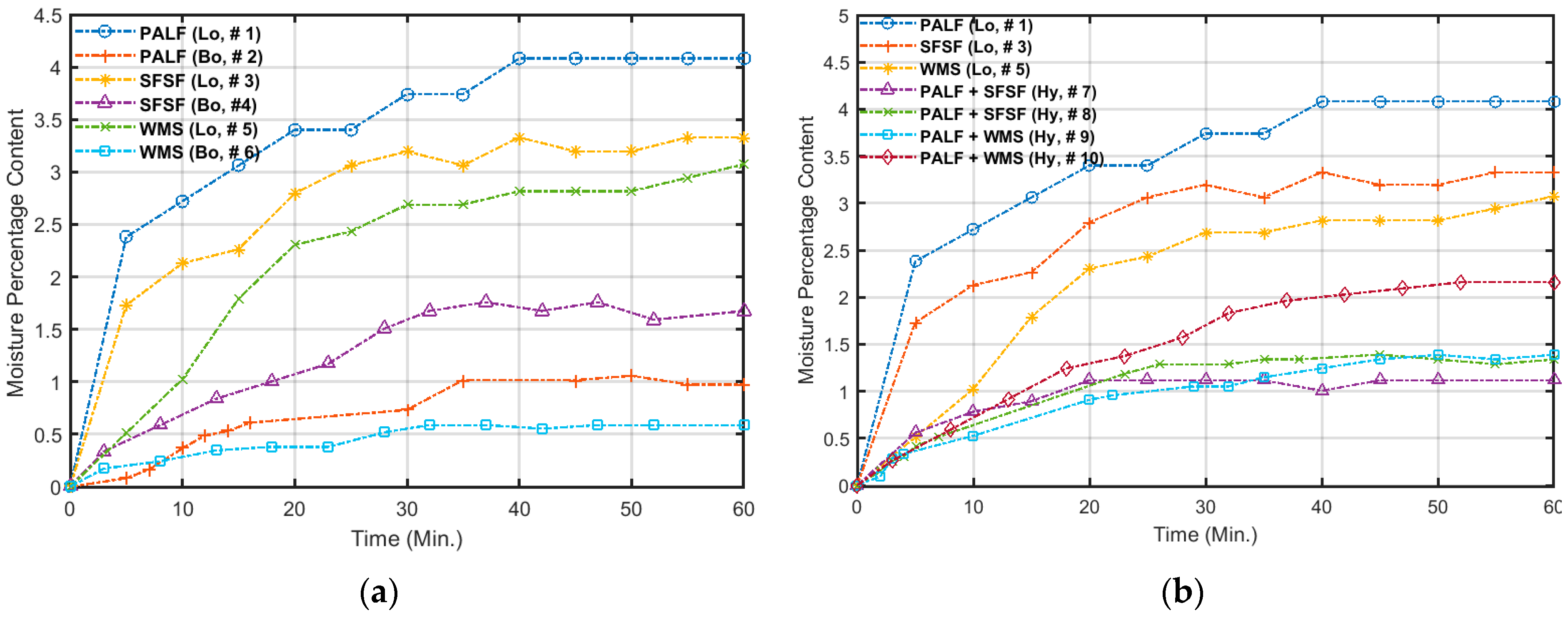

4.5. Moisture Content

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclatures

| Bo | Bound |

| DSC | Differential Scanning Calorimetry |

| DTGA | Differential thermogravimetric analysis |

| Hy | Hybrid |

| Lo | Loose |

| K | Thermal conductivity coefficient |

| NRC | Noise reduction coefficient |

| PALF | Pineapple leaf fiber |

| RH | Relative humidity |

| SAC | Sound absorption coefficient |

| SFS | Sunflower seed |

| SFSF | Sunflower seed fiber |

| TGA | Thermogravimetric analysis |

| WMS | Watermelon seed |

References

- Malina, R.; McConnachie, D.; Winchester, N.; Wollersheim, C.; Paltsev, S.; Waitz, I. The impact of the European Union Emissions Trading Scheme on US aviation. J. Air Transp. Manag. 2012, 19, 36–41. [Google Scholar] [CrossRef]

- Rangappa, S.M.; Siengchin, S. Natural fibers as perspective materials. Appl. Sci. Eng. Prog. 2018, 11, 233. [Google Scholar] [CrossRef]

