Abstract

Pectin and alginate satisfy multiple functional requirements in the food industry, especially relating to natural packaging formulation. The continuous need for economic and environmental benefits has promoted sourcing and investigating alternative biomaterials, such as cactus pear mucilage from the cladodes of Opuntia spp., as natural packaging alternatives. The structural and mechanical properties of mucilage, pectin and alginate films developed at a 5% (w/w) concentration were modified by treating the films with calcium (Ca) in the calcium chloride (CaCl2) form. Scanning electron microscopy (SEM) showed the 5% (w/w) ‘Algerian’ and ‘Morado’ films to display considerable microstructure variation compared to the 5% (w/w) pectin and alginate films, with calcium treatment of the films influencing homogeneity and film orientation. Treating the alginate films with a 10% (w/w) stock CaCl2 solution significantly increased (p < 0.05) the alginate films’ tensile strength (TS) and puncture force (PF) values. Consequently, the alginate films reported significantly higher (p < 0.05) film strength (TS and PF) than the pectin + Ca and mucilage + Ca films. The mucilage film’s elasticity was negatively influenced by CaCl2, while the pectin and alginate films’ elasticity was positively influenced by calcium treatment. These results suggest that the overall decreased calcium sensitivity and poor mechanical strength displayed by ‘the Algerian’ and ‘Morado’ films would not make them viable replacements for the commercial pectin and alginate films unless alternative applications were found.

1. Introduction

The increased demands for naturally biodegradable packaging solutions have resulted in various biopolymers being investigated for their film-forming potential. Biopolymers displaying functional potential, which can be used in the development of biopolymer films, are of growing interest. Given the nature of biopolymer films’ functionality and biocompatibility, they have also been considered for a diverse range of applications other than packaging, specifically relating to medical applications such as intervertebral disc replacement and, consequently, bone regeneration [1,2]. Due to their diverse and desirable functional properties, pectin and alginate have specifically found favourable applications in developing biopolymer films. However, factors that influence the formation of these biopolymer films have been identified, such as the addition of a cross-linker [3,4].

The diverse chemical and physical properties, biodegradability and biocompatibility of pectin have resulted in its use in developing biopolymer films [5]. The chemical composition of different pectins can vary, although about 60–65% of the molecule must be composed of galacturonic acid (GalA), which can display varying degrees of methyl esterification [6,7]. The presence of these charged groups associated with the pectin polymer is predominantly responsible for altering the polymers’ functional properties in the presence of acidic and basic pH environments and by the introduction of charged ions, such as calcium. Although calcium ions have the ability to alter the rheology of a pectin solution, the main consequence of pectin cross-linking is the formation of hydrogels, specifically harnessed in the development of biopolymer films [3,7,8]. Due to pectins’ ability to successfully form biopolymer films, displaying adequate mechanical and barrier properties, multiple authors have investigated the development of pectin biopolymer films for various applications, with and without the addition of a cross-linker [3,9].

Alginate is another polysaccharide used in the development of biopolymer films. The presence of functional groups, consisting of uronic acid, associated with the alginate polymer is of specific importance, as these charged groups directly determine alginate functionality. These functional groups can be modified to alter alginates’ rheological, biochemical and film mechanical properties [9,10,11]. Typically, the functional properties of alginate can be influenced by the presence of cross-linkers, such as calcium and magnesium. Alginate cross-linking is often described by the ‘egg-box’ model, characteristic of the formation of a three-dimensional (3D) network. This model is similar to that used to describe pectin–calcium cross-linking, although differences can be expected between the two mechanisms [6,7,8]. It was reported that alginate–calcium films displayed overall increased mechanical properties regarding tensile strength than pectin–calcium films, indicating that alginate displays increased cross-linking ability due to its structural conformation and chemical composition, ultimately influencing biopolymer films’ physical properties [12]. Bierhalz et al. [13] reported on differences between pectin and alginate biopolymer film micrographs, with alginate films showing a more homogenous and regular morphology than pectin films. Consequently, alginate films were, in some instances, associated with superior mechanical properties [13].

One of the most, if not the most, important properties of biopolymer films is their mechanical properties (physical strength and elasticity). These properties are essential to ensure the protection and maintenance of the structural integrity of food during transportation, storage and handling [3]. Biopolymer films developed from polysaccharides, such as pectin and alginate, require a drying step to imitate pre-formed plastic packaging. However, the drying of these films is generally always associated with films displaying brittle and even fragile properties. Glycerol has been well established as a plasticizer to reduce brittleness and improve the ease of handling of pectin and alginate biopolymer films [14,15]. Kang et al. [16] investigated the TS and %E of pectin biopolymer films. The authors formed films by immersion of pectin films into 5 and 10% CaCl2 solutions, acting as a cross-linker. Films were prepared with no addition of calcium, considered the control films. The results confirmed that the films formed using 5% CaCl2 showed an increased TS, 198 MPa higher than that of the control films. Furthermore, the 5% CaCl2-cross-linked films showed the lowest elongation at a break potential of 2.6% [16]. Badita et al. [17] investigated the influence of calcium, used as a cross-linker, on ‘dry’ alginate biopolymer films’ properties. The authors found that the alginate–calcium films’ properties were considerably influenced by both the cross-linker as well as the concentration of the cross-linker used. It was further confirmed that hydroxyl and carboxylic groups, associated with the alginate polymer chemical structure, were responsible for the hydrogel formation with the addition of calcium, highlighting the benefits of calcium as a cross-linker in biopolymer films formation [17].

