The Interface Strengthening of Multi-Walled Carbon Nanotubes/Polylactic Acid Composites via the In-Loop Hybrid Manufacturing Method

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

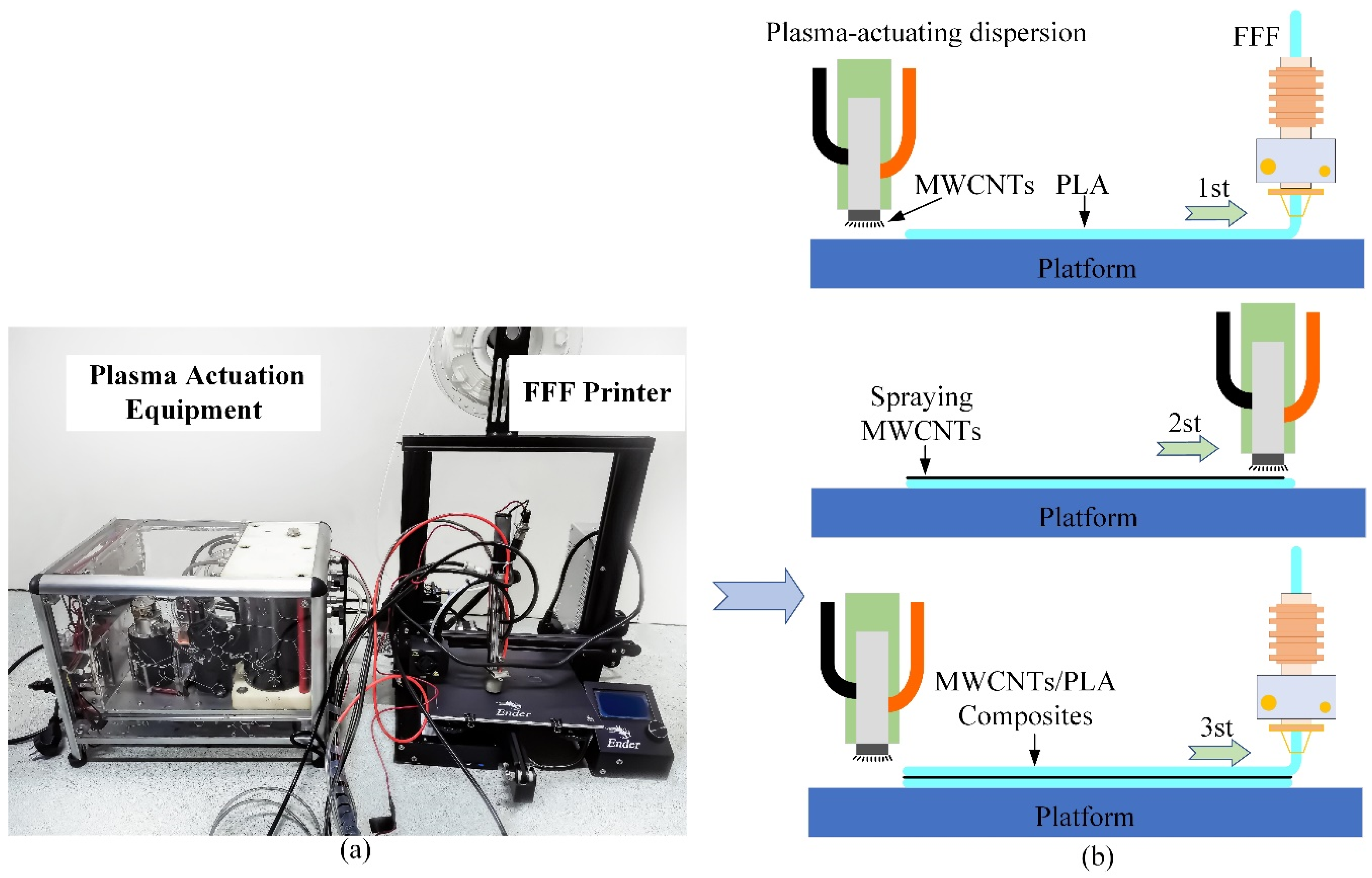

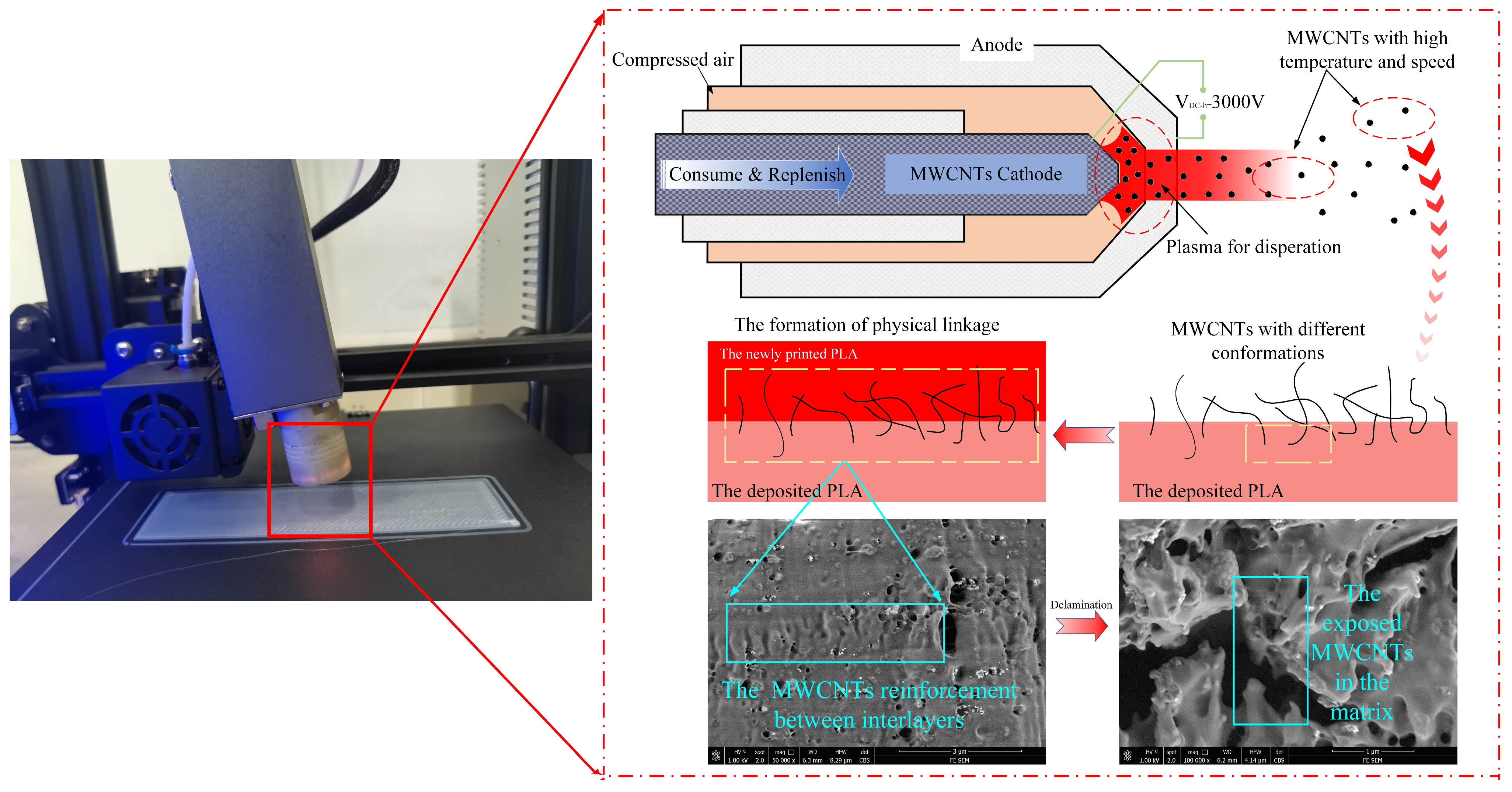

2.2. Experiment Design

3. Results and Discussion

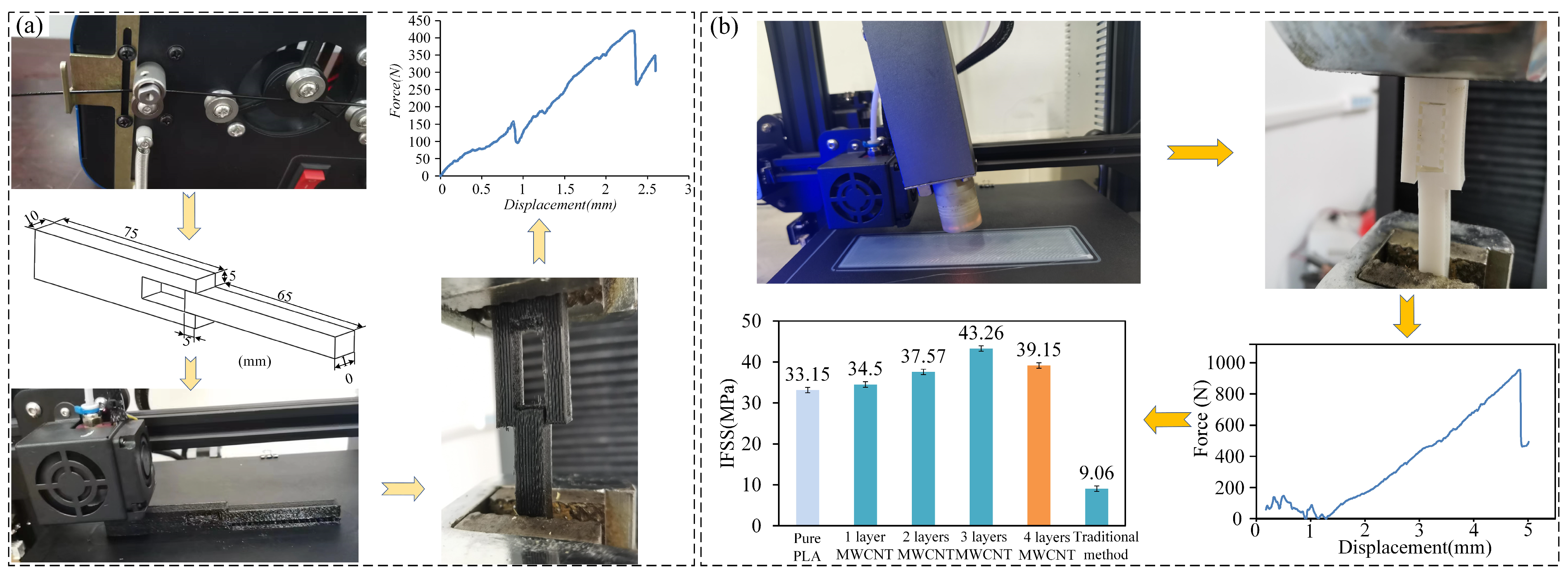

3.1. The IFSS Test Results

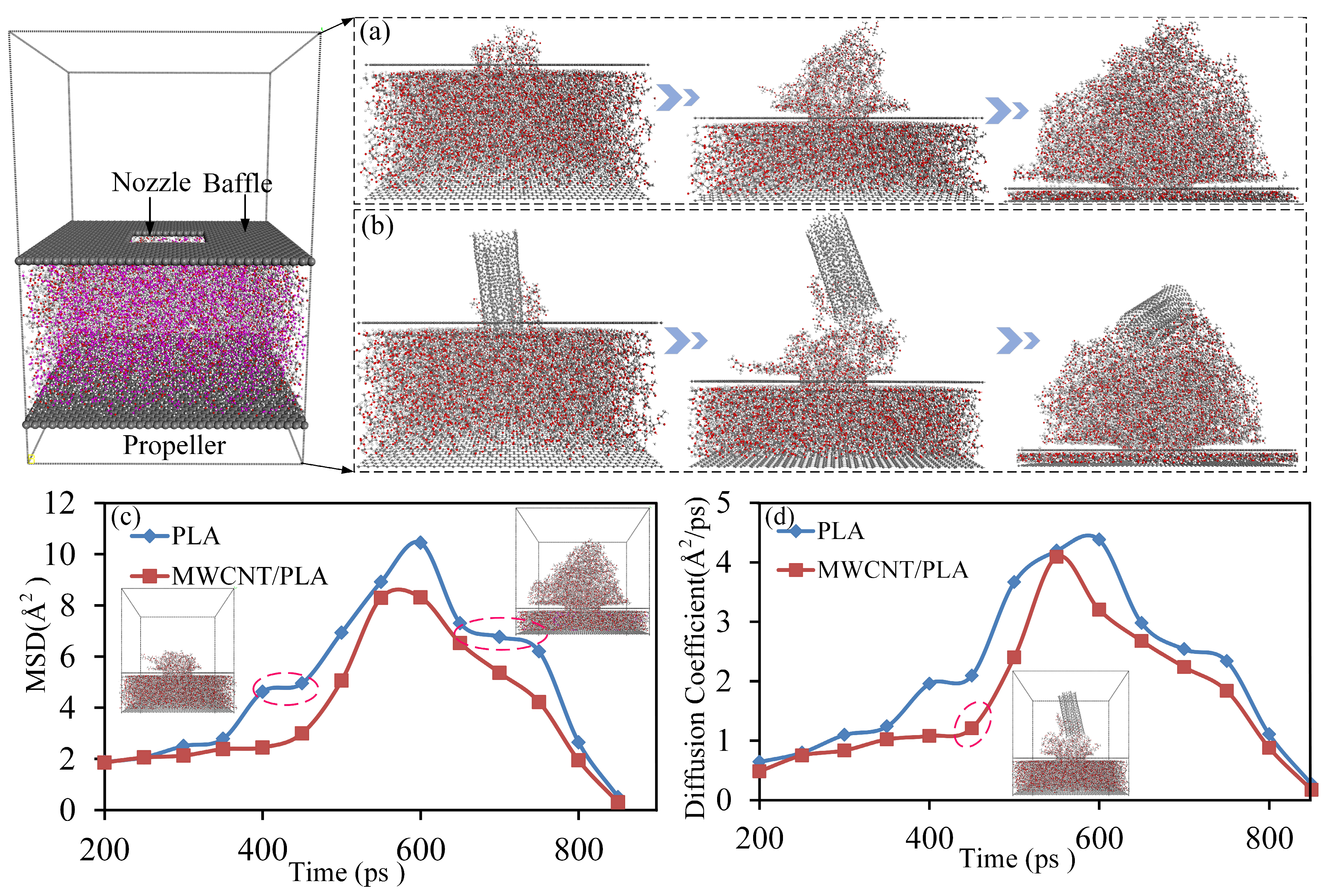

3.2. The Effect of the Proposed HM Method on Activity and Conformation of PLA Molecule

3.3. The Effect of Introducing MWCNTs on Interface Energy

4. Conclusions

