Challenges in Manufacturing of Hemp Fiber-Reinforced Organo Sheets with a Recycled PLA Matrix

Abstract

:1. Introduction

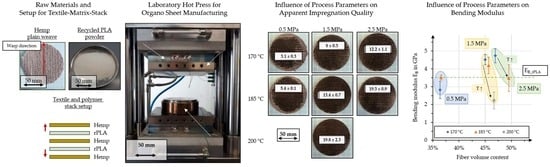

2. Materials and Methods

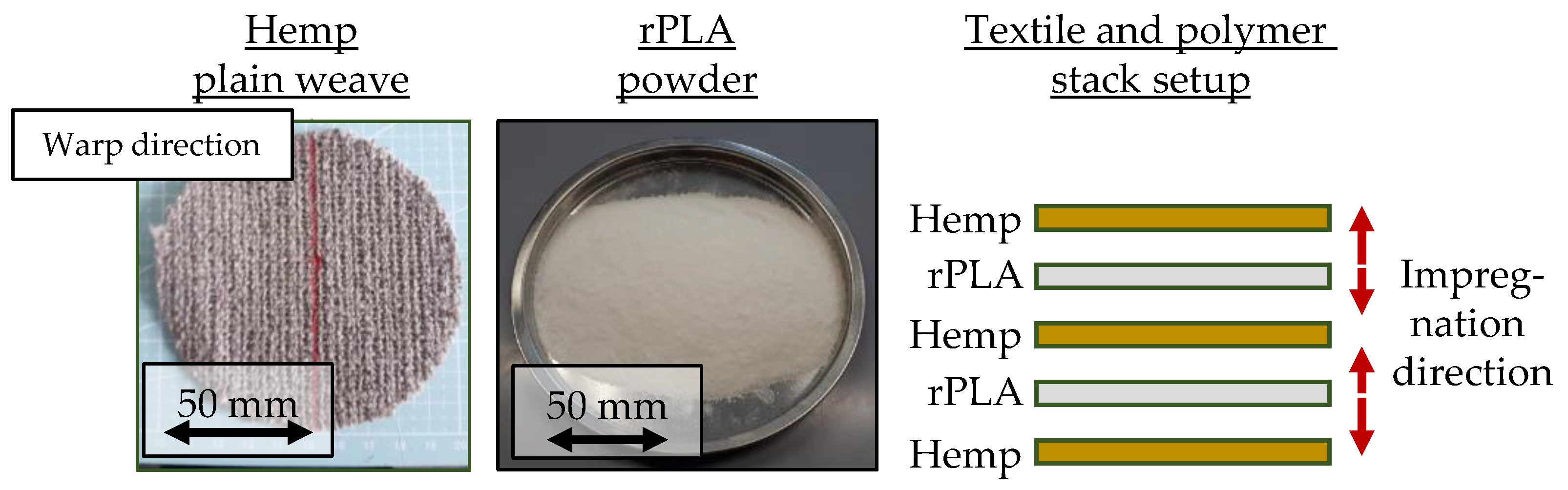

2.1. Materials

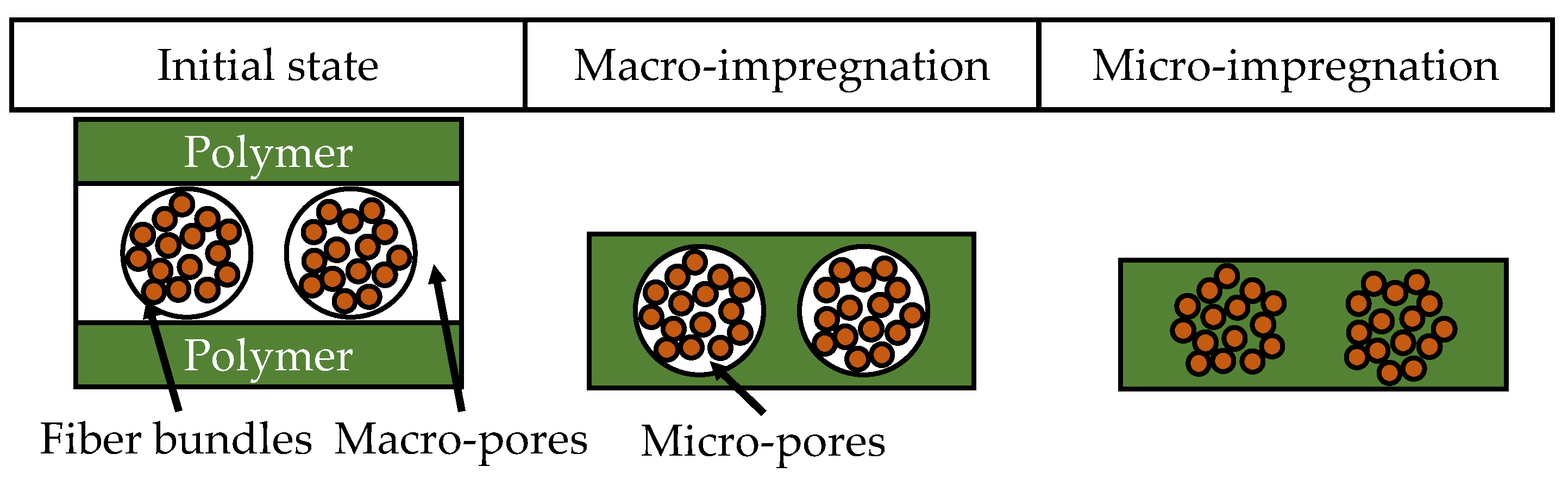

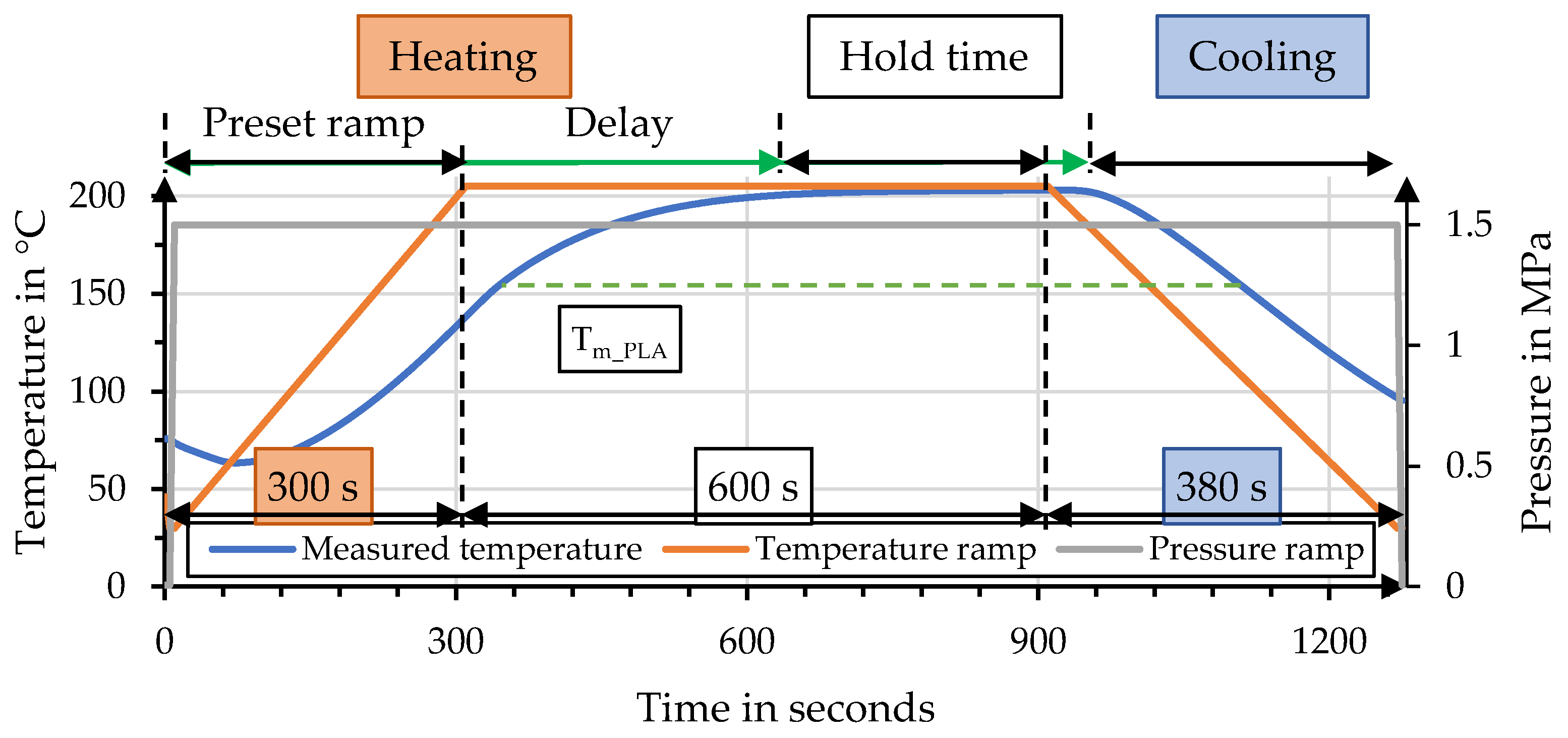

2.2. Organo Sheet Manufacturing

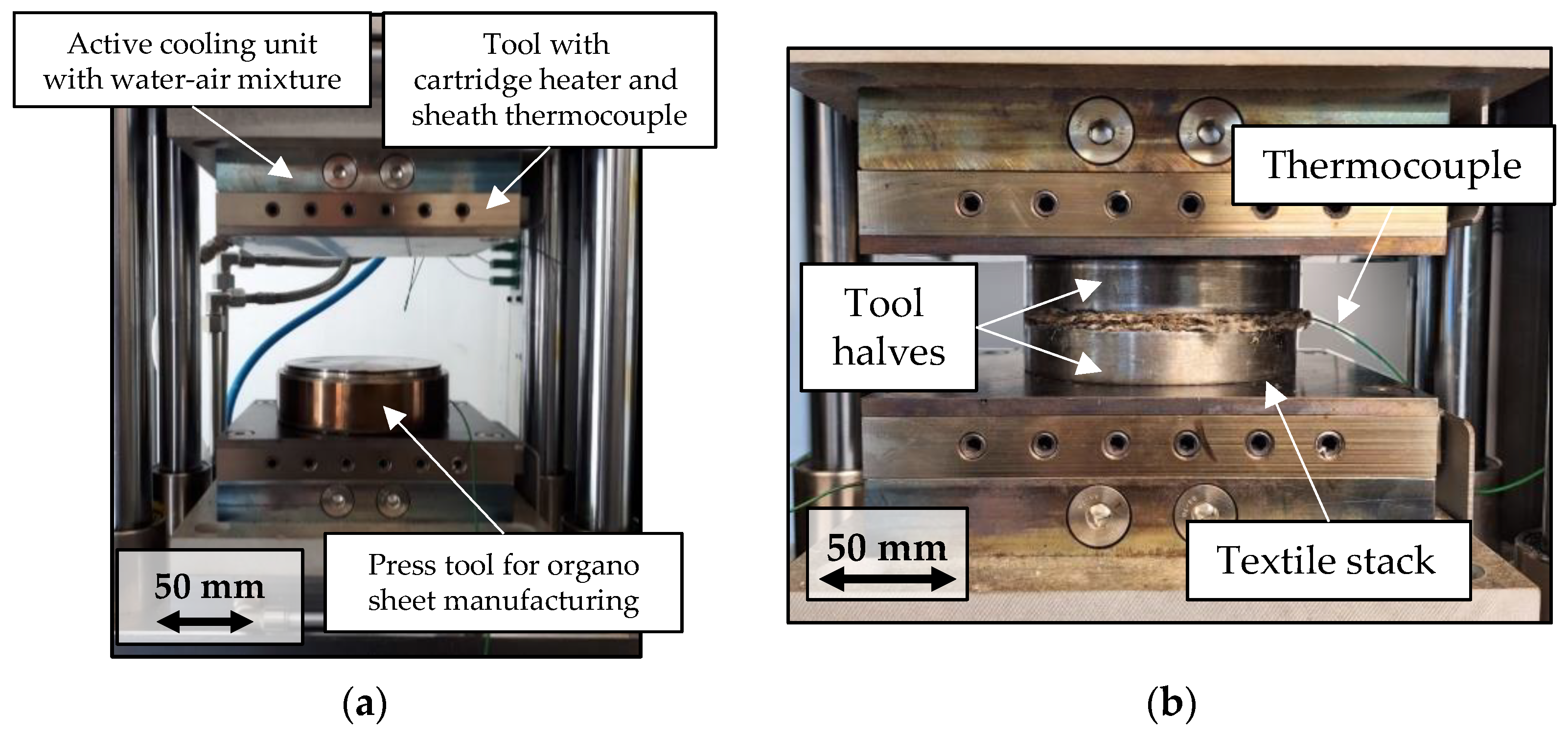

- an electromechanical cylinder for applying forces up to 20 kN in tandem with a membrane load cell as a means of force control,

- two fixed tool halves for active heating—each tool half with six cartridge heaters with a total output of 2.4 kW, together with sheath thermocouples for temperature control, as well as an active cooling unit with a water–air mixture.

- temperatures at different locations within the setup (sheath thermocouple within the tool with cartridge heater for temperature control and thermocouples for independent recording; accuracy ± 1 K),

- effective forces (membrane load cell; accuracy ± 1 N), and

- the stack thickness (high accuracy glass scale; accuracy ± 1 µm).