Although pectin and alginate have shown success in the development of biopolymer films, consequential high input costs, in addition to the variability and limitations regarding their availability and functionality, have led to the development and investigation of alternative film-forming polymers. The desirable functional properties displayed by the cactus pear mucilage from Opuntia ficus-indica have resulted in its investigation as an alternative biopolymeric material in the development of biopolymer films to address certain shortcomings associated with the current polysaccharides films [14,18,19]. Considering the mucilage precipitate from the cactus pear as a functional polymer can prove beneficial because it is often considered an unwanted by-product from cactus pear processing, resulting in favourable cost implications and general ease of availability.

Although the native mucilage precipitate has been well investigated, variations in its chemical structure and composition have been reported. In general, mucilage is considered a highly flexible heteropolysaccharide with a high molecular weight, which has the potential to carry a negative charge due to the presence of galacturonic acid associated with its chemical structure [20,21,22]. In addition to charged sugars, various amounts of neutral sugars have also been associated with the mucilage precipitate, which includes L-arabinose, D-galactose, L-rhamnose and D-xylose in varying quantities [20,21,22]. Structurally, the mucilage precipitate has been reported to be composed of a charged linear core with many natural sugar side chains. These two main fractions of the mucilage precipitate have been referred to as a gelling, pectin-like fraction and a more neutral, pure mucilage fraction. However, great variability in sugar composition for both fractions has been reported by authors [23,24,25].

In a recent study by van Rooyen et al. [26], the authors showed mucilage, when added at 0.25% and 1.0% to pectin-based composite (blended) films, to enhance certain mechanical properties of pectin films. The authors further suggested these enhanced film mechanical properties could directly be linked to the addition of mucilage to the pectin films [26]. Although this before-mentioned study evaluated mucilages’ compatibility in combination with commercially available polymers, limited knowledge is available on mucilages’ comparative ability to produce single-biopolymer (homopolymeric) films displaying suitable mechanical properties with sights on using them as biodegradable packaging. Logically, comparing single-polymer mucilage films to well-established pectin and alginate films will further advance the understanding of mucilage’s potential to be considered as a homopolymeric film-forming polymer, consequently providing insight into the polymer’s functional potential. The factors that have been shown to alter well-established polymer films’ properties also remain greatly unexplored for single-polymer mucilage-based biopolymer films. Therefore, this study aimed to gain a better understanding of single-polymer (homopolymeric) mucilage films relative to commercially produced single-polymer pectin and alginate films, specifically, to understand the influence a gelling cation (calcium, in the form of calcium chloride) would have on mucilage films’ physical properties so to possibly consider them as alternative biopolymers to pectin and alginate in developing biodegradable packaging. Consequently, exploring the physical properties of these single-polymer mucilage films will contribute to the understanding of the native mucilage precipitate, creating a clearer image of its structural functionality and single-polymer film-forming potential.

2. Materials and Methods

2.1. Materials

2.1.1. Commercial Polymers

Pectin powder with ≤10% moisture content, sourced from apple and sodium alginate powder with both glucuronic and mannuronic acid content, both supplied by Sigma-Aldrich, Cape Town, South Africa, was used.

2.1.2. Mucilage Precipitate and Freeze-Dried Mucilage Powders

The ‘Algerian’ and ‘Morado’ cultivars of Opuntia ficus-indica were used to prepare freeze-dried mucilage powders from a liquid mucilage precipitate with ≤10% moisture content. Following a well-established extraction procedure, described by Du Toit and De Wit [27], which is cost-effective and easily replicated, native mucilage precipitates were prepared. The resultant mucilage precipitates were well characterized in previous studies [28,29]. We used ~24-month-old cactus pear plant cladodes from the ‘Algerian’ and ‘Morado’ cultivars sourced from an orchard (University of the Free State, 29.1076° S, 26.1925° E) with a cactus pear density of 666 cactus pear/h, without irrigation. Firstly, to promote liquid mucilage precipitation, whole cladodes were cubed and microwaved at 900 W for 4 min and then macerated. Secondly, the macerated cladodes were centrifuged using a Beckman® Centrifuge (2315, Brea, CA, USA) at 8000 rpm for 15 min at a constant temperature of 4 °C, which effectively separated the mucilage precipitate from the solids. The liquid mucilage precipitate was then used to prepare the freeze-dried mucilage powders used in this current work. Freeze-drying involved moisture removal from the mucilage precipitate at a low temperature (−30 °C to −40 °C) and constant vacuum until a 95% sample weight loss was obtained. The freeze-dried samples were then milled finely, using a standard mortar and pestle, obtaining a consistent powder with a moisture content of ≤10%.

2.1.3. Cross-Linker and Plasticizer

Granular calcium chloride, anhydrous, purchased from Sigma-Aldrich, Cape Town, South Africa, with excellent water solubility, and glycerol (Merck, Johannesburg, South Africa) as a plasticizer, with a purity > 99% were used.

2.2. Film Preparation and Development

2.2.1. Film-Forming Solutions

Using film-forming methods, as described by van Rooyen et al. [26], all film-forming solutions were prepared. The basic method involved dispersing the desired amounts of polymer powder into distilled water containing glycerol. The pectin and alginate films required a minimum of 60% glycerol (w/w, based on the polymer weight used in the films). The mucilage films required 20% glycerol addition.

Making use of a magnetic stirrer (Freed Electric-Model MH-4, Rehovot, Israel), all film-forming solutions were allowed to homogenize for 30 min, promoting polymer rehydration at ambient temperature (~25 °C). The rehydrated samples were then further mechanically homogenized by means of a Stick Blender (Mellerwave-Model 85200, Cape Town, South Africa) for 10 s. To reduce the potential volume and structural differences caused by excess entrapped air, the homogenized samples were degassed under vacuum (Genesis Vacuum Sealer, Verimark (Pty) Ltd., Pretoria, South Africa) [26].