- An evaluation of varying MWCNT contents’ impact on interfacial properties via MD simulations and experimental validation, revealing that a higher MWCNT content correlated with stronger interfacial properties.

- The in-loop HM method showcased a significant enhancement in the IFSS of specimens by 30.50%, reaching 43.26 MPa, 4.77 times higher than that of traditional MWCNTs/PLA composites.

- MD simulations suggest nozzle-based extrusion might impede PLA chain extension and diffusion, supporting the IFSS results observed in specimens made via the traditional method.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Xiao, X.; Roh, B.-M.; Zhu, F. Strength Enhancement in Fused Filament Fabrication via the Isotropy Toolpath. Appl. Sci. 2021, 11, 6100. [Google Scholar] [CrossRef]

- Gu, D.D.; Meiners, W.; Wissenbach, K.; Poprawe, R. Laser additive manufacturing of metallic components: Materials, processes and mechanisms. Int. Mater. Rev. 2012, 57, 133–164. [Google Scholar] [CrossRef]

- Sun, Q.; Rizvi, G.M.; Bellehumeur, C.T.; Gu, P. Effect of processing conditions on the bonding quality of FFF polymer filaments. Rapid Prototyp. J. 2008, 14, 72–80. [Google Scholar] [CrossRef]

- Ren, Z.; Guo, R.; Bi, H.; Jia, X.; Xu, M.; Cai, L. Interfacial Adhesion of Polylactic Acid on Cellulose Surface: A Molecular Dynamics Study. ACS Appl. Mater. Interfaces 2020, 12, 3236–3244. [Google Scholar] [CrossRef]

- Caminero, M.A.; Chacón, J.M.; García-Moreno, I.; Reverte, J.M. Inter-laminar bonding performance of 3D printed continuous fibre reinforced thermoplastic composites using fused deposition modeling. Polym. Test. 2018, 68, 415–423. [Google Scholar] [CrossRef]

- Penumakala, P.K.; Santo, J.; Thomas, A. A critical review on the fused deposition modeling of thermoplastic polymer composites. Compos. Part B Eng. 2020, 201, 108336. [Google Scholar] [CrossRef]