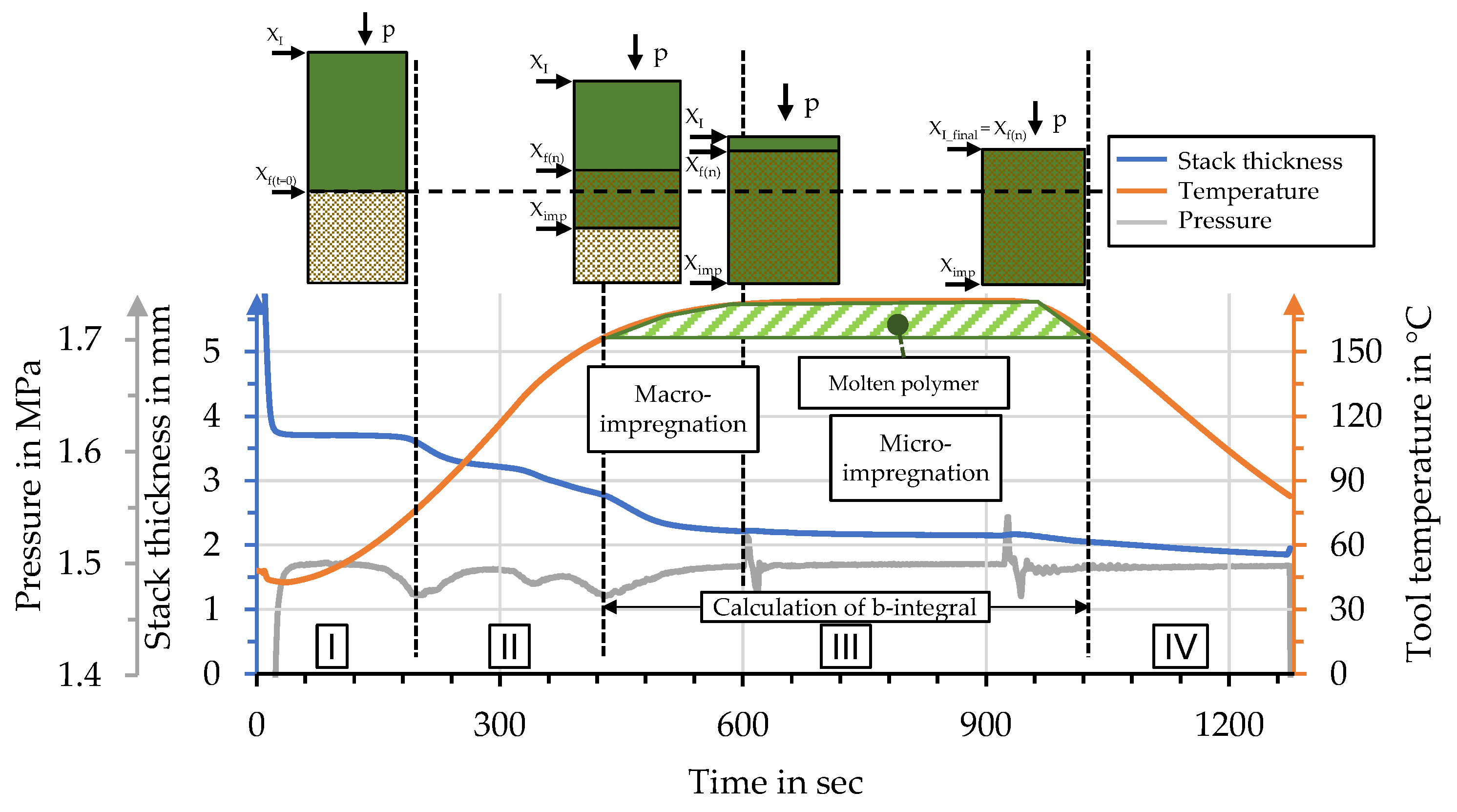

2.3. Interpretation of Process Data for B-Factor Calculation

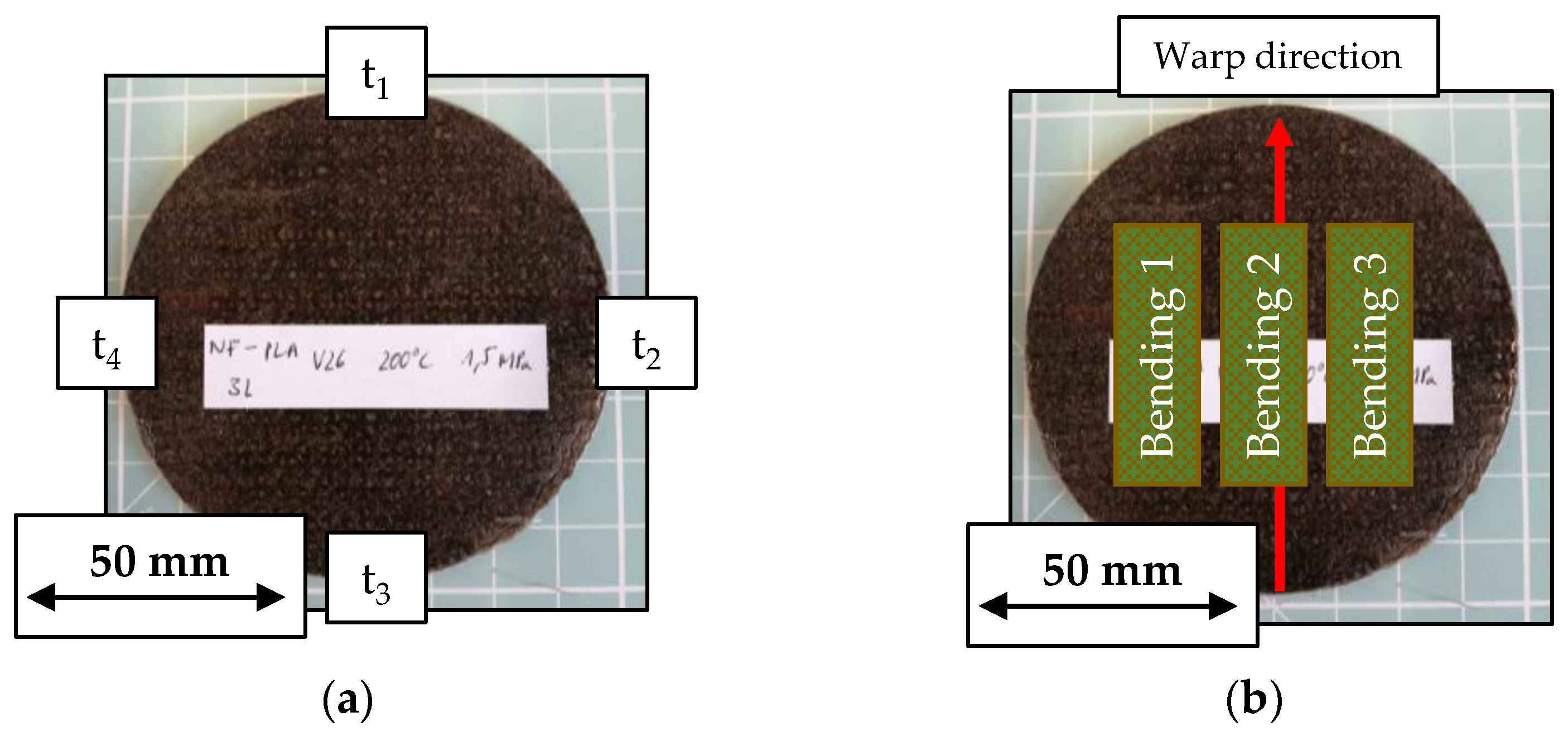

2.4. Consideration of Physical Organo Sheet Properties

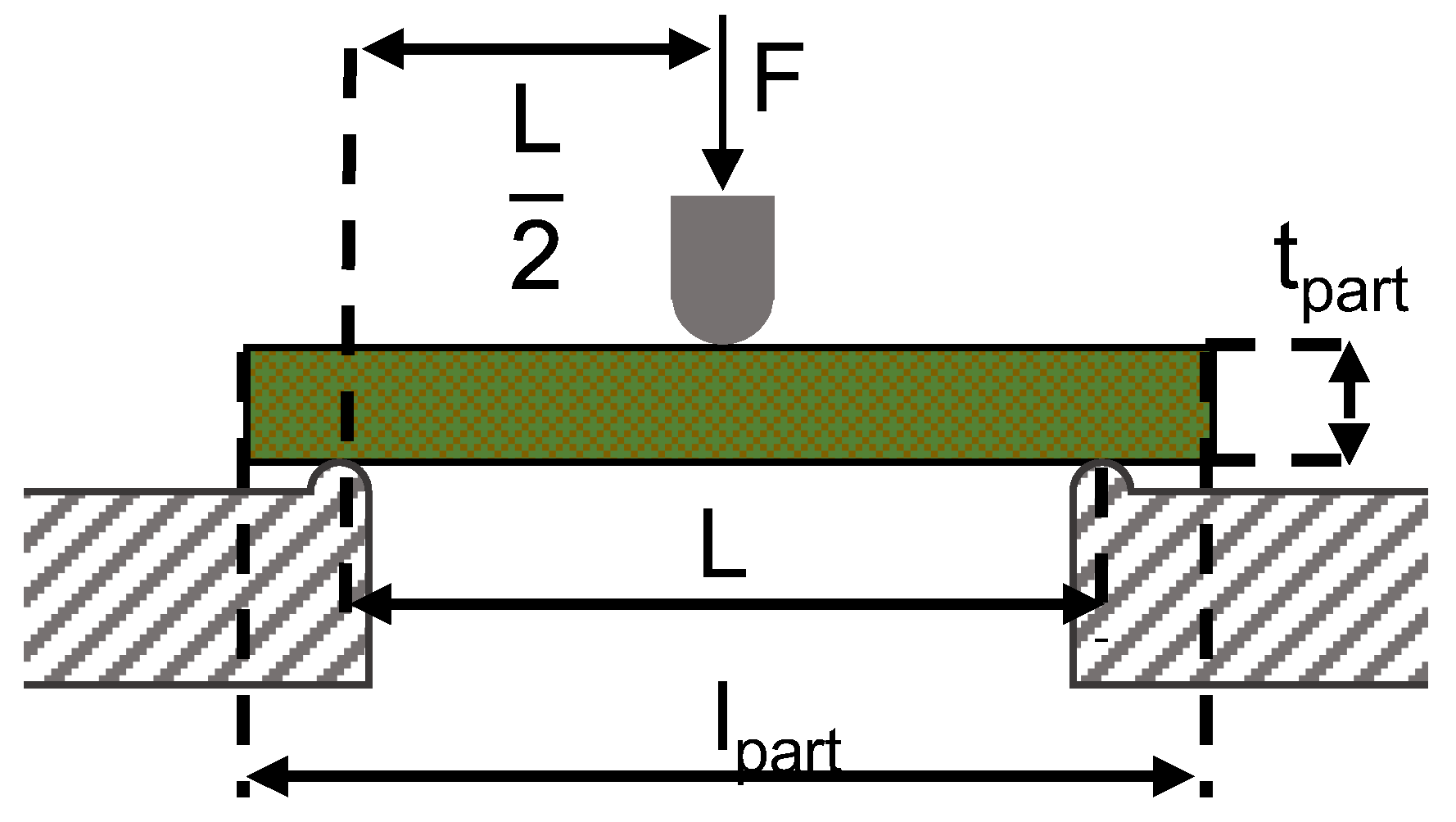

2.5. Evaluation of Organo Sheet Properties Based on Three Point Bending Tests

3. Results

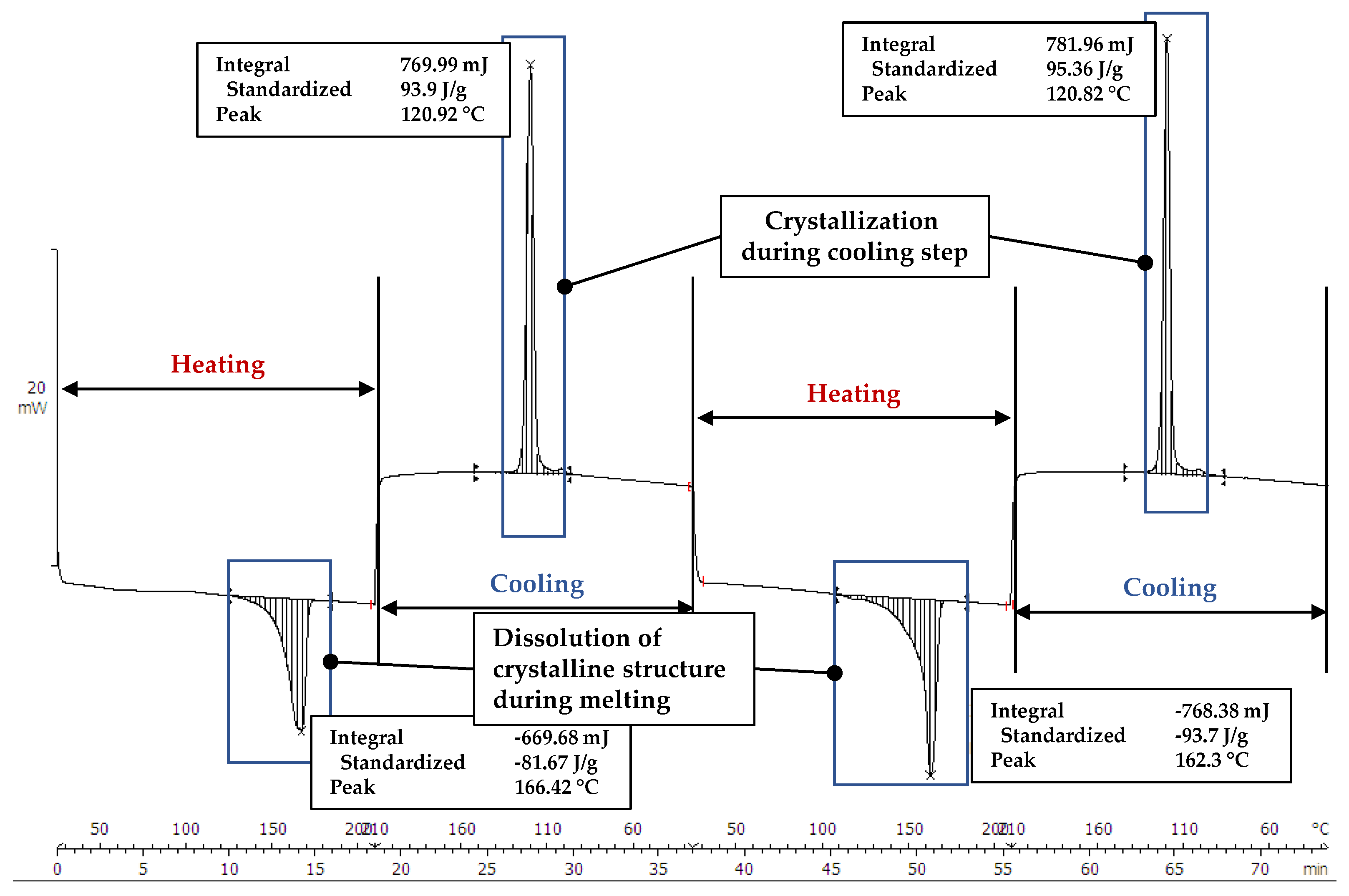

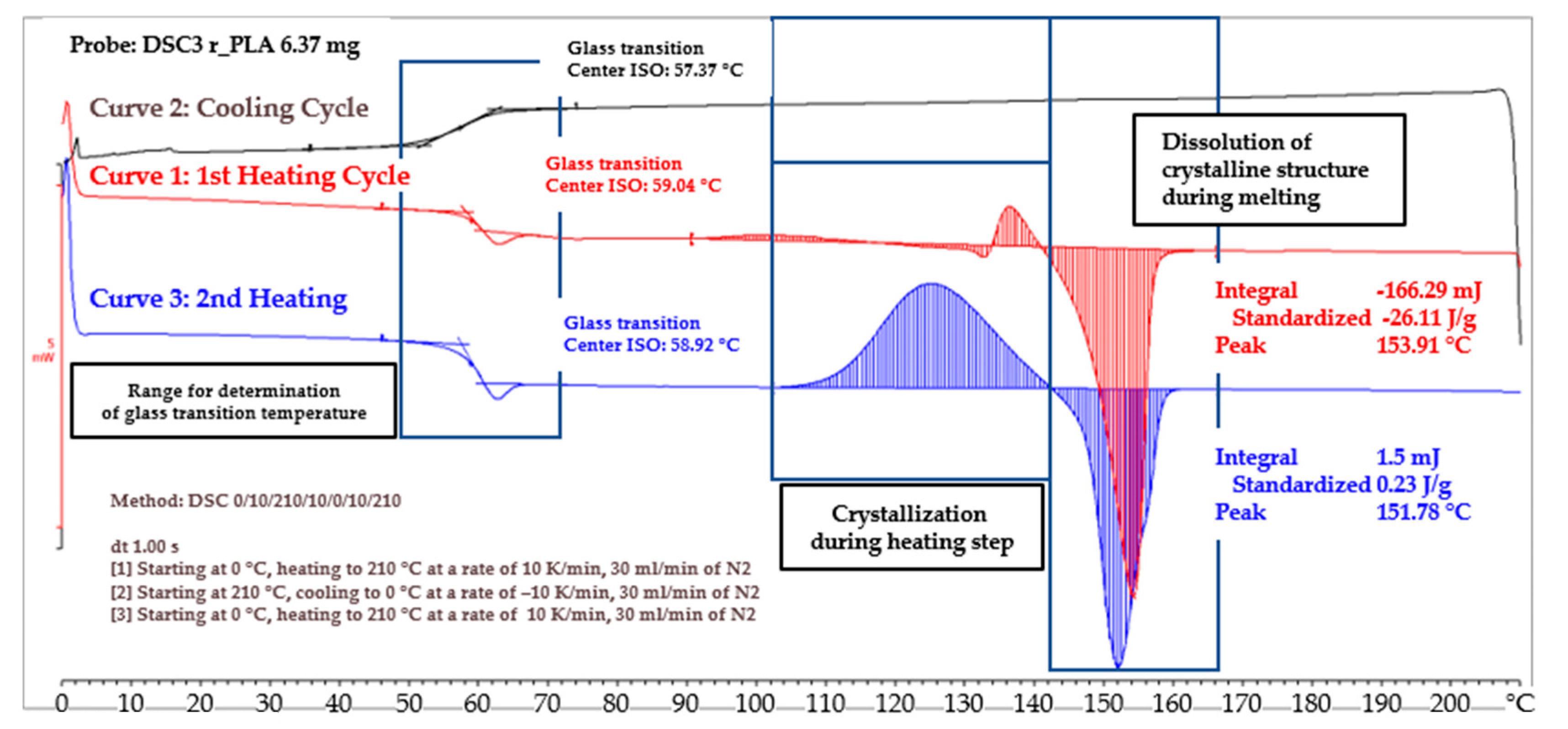

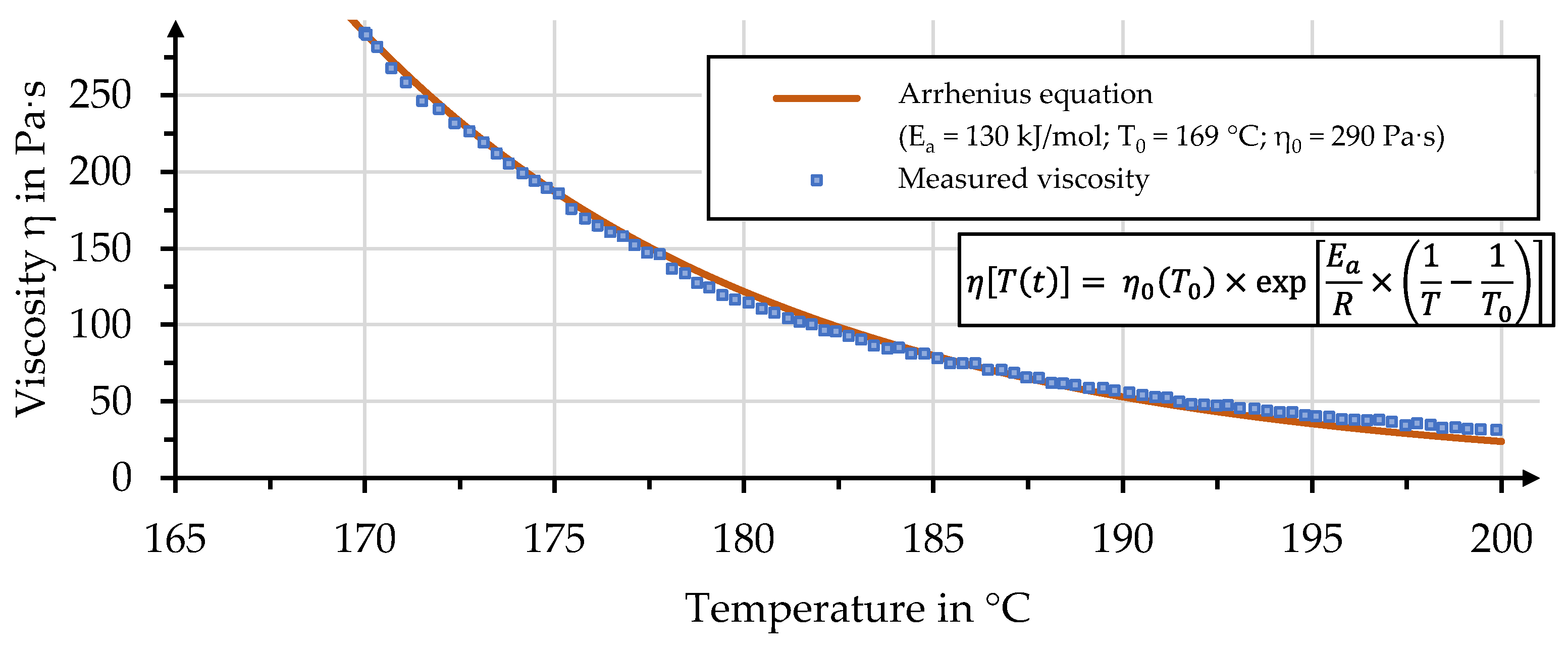

3.1. Polymer Properties

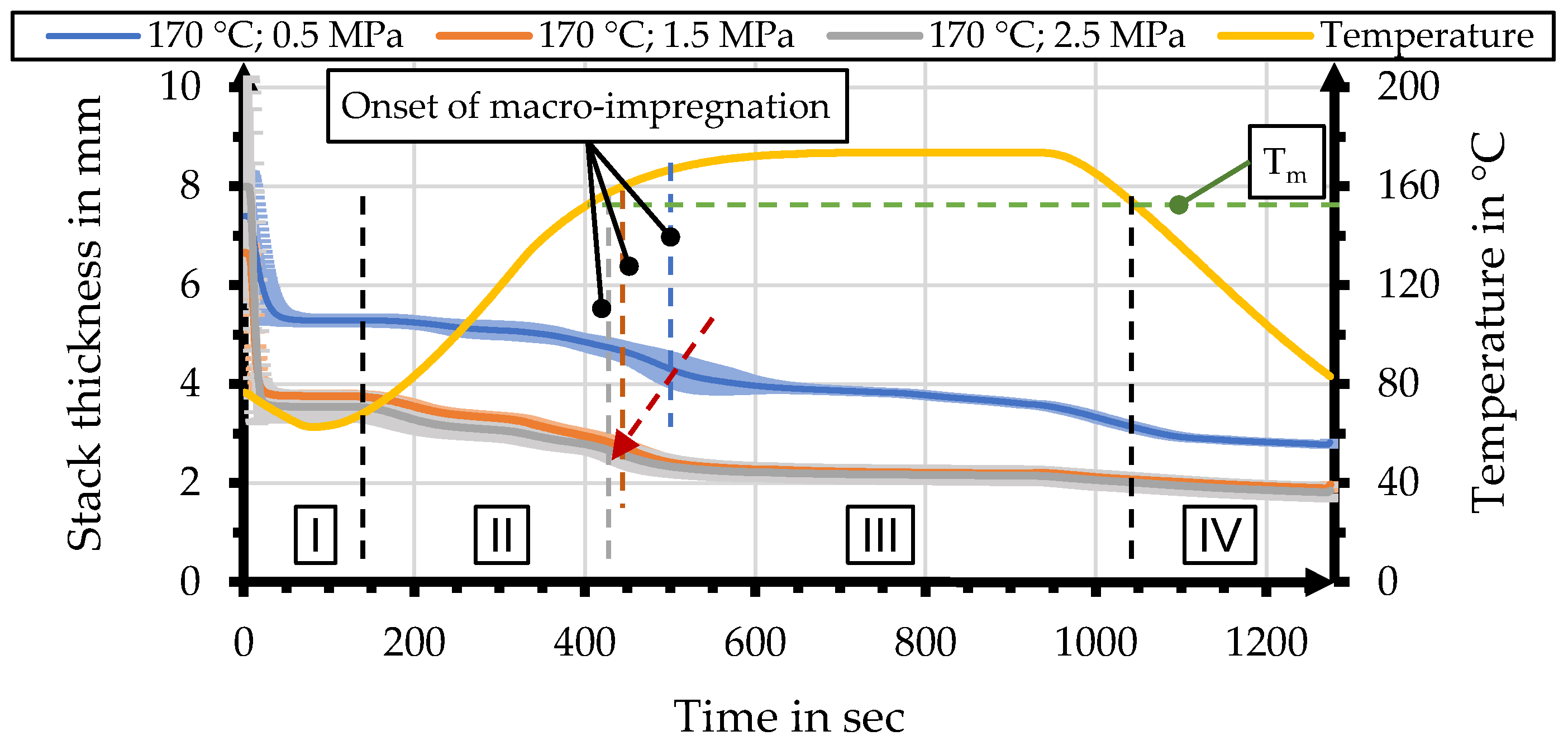

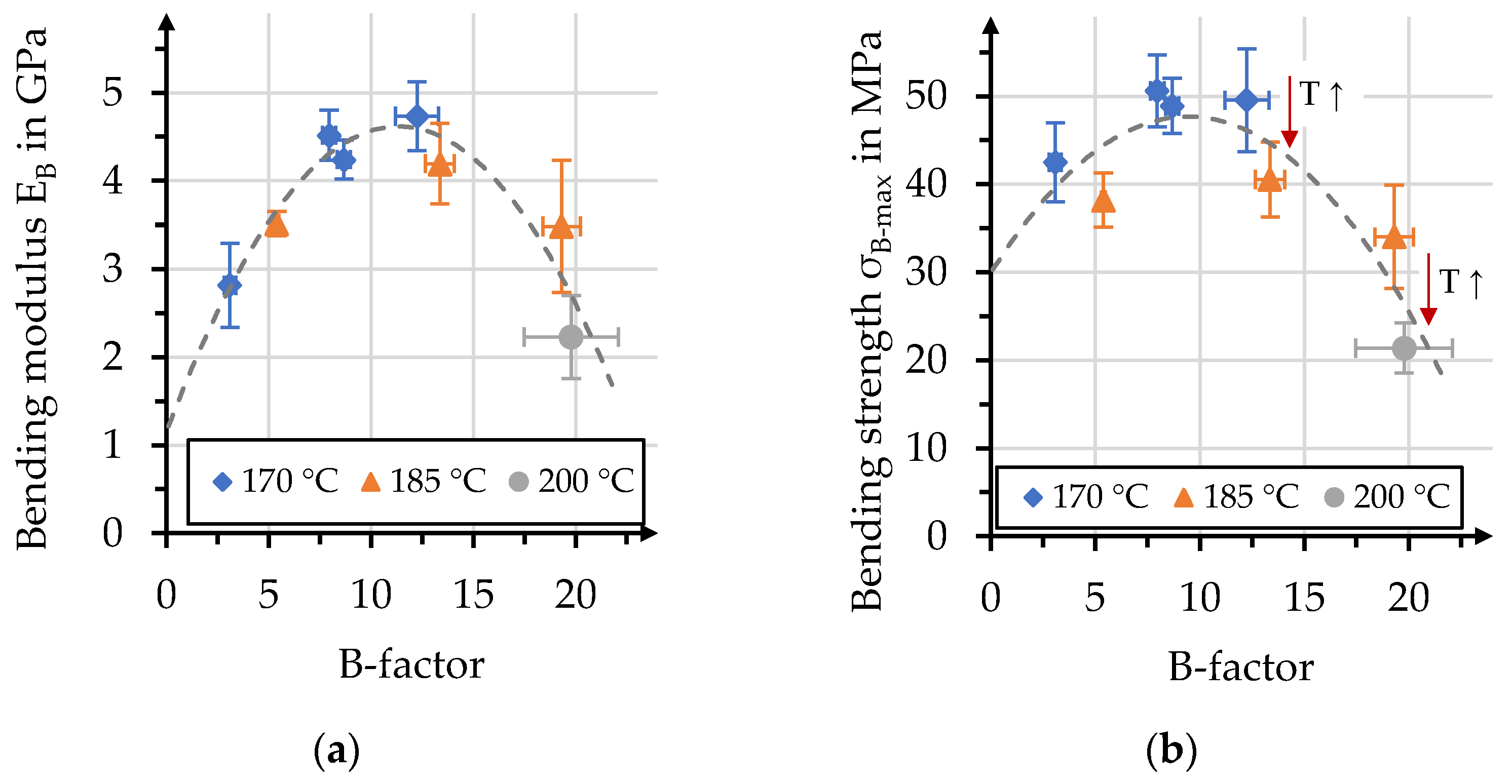

3.2. Interpretation of Process Data and B-Factor Calculation

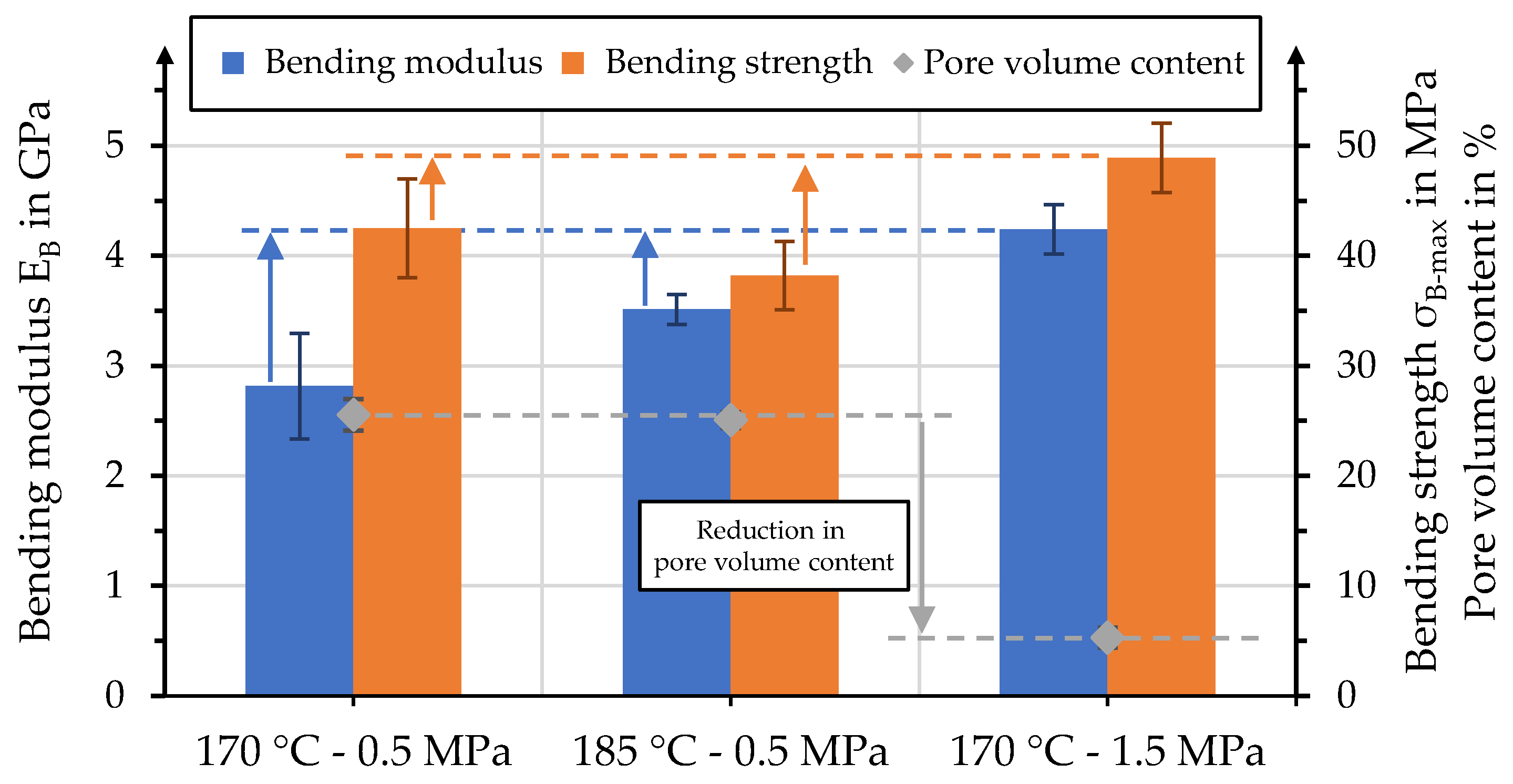

3.3. Examination of Physical Organo Sheet Properties

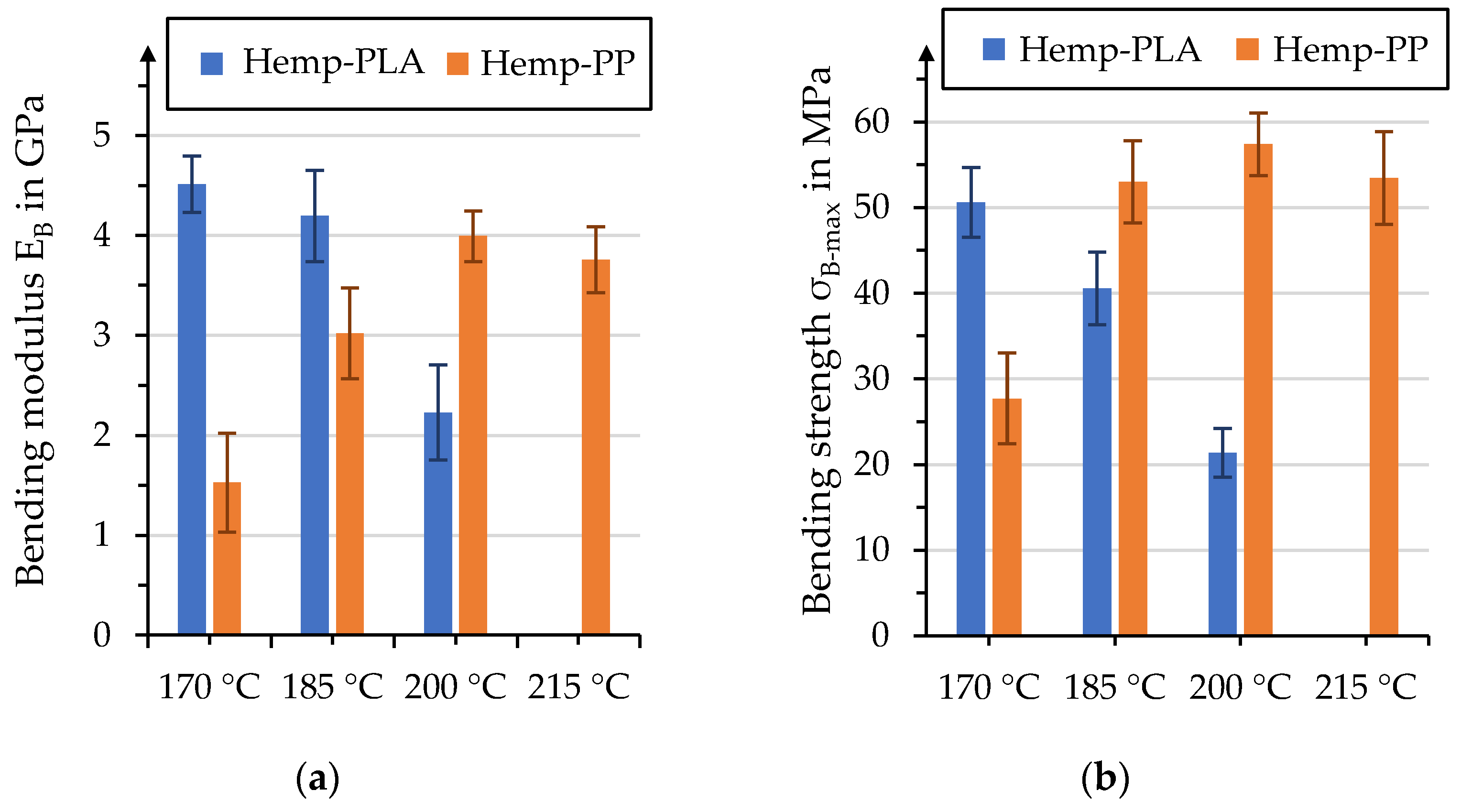

3.4. Bending Properties

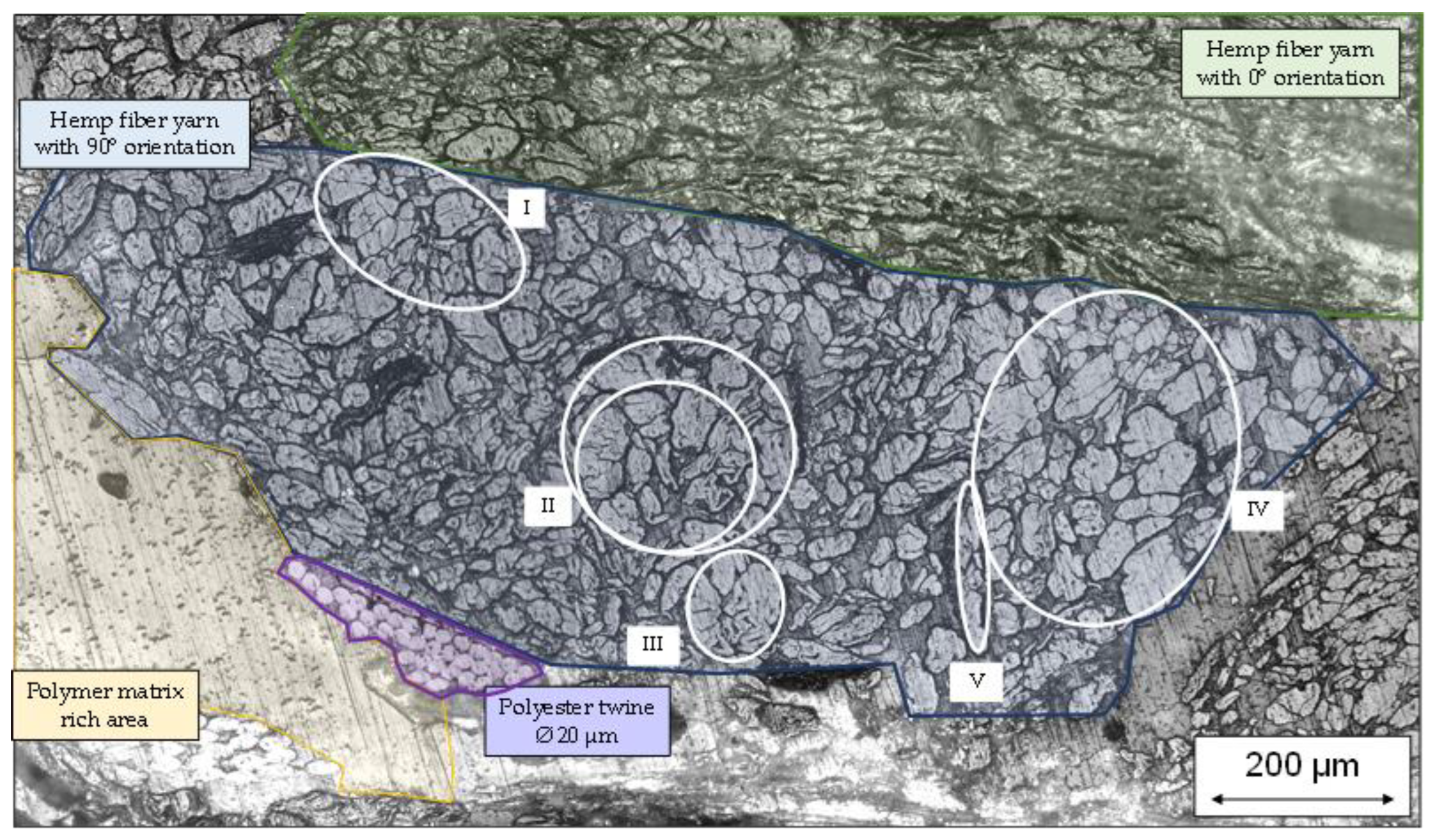

3.5. Consideration of Natural Fiber Morphology

4. Discussion

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

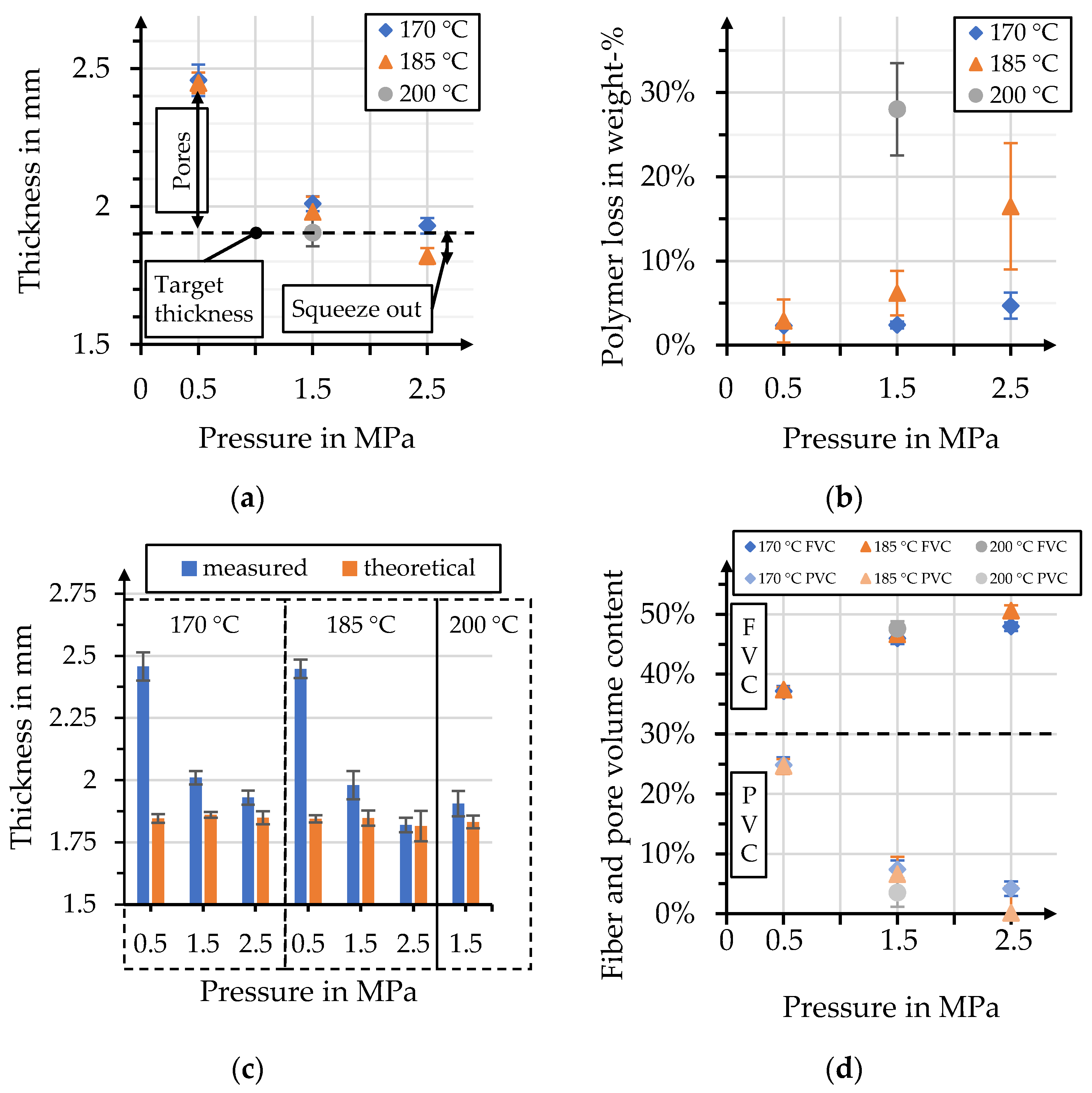

| Temp. | Pressure | Measured Thickness | Theoretical Thickness | Polymer Weight Loss | Pore Volume Content | Fiber Volume Content |

|---|---|---|---|---|---|---|

| in mm | in % | |||||

| 170 °C | 0.5 MPa | 2.46 ± 0.06 | 1.85 ± 0.02 | 2.3 ± 0.2 | 24.8 ± 1.3 | 37.2 ± 0.9 |

| 170 °C | 1.5 MPa | 2.01 ± 0.03 | 1.86 ± 0.01 | 2.4 ± 0.4 | 7.4 ± 1.5 | 46 ± 0.9 |

| 170 °C | 2.5 MPa | 1.93 ± 0.03 | 1.85 ± 0.03 | 4.7 ± 1.6 | 4.2 ± 1.2 | 47.9 ± 0.7 |

| 185 °C | 0.5 MPa | 2.45 ± 0.04 | 1.84 ± 0.01 | 2.9 ± 2.6 | 24.6 ± 1.2 | 37.4 ± 0.5 |