2.2.2. Development of Single-Polymer Films

The films used in this study were developed using a standardized batch film casting method with some modifications [5,12,26,30,31]. According to the casting method, the film-forming solution was evenly spread onto a non-stick surface. Upon drying, measurable films formed [5]. Using 140 mm diameter Petri dishes, 70 g of film-forming solution was evenly spread onto the Petri dishes. The dried films were formed by placing the Petri dishes, containing 70 g of film-forming solution, into a ventilated oven (EcoTherm—Model 920, 1000 W, Labotec) at 40 °C for 24 h [26]. Before film evaluation could be completed, all dried films were equilibrated in a closed container at room temperature (~25 °C) for 24 h to achieve ~52% RH.

2.2.3. Calcium Treatment of Single-Polymer Films

The calcium treatment of the pectin and alginate films required a calcium chloride (CaCl2) solution to be directly poured into a polymer solution contained in Petri dishes. After a 5-minute reaction time, the excessive CaCl2 solution was removed from the Petri dishes, with the excess CaCl2 gently being dabbed off the resultant films with a paper towel [26]. The stock CaCl2 solution was prepared at 10% (w/w) with distilled water; this was considered a more than adequate amount of calcium to react with pectin and alginate [32]. The mucilage films, however, required CaCl2 to be directly mixed into the prepared, fully rehydrated, film-forming solution before casting and drying the films. The CaCl2 addition was calculated at 30% (w/w, based on the polymer weight used in the films). Espino-Díaz et al. [18] described similar procedures and calcium concentrations for the calcium treatment of mucilage films. Trachtenberg and Mayer [33] also suggested 30% CaCl2 additions to be more than adequate to interact with mucilage. Once the various polymers had been treated with calcium, the films were dried.

2.3. Film Characterization

2.3.1. Scanning Electron Microscopy

All biopolymer films were subjected to scanning electron microscopy (SEM) imaging. The various samples were first mounted on carbon tape and splutter-coated with iridium. Imaging was then carried out on the various samples at 3.0 KV by making use of a JEOL (JSM-7800F Field Emission, Tokyo, Japan) scanning electron microscope.

2.3.2. Film Microstructure Evaluation

The images used in this current work were evaluated and selected by a team of five researchers with experience in microscopy, so to represent the overall microstructures of the different images taken of the various films at 10,000× magnification. Additionally, differences observed by the five researchers regarding the differently treated films’ surface roughness/smoothness were also considered by examining visual differences in the surface morphology of the resultant film SEM images.

2.3.3. Mechanical Properties

Tensile and puncture tests were completed to determine the various films’ mechanical properties using a Texture Analyzer CT3™ (Brookfield AMETEK®, Westville, South Africa) with similar methods as those described by van Rooyen et al. [26]. All the film mechanical tests were approached and completed by thoroughly consulting the ASTM international standard methods (ASTM-D882; 2010), as also described by Harper [34]. The various films were cut into 25 × 80 mm rectangular strips, which could then be used to determine their mechanical properties. Twelve films were tested per treatment. The different film thicknesses were measured on all the conditioned films before completing the mechanical tests using a digital micrometre (Grip, South Africa).

Film Tensile Test

The Roller Cam Accessory grips (TA-RCA), set at a spacing of 50 mm and a test speed of 0.80 mm·s−1, measured the films’ tensile strength and elongation at break values (Brookfield AMETEK®, Westville, South Africa). Specifically, a film’s tensile strength is representative of the maximum stress (force/area) any given film can withstand when a force is applied to it [12]. The film tensile strength is specifically calculated by dividing the maximum load (N) by the initial cross-sectional area of a film and is expressed in MPa [14,18,35]. A second tensile test, that is, the elongation at break percentage of a film, specifically measures a film’s maximum capacity to extend before reaching its breaking point [12], calculated by dividing the difference in length of the film at rupture by the initial film length [36].

Puncture Test

The various films’ puncture force and distance to puncture were determined by making use of the texture analyzer, accompanied by a Probe TA44 (4 mm diameter probe). A film’s puncture force is defined as the maximum force (N) required to tear the film [37]. All puncture tests were completed by selecting a test speed of 0.80 mm·s−1 on the texture analyzer.

2.4. Experimental Design

The impact CaCl2 had on mucilage, pectin and alginate films’ microstructures and mechanical properties was considered. Firstly, using SEM, the various films’ surface microstructures were also investigated. Non-calcium-treated and calcium-treated micrographs were investigated for mucilage, pectin and alginate at 10,000× magnifications. Secondly, the influence CaCl2 had on the mucilage, pectin and alginate films’ mechanical properties was evaluated. Due to the calcium sensitivity displayed by the pectin and alginate polymers, CaCl2 solutions were prepared and used to cross-link the liquid film-forming pectin and alginate solutions once they had been cast into the Petri dishes. However, Espino-Díaz et al. [18] suggested mucilage’s lower sensitivity to calcium requires CaCl2 to be directly mixed into the prepared mucilage film-forming solutions, whereafter film casting, drying, and evaluation could be completed.

2.5. Statistical Analysis

The results of the various trials were captured using Microsoft Excel (2016), and the data were subjected to statistical analysis (ANOVA) using one-way analysis of variance (NCSS Statistical Software package, version 11.0.20). Using the Tukey–Kramer multiple comparison test (α = 0.05), significant differences between the treatment means (NCSS Statistical Software package, version 11.0.20) were identified accordingly.