- Sangmesh, B.; Patil, N.; Jaiswal, K.K.; Gowrishankar, T.P.; Selvakumar, K.K.; Jyothi, M.S.; Jyothilakshmi, R.; Kumar, S. Development of sustainable alternative materials for the construction of green buildings using agricultural residues: A review. Constr. Build. Mater. 2023, 368, 130457. [Google Scholar]

- Silva, G.; Kim, S.; Aguilar, R.; Nakamatsu, J. Natural fibers as reinforcement additives for geopolymers—A review of potential eco-friendly applications to the construction industry. Sustain. Mater. Technol. 2020, 23, e00132. [Google Scholar] [CrossRef]

- Saudi and Middle East Green Initiatives. Available online: https://www.greeninitiatives.gov.sa/ar-sa/about-mgi/mgi-targets/planting-trees/plant-trees-across-the-middle-east/ (accessed on 9 February 2023).

- Buckle, K. Biotechnology opportunities in waste treatment and utilisation for the food industry. In Biotechnology and the Food Industry; Benthame Electronic Books: Sharjah, United Arab Emirates, 1989; pp. 261–277. [Google Scholar]

- Tangjuank, S. Thermal insulation and physical properties of particleboards from pineapple leaves. Int. J. Phys. Sci. 2011, 6, 4528–4532. [Google Scholar]

- Kumfu, S.; Jintakosol, T. Thermal Insulation Produced from Pineapple Leaf and Natural Rubber Latex. Adv. Mater. Res. 2012, 506, 453–456. [Google Scholar] [CrossRef]

- Thilagavathi, G.; Muthukumar, N.; Neela Krishnanan, S.; Senthilram, T. Development and Characterization of Pineapple Fibre Nonwovens for Thermal and Sound Insulation Applications. J. Nat. Fibers 2020, 17, 1391–1400. [Google Scholar] [CrossRef]

- Do, N.H.; Tran, V.T.; Tran, Q.B.; Le, K.A.; Thai, Q.B.; Nguyen, P.T.; Duong, H.M.; Le, P.K. Recycling of Pineapple Leaf and Cotton Waste Fibers into Heat-insulating and Flexible Cellulose Aerogel Composites. J. Polym. Environ. 2021, 29, 1112–1121. [Google Scholar] [CrossRef]

- Flagella, Z.; Monteleone, M. Perspectives on sunflower as an energy crop. In Energy Crops; Halford, G., Karp, A., Eds.; RSC Energy and Environment, Series No. 3; Royal Society of Chemistry: Cambridge, UK, 2011; Chapter 9. [Google Scholar]

- de Carvalho, P.S.; Dalla Nora, M.; da Rosa, L.C. Development of an acoustic absorbing material based on sunflower residue following the cleaner production techniques. J. Clean. Prod. 2020, 270, 122478. [Google Scholar] [CrossRef]

- Georgiev, A.; Yoleva, A.; Djambazov, S. Effect of wheat straw and sunflower seeds husks as pore forming agents on the properties of porous clay bricks. J. Chem. Technol. Met. 2017, 52, 885–891. [Google Scholar]

- Binici, H.; Eken, M.; Kara, M.; Dolaz, M. An environment-friendly thermal insulation material from sunflower stalk, textile waste and stubble fibers. In Proceedings of the 2013 International Conference on Renewable Energy Research and Applications (ICRERA), Madrid, Spain, 20–23 October 2013. [Google Scholar]

- Darvishi, H.; Zarein, M. Thermal Conductivity of Sunflower Seed as a Function of Moisture Content and Bulk Density. World Appl. Sci. J. 2012, 18, 1321–1325. [Google Scholar] [CrossRef]

- Binici, H.; Aksogana, O.; Dıncerc, A.; Lugad, E.; Ekene, M.; Isikaltunf, O. The possibility of vermiculite, sunflower stalk and wheat stalk using for thermal insulation material production. Therm. Sci. Eng. Prog. 2020, 18, 100567. [Google Scholar] [CrossRef]

- FAOSTAT. Food and Agriculture Data. Food and Agriculture Organization of the United Nations, Statistics Division. Available online: http://www.fao.org/faostat/en/#home (accessed on 25 October 2017).