| 185 °C | 1.5 MPa | 1.98 ± 0.06 | 1.85 ± 0.03 | 6.2 ± 2.7 | 6.6 ± 2.8 | 46.6 ± 0.9 |

| 185 °C | 2.5 MPa | 1.82 ± 0.03 | 1.82 ± 0.06 | 16.5 ± 7.5 | 0.16 ± 4.4 | 50.6 ± 1 |

| 200 °C | 1.5 MPa | 1.91 ± 0.05 | 1.83 ± 0.03 | 28 ± 5.5 | 3.5 ± 2.4 | 47.6 ± 1.3 |

References

- Manaia, J.P.; Manaia, A.T.; Rodriges, L. Industrial Hemp Fibers: An Overview. Fibers 2019, 7, 106. [Google Scholar] [CrossRef]

- Kamarudin, S.H.; Mohd Basri, M.S.; Rayung, M.; Abu, F.; Ahmad, S.; Norizan, M.N.; Osman, S.; Sarifuddin, N.; Desa, M.S.Z.M.; Abdullah, U.H.; et al. A Review on Natural Fiber Reinforced Polymer Composites (NFRPC) for Sustainable Industrial Applications. Polymers 2022, 14, 3698. [Google Scholar] [CrossRef] [PubMed]

- Kumar, S.; Manna, A.; Dang, R. A review on applications of natural Fiber-Reinforced composites (NFRCs). Mater. Today Proc. 2022, 50, 1632–1636. [Google Scholar] [CrossRef]

- Carus, M.; Partanen, A. Bioverbundwerkstoffe—Naturfaserverstärkte Kunststoffe (NFK) und Holz-Polymer-Werkstoffe (WPC); Fachagentur Nachwachsende Rohstoffe e.V. (FNR): Gülzow-Prüzen, Germay, 2019. [Google Scholar]

- Thielen, M. Biokunststoffe—Pflanzen, Rohstoffe, Produkte; Fachagentur Nachwachsende Rohstoffe e.V. (FNR): Gülzow-Prüzen, Germay, 2020. [Google Scholar]

- Nijjar, S.; Sudhakara, P.; Sharma, S.; Saini, S. Overview on the latest trend and development on mechanical, tribological & microstructural properties of natural fibre polymer composites. Mater. Today Proc. 2022, 63, 663–672. [Google Scholar] [CrossRef]

