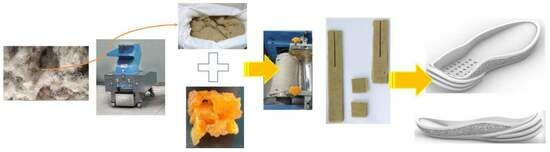

Eco-Friendly Natural Rubber–Jute Composites for the Footwear Industry

Abstract

:1. Introduction

2. Materials and Methods

Alkaline Treatment

3. Results and Discussion

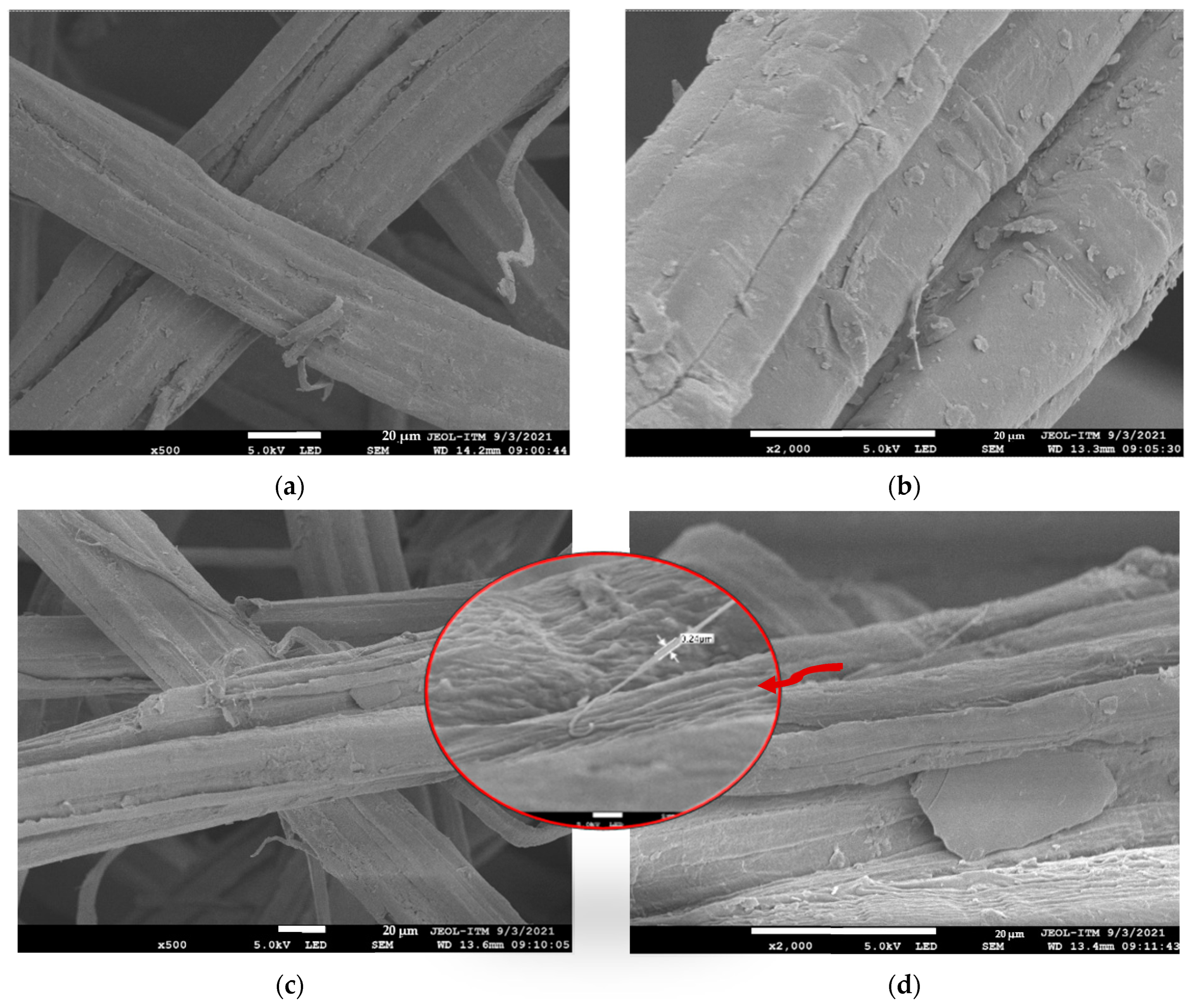

3.1. Evaluation of the Fibers

3.2. Rheometry

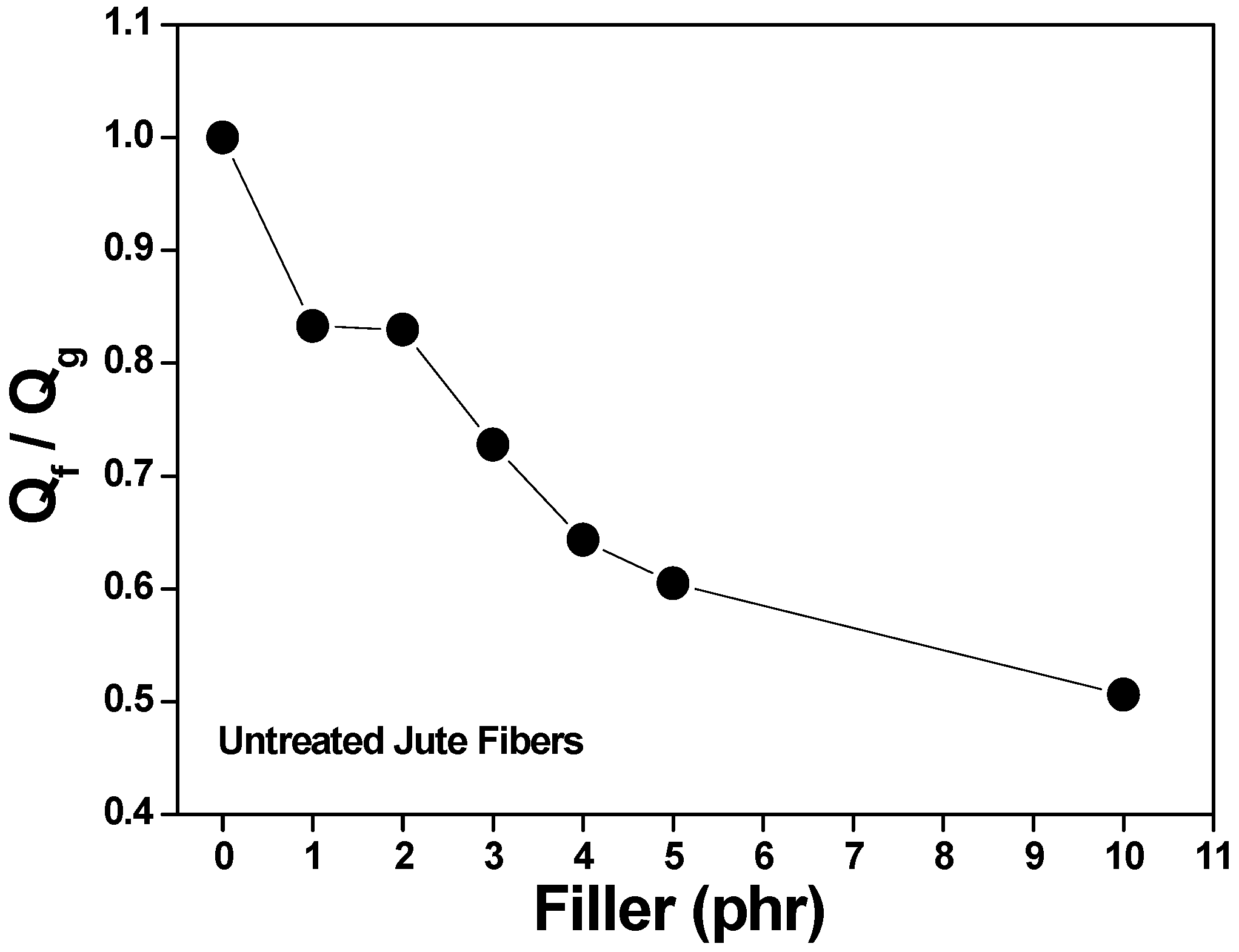

3.3. Determining Crosslinking Density

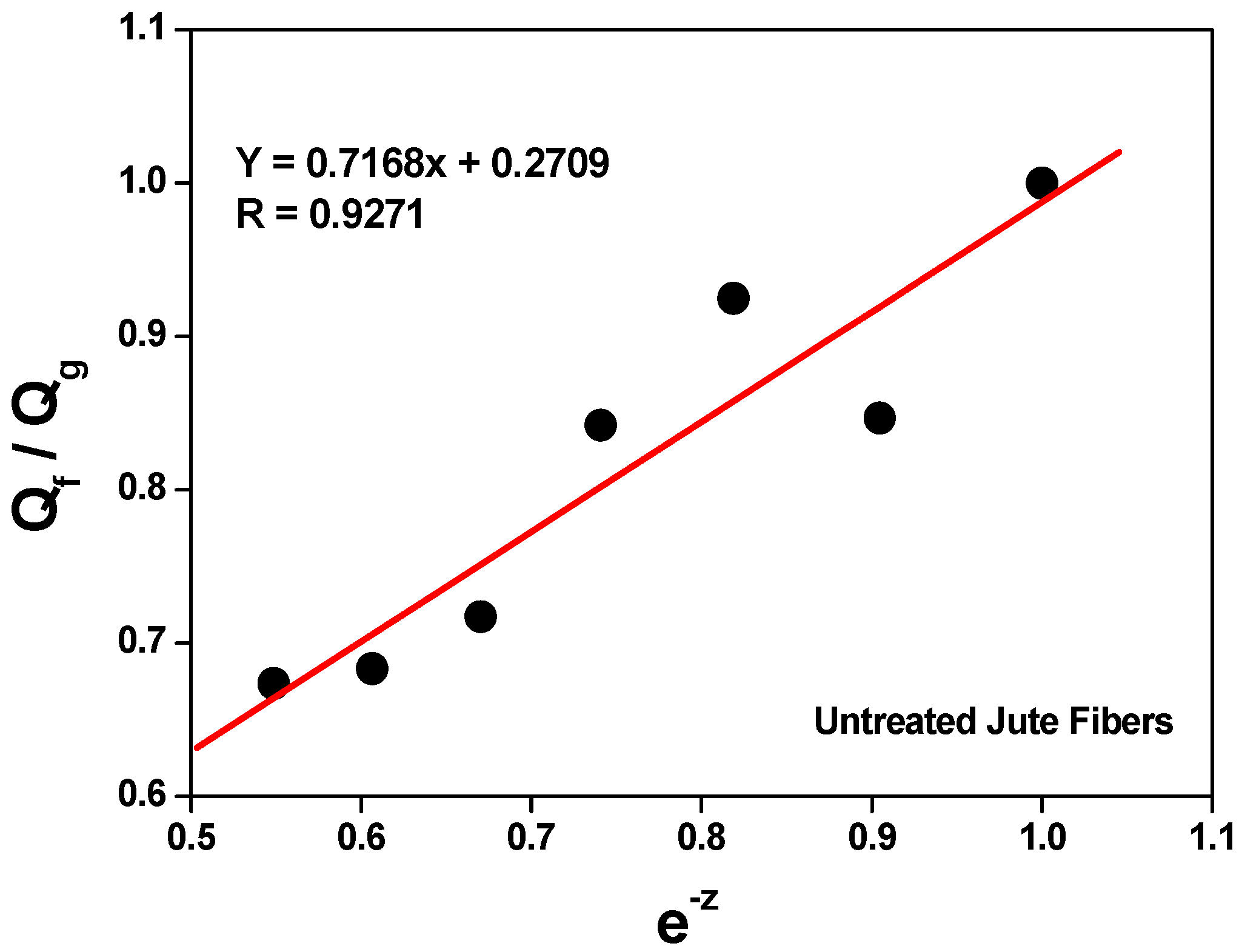

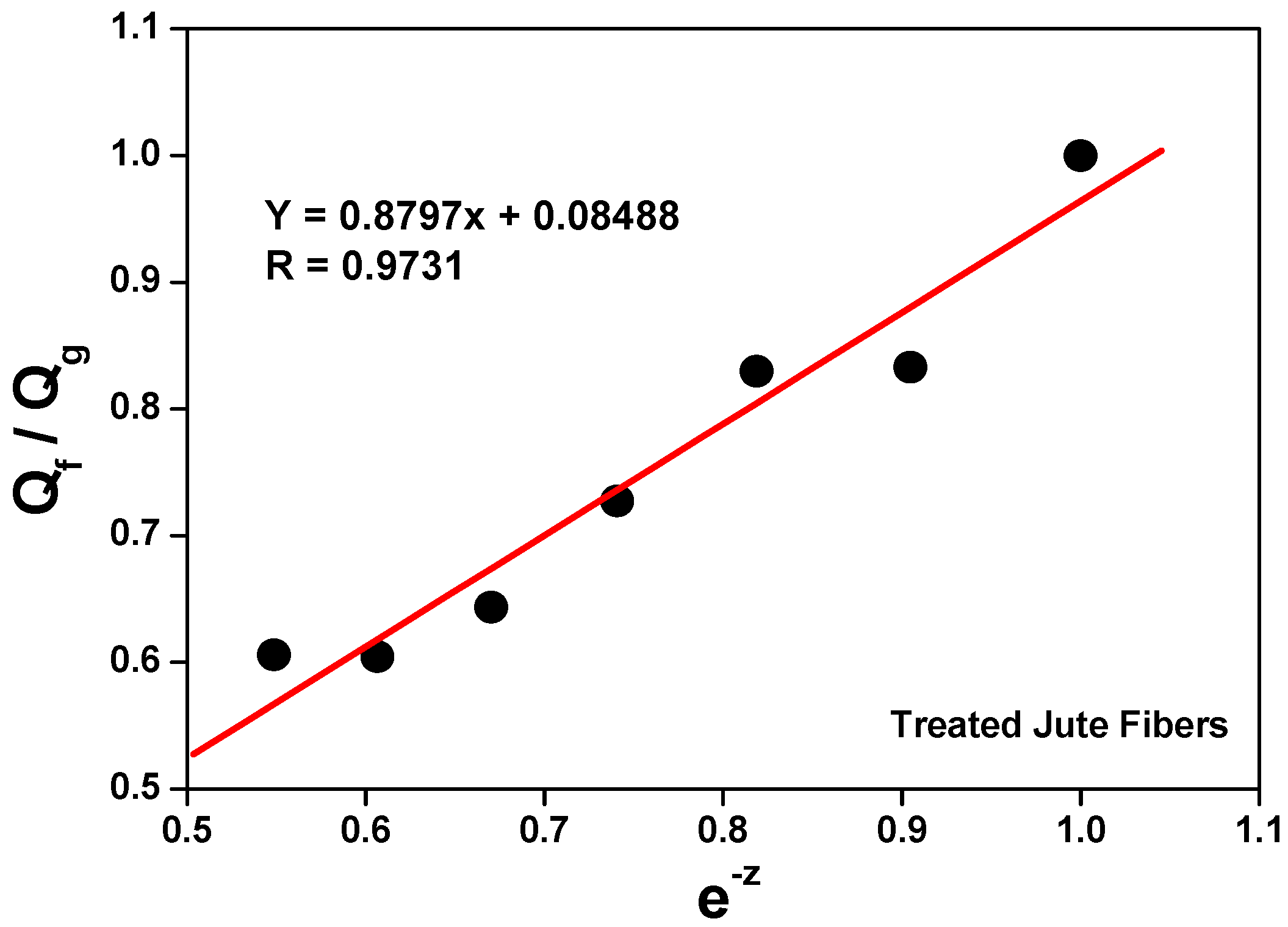

3.4. Analysis of Rubber/Jute Fiber Interactions Using the Lorenz–Park Equation

- Q = weight of toluene absorbed per gram of rubber, where subscripts l and r denote the composites vulcanized with a loading and pure rubber, respectively;

- z = ratio of filling mass per unit mass of rubber;

- a and b = constants.

- Ws = weight of the swollen composite when the balance between the organic solvent and the polymer is achieved;

- Wd = weight of the dry composite;

- Wr = weight of the rubber in the dry composite;

- WF = total weight of the formulation.