3. Results

3.1. Film Microstructure Characterization

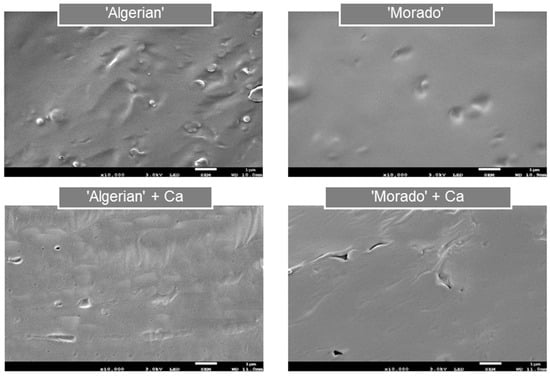

A biopolymer film’s microstructure is often directly associated with its resultant mechanical behaviour [38,39]. Investigating scanning electron microscopy (SEM) micrographs were considered to provide a more holistic insight into the homogeneity and microstructures of non-calcium-treated and calcium-treated mucilage, pectin and alginate films, as calcium is specifically known for its ability to physically alter a film network. Firstly, the surface morphology of ‘Algerian’ and ‘Morado’ mucilage films was considered, as displayed in Figure 1.

Figure 1.

Surface scanning electron microscopy (SEM) images of ‘Algerian’ and ‘Morado’ mucilage ‘dry’ films, with and without calcium (Ca) treatment at 10,000× magnification.

The non-calcium-treated ‘Algerian’ films showed a lack of homogeneity, with a surface roughness, compared to the calcium-treated ‘Algerian’ films. The non-calcium-treated ‘Morado’ films showed a smoother, more homogeneous surface morphology than the non-calcium-treated ‘Algerian’ films. However, some cracks and breaks in film homogeneity were observed when treating the ‘Morado’ films with calcium. Guadarrama-Lezama et al. [40] suggested that the appearance of cracks and holes observed in a film microstructure could indicate a denser film formation. The breaks in structure observed in the calcium-treated ‘Morado’ films could thus be related to films of increased density compared to calcium-treated ‘Algerian’ films. Furthermore, treating the mucilage films with calcium showed indications of the development of a more organized mucilage film network (Figure 1). Authors suggested that the presence of a pectin-like fraction that displays sensitivity to calcium could be the reason for the development of these more organized film networks when the mucilage films were treated with calcium [19,23].

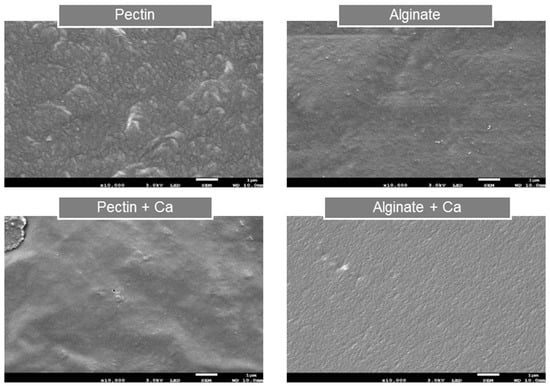

The SEM imaging of the surface morphology of the pectin and alginate films, with and without calcium treatment, is presented in Figure 2.

Figure 2.

SEM imaging of the surface microstructures of ‘dry’ pectin and alginate films, with and without calcium (Ca) treatments at 10,000× magnification.

Less homogeneous and more rough surfaces were observed in both the non-calcium-treated pectin and the alginate films’ microstructures compared to their calcium-treated counterparts (Figure 2). Specifically, the calcium treatment was shown to change the surface morphology of the pectin and alginate films noticeably. However, the calcium-treated alginate films showed homogeneity, represented by a more uniform microstructure than the calcium-treated pectin films. This observation indicates the different internal arrangements of the different polymers during film formation, with alginates displaying a more organized network than pectin films [41].

Paşcalau et al. [42] also reported that alginate films treated with calcium resulted in the formation of a more homogeneous film network, typically expected for films that underwent cross-linking (which was not observed for the uncross-linked alginate films), similar to that observed in the current research for uncross-linked and calcium cross-linked alginate films (Figure 2). As observed in the current research, the pectin and alginate films’ microstructures were, therefore, similar to those observed in the literature, with alginate films forming a more organized, homogeneous film network when treated with calcium than pectin films (Figure 2).

The results proved that treating the mucilage, pectin and alginate films with calcium led to noticeable morphological changes in the films’ structures. Microstructure differences were also clearly observed between the mucilage, pectin and alginate films. More homogeneous and organized film networks were found in both pectin and alginate films’ microstructures. In contrast, the mucilage films appeared to be more non-homogeneous and irregular and sometimes contained aggregates and pores.

3.2. Film Mechanical Properties

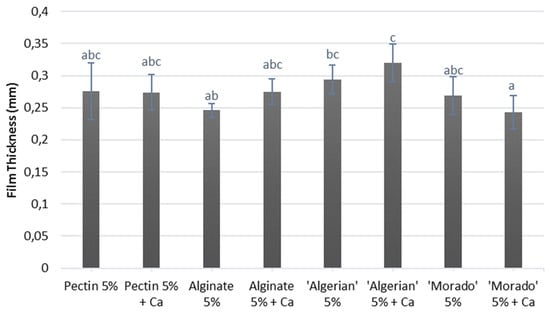

3.2.1. The Influence of Calcium on Film Thickness

The influence calcium treatments had on mucilage, pectin and alginate films’ thickness is presented in Figure 3. Most films displayed only minimal differences in film thickness. Similar trends in film thickness were reported for films treated with calcium developed at a 5% (w/w) polymer concentration [26]. However, the ‘Algerian’ + Ca films were significantly thicker (p < 0.05) than the ‘Morado’ + Ca films. A decrease in film thickness with the addition of calcium could be related to a higher degree of cross-linking observed in the films due to a possible decrease in inter-chain polymer spacing [9,13].

