Life Expectancy of Transformer Paper Insulation Retrofilled with Natural Ester in the Laboratory

Abstract

:1. Introduction

2. Objective and Scope of the Ageing Study

- Kraft paper immersed in MO.

- Kraft paper immersed in NE.

- Kraft paper aged for some time in the presence of MO and, then, after the replacement of the MO with NE, aged in the presence of the NE.

3. Materials and Methods

3.1. Preparation of the Samples

3.2. Ageing Process

3.3. Sample Testing

4. Results

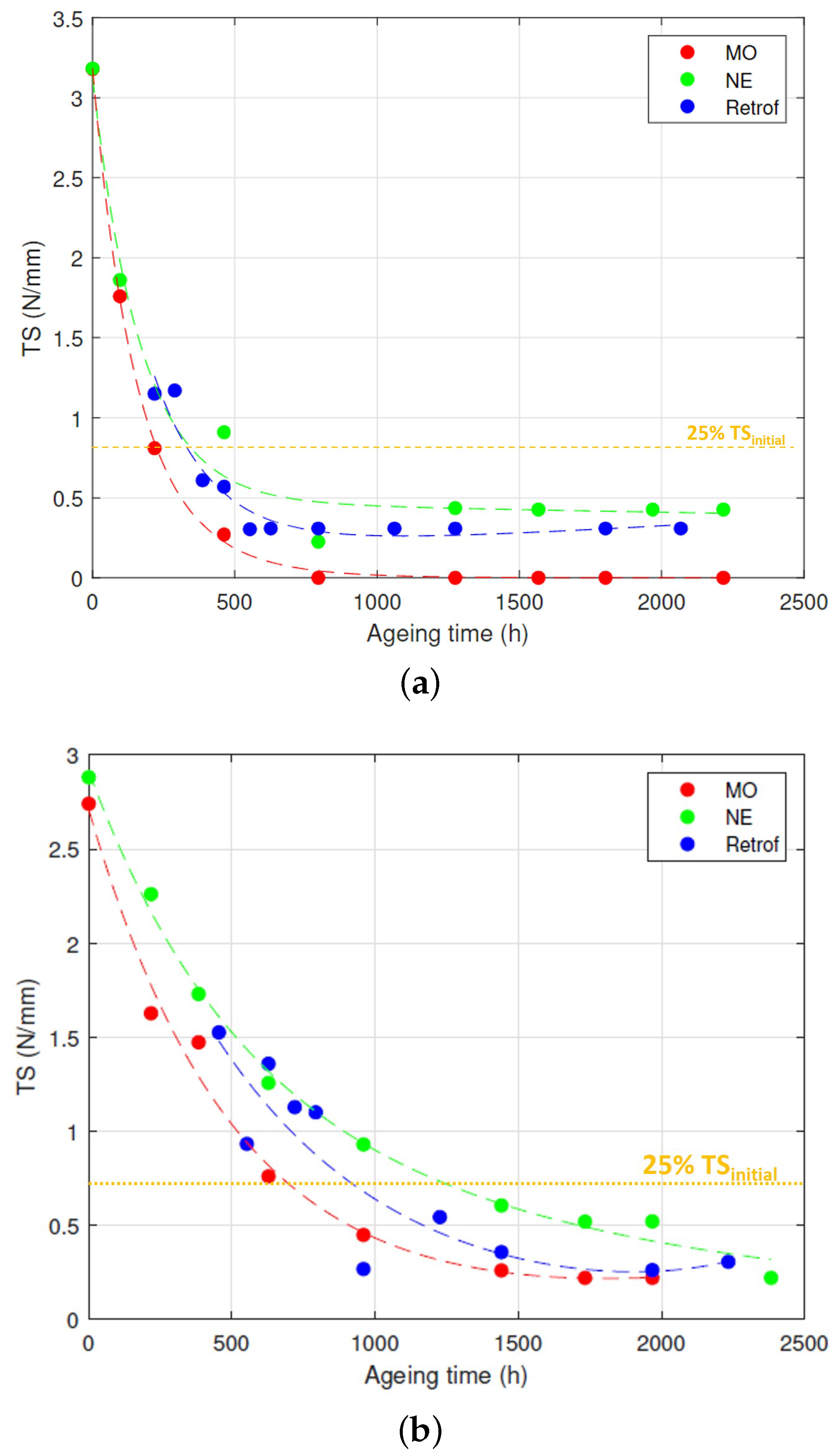

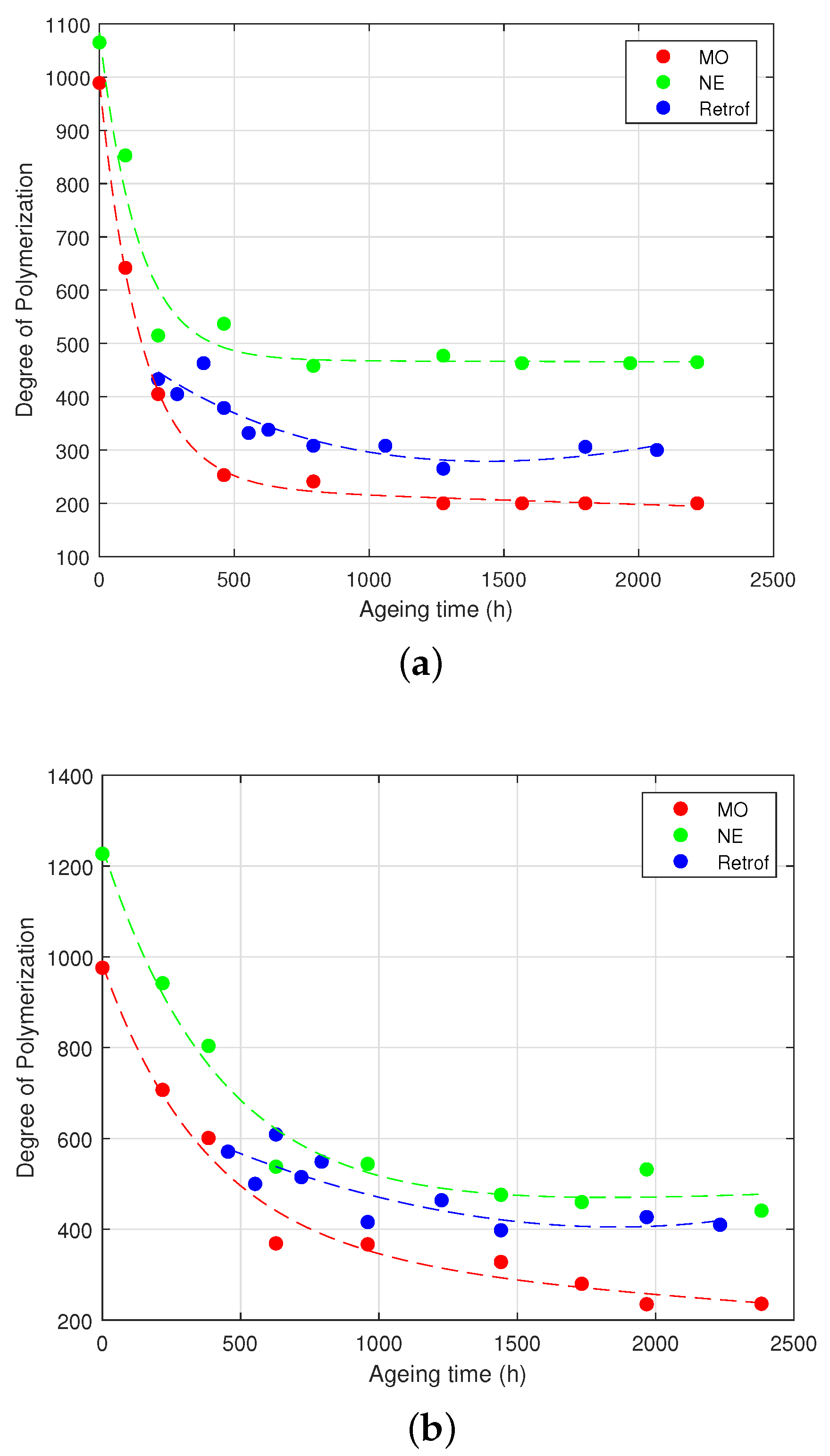

4.1. Evaluation of the Paper Degradation

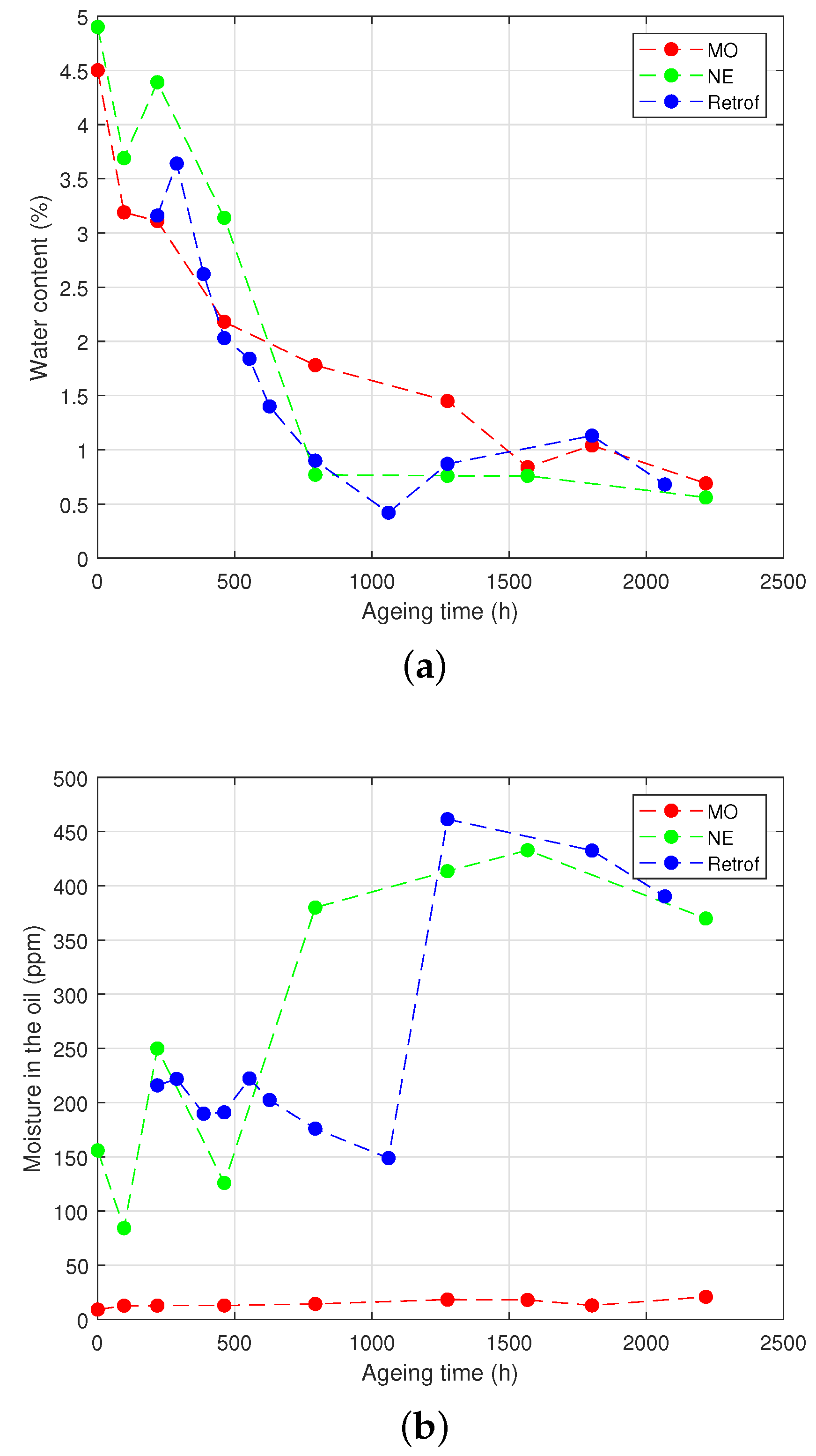

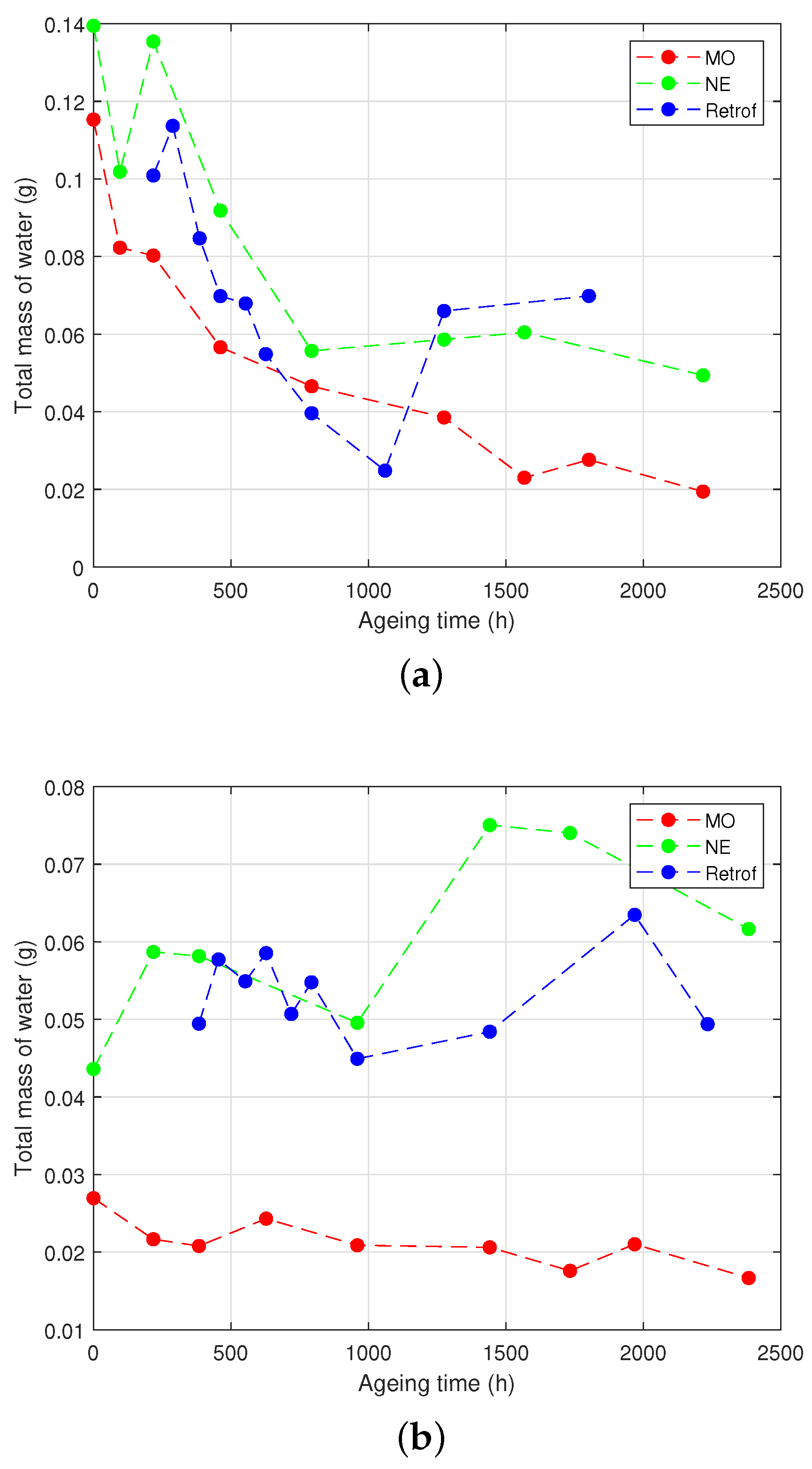

4.2. Evolution of the Moisture Content in Paper and Oil