3.5. Analysis of Rubber/Loading Interactions Using the Lorentz–Park Equation

3.6. Shore OO Hardness

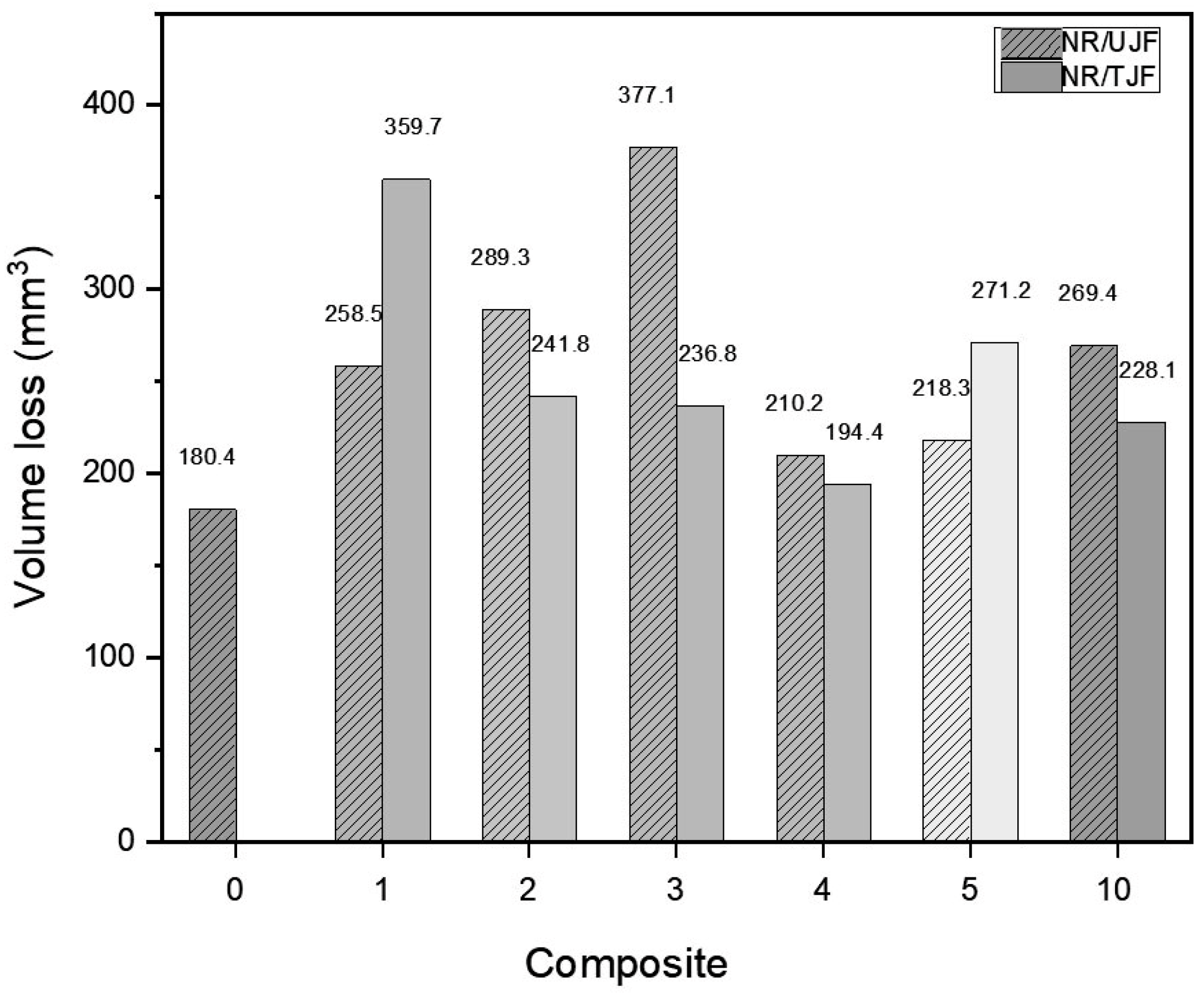

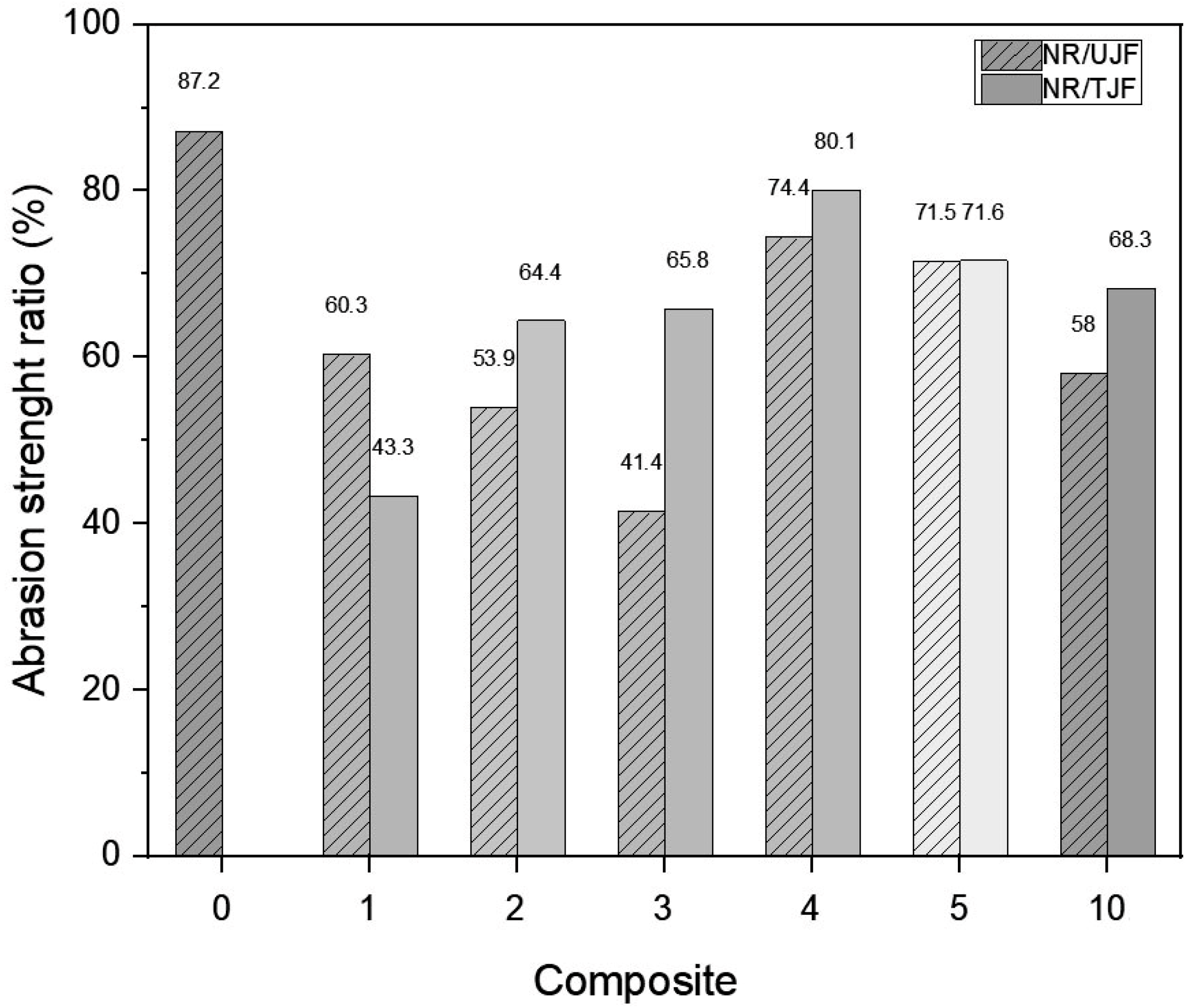

3.7. Abrasion Resistance

- Iar = abrasion resistance index (%);

- m1 = initial mass of reference rubber (mg);

- mt = initial mass of test rubber (mg);

- d1 = initial mass of reference rubber (mg/cm3);

- dt = final mass of test rubber (mg/cm3).