Figure 3.

Thickness of the pectin, alginate and mucilage films with and without calcium (Ca) treatment. The mean values of 8 treatments are displayed together with their standard deviations. Error bars represented by differet superscripts differ significantly (p < 0.05).

3.2.2. Tensile Test

Further differences were observed between the mechanical properties of the mucilage, pectin and alginate films treated with calcium, as indicated in Table 1. When evaluating the influence the calcium treatment had on the various films’ tensile strength (TS), it was seen that only the alginate film’s TS values were significantly increased (p < 0.05) (Table 1). Bierhalz et al. [13] also found alginate films to display superior TS due to the alginate’s linear polymer chains, allowing for a more efficient cross-linking with calcium compared to the cross-linking of the pectin polymer chains. Additionally, alginate also produced films displaying significantly higher (p < 0.05) TS values in comparison to the various other films investigated. These findings are also supported by the literature, as authors found alginate to produce films of superior strength due to a more efficient calcium cross-linking of the polymer [12,43,44]. Although calcium-treating the mucilage films showed to have no significant (p > 0.05) influence on the film TS, the ‘Morado’ + Ca films did show trends of increased strength, as the TS value increased from 0.31 (TS of the non-calcium-treated ‘Morado’ film) to 1.01 MPa. These findings indicated a slight potential of the ‘Morado’ mucilage to cross-link with calcium.

Table 1.

Tensile test mechanical properties of non-calcium-treated and calcium-treated mucilage, pectin and alginate films.

The film %E showed the calcium treatments to have a considerable and varying influence on film elasticity. The calcium treatments significantly increased (p < 0.05) both pectin and alginate films’ %E values whilst significantly decreasing (p < 0.05) the ‘Algerian’ and ‘Morado’ mucilage films’ elasticity. It has come to be expected that the addition of calcium would aid in increasing the cohesion forces between the polymer chains of alginate and pectin, increasing film strength and elasticity [13,43]. As regards the decreases in the mucilage film %E values observed in Table 1, research has suggested that, due to the low occurrence of carboxyl groups in the native mucilage structure, the addition of calcium could induce polymer chain contraction or the ionic condensation of the mucilage polymers rather than cross-link the polymer chains, as adequate binding sites for calcium would not be available, in turn reducing the film’s cohesion forces and thus its elasticity [18,23]. The ‘Morado’ + Ca film showed significantly higher (p < 0.05) %E values when compared to the ‘Algerian’ + Ca film.

3.2.3. Puncture Test

Similar observations were reported when investigating the various films’ puncture force (PF) values compared to those observed for the films’ TS (Table 2). The calcium treatment of the alginate films significantly increased (p < 0.05) the films’ PF values, with the Alginate + Ca films showing the overall highest strength compared to the various other films investigated (Table 2). Again, both ‘Algerian’ and ‘Morado’ mucilage films showed to be only minimally influenced by calcium treatment, producing films with the lowest PF. Interestingly, the puncture tests indicated that the Alginate + Ca films had the highest DTP values compared to the other films. The mucilage films showed the lowest DTP values, with calcium treatment of the films further significantly lowering (p < 0.05) them. These trends were similar to those reported for the tensile test %E evaluation.

Table 2.

Puncture test mechanical properties of non-calcium-treated and calcium-treated mucilage, pectin and alginate films.

4. Discussion

When considering the scanning electron microscopy (SEM) imaging micrographs (Figure 1 and Figure 2) and the mechanical properties (Table 1 and Table 2) of the various films investigated, treating the alginate films with calcium resulted in producing films displaying superior strength compared to the pectin and mucilage films. Guadarrama-Lezama et al. [40] suggested that films with smoother surfaces, lacking pores in the film network, would display superior mechanical properties. Specifically, the calcium-treated alginate films displayed the greatest homogeneity among all the various films investigated. The Alginate + Ca films’ microstructures showed a highly ‘organized’ film network, compared to the calcium-treated pectin films, which were characterized by a less homogeneous surface morphology with visible rough surfaces. Bierhalz et al. [13] also reported that ‘dry’ alginate films’ microstructures presented a more homogenous and regular network than those of ‘dry’ pectin films treated with calcium.

Furthermore, the authors also suggested that alginate’s more linear structure would allow for a more efficient calcium cross-linking than that present in pectin polymers, which consequently would also influence films’ mechanical properties [13]. Therefore, the Pectin + Ca films reported significantly lower (p < 0.05) tensile strength (TS) and puncture force (PF) values in comparison to the Alginate + Ca films. Differences in the chemical structures between pectin and alginate have been strongly suggested to be the main reason for the morphological and mechanical differences observed between these two commercially available polymers. As the alginate polymer’s linear chains allow for a more efficient and organized cross-linking, the pectin polymer generally results in a more random orientation with calcium due to its branched chemical structure. Additionally, varying degrees of esterification of the pectin polymer will influence its ability to react with calcium [33,34,35].