- FNR. Basisdaten Biobasierte Produkte 2020; Fachagentur Nachwachsende Rohstoffe e.V. (FNR): Gülzow-Prüzen, Germay, 2020. [Google Scholar]

- Medina, L.A.; Dzalto, J. 1.11 Natural Fibers. In Comprehensive Composite Materials II; Elsevier: Amsterdam, The Netherlands, 2018; pp. 269–294. [Google Scholar] [CrossRef]

- Cherif, C. (Ed.) Textile Werkstoffe für den Leichtbau: Techniken–Verfahren–Materialien–Eigenschaften; Springer: Berlin/Heidelberg, Germany, 2011. [Google Scholar] [CrossRef]

- Neitzel, M.; Mitschang, P.; Breuer, U. Handbuch Verbundwerkstoffe: Werkstoffe, Verarbeitung, Anwendung; Carl Hanser Fachbuchverlag: Munich, Germany, 2014. [Google Scholar]

- Cherney, J.H.; Small, E. Industrial Hemp in North America: Production, Politics and Potential. Agronomy 2016, 6, 58. [Google Scholar] [CrossRef]

- Fortenbery, T.R.; Bennett, M. Opportunities for Commercial Hemp Production. Appl. Econ. Perspect. Policy 2004, 26, 97–117. [Google Scholar] [CrossRef]

- Duval, A.; Bourmaud, A.; Augier, L.; Baley, C. Influence of the sampling area of the stem on the mechanical properties of hemp fibers. Mater. Lett. 2011, 65, 797–800. [Google Scholar] [CrossRef]

- Liu, M.; Silva, D.A.S.; Fernando, D.; Meyer, A.S.; Madsen, B.; Daniel, G.; Thygesen, A. Controlled retting of hemp fibres: Effect of hydrothermal pre-treatment and enzymatic retting on the mechanical properties of unidirectional hemp/epoxy composites. Compos. Part A Appl. Sci. Manuf. 2016, 88, 253–262. [Google Scholar] [CrossRef]