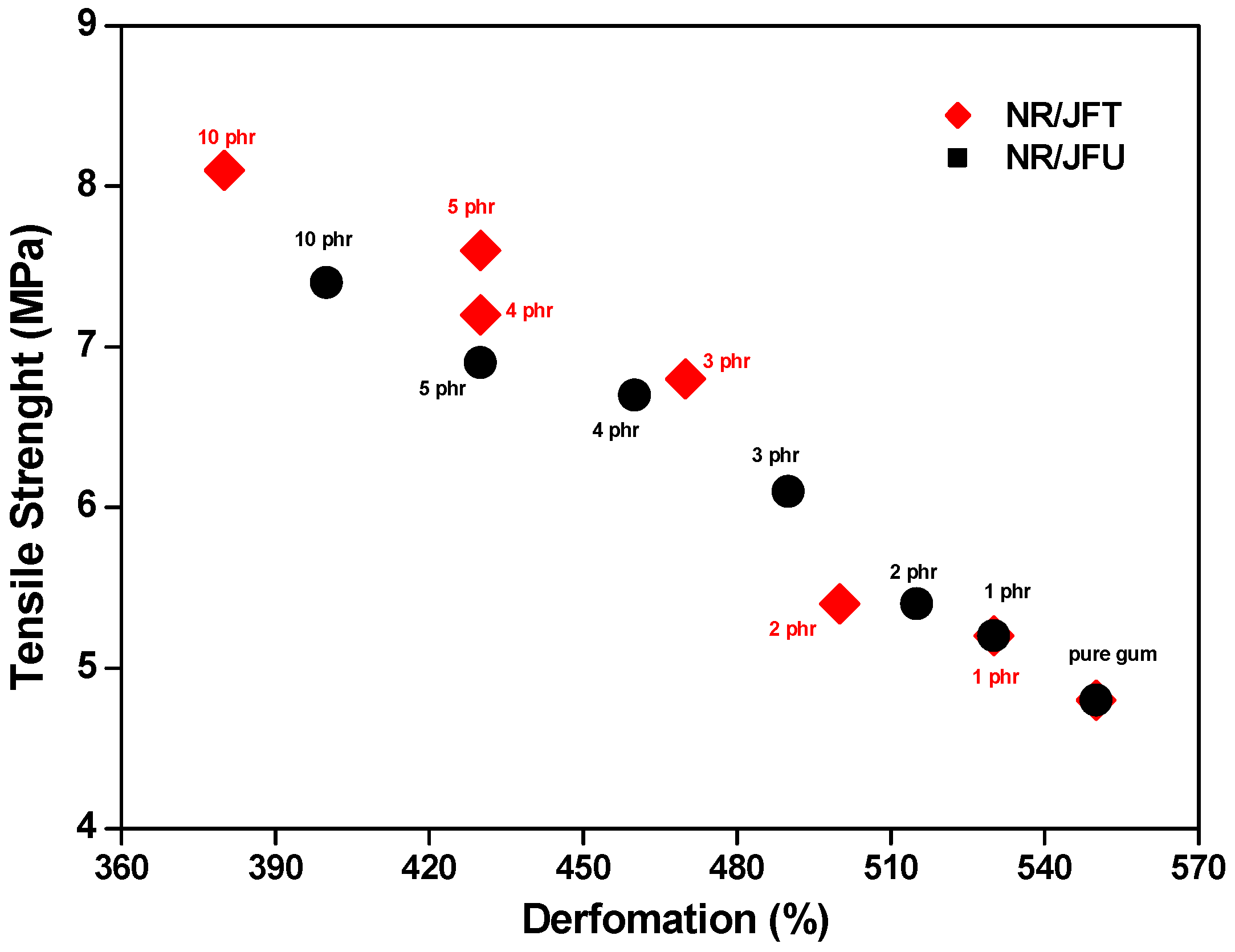

3.8. Tensile Strength

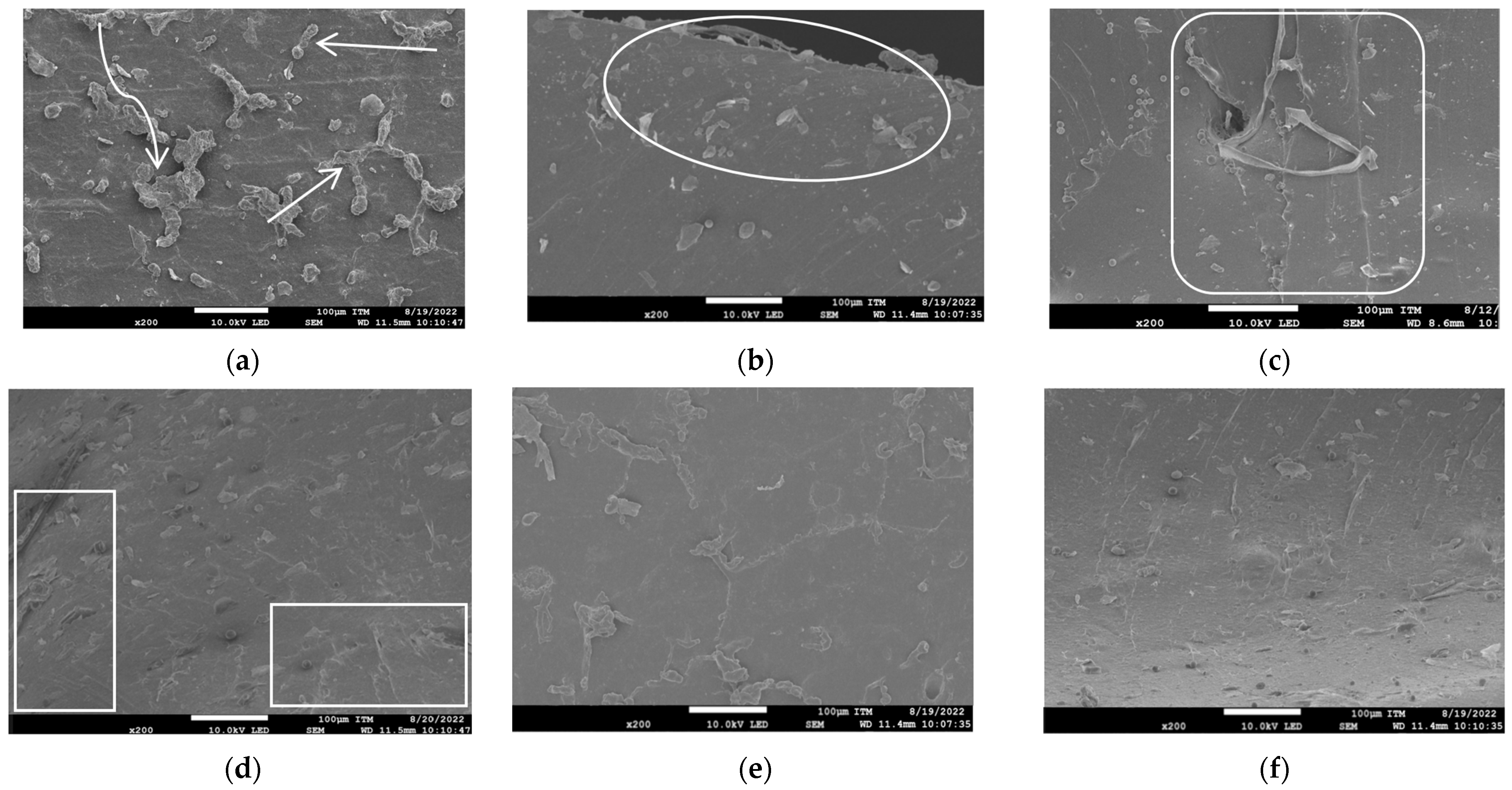

3.9. Morphology of the Composites and Jute Fibers

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ramesh, M.; Palanikumar, K.; Reddy, K.H. Plant Fibre Based Bio-Composites: Sustainable and Renewable Green Materials. Renew. Sustain. Energy Rev. 2017, 79, 558–584. [Google Scholar] [CrossRef]

- Datta, J.; Włoch, M. Preparation, Morphology and Properties of Natural Rubber Composites Filled with Untreated Short Jute Fibres. Polym. Bull. 2017, 74, 763–782. [Google Scholar] [CrossRef]

- George, J.; Sreekala, M.S.; Thomas, S. A Review on Interface Modification and Characterization of Natural Fiber Reinforced Plastic Composites. Polym. Eng. Sci. 2001, 41, 1471–1485. [Google Scholar] [CrossRef]

- John, M.J.; Thomas, S. Biofibres and Biocomposites. Carbohydr. Polym. 2008, 71, 343–364. [Google Scholar] [CrossRef]

- Stelescu, M.D.; Manaila, E.; Craciun, G.; Chirila, C. Development and Characterization of Polymer Eco-Composites Based on Natural Rubber Reinforced with Natural Fibers. Materials 2017, 10, 787. [Google Scholar] [CrossRef]