When comparing the influence calcium had on the mucilage films, it was seen that both ‘Algerian’ and ‘Morado’ films showed the poorest mechanical properties when compared to the commercially available pectin and alginate films. Authors also reported on calcium-treated mucilage films with low TS and %E values [18]. The lack of homogeneity and the irregular nature of the ‘Algerian’ and ‘Morado’ films must be strongly considered, as these morphological features have been thought to account for films displaying reduced mechanical properties. The expected highly branched chemical structure of mucilage has also been suggested to be strongly associated with the lack of homogeneity and the irregular appearance of mucilage films [19,40]. Furthermore, variations in the surface morphology and mechanical properties were also observed between the two mucilage cultivars. The ‘Morado’ films showed the possibility of increased calcium sensitivity, resulting in films displaying trends of increased strength and elasticity when compared to the ‘Algerian’ films treated with calcium. These findings were supported by examining the microstructural variations between the ‘Algerian’ and the ‘Morado’ films, with less rough film surfaces observed for the ‘Morado’ films.

Lastly, the ‘Algerian’ + Ca films presented a greater film thickness compared to the ‘Morado’ + Ca films. These findings strongly suggest that the ‘Algerian’ films, being rougher, denser and thicker, would display decreased strength and elasticity compared to the ‘Morado’ mucilage films. Research has suggested that increased film thickness and roughness and decreased film homogeneity could strongly indicate reduced polymer chain interaction in a film matrix, resulting in films displaying reduced strength and elasticity [9,13].

5. Conclusions

With global efforts aimed at reducing single-use plastics, the need to develop biopolymer packaging from sustainable sources is being strongly considered. Mucilage, pectin and alginate films displayed varying degrees of mechanical alteration by adding calcium. Although the alginate films showed superior strength, the mucilage films had exceptional elasticity. Cross-linking the various films with calcium showed to enhance further only the alginate films’ tensile strength and puncture strength whilst having only a minimal influence on the pectin and mucilage films’ strength. The superior homogeneity observed in the scanning electron microscopy (SEM) images of the alginate films was clearly identifiable compared to the less organized pectin and mucilage films’ microstructures. The pectin and alginate films’ elasticity was further enhanced by treating the films with calcium, with the mucilage film elongation at break percentage and distance to puncture values negatively influenced by calcium. The various polymers’ diverse interactions with calcium accounted for possible structural variations between the polymers. However, the ‘Algerian’ mucilage polymer showed the likeliness to carry less of a charge than the ‘Morado’ mucilage, showing an overall reduced functionality in this work. Regardless of the mucilage cultivar, the results indicated that the mucilage films were much weaker overall than the pectin and alginate films, although they had, in most instances, superior elasticity. The native mucilage films display commercial viability. Therefore, evaluating the water and gas barrier, crystallization, and anti-fogging properties of these films would be a logical next step in a phased approach to establish a holistic view of cactus pear mucilage to be used as an alternative packaging solution. Regardless thereof, the mechanical properties of these films suggest their success as an alternative, application-specific packaging, likely not finding similar applications as alginate and pectin films.

Author Contributions

Conceptualization, B.V.R. and M.D.W.; methodology, B.V.R., M.D.W. and G.O.; formal analysis, A.H., M.D.W. and G.O.; investigation, B.V.R.; resources, M.D.W. and J.V.N.; data curation, B.V.R., A.H., G.O. and M.D.W.; writing—original draft preparation, B.V.R.; writing—review and editing, B.V.R. and J.V.N.; supervision, M.D.W., G.O., A.H. and J.V.N.; project administration, B.V.R., M.D.W. and J.V.N. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

The authors wish to thank Herman Fouché for his assistance with the harvesting of the raw cactus pear cladode material.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Zhang, Y.; Gao, H.; Luo, H.; Chen, D.; Zhou, Z.; Cao, X. High Strength HA-PEG/NAGA-Gelma Double Network Hydrogel for Annulus Fibrosus Rupture Repair. Smart Mater. Med. 2022, 3, 128–138. [Google Scholar] [CrossRef]

- Huang, C.; Ye, Q.; Dong, J.; Li, L.; Wang, M.; Zhang, Y.; Zhang, Y.; Wang, X.; Wang, P.; Jiang, Q. Biofabrication of Natural Au/Bacterial Cellulose Hydrogel for Bone Tissue Regeneration via in-Situ Fermentation. Smart Mater. Med. 2023, 4, 1–14. [Google Scholar] [CrossRef]

- Otoni, C.G.; Avena-Bustillos, R.J.; Azeredo, H.M.C.; Lorevice, M.V.; Moura, M.R.; Mattoso, L.H.C.; McHugh, T.H. Recent Advances on Edible Films Based on Fruits and Vegetables—A Review. Compr. Rev. Food Sci. Food Saf. 2017, 16, 1151–1169. [Google Scholar] [CrossRef] [PubMed]

- Gawkowska, D.; Ciesla, J.; Zdunek, A.; Cybulska, J. The Effect of Concentration on the Cross-Linking and Gelling of Sodium Carbonate-Soluble Apple Pectins. Molecules 2019, 24, 1635. [Google Scholar] [CrossRef] [PubMed]

- Espitia, P.J.P.; Du, W.-X.; de Avena-Bustillos, R.J.; Soares, N.; de Fátima Ferreira Soares, N.; McHugh, T.H. Edible Films from Pectin: Physical-Mechanical and Antimicrobial Properties—A Review. Food Hydrocoll. 2014, 35, 287–296. [Google Scholar] [CrossRef]

- Ridley, B.L.; O’Neill, M.A.; Mohnen, D. Pectins: Structure, Biosynthesis, and Oligogalacturonide-Related Signaling. Phytochemistry 2001, 57, 929–967. [Google Scholar] [CrossRef]

- Willats, W.G.T.; Knox, J.P.; Mikkelsen, J.D. Pectin: New Insights into an Old Polymer Are Starting to Gel. Trends Food Sci. Technol. 2006, 17, 97–104. [Google Scholar] [CrossRef]