- Cole, D.P.; Riddick, J.C.; Iftekhar Jaim, H.M.; Strawhecker, K.E.; Zander, N.E. Interfacial mechanical behavior of 3D printed ABS. J. Appl. Polym. Sci. 2016, 133, 101002. [Google Scholar] [CrossRef]

- Percoco, G.; Lavecchia, F.; Galantucci, L.M. Compressive Properties of FFF Rapid Prototypes Treated with a Low Cost Chemical Finishing. Res. J. Appl. Sci. Eng. Technol. 2012, 4, 3838–3842. [Google Scholar]

- Sood, A.K.; Ohdar, R.K.; Mahapatra, S.S. Experimental investigation and empirical modelling of FFF process for compressive strength improvement. J. Adv. Res. 2012, 3, 81–90. [Google Scholar] [CrossRef]

- Gomez-Gras, G.; Jerez-Mesa, R.; Travieso-Rodriguez, J.A.; Lluma-Fuentes, J. Fatigue performance of fused filament fabrication PLA specimens. Mater. Des. 2018, 140, 278–285. [Google Scholar] [CrossRef]

- Domingo-Espin, M.; Travieso-Rodriguez, J.A.; Jerez-Mesa, R.; Lluma-Fuentes, J. Fatigue Performance of ABS Specimens Obtained by Fused Filament Fabrication. Materials 2018, 11, 2521. [Google Scholar] [CrossRef]

- Puigoriol-Forcada, J.M.; Alsina, A.; Salazar-Martín, A.G.; Gomez-Gras, G.; Pérez, M.A. Flexural fatigue properties of polycarbonate fused-deposition modelling specimens. Mater. Des. 2018, 155, 414–421. [Google Scholar] [CrossRef]

- Parandoush, P.; Tucker, L.; Zhou, C.; Lin, D. Laser assisted additive manufacturing of continuous fiber reinforced thermoplastic composites. Mater. Des. 2017, 131, 186–195. [Google Scholar] [CrossRef]

- Aliheidari, N.; Tripuraneni, R.; Ameli, A.; Nadimpalli, S. Fracture resistance measurement of fused deposition modeling 3D printed polymers. Polym. Test. 2017, 60, 94–101. [Google Scholar] [CrossRef]

- Ferretti, P.; Leon-Cardenas, C.; Santi, G.M.; Sali, M.; Ciotti, E.; Frizziero, L.; Donnici, G.; Liverani, A. Relationship between FDM 3D Printing Parameters Study: Parameter Optimization for Lower Defects. Polymers 2021, 13, 2190. [Google Scholar] [CrossRef] [PubMed]

- Torres, J.; Cole, M.; Owji, A.; DeMastry, Z.; Gordon, A.P. An approach for mechanical property optimization of fused deposition modeling with polylactic acid via design of experiments. Rapid Prototyp. J. 2016, 22, 387–404. [Google Scholar] [CrossRef]

- Wang, S.H.; Gao, J.; Lin, S.X.; Zhang, P.; Huang, J.; Xu, L.L. Tensile deformation mechanisms of ABS/PMMA/EMA blendsIOP. Conf. Ser. Mater. Sci. Eng. 2014, 62, 012028. [Google Scholar]

- Ning, F.; Cong, W.; Qiu, J.; Wei, J.; Wang, S. Additive manufacturing of carbon fiber reinforced thermoplastic composites using fused deposition modeling. Compos. Part B Eng. 2015, 80, 369–378. [Google Scholar] [CrossRef]

- Sweeney, C.B.; Lackey, B.A.; Pospisil, M.J.; Achee, T.C.; Hicks, V.K.; Moran, A.G.; Teipel, B.R.; Saed, M.A.; Green, M.J. Welding of 3D-printed carbon nanotube–polymer composites by locally induced microwave heating. Sci. Adv. 2017, 3, e1700262. [Google Scholar] [CrossRef]

- Hart, K.R.; Dunn, R.M.; Sietins, J.M.; Mock, C.M.H.; Mackay, M.E.; Wetzel, E.D. Increased fracture toughness of additively manufactured amorphous thermoplastics via thermal annealing. Polymer 2018, 144, 192–204. [Google Scholar] [CrossRef]