- Townsend, T. World Natural Fibre Production and Employment. In Handbook of Natural Fibres; Elsevier: Amsterdam, The Netherlands, 2020; pp. 15–36. [Google Scholar]

- Ramesh, M. Kenaf (Hibiscus cannabinus L.) Fibre Based Bio-Materials: A Review on Processing and Properties. Prog. Mater. Sci. 2016, 78–79, 1–92. [Google Scholar] [CrossRef]

- Albinante, S.R.; Acordi, B.; Pacheco, V.; Lea, L.; Visconte, Y. Revisão dos tratamentos químicos da fibra natural para mistura com poliolefinas. Química Nova 2013, 36, 114–122. [Google Scholar] [CrossRef]

- Campilho, R.D.S.G. Recent Innovations in Biocomposite Products. In Biocomposites for High-Performance Applications; Elsevier: Amsterdam, The Netherlands, 2017; pp. 275–306. [Google Scholar]

- Sdos Santos, R.J.; da Silva Agostini, D.L.; Cabrera, F.C.; dos Reis, E.A.P.; Ruiz, M.R.; Budemberg, E.R.; Teixeira, S.R.; Job, A.E. Sugarcane Bagasse Ash: New Filler to Natural Rubber Composite. Polímeros 2014, 24, 646–653. [Google Scholar] [CrossRef]

- Mahesh, V.; Joladarashi, S.; Kulkarni, S.M. A Comprehensive Review on Material Selection for Polymer Matrix Composites Subjected to Impact Load. Def. Technol. 2021, 17, 257–277. [Google Scholar] [CrossRef]