- Liu, M.; Fernando, D.; Daniel, G.; Madsen, B.; Meyer, A.S.; Ale, M.T.; Thygesen, A. Effect of harvest time and field retting duration on the chemical composition, morphology and mechanical properties of hemp fibers. Ind. Crops Prod. 2015, 69, 29–39. [Google Scholar] [CrossRef]

- Manian, A.P.; Cordin, M.; Pham, T. Extraction of cellulose fibers from flax and hemp: A review. Cellulose 2021, 28, 8275–8294. [Google Scholar] [CrossRef]

- Marrot, L.; Lefeuvre, A.; Pontoire, B.; Bourmaud, A.; Baley, C. Analysis of the hemp fiber mechanical properties and their scattering (Fedora 17). Ind. Crops Prod. 2013, 51, 317–327. [Google Scholar] [CrossRef]

- Li, X.; Wang, S.; Du, G.; Wu, Z.; Meng, Y. Variation in physical and mechanical properties of hemp stalk fibers along height of stem. Ind. Crops Prod. 2013, 42, 344–348. [Google Scholar] [CrossRef]

- Placet, V.; Trivaudey, F.; Cisse, O.; Gucheret-Retel, V.; Boubakar, M.L. Diameter dependence of the apparent tensile modulus of hemp fibres: A morphological, structural or ultrastructural effect? Compos. Part A Appl. Sci. Manuf. 2012, 43, 275–287. [Google Scholar] [CrossRef]

- Singh, S.; Deepak, D.; Aggarwal, L.; Gupta, V.K. Tensile and Flexural Behavior of Hemp Fiber Reinforced Virgin-recycled HDPE Matrix Composites. Procedia Mater. Sci. 2014, 6, 1696–1702. [Google Scholar] [CrossRef]

- Espinach, F.X.; Julian, F.; Verdaguer, N.; Torres, L.; Pelach, M.A.; Vilaseca, F.; Mutje, P. Analysis of tensile and flexural modulus in hemp strands/polypropylene composites. Compos. Part B Eng. 2013, 47, 339–343. [Google Scholar] [CrossRef]