- Odewunmi, N.A.; Umoren, S.A.; Gasem, Z.M. Watermelonwaste products as green corrosion inhibitors for mild steel in HCl solution. J. Environ. Chem. Eng. 2015, 3, 286–296. [Google Scholar] [CrossRef]

- Bharath, K.N.; Basavarajappa, S. Applications of biocomposite materials based on natural fibers from renewable resources: A review. Sci. Eng. Compos. Mater. 2016, 23, 123–133. [Google Scholar] [CrossRef]

- Sanjay, M.; Arpitha, G.R.; Naik, L.L.; Gopalakrishna, K.; Yogesha, B.J.N.R. Applications of natural fibers and its composites: An overview. Nat. Resour. 2016, 7, 108–114. [Google Scholar] [CrossRef]

- Sen, T.; Reddy, H.J. Various industrial applications of hemp, kinaf, flax and ramie natural fibres. Int. J. Innov. Manag. Technol. 2011, 2, 192. [Google Scholar]

- Ali, M.; Alabdulkarem, A.; Nuhait, A.; Al-Salem, K.; Iannace, G.; Almuzaiqer, R.; Al-Turki, A.; Al-Ajlan, F.; Al-Mosabi, Y.; Al-Sulaimi, A. Thermal and acoustic characteristics of novel thermal insulating materials made of Eucalyptus Globulus leaves and wheat straw fibers. J. Build. Eng. 2020, 32, 101452. [Google Scholar] [CrossRef]

- Ali, M.; Alabdulkarem, A.; Nuhait, A.; Al-Salem, K.; Almuzaiqer, R.; Bayaquob, O.; Salah, H.; Alsaggaf, A.; Algafri, Z. Thermal analyses of loose agave, wheat straw fibers and agave/wheat straw as new hybrid thermal insulating materials for buildings. J. Nat. Fibers 2021, 18, 2173–2188. [Google Scholar] [CrossRef]

- Arenas, J.P.; Crocker, M.J. Recent trends in porous sound-absorbing materials. Sound Vib. 2010, 44, 12–18. [Google Scholar]

- Alabdulkarem, A.; Ali, M.; Iannace, G.; Sadek, S.; Almuzaiqer, R. Thermal analysis, microstructure and acoustic characteristics of some hybrid natural insulating materials. Constr. Build. Mater. 2018, 187, 185–196. [Google Scholar] [CrossRef]

- Ali, M.E.; Alabdulkarem, A. On thermal characteristics and microstructure of a new insulation material extracted from date palm trees surface fibers. Constr. Build. Mater. 2017, 138, 276–284. [Google Scholar] [CrossRef]

- Fouladi, M.H.; Nassir, M.H.; Ghassem, M.; Shamel, M.; Peng, S.Y.; Wen, S.Y.; Xin, P.Z.; Nor, M.J.M. Utilizing Malaysian natural fibers as sound absorber. In Modeling and Measurement Methods for Acoustic Waves and for Acoustic Microdevices; Electronic Books; Intech Open: London, UK, 2013; pp. 161–170. [Google Scholar]

- Berardi, U.; Iannace, G. Acoustic characterization of natural fibers for sound absorption applications. Build. Environ. 2015, 94, 840–852. [Google Scholar] [CrossRef]

- Available online: https://www.gulfindustrialgroup.com/saaf/wp-content/uploads/2016/08/WOOD-ADHESIVE-78-1040-MSDS.pdf (accessed on 1 October 2023).

- ASTM D2196; Standard Test Methods for Rheological Properties of Non-Newtonian Materials by Rotational Viscometer. ASTM International: West Conshohocken, PA, USA, 2020.

- ASTM D1172; Standard Guide for pH of Aqueous Solutions of Soaps and Detergents. ASTM International: West Conshohocken, PA, USA, 2015.

- ASTM D1644; Standard Test Methods for Nonvolatile Content of Varnishes. ASTM International: West Conshohocken, PA, USA, 2017.

- ASTM D790-03;A; Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials. ASTM International: West Conshohocken, PA, USA, 2003. Available online: www.astm.org (accessed on 1 October 2023).