- Nair, A.B.; Joseph, R. Eco-Friendly Bio-Composites Using Natural Rubber (NR) Matrices and Natural Fiber Reinforcements. In Chemistry, Manufacture and Applications of Natural Rubber; Elsevier: Amsterdam, The Netherlands, 2014; pp. 249–283. [Google Scholar]

- Ng, W.K.; Johar, M.; Israr, H.A.; Wong, K.J. A Review on the Interfacial Characteristics of Natural Fibre Reinforced Polymer Composites. In Interfaces in Particle and Fibre Reinforced Composites; Elsevier: Amsterdam, The Netherlands, 2020; pp. 163–198. [Google Scholar]

- Wang, B.; Panigrahi, S.; Tabil, L.; Crerar, W. Pre-Treatment of Flax Fibers for Use in Rotationally Molded Biocomposites. J. Reinf. Plast. Compos. 2007, 26, 447–463. [Google Scholar] [CrossRef]

- Li, M.; Pu, Y.; Thomas, V.M.; Yoo, C.G.; Ozcan, S.; Deng, Y.; Nelson, K.; Ragauskas, A.J. Recent Advancements of Plant-Based Natural Fiber–Reinforced Composites and Their Applications. Compos. B Eng. 2020, 200, 108254. [Google Scholar] [CrossRef]

- Zhou, Y.; Fan, M.; Chen, L.; Zhuang, J. Lignocellulosic Fibre Mediated Rubber Composites: An Overview. Compos. B Eng. 2015, 76, 180–191. [Google Scholar] [CrossRef]

- Roy, K.; Debnath, S.C.; Tzounis, L.; Pongwisuthiruchte, A.; Potiyaraj, P. Effect of Various Surface Treatments on the Performance of Jute Fibers Filled Natural Rubber (NR) Composites. Polymers 2020, 12, 369. [Google Scholar] [CrossRef] [PubMed]

- Velásquez Restrepo, S.M.; Pelaéz Arroyave, G.J.; Giraldo Vásquez, D.H. Uso de Fibras Vegetales En Materiales Compuestos de Matriz Polimérica: Una Revisión Con Miras a Su Aplicación En El Diseño de Nuevos Productos. Inf. Técnico 2016, 80, 77. [Google Scholar] [CrossRef]

- Vigneshwaran, S.; Sundarakannan, R.; John, K.M.; Joel Johnson, R.D.; Prasath, K.A.; Ajith, S.; Arumugaprabu, V.; Uthayakumar, M. Recent Advancement in the Natural Fiber Polymer Composites: A Comprehensive Review. J. Clean. Prod. 2020, 277, 124109. [Google Scholar] [CrossRef]

- Kumar, R.; Ul Haq, M.I.; Raina, A.; Anand, A. Industrial Applications of Natural Fibre-Reinforced Polymer Composites–Challenges and Opportunities. Int. J. Sustain. Eng. 2019, 12, 212–220. [Google Scholar] [CrossRef]

- John, M.J.; Varughese, K.T.; Thomas, S. Green Composites from Natural Fibers and Natural Rubber: Effect of Fiber Ratio on Mechanical and Swelling Characteristics. J. Nat. Fibers 2008, 5, 47–60. [Google Scholar] [CrossRef]

- Chang, B.P.; Mohanty, A.K.; Misra, M. Studies on Durability of Sustainable Biobased Composites: A Review. RSC Adv. 2020, 10, 17955–17999. [Google Scholar] [CrossRef]

- Gdoutos, E.E. Composite Materials. In Fracture Mechanics; Springer: Cham, Switzerland, 2020; pp. 333–352. [Google Scholar]

- Masłowski, M.; Miedzianowska, J.; Strąkowska, A.; Strzelec, K.; Szynkowska, M.I. The Use of Rye, Oat and Triticale Straw as Fillers of Natural Rubber Composites. Polym. Bull. 2018, 75, 4607–4626. [Google Scholar] [CrossRef]

- Zini, E.; Scandola, M. Green Composites: An Overview. Polym. Compos. 2011, 32, 1905–1915. [Google Scholar] [CrossRef]

- Peças, P.; Carvalho, H.; Salman, H.; Leite, M. Natural Fibre Composites and Their Applications: A Review. J. Compos. Sci. 2018, 2, 66. [Google Scholar] [CrossRef]

- Rainho Teixeira, S.; Eunice de Souza, A.; Fidel Vilche Peña, A.; Godoy de Lima, R.; Gil Miguel, Á. 8 Use of Charcoal and Partially Pirolysed Biomaterial in Fly Ash to Produce Briquettes: Sugarcane Bagasse. In Alternative Fuel; IntechOpen: London, UK, 2011. [Google Scholar]

- Barrera Torres, G.; Dognani, G.; da Silva Agostini, D.L.; dos Santos, R.J.; Camargo Cabrera, F.; Gutierrez Aguilar, C.M.; de Paiva, F.F.G.; Rainho Teixeira, S.; Job, A.E. Potential Eco-Friendly Application of Sugarcane Bagasse Ash in the Rubber Industry. Waste Biomass Valorization 2021, 12, 4599–4613. [Google Scholar] [CrossRef]

- Nunes, R.C.R. Natural Rubber (NR) Composites Using Cellulosic Fiber Reinforcements. In Chemistry, Manufacture and Applications of Natural Rubber; Elsevier: Amsterdam, The Netherlands, 2014; pp. 284–302. [Google Scholar]

- Masłowski, M.; Miedzianowska, J.; Strzelec, K. Influence of Wheat, Rye, and Triticale Straw on the Properties of Natural Rubber Composites. Adv. Polym. Technol. 2018, 37, 2866–2878. [Google Scholar] [CrossRef]

- Roy, K.; Debnath, S.C.; Potiyaraj, P. A Review on Recent Trends and Future Prospects of Lignin-Based Green Rubber Composites. J. Polym. Environ. 2020, 28, 367–387. [Google Scholar] [CrossRef]

- Roy, K.; Chandra Debnath, S.; Das, A.; Heinrich, G.; Potiyaraj, P. Exploring the Synergistic Effect of Short Jute Fiber and Nanoclay on the Mechanical, Dynamic Mechanical and Thermal Properties of Natural Rubber Composites. Polym. Test. 2018, 67, 487–493. [Google Scholar] [CrossRef]

- Jacob, M.; Thomas, S.; Varughese, K.T. Mechanical Properties of Sisal/Oil Palm Hybrid Fiber Reinforced Natural Rubber Composites. Compos. Sci. Technol. 2004, 64, 955–965. [Google Scholar] [CrossRef]

- Yantaboot, K.; Amornsakchai, T. Effect of Preparation Methods and Carbon Black Distribution on Mechanical Properties of Short Pineapple Leaf Fiber-Carbon Black Reinforced Natural Rubber Hybrid Composites. Polym. Test. 2017, 61, 223–228. [Google Scholar] [CrossRef]

- AL-Oqla, F.M.; Salit, M.S. Natural Fiber Composites. In Materials Selection for Natural Fiber Composites; Elsevier: Amsterdam, The Netherlands, 2017; pp. 23–48. [Google Scholar]