- Shivnand, H.K.; Inamdar, P.S.; Sapthagiri, G. Evaluation of tensile and flexural properties of hemp and polypropylene based natural fiber composites. In Proceedings of the 2010 2nd International Conference on Chemical, Biological and Environmental Engineering, Cairo, Egypt, 2–4 November 2010; pp. 90–95. [Google Scholar] [CrossRef]

- Hargitai, H.; Rácz, I.; Anandjiwala, R.D. Development of HEMP Fiber Reinforced Polypropylene Composites. J. Thermoplast. Compos. Mater. 2008, 21, 165–174. [Google Scholar] [CrossRef]

- Suardana, N.P.G.; Piao, Y.; Lim, J.K. Mechanical Properties of Hemp Fibers and Hemp/PP Composites: Effects of Chemical Surface Treatment. Mater. Phys. Mech. 2011, 11, 1–8. [Google Scholar]

- Džalto, J.; Medina, L.A.; Mitschang, P. Prozessoptimierung beim Einsatz von Naturfaser-Organoblechen: Automobilindustrie. Lightweight Des. 2014, 7, 50–57. [Google Scholar] [CrossRef]

- Sullins, T.; Pillay, S.; Komus, A.; Ning, H. Hemp fiber reinforced polypropylene composites: The effects of material treatments. Compos. Part B Eng. 2017, 114, 15–22. [Google Scholar] [CrossRef]

- Bledzki, A.K.; Fink, H.-P.; Specht, K. Unidirectional hemp and flax EP- and PP-composites: Influence of defined fiber treatments. J. Appl. Polym. Sci. 2004, 93, 2150–2156. [Google Scholar] [CrossRef]

- Vallejos, M.E.; Aguado, R.J.; Morcillo-Martín, R.; Méndez, J.A.; Vilaseca, F.; Tarrés, Q.; Mutjé, P. Behavior of the Flexural Strength of Hemp/Polypropylene Composites: Evaluation of the Intrinsic Flexural Strength of Untreated Hemp Strands. Polymers 2023, 15, 371. [Google Scholar] [CrossRef] [PubMed]