- ASTM E1131-08; Standard Test Method for Compositional Analysis by Thermogravimetry. ASTM International: West Conshohocken, PA, USA, 2008.

- ASTM D3418; Standard Test Method for Transition Temperatures of Polymers by Differential Scanning Calorimetry. ASTM International: West Conshohocken, PA, USA, 2008.

- ASTM-C518; Standard Test Method for Steady-State Thermal Transmission Properties by Means of the Heat Flow Meter Apparatus (C 518). American Society of Testing and Materials (ASTM): West Conshohocken, PA, USA, 2010; pp. 152–166.

- Ali, M.; Almuzaiqer, R.; Al-Salem, K.; Alabdulkarem, A.; Nuhait, A. New novel thermal insulation and sound-absorbing materials from discarded facemasks of COVID-19 pandemic. Sci. Rep. 2021, 11, 23240. [Google Scholar] [CrossRef] [PubMed]

- ISO 10534-1, A; Determination of Sound Absorption Coefficient and Impedance in Impedance Tubes—Part 1: Method Using Standing Wave Ratio. International Organization for Standardization: Geneva, Switzerland, 1996.

- ISO 10534-2, A; Determination of Sound Absorption Coefficient and Impedance in Impedance Tubes—Part 2: Transfer-function Method. International Organization for Standardization: Geneva, Switzerland, 1998.

- ASTM D2974—07A ASTM D2974-07; Standard Test Methods for Moisture, Ash, and Organic Matter of Peat and Other Organic Soils. ASTM International: West Conshohocken, PA, USA, 2007.

- RILEM-TC. Test for the determination of modulus of rupture and limit of proportionality of thin fibre reinforced cement sections. In RILEM Recommendations for the Testing and Use of Constructions Materials; RILEM, Ed.; E & F SPON: London, UK, 1984; pp. 161–163. ISBN 2351580117. [Google Scholar]

- Moffat, R.J. Describing uncertainties in experimental results. Exp. Therm. Fluid Sci. 1988, 1, 3–7. [Google Scholar] [CrossRef]

- Asdrubali, F.; D’Alessandr, F.; Schiavoni, S. A review of unconventional sustainable building insulation materials. Sustain Mater Technol. 2015, 4, 1–17. [Google Scholar] [CrossRef]

- Korjenic, A.; Petranek, V.; Zach, J.; Hroudova, J. Development and performance evaluation of natural thermal-insulation materials composed of renewable resources. Energy Build. 2011, 43, 2518–2523. [Google Scholar] [CrossRef]

- Manohar, K.; Ramlakhan, D.; Kochhar, G.; Haldar, S. Biodegradable fibrous thermal insulation. J. Braz. Soc. Mech. Sci. Eng. 2006, 28, 45–47. [Google Scholar] [CrossRef]

- Danihelova, A.; Nemec, M.; Gergel, T.; Gejdos, M.; Gordanova, J.; Scensny, P. Usage of Recycled Technical Textiles as Thermal Insulation and an Acoustic Absorber. Sustainability 2019, 11, 2968. [Google Scholar] [CrossRef]

- Nandanwar, A.; Kiran, M.C.; Varadarajulu, K.C. Influence of Density on Sound Absorption Coefficient of Fiber Board. Open J. Acoust. 2017, 7, 1–9. [Google Scholar] [CrossRef]

- Na, Y.; Lancaster, J.; Casali, J.; Cho, G. Sound Absorption Coefficients of Micro-fiber Fabrics by Reverberation Room Method. Text. Res. J. 2007, 77, 330–335. [Google Scholar] [CrossRef]

- Shahid, N.S.M.; Ahmad, M.A.; Tahir, F.L. Sound Absorption Coefficient of Different Green Materials Polymer on Noise Redction. Int. J. Innov. Tech. Explor. Eng. 2020, 9, 2773–2777. [Google Scholar] [CrossRef]