- Sanatgar, R.H.; Campagne, C.; Nierstrasz, V. Investigation of the adhesion properties of direct 3D printing of polymers and nanocomposites on textiles: Effect of FFF printing process parameters. Appl. Surf. Sci. 2017, 403, 551–563. [Google Scholar] [CrossRef]

- Sezer, H.K.; Eren, O. FFF 3D printing of MWCNT reinforced ABS nanocomposite parts with enhanced mechanical and electrical properties. J. Manuf. Process. 2019, 37, 339–347. [Google Scholar] [CrossRef]

- Dorigato, A.; Moretti, V.; Dul, S.; Unterberger, S.; Pegoretti, A. Electrically conductive nanocomposites for fused deposition modelling. Synth. Met. 2017, 226, 7–14. [Google Scholar] [CrossRef]

- Hsu, Y.-W.; Wu, C.-C.; Wu, S.-M.; Su, C.-C. Synthesis and Properties of Carbon Nanotube-Grafted Silica Nanoarchitecture-Reinforced Poly(Lactic Acid). Materials 2017, 10, 829. [Google Scholar] [CrossRef]

- Dul, S.; Fambri, L.; Pegoretti, A. Filaments Production and Fused Deposition Modelling of ABS/Carbon Nanotubes Composites. Nanomaterials 2018, 8, 49. [Google Scholar] [CrossRef]

- Spinelli, G.; Kotsilkova, R.; Ivanov, E.; Petrova-Doycheva, I.; Menseidov, D.; Georgiev, V.; Di Maio, R.; Silvestre, C. Effects of Filament Extrusion, 3D Printing and Hot-Pressing on Electrical and Tensile Properties of Poly(Lactic) Acid Composites Filled with Carbon Nanotubes and Graphene. Nanomaterials 2020, 10, 35. [Google Scholar] [CrossRef]

- Papon, E.A.; Haque, A. Tensile properties, void contents, dispersion and fracture behavior of 3D printed carbon nanofiber reinforced composites. J. Reinf. Plast. Compos. 2018, 37, 381–395. [Google Scholar] [CrossRef]

- Zhou, Y.; Lei, L.; Yang, B.; Li, J.; Ren, J. Preparation and characterization of polylactic acid (PLA) carbon nanotube nanocomposites. Polym. Test. 2018, 68, 34–38. [Google Scholar] [CrossRef]

- Kim, H.-G.; Hajra, S.; Oh, D.; Kim, N.; Kim, H.J. Additive manufacturing of high-performance carbon-composites: An integrated multi-axis pressure and temperature monitoring sensor. Compos. Part B Eng. 2021, 222, 109079. [Google Scholar] [CrossRef]

- Cobos, C.M.; Garzón, L.; Martinez, J.L.; Fenollar, O.; Ferrandiz, S. Study of thermal and rheological properties of PLA loaded with carbon and halloysite nanotubes for additive manufacturing. Rapid Prototyp. J. 2019, 25, 738–743. [Google Scholar] [CrossRef]

- Vidakis, N.; Petousis, M.; Kourinou, M.; Velidakis, E.; Mountakis, N.; Fischer-Griffiths, P.E.; Grammatikos, S.; Tzounis, L. Additive manufacturing of multifunctional polylactic acid (PLA)—Multiwalled carbon nanotubes (MWCNTs) nanocomposites. Nanocomposites 2021, 7, 184–199. [Google Scholar] [CrossRef]

- Batakliev, T.; Georgiev, V.; Ivanov, E.; Kotsilkova, R.; Di Maio, R.; Silvestre, C.; Cimmino, S. Nanoindentation analysis of 3D printed poly(lactic acid)-based composites reinforced with graphene and multiwall carbon nanotubes. J. Appl. Polym. Sci. 2018, 136, 47260. [Google Scholar] [CrossRef]

- Bardot, M.; Schulz, M.D. Biodegradable Poly(Lactic Acid) Nanocomposites for Fused Deposition Modeling 3D Printing. Nanomaterials 2020, 10, 2567. [Google Scholar] [CrossRef]

- Yu, L.; Huo, S.; Wang, C.; Ye, G.; Song, P.; Feng, J.; Fang, Z.; Wang, H.; Liu, Z. Flame-retardant poly(L-lactic acid) with enhanced UV protection and well-preserved mechanical properties by a furan-containing poly phosphoramide. Int. J. Biol. Macromol. 2023, 234, 123707. [Google Scholar] [CrossRef]