- Mutjé, P.; Vallejos, M.E.; Gironès, J.; Vilaseca, F.; López, A.; López, J.P.; Méndez, J.A. Effect of maleated polypropylene as coupling agent for polypropylene composites reinforced with hemp strands. J. Appl. Polym. Sci. 2006, 102, 833–840. [Google Scholar] [CrossRef]

- Song, Y.; Liu, J.; Chen, S.; Zheng, Y.; Ruan, S.; Bin, Y. Mechanical Properties of Poly (Lactic Acid)/Hemp Fiber Composites Prepared with a Novel Method. J. Polym. Environ. 2013, 21, 1117–1127. [Google Scholar] [CrossRef]

- Sawpan, M.A.; Pickering, K.L.; Fernyhough, A. Flexural properties of hemp fibre reinforced polylactide and unsaturated polyester composites. Compos. Part A Appl. Sci. Manuf. 2012, 43, 519–526. [Google Scholar] [CrossRef]

- Kobayashi, S.; Takada, K. Processing of unidirectional hemp fiber reinforced composites with micro-braiding technique. Compos. Part A Appl. Sci. Manuf. 2013, 46, 173–179. [Google Scholar] [CrossRef]

- Dasore, A.; Rajak, U.; Balijepalli, R.; Verma, T.N.; Ramakrishna, K. An overview of refinements, processing methods and properties of natural fiber composites. Mater. Today Proc. 2022, 49, 296–300. [Google Scholar] [CrossRef]

- Mehta, G.; Drzal, L.T.; Mohanty, A.K.; Misra, M. Effect of fiber surface treatment on the properties of biocomposites from nonwoven industrial hemp fiber mats and unsaturated polyester resin. J. Appl. Polym. Sci. 2006, 99, 1055–1068. [Google Scholar] [CrossRef]

- Corbin, A.-C.; Sala, B.; Soulat, D.; Ferreira, M.; Labanieh, A.-R.; Placet, V. Development of quasi-unidirectional fabrics with hemp fiber: A competitive reinforcement for composite materials. J. Compos. Mater. 2021, 55, 551–564. [Google Scholar] [CrossRef]

- Oksman, K.; Skrifvars, M.; Selin, J.-F. Natural fibres as reinforcement in polylactic acid (PLA) composites. Compos. Sci. Technol. 2003, 63, 1317–1324. [Google Scholar] [CrossRef]

- Pornwannachai, W.; Horrocks, A.R.; Kandola, B.K. Surface Modification of Commingled Flax/PP and Flax/PLA Fibres by Silane or Atmospheric Argon Plasma Exposure to Improve Fibre–Matrix Adhesion in Composites. Fibers 2022, 10, 2. [Google Scholar] [CrossRef]

- Van de Velde, K.; Kiekens, P. Effect of material and process parameters on the mechanical properties of unidirectional and multidirectional flax/polypropylene composites. Compos. Struct. 2003, 62, 443–448. [Google Scholar] [CrossRef]

- Ilyas, R.A.; Sapuan, S.M.; Harussani, M.M.; Hakimi, M.Y.A.Y.; Haziq, M.Z.M.; Atikah, M.S.N.; Asyraf, M.R.M.; Ishak, M.R.; Razman, M.R.; Nurazzi, N.M.; et al. Polylactic Acid (PLA) Biocomposite: Processing, Additive Manufacturing and Advanced Applications. Polymers 2021, 13, 1326. [Google Scholar] [CrossRef] [PubMed]

- Jem, K.J.; Tan, B. The development and challenges of poly (lactic acid) and poly (glycolic acid). Adv. Ind. Eng. Polym. Res. 2020, 3, 60–70. [Google Scholar] [CrossRef]

- Van de Velde, K.; Kiekens, P. Biopolymers: Overview of several properties and consequences on their applications. Polym. Test. 2002, 21, 433–442. [Google Scholar] [CrossRef]

- Teixeira, S.; Eblagon, K.M.; Miranda, F.; Pereira, M.F.R.; Figueiredo, J.L. Towards Controlled Degradation of Poly(lactic) Acid in Technical Applications. C 2021, 7, 42. [Google Scholar] [CrossRef]

- Jamshidi, K.; Hyon, S.-H.; Ikada, Y. Thermal characterization of polylactides. Polymer 1988, 29, 2229–2234. [Google Scholar] [CrossRef]

- Gupta, M.C.; Deshmukh, V.G. Thermal oxidative degradation of poly-lactic acid. Colloid Polym. Sci. 1982, 260, 308–311. [Google Scholar] [CrossRef]

- Oliveira, M.; Santos, E.; Araújo, A.; Fechine, G.J.M.; Machado, A.V.; Botelho, G. The role of shear and stabilizer on PLA degradation. Polym. Test. 2016, 51, 109–116. [Google Scholar] [CrossRef]

- Kopinke, F.-D.; Remmler, M.; Mackenzie, K.; Möder, M.; Wachsen, O. Thermal decomposition of biodegradable polyesters—II. Poly(lactic acid). Polym. Degrad. Stab. 1996, 53, 329–342. [Google Scholar] [CrossRef]

- Dreier, J.; Brütting, C.; Ruckdäschel, H.; Altstädt, V.; Bonten, C. Investigation of the Thermal and Hydrolytic Degradation of Polylactide during Autoclave Foaming. Polymers 2021, 13, 2624. [Google Scholar] [CrossRef]

- Garlotta, D. A Literature Review of Poly(Lactic Acid). J. Polym. Environ. 2001, 9, 63–84. [Google Scholar] [CrossRef]

- Michaud, V.; Månson, J.-A.E. Impregnation of Compressible Fiber Mats with a Thermoplastic Resin. Part I: Theory. J. Compos. Mater. 2001, 35, 1150–1173. [Google Scholar] [CrossRef]

- Michaud, V.; Törnqvist, R.; Månson, J.-A.E. Impregnation of Compressible Fiber Mats with a Thermoplastic Resin. Part II: Experiments. J. Compos. Mater. 2001, 35, 1174–1200. [Google Scholar] [CrossRef]

- Christmann, M. Optimierung der Organoblechherstellung durch 2D-Imprägnierung; IVW-Schriftenreihe, Band 114; Institut für Verbundwerkstoffe: Kaiserslautern, Germany, 2014. (In German) [Google Scholar]

- Gennaro, R.; Christmann, M.; Greco, A.; Rieber, G.; Mitschang, P.; Maffezzoli, A. Experimental measurement of transversal micro- and macro permeability during compression molding of PP/Glass composites. Polym. Compos. 2014, 35, 105–112. [Google Scholar] [CrossRef]

- Mayer, C. Prozeßanalyse und Modellbildung zur Herstellung Gewebeverstärkter, Thermoplastischer Halbzeuge; Schriftenreihe/Institut für Verbundwerkstoffe GmbH, IVW, Band 5; Institut für Verbundwerkstoffe GmbH: Kaiserslautern, Germany, 2000. (In German) [Google Scholar]

- Piott, F.; Krämer, A.; Lück, A.; Hoffmann, L.; Mitschang, P.; Drummer, D. Increasing the performance of continuous compression moulding by local pressure adaption. Adv. Manuf. Polym. Compos. Sci. 2021, 7, 1–14. [Google Scholar] [CrossRef]

- Christmann, M.; Mitschang, P.; Medina, L. Impregnation Performance of Non-Isobaric Processes. In Proceedings of the 20th International Conference on Composite Materials, Copenhagen, Denmark, 19–24 July 2015. [Google Scholar]

- Thyavihalli Girijappa, Y.G.; Mavinkere Rangappa, S.; Parameswaranpillai, J.; Siengchin, S. Natural Fibers as Sustainable and Renewable Resource for Development of Eco-Friendly Composites: A Comprehensive Review. Front. Mater. 2019, 6, 226. [Google Scholar] [CrossRef]

- DIN EN ISO 14125; Faserverstärkte Kunststoffe: Bestimmung der Biegeeigenschaften. Beuth Verlag GmbH: Berlin, Germany, 2011.

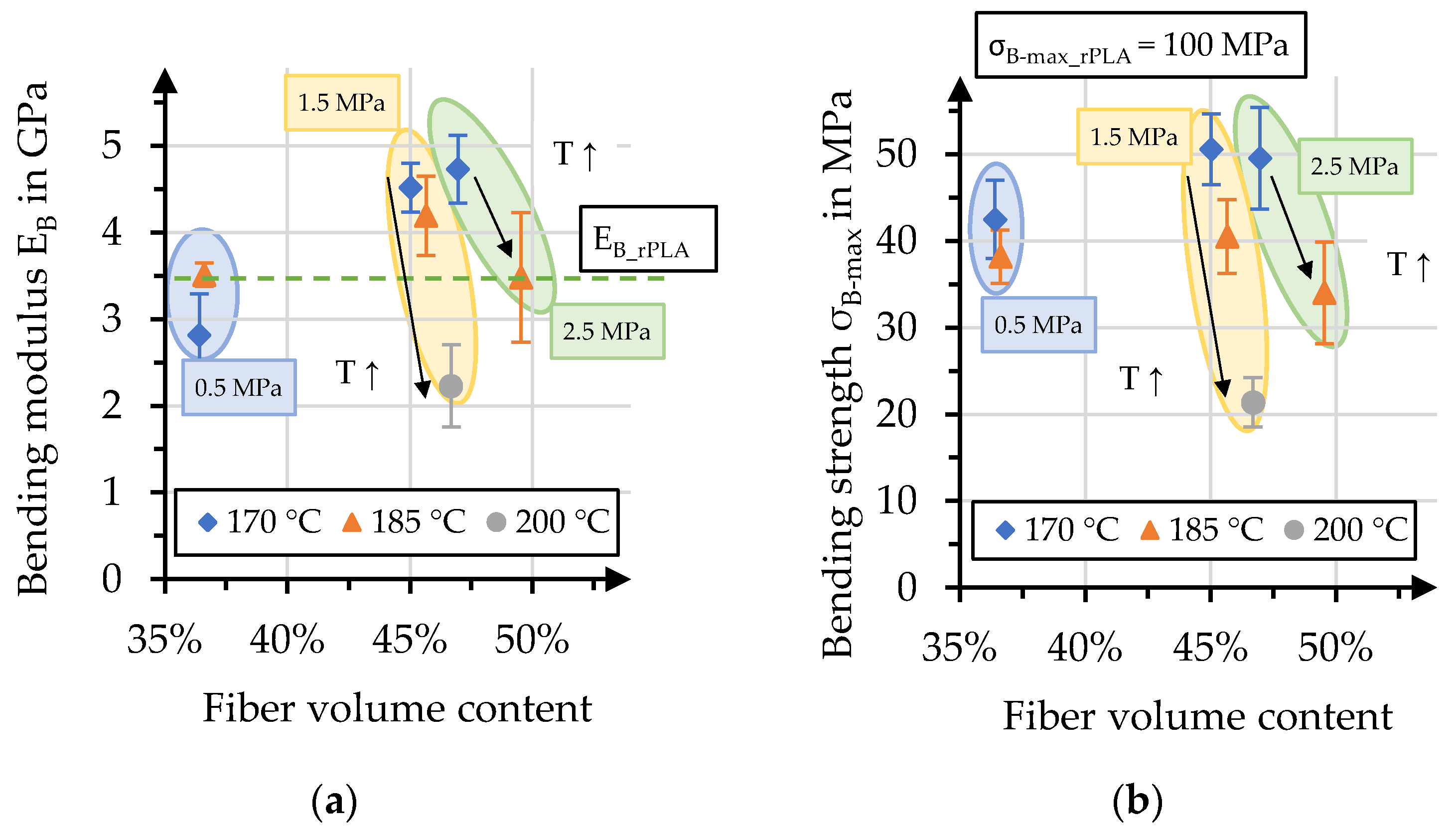

| Polymer | Density | Glass Transition Temperature | Melt Temperature | Bending Modulus | Bending Strength |