- Bainbridge, D.A. High performance low cost buildings of straw. Agric. Ecosyst. Environ. 1986, 16, 281–284. [Google Scholar] [CrossRef]

| Ingredients | |||

|---|---|---|---|

| Name | Case No. | Content % | |

| Polyvinyl Acetate | 9003-20-7 | 77–85 | |

| Water | 1132-18-58 | 5–10 | |

| Dibutyl phthalate (DBP) | 84-74-2 | 1–3 | |

| Calcium Carbonate | 1317-65-3 | 10–20 | |

| Physical and chemical properties | |||

| Base material | Polyvinyl Acetate | Coverage (Approx.) | 4–5 m3/kg, depending on the surfaces |

| Color | Milky white | Application temperature | 5–50 °C |

| Viscosity at 25 °C, ASTM D2196 [30] | 25,000–34,000 CPS (Sp.# 7 at 20 rpm) | Drying time | 30 min to approx. 1 h (depends on the thickness of the adhesive layer, kind of wood, and climatic conditions) |

| Density | 1.10–1.5 g/cm3 | Open time | 1–5 min (depends on climatic conditions) |

| PH, ASTM D1172 [31] | 6.5–8 | Full cure | 24 h (depending on climatic conditions) |

| Solid contents, ASTM D1644 [32] | 51–56% | Pressing time | 1–2 h (depending on climatic conditions and wood type) |

| Material | Sample Number | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Lo (# 1) | Bo (# 2) | Lo (# 3) | Bo (# 4) | Lo (# 5) | Bo (# 6) | Hy (# 7) | Hy (# 8) | Hy (# 9) | Hy (# 10) | Bo (# 11) | |

| PALF % | 100 | 87 | 0.0 | 0.0 | 0.0 | 0.0 | 42.0 | 17.0 | 33.0 | 17.0 | 0.0 |

| SFSF % | 0.0 | 0.0 | 100 | 69 | 0.0 | 0.0 | 42.0 | 55.0 | 0.0 | 0.0 | 46.0 |

| WMS% | 0.0 | 00 | 0.0 | 0.0 | 100 | 69.0 | 0.0 | 0.0 | 33.0 | 52.0 | 0.0 |

| The ratio of the polymerized binder to the total mass % | 0.0 | 13 | 0.0 | 31 | 0.0 | 31.0 | 16.0 | 28.0 | 34.0 | 31.0 | 54.0 |

| Thickness, H (mm) | 21.0 | 13.0 | 21.0 | 21.0 | 21.0 | 11.0 | 21.0 | 22.0 | 11.0 | 26.0 | 18.0 |

| Figure # | Figure 1c | Figure 5a | Figure 2b | Figure 5b | Figure 3b | Figure 5c | Figure 5d | Figure 5e | Figure 5f | Figure 5g | Figure 5h |

| Density of dried specimen (kg/m3) | 76.5 | 329 | 148 | 248 | 235 | 472 | 247 | 299 | 478 | 256 | 432 |

| Total dried mass (g) | 106 | 370 | 210 | 469 | 333 | 467 | 475 | 592 | 486 | 600 | 700 |

| Sample No. | Thickness d, (mm) | Width b, (mm) | Span, L (mm) | Slope (S) (N/mm) |

|---|---|---|---|---|

| 2 | 13.0 | 49.5 | 150 | 6.39 |

| 4 | 21.0 | 54.0 | 150 | 9.20 |

| 6 | 11.0 | 48.0 | 150 | 7.85 |

| 7 | 21.0 | 52.0 | 150 | 4.51 |

| 8 | 22.0 | 49.0 | 150 | 31.13 |

| 10 | 26.0 | 48.0 | 150 | 1.98 |

| Sample No. | Slope (N/mm), S | Flexure Modulus (MPa), Ef | Flexural Stress (MPa), σf | Flexural Strain at Flexural Strength, ϵf |