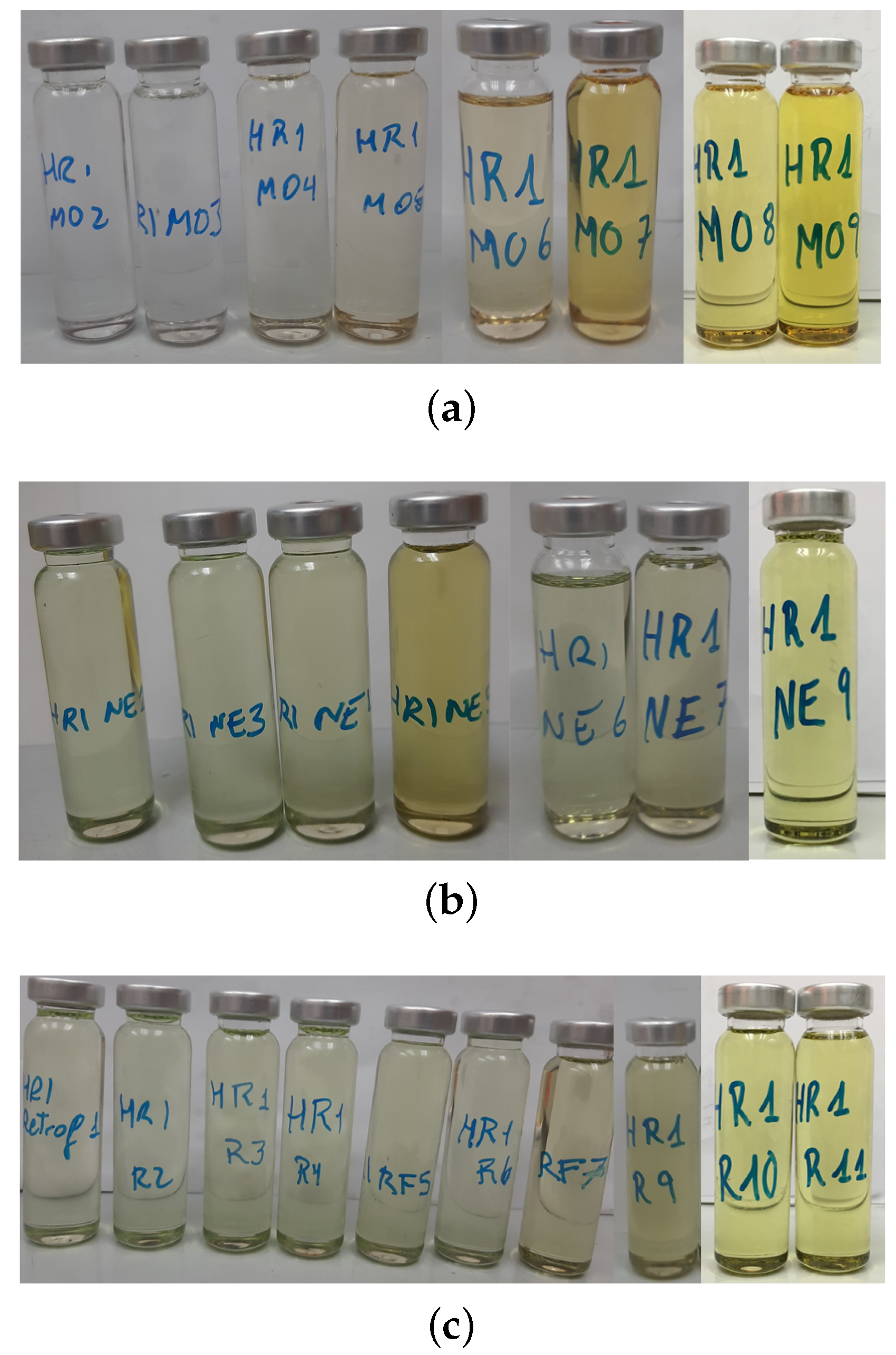

4.3. Acidity and Colour of the Liquid Insulation

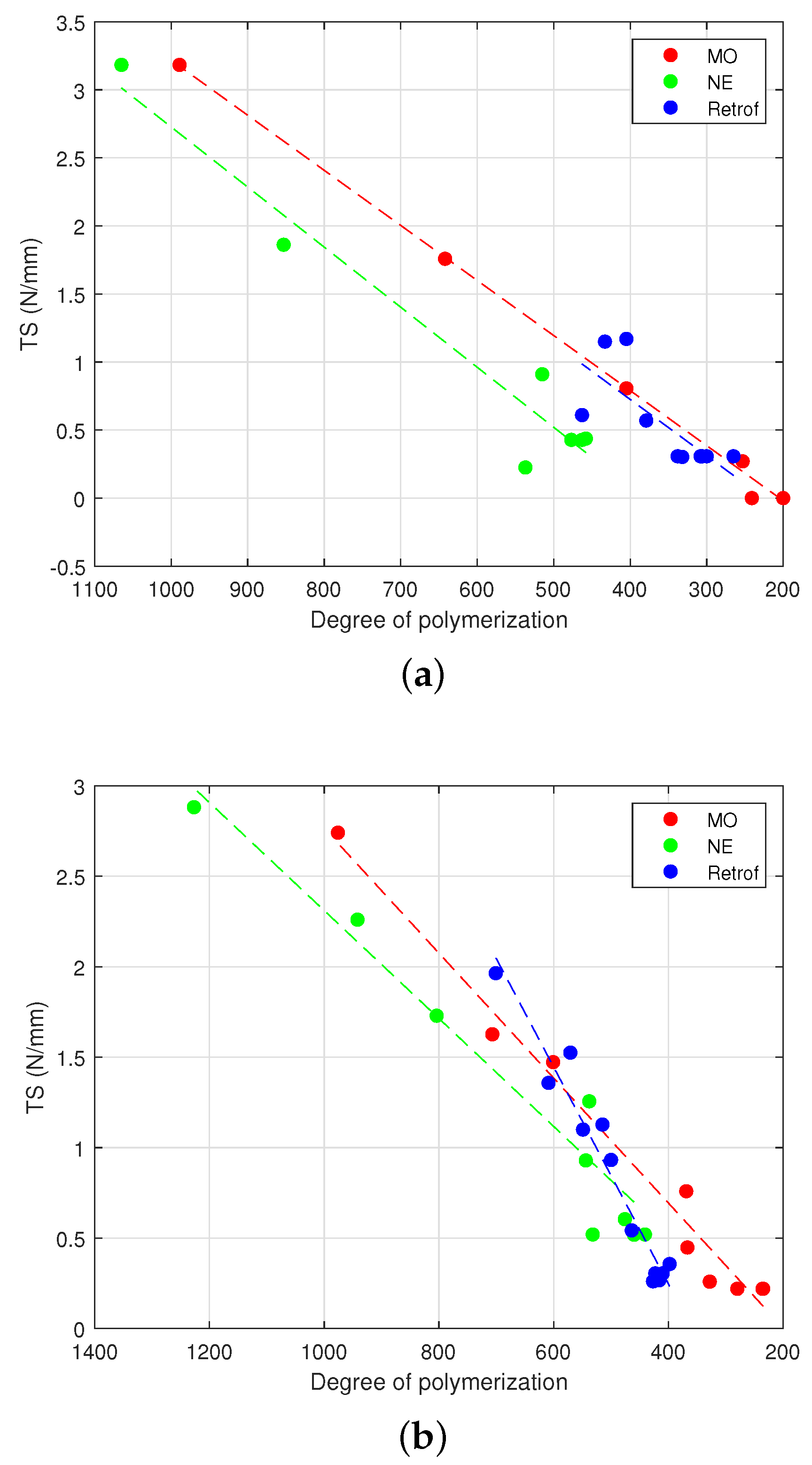

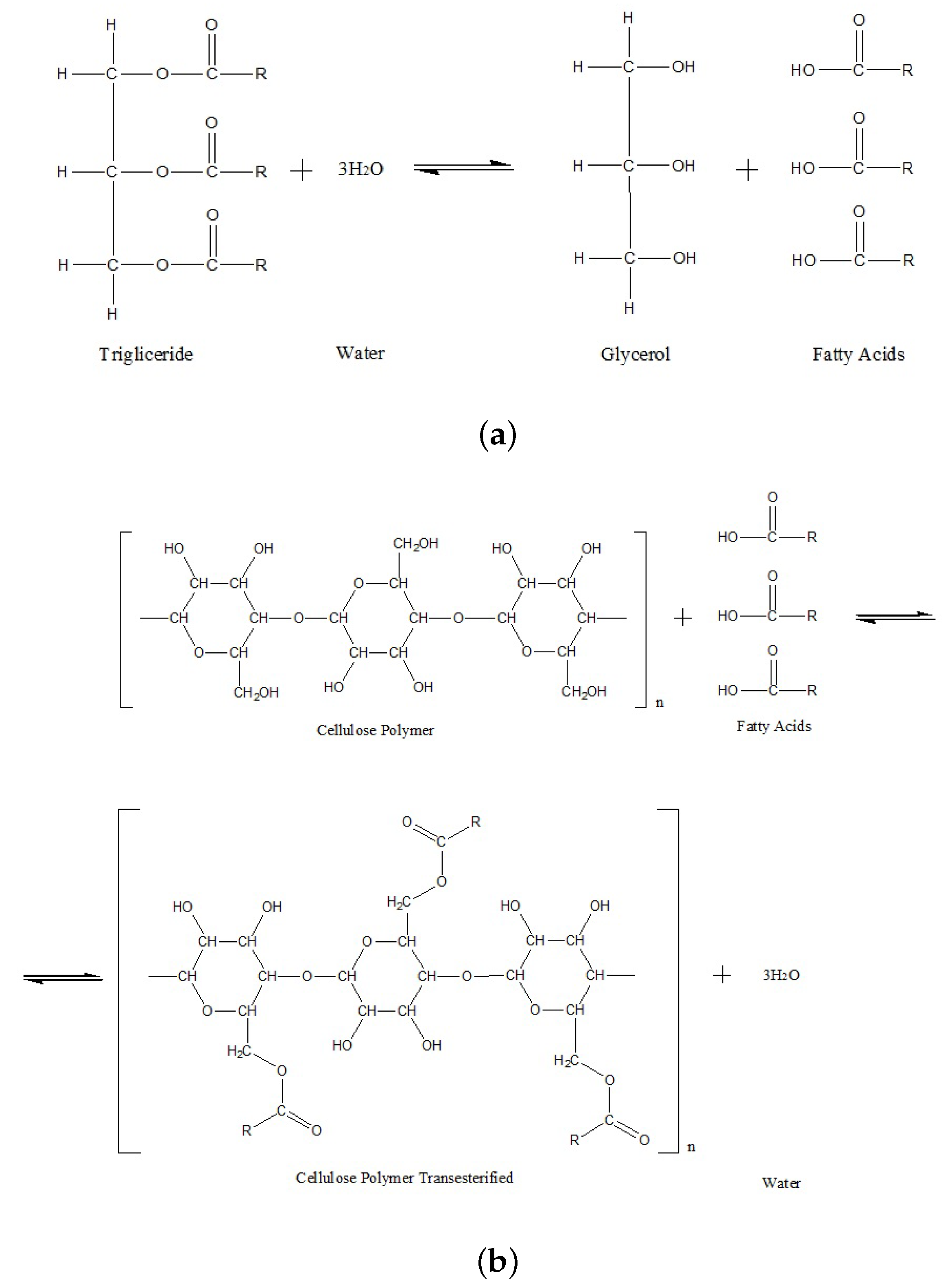

5. Global Analysis of the Ageing Process in Retrofilled Samples

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Cargill. FR3® Fluid Retrofilling Power Class Transformers Guide. 2020. Available online: https://www.cargill.com/doc/1432076502266/r2040-retrofill-guide-power-tds.pdf (accessed on 11 September 2023).

- MIDEL SAFETY INSIDE Retrofilling with MIDEL [Your Questions Answered]. Available online: https://www.specialtyengineering.net/wp-content/uploads/Retrofilling_with_MIDEL_your_questions_answered.pdf (accessed on 11 September 2023).