|---|---|---|---|---|---|

| rPLA (Looplife polymers) | 1.26 g/cm3 | 59 °C | 152.8 °C | 3.44 GPa | 98 MPa |

| PP (Borealis bj100hp) | 0.9 g/cm3 | <0 °C * | 165 °C | 1.25 GPa | 35 MPa |

| Material | Temperature | Pressure | Fiber Volume Content |

|---|---|---|---|

| Hemp–rPLA | 170 °C 185 °C 200 °C | 0.5 MPa 1.5 MPa 2.5 MPa | 37–50 vol.-% |

| Hemp–PP | 170 °C 185 °C 200 °C 215 °C | 1.5 MPa | 43–48 vol.-% |

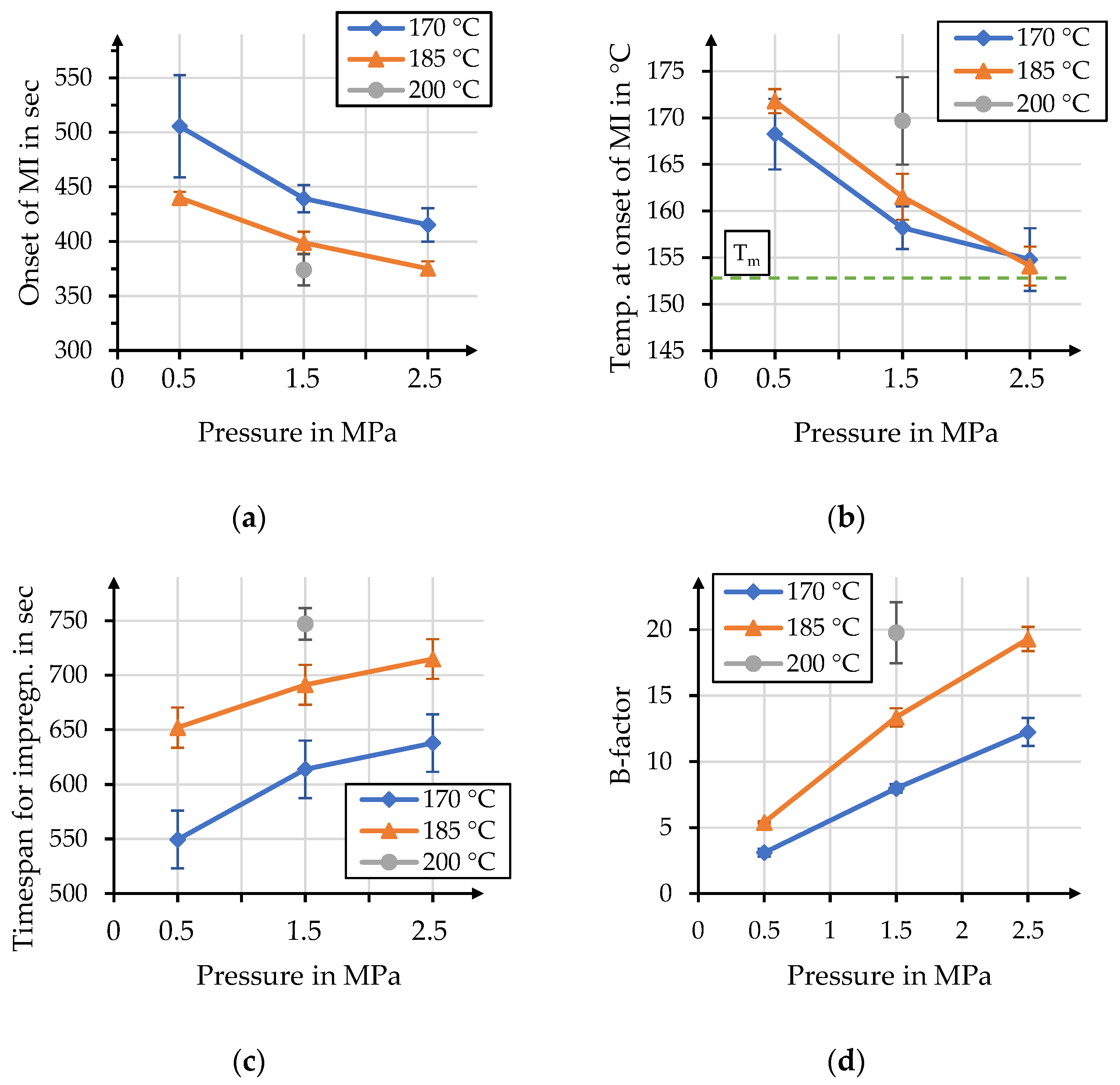

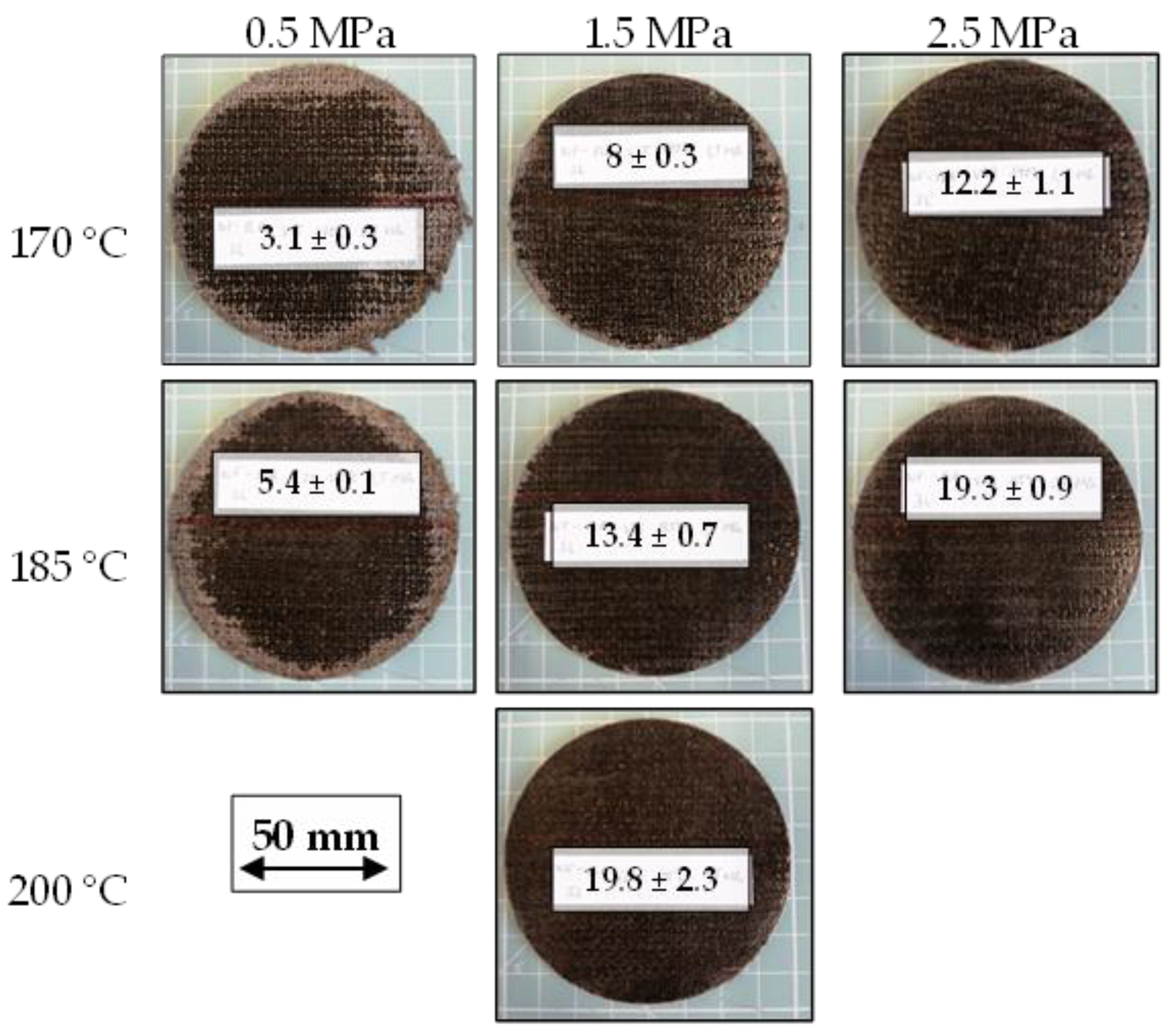

| Temperature | Pressure | Onset of MI in Seconds | Temp. at Onset | Timespan for Impregnation in Seconds | B-Factor |

|---|---|---|---|---|---|

| 170 °C | 0.5 MPa | 506 ± 46 | 168 ± 4 °C | 550 ± 46 | 3.1 ± 0.3 |

| 170 °C | 1.5 MPa | 439 ± 12 | 158 ± 2 °C | 614 ± 12 | 8 ± 0.3 |

| 170 °C | 2.5 MPa | 415 ± 15 | 155 ± 3 °C | 638 ± 15 | 12.2 ± 1.1 |

| 185 °C | 0.5 MPa | 440 ± 6 | 172 ± 1 °C | 652 ± 6 | 5.4 ± 0.1 |

| 185 °C | 1.5 MPa | 399 ± 10 | 162 ± 3 °C | 691 ± 10 | 13.4 ± 0.7 |

| 185 °C | 2.5 MPa | 375 ± 7 | 154 ± 2 °C | 715 ± 7 | 19.3 ± 0.9 |

| 200 °C | 1.5 MPa | 374 ± 15 | 165 ± 5 °C | 747 ± 15 | 19.8 ± 2.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Salmins, M.; Gortner, F.; Mitschang, P. Challenges in Manufacturing of Hemp Fiber-Reinforced Organo Sheets with a Recycled PLA Matrix. Polymers 2023, 15, 4357. https://doi.org/10.3390/polym15224357

Salmins M, Gortner F, Mitschang P. Challenges in Manufacturing of Hemp Fiber-Reinforced Organo Sheets with a Recycled PLA Matrix. Polymers. 2023; 15(22):4357. https://doi.org/10.3390/polym15224357

Chicago/Turabian StyleSalmins, Maximilian, Florian Gortner, and Peter Mitschang. 2023. "Challenges in Manufacturing of Hemp Fiber-Reinforced Organo Sheets with a Recycled PLA Matrix" Polymers 15, no. 22: 4357. https://doi.org/10.3390/polym15224357

APA StyleSalmins, M., Gortner, F., & Mitschang, P. (2023). Challenges in Manufacturing of Hemp Fiber-Reinforced Organo Sheets with a Recycled PLA Matrix. Polymers, 15(22), 4357. https://doi.org/10.3390/polym15224357