|---|---|---|---|---|

| 2 | 6.39 | 44.30 | 0.64 | 0.013 |

| 4 | 9.20 | 22.33 | 0.38 | 0.019 |

| 6 | 7.85 | 103.65 | 1.37 | 0.017 |

| 7 | 4.51 | 8.65 | 0.23 | 0.037 |

| 8 | 31.13 | 60.81 | 1.09 | 0.032 |

| 10 | 1.98 | 2.54 | 0.10 | 0.046 |

| Figure # | A | B | R2, % | |

|---|---|---|---|---|

| Sample 1, ● | Figure 15 | 0.038 | 0.0002 | 99.6 |

| Sample 2, ○ | Figure 15 | 0.049 | 0.0003 | 99.9 |

| Sample 3, ■ | Figure 15 | 0.045 | 0.0002 | 98.9 |

| Sample 4, □ | Figure 15 | 0.054 | 0.0003 | 99.7 |

| Sample 5, ▲ | Figure 15 | 0.047 | 0.0002 | 98.0 |

| Sample 6, Δ | Figure 15 | 0.058 | 0.0005 | 99.7 |

| Sample 7, * | Figure 16a | 0.049 | 0.0002 | 100.0 |

| Sample 8, ♦ | Figure 16a | 0.054 | 0.0003 | 99.8 |

| Sample 9, ♦ | Figure 16b | 0.049 | 0.0003 | 99.95 |

| Sample 10, ⁎ | Figure 16b | 0.055 | 0.0003 | 99.6 |

| Natural Raw Materials | Density (kg/m3) | Thermal Conductivity (W/(m.K) | References |

|---|---|---|---|

| Bo PALF (#2) | 329 | 0.0541–0.0721 | Current |

| Bo SFSF (#4) | 248 | 0.0617–0.0801 | Current |

| Bo WMS (#6) | 472 | 0.0669–0.0982 | Current |

| Hy (#7) | 247 | 0.0528–0.0652 | Current |

| Hy (#8) | 299 | 0.0604–0.0772 | Current |

| Hy (#9) | 478 | 0.0566–0.0755 | Current |

| Hy (#10) | 256 | 0.0616–0.0795 | Current |

| Bound Eucalyptus globulus leaves | 153.0 | 0.0472–0.0599 | [22] |

| Bound wheat straw fibers | 130.0 | 0.0466–0.0569 | [22] |

| Hybrid of Eucalyptus globulus leaves + wheat straw fibers | 211.0 | 0.0460–0.0574 | [22] |

| Hybrid (date palm tree surface fibers + apple of Sodom fibers) | 114.0–233.0 | 0.0423–0.0529 | [25] |

| Date palm surface fibers | 176–260 | 0.0475–0.0697 | [26] |

| Bagasse | 70–350 | 0.0460–0.0550 | [43] |

| Straw bale | 50–150 | 0.0380–0.0670 | [43] |

| Rice husk | 154–168 | 0.0464–0.566 | [43] |

| Corn cob | 171–334 | 0.101 | [43] |

| Jute | 26.1 | 0.0458 | [44] |

| Flax | 32.1 | 0.0429 | [44] |

| Technical hemp | 30.2 | 0.0486 | [44] |

| Coconut fiber | 40–90 | 0.0480–0.0576 | [45] |

| Rock wool | 40–200 | 0.033–0.040 | [43] |

| Expanded polystyrene | 15–35 | 0.031–0.038 | [43] |

| Kenaf | 30–180 | 0.034–0.043 | [43] |

| Natural Fiber Materials | Density, kg/m3 | Thickness of Board or Fiber, m | Sound Absorption Coefficients | NRC | References | |||

|---|---|---|---|---|---|---|---|---|

| Frequency, Hz | ||||||||

| 250 | 500 | 1000 | 2000 | |||||

| PALF (Bo, 2) | 329 | 0.013 | 0.05 | 0.07 | 0.05 | 0.10 | 0.05 | Current study |

| SFSF (Bo, 4) | 248 | 0.021 | 0.07 | 0.13 | 0.32 | 0.52 | 0.25 | Current study |

| WMS (Bo, 6) | 472 | 0.011 | 0.05 | 0.07 | 0.05 | 0.09 | 0.05 | Current study |

| (PALF + SFSF) (Hy, 7) | 247 | 0.021 | 0.03 | 0.05 | 0.11 | 0.13 | 0.10 | Current study |

| (PALF + SFSF) (Hy, 8) | 299 | 0.022 | 0.007 | 0.05 | 0.25 | 0.35 | 0.15 | Current study |

| (PALF + WMS) (Hy, 9) | 478 | 0.011 | 0.03 | 0.06 | 0.13 | 0.21 | 0.10 | Current study |

| (PALF + WMS) (Hy, 10) | 256 | 0.026 | 0.12 | 0.21 | 0.91 | 0.52 | 0.45 | Current study |