- Gawkowska, D.; Cybulska, J.; Zdunek, A. Structure-Related Gelling of Pectins and Linking with Other Natural Compounds: A Review. Polymers 2018, 10, 762. [Google Scholar] [CrossRef]

- Yang, J.S.; Xie, Y.J.; He, W. Research Progress on Chemical Modification of Alginate: A Review. Carbohydr. Polym. 2011, 84, 33–39. [Google Scholar] [CrossRef]

- Bouhadir, K.H.; Lee, K.Y.; Alsberg, E.; Damm, K.L.; Anderson, K.W.; Mooney, D.J. Degradation of Partially Oxidized Alginate and Its Potential Application for Tissue Engineering. Biotechnol. Prog. 2001, 17, 945–950. [Google Scholar] [CrossRef]

- Larsen, B.; Salem, D.M.S.A.; Sallam, M.A.E.; Mishrikey, M.M.; Beltagy, A.I. Characterization of the Alginates from Algae Harvested at the Egyptian Red Sea Coast. Carbohydr. Res. 2003, 338, 2325–2336. [Google Scholar] [CrossRef] [PubMed]

- Da Silva, M.A.; Bierhalz, A.C.K.; Kieckbusch, T.G. Alginate and Pectin Composite Films Crosslinked with Ca2+ Ions: Effect of the Plasticizer Concentration. Carbohydr. Polym. 2009, 77, 736–742. [Google Scholar] [CrossRef]

- Bierhalz, A.C.K.; Silva, M.A.D.; Kieckbusch, T.G. Natamycin Release from Alginate/Pectin Films for Food Packaging Applications. J. Food Eng. 2012, 110, 18–25. [Google Scholar] [CrossRef]

- Gheribi, R.; Puchot, L.; Verge, P.; Jaoued-Grayaa, N.; Mezni, M.; Habibi, Y.; Khwaldia, K. Development of Plasticized Edible Films from Opuntia Ficus-Indica Mucilage: A Comparative Study of Various Polyol Plasticizers. Carbohydr. Polym. 2018, 190, 204–211. [Google Scholar] [CrossRef]

- Zibaei, R.; Hasanvand, S.; Hashami, Z.; Roshandel, Z.; Rouhi, M.; de Guimarães, J.T.; Mortazavian, A.M.; Sarlak, Z.; Mohammadi, R. Applications of Emerging Botanical Hydrocolloids for Edible Films: A Review. Carbohydr. Polym. 2021, 256, 117554. [Google Scholar] [CrossRef]

- Kang, H.J.; Jo, C.; Lee, N.Y.; Kwon, J.H.; Byun, M.W. A Combination of Gamma Irradiation and CaCl2 Immersion for a Pectin-Based Biodegradable Film. Carbohydr. Polym. 2005, 60, 547–551. [Google Scholar] [CrossRef]

- Badita, C.R.; Aranghel, D.; Burducea, C.; Mereuta, P.; Engineering, N. Characterization of Sodium Alginate based Films. Rom. J. Phys. 2019, 602, 1–8. [Google Scholar]

- Espino-Díaz, M.; Ornelas-Paz, J.D.J.; Martínez-Téllez, M.A.; Santillán, C.; Barbosa-Cánovas, G.V.; Zamudio-Flores, P.B.; Olivas, G.I. Development and Characterization of Edible Films Based on Mucilage of Opuntia ficus-indica (L.). J. Food Sci. 2010, 75, 347–352. [Google Scholar] [CrossRef]

- Lira-Vargas, A.A.; Corrales-Garcia, J.J.E.; Valle-Guadarrama, S.; Peña-Valdivia, C.B.; Trejo-Marquez, M.A. Biopolymeric Films Based on Cactus (Opuntia Ficus-Indica) Mucilage Incorporated with Gelatin and Beeswax. J. Prof. Assoc. Cactus Dev. 2014, 16, 51–70. [Google Scholar]

- Majdoub, H.; Roudesli, S.; Picton, L.; Cerf, D.L.; Muller, G.; Grisel, M. Prickly Pear Nopals Pectin from Opuntia Ficus-Indica Physico-Chemical Study in Dilute and Semi-Dilute Solutions. Carbohydr. Polym. 2001, 46, 69–79. [Google Scholar] [CrossRef]

- Sáenz, C.; Sepúlveda, E.; Matsuhiro, B. Opuntia Spp. Mucilage’s: A Functional Component with Industrial Perspectives. J. Arid Environ. 2004, 57, 275–290. [Google Scholar] [CrossRef]

- Sepúlveda, E.; Sáenz, C.; Aliaga, E.; Aceituno, C. Extraction and Characterization of Mucilage in Opuntia Spp. J. Arid Environ. 2007, 68, 534–545. [Google Scholar] [CrossRef]

- Goycoolea, F.M.; Cárdenas, A. Pectins from Opuntia Spp.: A Short Review. J. Prof. Assoc. Cactus Dev. 2003, 5, 17–29. [Google Scholar]

- Cárdenas, A.; Goycoolea, F.M.; Rinaudo, M. On the Gelling Behaviour of “nopal” (Opuntia Ficus Indica) Low Methoxyl Pectin. Carbohydr. Polym. 2008, 73, 212–222. [Google Scholar] [CrossRef]

- Rodríguez-González, S.; Martínez-Flores, H.E.; Chávez-Moreno, C.K.; Macías-Rodríguez, L.I.; Zavala-Mendoza, E.; Garnica-Romo, M.G.; Chacõn-García, L. Extraction and Characterization of Mucilage from Wild Species of Opuntia. J. Food Process Eng. 2014, 37, 285–292. [Google Scholar] [CrossRef]