- Roy, K.; Debnath, S.C.; Potiyaraj, P. A Critical Review on the Utilization of Various Reinforcement Modifiers in Filled Rubber Composites. J. Elastomers Plast. 2020, 52, 167–193. [Google Scholar] [CrossRef]

- Abdelmouleh, M.; Boufi, S.; Belgacem, M.N.; Dufresne, A. Short Natural-Fibre Reinforced Polyethylene and Natural Rubber Composites: Effect of Silane Coupling Agents and Fibres Loading. Compos. Sci. Technol. 2007, 67, 1627–1639. [Google Scholar] [CrossRef]

- Mwaikambo, L.Y.; Ansell, M.P. Chemical Modification of Hemp, Sisal, Jute, and Kapok Fibers by Alkalization. J. Appl. Polym. Sci. 2002, 84, 2222–2234. [Google Scholar] [CrossRef]

- Chandrasekar, M.; Ishak, M.R.; Sapuan, S.M.; Leman, Z.; Jawaid, M. A Review on the Characterisation of Natural Fibres and Their Composites after Alkali Treatment and Water Absorption. Plast. Rubber Compos. 2017, 46, 119–136. [Google Scholar] [CrossRef]

- de Paiva, F.F.G.; de Maria, V.P.K.; Torres, G.B.; Dognani, G.; dos Santos, R.J.; Cabrera, F.C.; Job, A.E. Sugarcane Bagasse Fiber as Semi-Reinforcement Filler in Natural Rubber Composite Sandals. J. Mater. Cycles Waste Manag. 2019, 21, 326–335. [Google Scholar] [CrossRef]

- Shimazaki, Y.; Nozu, S.; Inoue, T. Shock-Absorption Properties of Functionally Graded EVA Laminates for Footwear Design. Polym. Test. 2016, 54, 98–103. [Google Scholar] [CrossRef]

- ASTM D 2084-01; Standard Test Method for Rubber Property-Vulcanization Using Oscillating Disk Cure Meter. American Society for Testing Materials (ASTM): West Conshohocken, PA, USA, 2020.

- ASTM D5963-19a; Standard Test Method for Rubber Property—Vulcanization Using Rotorless Cure Meters. American Society for Testing Materials (ASTM): West Conshohocken, PA, USA, 2019.

- ASTM D5963; Test Method for Rubber Property—Abrasion Resistance (Rotary Drum Abrader). American Society for Testing Materials (ASTM): West Conshohocken, PA, USA, 2010.

- ASTM D2240; Test Method for Rubber Property—Durometer Hardness. American Society for Testing Materials (ASTM): West Conshohocken, PA, USA, 2010.

- da Silva Ozório, M.; dos Reis, E.A.P.; Teixeira, S.R.; Bellucci, F.S.; Job, A.E. Sugarcane Bagasse Ash as a Reinforcing Filler in Thermoplastic Elastomers: Structural and Mechanical Characterizations. J. Appl. Polym. Sci. 2015, 132, 41466. [Google Scholar] [CrossRef]

- Vieyres, A.; Pérez-Aparicio, R.; Albouy, P.A.; Sanseau, O.; Saalwächter, K.; Long, D.R.; Sotta, P. Sulfur-Cured Natural Rubber Elastomer Networks: Correlating Cross-Link Density, Chain Orientation, and Mechanical Response by Combined Techniques. Macromolecules 2013, 46, 889–899. [Google Scholar] [CrossRef]

- Flory, P.J.; Rehner, J. Statistical Mechanics of Cross-Linked Polymer Networks I. Rubberlike Elasticity. J. Chem. Phys. 1943, 11, 512–520. [Google Scholar] [CrossRef]

- Manral, A.; Bajpai, P.K. Analysis of Natural Fiber Constituents: A Review. IOP Conf. Ser. Mater. Sci. Eng. 2018, 455, 012115. [Google Scholar] [CrossRef]

- Escócio, V.A.; Martins, A.F.; Visconte, L.L.Y.; Nunes, R.C.R.; Costa, D.M.R. Influência Da Mica Nas Propriedades Mecânicas e Dinâmico-Mecânicas de Composições de Borracha Natural. Polímeros 2003, 13, 130–134. [Google Scholar] [CrossRef]

- Lorenz, O.; Parks, C.R. The Crosslinking Efficiency of Some Vulcanizing Agents in Natural Rubber. J. Polym. Sci. 1961, 50, 299–312. [Google Scholar] [CrossRef]

- Santos, R.J.; Hiranobe, C.T.; Dognani, G.; Silva, M.J.; Paim, L.L.; Cabrera, F.C.; Torres, G.B.; Job, A.E. Using the Lorenz–Park, Mooney–Rivlin, and Dynamic Mechanical Analysis Relationship on Natural Rubber/Leather Shavings Composites. J. Appl. Polym. Sci. 2022, 139, 51880. [Google Scholar] [CrossRef]

- Haseena, A.P.; Dasan, K.P.; Namitha, R.; Unnikrishnan, G.; Thomas, S. Investigation on Interfacial Adhesion of Short Sisal/Coir Hybrid Fibre Reinforced Natural Rubber Composites by Restricted Equilibrium Swelling Technique. Compos. Interfaces 2004, 11, 489–513. [Google Scholar] [CrossRef]

- He, F.; Yuan, T.; Li, C.; Sun, L.; Liao, S. Interfacial Interactions and Properties of Natural Rubber-Silica Composites with Liquid Natural Rubber as a Compatibilizer and Prepared by a Wet-Compounding Method. J. Appl. Polym. Sci. 2018, 135, 46457. [Google Scholar] [CrossRef]

- Nurul Aizan, M.Z.; Zainathul Akhmar, S.A.S.; Mohd Muhiddin, A.; Nor Hazwani, Z.; Siti Sarah, J. Study on Cure Characteristics and Mechanical Behaviours of Kenaf Fibre Reinforced Natural Rubber Composites. Adv. Mater. Res. 2013, 812, 66–72. [Google Scholar] [CrossRef]

- Ravichandran, K.; Natchimuthu, N. Vulcanization Characteristics and Mechanical Properties of Natural Rubber-Scrap Rubber Compositions Filled with Leather Particles. Polym. Int. 2005, 54, 553–559. [Google Scholar] [CrossRef]

- De, D.; De, D.; Adhikari, B. Curing Characteristics and Mechanical Properties of Alkali-Treated Grass-Fiber-Filled Natural Rubber Composites and Effects of Bonding Agent. J. Appl. Polym. Sci. 2006, 101, 3151–3160. [Google Scholar] [CrossRef]

- Wan Busu, W.N.; Anuar, H.; Ahmad, S.H.; Rasid, R.; Jamal, N.A. The Mechanical and Physical Properties of Thermoplastic Natural Rubber Hybrid Composites Reinforced with Hibiscus cannabinus, L. and Short Glass Fiber. Polym. Plast. Technol. Eng. 2010, 49, 1315–1322. [Google Scholar] [CrossRef]