| Kenaf (light) | 50 | 0.06 | 0.19 | 0.33 | 0.68 | 0.9 | 0.55 | [28] |

| Kenaf (dense) | 100 | 0.04 | 0.18 | 0.32 | 0.70 | 0.94 | 0.55 | [28] |

| Wood (fibers) | 100 | 0.04 | 0.40 | 0.50 | 0.65 | 0.91 | 0.60 | [28] |

| Wood (mineralized) | 260 | 0.03 | 0.10 | 0.10 | 0.20 | 0.40 | 0.20 | [28] |

| Coconut | 60 | 0.04/0.06 | 0.2 | 0.34 | 0.67 | 0.79 | 0.50 | [28] |

| Cork | 100 | 0.03 | 0.02 | 0.10 | 0.30 | 0.86 | 0.30 | [28] |

| Cane (only wooden) | 400 | 0.04 | 0.06 | 0.12 | 0.47 | 0.43 | 0.25 | [28] |

| Fleece (100% polyester) fiber | 60 | 0.0035 | 0.08 | 0.12 | 0.19 | 0.21 | 0.15 | [48] |

| Queenscord fiber | 160 | 0.0019 | 0.05 | 0.14 | 0.34 | 0.30 | 0.20 | [48] |

| Mesh fiber | 100 | 0.0033 | 0.18 | 0.02 | 0.05 | 0.07 | 0.10 | [48] |

| Suede fiber | 300 | 0.0006 | 0.09 | 0.13 | 0.24 | 0.28 | 0.20 | [48] |

| Wood fiberboard | 480 | 0.018 | 0.11 | 0.14 | 0.21 | 0.34 | 0.20 | [47] |

| Wood fiberboard | 380 | 0.025 | 0.16 | 0.17 | 0.31 | 0.33 | 0.25 | [47] |

| Wood fiberboard | 240 | 0.018 | 0.16 | 0.20 | 0.30 | 0.40 | 0.25 | [47] |

| Banana stem | 100 | 0.010 | --- | 0.05 | 0.10 | 0.42 | 0.15 | [49] |

| Grass | 48 | 0.010 | --- | 0.06 | 0.15 | 0.44 | 0.20 | [49] |

| Palm oil leaves | 152 | 0.010 | --- | 0.05 | 0.08 | 0.19 | 0.10 | [49] |

| Lemongrass | 201 | 0.010 | --- | 0.06 | 0.15 | 0.45 | 0.20 | [49] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ali, M.; Al-Suhaibani, Z.; Almuzaiqer, R.; Al-Salem, K.; Nuhait, A.; Algubllan, F.; Al-Howaish, M.; Aloraini, A.; Alqahtani, I. Sunflower and Watermelon Seeds and Their Hybrids with Pineapple Leaf Fibers as New Novel Thermal Insulation and Sound-Absorbing Materials. Polymers 2023, 15, 4422. https://doi.org/10.3390/polym15224422

Ali M, Al-Suhaibani Z, Almuzaiqer R, Al-Salem K, Nuhait A, Algubllan F, Al-Howaish M, Aloraini A, Alqahtani I. Sunflower and Watermelon Seeds and Their Hybrids with Pineapple Leaf Fibers as New Novel Thermal Insulation and Sound-Absorbing Materials. Polymers. 2023; 15(22):4422. https://doi.org/10.3390/polym15224422

Chicago/Turabian StyleAli, Mohamed, Zeyad Al-Suhaibani, Redhwan Almuzaiqer, Khaled Al-Salem, Abdullah Nuhait, Fahad Algubllan, Meshari Al-Howaish, Abdullah Aloraini, and Ibrahim Alqahtani. 2023. "Sunflower and Watermelon Seeds and Their Hybrids with Pineapple Leaf Fibers as New Novel Thermal Insulation and Sound-Absorbing Materials" Polymers 15, no. 22: 4422. https://doi.org/10.3390/polym15224422

APA StyleAli, M., Al-Suhaibani, Z., Almuzaiqer, R., Al-Salem, K., Nuhait, A., Algubllan, F., Al-Howaish, M., Aloraini, A., & Alqahtani, I. (2023). Sunflower and Watermelon Seeds and Their Hybrids with Pineapple Leaf Fibers as New Novel Thermal Insulation and Sound-Absorbing Materials. Polymers, 15(22), 4422. https://doi.org/10.3390/polym15224422