- McShane, C.; Corkran, J.; Rapp, K.; Luksich, J. Aging of paper insulation retrofilled with natural ester dielectric fluid. In Proceedings of the 2003 Annual Report Conference on Electrical Insulation and Dielectric Phenomena, Albuquerque, NM, USA, 19–22 October 2003; pp. 124–127. [Google Scholar] [CrossRef]

- Gutiérrez, C.M.; Fernández, A.O.; Renedo Estébanez, C.J.; Salas, C.O.; Maina, R. Understanding the Ageing Performance of Alternative Dielectric Fluids. IEEE Access 2023, 11, 9656–9671. [Google Scholar] [CrossRef]

- Garcia, B.; Garcia, T.; Primo, V.; Burgos, J.C.; Urquiza, D. Studying the loss of life of natural-ester-filled transformer insulation: Impact of moisture on the ageing rate of paper. IEEE Electr. Insul. Mag. 2017, 33, 15–23. [Google Scholar] [CrossRef]

- Frimpong, G.K.; Oommen, T.V.; Asano, R. A survey of ageing characteristics of cellulose insulation in natural ester and mineral oil. IEEE Electr. Insul. Mag. 2011, 27, 36–48. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, R.; Pan, K.; Xu, Y.; Rapp, K. Detailed procedures of retrofilling transformers with FR3 natural ester and residual mineral oil content testing. IET Gener. Transm. Distrib. 2022, 16, 1901–1913. Available online: https://ietresearch.onlinelibrary.wiley.com/doi/pdf/10.1049/gtd2.12402 (accessed on 22 January 2022). [CrossRef]

- Toudja, T.; Chetibi, F.; Beldjilali, A.; Moulai, H.; Beroual, A. Electrical and physicochemical properties of mineral and vegetable oils mixtures. In Proceedings of the 2014 IEEE 18th International Conference on Dielectric Liquids (ICDL), Bled, Slovenia, 29 June–3 July 2014; pp. 1–4. [Google Scholar] [CrossRef]

- Beroual, A.; Khaled, U.; Mbolo Noah, P.S.; Sitorus, H. Comparative Study of Breakdown Voltage of Mineral, Synthetic and Natural Oils and Based Mineral Oil Mixtures under AC and DC Voltages. Energies 2017, 10, 511. [Google Scholar] [CrossRef]

- Montero, A.; García, B.; Burgos, J.C. Study on the Contamination Rate of Mineral Oil in Natural-Ester Retrofilled Transformers. IEEE Trans. Dielectr. Electr. Insul. 2023, 30, 1641–1648. [Google Scholar] [CrossRef]

- Montero, A.; García, B.; Cabanelas, J.C. A New Method for the Quantification of the Remaining Mineral Oil in Natural-Ester Retrofilled Transformers. IEEE Electr. Insul. Mag. 2023, 39, 17–25. [Google Scholar] [CrossRef]

- García, B.; Urquiza, D.; Burgos, J. Investigating the influence of moisture on the 2FAL generation rate of transformers: A new model to estimate the DP of cellulosic insulation. Electr. Power Syst. Res. 2016, 140, 87–94. [Google Scholar] [CrossRef]

- IEC 60078-7; Power Transformers. Part 7. Loading Guide for Mineral-Oil-Immersed Power Transformers. International Electrotechnical Comission: Geneva, Switzerland, 2018.

- IEEE Std C57.91-2011 (Revision of IEEE Std C57.91-1995); IEEE Guide for Loading Mineral-Oil-Immersed Transformers and Step-Voltage Regulators. IEEE: New York, NY, USA, 2012; pp. 1–123. [CrossRef]

- Duval, M.; De Pablo, A.; Atanasova-Hoehlein, I.; Grisaru, M. Significance and detection of very low degree of polymerization of paper in transformers. IEEE Electr. Insul. Mag. 2017, 33, 31–38. [Google Scholar] [CrossRef]

- ISO 1924-3:2005; Paper and Board—Determination of Tensile Properties—Part 3: Constant Rate of Elongation Method (100 mm/min). International Organization for Standardization: Geneva, Switzerland, 2005.

- IEC 60450:2004; Measurement of the Average Viscometric Degree of Polymerization of New and Aged Cellulosic Electrically Insulating Materials. International Electrotechnical Commission: Geneva, Switzerland, 2004.

- IEC 60814:1997; Insulating Liquids—Oil-Impregnated Paper and Pressboard—Determination of Water by Automatic Coulometric Karl Fischer Titration. International Electrotechnical Commission: Geneva, Switzerland, 1997.

- IEC 61021-3:2014; Insulating Liquids—Determination of Acidity—Part 3: Test Methods for Non-Mineral Insulating Oils. International Electrotechnical Commission: Geneva, Switzerland, 2014.