- Tofangchi, A.; Han, P.; Izquierdo, J.; Iyengar, A.; Hsu, K. Effect of Ultrasonic Vibration on Interlayer Adhesion in Fused Filament Fabrication 3D Printed ABS. Polymers 2019, 11, 315. [Google Scholar] [CrossRef]

- Li, H.; Jiang, Z.; Zhang, Q.; Zhang, H.; Zhang, J. Improving the mechanical property of continuous fibre reinforced composites by promoting the polymer molecular chain activity. Compos. Commun. 2023, 38, 101518. [Google Scholar] [CrossRef]

- Sun, S.; Jin, Z.; Liu, X.; Han, Z.; Wang, Y. In situ consolidation process-based fabrication and interlaminar modification mechanism associated with CF/PEEK multiscale nanocomposites characterized by interlaminar doping of CNTs. Compos. Sci. Technol. 2022, 222, 109356. [Google Scholar] [CrossRef]

- Wu, T.H.; Mei, X.H.; Liang, L.B.; Ma, Y.M.; Bin Wang, G.; Zhang, S.L. Achieving structurally and functionally integrated electromagnetic shielding composites based on polyetheretherketone by sandwich structure. J. Sandw. Struct. Mater. 2022, 24, 484–502. [Google Scholar] [CrossRef]

- Zhang, Y.; Jing, J.; Liu, T.; Xi, L.; Sai, T.; Ran, S.; Fang, Z.; Huo, S.; Song, P. A molecularly engineered bioderived polyphosphate for enhanced flame retardant, UV-blocking and mechanical properties of poly(lactic acid). Chem. Eng. J. 2021, 411, 128493. [Google Scholar] [CrossRef]

- Ivanov, E. PLA/Graphene/MWCNT composites with improved electrical and thermal properties suitable for FFF 3D printing applications. Appl. Sci. 2019, 9, 1209. [Google Scholar] [CrossRef]

- Kotsilkov, S.; Ivanov, E.; Vitanov, N.K. Release of Graphene and Carbon Nanotubes from Biodegradable Poly(Lactic Acid) Films during Degradation and Combustion: Risk Associated with the End-of-Life of Nanocomposite Food Packaging Materials. Materials 2018, 11, 2346. [Google Scholar] [CrossRef]

- Eggeler, Y.M.; Chan, K.C.; Sun, Q.; Lantada, A.D.; Mager, D.; Schwaiger, R.; Gumbsch, P.; Schröder, R.; Wenzel, W.; Korvink, J.G.; et al. A Review on 3D Architected Pyrolytic Carbon Produced by Additive Micro/Nanomanufacturing. Adv. Funct. Mater. 2023, 2302068. [Google Scholar] [CrossRef]

- Ye, Z.; Zhao, B.; Wang, Q.; Chen, K.; Su, M.; Xia, Z.; Han, L.; Li, M.; Kong, X.; Shang, Y.; et al. Crack-Induced Superelastic, Strength-Tunable Carbon Nanotube Sponges. Adv. Funct. Mater. 2023, 33, 2303475. [Google Scholar] [CrossRef]

- Li, S.; Zhang, C.; He, Y.; Feng, M.; Ma, C.; Cui, Y. Multi-interpolation mixing effects under the action of micro-scale free arc. J. Mater. Process. Technol. 2019, 271, 645–650. [Google Scholar] [CrossRef]

- Li, H.; Li, Z.; Wang, N.; Peng, Y.; Jiang, Z.; Zhang, Q. Plasma actuating modified multiwalled carbon nanotubes (MWCNTs) to strengthen interface of MWCNTs/Polylactic acid composites by constructing interlaminar stress-transfer bridge. Polym. Test. 2023, 129, 108261. [Google Scholar] [CrossRef]

- Adams, J.W.; Merrett, C.G. Comparing different data processing methods fordetermining a Prony series from Dynamic MechanicalAnalyzer frequency data. Polym. Eng. Sci. 2023, 63, 1459–1470. [Google Scholar] [CrossRef]