- van Rooyen, B.; de Wit, M.; Osthoff, G.; Van Niekerk, J.; Hugo, A. Effect of Native Mucilage on the Mechanical Properties of Pectin-Based and Alginate-Based Polymeric Films. Coatings 2023, 13, 1611. [Google Scholar] [CrossRef]

- Du Toit, A.; De Wit, M. Patent PA153178P A Process for Extracting Mucilage from Opuntia Ficus-Indica, Aloe Barbadensis and Agave Americana. Ph.D. Thesis, University of the Free State, Bloemfontein, South Africa, 2021. [Google Scholar] [CrossRef]

- Du Toit, A. Selection, Extraction, Characterization and Application of Mucilage from Cactus Pear (Opuntia Ficus-Indica and Opuntia Robusta) Cladodes. Ph.D. Thesis, University of the Free State, Bloemfontein, South Africa, August 2016; pp. 1–13. [Google Scholar]

- Du Toit, A.; De Wit, M.; Fouché, H.J.; Taljaard, M.; Venter, S.L.; Hugo, A. Mucilage Powder from Cactus Pears as Functional Ingredient: Influence of Cultivar and Harvest Month on the Physicochemical and Technological Properties. J. Food Sci. Technol. 2019, 56, 2404–2416. [Google Scholar] [CrossRef]

- Campos, C.; Gerschenson, L.; Flores, S. Development of Edible Films and Coatings with Antimicrobial Activity. Food Bioprocess Technol. 2010, 4, 849–875. [Google Scholar] [CrossRef]

- Du, W.X.; Avena-Bustillos, R.J.; Sheng, S.; Hua, T.; McHugh, T.H. Antimicrobial Volatile Essential Oils in Edible Films for Food Safety. Sci. Against Microb. Pathog. Commun. Curr. Res. Technol. Adv. 2011, 2, 1124–1134. [Google Scholar]

- Fazilah, A.; Maizura, M.; Karim, A.A.; Bhupinder, K.; Rajeev, B.; Uthumporn, U.; Chew, S.H. Physical and Mechanical Properties of Sago Starch—Alginate Films Incorporated with Calcium Chloride. Int. Food Res. J. 2011, 18, 1027–1033. [Google Scholar]

- Trachtenberg, S.; Mayer, A.M. Mucilage Cells, Calcium Oxalate Crystals and Soluble Calcium in Opuntia Ficus-Indica. Ann. Bot. 1982, 50, 549–557. [Google Scholar] [CrossRef]

- Harper, B.A. Understanding Interactions in Wet Alginate Film Formation Used for In-Line Food Processes; Doctor of Philosophy in Food Science, The University of Guelph: Guelph, ON, Canada, 2013. [Google Scholar]

- Xu, Y.X.; Kim, K.M.; Hanna, M.A.; Nag, D. Chitosan-Starch Composite Film: Preparation and Characterization. Ind. Crops Prod. 2005, 21, 185–192. [Google Scholar] [CrossRef]

- Rhim, J.W. Physical and Mechanical Properties of Water Resistant Sodium Alginate Films. LWT—Food Sci. Technol. 2004, 37, 323–330. [Google Scholar] [CrossRef]

- Wang, L.Z.; Liu, L.; Holmes, J.; Kerry, J.F.; Kerry, J.P. Assessment of Film-Forming Potential and Properties of Protein and Polysaccharide-Based Biopolymer Films. Int. J. Food Sci. Technol. 2007, 42, 1128–1138. [Google Scholar] [CrossRef]

- Gheribi, R.; Gharbi, M.A.; Ouni, M.E.; Khwaldia, K. Enhancement of the Physical, Mechanical and Thermal Properties of Cactus Mucilage Films by Blending with Polyvinyl Alcohol. Food Packag. Shelf Life 2019, 22, 100386. [Google Scholar] [CrossRef]

- Gheribi, R.; Habibi, Y.; Khwaldia, K. Prickly Pear Peels as a Valuable Resource of Added-Value Polysaccharide: Study of Structural, Functional and Film Forming Properties. Int. J. Biol. Macromol. 2019, 126, 238–245. [Google Scholar] [CrossRef]

- Guadarrama-Lezama, A.Y.; Castaño, J.; Velázquez, G.; Carrillo-Navas, H.; Alvarez-Ramírez, J. Effect of Nopal Mucilage Addition on Physical, Barrier and Mechanical Properties of Citric Pectin-Based Films. J. Food Sci. Technol. 2018, 55, 3739–3748. [Google Scholar] [CrossRef] [PubMed]

- Galus, S.; Lenart, A. Development and Characterization of Composite Edible Films Based on Sodium Alginate and Pectin. J. Food Eng. 2013, 115, 459–465. [Google Scholar] [CrossRef]

- Paşcalau, V.; Popescu, V.; Popescu, G.L.; Dudescu, M.C.; Borodi, G.; Dinescu, A.; Perhaiţa, I.; Paul, M. The Alginate/k-Carrageenan Ratio’s Influence on the Properties of the Cross-Linked Composite Films. J. Alloys Compd. 2012, 536 (Suppl. 1), 418–423. [Google Scholar] [CrossRef]

- Fang, Y.; Al-Assaf, S.; Phillips, G.O.; Nishinari, K.; Funami, T.; Williams, P.A. Binding Behavior of Calcium to Polyuronates: Comparison of Pectin with Alginate. Carbohydr. Polym. 2008, 72, 334–341. [Google Scholar] [CrossRef]

- Sriamornsak, P.; Kennedy, R.A. Swelling and Diffusion Studies of Calcium Polysaccharide Gels Intended for Film Coating. Int. J. Pharm. 2008, 358, 205–213. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).