- Rapp, K.; McShane, C.; Luksich, J. Interaction mechanisms of natural ester dielectric fluid and Kraft paper. In Proceedings of the IEEE International Conference on Dielectric Liquids, ICDL 2005, Coimbra, Portugal, 26 June–1 July 2005; pp. 393–396. [Google Scholar] [CrossRef]

- Yang, L.; Liao, R.; Sun, C.; Yin, J.; Zhu, M. Influence of vegetable oil on the thermal ageing rate of kraft paper and its mechanism. In Proceedings of the 2010 International Conference on High Voltage Engineering and Application, New Orleans, LA, USA, 11–14 October 2010; pp. 381–384. [Google Scholar] [CrossRef]

| Ageing Time (h) | HM (4.5%) | LM (1%) | ||||

|---|---|---|---|---|---|---|

| MO | NE | RF | MO | NE | RF | |

| 0 | x | x | x | x | ||

| 96 | x | x | ||||

| 218 | x | x | x | x | x | |

| 288 | x | |||||

| 386 | x | x | x | x | ||

| 458 | x | x | x | x | ||

| 552 | x | x | ||||

| 627 | x | x | x | x | ||

| 793 | x | x | x | x | ||

| 959 | x | x | x | |||

| 1060 | x | |||||

| 1226 | x | |||||

| 1275 | x | x | x | |||

| 1441 | x | x | x | |||

| 1567 | x | x | ||||

| 1733 | x | x | ||||

| 1802 | x | x | ||||

| 1968 | x | x | x | |||

| 2067 | x | x | ||||

| 2217 | x | x | ||||

| 2383 | x | x | x | |||

| Number of samples | 9 | 8 | 11 | 9 | 9 | 12 |

| High-Moisture Samples | Low-Moisture Samples | |

|---|---|---|

| TS retained | 36.1% | 71.1% |

| DP retained | 43.8% | 71.8% |

| a | b | c | d | R | ||

|---|---|---|---|---|---|---|

| HM | MO | 1.598 | −0.00829 | 1.586 | −0.00460 | 0.9994 |

| NE | 2.653 | −0.0059 | 0.4779 | −7.504 | 0.9791 | |

| Retrof | 3.074 | −0.00484 | 0.175 | 0.00031 | 0.9254 | |

| LM | MO | 2.668 | −0.00202 | 0.0453 | 0.00063 | 0.9904 |

| NE | 2.814 | −0.00141 | 0.0952 | 0.00063 | 0.9981 | |

| Retrof | 3.95 | −0.00212 | 0.0732 | 0.00056 | 0.8765 | |

| a | b | c | d | R | ||

|---|---|---|---|---|---|---|

| HM | MO | 758.9 | −0.006565 | 232.4 | 8.014 | 0.9989 |

| NE | 615 | −0.00696 | 468 | −2.389 | 0.9601 | |

| Retrof | 443.4 | −0.001096 | 86.46 | 0.000537 | 0.8302 | |

| LM | MO | 623.2 | −0.00265 | 360.4 | −0.000176 | 0.9829 |

| NE | 831.7 | −0.00231 | 409.6 | 6.119 | 0.9747 | |

| Retrof | 679.9 | −0.00053 | 28.41 | 0.0008959 | 0.693 | |

| (N/mm) = | a | b | R | |

|---|---|---|---|---|

| HM | MO | 0.0038 | −0.5813 | 0.974 |

| NE | 0.0045 | −1.765 | 0.960 | |

| Retrof | 0.004 | −0.885 | 0.586 | |

| LM | MO | 0.0036 | −0.7126 | 0.981 |

| NE | 0.0031 | −0.8135 | 0.952 | |

| Retrof | 0.0043 | −1.1937 | 0.477 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Montero, A.; García, B.; López, C. Life Expectancy of Transformer Paper Insulation Retrofilled with Natural Ester in the Laboratory. Polymers 2023, 15, 4345. https://doi.org/10.3390/polym15224345

Montero A, García B, López C. Life Expectancy of Transformer Paper Insulation Retrofilled with Natural Ester in the Laboratory. Polymers. 2023; 15(22):4345. https://doi.org/10.3390/polym15224345

Chicago/Turabian StyleMontero, Andrés, Belén García, and Carlos López. 2023. "Life Expectancy of Transformer Paper Insulation Retrofilled with Natural Ester in the Laboratory" Polymers 15, no. 22: 4345. https://doi.org/10.3390/polym15224345

APA StyleMontero, A., García, B., & López, C. (2023). Life Expectancy of Transformer Paper Insulation Retrofilled with Natural Ester in the Laboratory. Polymers, 15(22), 4345. https://doi.org/10.3390/polym15224345