- Li, H.; Li, Z.; Wang, N.; Peng, Y.; Jiang, Z.; Zhang, Q. Improving the Mechanical Properties of CCFRPLA by Enhancing the Interface Binding Energy and Strengthening the Anti-Separation Ability of a PLA Matrix. Polymers 2023, 15, 2554. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Lv, Q.; Chen, S.; Faller, R.; Li, C.; Sun, S.; Hu, S. Molecular dynamics simulations on heterogeneity and percolation of epoxy nanofilm during glass transition process. Mater. Chem. Phys. 2018, 213, 239–248. [Google Scholar] [CrossRef]

- Yan, Y.; Xu, J.; Zhu, H.; Xu, Y.; Wang, M.; Wang, B.; Yang, C. Molecular dynamics simulation of the interface properties of continuous carbon fiber/ polyimide composites. Appl. Surf. Sci. 2021, 563, 150370. [Google Scholar] [CrossRef]

- Hao, Z.; Ghanekarade, A.; Zhu, N.; Randazzo, K.; Kawaguchi, D.; Tanaka, K.; Wang, X.; Simmons, D.S.; Priestley, R.D.; Zuo, B. Mobility gradients yield rubbery surfaces on top of polymer glasses. Nature 2021, 596, 372–376. [Google Scholar] [CrossRef]

- Sun, S.; Chen, S.; Weng, X.; Shan, F.; Hu, S. Effect of Carbon Nanotube Addition on the Interfacial Adhesion between Graphene and Epoxy: A Molecular Dynamics Simulation. Polymers 2019, 11, 121. [Google Scholar] [CrossRef] [PubMed]

| Study | Method | Key Findings/Technical Data |

|---|---|---|

| Caminero et al. [5] Ning et al. [18] | Carbon Fiber-Reinforced | —Tensile strength increased by 20–40% —Flexural strength increased by 35% —Enhanced stiffness and durability |

| Sweeney et al. [19] Hart et al. [20] | Heat-Treating PLA (FFF) | —Tensile strength increased by 10–15% —Layer adhesion strength improved due to crystalline structure —Enhanced overall mechanical properties, especially stiffness |

| Alireza et al. [35] Li et al. [36] | Ultrasonic vibration | —Interlayer adhesion increased by 10% —Tensile strength increased by 10.7% |

| Sun et al. [37] Wu et al. [38] | MWCNTs-Reinforced | —Inter-laminar shear strength increased by 22.7% —The mechanical properties and electromagnetic shielding efficiency were improved |

| Parameter | Value |

|---|---|

| Nozzle diameter | 0.4 mm |

| Layer thickness | 0.2 mm |

| Top/bottom solid layers | 0.8 mm |

| Infill speed | 80 mm/s |

| Printing speed (shells) | 25 mm/s |

| Infill density | 100% |

| Extruder temperature | 200 °C |

| Bed temperature | 60 °C |

| Outline perimeters/shells | 2 |

| Raster angle | ±45° |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, H.; Jiang, Z.; Li, Z.; Peng, Y.; Zhang, Q.; Xiao, X. The Interface Strengthening of Multi-Walled Carbon Nanotubes/Polylactic Acid Composites via the In-Loop Hybrid Manufacturing Method. Polymers 2023, 15, 4426. https://doi.org/10.3390/polym15224426

Li H, Jiang Z, Li Z, Peng Y, Zhang Q, Xiao X. The Interface Strengthening of Multi-Walled Carbon Nanotubes/Polylactic Acid Composites via the In-Loop Hybrid Manufacturing Method. Polymers. 2023; 15(22):4426. https://doi.org/10.3390/polym15224426

Chicago/Turabian StyleLi, Hongbin, Zhuang Jiang, Zhihua Li, Yubao Peng, Qiushuang Zhang, and Xinyi Xiao. 2023. "The Interface Strengthening of Multi-Walled Carbon Nanotubes/Polylactic Acid Composites via the In-Loop Hybrid Manufacturing Method" Polymers 15, no. 22: 4426. https://doi.org/10.3390/polym15224426

APA StyleLi, H., Jiang, Z., Li, Z., Peng, Y., Zhang, Q., & Xiao, X. (2023). The Interface Strengthening of Multi-Walled Carbon Nanotubes/Polylactic Acid Composites via the In-Loop Hybrid Manufacturing Method. Polymers, 15(22), 4426. https://doi.org/10.3390/polym15224426