- Mahesh, V.; Joladarashi, S.; Kulkarni, S.M. Three Body Abrasive Wear Assessment of Novel Jute/Natural Rubber Flexible Green Composite. J. Thermoplast. Compos. Mater. 2021, 34, 1566–1576. [Google Scholar] [CrossRef]

- Sareena, C.; Ramesan, M.T.; Purushothaman, E. Utilization of Peanut Shell Powder as a Novel Filler in Natural Rubber. J. Appl. Polym. Sci. 2012, 125, 2322–2334. [Google Scholar] [CrossRef]

- Mathew, L.; Joseph, R. Mechanical Properties of Short-Isora-Fiber-Reinforced Natural Rubber Composites: Effects of Fiber Length, Orientation, and Loading; Alkali Treatment; and Bonding Agent. J. Appl. Polym. Sci. 2007, 103, 1640–1650. [Google Scholar] [CrossRef]

| Function | NR/TJF 1 | NR/UJF 2 | Phr 3 |

|---|---|---|---|

| Matrix | NR | NR | 100 |

| Activator | Stearic acid | Stearic acid | 4.0 |

| Activator | ZnO | ZnO | 6.0 |

| (Filler) jute fibers | TJF 1 | UJF 2 | 0, 1, 2, 3, 4, 5, 10 |

| Curing agent | S | S | 1.75 |

| Lubricant | Paraffin | Paraffin | 3.5 |

| Accelerator | TTBS 4 | TTBS | 0.8 |

| Composite | ML (dNm) | MH (dNm) | ∆M (dNm) | t90 (dNm) |

|---|---|---|---|---|

| Pure rubber | 1.96 ± 0.16 | 4.33 ± 2.16 | 3.04 ± 2.06 | 6.91± 0.06 |

| NR/UJF 1.0 | 1.26 ± 0.12 | 3.49 ± 1.56 | 2.23 ± 0.06 | 8.92 ± 0.11 |

| NR/UJF 2.0 | 1.28 ± 0.06 | 3.52 ± 2.26 | 2.24 ± 2.25 | 10.29 ± 0.11 |

| NR/UJF 3.0 | 1.45 ± 0.13 | 3.47 ± 2.16 | 2.02 ± 0.06 | 10.36 ± 0.02 |

| NR/UJF 4.0 | 1.49 ± 0.12 | 3.46 ± 1.26 | 1.97 ± 1.14 | 11.04 ± 0.10 |

| NR/UJF 5.0 | 1.39 ± 0.12 | 3.49 ± 2.16 | 2.10 ± 2.03 | 10.42 ± 0.12 |

| NR/UJF 10 | 1.23 ± 0.10 | 3.26 ± 2.06 | 2.03 ± 2.01 | 10.75 ± 0.08 |

| NR/TJF 1.0 | 0.85 ± 0.13 | 1.81 ± 1.36 | 0.96 ± 1.03 | 8.26 ± 0.02 |

| NR/TJF 2.0 | 0.86 ± 0.09 | 2.24 ± 2.28 | 1.38 ± 2.16 | 9.22 ± 0.05 |

| NR/TJF 3.0 | 0.98 ± 0.14 | 3.05 ± 2.07 | 2.07 ± 2.06 | 8.95 ± 0.06 |

| NR/TJF 4.0 | 1.09 ± 0.14 | 3.06 ± 1.46 | 1.97 ± 1.33 | 9.82 ± 0.09 |

| NR/TJF 5.0 | 1.10 ± 0.11 | 3.61 ± 2.37 | 2.51 ± 2.25 | 7.35 ± 0.08 |

| NR/TJF 10 | 0.93 ± 0.10 | 2.41 ± 2.09 | 1.48 ± 2.01 | 8.51 ± 0.07 |

| Composite (Phr) | Shore OO Harness | |

|---|---|---|

| NR/UJF | NR/TJF | |

| 0 | 81.8 ± 3 | |

| 1 | 78.4 ± 1 | 79.3 ± 2 |

| 2 | 79.9 ± 1 | 79.8 ± 2 |

| 3 | 78.5 ± 2 | 79.8 ± 2 |

| 4 | 81.1 ± 2 | 79.2 ± 3 |

| 5 | 79.8 ± 2 | 79.9 ± 3 |

| 10 | 78.1 ± 2 | 79.6 ± 3 |

| Amount (Phr) | Volume Loss (mm3) | Abrasion Resistance (%) | ||

|---|---|---|---|---|

| NR/UJF | NR/TJF | NR/UJF | NR/TJF | |

| 0 | 180.4 ± 3 | 87.2 ± 3 | ||

| 1 | 258.5 ± 2 | 289.3 ± 2 | 60.3 ± 1 | 43.3 ± 3 |

| 2 | 289.3 ± 2 | 377.1 ± 2 | 53.9 ± 1 | 64.4 ± 3 |

| 3 | 377.1 ± 2 | 210.2 ± 2 | 41.4 ± 1 | 65.8 ± 3 |

| 4 | 210.2 ± 2 | 218.3 ± 2 | 74.4 ± 2 | 80.1 ± 2 |

| 5 | 218.3 ± 2 | 269.4 ± 2 | 71.5 ± 2 | 71.6 ± 2 |

| 10 | 269.4 ± 2 | 228.1 ± 3 | 58.0 ± 2 | 68.3 ± 2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Torres, G.B.; Hiranobe, C.T.; da Silva, E.A.; Cardim, G.P.; Cardim, H.P.; Cabrera, F.C.; Lozada, E.R.; Gutierrez-Aguilar, C.M.; Sánchez, J.C.; Carvalho, J.A.J.; et al. Eco-Friendly Natural Rubber–Jute Composites for the Footwear Industry. Polymers 2023, 15, 4183. https://doi.org/10.3390/polym15204183

Torres GB, Hiranobe CT, da Silva EA, Cardim GP, Cardim HP, Cabrera FC, Lozada ER, Gutierrez-Aguilar CM, Sánchez JC, Carvalho JAJ, et al. Eco-Friendly Natural Rubber–Jute Composites for the Footwear Industry. Polymers. 2023; 15(20):4183. https://doi.org/10.3390/polym15204183

Chicago/Turabian StyleTorres, Giovanni Barrera, Carlos T. Hiranobe, Erivaldo Antonio da Silva, Guilherme P. Cardim, Henrique P. Cardim, Flavio C. Cabrera, Elizabeth R. Lozada, Carlos M. Gutierrez-Aguilar, Juan C. Sánchez, Jaime A. Jaramillo Carvalho, and et al. 2023. "Eco-Friendly Natural Rubber–Jute Composites for the Footwear Industry" Polymers 15, no. 20: 4183. https://doi.org/10.3390/polym15204183

APA StyleTorres, G. B., Hiranobe, C. T., da Silva, E. A., Cardim, G. P., Cardim, H. P., Cabrera, F. C., Lozada, E. R., Gutierrez-Aguilar, C. M., Sánchez, J. C., Carvalho, J. A. J., Job, A. E., & Santos, R. J. (2023). Eco-Friendly Natural Rubber–Jute Composites for the Footwear Industry. Polymers, 15(20), 4183. https://doi.org/10.3390/polym15204183